Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Simple rolling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick chromium-molybdenum steel plate for hydrogenation equipment and production method thereof

InactiveCN102181806AImprove toughnessDoes not reduce weldabilityRoll mill control devicesMetal rolling arrangementsSheet steelIngot

The invention discloses a thick chromium-molybdenum steel plate for hydrogenation equipment, and also discloses a production method of a steel plate. The steel plate comprises the following components by weight percent: 0.12%-0.15% of C, 0.02%-0.07% of Si, 0.50%-0.60% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, 2.35%-2.50% of Cr, 0.95%-1.10% of Mo, 0.012%-0.02% ofNb, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.005% of Sn, less than or equal to 0.016% of As, less than or equal to 0.003% of O, less than or equal to 0.008% of N and less or equal to 0.0002% of H, the balance of Fe and inevitable impurities. For the steel plate, an electroslag remelting technology is adopted,electroslag ingot with the maximum piece weight being 50t is melted, and the maximum thickness of the produced thick chromium-molybdenum steel plate for the hydrogenation equipment can achieve 198mm,and the maximum piece weight of the single-piece finished steel plate can achieve 37.2t by a heating-rolling technology and thermal-processing production equipment of normalizing plus accelerated cooling plus tempering.

Owner:WUYANG IRON & STEEL +1

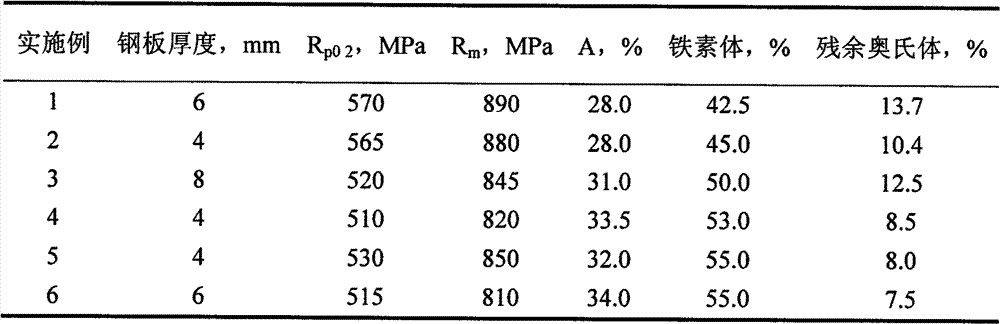

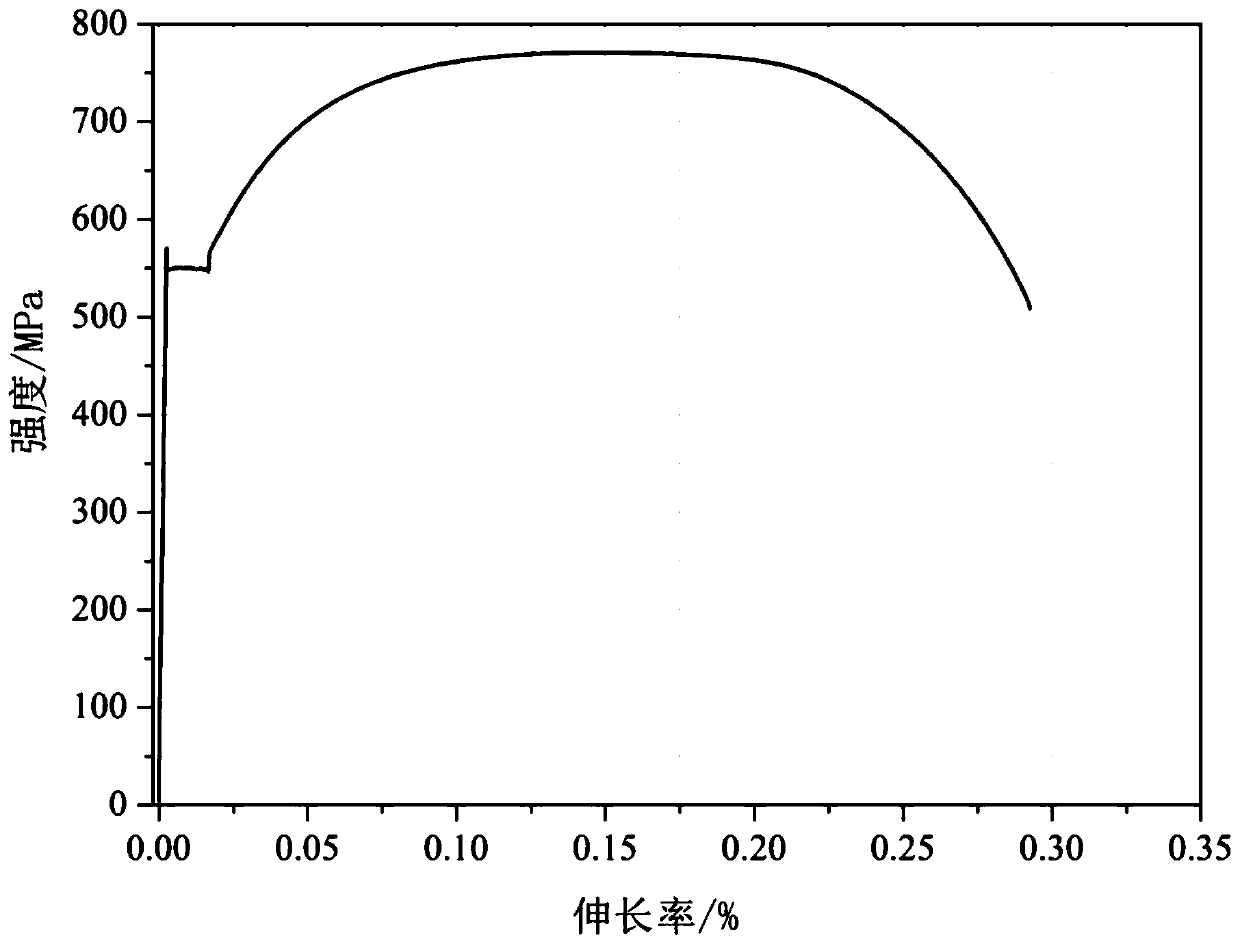

High-strength and high-plasticity medium manganese cold-roll steel sheet and manufacturing method thereof

InactiveCN103103438AImprove mechanical propertiesSimple and economical ingredientsTime rangeSheet steel

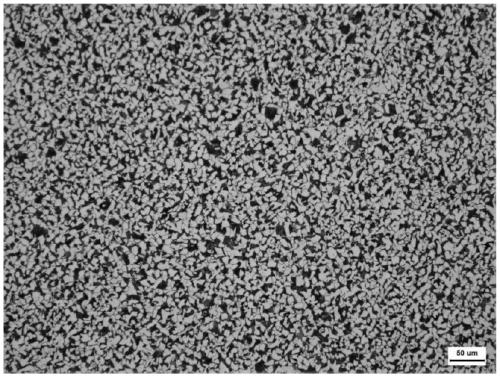

The invention discloses a high-strength and high-plasticity medium manganese cold-roll steel sheet and a manufacturing method thereof, and belongs to the technical field of metal material manufacturing. The high-strength and high-plasticity medium manganese cold-roll steel sheet comprises the following main components in percentage by mass: 0.15-0.25% of C, 7-8% of Mn, 1.2-1.8% of Si, and less than or equal to 0.05% of Al. The components are smelted and cast into a blank, and then the casting blank is subjected to multi-pass hot rolling so as to obtain a hot-rolled plate; the hot-rolled plate is subjected to intermediate heat treatment two times and two stages of cold rolling; the temperature of the intermediate heat treatment is 80-120 DEG C larger than Ar1, and the heat preservation time is 8 hours and above; in the two stages of cold rolling, the deformation is 30-50%; and the temperature of final heat treatment of the cold-roll steel sheet is Ar1+70 DEG C and above, and the annealing time ranges from 10 minutes to 2 hours. The cold-roll steel sheet disclosed by the invention is simple in preparation method, low in cost, and wide in application prospect. A prepared high-strength and high-plasticity medium manganese cold-roll steel sheet has excellent mechanical properties, and the product of strength and elongation of the cold-roll steel sheet can be up to 44.9 GPa*%.

Owner:UNIV OF SCI & TECH BEIJING

400-MPa-grade fine-grain hot rolled steel bar and manufacturing process thereof

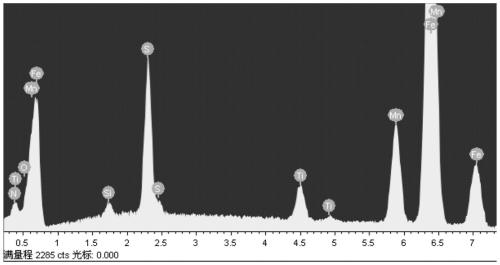

ActiveCN110042303AImprove performanceHigh strengthProcess efficiency improvementManganese sulfideRebar

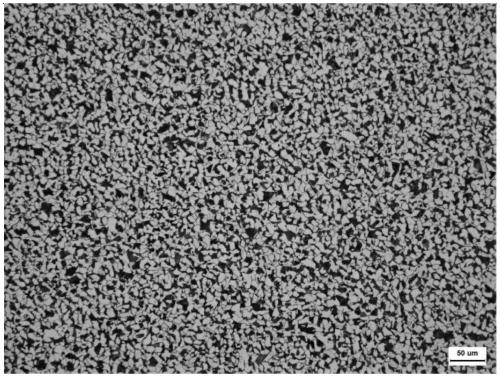

The invention discloses a 400-MPa-grade fine-grain hot rolled steel bar and a manufacturing process thereof, and belongs to the field of hot-rolled steel bar production. The steel bar comprises the following components in percentage by mass: 0.20-0.25% of C, 0.3-0.8% of Si, 1.2-1.6% of Mn, 0.01-0.04% of P, 0.01-0.04% of S, 0.005-0.03% of Ti, 0.001-0.08 % of Cr, 0.0001-0.008% of V, 0.0001-0.008% ofNb, 0.0001-0.008% of Al, 0.01-0.02% of O, 0.003-0.01% of N, and the balance Fe and inevitable impurities; and the steel bar further comprises manganese silicate inclusions, titanium oxide manganese sulfide multiphase inclusions, manganese sulfide inclusions, and other inevitable inclusions. The manufacturing process comprises the following steps of smelting molten steel, heating a continuous casting billet, and rolling a steel bar. According to the process, by combining optimization of the components and the inclusions with smelting continuous casting and rolling improvement as well as the inclusion induced fine grain strengthening mechanism, the strength of the steel bar is improved, the addition of precious alloy elements is reduced, and low-cost and high-quality production of the hot-rolled steel bar is achieved.

Owner:NORTHEASTERN UNIV

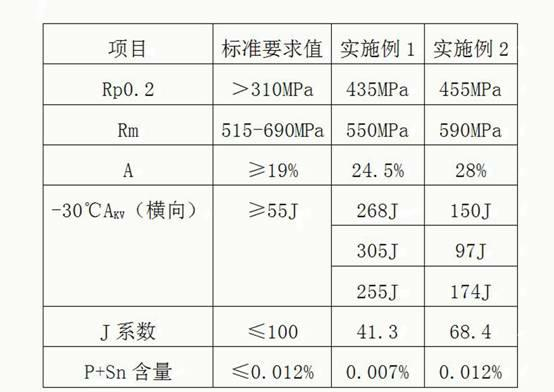

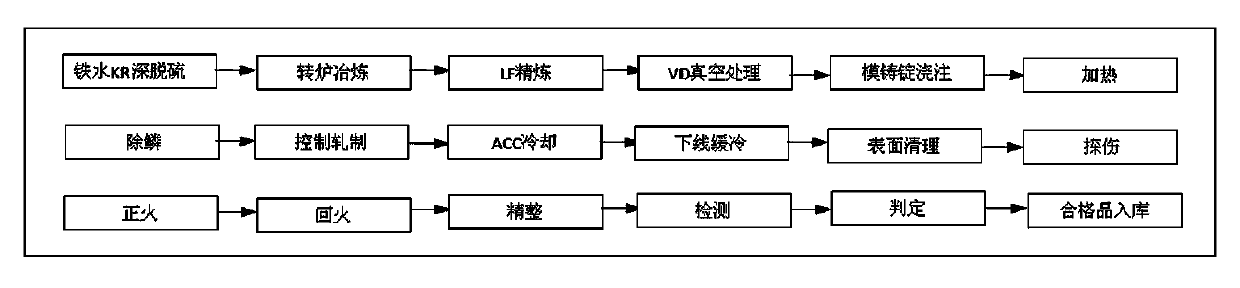

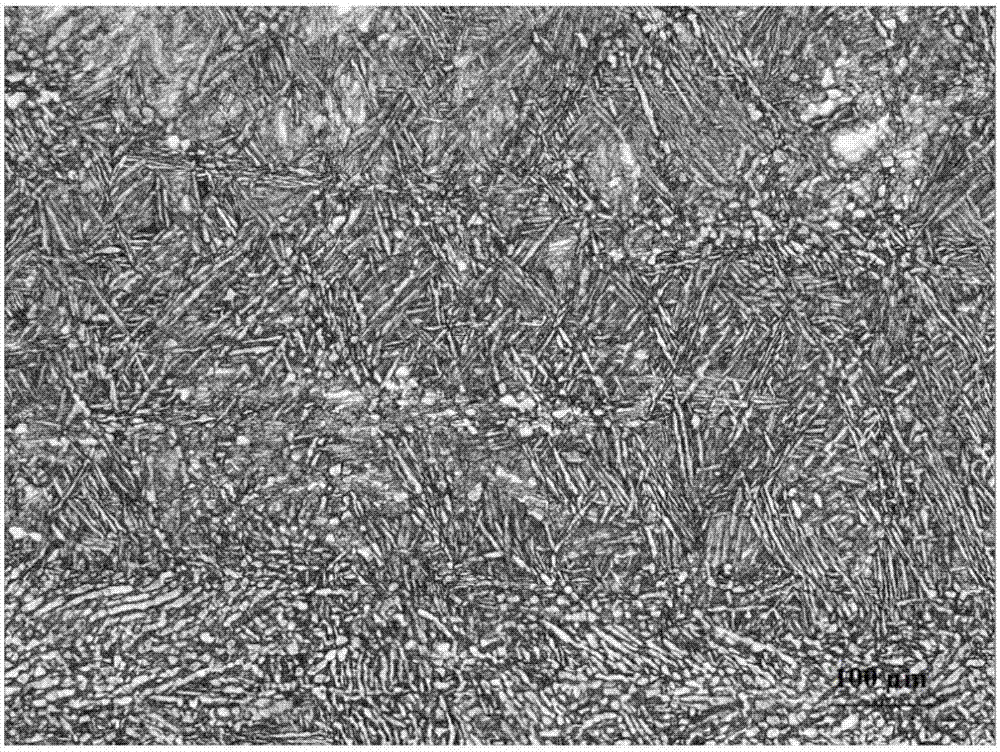

Large-thickness hydrogenating 14Cr1MoR steel plate and production method thereof

InactiveCN103710628AImprove low temperature toughnessGood welding performanceRolling millImpact toughness

The invention provides a large-thickness hydrogenating 14Cr1MoR steel plate and a production method thereof. The large-thickness hydrogenating 14Cr1MoR steel plate is composed of following elements: 0.10%-0.17% of C, less than or equal to 0.55% of Si, 0.40%-0.65% of Mn, less than or equal to 0.008% of P, less than or equal to 0.03% of S, less than or equal to 0.20% of Ni, 1.20%-1.50% of Cr, less than or equal to 0.10% of Cu, 0.45%-0.65% of Mo, 0.025%-0.050% of Al, less than or equal to 0.016% of As, less than or equal to 0.005% of Sn, less than or equal to 0.003% of Sb, less than or equal to 0.003% of O, less than or equal to 0.008% of N, less than or equal to 0.0002% of H and the balance of Fe and unavoidable impurities. The production method comprises the following steps: smelting; pouring; heating; rolling; carrying out water cooling; slowly cooling; carrying out heat treatment. The steel plate adopts a two-phase control rolling process, namely an II type control rolling process, so that the problems that the rolling pressure of a rolling machine is not enough, crystal grains are rough and not uniform and the impact toughness is reduced are solved; the rolling process of the steel plate is simple and easy, is easy to operate and is suitable for production of common steel factories with normalizing furnaces, outer machine furnaces and car bottom furnaces.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

400 MPa level fine grain threaded reinforcing bar and manufacturing method thereof

ActiveCN109930056AImprove performanceHigh strengthTemperature control deviceBuilding reinforcementsRebarAlloy element

The invention discloses a 400 MPa level fine grain threaded reinforcing bar and a manufacturing method thereof, and belongs to the field of threaded reinforcing bar production. The reinforcing bar comprises, by mass percentage, 0.20-0.25% of C, 0.3-0.8% of Si, 1.2-1.6% of Mn, 0.01-0.04% of P, 0.01-0.04% of S, 0.004-0.02% of Ti, 0.001-0.08% of Cr, 0.0001-0.008% of V, 0.0001-0.008% of Nb, 0.0001-0.008% of Al, 0.003-0.01% of O, 0.003-0.01% of N and the balanced of Fe and unavoidable impurities; manganese silicate inclusion, titanium oxide manganese sulfide complex inclusion, manganese sulfide complex inclusion and other unavoidable inclusions are included. The method comprises the steps of molten steel smelting, inclusion controlling, continuous casting, continuous casting blank heating and rolling cooling. The method has the advantages that optimizing designing is conducted on components and the inclusions, smelting and rolling are combined, a reinforcing mechanism of using the inclusions to induce fine crystalline to improve the strength of the reinforcing bar, the addition of precious alloy elements is reduced, and therefore the low-cost high-quality production of the threaded reinforcing bars is achieved.

