Three-layer coextrusion heavy packaging membrane and fabrication method thereof

A three-layer co-extrusion, packaging film technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of difficult to popularize and use, increase production cost of heavy packaging film, and difficult production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] A three-layer co-extruded heavy-duty packaging film, including an inner layer, a middle layer and an outer layer that are co-extruded sequentially, and the inner layer is composed of the following components by weight percentage:

[0115] Linear low density polyethylene 20~80%

[0116] Metallocene linear low density polyethylene 20~80%,

[0117] The middle layer is composed of the following components by weight percentage:

[0118] Linear low density polyethylene 20~50%

[0119] Metallocene linear low density polyethylene 20~50%

[0120] Ethylene-vinyl acetate copolymer 3~15%

[0121] Medium density polyethylene 20~50%

[0122] Masterbatch 3~10%,

[0123] The outer layer comprises the following components by weight percentage:

[0124] Linear low density polyethylene 15~60%

[0125] Metallocene linear low density polyethylene 20~60%

[0126] Low density polyethylene 15~40%.

[0127] The above-mentioned raw materials of this embodiment were all purchased from th...

Embodiment 2

[0155] The difference between a kind of three-layer co-extruded heavy packaging film of the present embodiment and embodiment 1 is that the components of the three-layer co-extruded heavy packaging film are as follows:

[0156] The inner layer is composed of the following components by weight percentage:

[0157] Linear low density polyethylene 40~60%

[0158] Metallocene linear low density polyethylene 40~60%,

[0159] The middle layer is composed of the following components by weight percentage:

[0160] Linear low density polyethylene 25~40%

[0161] Metallocene linear low density polyethylene 25~40%

[0162] Ethylene-vinyl acetate copolymer 5~10%

[0163] Medium density polyethylene 20~40%

[0164] Masterbatch 4~6%,

[0165] The outer layer is composed of the following components by weight percentage:

[0166] Linear low density polyethylene 20~40%

[0167] Metallocene linear low density polyethylene 30~50%

[0168] Low density polyethylene 15~25%

[0169] Antist...

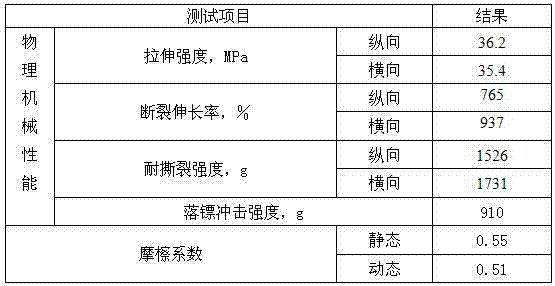

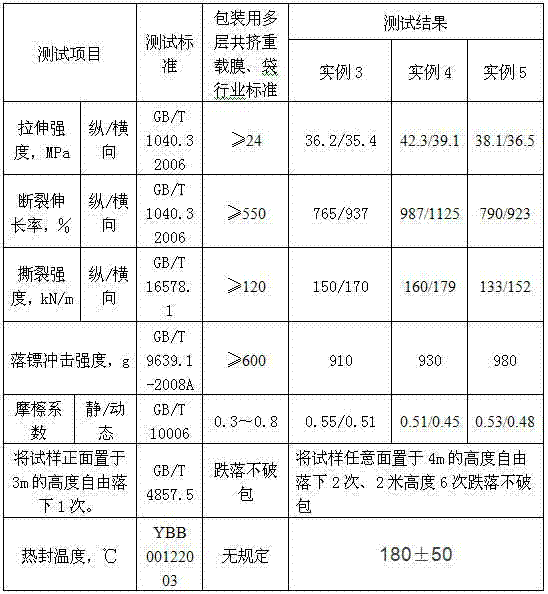

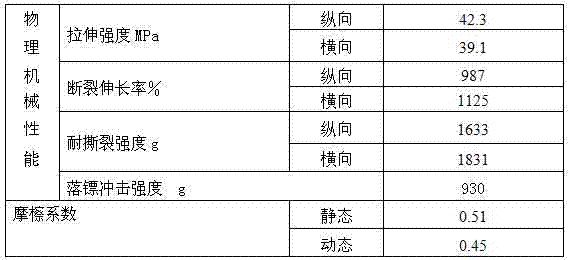

Embodiment 3

[0174] The difference between a kind of three-layer co-extruded heavy packaging film of the present embodiment and embodiment 1 is that the components of the three-layer co-extruded heavy packaging film are as follows:

[0175] The inner layer is composed of the following components by weight percentage:

[0176] Linear Low Density Polyethylene 50%

[0177] Metallocene LLDPE 50%,

[0178] The middle layer is composed of the following components by weight percentage:

[0179] Linear Low Density Polyethylene 30%

[0180] Metallocene LLDPE 37%

[0181] Ethylene-vinyl acetate copolymer 3%

[0182] Medium Density Polyethylene 25%

[0183] Masterbatch 5%,

[0184] The outer layer is composed of the following components by weight percentage:

[0185] Linear Low Density Polyethylene 20%

[0186] Metallocene LLDPE 50%

[0187] LDPE 29%

[0188] Antistatic agent 1%.

[0189] Among them, the metallocene linear low-density polyethylene of the inner layer is selected from the 53...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com