HIC-resistant heat resistant steel in iron element system and preparation process thereof

A preparation process and technology of heat-resistant steel, applied in the field of ferritic heat-resistant steel and its manufacturing process, can solve the problems of not mentioning anti-HIC performance, not involving HIC performance, high temperature performance limitation, etc., and reaching the thickness specification range The effect of wide, small number, and small alloy types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 The chemical components of the HIC-resistant ferritic heat-resistant steel are: C: 0.1-0.15%, Si: 0.2-0.5%, Mn: 0.3-0.6%, Cr: 2.0-2.5%, Mo: 0.9-1.1%, S≤0.003% and P≤0.010%, the rest is Fe and unavoidable impurities; the content of S, P and other impurity elements is strictly controlled in the steelmaking process. After calculation, the J coefficient of this steel is 33.5, and the X coefficient is 7.1; the rolling process is shown in Table 1:

[0044] The rolling process of table 1 embodiment 1

[0045]

[0046] The heat treatment process consists of two parts: normalizing and tempering. Normalizing process: heating temperature 930°C, holding time 1.6min / mm±10min, cooling speed controlled at 0.1~2°C / s; tempering process: heating temperature 720°C, The holding time is 2.5min / mm±10min, and air-cooled to room temperature.

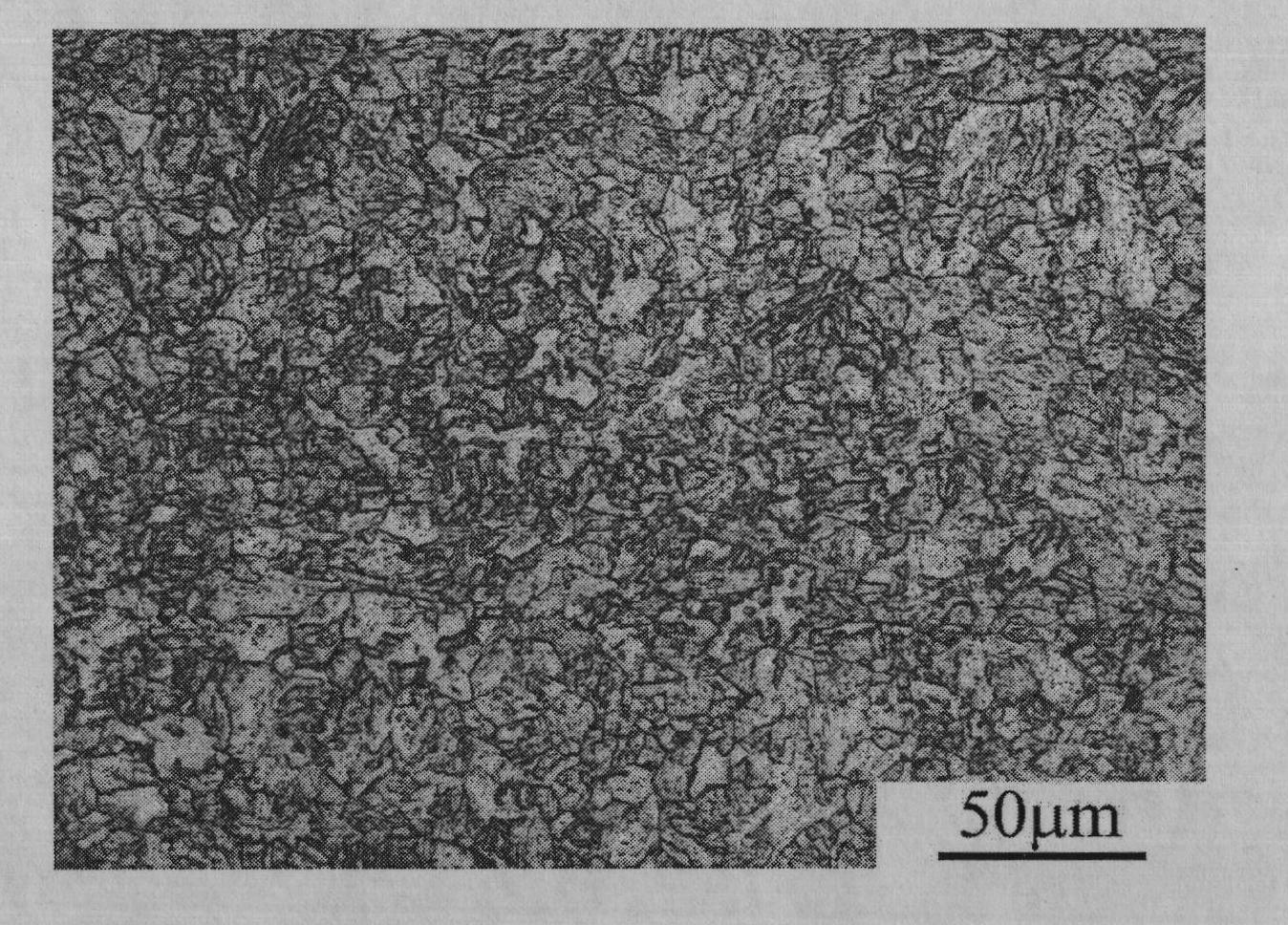

[0047] The performance after heat treatment is shown in Table 2, and its metallographic structure refers to image 3 , TEM detection fou...

Embodiment 2

[0050] Example 2 The chemical components of the HIC-resistant ferritic heat-resistant steel are: C: 0.1-0.15%, Si: 0.2-0.5%, Mn: 0.3-0.6%, Cr: 2.0-2.5%, Mo: 0.9-1.1%, S≤0.003% and P≤0.010%, the rest is Fe and unavoidable impurities; the content of S, P and other impurity elements is strictly controlled in the steelmaking process. After calculation, the J coefficient of this steel is 33.2, and the X coefficient 7.0; during the hot-rolled plate production process, the slab heating temperature: 1120°C; during the controlled rolling process, the second rolling temperature is 870°C, the end rolling temperature is 810°C, and then the cooling rate is 0.5-3°C / s to room temperature.

[0051] The heat treatment process consists of two parts: normalizing and tempering. Normalizing process: heating temperature 920°C, holding time 1.6min / mm±10min, cooling speed controlled at 0.1-2°C / s; tempering process: heating temperature 710°C, The holding time is 2.5min / mm±10min, and air-cooled to roo...

Embodiment 3

[0054] Example 3 The chemical components of the HIC-resistant ferritic heat-resistant steel are: C: 0.1-0.15%, Si: 0.2-0.5%, Mn: 0.3-0.6%, Cr: 2.0-2.5%, Mo: 0.9-1.1%, S≤0.003% and P≤0.010%, the rest is Fe and unavoidable impurities; the content of S, P and other impurity elements is strictly controlled in the steelmaking process, and the J coefficient of this steel is calculated to be 33.6, and the X coefficient 7.5; during the hot-rolled plate production process, the slab heating temperature: 1130°C; during the controlled rolling process, the second rolling temperature is 875°C, the end rolling temperature is 815°C, and then the cooling rate is 0.5-3°C / s to room temperature.

[0055] The heat treatment process consists of two parts: normalizing and tempering. Normalizing process: heating temperature 910°C, holding time 1.6min / mm±10min, cooling speed controlled at 0.1-2°C / s; tempering process: heating temperature 710°C, The holding time is 2.5min / mm±10min, and air-cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com