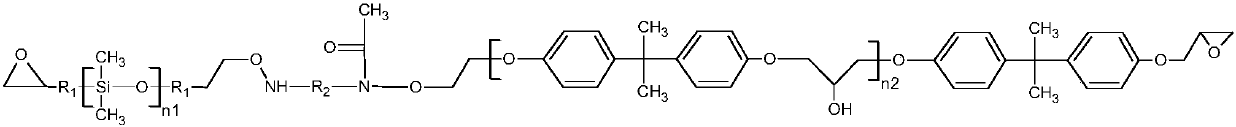

Silicone-modified waterborne epoxy curing agent and preparation method thereof

A water-based epoxy and curing agent technology, applied in the field of coatings, can solve the problems of short trial period, affecting the film formation and film performance of epoxy resin, and poor stability of two components, so as to improve hydrophobicity and toughness, and solve high VOC , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

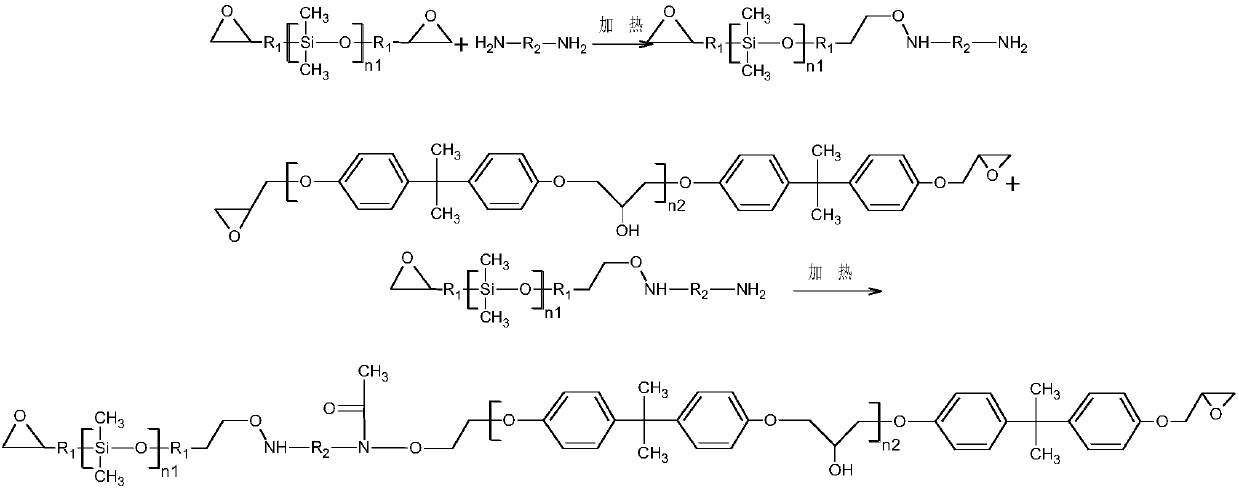

Method used

Image

Examples

Embodiment 1

[0032] Dissolve 100 parts of diethylenetriamine into 30 parts of propylene glycol methyl ether, stir evenly at a stirring speed of 300r / min, then keep the reactant in a water bath at a constant temperature of 50°C, and dropwise dissolve 50 parts of propylene glycol under the protection of nitrogen. The solution of 20 parts of oxyethyl-terminated polymethicone oil in propylene glycol methyl ether was added dropwise for 1 hour, and after the dropwise addition was completed, the reaction was continued for 1.5 hours at 50°C. In a nitrogen atmosphere, 20 parts of propylene glycol methyl ether solution dissolved with 40 parts of E42 was added dropwise at a constant speed at 100°C for 2 hours, and the reaction was continued at 100°C for 1 hour. Cool down to 60°C, add 30 parts of propionic acid for neutralization, add dropwise for 0.5h, and finally add water dropwise and stir to prepare a silicone-modified water-based epoxy curing agent aqueous solution with a solid content of 30%.

Embodiment 2

[0034] Dissolve 100 parts of triethylenetetramine into 40 parts of propylene glycol methyl ether, stir evenly at a stirring speed of 300r / min, then keep the reactant in a water bath at a constant temperature of 75°C, and drop and dissolve 50 parts of cyclo The solution of 20 parts of oxyethyl-terminated polymethicone oil in propylene glycol methyl ether was added dropwise for 1.5 hours. After the dropwise addition was completed, the reaction was continued for 2 hours at 75°C. In a nitrogen atmosphere, 20 parts of propylene glycol methyl ether solution dissolved with 50 parts of E42 was added dropwise at a constant speed at 120°C for 2 hours, and the reaction was continued at 120°C for 2 hours. Cool down to 60°C, add 60 parts of propionic acid for neutralization, add dropwise for 0.5 h, and finally add water dropwise and stir to prepare a silicone-modified water-based epoxy curing agent aqueous solution with a solid content of 30%.

Embodiment 3

[0036] Dissolve 100 parts of triethylenetetramine into 40 parts of propylene glycol methyl ether, stir evenly at a stirring speed of 400r / min, then keep the reactant in a water bath at a constant temperature of 100°C, and drop and dissolve 50 parts of cyclo 30 parts of propylene glycol methyl ether solution of oxypropyl-terminated polymethicone oil was added dropwise for 2 hours. After the dropwise addition was completed, the reaction was continued for 2 hours at 100°C. In a nitrogen atmosphere, 20 parts of propylene glycol methyl ether solution dissolved with 50 parts of E44 was added dropwise at a constant speed at 120°C for 2.5 hours, and the reaction was continued at 120°C for 2 hours. Cool down to 60°C, add 40 parts of propionic acid for neutralization, add dropwise for 1 hour, and finally add water dropwise and stir to prepare a silicone-modified water-based epoxy curing agent aqueous solution with a solid content of 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com