Bionic coupling cast iron guide rail and manufacturing method thereof and regeneration method of waste machine tool guide rail

A guide rail, cast iron technology, applied in the direction of manufacturing tools, metal processing machinery parts, laser welding equipment, etc., can solve the problems of affecting the machining accuracy of machine tools, unable to guarantee machining accuracy, and scrapping of machine tools, and achieve excellent fatigue resistance and wear resistance, eutectic Small cluster size and improved tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

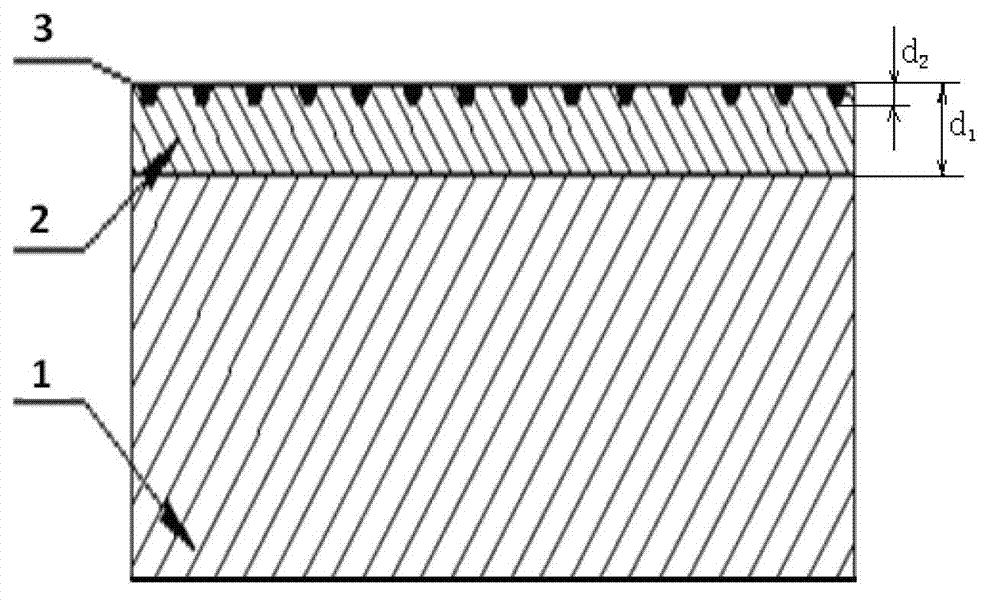

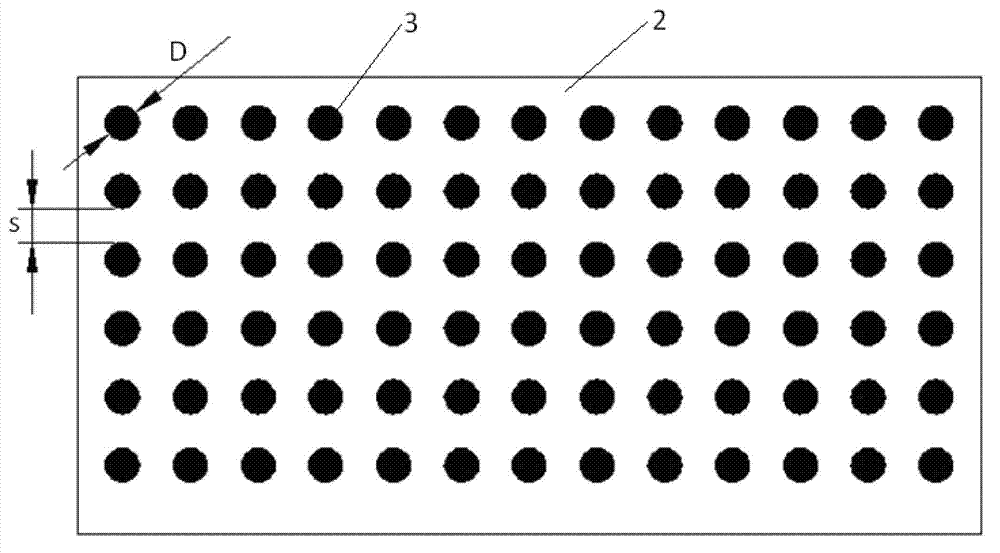

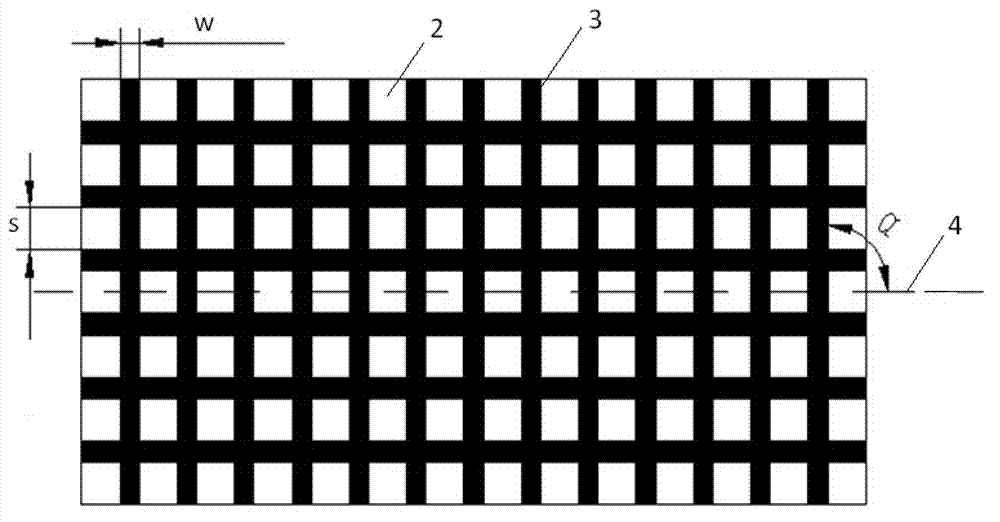

[0032] Such as figure 1 As shown, the biomimetic coupling cast iron guide rail of the present invention is composed of a guide rail main body 1 and its surface structure refinement layer 2; nano-scale martensite units 3 are distributed on the surface structure refinement layer 2. The average size of eutectic clusters in the surface structure refinement layer 2 is 0.01-0.3 mm. Depth d of surface texture refinement layer 2 1 The range is 0.8-2mm. The unit body 3 can be cylindrical (such as figure 2 shown), the diameter D is 0.5~4mm, the spacing s is 0.5~4mm, and the depth d 2 0.1-0.8mm, and the cylindrical units are uniformly or randomly distributed on the surface texture refinement layer 2 . The unit body 3 can also be in the form of a grid formed by stripes intersecting (such as image 3 shown), the stripe width w of the grid-like unit body is 0.5-4mm, the spacing s is 0.5-4mm, the inclination angle α (that is, the angle between the stripe unit body and the guide rail ax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com