Self-emulsifying water-borne epoxy resin emulsion and preparation method thereof

A water-based epoxy resin, self-emulsifying technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the effect of the amount of hydrophilic segment on the curing performance of the emulsion, can not use two-component epoxy coating system, polyoxyalkylene It is easy to popularize, good performance, good acid and alkali resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 prepares quaternizing agent A1~A3

[0025] (1) Formula

[0026] The quaternizing agent of the present invention is prepared by reacting polyisocyanate and ethanolamine containing tertiary amino groups under the action of heating and catalyst, and then neutralizing tertiary ammonia with organic acid. The amount of each raw material is calculated by weight percentage: polyisocyanate 40-70%, 15-30% ethanolamine containing tertiary amine groups, 10-20% organic acid, 0-20% co-solvent, 0.045-0.050% catalyst, and the sum of the weight percentages of the above-mentioned raw materials is 100%; , polyisocyanate is one or more of biuret, trimer and trimethylolpropane adduct, ethanolamine containing tertiary amino group is N,N-dimethylethanolamine, N,N-diethyl Any one of base ethanolamine, N,N-diisopropylethanolamine and N,N-dibutylethanolamine, the cosolvent is ethylene glycol esters or propylene glycol esters, the organic acid is lactic acid or glacial acetic acid; ...

Embodiment 2

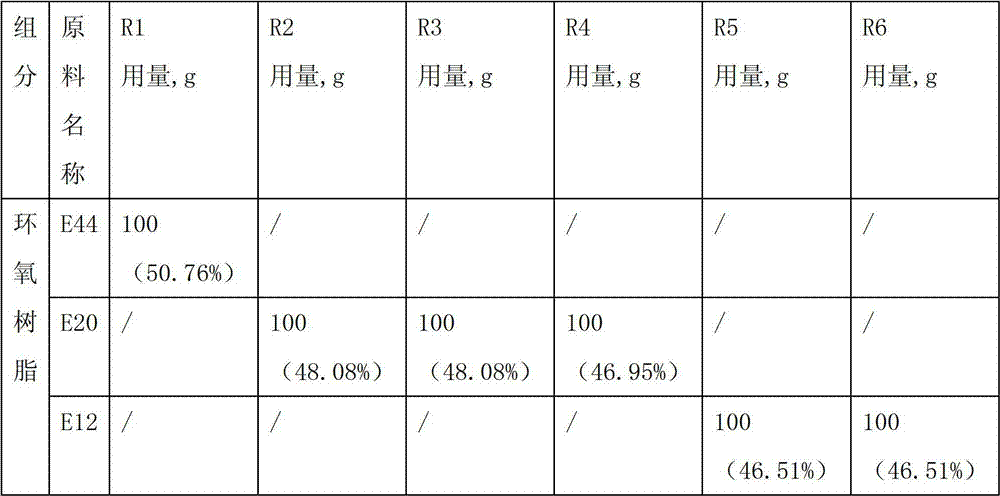

[0035] Embodiment 2 prepares self-emulsifying type waterborne epoxy resin emulsion R1~R6

[0036] (1) Formula

[0037]Prepare the self-emulsifying type water-based epoxy resin emulsion of the present invention according to the weight percent of each raw material consumption: epoxy resin 40~60%, cosolvent 0~20%, step ① prepares quaternizing agent 5~15%, removes 30-50% of ionized water is used to prepare the raw materials, and the sum of the weight percentages of the above-mentioned raw materials is 100%, and the specific formula is shown in Table 2;

[0038] Table 2

[0039]

[0040]

[0041] Note: ① The numbers in brackets are the amount of each raw material in weight percentage;

[0042] ②The raw materials used in the formula are not limited by Table 2, and can be selected from the varieties listed above.

[0043] (2) Preparation

[0044] In a 1000ml four-necked flask equipped with a thermometer, a stirring device and a condensing device, add epoxy resin or epoxy re...

Embodiment 3

[0050] Embodiment 3 prepares two-component waterborne epoxy paint

[0051] (1) Preparation of two-component waterborne epoxy coatings

[0052] The self-emulsifying type water-based epoxy resin emulsion R1, R2, R3 prepared in Example 2 is the basic film-forming resin, with Anquamine701 as the curing agent (product of Gas Chemical Company), according to the epoxy group in the emulsion and the mole of active hydrogen in the curing agent The ratio is 1:0.8 to calculate the amount of the two, according to the existing two-component water-based epoxy coating common formula, add defoamer, leveling agent, anti-rust pigments and fillers, etc., and prepare two-component dry at room temperature according to the existing method Waterborne epoxy paint T1, T2, T3.

[0053] (2) Testing the performance of the coating film

[0054] ①Preparation of samples for testing

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com