Owner:NORTHEASTERN UNIV

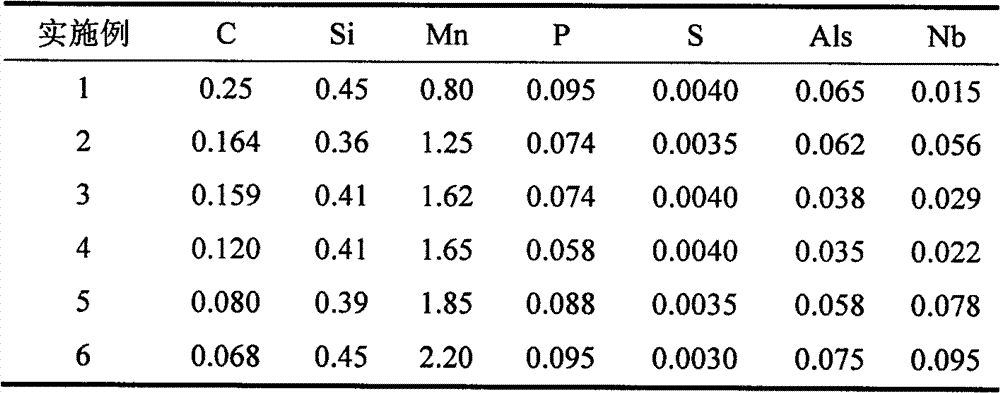

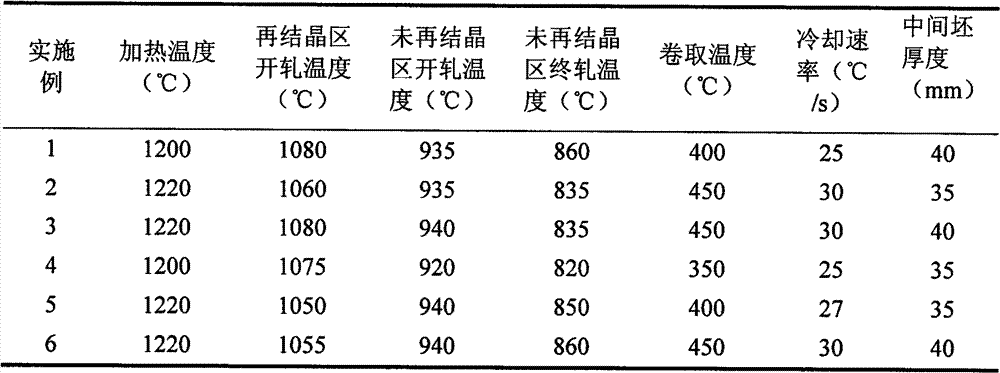

800MPa-grade hot-rolling transformation induced plasticity steel plate and its manufacturing method

The invention provides a 800MPa-grade hot-rolling transformation induced plasticity steel plate and its manufacturing method. The transformation induced plasticity steel plate and its manufacturing method comprises 0.05-0.3% of C, 0.5% or less of Si, 0.6-3.0% of Mn, 0.01-0.08% of Als, 0.05-0.1% of P, 0.01-0.1% of Nb, below 0.005% of S, and the balance Fe. The manufacturing method comprises the steps of slab continuous casting, direct heat charging, heating, rough rolling, precision rolling, laminar cooling and reeling, wherein the thickness of the continuous casting slab is 135-200mm, the heat charging temperature is not less than 400DEG C, the heating temperature is 1180-1220DEG C, two-phase control rolling is carried out at a maintained temperature for 1-3h, the rolling temperature is a recrystallization region is 1050-1100DEG C, the rolling temperature in a non-recrystallization region is 900-940DEG C, the finishing temperature is 820-880DEG C, the reduction rate is greater than 70%, the laminar cooling speed after rolling is 20-40DEG C / s, the reeling temperature is 350-500DEG C, and the finished product thickness is 3-10mm.

Owner:ANGANG STEEL CO LTD

Low-cost Mo-free plastic mould steel plate and production technology thereof

The invention relates to a low-cost Mo-free plastic mould steel plate and a production technology thereof. The low-cost Mo-free plastic mould steel plate comprises the following chemical components in percentage by weight: 0.36-0.42% of C, 0.26-0.34% of Si, 0.55-0.59% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 1.25-1.55% of Cr, 0-0.015% of Nb, 0.0015-0.0025% of B and the balance of Fe and inevitable impurities, wherein Cr / Mn is 2.1-2.6, and Si+Cr+Mn is 2.1%-2.4%. The low-cost Mo-free plastic mould steel plate has the advantages that a hot rolling+online quenching+tempering technology is adopted, the structure of the steel plate is martensite, martensite+bainite or martensite+bainite+few pearlites, and the hardness of the low-cost Mo-free plastic mould steel plate is 28-34HRC (Rockwell hardness). The low-cost Mo-free plastic mould steel plate does not contain valuable alloys such as Mo, is simple in process, short in period and low in cost and can be widely applied to various plastic molds.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

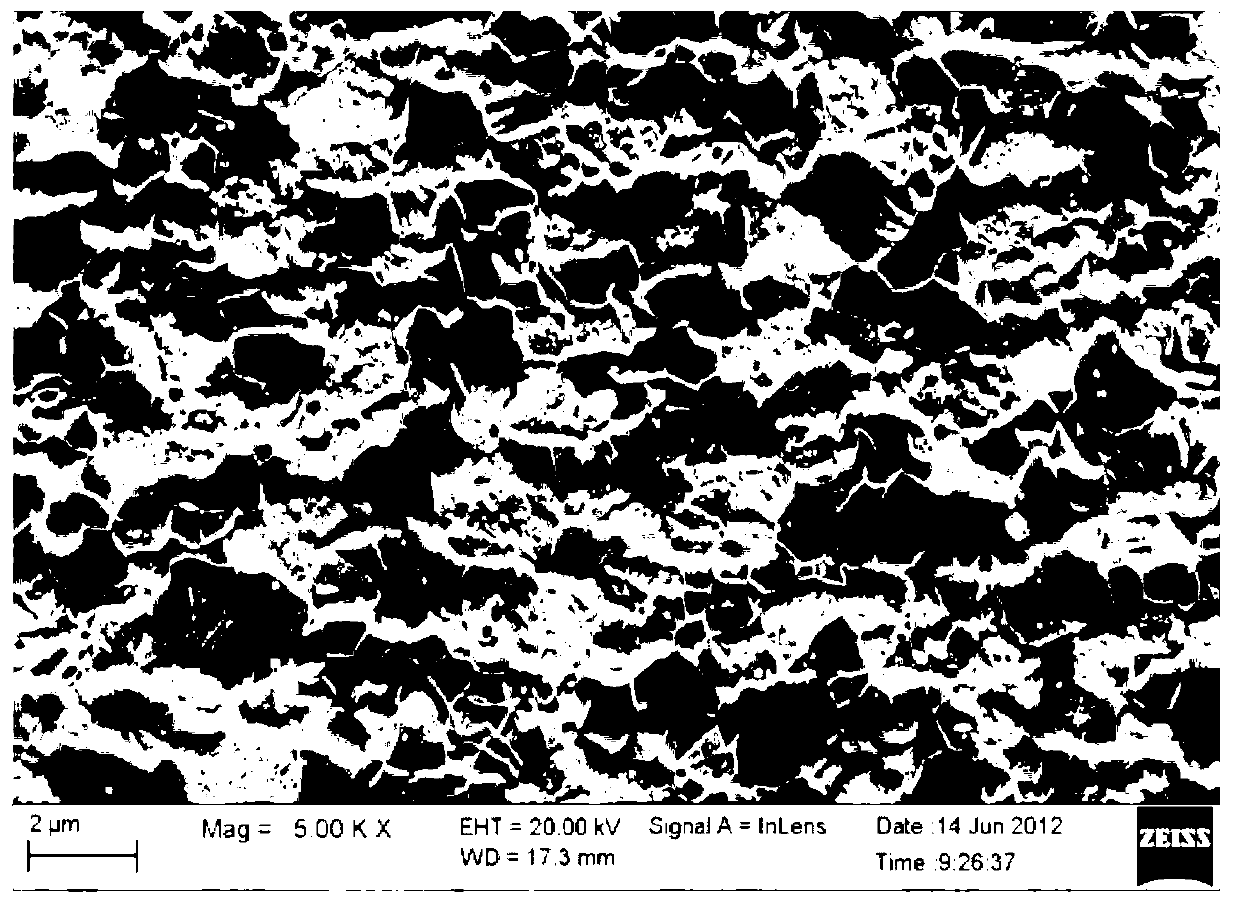

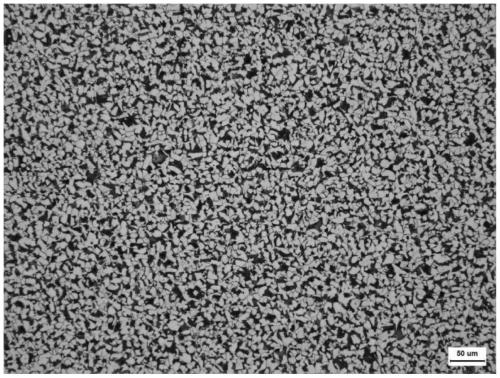

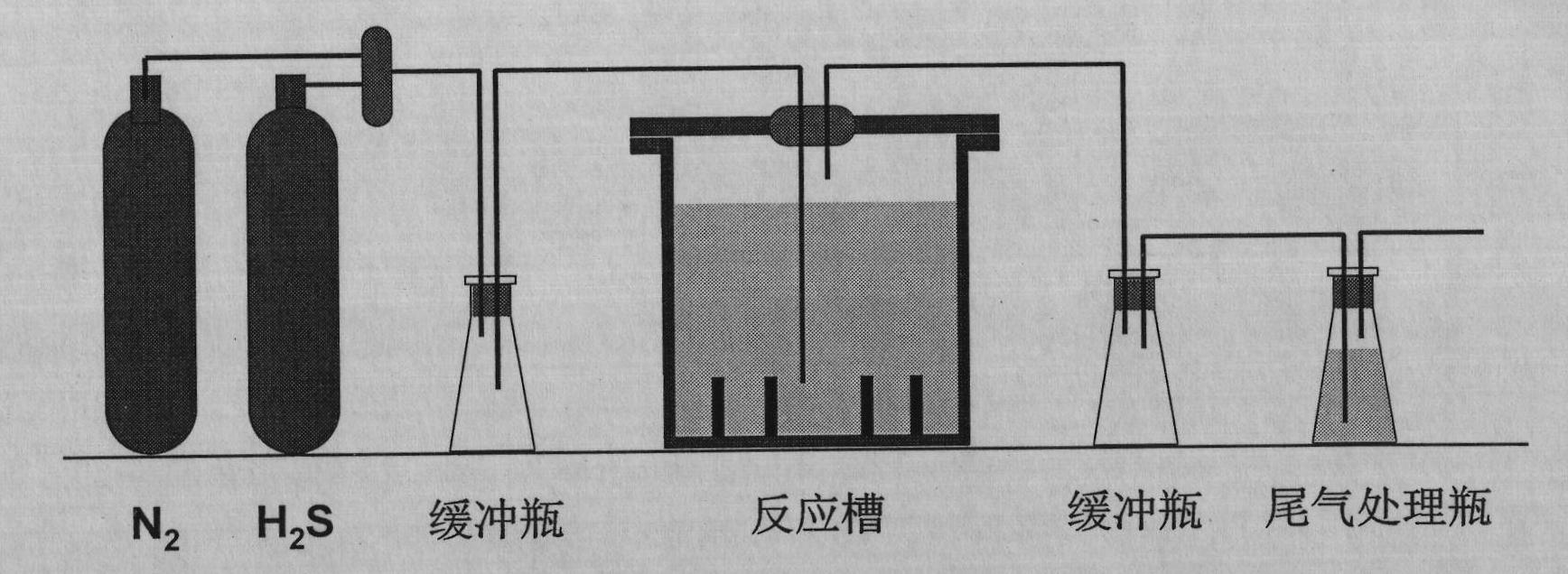

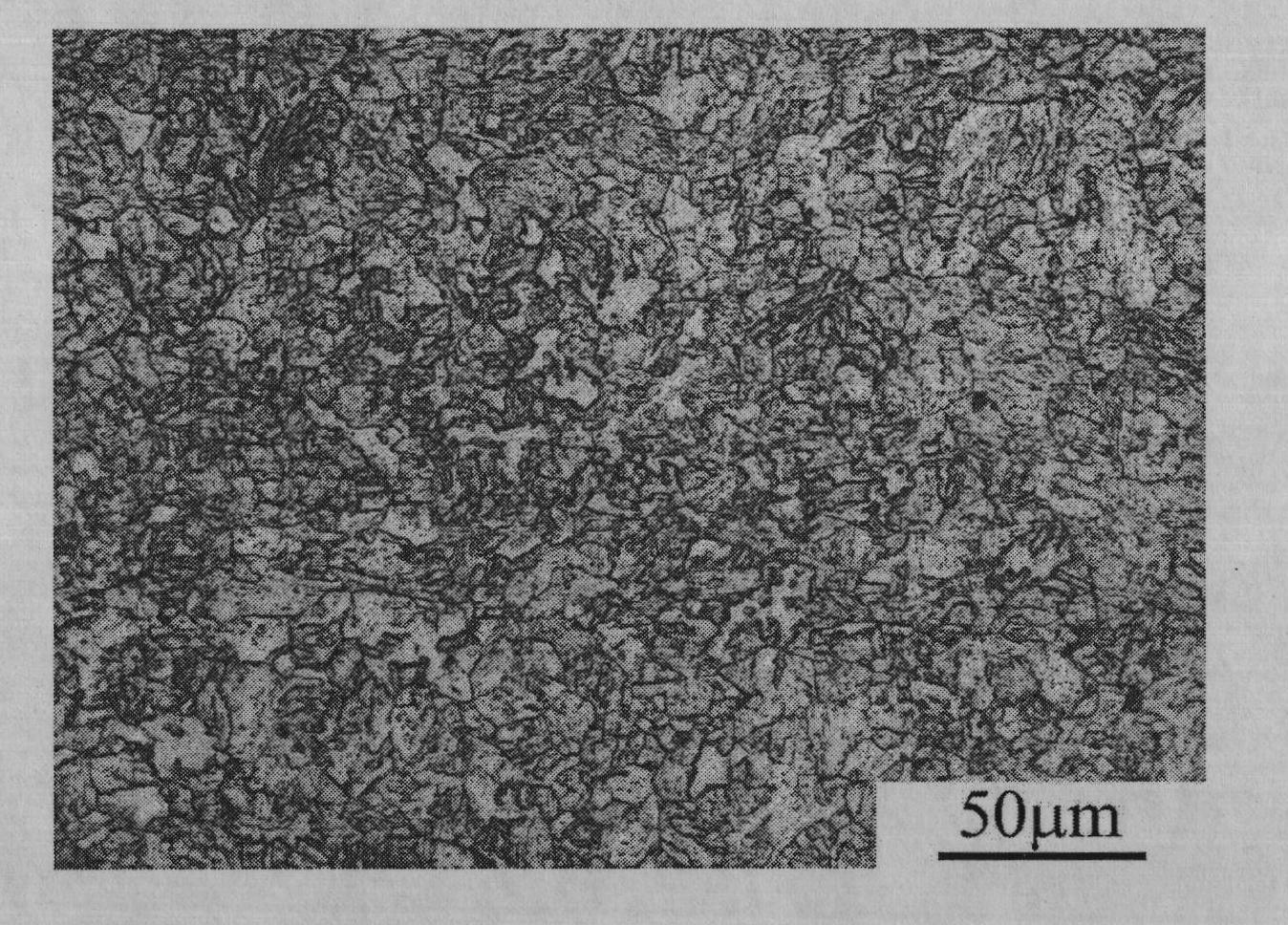

HIC-resistant heat resistant steel in iron element system and preparation process thereof

