Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121 results about "Epoxy amine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

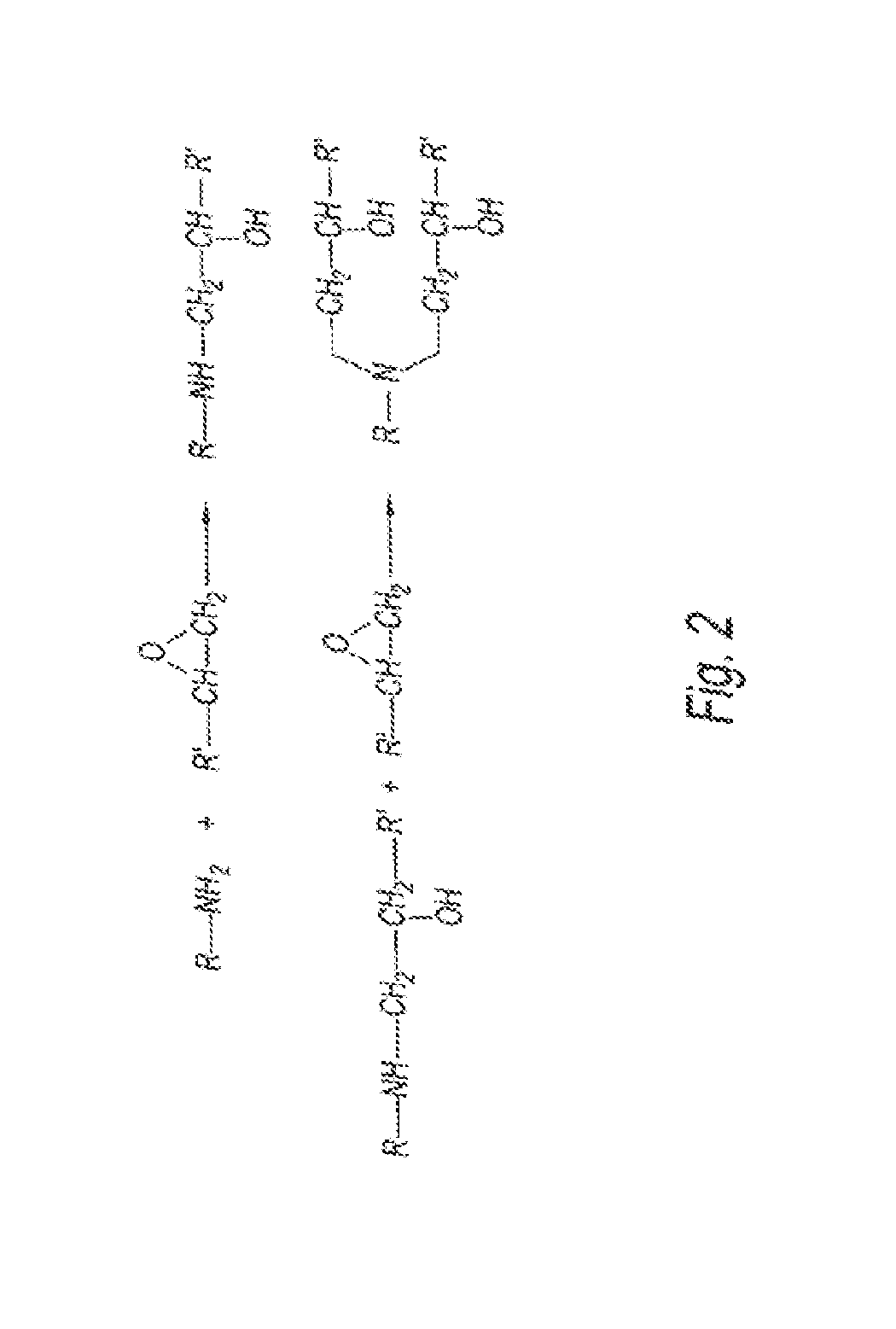

An amine cured epoxy coating is an epoxy coating where an anime-based hardener was used in the curation process. In the most general sense, these epoxy coatings are described on the molecular level as having anime and alcohol functional groups formed during the curing. Four classes of amine hardeners are available: Aliphatic amines.

Aqueous dispersion of epoxy resin and blend of epoxy resin-polyoxyalkylene amines

PCT No. PCT / EP97 / 06364 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Nov. 14, 1997 PCT Pub. No. WO98 / 25988 PCT Pub. Date Jun. 18, 1998A blend of epoxy-amine adducts are useful as emulsifiers of aqueous epoxy resin dispersions comprises (A-1) one or more epoxy-amine adduct(s) obtained by the reaction of (i) one or more aromatic, cycloaliphatic or novolac epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (A-2) one or more epoxy-amine adduct(s) derived from the reaction of (i) one or more aliphatic epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (B-1) aromatic, cycloaliphatic or novolac polyglycidyl ethers; (B-2) optionally, polyglycidyl esters of aromatic or cycloaliphatic polycarboxylic acids; and (C) optionally, at least one of reactive thinners, pigments, filler or other addtitives.

Owner:SIKA CHEM

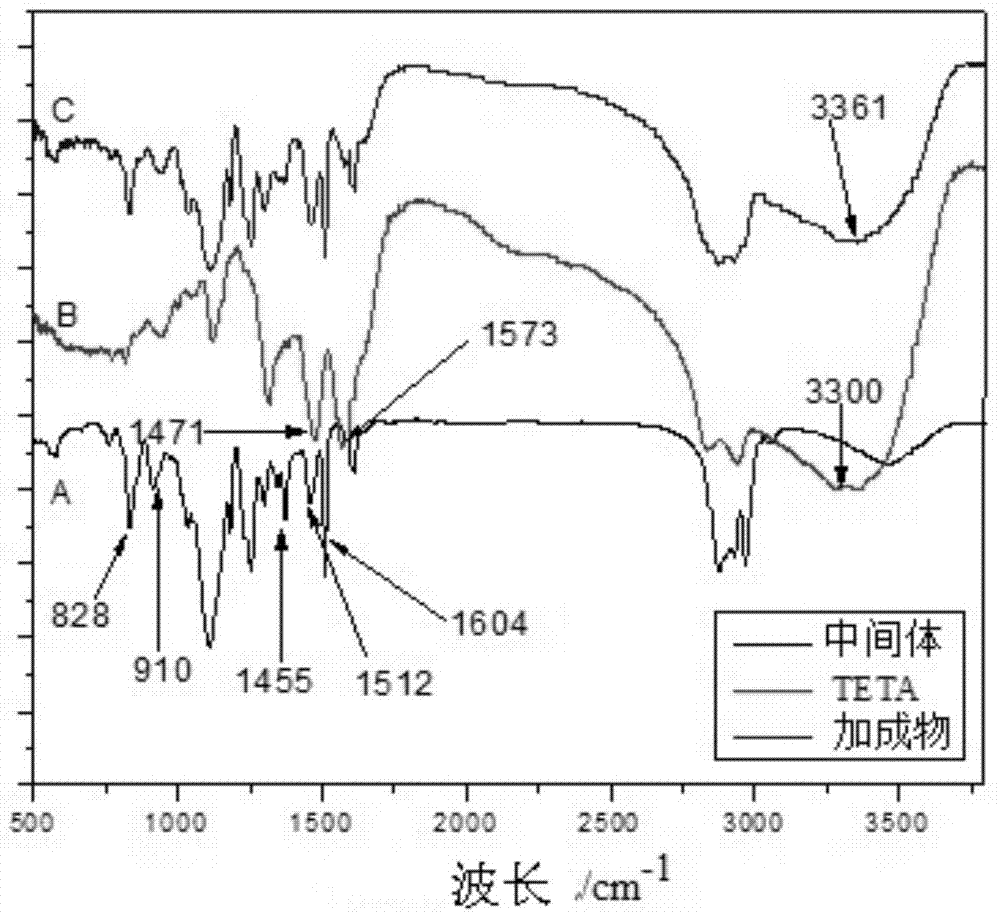

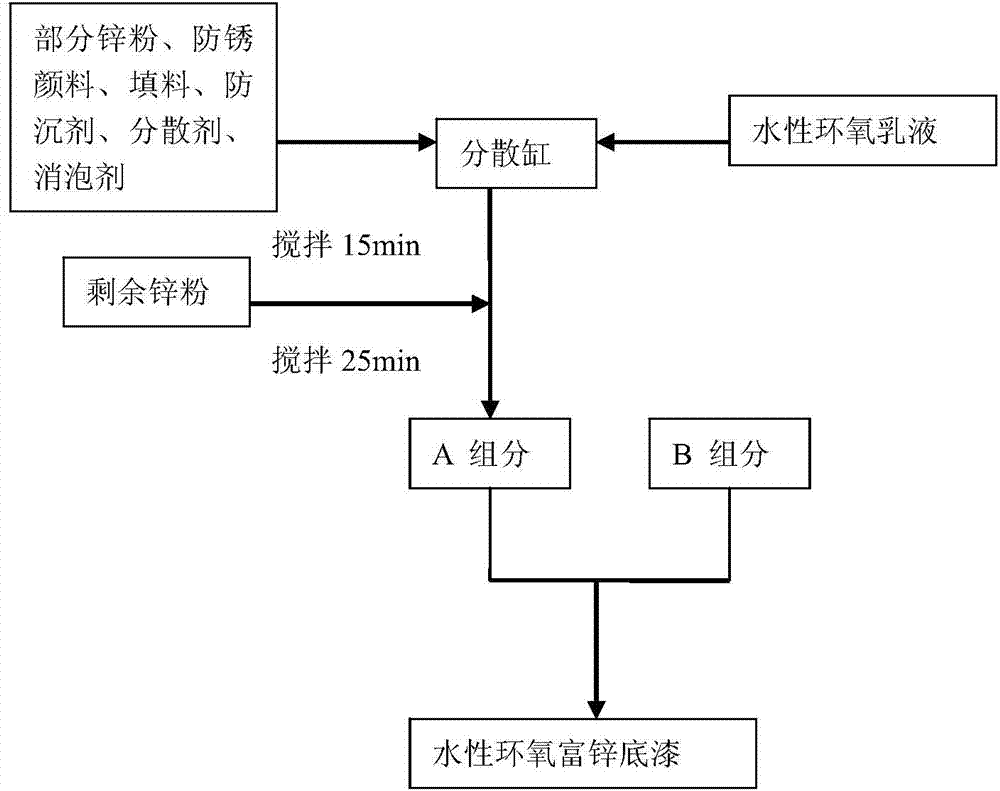

VOC (Volatile Organic Compounds)-free water-based epoxy curing agent

ActiveCN103788343AHas emulsifying effectGood compatibilityEpoxy resin coatingsWater basedPetrochemical

The invention belongs to the field of chemical coatings, and specifically relates to a VOC (Volatile Organic Compounds)-free water-based epoxy curing agent. The curing agent comprises the following components in percentage by weight: 12-25% of epoxy resin, 15-30% of terminal epoxy glycidyl ether, 3-11% of polyether amine, 18-35% of an amine compound and 40-60% of deionized water. The preparation method of the curing agent comprises the following steps: preparation of an intermediate, epoxy-amine addition and dispersion by using deionized water. The preparation method of the curing agent is simple, the reaction process is easy to control, no organic solvent is used in the preparation process and the storage stability of the curing agent is good. A water-based epoxy zinc-enriched primer which is made of the curing agent has the characteristics of high drying speed, low applicable temperature, good film flexibility, high hardness, excellent corrosion resistance and the like, and can be applied to the fields such as ocean engineering, bridges, grade levels, high-speed rail facilities, wind power equipment, petrochemical engineering and heavy machinery.

