Heat processing technology for improving impact energy of 20CrNiMo alloy steel

An alloy steel and impact energy technology, which is applied in the field of heat treatment process for improving the impact energy of 20CrNiMo alloy steel, can solve the problems of low impact energy and the inability of 20CrNiMo alloy steel to fully function due to its good properties, and achieves good impact resistance and a wide range of applications. , the effect of good impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

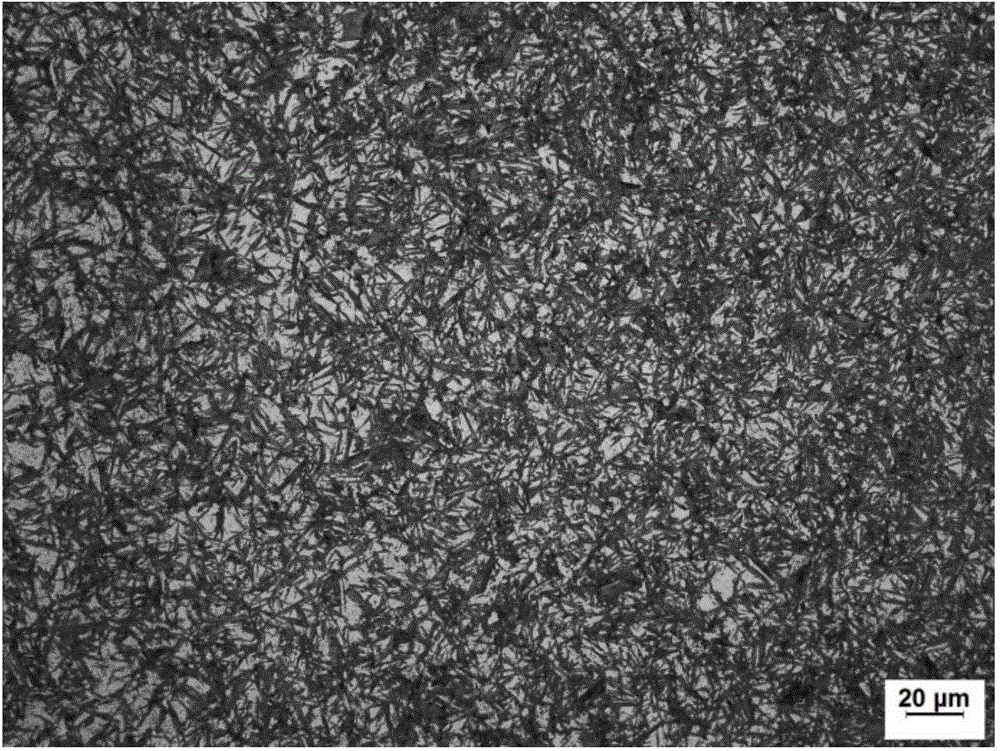

Embodiment 1

[0033] The heat treatment process that present embodiment improves 20CrNiMo alloy steel impact energy comprises the following steps:

[0034] Step 1, carburizing: Carburizing the 20CrNiMo alloy steel after electroslag remelting at a temperature of 930°C until the carburizing layer has a depth of 1.5mm;

[0035] Step 2, primary quenching: the 20CrNiMo alloy steel after carburizing in step 1 is cooled to 880°C, kept at a carbon potential of 0.85% for 2.5h, and then oil quenched;

[0036] Step 3, primary tempering: heat up the 20CrNiMo alloy steel after primary quenching in step 2 to 600°C, keep it warm for 3 hours, and then air-cool;

[0037] Step 4, secondary quenching: heat up the 20CrNiMo alloy steel after the primary tempering in step 3 to 840° C., heat it for 3 hours under the condition that the carbon potential is 0.85%, and then quench it with oil;

[0038] Step 5, secondary tempering: heat up the 20CrNiMo alloy steel after secondary quenching in step 4 to 200° C., keep ...