The invention relates to hydrogen induced cracking (HIC)-resistant heat resistant steel in an iron element system and a preparation process thereof. The steel comprises the following components in percentage by weight: 0.1 to 0.15 percent of C, 0.2 to 0.5 percent of Si, 0.3 to 0.6 percent of Mn, 2.0 to 2.5 percent of Cr, 0.9 to 1.1 percent of Mo, less than or equal to 0.003 percent of S, less than or equal to 0.010 percent of P and the balance of iron and impurities. The preparation process comprises a heating process, a hot rolling process and a heat treatment process sequentially, wherein the heat treatment process comprises a normalizing process and a tempering process. The steel has a high comprehensive mechanical property, a high low-temperature impact property, high HIC resistance and relatively low tempering tendering sensitivity; and the preparation process is simple, easy to operate, low in cost, high in yield and wide in thickness specification ranges, and a small number of alloys with a few varieties are added.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Low yield ratio chromium-molybdenum steel plate and production method thereof

The invention relates to a low yield ratio chromium-molybdenum steel plate and a production method thereof, belonging to the technical field of steel smelting. The production method comprises the following processes of smelting continuous casting, heating and rolling, and thermal treating. The steel plate comprises the following components by weight percent: more than or equal to 0.13% and less than or equal to 0.17% of C, more than or equal to 0.30% and less than or equal to 0.40% of Si, more than or equal to 0.50% and less than or equal to 0.70% of Mn, less than or equal to 0.007% of P, less than or equal to 0.005% of S, more than or equal to 1.00% and less than or equal to 1.10% of Cr, more than or equal to 0.50% and less than or equal to 0.65% of Mo, less than or equal to 0.20% of Cu, more than or equal to 0.10% and less than or equal to 0.20% of Ni, less than or equal to 0.003% of Sb, less than or equal to 0.010% of Sn, less than or equal to 0.010% of As, the balance of Fe and inevitable impurities. The low yield ratio chromium-molybdenum steel plate meets the requirement of domestic and aboard petrifaction and coalification industries on lowing the yield ratio of the chromium-molybdenum steel plate used at high temperature environment, can be widely used on devices such as delay coking devices of coke drums and hydrogenation reactor and the like, has good cold bending property, does not crack when being manufactured, and has good rebound elasticity and good plate shape.

Owner:WUYANG IRON & STEEL +1

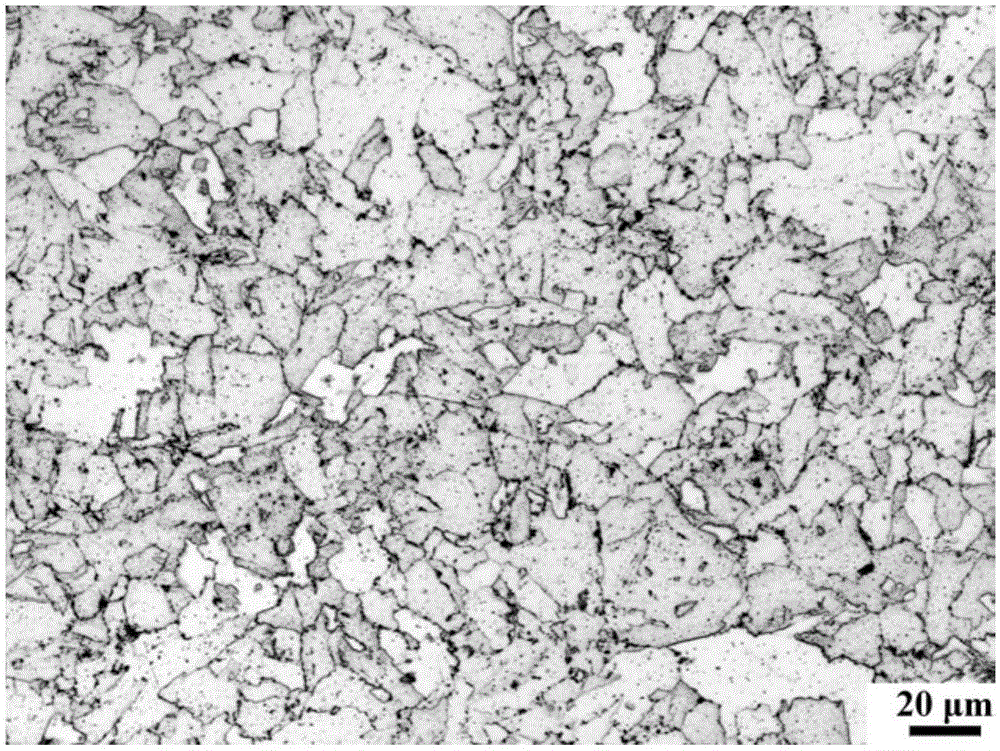

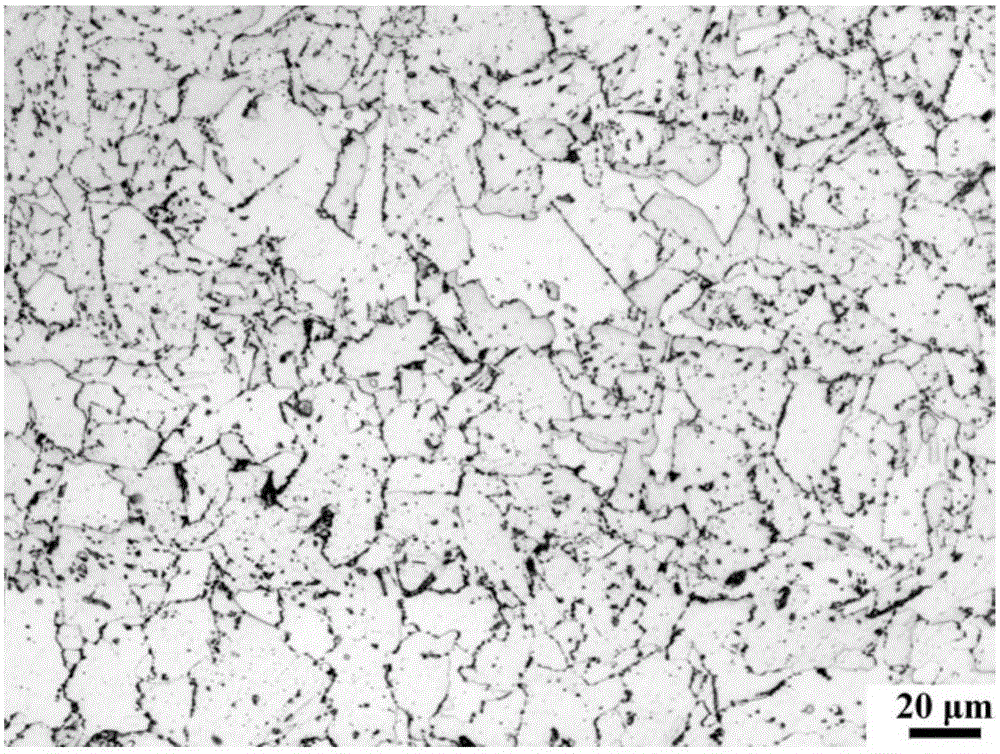

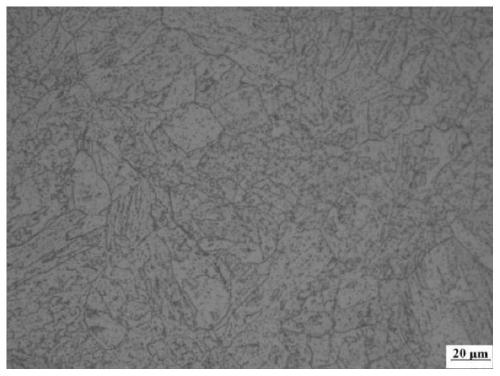

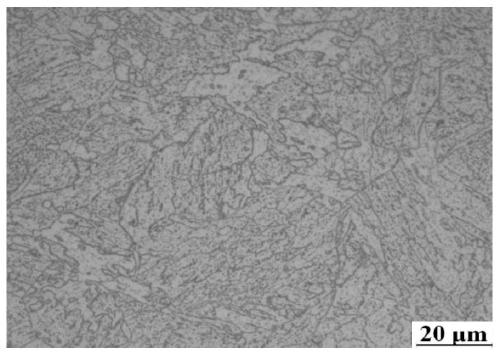

Single fire rolling method of TC4 titanium alloy moderate-thickness plate

ActiveCN107952794AImprove uniformityImprove surface qualityTemperature control deviceWork treatment devicesNational standardHot working

The invention belongs to the technical field of titanium alloy hot working forming and particularly relates to a single fire rolling method of a TC4 titanium alloy moderate-thickness plate. For the problems that the multi-fire-time rolling technology generally needs to be adopted for preparing and obtaining a TC4 titanium alloy with an excellent structure property, and forming performance of an alloy rolled in a single fire manner is poor, the single fire rolling method of the TC4 titanium alloy moderate-thickness plate comprises the following steps that a, a TC4 titanium alloy plate blank isheated; b, after soaking is completed, the soaking temperature is increased to 1000 DEG C to 1020 DEG C, the temperature continues to be kept for 30-60 min, and then the plate blank is discharged froma furnace and rolled; c, before rolling is carried out, roller way cooling water and phosphorus removal water are turned off, the beginning rolling temperature is larger than or equal to 950 DEG C, and the final rolling temperature is larger than 800 DEG C; and d, the rolled plate blank is subjected to annealing heat treatment, then the plate blank is discharged from the furnace and cooled in air, and the TC4 titanium alloy is obtained. According to the method, structure uniformity of the rolled TC4 titanium alloy moderate-thickness plate is good, the surface quality is good, and the requirement of the national standard can be met. The rolling technology is simplified, the rolling efficiency is improved, and the production cost is reduced remarkably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Magnesium-lithium alloy foil and preparation method and application thereof

ActiveCN111004951AShort preparation processImprove efficiencyTemperature control deviceMetal rolling arrangementsIngotAluminum foil

The invention belongs to the technical field of magnesium-lithium alloy materials, and particularly relates to a magnesium-lithium alloy foil and a preparation method and application thereof. A magnesium-lithium alloy cast ingot is coiled into an alloy coiled tape with the thickness of 1.5-3.5 mm through large-deformation hot extrusion cogging, then, multi-pass coiling type cooling rolling is conducted through a four-roller aluminum foil rolling mill provided with a tension roller set and a coiling machine, and thus the magnesium-lithium alloy foil is obtained, wherein the minimum thickness ofthe magnesium-lithium alloy foil can be rolled to 0.014 mm. The foil is short in preparation process, high in efficiency, small in residual stress, fine in grain, smooth, free of burrs and high in yield, and the yield can reach 80% or above. The magnesium-lithium alloy foil is used for preparing a vibrating diaphragm or a vibrating diaphragm dome base material, and has good shock absorption performance and high fidelity.

Owner:郑州轻研合金科技有限公司

High-strength ultra-thick steel plate and production method thereof

The invention relates to a high-strength ultra-thick steel plate and a production method thereof. The chemical components of the steel plate include, by weight, 0.0025-0.025% of C, 0.16-0.36% of Si, 0.85-1.15% of Mn, 2.1-4.5% of Ni, 0.8-1.2% of Cu, 0.008-0.035% of Ti, 0.8-1.2% of Al and the balance Fe and unavoidable impurities. The high-strength ultra-thick steel plate adopts an ultra-low carbon component, the alloy contents of Ni, Cu, Al and Ti are reasonably configured, a normalizing plus tempering process is adopted, and three nanoscale intermetallic compounds of Ni3Al, Ni3Cu and Ni3Ti and a Cu-rich phase are sufficiently formed in the tempering process. The thickness of the steel plate made from the components and through the process is larger than or equal to 100 mm, the yield strength Rp0.2 is larger than or equal to 900 MPa, the tensile strength Rm is larger than or equal to 1000 MPa, the percentage elongation after fracture is larger than or equal to 12%, the welding performance, cold bending performance and a plate profile are good, the grain performance in the thickness direction is uniform, and a plate thickness effect is avoided. The steel plate produced through the method can be widely applied to various large-thickness steel plate application fields such as heavy engineering machinery, large building structures and bridge structures.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