Owner:浙江纳宝莱化工科技有限公司

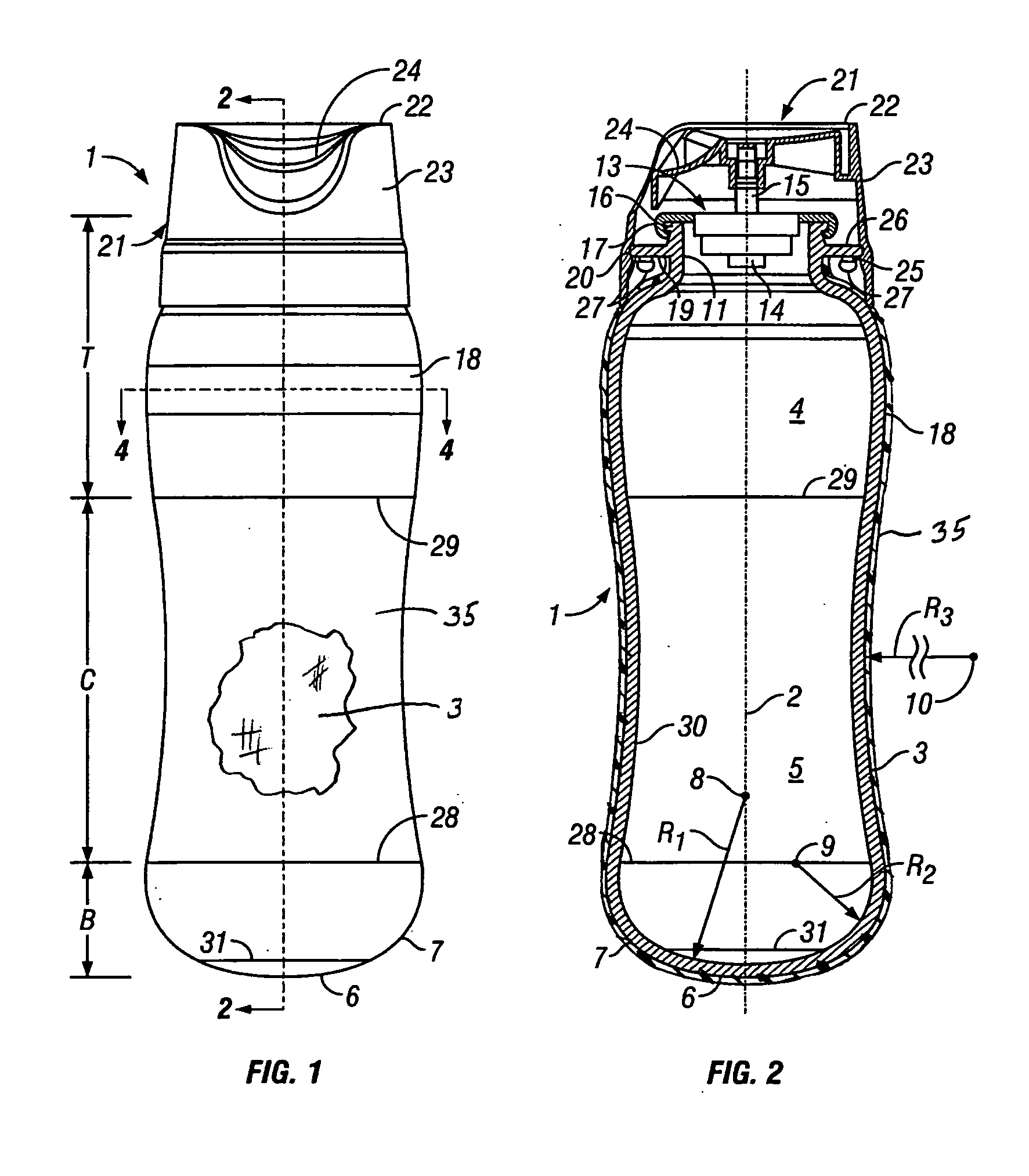

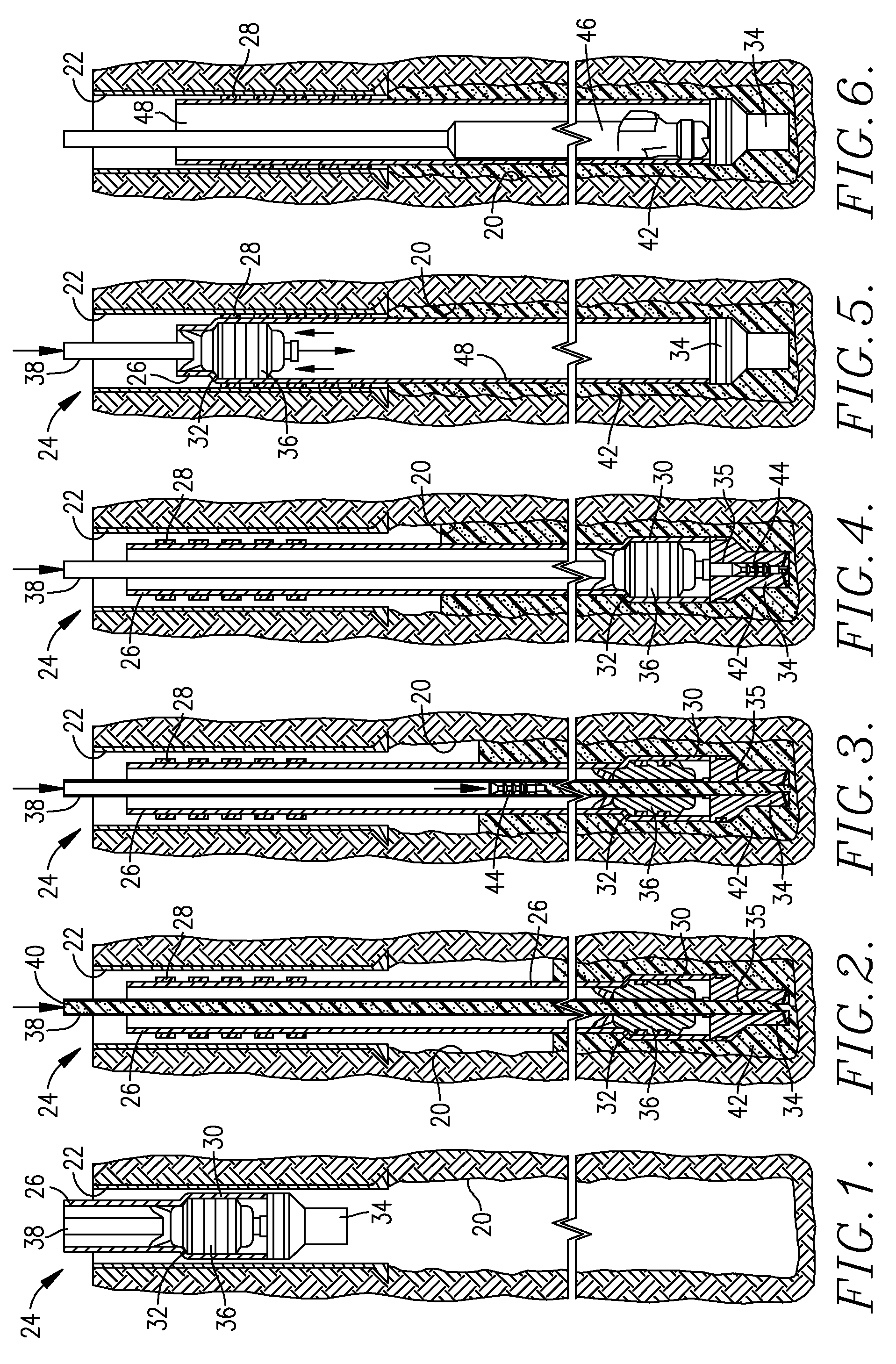

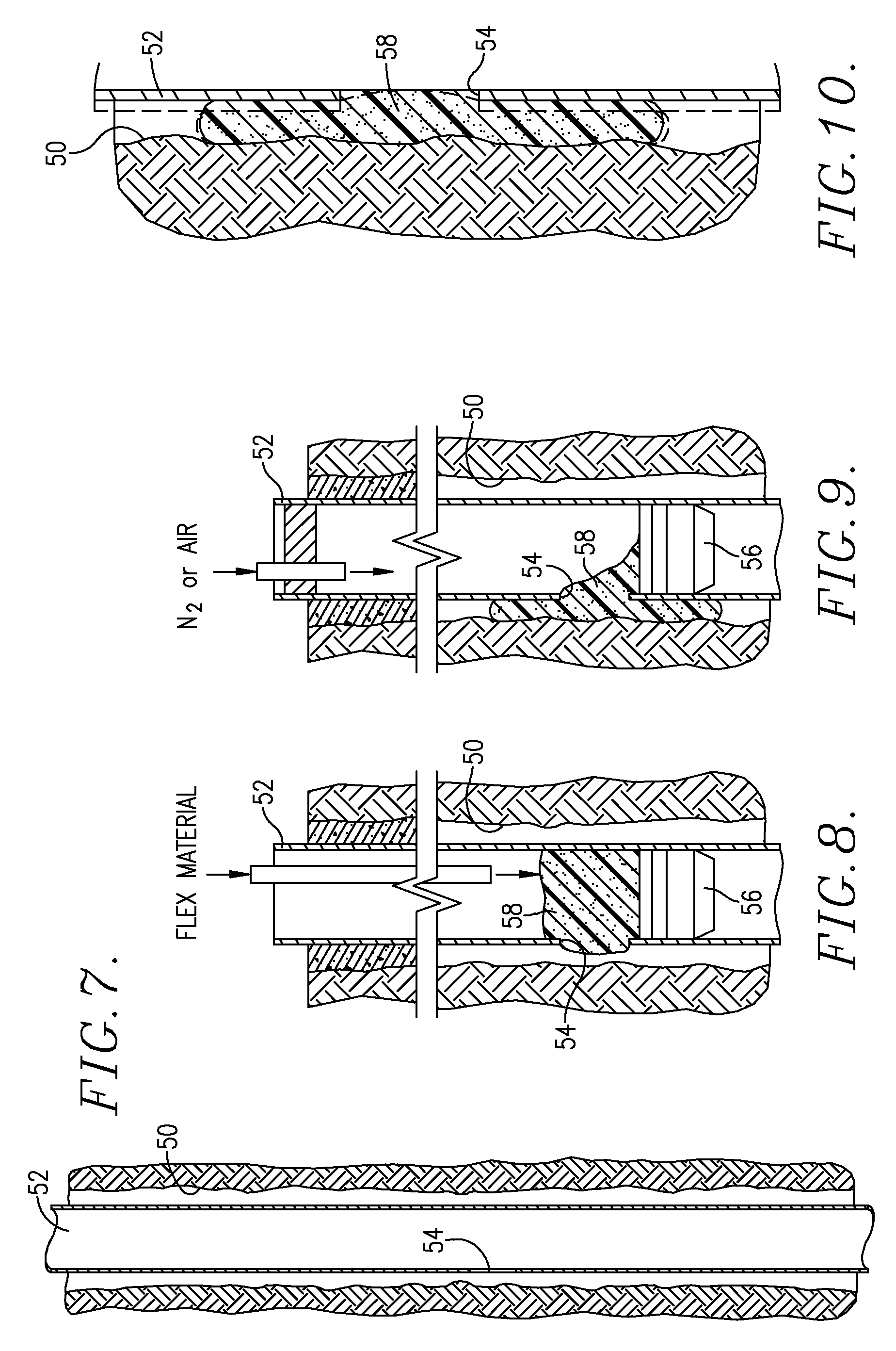

Seal-coated plastic container for dispensing a pressurized product

InactiveUS20050242101A1Inhibit migrationExtended shelf lifePackage recyclingWrappersHigh resistancePolyester

A seal coated plastic container for dispensing a pressurized product such as an aerosol or pressurized liquid, gel, or foam. The seal coating is applied to the exterior surface of the plastic container and effectively inhibits migration of non-liquefiable gas propellants and oxygen through the walls of the container. The plastic bottle is composed of a gas permeable polymeric material such as a polyolefin, polyester, or nylon or polycarbonate, and the seal coating is composed of at least one layer of a barrier material which has a low permeability to the non-liquefiable gas used as the propellant, i.e. the seal coating exhibits a high resistance to the passage of the non-liquefiable gas therethrough. The preferred polymeric material for the plastic bottle is polyethylene terephthalate, and the preferred seal coating is an epoxy-amine. The seal coating provides a coating of the barrier material that is about 0.005 to about 0.025 mm thick, but yet can greatly extend the shelf life of pressurized products such as an aerosol.