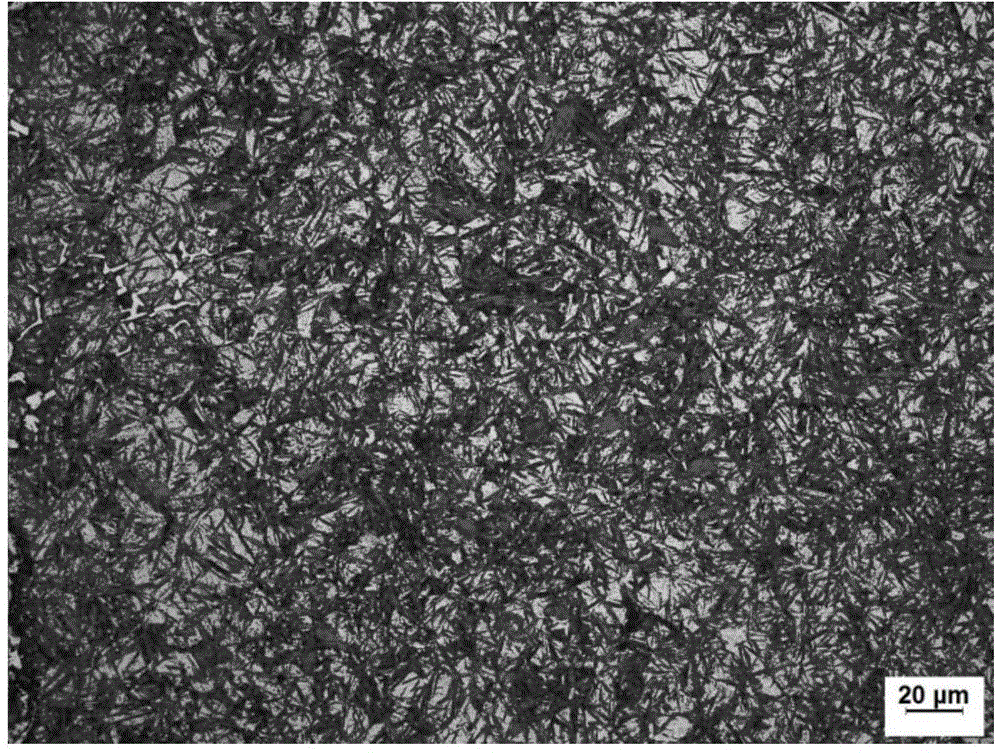

Embodiment 2

[0040] The heat treatment process that present embodiment improves 20CrNiMo alloy steel impact energy comprises the following steps:

[0041] Step 1, carburizing: Carburizing the 20CrNiMo alloy steel after electroslag remelting at a temperature of 930°C until the carburizing layer has a depth of 1.7 mm;

[0042] Step 2, primary quenching: the 20CrNiMo alloy steel after carburizing in step 1 is cooled to 890°C, kept at a carbon potential of 0.9% for 2.5h, and then oil quenched;

[0043] Step 3, primary tempering: heat up the 20CrNiMo alloy steel after primary quenching in step 2 to 610°C, keep it warm for 3 hours, and then air-cool;

[0044] Step 4, secondary quenching: heat up the 20CrNiMo alloy steel after the primary tempering in step 3 to 850°C, heat it for 3 hours under the condition of carbon potential of 0.9%, and then oil quench;

[0045] Step 5, secondary tempering: heat up the 20CrNiMo alloy steel after secondary quenching in step 4 to 210° C., keep it warm for 4 hours...

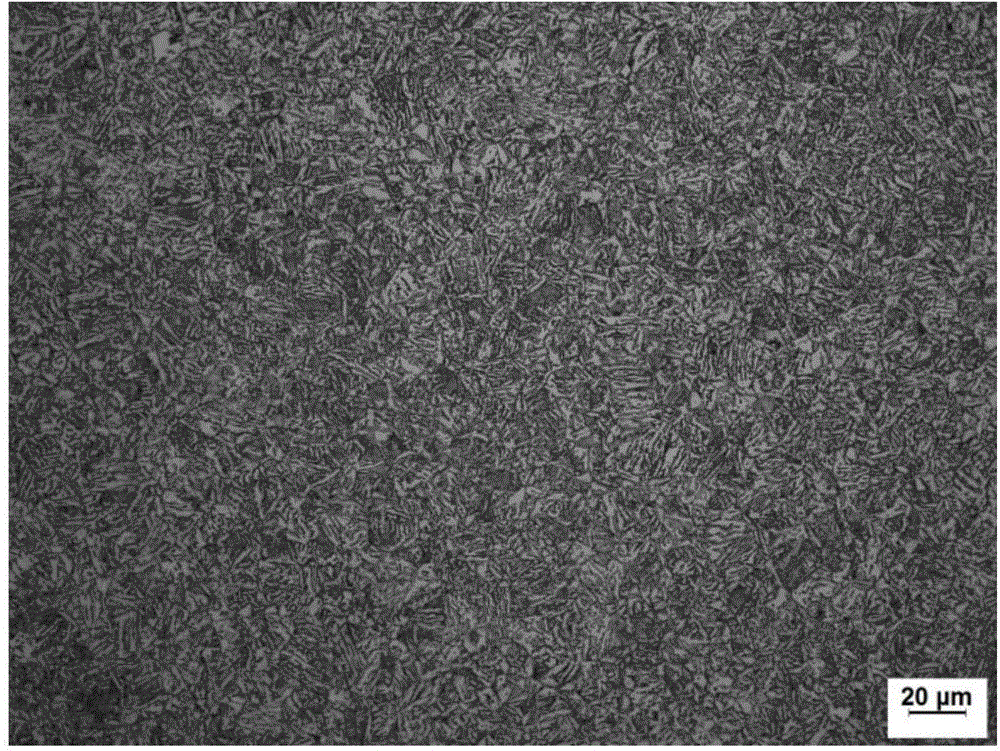

Embodiment 3

[0047] The heat treatment process that present embodiment improves 20CrNiMo alloy steel impact energy comprises the following steps:

[0048] Step 1, carburizing: Carburizing the 20CrNiMo alloy steel after electroslag remelting at a temperature of 930°C until the carburizing layer has a depth of 1.4mm;

[0049] Step 2, primary quenching: the 20CrNiMo alloy steel after carburizing in step 1 is cooled to 870°C, kept at a carbon potential of 0.8% for 2.5h, and then oil quenched;

[0050] Step 3, primary tempering: heat up the 20CrNiMo alloy steel after primary quenching in step 2 to 590°C, keep it warm for 3 hours, and then air-cool;

[0051] Step 4, secondary quenching: heat up the 20CrNiMo alloy steel after the primary tempering in step 3 to 830°C, heat it for 3 hours under the condition that the carbon potential is 0.8%, and then quench it with oil;

[0052] Step 5, secondary tempering: heat up the 20CrNiMo alloy steel after secondary quenching in step 4 to 190° C., keep it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com