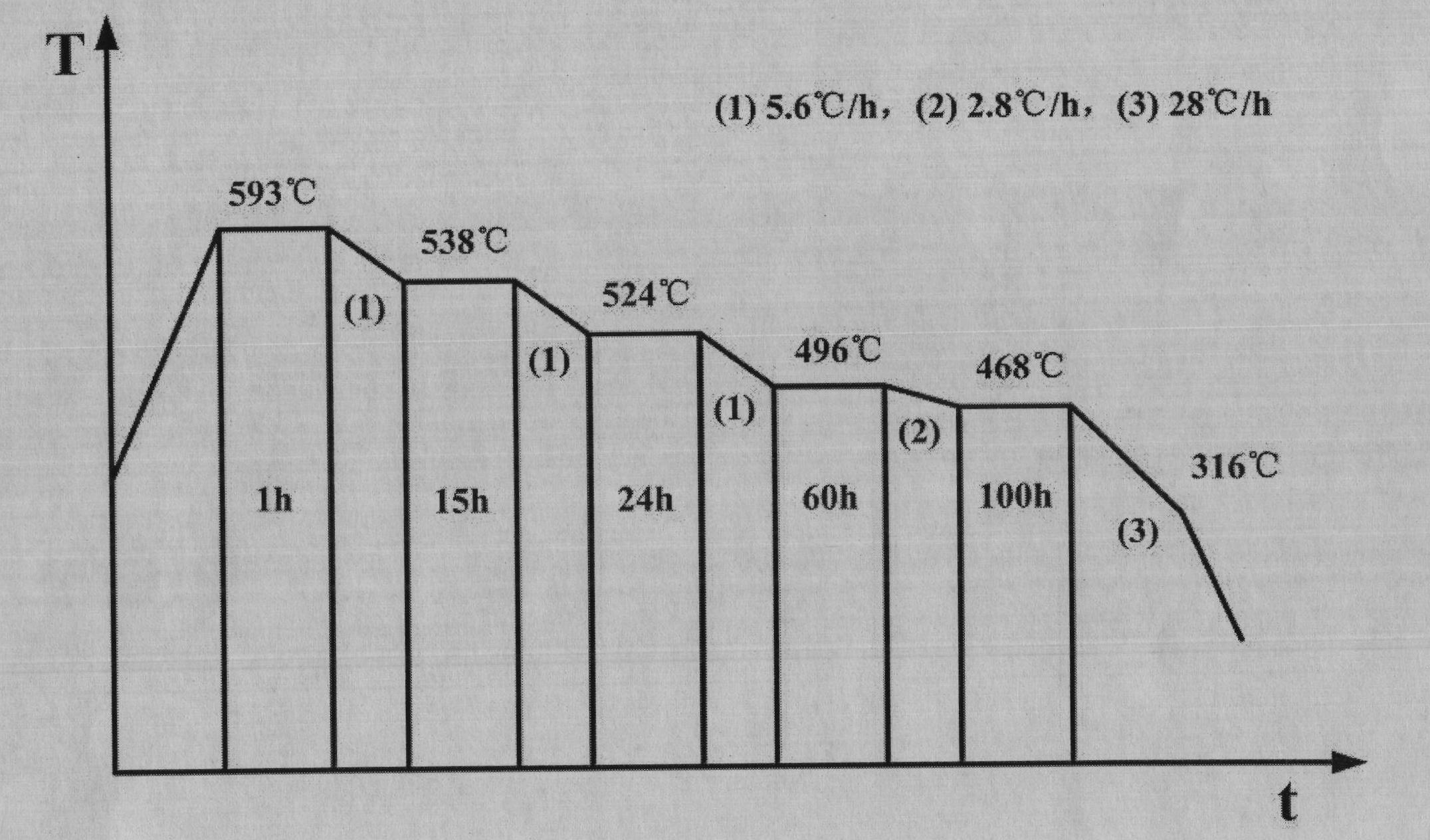

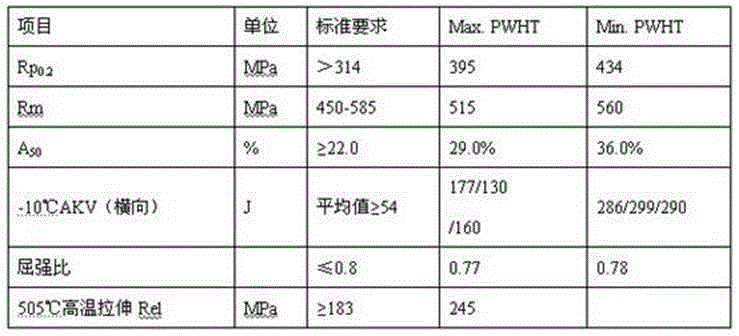

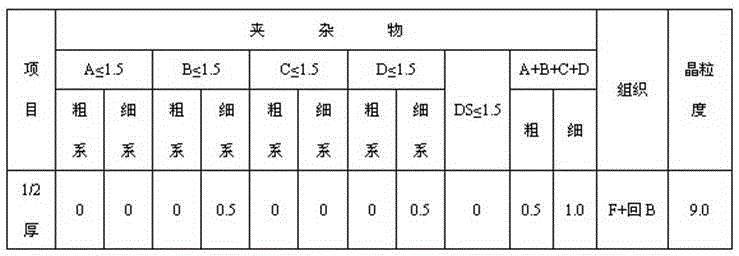

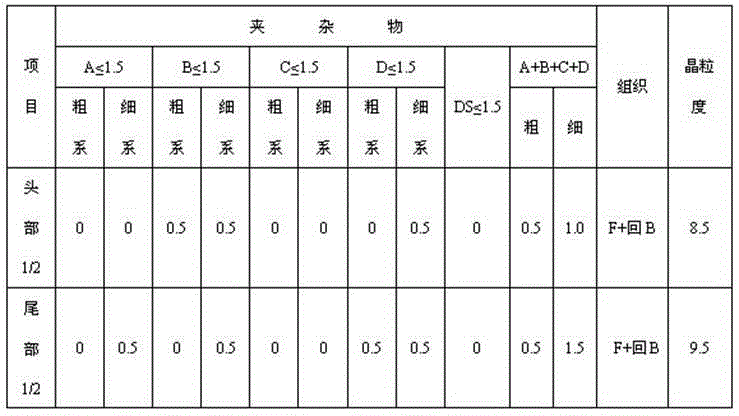

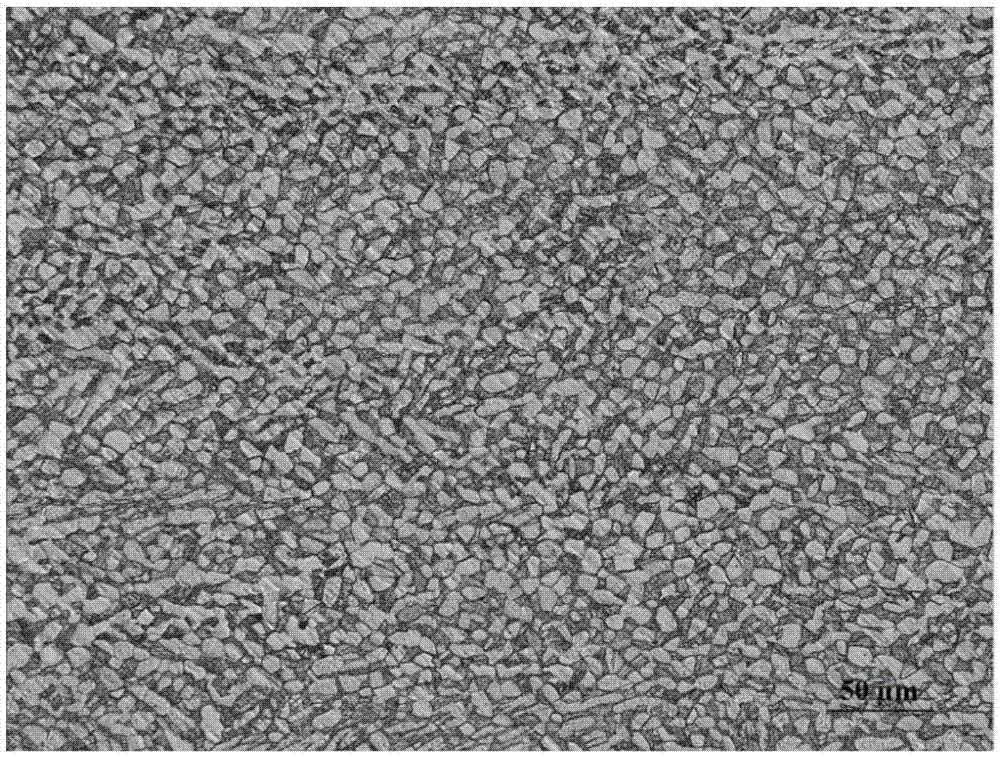

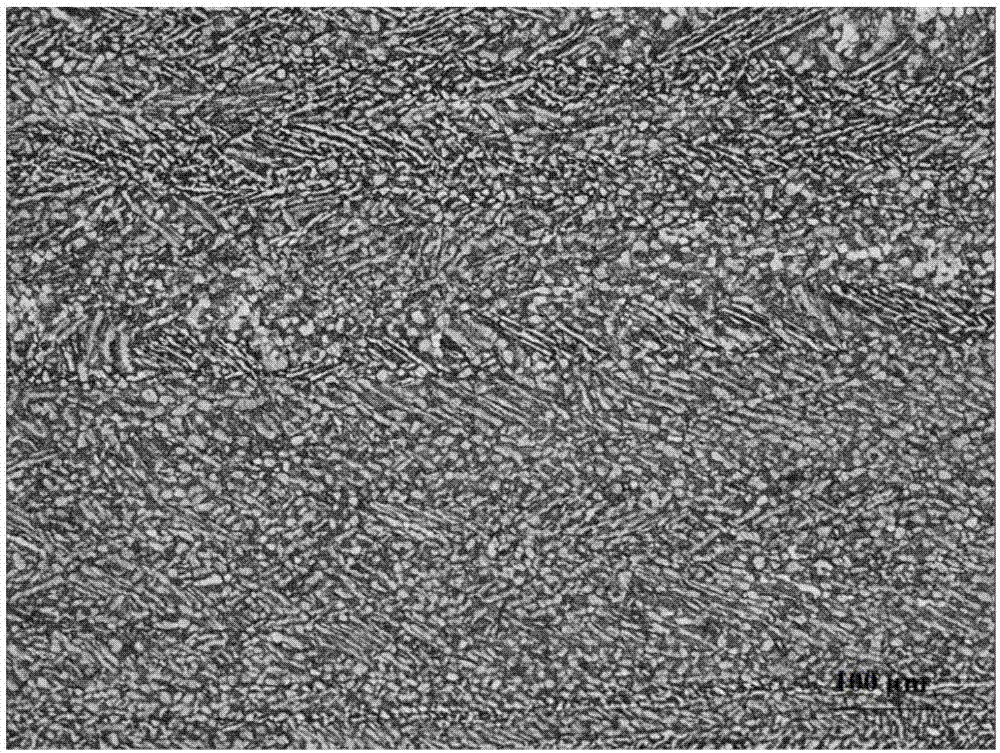

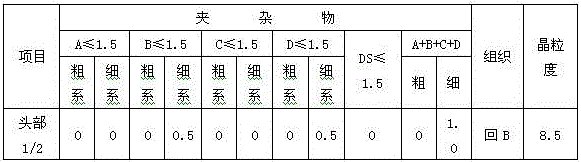

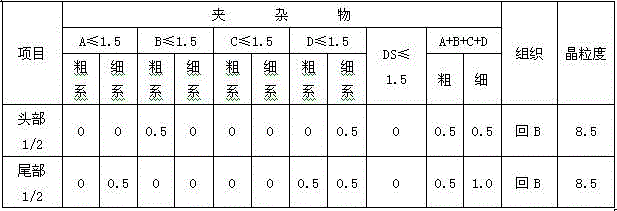

Large-thickness 14Cr1MoR steel plate and production method thereof

The invention discloses a large-thickness 14Cr1MoR steel plate and a production method thereof. The large-thickness 14Cr1MoR steel plate comprises the following chemical components in percentage by mass: 0.12-0.14% of C, 0.5-0.6% of Si, 0.40-0.50% of Mn, 0.006-0.007% of P, equal to or less than 0.005% of S, 1.3-1.5% of Cr, 0.58-0.60% of Mo, 0.10-0.20% of Ni, equal to or less than 0.05% of Nb, equal to or less than 0.20% of Cu, equal to or less than 0.003% of Sb, equal to or less than 0.010% of Sn, equal to or less than 0.010% of As and the balance of Fe and unavoidable impurities. The production method comprises the procedures of smelting, continuous casting, heating, rolling and thermal treatment. According to the production method, the two-stage rolling control technology and the thermaltreatment technology of normalizing and tempering are adopted to solve the problems that the crystal particles are thick, non-uniform, lower in impact toughness and higher in hardness, and the head performance and the tail performance of the steel plate differ widely.

Owner:WUYANG IRON & STEEL

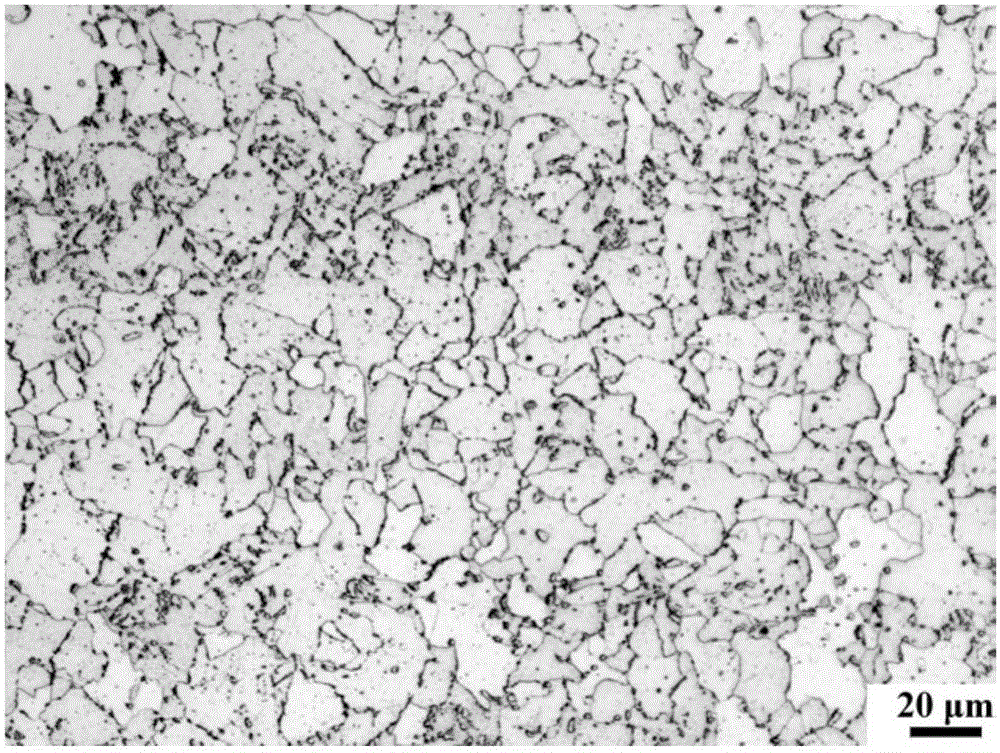

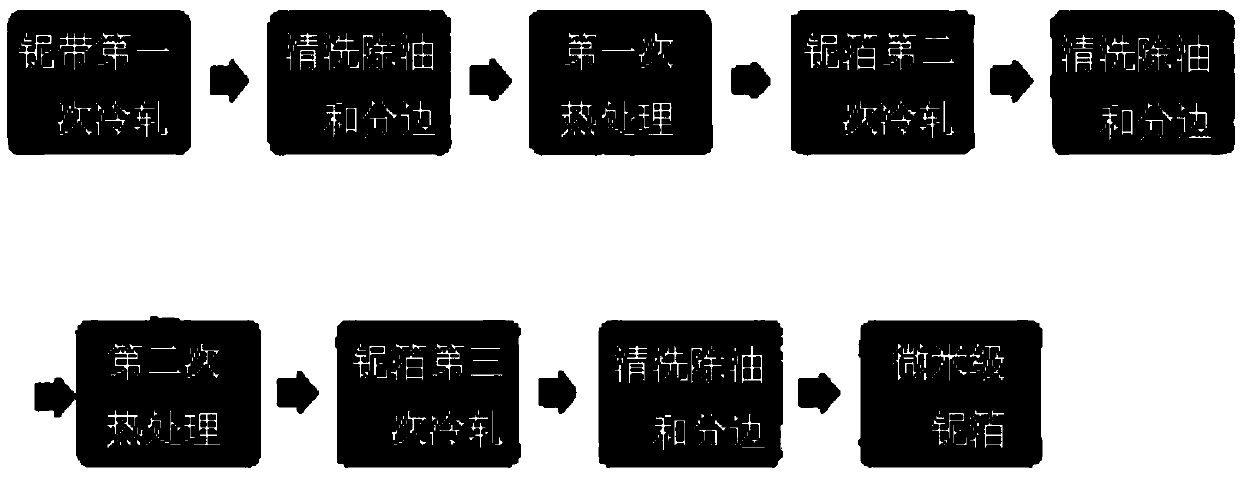

Preparation method of micro order niobium foil

The invention discloses a preparation method of a micro order niobium foil. According to the method, three rolling process reversible type rolling is performed on a niobium belt by utilizing a Sendzimir twenty-roller cold rolling machine, the obtained niobium foil is cleaned, and subjected to edge splitting and heat treatment after each rolling process reversible type rolling, and finally, the micro order niobium foil is obtained. According to the method, three rolling process rolling is performed on the niobium belt with the width being 100 mm to 120 mm and the thickness being 0.15 mm to 0.2mm by adopting the Sendzimir twenty-roller cold rolling machine. Due to the beneficial effects that the Sendzimir twenty-roller cold rolling machine is large in rolling force and high in rolling precision, by designing a reasonable rolling process, the thickness precision of the micro order niobium foil is greatly guaranteed; meanwhile, through a reasonable annealing process, the structure internal stress of the niobium foil is eliminated in time, influences on the niobium foil in the rolling process are reduced, and finally, the micro order niobium foil with the thickness being 0.007 mm to 0.009 mm is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