Owner:SAMSUNG ELECTRONICS CO LTD

Cathodic electrocoating composition containing morpholine dione blocked polyisocyanate crosslinking agent

InactiveUS20050187314A1Reduced bake-off lossFacilitate cross-linkingPolyurea/polyurethane coatingsPaints for electrolytic applicationsEndcappingMorpholine

An improved aqueous cathodic electrocoating composition having a binder of an epoxy-amine adduct and a polyisocyanate crosslinking agent; wherein the improvement is the use of a polyisocyanate crosslinking agent having at least one crosslinkable morpholine dione group per molecule. Electrodeposited finishes are formed that have reduced volatile emissions and film weight loss when heated to cure.

Owner:ANDERSON ALBERT G +1

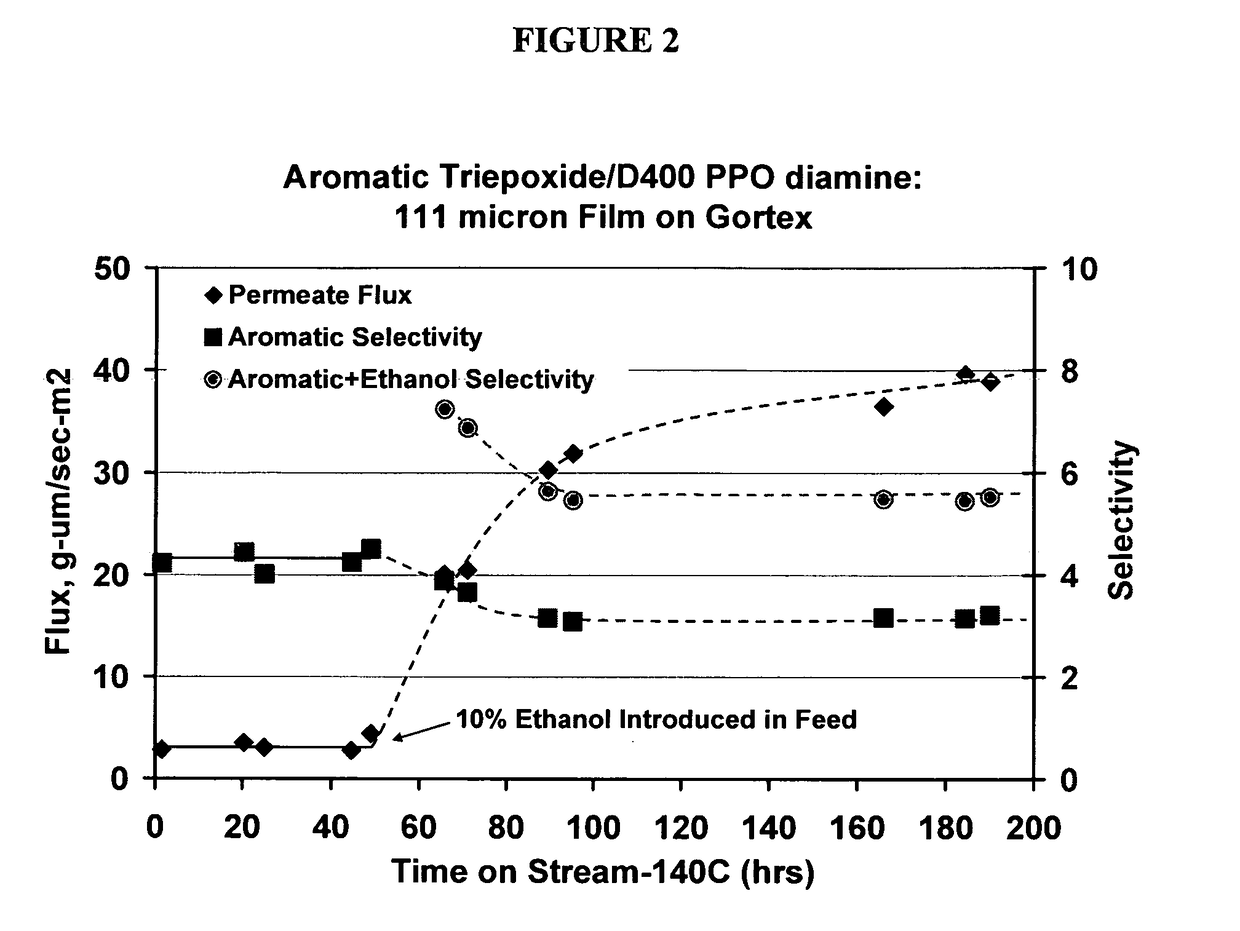

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508AImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Water borne capped ester containing epoxy amine adduct curing agents compositions for self-curing epoxy resins at ambient or sub-ambient temperatures

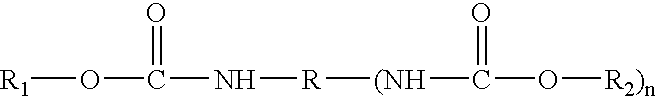

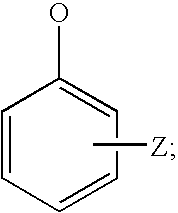

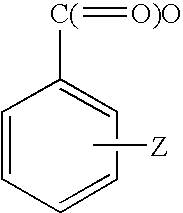

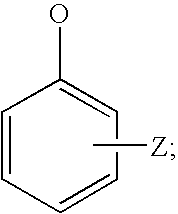

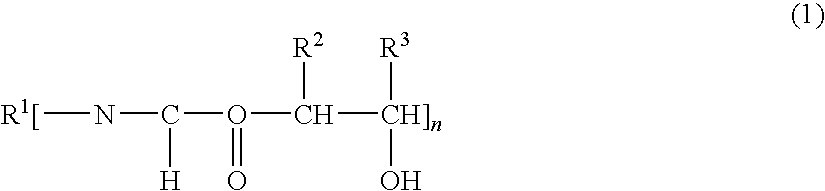

There is provided a surfactant composition, a stable, self emulsifiable water borne curing agent composition, and methods for the manufacture of each, and two component water borne curable epoxy resin compositions. The surfactant composition comprises the reaction product of an a) a phenolic acid substituted with at least one carboxyl group and at least one hydrocarbyl group having at least 1 carbon atom; b) a polyepoxide compound; c) a polyamine compound having at least two primary amine groups; d) a reactive surfactant; and optionally e) a monoglycidyl, monocarboxylic acid, or monoisocyanate capping agent; wherein the reactive surfactant comprises an epoxide, a carboxylic acid or anhydrides thereof, or an isocyanate functional moeity, and a hydrophilic moiety comprising a polyoxyalkylene monool or polyol residue. The reactive surfactant comprises a compound represented by one of the following formulas:

