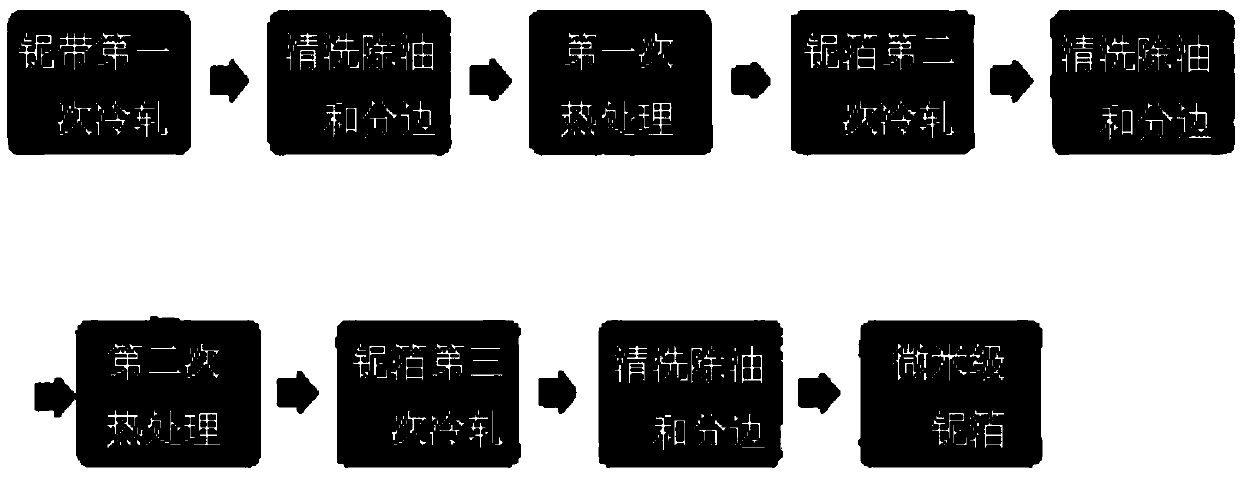

Preparation method of micro order niobium foil

A micron-level, niobium foil technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problem of micron-level niobium foil that has not yet reached the thickness, and has not seen thickness, so as to reduce the number of total rolling processes and reduce the number of rolling processes. The effect of large restraining force and guaranteed thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of this embodiment includes the following steps:

[0039] Step 1. The niobium strip is reversibly rolled by a Sendzimir 20-high cold rolling mill under the temperature condition of 15°C to 25°C to obtain the first rolling pass niobium foil; the width of the niobium strip is 100mm and a thickness of 0.15mm, the lateral same plate difference of the niobium strip is 0.01mm, the mass content of niobium in the niobium strip is 99.7%, the mass content of impurity element Fe is 0.005%, and the mass content of C is 0.01% , The mass content of O is 0.015%, and the mass content of H is 0.0008%; the conditions of the reversible rolling in the first pass are: the left coiler and the right coiler of the Sendzimir 20-high cold rolling mill The given rolling tension is 120kg~180kg, the pressure of the pressing cylinder is 25.5kN~26.7kN, the first intermediate roll is a crown roll, and the sum of the crowns of the first intermediate roll is 0.06mm; the first rolling...

Embodiment 2

[0047] The preparation method of this embodiment includes the following steps:

[0048] Step 1. The niobium strip is reversibly rolled by a Sendzimir 20-high cold rolling mill under the temperature condition of 15°C to 25°C to obtain the first rolling pass niobium foil; the width of the niobium strip is 120mm and a thickness of 0.20mm, the lateral same plate difference of the niobium strip is 0.007mm, the mass content of niobium in the niobium strip is 99.5%, the mass content of the impurity element Fe is 0.003%, and the mass content of C is 0.006% , The mass content of O is 0.009%, and the mass content of H is 0.001%; the conditions for the reversible rolling in the first pass are: the left coiler and the right coiler of the Sendzimir 20-high cold rolling mill The given rolling tension is 120kg~180kg, the pressure of the pressing cylinder is 25.5kN~26.7kN, the first intermediate roll is a crown roll, and the sum of the crowns of the first intermediate roll is 0.066mm; the firs...

Embodiment 3

[0056] The preparation method of this embodiment includes the following steps:

[0057] Step 1. Under the temperature condition of 15℃~25℃, the niobium strip is reversibly rolled in the first rolling pass by a Sendzimir 20-high cold rolling mill to obtain a first rolling pass niobium foil; the width of the niobium strip is 110mm, thickness of 0.18mm, the lateral same plate difference of the niobium strip is 0.009mm, the mass content of niobium in the niobium strip is 99.65%, the mass content of impurity element Fe is 0.004%, and the mass content of C is 0.006% , The mass content of O is 0.009%, and the mass content of H is 0.001%; the conditions for the reversible rolling in the first pass are: the left coiler and the right coiler of the Sendzimir 20-high cold rolling mill The given rolling tension is 120kg~180kg, the pressure of the pressing cylinder is 25.5kN~26.7kN, the first intermediate roll is a crown roll, and the sum of the crowns of the first intermediate roll is 0.055...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com