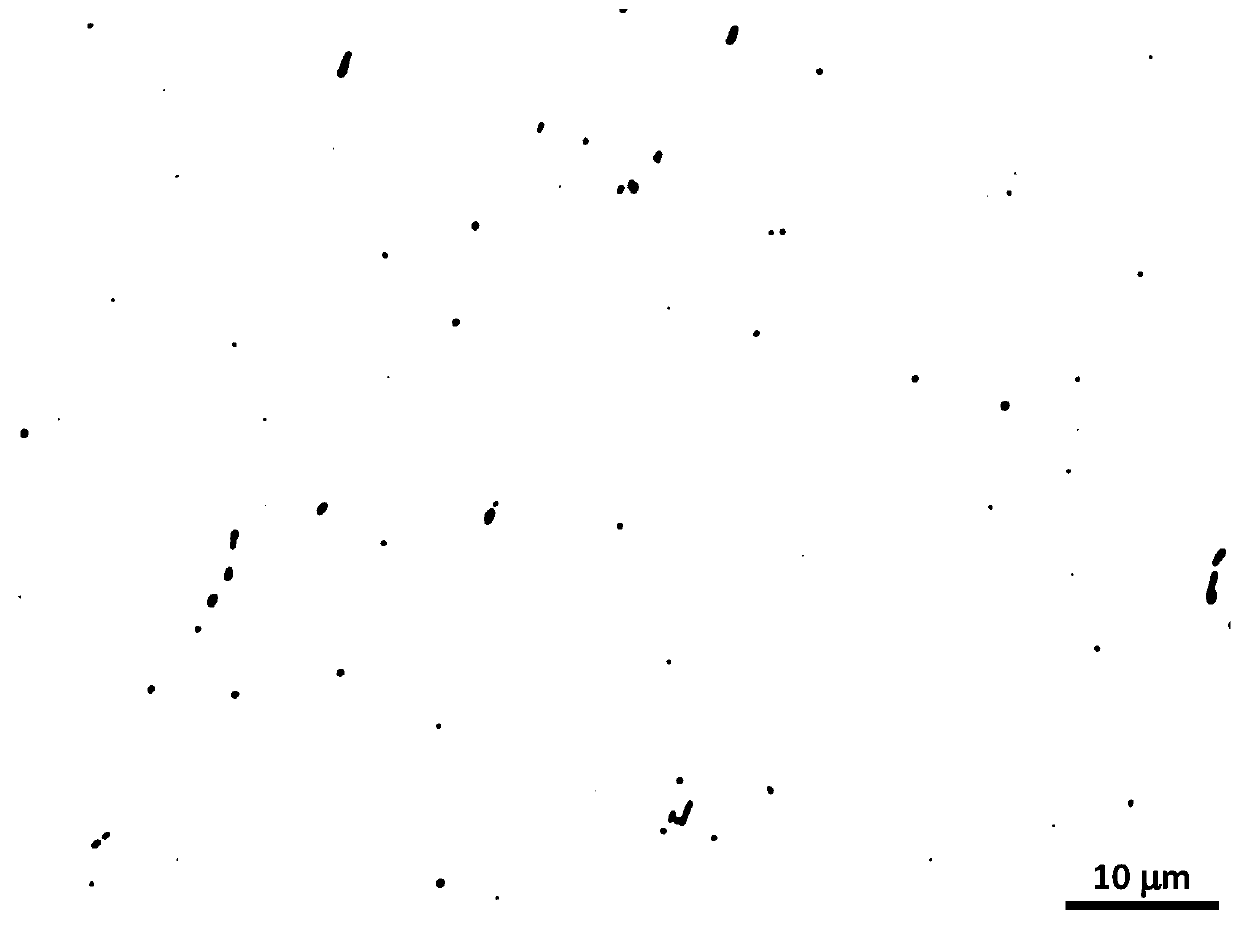

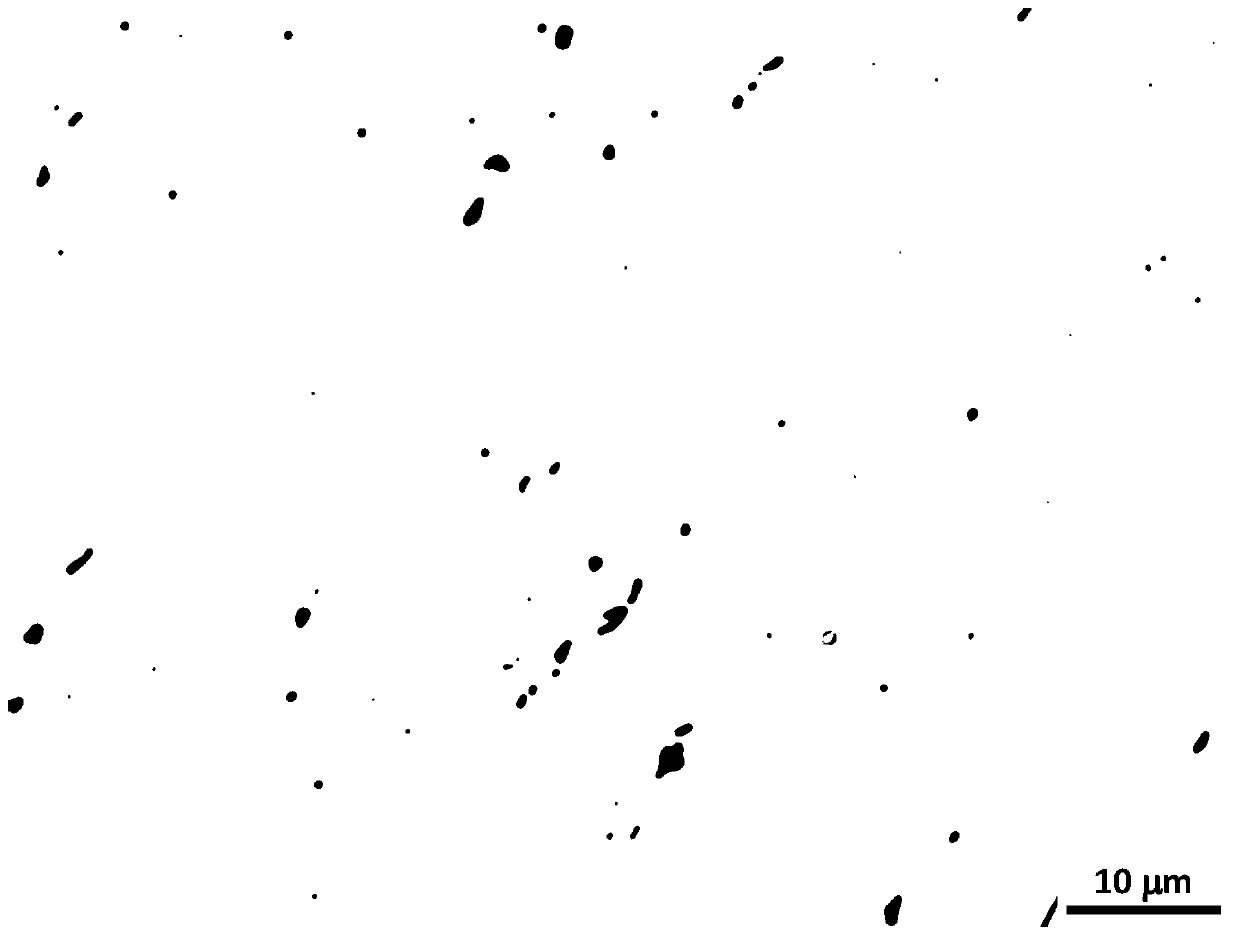

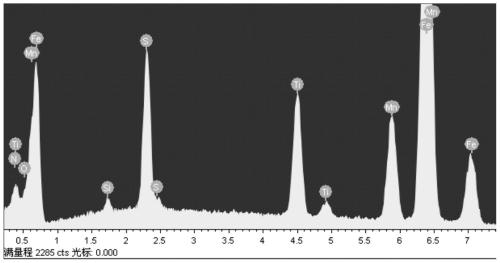

500MPa-grade niobium-containing screw-thread reinforcing steel bar and manufacturing method thereof

The invention relates to a 500MPa-grade niobium-containing screw-thread reinforcing steel bar and a manufacturing method thereof, and belongs to the field of screw-thread reinforcing steel bar production. The reinforcing steel bar comprises 0.20 to 0.25 percent of C, 0.5 to 0.8 percent of Si, 1.2 to 1.6 percent of Mn, 0.01 to 0.04 percent of P, 0.01 to 0.04 percent of S, 0.005 to 0.02 percent of Ti, 0.001 to 0.01 percent of RE, 0.015 to 0.035 percent of Nb, 0.003 to 0.01 percent of O, 0.003 to 0.01 percent of N, and the balance Fe and inevitable impurities. In the reinforcing steel bar, the quantity of Nb-compound-containing precipitates with the equivalent diameter being 0.003 to 0.03mum is 50 to 500pcs / mum<2>; and the total quantity of RE-compound-containing and / or Tti-compound-containing occluded foreign substances with the equivalent diameter being 0.03 to 3mum is 2000 to 4000pcs / mm<2>. The preparation method of the 500MPa-grade niobium-containing screw-thread reinforcing steel barcomprises the steps of smelting, controlling the occluded foreign substances, continuously casting, heating a continuous casting blank, and rolling the reinforcing steel bar. The method can realize the low-cost high-quality production of the 500MPa-grade screw-thread reinforcing steel bars.

Owner:NORTHEASTERN UNIV

Acid corrosion resistance martensite wear-resisting steel plate and manufacturing method thereof

ActiveCN111575581AGuaranteed corrosion resistanceImprove mechanical propertiesFurnace typesHeat treatment furnacesAcid corrosionMartensite

The invention discloses an acid corrosion resistance martensite wear-resisting steel plate. The steel plate is prepared from, by mass, 0.14-0.22 wt% of C, 0.30-0.60 wt% of Si, 0.30-1.00 wt% of Mn, 0.010-0.020 wt% of Ti, 0.02-0.04 wt% of Nb, 0.50-1.0 wt% of Ni, 0.20-0.50 wt% of Cu, 0.9-1.3 wt% of Cr, 0.08-0.12 wt% of Sb, 0.0010-0.0020 wt% of B, 0-0.003 wt% of S and 0-0.012 wt% of P. The acid corrosion resistance martensite wear-resisting steel plate can achieve the purposes of good hardness, plasticity, wear resistance and corrosion resistance of the steel plate.

Owner:湖南华菱涟源钢铁有限公司 +3

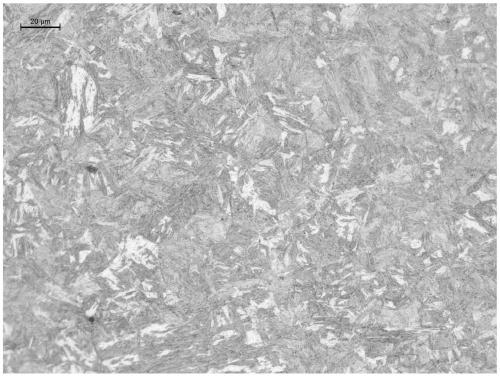

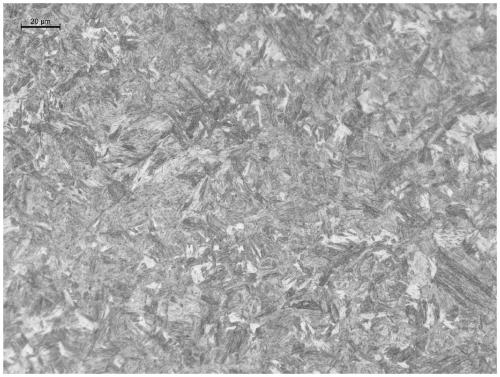

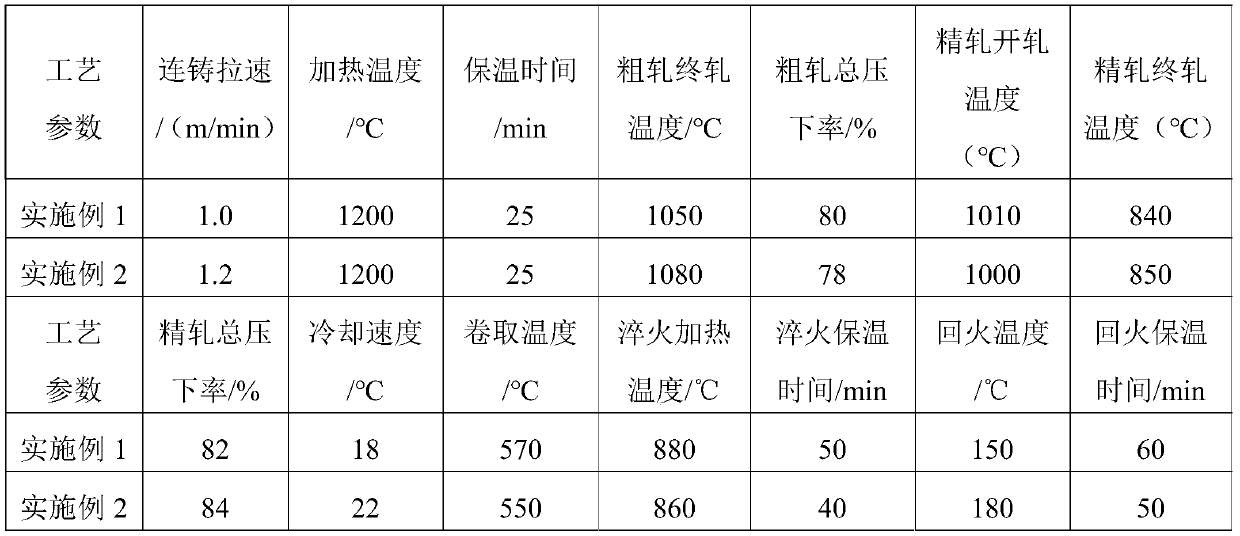

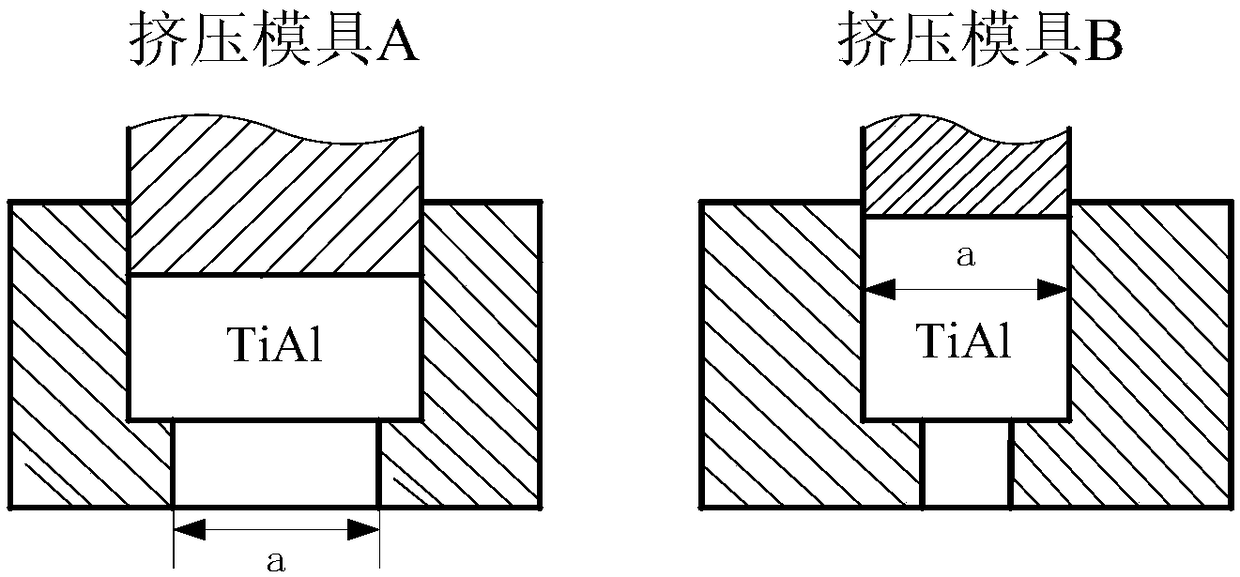

One-step large-deformation rolling method of beta solidification TiAl alloy plate