Owner:SHELL OIL CO

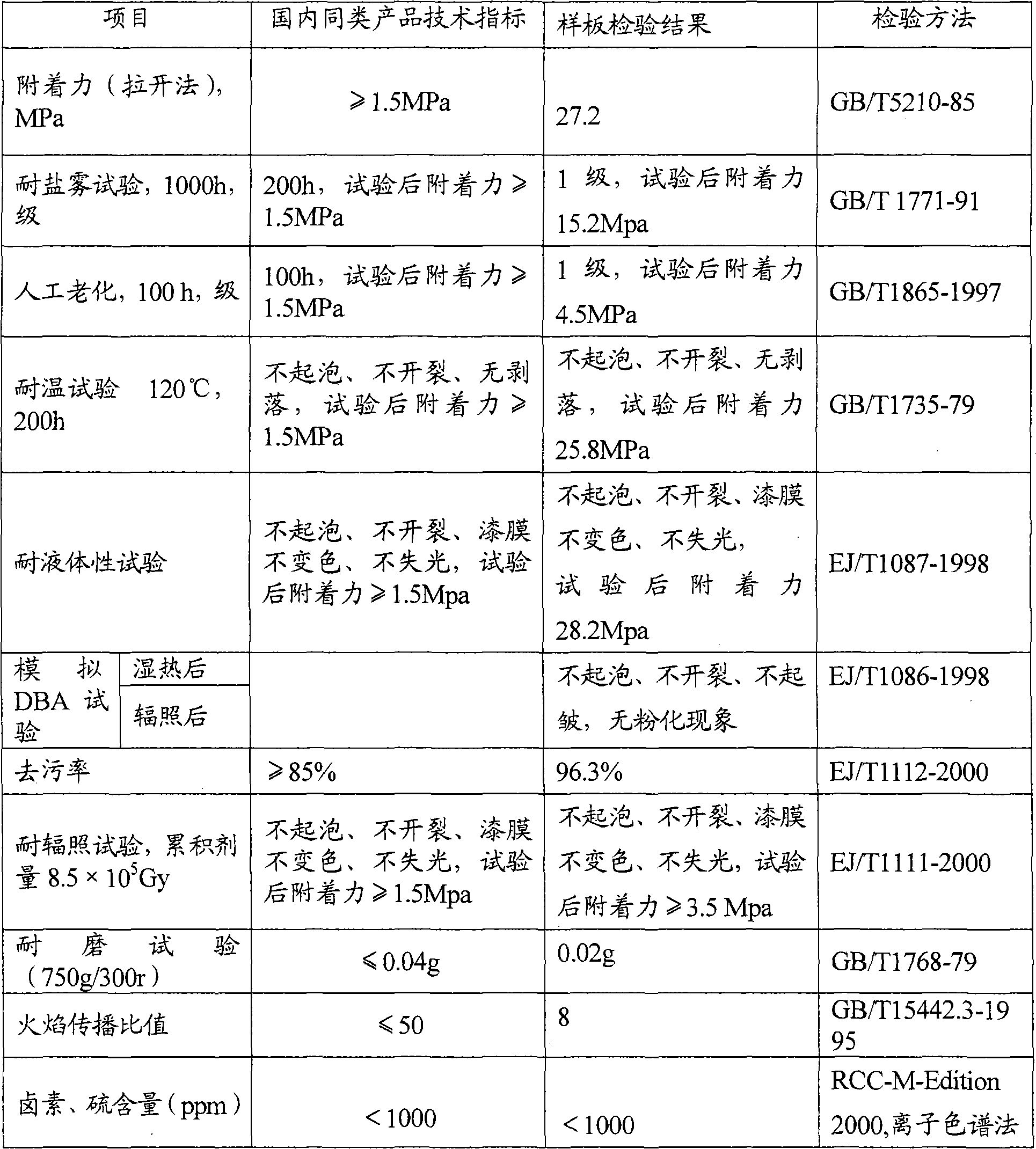

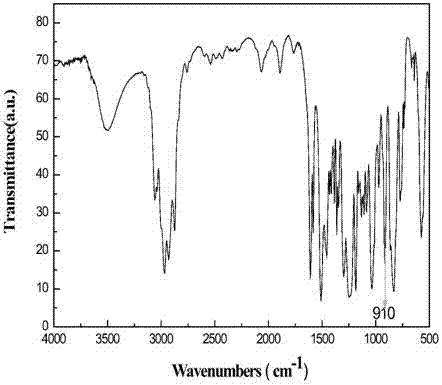

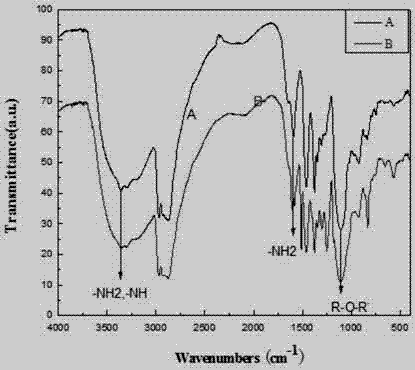

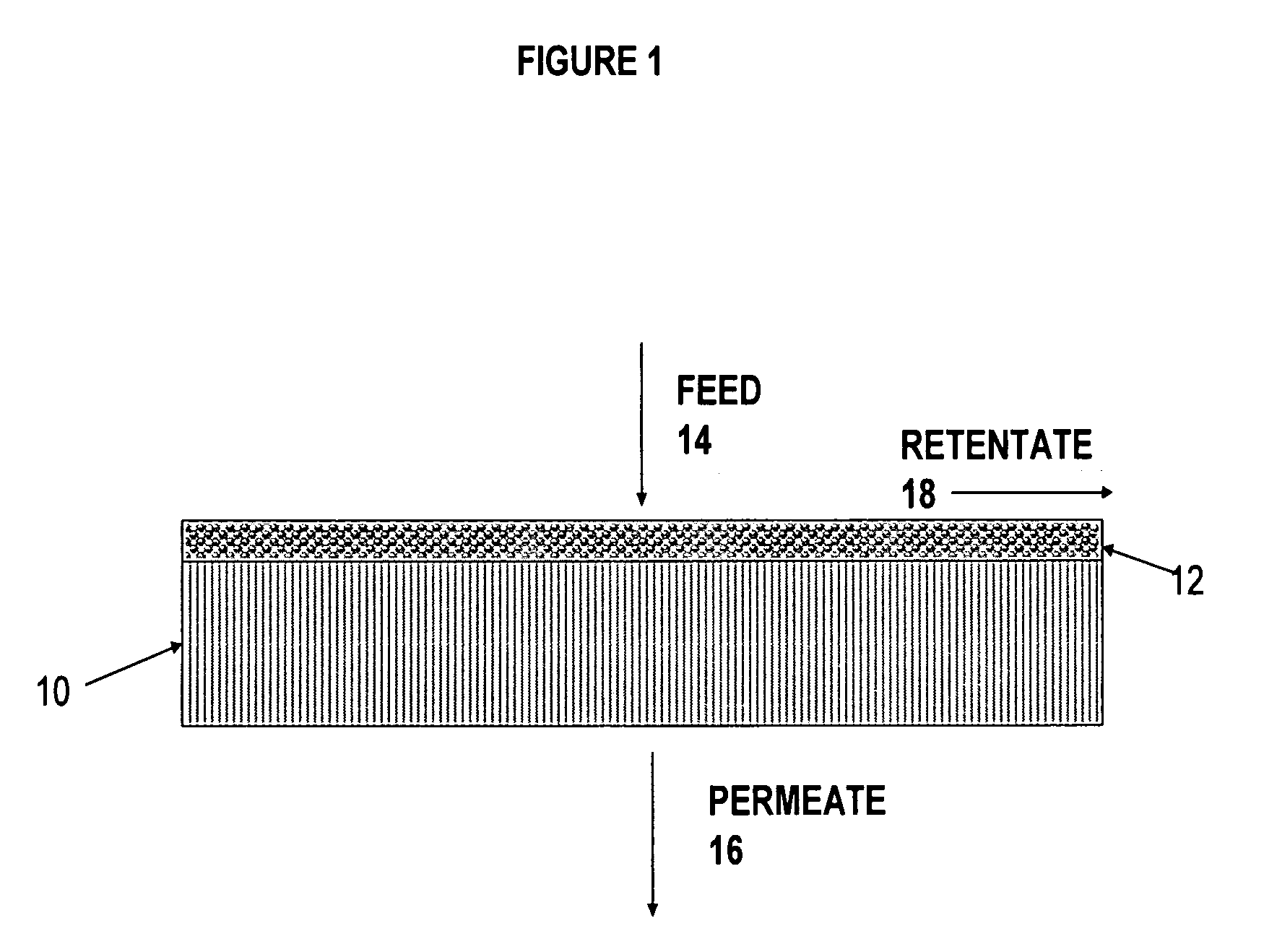

Ethanol stable epoxy amine based membrane for aromatics separation

ActiveUS8119006B2Improve integrityEfficient separationMembranesSolid sorbent liquid separationAlcoholEpoxy amine

The present invention is directed to a membrane for aromatics separation that is stable in an alcohol containing environment. The polymeric membrane is a epoxy amine based membrane.

Owner:EXXON RES & ENG CO

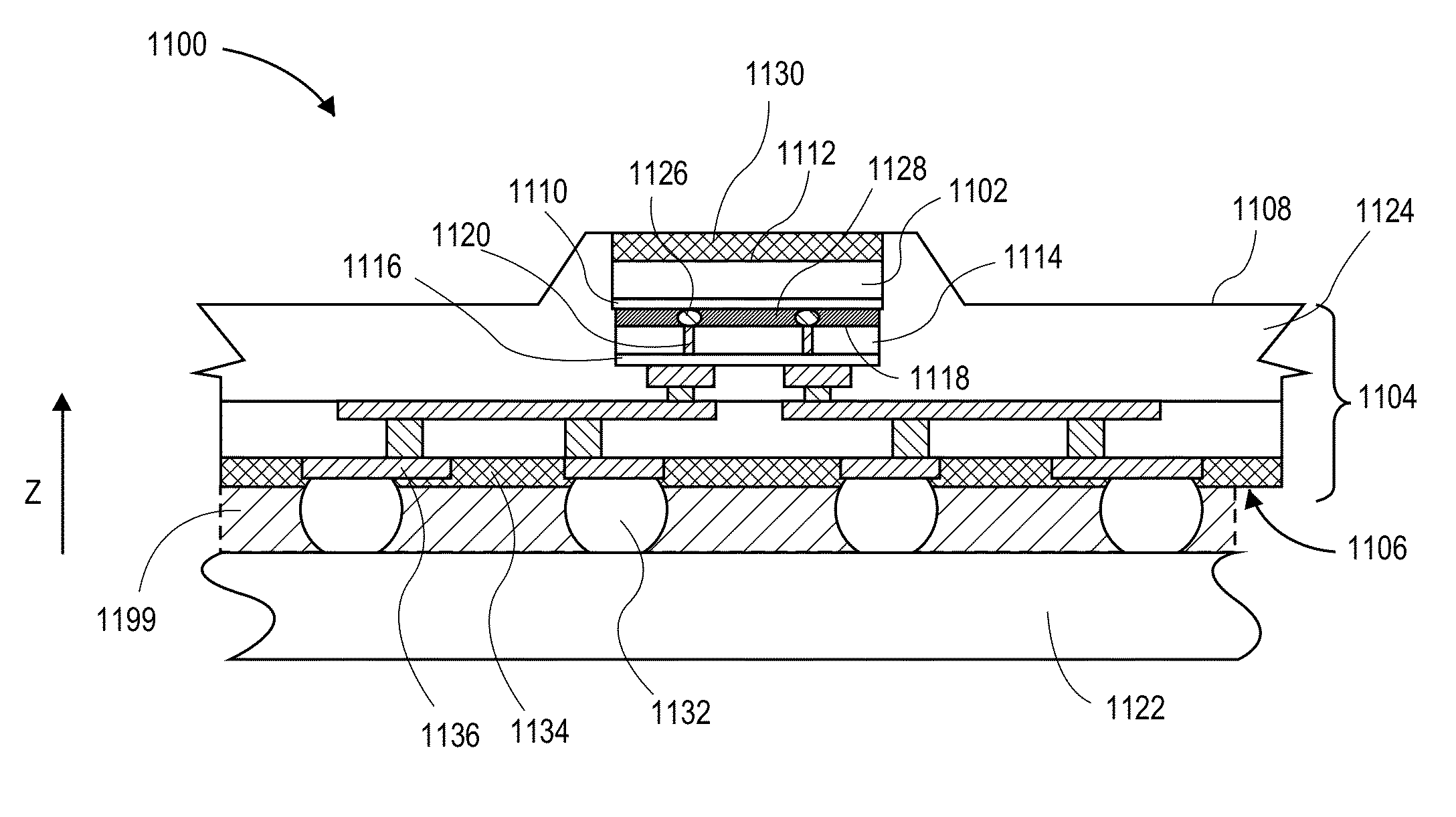

Epoxy-amine underfill materials for semiconductor packages

InactiveUS8916981B2Semiconductor/solid-state device detailsSolid-state devicesContact padFilling materials

Epoxy-amine underfill materials for semiconductor packages and semiconductor packages having an epoxy-amine underfill material are described. In an example, a semiconductor apparatus includes a semiconductor die having a surface with an integrated circuit thereon. A semiconductor package substrate has a surface with a plurality of contact pads thereon. A plurality of conductive contacts couples the surface of the semiconductor die to the surface of the semiconductor package substrate. An epoxy-amine underfill material is disposed between the surface of the semiconductor die and the surface of the semiconductor package substrate and surrounds the plurality of conductive contacts. The epoxy-amine underfill has high adhesion and is based on a low volatility multi-functional amine species.

Owner:INTEL CORP

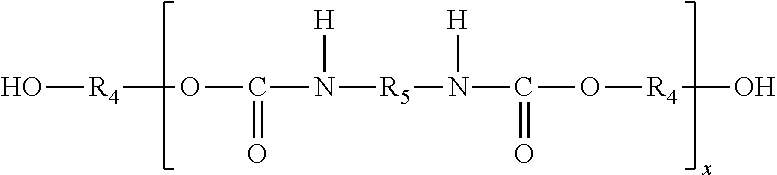

Ionically on nonionically stabilized epoxy adducts as water-dilutable base resins for 2-component isocyanate crosslinkable systems

InactiveUS6350796B1Polyurea/polyurethane coatingsPaints for electrolytic applicationsEpoxy amineAdduct

Two-component systems based on aqueous dispersions of hydrophilic epoxy adducts Ah having hydroxyl groups as reactive groups and unblocked difunctional or polyfunctional isocyanates B, said hydrophilic epoxy adducts Ah being selected from cationically stabilized hydrophilic epoxy adducts Ak, anionically stabilized hydrophilic epoxy adducts Aa and also nonionically stabilized epoxy adducts An and zwitterionically stabilized epoxy-amine adducts Aak.

