Steel for linear guide rail and hot-rolling production method for steel

A technology of linear guides and production methods, applied in the direction of improving process efficiency, etc., can solve problems such as damage to metal continuity and uniformity, sensitivity to crack tendency, large water quenching deformation, etc., to improve service life, prevent large-scale production, increase Effect of Large Gas Stirring Flow Rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

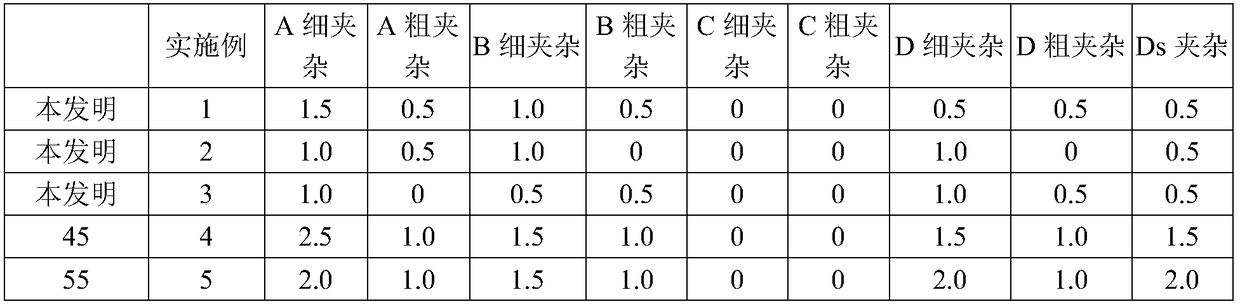

[0049] Below in conjunction with embodiment the present invention is described in further detail.

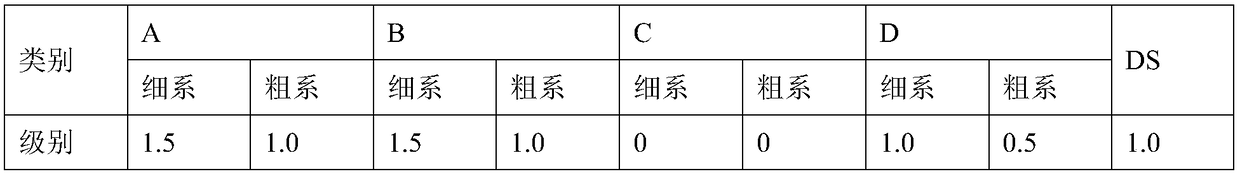

[0050] Various embodiments of the present invention The present invention and (as a comparison) the chemical composition (wt%) of 45# and 55# steel currently used in the market are shown in Table 3 and Table 4.

[0051] table 3

[0052]

Example

C

Si

mn

P

S

Cr

Cu

Ni

Al

this invention

1

0.58

0.26

1.46

0.014

0.010

0.41

0.08

0.06

0.016

this invention

2

0.59

0.30

1.45

0.015

0.012

0.38

0.08

0.05

0.018

this invention

3

0.60

0.27

1.48

0.015

0.010

0.40

0.07

0.05

0.012

45#

4

0.45

0.20

0.62

0.020

0.012

0.08

0.05

0.05

Does not require

55#

5

0.55

0.22

0.65

0.021

0.010

0.10

0.08

0.06

Does not require

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com