ActiveCN108787750AAvoid bulkyAvoid small amount of deformation in a single passForging/pressing devicesFurnace typesBeta phaseRoom temperature

The invention provides a one-step large-deformation rolling method of a beta solidification TiAl alloy plate. The method comprises the following steps that 1, raw materials are weighed; 2, a TiAl alloy casted ingot is manufactured by utilizing a vacuum induction melting technology, and heat treatment is carried out; 3, two-step hot extrusion deformation is carried out on the alloy; and 4, one-steplarge-deformation packing rolling is carried out on the alloy, and a pack is removed so as to obtain the TiAl alloy plate which is uniform and fine in structure. According to the one-step large-deformation rolling method of the beta solidification TiAl alloy plate, the beta solidification TiAl alloy with excellent high-temperature deformation capability is adopted, the beta phase content is controlled to be 15%-25%, and the excellent high-temperature deformation capability of the TiAl alloy is ensured; meanwhile, the alloy structure of a blank is refined violently through the two-step extrusion so as to remarkably improve the structure uniformity of the alloy, and therefore, one-step large-deformation rolling of the blank can be guaranteed, finally, the TiAl alloy plate with the uniform and fine structure and good room temperature plasticity is obtained, and the problems that in the prior art, a TiAl alloy rolled blank is coarse in structure, plate forming is difficult, and the platestructure uniformity is poor are solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Steel plate with shear strength above 1150 MPa and production method thereof

The invention discloses a steel plate with shear strength above 1150 MPa and a production method thereof. The production method comprises a smelting and continuous casting procedure, a heating and rolling procedure and a heat treatment procedure; a continuously cast billet obtained in the smelting and continuous casting procedure comprises the following components in percentage by weight: 0.21%-0.26% of C, 0.20%-0.50% of Si, 1.15%-1.55% of Mn, 0-0.012% of P, 0-0.005% of S, 0.50%-0.80% of Cr, 0.30%-0.50% of Mo, 0.30%-0.50% of Ni, 0.040%-0.060% of V, 0.02%-0.03% of Nb, 0.020-0.030% of Ti, 0.020%-0.050% of Al, 0.0016%-0.004% of B, and Fe and inevitable impurities in balancing amount; and a two-stage rolling control technology is adopted in the heating and rolling procedure. Through the method, a low carbon equivalent chemical constituent design is realized, meanwhile the steel plate with a uniform and fine organization structure and excellent comprehensive mechanical properties is obtained, all mechanical property indexes of the produced steel plate meet requirements of technical specifications, and the production cost is remarkably reduced.

Owner:WUYANG IRON & STEEL

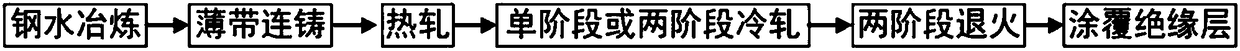

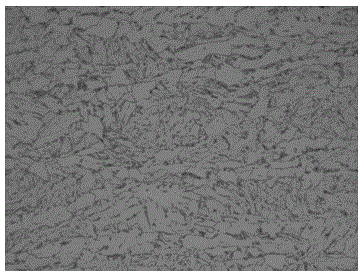

A method for preparing non-oriented silicon steel thin strip with developed {100} plane texture based on thin strip continuous casting

The invention belongs to the field of metallurgical technology, and particularly relates to a method for preparing non-oriented silicon steel thin strips with developed {100} surface texture based on continuous casting of thin strips. Follow the following steps: (1) Smelt molten steel according to the set composition. Its composition by weight is: C 0.01~0.05%, Si 1.5~3.0%, Mn 0.2~0.3%, Al≤0.005%, V 0.01~0.04% , S 0.002~0.005%, the balance is Fe and inevitable impurities; (2) Cast strip is formed after thin strip continuous casting process; (3) Hot rolling under inert atmosphere conditions; (4) Pickling to remove oxide scale, Then perform single-stage or two-stage cold rolling; (6) two-stage recrystallization annealing, coating with insulating coating and drying to obtain high-performance non-oriented silicon steel. The present invention provides a method for preparing non-oriented silicon steel thin strips with developed {100} surface texture based on thin strip continuous casting. On the basis of partially utilizing the genetic effect of {100} texture in the initial solidification structure, it provides driving force through subsequent decarburization phase transformation. The force promotes the formation of a developed {100} plane texture in the finished plate, thereby obtaining high-performance non-oriented silicon steel.

Owner:NORTHEASTERN UNIV LIAONING

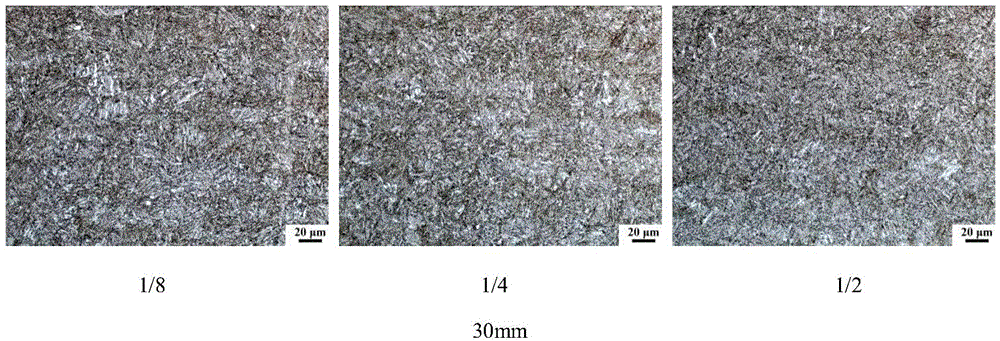

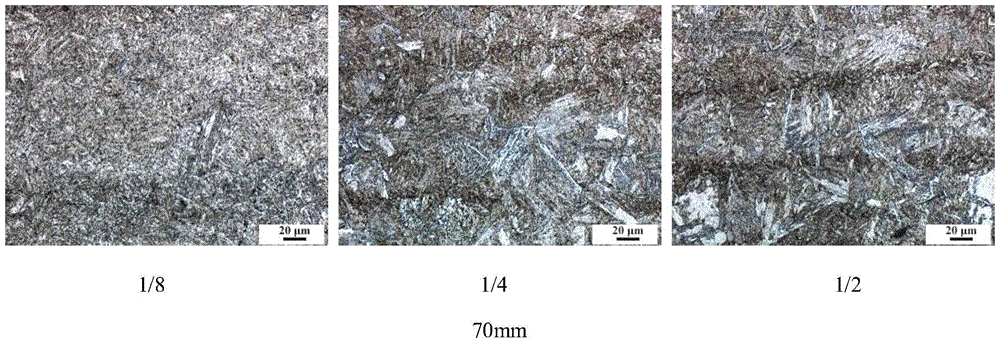

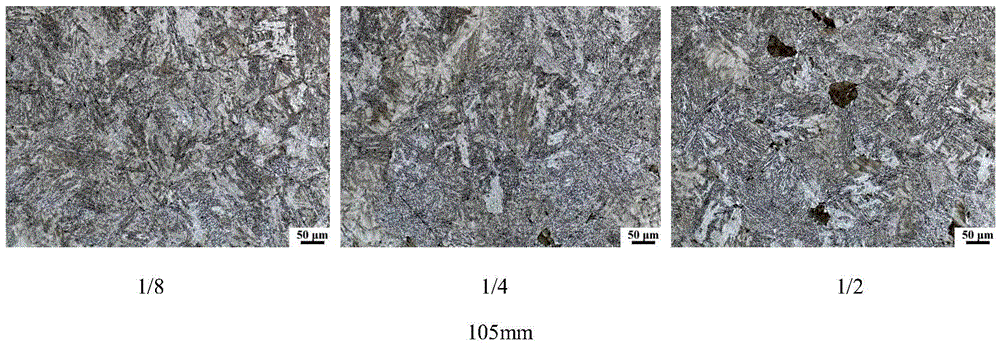

Large, thick, high-strength and high-toughness TMCP type steel plate and production method thereof

The invention discloses a large, thick, high-strength and high-toughness TMCP type steel plate and a production method thereof. The large, thick, high-strength and high-toughness TMCP type steel plate is composed of, by weight, 0.06%-0.08% of C, 0.20%-0.40% of Si, 1.40%-1.50% of Mn, 0.015% or less of P, 0.005% or less of S, 0.020-0.030% of Nb, 0.030%-0.050% of Alt, the balance Fe and inevitable impurities and 0.20% or less of Pcm. According to the steel plate, the components are simple, only a proper amount of microalloy Nb is added, and the precious elements such as V, Ti and Ni are not added; production cost is low, and the probability of large-scale production is increased. The steel plate is of a mixed structure mainly containing bainite, ferrite, pearlite and martensite and has a good comprehensive mechanical property; the steel plate is better in matching of the components and the strength and toughness, and it is guaranteed that the steel plate has the excellent comprehensive mechanical property; particularly, the impact performance of half of the plate in the thickness direction is good at the low temperature of minus 40 DEG C, and the method can be widely used for producing low-temperature-resistant building steel and engineering steel used in extremely cold climate. The method has the advantages that the production cost is low, and the technique is simple; the performance of products is excellent, and the comprehensive mechanical property of the products is stable.

Owner:WUYANG IRON & STEEL

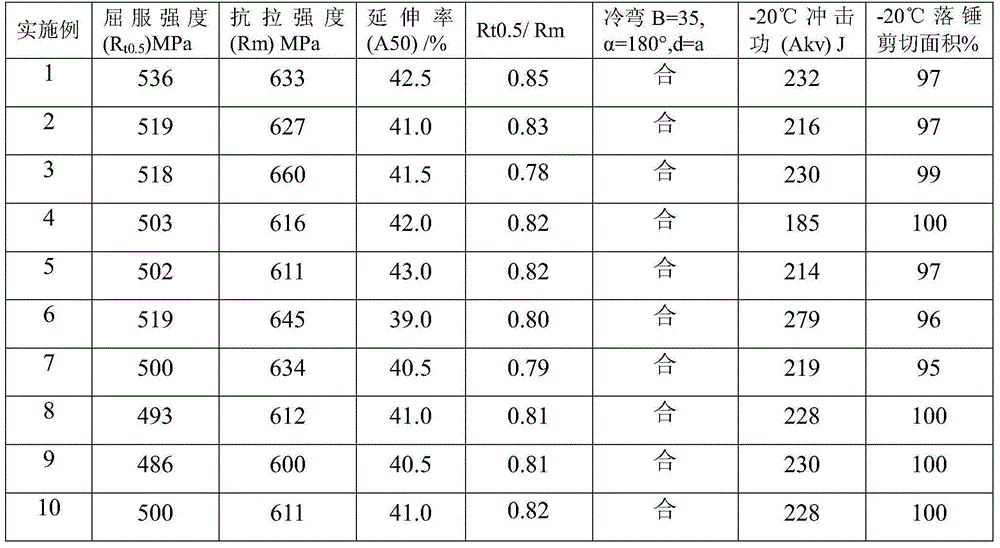

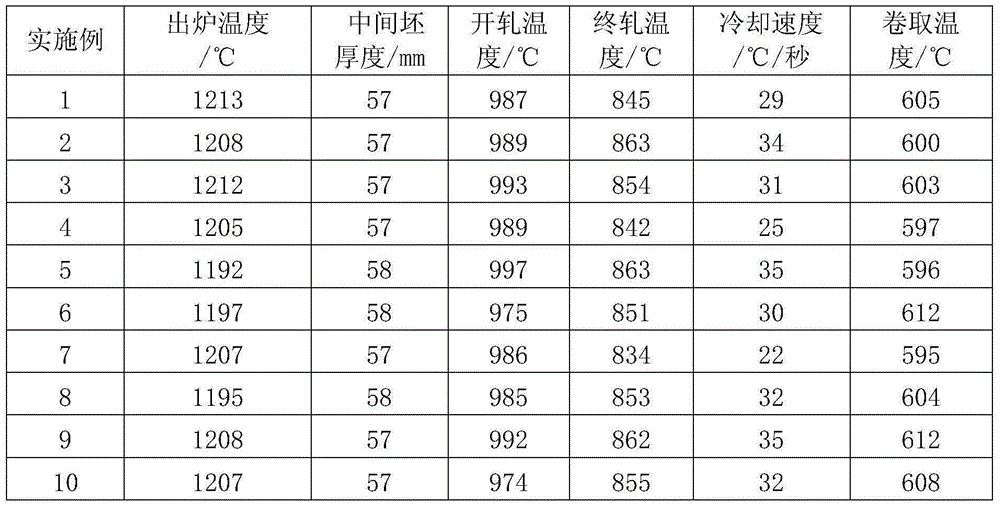

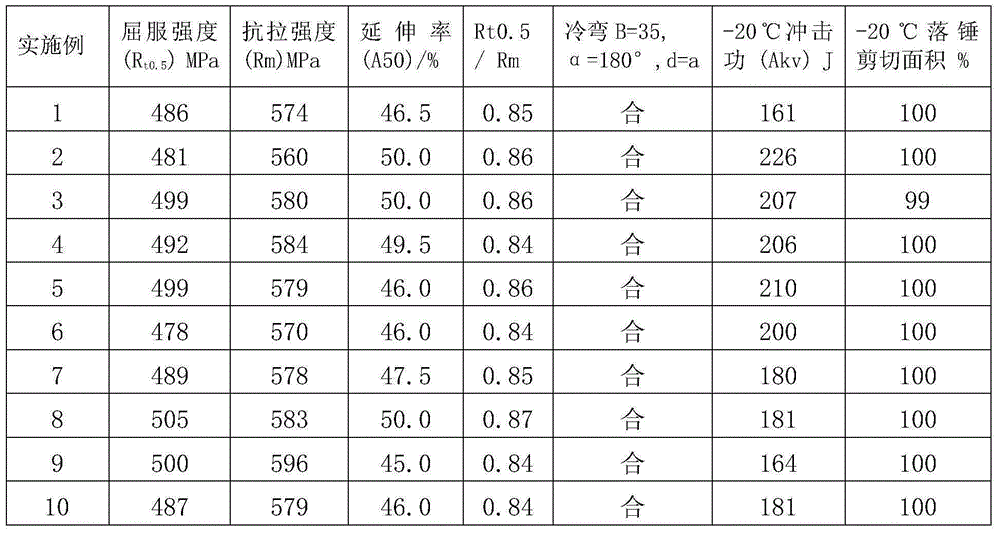

X65 pipeline steel and production method thereof

The invention belongs to the technical field of production of hot-continuous-rolled plate strips and particularly relates to X65 pipeline steel and a production method thereof. According to the technical scheme used for solving technical problems, the X65 pipeline steel comprises, by weight, 0.065%-0.10% of C, 0.10%-0.30% of Si, 1.40%-1.60% of Mn, equal to or less than 0.020% of P, equal to or less than 0.010% of S, 0.030-0.039% of Nb, 0.06%-0.08% of V, 0.008%-0.020% of Ti and the balance Fe and inevitable impurities. The X65 pipeline steel and the production method thereof have the characteristics that the cost is relatively low, the rolling technique is simple, and the operability is high. The yield strength of the X65 pipeline steel produced through the method is 480-540 MPa, the tensile strength of the X65 pipeline steel is 600-660 MPa, and the impact energy of the X65 pipeline steel at the temperature of minus 20 DEG C is equal to or larger than 180 J.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

High-chromium chromium-molybdenum steel plate and production method thereof

The invention discloses a high-chromium chromium-molybdenum steel plate and a production method thereof. The steel plate is composed of the following components in percentage by weight: 0.09%-0.15% of C, 0.5%-0.90% of Si, 0.30%-0.60% of Mn, at most 0.007% of P, at most 0.005% of S, 8.00%-10% of Cr, 0.90%-1.1% of Mo, at most 0.20% of Cu, 0.05%-0.10% of Ni, at most 0.003% of Sb, at most 0.005% of Sn, at most 0.012% of As, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and die casting, heating and rolling, and heat treatment. The high-chromium chromium-molybdenum steel plate satisfies the requirements of high strength, high toughness and high processability for domestic power equipment industry, and can be widely used for manufacturing of domestic power equipment. The steel plate has the advantages of favorable cold bending property, no cracking in the material manufacturing process, and favorable resilience.