Owner:SOLUTIA AUSTRIA GMBH

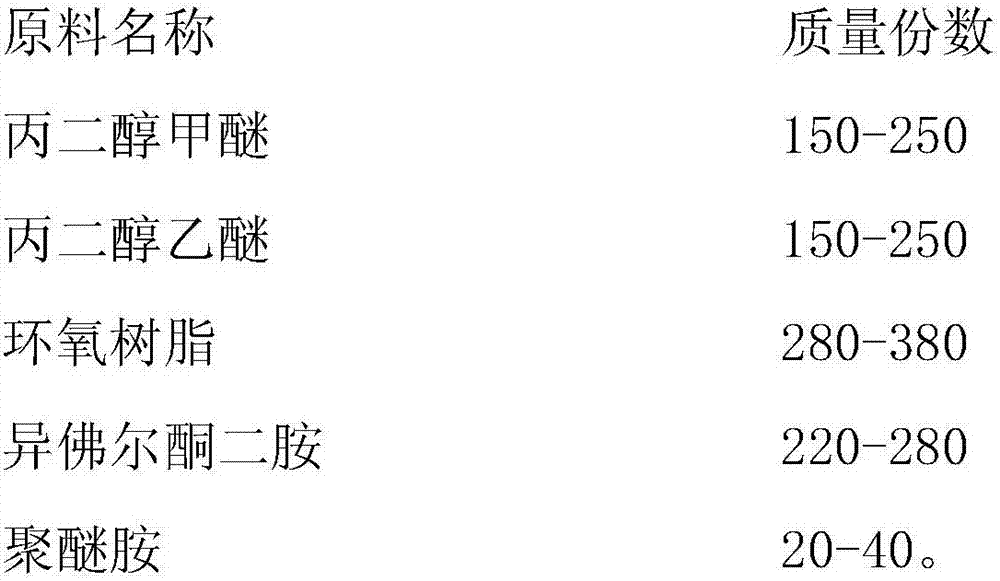

Polyether amine modified waterborne epoxy floor hardener and preparation method thereof

InactiveCN104231232AGood water dispersibilitySimple processEpoxy resin coatingsReaction temperatureEpoxy amine

The invention relates to a polyether amine modified waterborne epoxy floor hardener and a preparation method thereof. The polyether amine modified waterborne epoxy floor hardener is prepared through modification of polyether amine, synthesis of epoxy-amine and dispersion of deionized water; the molar ration of the polyether amine, epoxy-terminated glycidyl ether and epoxy resin is 2-6:0.5-4.5:0.5-4.5; during reaction, the polyether amine is firstly added into a reactor, then the epoxy-terminated glycidyl ether is added, the epoxy resin is added in drops, and lastly, the reactants are dispersed through the deionized water to obtain the polyether amine modified waterborne epoxy floor hardener. The preparation method of the polyether amine modified waterborne epoxy floor hardener is simple in process; the reaction temperature is easy to control; waterborne epoxy floor paints produced with the polyether amine modified waterborne epoxy floor hardener are high in hardness and glossiness, reach level-1 impact resistance and obtain high acid and alkali resistance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Ethanol stable epoxy amine based membrane for aromatics separation

ActiveUS20100059441A1Improve integrityEfficient separationMembranesSolid sorbent liquid separationAlcoholEpoxy amine

The present invention is directed to a membrane for aromatics separation that is stable in an alcohol containing environment. The polymeric membrane is a epoxy amine based membrane.

Owner:EXXON RES & ENG CO

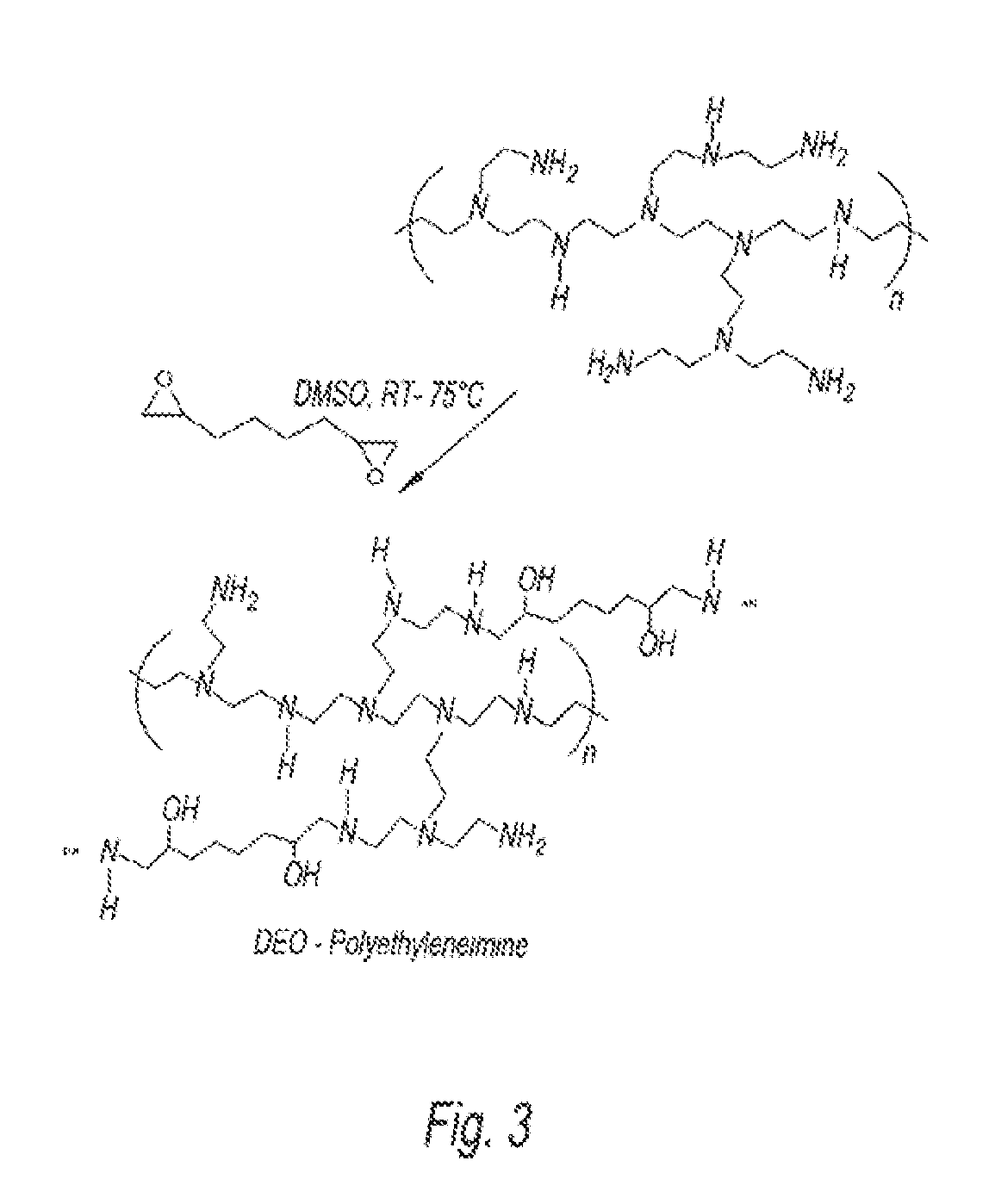

Epoxy-amine acid gas adsorption-desorption polymers and oligomers, processes for preparing same, and uses thereof

Owner:EXXON RES & ENG CO

Modified epoxy-amine compositions for oil field uses

Compressible and resilient sealing compositions for injection into oil or gas wells are provided, which are capable of forming effective seals adjacent well casings even at elevated downhole temperatures. The compositions comprise an epoxy component present in a predominant weight percentage, including an epoxy resin and a glycidyl ether modifier, as well as additional components rendering the cured compositions both compressive and resilient. The compositions are used as a partial or complete substitute for casing cements, and can be used to good effect with expandable casing installations or for sealing casing breaks. High set-up temperature (220-300° F.) compositions preferably include an ethoxylated alkyl (C10-C20) monoamine or diamine, and alkyl pyridine quaternary ammonium components.