Owner:WUYANG IRON & STEEL

X60 pipeline steel and manufacturing method thereof

ActiveCN105063482ALow costSimple rolling processTemperature control deviceMetal rolling arrangementsChemical compositionContinuous rolling

The invention relates to a hot continuous rolling steel strip and a manufacturing method thereof, in particular to X60 pipeline steel and a manufacturing method thereof. According to the technical scheme, the X60 pipeline steel is composed of, by weight, 0.05%-0.10% of C, 0.10%-0.30% of Si, 1.20%-1.40% of Mn, 0-0.020% of P, 0-0.010% of S, 0.020%-0.034% of Nb, 0.05%-0.08% of V, 0.008%-0.019% of Ti, and the balance Fe and unavoidable impurities. No expensive elements such as Mo and Ni are needed to be added, so that cost is relatively low; the rolling technique is simple and high in operability. In addition, the manufactured X60 pipeline steel has the characteristics of being stable in mechanical property, good in matching between strength and toughness and excellent in welding property.

Owner:攀钢集团西昌钢钒有限公司

690MPa-grade quenched and tempered high-strength steel plate and production method thereof

InactiveCN108441771ALow costReduce leveling costsElectric furnaceProcess efficiency improvementSheet steelChemical composition

The invention discloses a 690MPa-grade quenched and tempered high-strength steel plate and a production method of the 690MPa-grade quenched and tempered high-strength steel plate. According to the chemical components, the 690MPa-grade quenched and tempered high-strength steel plate comprises, by mass percentage, 0.18%-0.22% of C, 0.20%-0.40% of Si, smaller than or equal to 0.025% of P, smaller than or equal to 0.015% of S, 1.7%-2.2% of Mn, 0.0060%-0.0120% of N, 0.090%-0.12% of V, 0.003%-0.005% of B and the balance Fe and inevitable impurity elements. The production method comprises the steps of a smelting working procedure, a heating working procedure, a rolling working procedure, a cooling working procedure, a slow cooling working procedure and a quenching and tempering thermal treatmentworking procedure, wherein a quenching and tempering technology is adopted by the quenching and tempering thermal treatment working procedure. According to the 690MPa-grade quenched and tempered high-strength steel plate and the production method of the 690MPa-grade quenched and tempered high-strength steel plate, the organization type of the steel plate is tempered sorbite and tempered martensite, the yield strength Rp0.2 of the steel plate is larger than or equal to 670MPa, the tensile strength Rm is larger than or equal to 730MPa, A50 is larger than or equal to 20%, the -20 DEG C transverseimpact energy is larger than or equal to 80J, and the surface hardness HB is larger than or equal to 360.

Owner:WUYANG IRON & STEEL

Winding technique for waist drum type spring

ActiveCN101269396ASimple rolling processImprove rolling qualityFurnace typesHeat treatment furnacesHot springEngineering

The invention relates to a rolling process of a drum-type spring, which is a hot-roll molding technology, including a first process: blank is turned into a plurality of bars which are changed from both ends into the diameters of the bars; a second process: After turning, the bars are heated; a third process: the bars heated after the three steps are heated and rolled into a drum-type hot spring: by a first spring coiling machine, the bars are rolled from the beginning of one end into the drum-type spring; by a second spring coiling machine, the bars are rolled from the other end into another drum-type spring which is symmetrical to the former one, with a straight line left in the middle part which is punched into a preset outer diameter; a fourth process: the drum-type spring made by heat rolling is carried out quenching and tempering, so as to make the drum-type spring. The rolling process is simple, the rolling quality is high and the speed is high; both transitional rings of the drum-type spring can be greater than 2.5, besides, all the line diameter, the outside diameter, the stiffness and the pitch can be changed.

Owner:SHANGHAI SPRING CORP

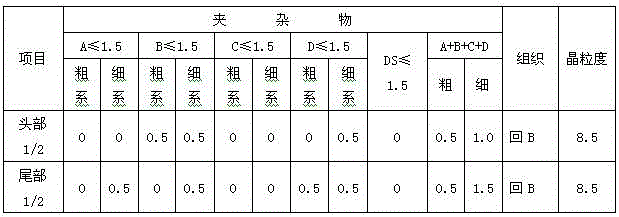

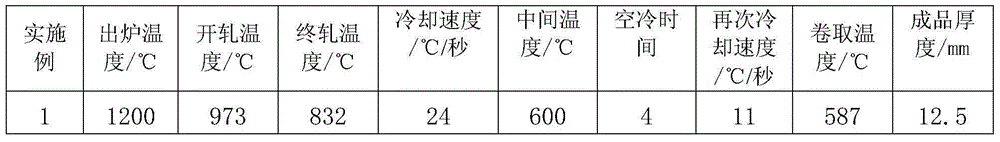

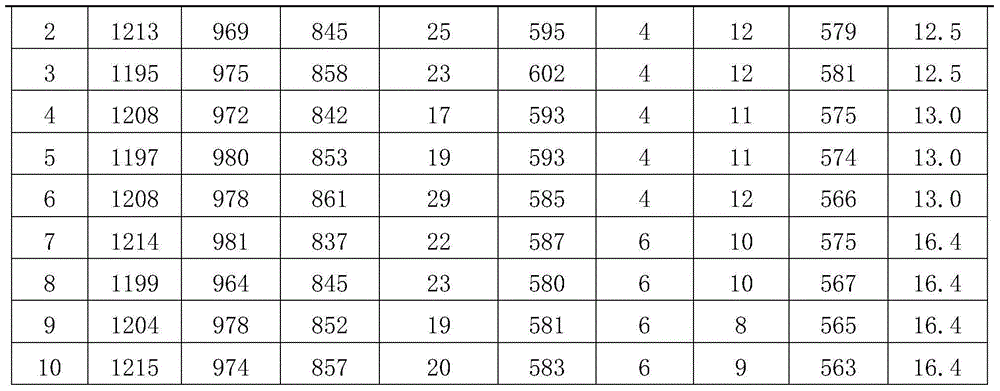

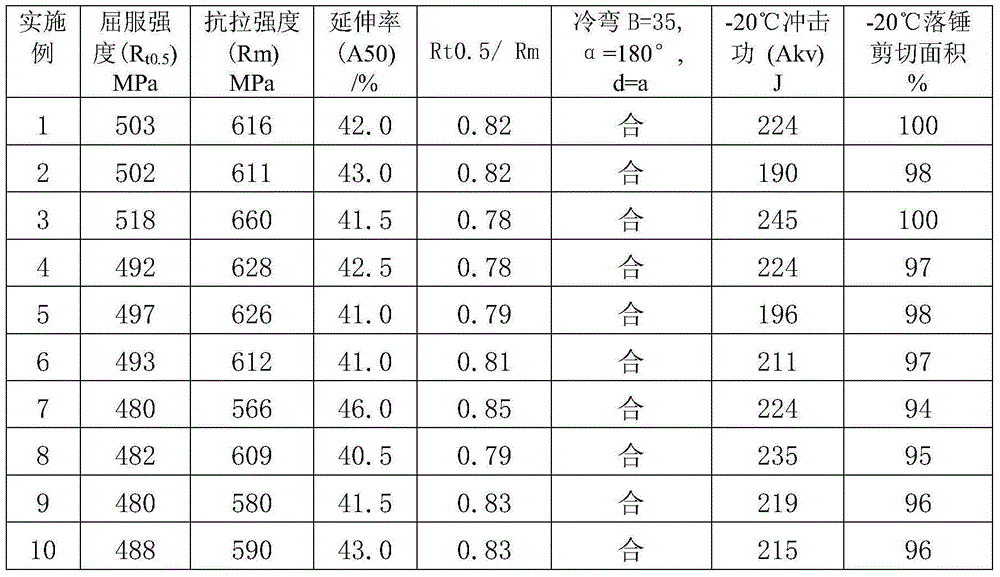

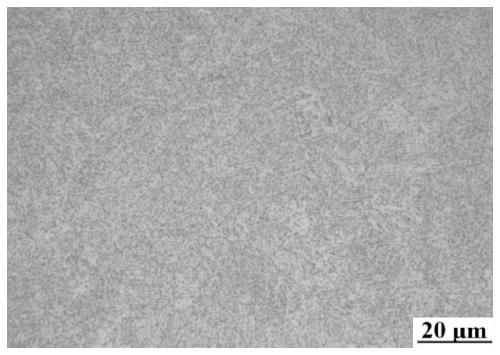

Thick X65 pipeline steel and production method thereof

The invention relates to a hot continuous rolling steel belt and a production method thereof, in particular to thick X65 pipeline steel and a production method thereof. The thick X65 pipeline steel is low in cost and can maintain good strength, toughness and drop weight tear performance. According to the technical scheme, the chemical components of the thick X65 pipeline steel comprise, in percentage by weight, 0.07%-0.10% of C, 0.10%-0.30% of Si, 1.40%-1.60% of Mn, 0.020% or less of P, 0.010% or less of S, 0.030%-0.039% of Nb, 0.06%-0.08% of V, 0.008%-0.019% of Ti, 0.15%-0.30% of Cr and the balance Fe and unavoidable impurities. According to the thick X65 pipeline steel and the production method thereof, addition of expensive Mo, Ni and other elements is not needed, the finish rolling inlet temperature of the thick X65 pipeline steel does not need to be lowered substantially, the cost is relatively low, the rolling technology is simple, and operability is high. In addition, the yield strength of the 12mm-17mm thick X65 pipeline steel is 480-518 MPa, the tensile strength of the 12mm-17mm thick X65 pipeline steel is 560-660 MPa, the impact energy at 20 DEG C below zero is 190 J or more, and the drop weight tear area at 20 DEG C below zero is larger than 94%.

Owner:攀钢集团西昌钢钒有限公司

12Cr2Mo1R steel plate for seal head and production method thereof

The invention discloses a 12Cr2Mo1R steel plate for a seal head and a production method thereof. The steel plate comprises the following chemical components, by mass percentage: 0.11-0.13% of C, 0.06-0.08% of Si, 0.40-0.60% of Mn, 0.007-0.009% of P, less than or equal to 0.004% of S, 2.2-2.5% of Cr, 1.00-1.10% of Mo, 0.10-0.20% of Ni, less than or equal to 0.05% of Nb, less than or equal to 0.20%of Cu, less than or equal to 0.003% of Sb, less than or equal to 0.01% of Sn, and less than or equal to 0.01% of As, with the balance being Fe and unavoidable impurities. The production method includes smelting, continuous casting, heating, rolling, heat treatment, sample processing and heat treatment processes. The 12Cr2Mo1R steel plate for a seal head and the production method thereof solve theproblems that a conventional 12Cr2Mo1R steel plate is prone to surface cracks, high hardness and easy cracking during processing, and ensures the comprehensive performance of the formed steel plate.

Owner:WUYANG IRON & STEEL

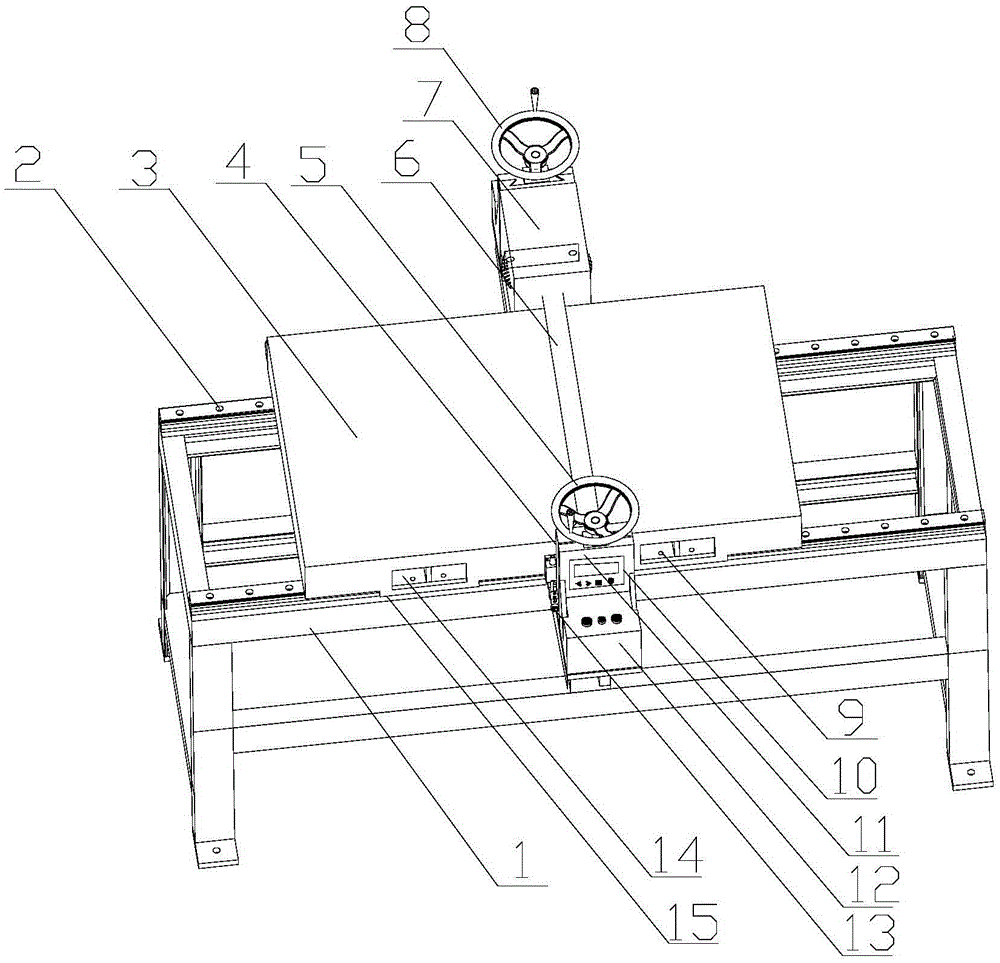

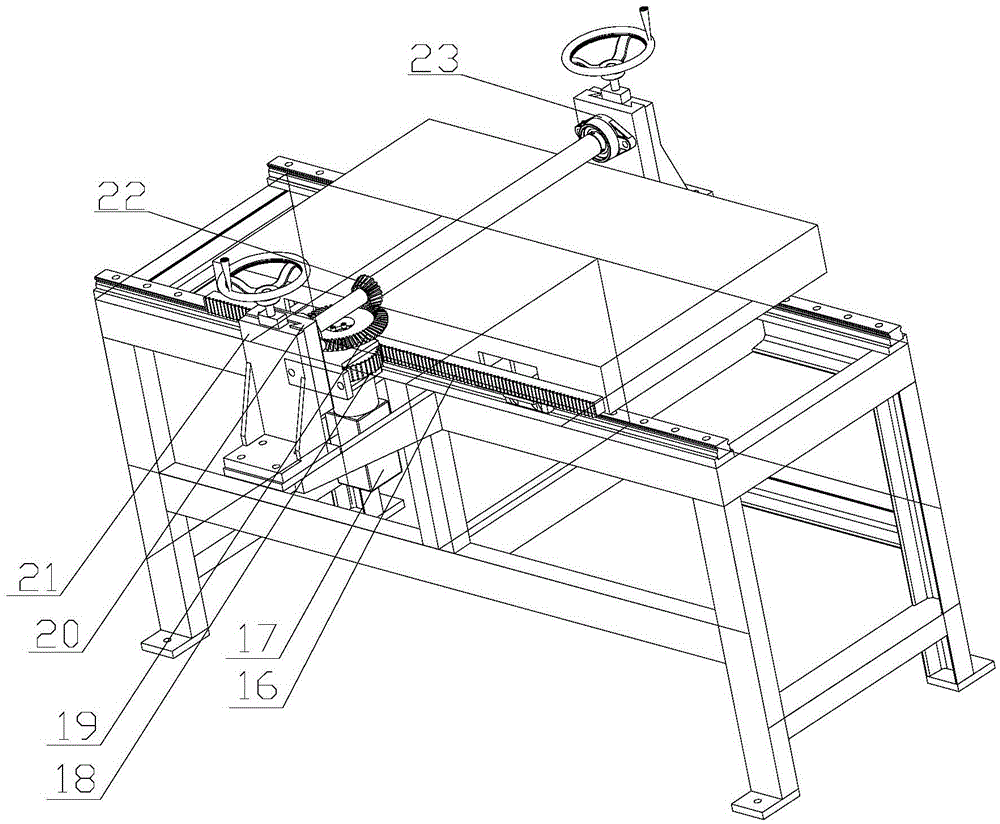

Flexible metal cloth rolling device and manufacturing method

ActiveCN105458267AAchieve roll formingRolling is fast and preciseRolling-element bearingVolumetric Mass Density

The invention discloses a flexible metal cloth rolling device and a manufacturing method. The device comprises a rack. A pair of sliding guide rails is arranged on the rack. A horizontal sliding block is arranged on the sliding guide rails. A rolling platform is installed on the horizontal sliding block. L-shaped dovetail groove supporting plates are fixedly installed on the two sides of the rack respectively. Perpendicular sliding blocks are installed on the L-shaped dovetail groove supporting plates. A roller is connected between the two perpendicular sliding blocks. Rolling bearings are installed at the two ends of the roller respectively. The rolling bearings are installed on rolling bearing seats fixed to the perpendicular sliding blocks. A driven bevel gear is installed on the roller and is engaged with a drive bevel gear. The drive bevel gear is fixed to a spindle of a stepping motor. The stepping motor is fixed to the first perpendicular sliding block. The spindle of the motor is provided with a straight gear. A first rack engaged with the straight gear is arranged on the side face of the rolling platform. According to the flexible metal cloth rolling device and the manufacturing method, flexible metal cloth different in thickness can be rolled rapidly and accurately, and the rolled metal cloth is good in flexibility and high in strength and density.

Owner:JIANGSU YANGMING SHIP EQUIP MFG TECH

Single fire rolling method for tc4 titanium alloy plate

ActiveCN107952794BImprove uniformityImprove surface qualityTemperature control deviceWork treatment devicesNational standardHot working

The invention belongs to the technical field of titanium alloy hot working forming and particularly relates to a single fire rolling method of a TC4 titanium alloy moderate-thickness plate. For the problems that the multi-fire-time rolling technology generally needs to be adopted for preparing and obtaining a TC4 titanium alloy with an excellent structure property, and forming performance of an alloy rolled in a single fire manner is poor, the single fire rolling method of the TC4 titanium alloy moderate-thickness plate comprises the following steps that a, a TC4 titanium alloy plate blank isheated; b, after soaking is completed, the soaking temperature is increased to 1000 DEG C to 1020 DEG C, the temperature continues to be kept for 30-60 min, and then the plate blank is discharged froma furnace and rolled; c, before rolling is carried out, roller way cooling water and phosphorus removal water are turned off, the beginning rolling temperature is larger than or equal to 950 DEG C, and the final rolling temperature is larger than 800 DEG C; and d, the rolled plate blank is subjected to annealing heat treatment, then the plate blank is discharged from the furnace and cooled in air, and the TC4 titanium alloy is obtained. According to the method, structure uniformity of the rolled TC4 titanium alloy moderate-thickness plate is good, the surface quality is good, and the requirement of the national standard can be met. The rolling technology is simplified, the rolling efficiency is improved, and the production cost is reduced remarkably.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

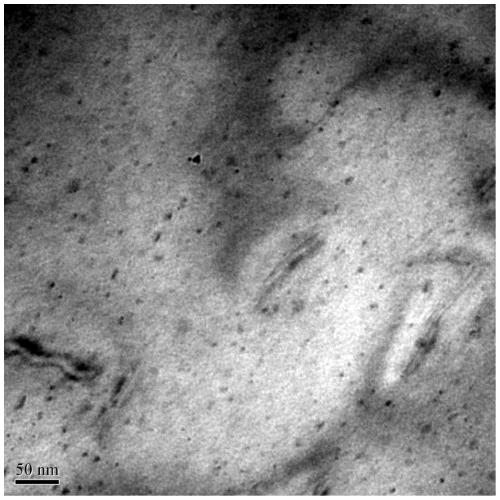

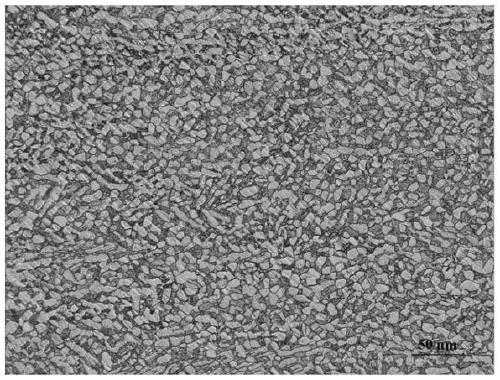

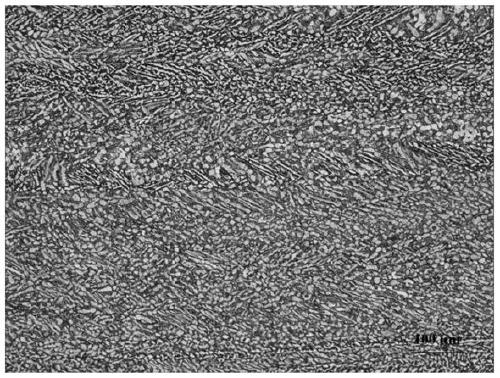

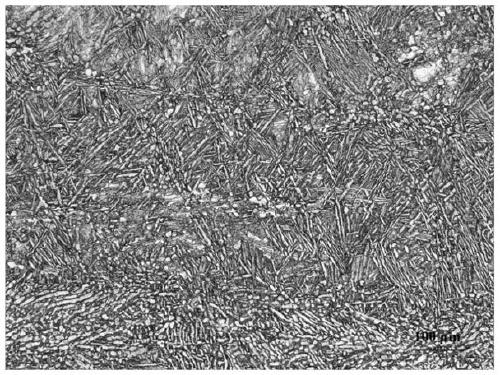

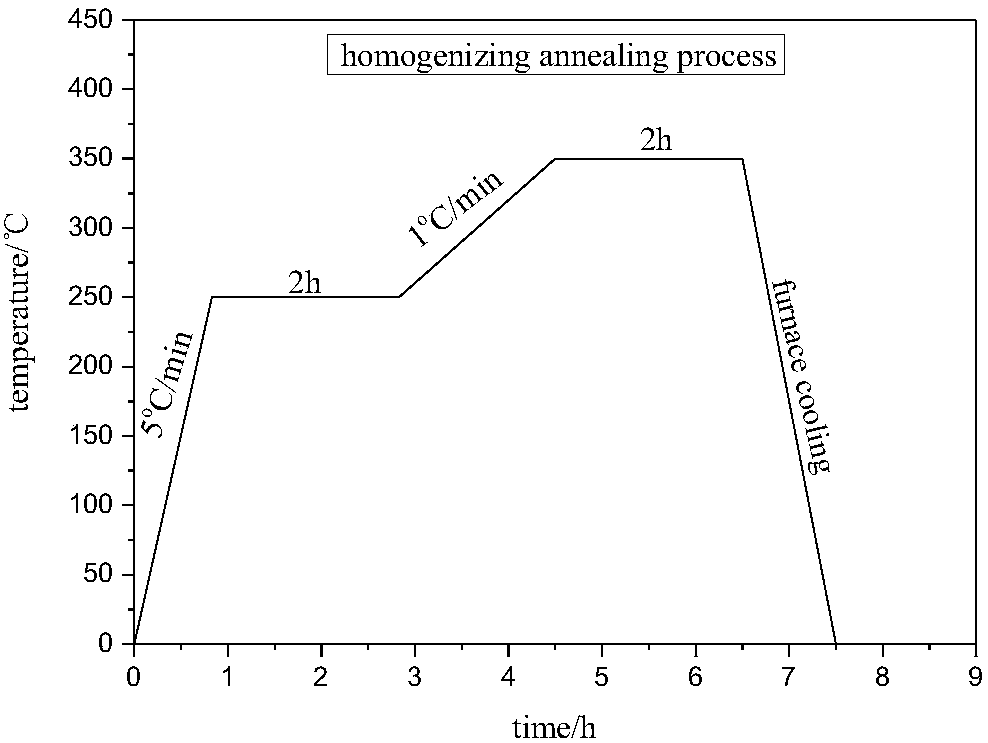

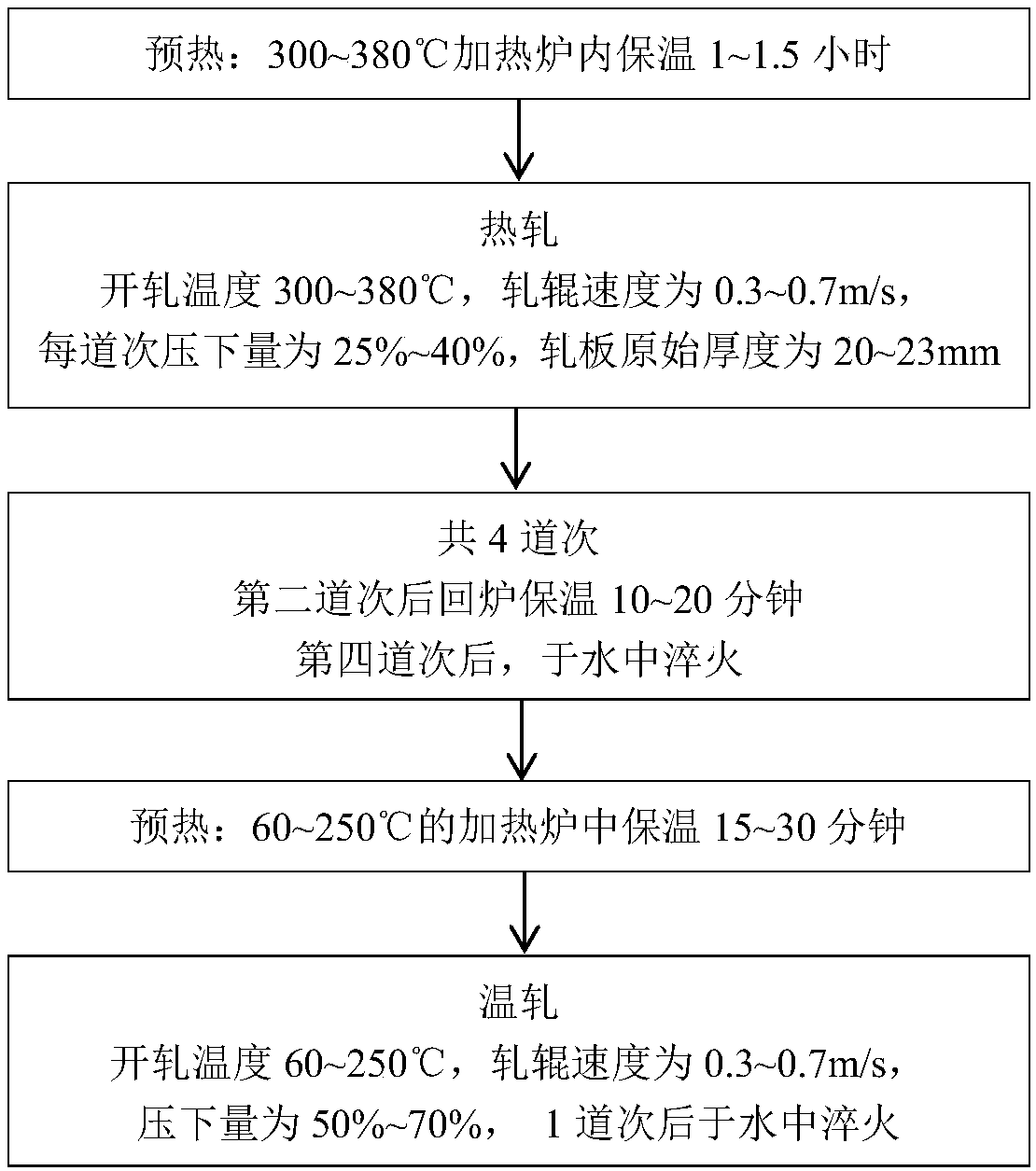

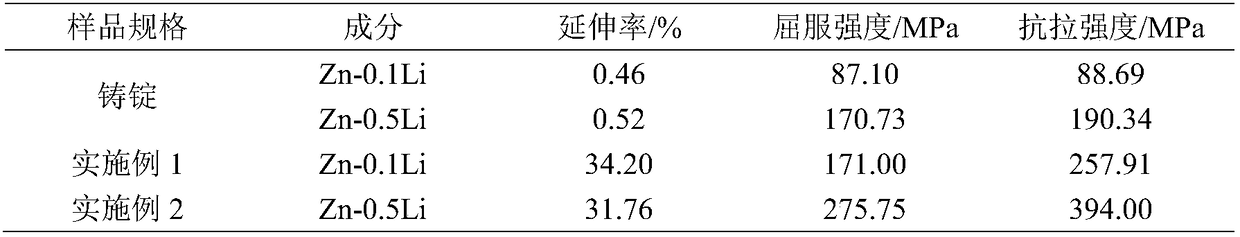

Rolling method of biodegradable medical Zn-Li alloy

ActiveCN108372203ASuitable degradabilityGood biocompatibilityTemperature control deviceMetal rolling arrangementsIngot castingUltimate tensile strength

The invention discloses a rolling method of a biodegradable medical Zn-Li alloy and belongs to the technical field of biodegradable medical materials and metal rolling. The method includes: homogenizing alloy ingots: rising temperature to 200-280 DEG C at a speed of 2-6 DEG C per min, holding the temperature for 1-2h, rising the temperature to 300-380 DEG C at a speed of 0.5-1 DEG C per min, holding the temperature for 1-2h, and cooling along with a furnace; after alloy is preheated, hot rolling: putting the alloy back into the furnace and holding the temperature for 10-20min after the secondtime of rolling, and quenching in water after the fourth time of rolling, wherein rolling start temperature is 300-380 Deg C, press-down amount of each time of rolling is 25-40%, and rolling is performed for four times in total; warm rolling: rolling once, and quenching in water, wherein rolling start temperature is 60-250 DEG C, and press-down amount is 50-70%. Through a simple rolling process, the biodegradable Zn-Li alloy with high strength and high plasticity is obtained, the problem of low section plasticity caused by common plastic processing methods is avoided, and material using requirements of various human implantation devices are met. The method is low in cost and easy for large-scale production in factories, thereby having extremely high popularization value and extensive application prospect in the field of medical materials.

Owner:北京尚宁科智医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com