Owner:CANADIAN ENERGY SERVICES

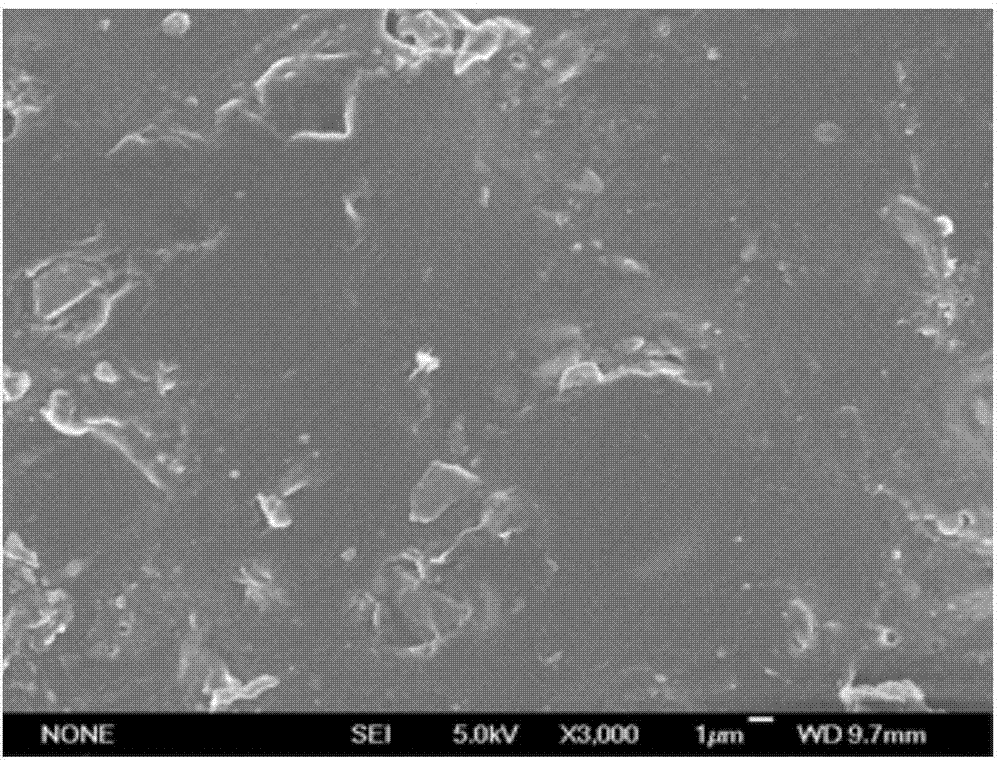

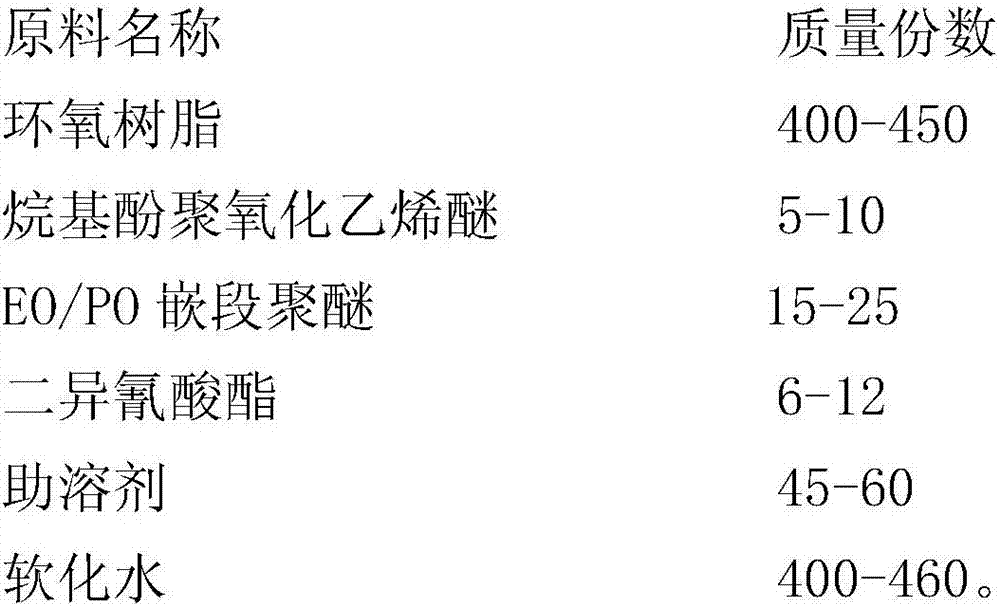

Aqueous epoxy graphene anticorrosive paint

ActiveCN107987680AImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsOrganic solventEmulsion

The invention relates to the anticorrosive paint field, and specifically relates to a preparation method of a dual component aqueous epoxy graphene anticorrosive paint. An epoxy polyether addition product is used to emulsify epoxy resin to prepare epoxy resin emulsion. Amino polyether, polyamine, and epoxy resin carry out reactions to prepare a polyether modified epoxy amine addition product curing agent. The epoxy resin amine addition product, zinc powder, pigments, fillers, and graphene are used to prepare zinc powder slurry, which is taken as an A component. A silane coupling agent and silicate carry out hydrolysis to prepare silicate sol, the silicate sol and epoxy resin emulsion are mixed, and the mixture is taken as a B component. A proper amount of graphene is used to modify zinc powder slurry, silicate sol is used to modify epoxy emulsion, two modifications obviously improve the anticorrosive performance of an aqueous zinc enriched primer, a same anticorrosive effect is reached, and the using amount of zinc powder is largely reduced. The obtained aqueous primer has the advantages that the VOC content is low, the pollution of organic solvents and zinc powder to the environment is largely reduced, and the safety hazards and fire are eliminated. The storage stability of paint is good, the paint is safe and convenient for construction, the coating can be quickly dried, theadhesion force of coating is strong, and the anticorrosive performance is strong.

Owner:MARINE CHEM RES INST

Spray polyurea elastomer applied to marine drilling platform corrosion prevention as well as preparation method and construction method thereof

ActiveCN103740247ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsAnti-corrosive paintsElastomerSalt resistance

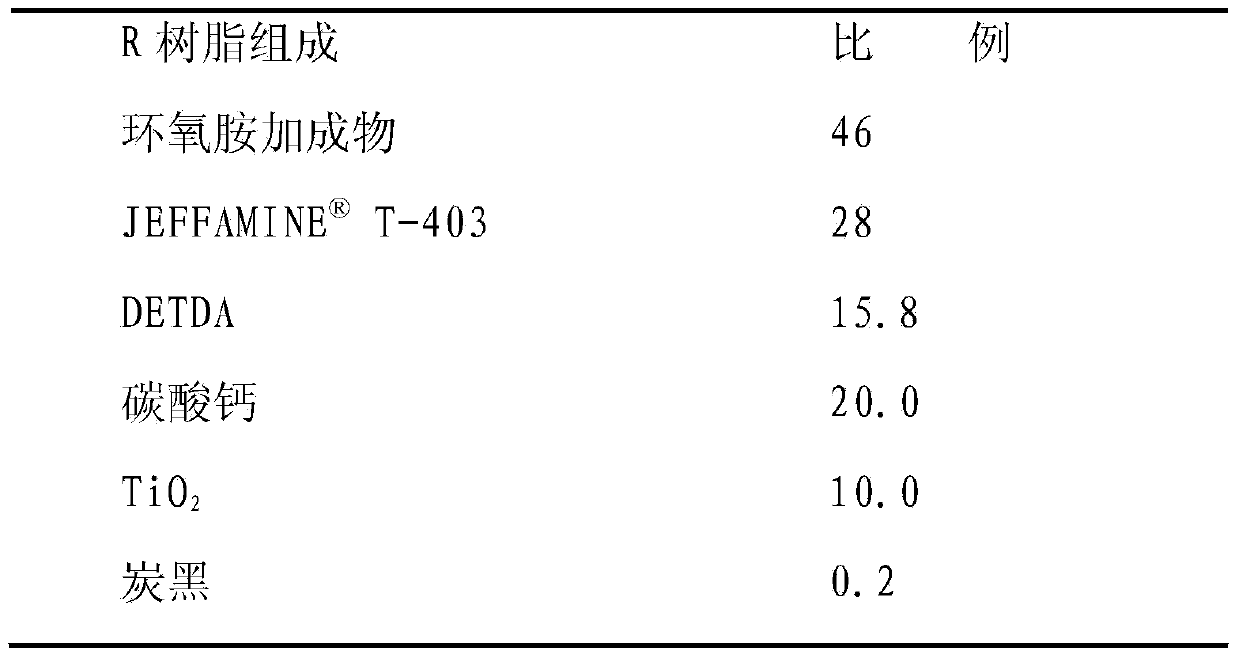

The invention provides a spray polyurea elastomer applied to marine drilling platforms as well as a preparation method and construction method thereof. The problems of poor adhesion and poor corrosion resistance in the marine environments in the prior art can be solved. The spray polyurea elastomer comprises components A and R and is characterized in that the component A is a semi-prepolymer synthesized by 10-40 parts of polyisocyanates, 20-90 parts of epoxy modified polyether polyol and 0-50 parts of polyether polyol by weight; the component R comprises 15-60 parts of epoxy amine adduct, 0-30 parts of amine-terminated polyether resin, 15-40 parts of chain extender and 5-25 parts of filler by weight. The spray polyurea elastomer material has good physical properties and high adhesion, simultaneously has excellent oil resistance, salt mist resistance, bacterium resistance, aging resistance and construction properties, can be shaped randomly, and can be widely applied to the parts with relatively high corrosion prevention requirements, such as platform decks, pile legs and the like of the marine drilling platforms.

Owner:MARINE CHEM RES INST

Matched coating for aluminium alloy base material

ActiveCN1803953AOvercome the disadvantage of poor adhesionBoth hardnessLiquid surface applicatorsPolyurea/polyurethane coatingsChain lengthEpoxy amine

The matched coating for aluminum alloy base material special to corrosion protection and decoration comprises: the primer with epoxy-amine addition system as double constituents, the middle painting as polyester / polyurethane system used polyester resin with acid number of as 8-10 and alternative soft and hard chain segments, and the top coat used polyester resin with acid number not more than 6 and main chain as hard segment and chain length and branching degree both more than the middle. Wherein, the polyamine on primer reacts with the epoxy resin to produce the secondary amine with more slow activity and enhance the adhesive force. This invention solves the aluminum alloy adhesion problem without smoke resistant material, and comes up to the first-level security standard.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Hydrolysable linkers and cross-linkers for absorbable polymers

The present invention relates to the discovery of new class of linear and multiarmed hydrolysable linkers and cross linkers for use in the synthesis of biodegradable polymers such as, polyesters, polyurethanes, polyamides, polyureas and degradable epoxy amine resin. The linear and multiarmed hydrolysable linkers of the present invention include symmetrical and / or unsymmetrical ether carboxylic acids, amines, amide diols, amine polyols and isocyanates.

Owner:BEZWADA BIOMEDICAL LLC

Bicomponent automobile cathode electrophoresis paint and preparation method thereof

ActiveCN101161742AImprove corrosion resistanceStrong adhesionLiquid surface applicatorsPaints for electrolytic applicationsEpoxy amineShock resistance

The invention relates to a bicomponent automobile cathode cataphoresis (BAC) coating and the preparation method thereof. The bicomponent cathode cataphoresis coating consists of epoxy resin grafted with acrylate (component I) and epoxy-amine resin (component II). The BAC paint film provided by the invention not only has the advantages of excellent corrosion resisting property, great adhesive force, good water resistance and high hardness, which are owned by a paint film formed by the single component II, but also has the advantages of excellent weathering resistance, good shock resistance, high fullness and brightness, which are owned by a paint film formed by the single component I. Thus, the paint film provided by the invention, which has better performance than that of single-component paint films is particularly suitable as automobile cathode cataphoresis coating and is also suitable as cathode cataphoresis coating of any work piece with complex forms.

Owner:GUANGDONG YATU CHEM +1

Waterborne epoxy resin cabin coating and preparation method thereof

InactiveCN110982380AStrong adhesionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

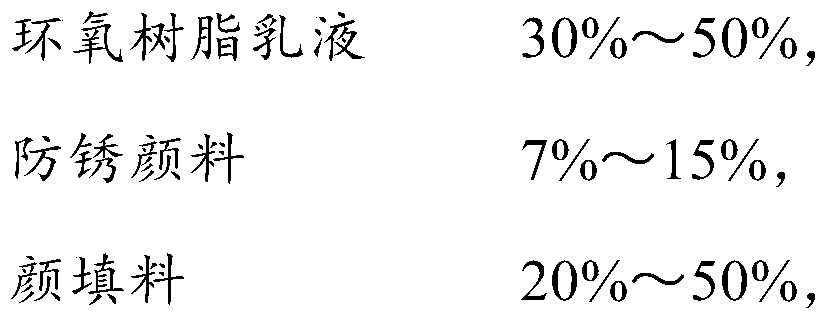

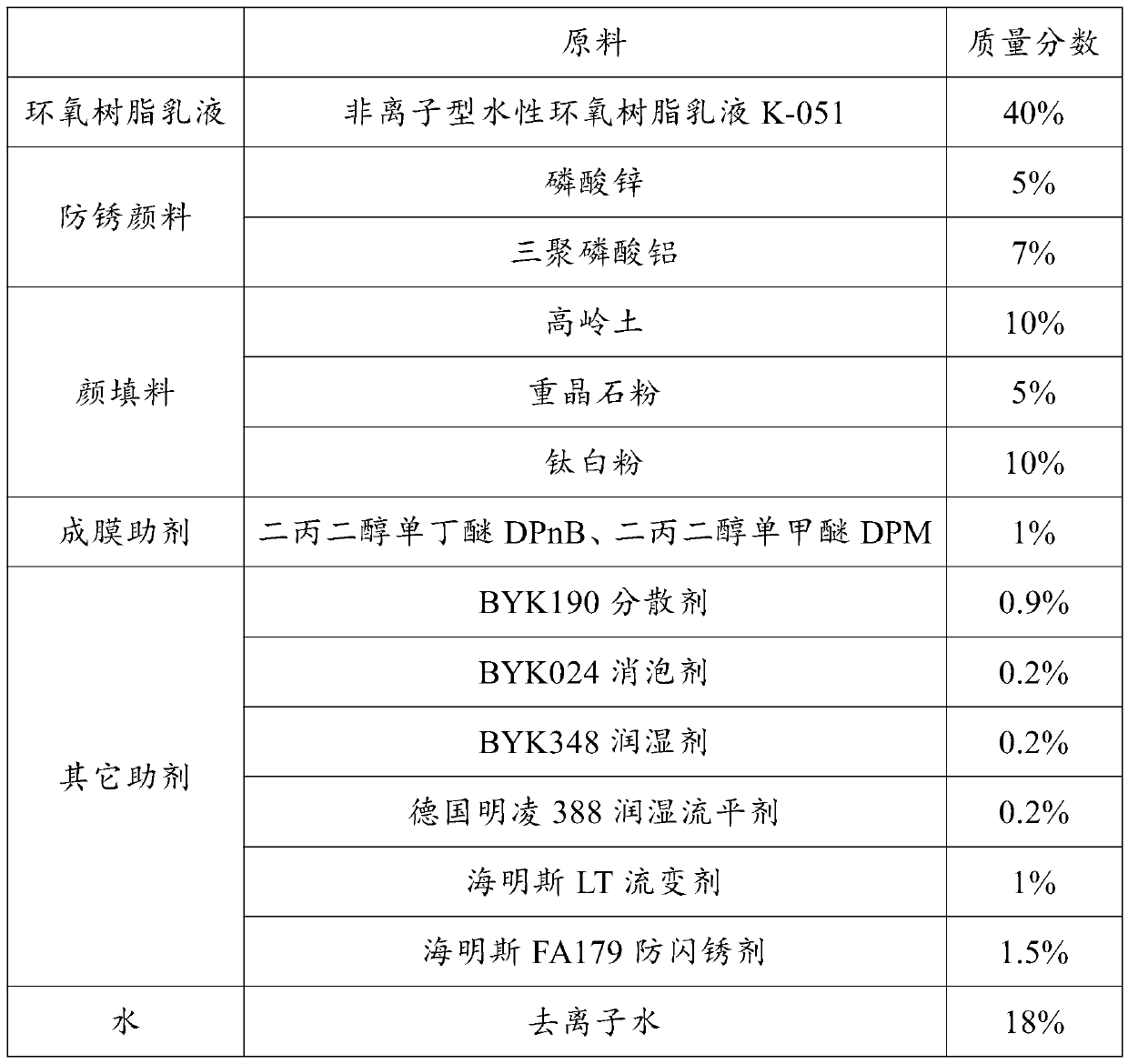

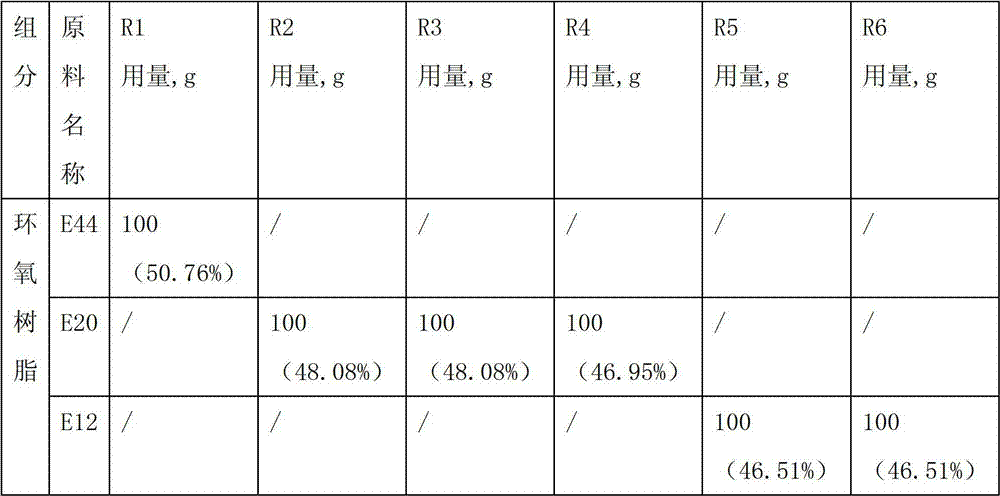

The invention provides a waterborne epoxy resin cabin coating. The coating comprises a component A and a component B in a weight ratio of (8-5): 1. The component A comprises the following components in percentage by mass: 30%-50% of an epoxy resin emulsion, 7%-15% of an antirust pigment, 20%-50% of a pigment filler, 1%-2% of a coalescing agent, 5%-8% of other auxiliaries and 5%-30% of water. The component B is a water-based epoxy amine curing agent with a solid content of 45-55% and with a solvent being water. According to the waterborne epoxy resin cabin coating, the VOC content of a cured paint film meets the environmental protection standard that the VOC content is smaller than or equal to 80 g / L, the adhesive force between the paint film and a substrate is larger than or equal to 5 MPa, the water contact angle of the paint film reaches 100 degrees or above and is kept stable, and recoating is easy; and the waterborne epoxy resin cabin coating has excellent salt spray resistance andcorrosion resistance.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

Self-emulsifying water-borne epoxy resin emulsion and preparation method thereof

ActiveCN102731798AImprove performanceImprove water resistanceEpoxy resin coatingsOrganic acidEmulsion

The invention relates to self-emulsifying water-borne epoxy resin emulsion and a preparation method thereof. The emulsion is formed by heating epoxy resin and a quaterisation agent to obtain a reaction product, adding water to carry out self-emulsifying, and adjusting until the solid content is 50-55 wt% for forming the emulsion, wherein the amounts of raw materials are as follows: 40-60% of epoxy resin, 0-20% of cosolvent, 5-15% of the quaterisation agent and 35-50% of deionized water; the quaterisation agent is obtained by reacting polyisocyanate and ethanolamine comprising tert-amino groupunder the actions of heating and a catalyst, and then neutralizing tert-ammonia through organic acid, and the amounts of raw materials are as follows: 40-70% of polyisocyanate, 15-30% of ethanolaminecomprising the tert-amino group, 10-20% of organic acid, 0-20% of cosolvent and 0.045-0.050% of catalyst. The preparation method has the advantages of convenience, simpleness and excellent emulsion stability, and can be cooperated with a commercial water-borne epoxy amine curing agent to prepare a water-borne dual-component epoxy coating with excellent comprehensive performance.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Self-cleaning corrosion-resistant aluminum profile

InactiveCN108250903AImprove corrosion resistanceStrong adhesionAntifouling/underwater paintsPaints with biocidesPolyethylene glycolResin coating

The invention discloses a self-cleaning corrosion-resistant aluminum profile and relates to the technical field of aluminum profiles. The self-cleaning corrosion-resistant aluminum profile comprises an aluminum profile matrix and an epoxy resin coating coating the surface of the aluminum profile matrix, wherein the epoxy resin coating is prepared by mixing a component A and a component B accordingto a weight ratio of 3-5 to 1; the component A comprises the following raw materials in parts by weight: 40-50 parts of a bisphenol A epoxy resin emulsion, 5-10 parts of modified titania nanoparticles, 0.5-2 parts of fumed silica, 5-10 parts of diatomite, 2-5 parts of graphene oxide, 3-7 parts of texanol, 2-5 parts of polyethyleneglycol diglycidyl ether, 0.5-2 parts of a dispersing agent, 0.5-2 parts of a flatting agent, 12-15 parts of water, 2-5 parts of a coupling agent and 0.2-1 part of nonylphenol polyoxyethylene ether; the component B is a waterborne epoxy amine curing agent. The coatingprepared by the invention is excellent in pollution resistance, bactericidal activity, corrosion resistance and wear resistance and is excellent in bonding strength with an aluminum alloy base material, a long-term protection effect is achieved, the service life of the aluminum alloy is prolonged, and the application range is widened.

Owner:安徽鑫铂铝业股份有限公司

Epoxy-Amine Acid Gas Adsorption-Desorption Polymers and Oligomers, Processes for Preparing Same, and Uses Thereof

InactiveUS20120160097A1Reduce stressLower cost of capitalGas treatmentOther chemical processesOligomerGram

This disclosure involves an adsorption-desorption material, e.g., crosslinked epoxy-amine material having an Mw from about 500 to about 1×106, a total pore volume from about 0.2 cc / g to about 2.0 cc / g, and a CO2 adsorption capacity of at least about 0.2 millimoles CO2 per gram of crosslinked material, and / or linear epoxy-amine material having an Mw from about 160 to about 1×106, a total pore volume from about 0.2 cc / g to about 2.0 cc / g, and a CO2 adsorption capacity of at least about 0.2 millimoles CO2 per gram of linear material. This disclosure also involves processes for preparing the crosslinked epoxy-amine materials and linear epoxy-amine materials, as well as selective removal of CO2 and / or other acid gases from a gaseous stream using the epoxy-amine materials.

Owner:EXXON RES & ENG CO

Sizing agent for carbon fiber

InactiveCN101982602AIncrease cross-linking pointImprove the interface bonding strengthCarbon fibresFiberCarbon fibers

The invention discloses a sizing agent for a carbon fiber, belonging to the fields of organic chemistry and fiber materials. The sizing agent is an epoxy water emulsion added with an aqueous curing agent, wherein the aqueous curing agent is modified epoxy amine curing agent, namely an amidated amine curing agent obtained by a reaction between a mono-fatty acid and an epoxy amine curing agent, a polyamide curing agent obtained by a reaction between a dimer acid and an epoxy amine curing agent and a curing agent obtained by a reaction between an epoxy amine curing agent and epoxy resin; the epoxy emulsion uses bisphenol A epoxy resin as the main body, and the epoxy equivalent is 200-500; the amount of the aqueous curing agent is 10% to 40% of theoretical one, and the theoretical amount should be calculated as follows: W=(Namine / NEP)*100, wherein Namine is the amine hydrogen equivalent of the curing agent, NEP is the epoxy equivalent of the epoxy resin, and W is the theoretical amount of the curing agent required by 100 grams of epoxy resin. The sizing agent is safe and healthy, the stability and the bundling performance are further improved, and the interface bonding strength of the composite material is enhanced.

Owner:BEIJING UNIV OF CHEM TECH

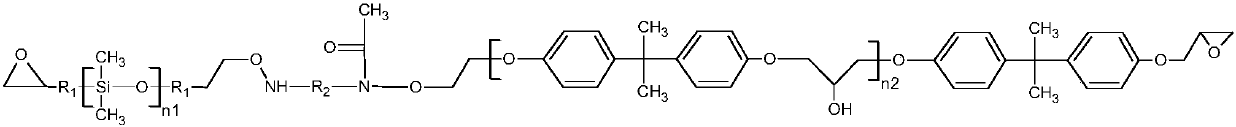

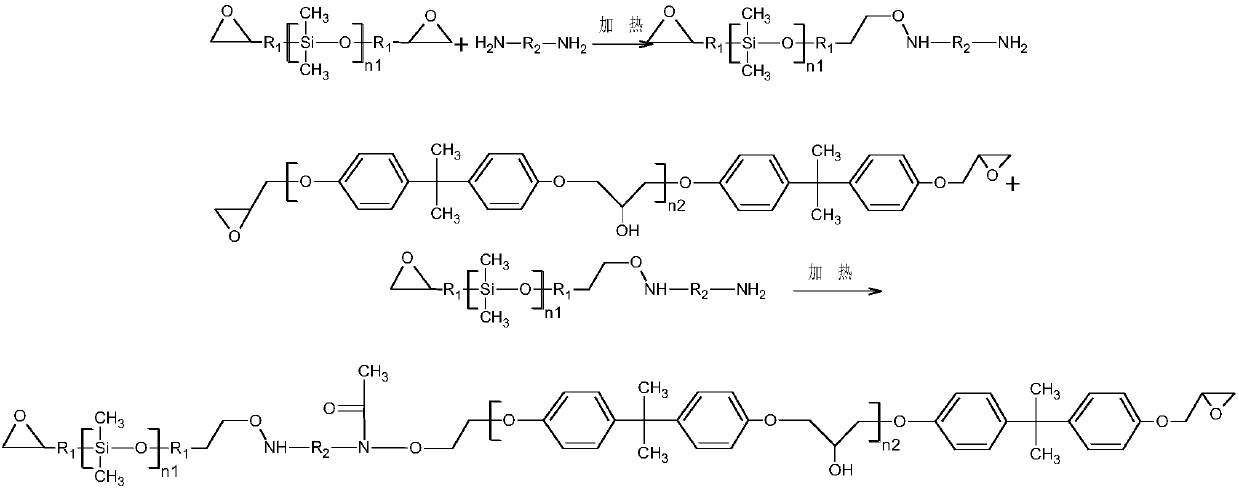

Silicone-modified waterborne epoxy curing agent and preparation method thereof

InactiveCN107814914AImprove hydrophobicityImprove toughnessGroup 4/14 element organic compoundsResin coatingEpoxy amine

The invention discloses a preparation method of a silicone-modified waterborne epoxy curing agent. The preparation method comprises the following steps: respectively dissolving polyamine and epoxy-terminated silicone oil into alcohol ether type organic solvents, uniformly stirring, dropwise adding the epoxy-terminated silicone oil into the polyamine under nitrogen protection, and heating to react;adding bisphenol A epoxy resin into the reaction product, heating and reacting; adding organic acid to perform waterborne modification; and finally, adding water, thereby obtaining the silicone-modified waterborne epoxy curing agent with the solid content of 30-90%. According to the method disclosed by the invention, silicone graft modification of the curing agent is performed by adopting a ring-opening reaction of amino epoxy groups carried out between the epoxy-terminated silicone oil and polyamine, and the hydrophobic nature and toughness of the epoxy resin coating are improved; a ring-opening grafting reaction of the amino epoxy groups is carried out between epoxy group in the epoxy resin and amino on the silicone-grafted polyamine at a high temperature, so that the compatibility of the curing agent and the epoxy resin is improved; and due to the waterborne modification, the defect that the traditional organic coating has high content of VOC (Volatile Organic Compounds) can be overcome.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

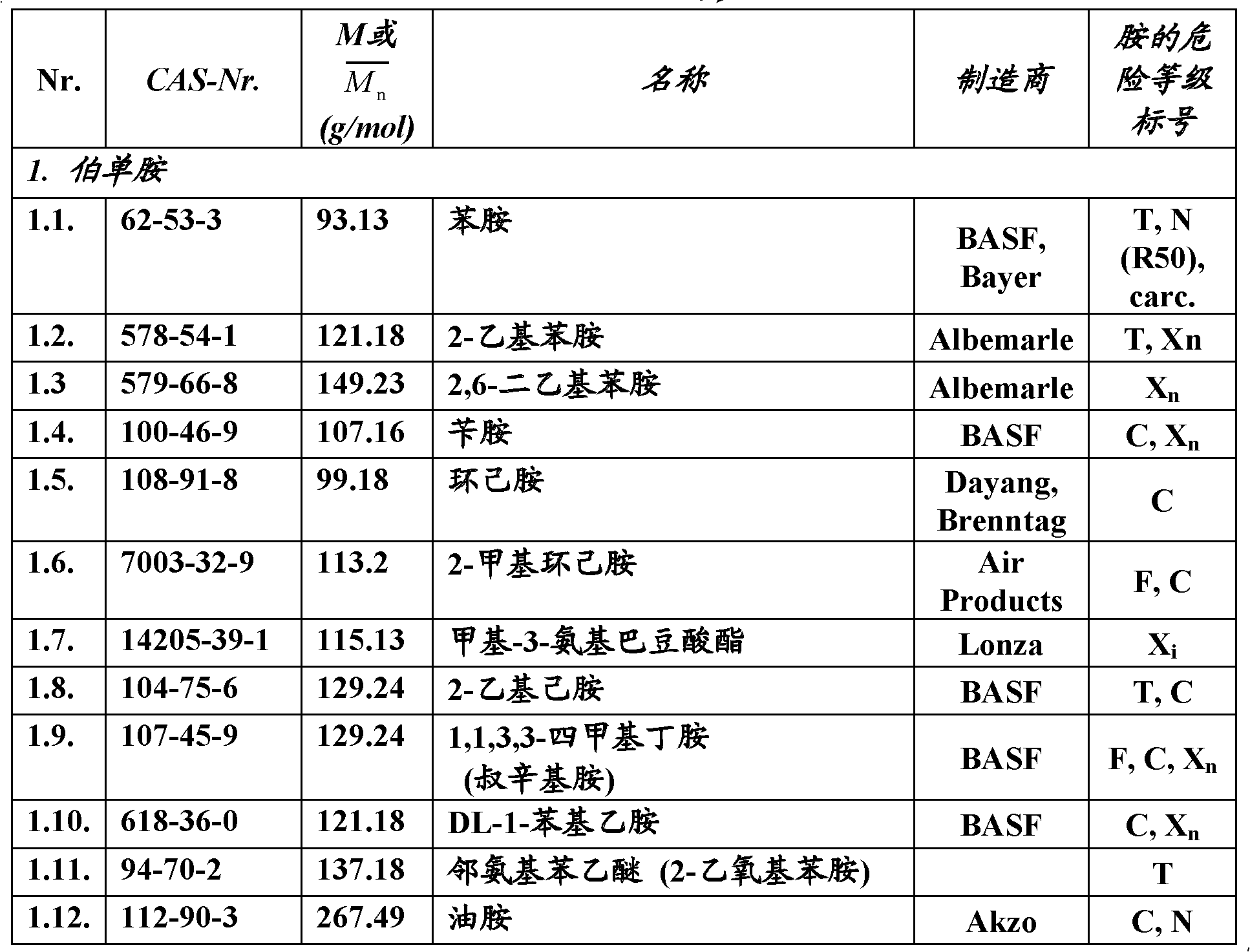

Amine-epoxy adducts and their use for preparing polyurea and polyurea-polyurethane coatings

InactiveCN102625815AImprove propertiesImprove adhesion strengthPolyurea/polyurethane coatingsEpoxy aminePolyurethane coating

The invention relates to amine-epoxy adducts with symmetrical and asymmetrical structures based on one hand on aliphatic, cycloaliphatic, araliphatic or aromatic mono-, di- and triamines, and on the other hand on aliphatic, cycloaliphatic and aromatic, mono-, di- or polyepoxy compounds, having an average molecular mass (Mn) of more than 300, but less than 8000, preferably less than 6000, containing at least one, preferably on an average more than one alcoholic hydroxyl group per molecule which is formed in the course of the epoxy-amine reaction, which contain at least two amino groups per molecule being able to react with isocyanate groups, among those maximum one is primary amine, the adduct molecules are of polymeric character and their viscosity is <=300 mPas at 70 DEG C. The invention also relates to the process for the preparation of these adducts, and to their use for preparing sprayable polyurea and polyurea-polyurethane coatings.

Owner:POLINVENT

Preparation method of hyperbranched poly (urethane-amine) with hydroxide radical serving as end group and internal branched units provided with vinyl

ActiveCN106519158ASynthetic raw materials are readily availableThe synthesis method is simpleEnd-groupChemical compound

The invention relates to a preparation method of hyperbranched poly (urethane-amine) with hydroxide radical serving as the end group and internal branched units provided with vinyl. Firstly, two-functionality-degree vinyloxirane and three-functionality-degree amine compounds serve as raw materials, and novel B3B'3 monomers (B represents hydroxyl, and B' represents vinyl) containing three hydroxyls and three vinyls simultaneously are synthesized through the epoxy-amine open-loop reaction; and then diisocyanate compounds serving as A2 monomers and the hydroxyls in the B3B'3 monomers react, and the hyperbranched poly (urethane-amine) of a clear structure and with hydroxide radical serving as the end group and the internal branched units provided with vinyl is synthesized. Raw materials are easy to obtain, the steps are easy to implement, and the hyperbranched polymer is obtained, specifically, the structure is controllable, two functionally groups namely the hydroxyl and the vinyl are contained simultaneously, and the end group and the internal branched units can be further modified functionally.

Owner:JIANGNAN UNIV

Capped ester containing epoxy amine adduct curing agents for curing epoxy resins at ambient or sub-ambient temperatures without external catalysts

There is provided a curing agent composition, a method for making a curing agent composition, two component curable epoxy resin compositions, methods of their manufacture, and the different cured products thereof. The curing agent comprises the reaction product of a a) phenolic acid substituted with at least one carboxyl group and at least one hydrocarbyl group having at least 1 carbon atom; b) a polyepoxide compound; c) a polyamine compound having at least two primary amine groups; and d) a monoglycidyl capping agent. The curing agents contain secondary amine groups, yet are reactive enough to cure epoxy resins without the necessity for external catalysts / accelerators, at a wide range of curing temperatures and are immediately compatible with a standard diglycidyl ether of Bisphenol-A epoxy resins.

Owner:SHELL OIL CO

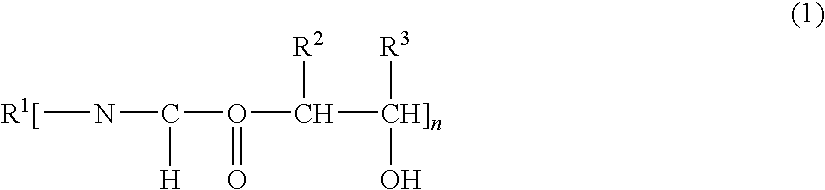

Epoxi-amine composition modified with hydroxyalkyl urethane

Disclosed is a novel epoxy-amine composition modified a hydroxyalkyl urethane, which is obtained as a result of a reaction between a primary amine (C1) and a monocyclocarbonate (C2), wherein modifier (C) is represented by the following formula (1):wherein R1 is a residue of the primary amine, R2 and R3 are the same or different and are selected from the group consisting of H, alkyl, hydroxyalkyl, and n satisfies the following condition: n≧2. Diluents, pigments and additives can be used. Doping with the hydroxyalkyl-urethane modifier imparts to the cured composition superior coating performance characteristics, such as pot-life / drying, strength-stress, bonding, appearance, resistance to abrasion and solvents, etc., in a well-balanced state.

Owner:LIFSCHITZ YAKOV MARK +1

Epoxy-amine composition modified with hydroxyalkyl urethane

Owner:LIFSCHITZ YAKOV MARK +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com