Waterborne epoxy resin cabin coating and preparation method thereof

A water-based epoxy resin and epoxy resin emulsion technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve the problems of low coating quality, cumbersome preparation process, low environmental protection performance, etc., and achieve a simple preparation process. , good environmental performance, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A waterborne epoxy resin cabin paint, wherein the A component is calculated as a percentage of gravity and includes the following components:

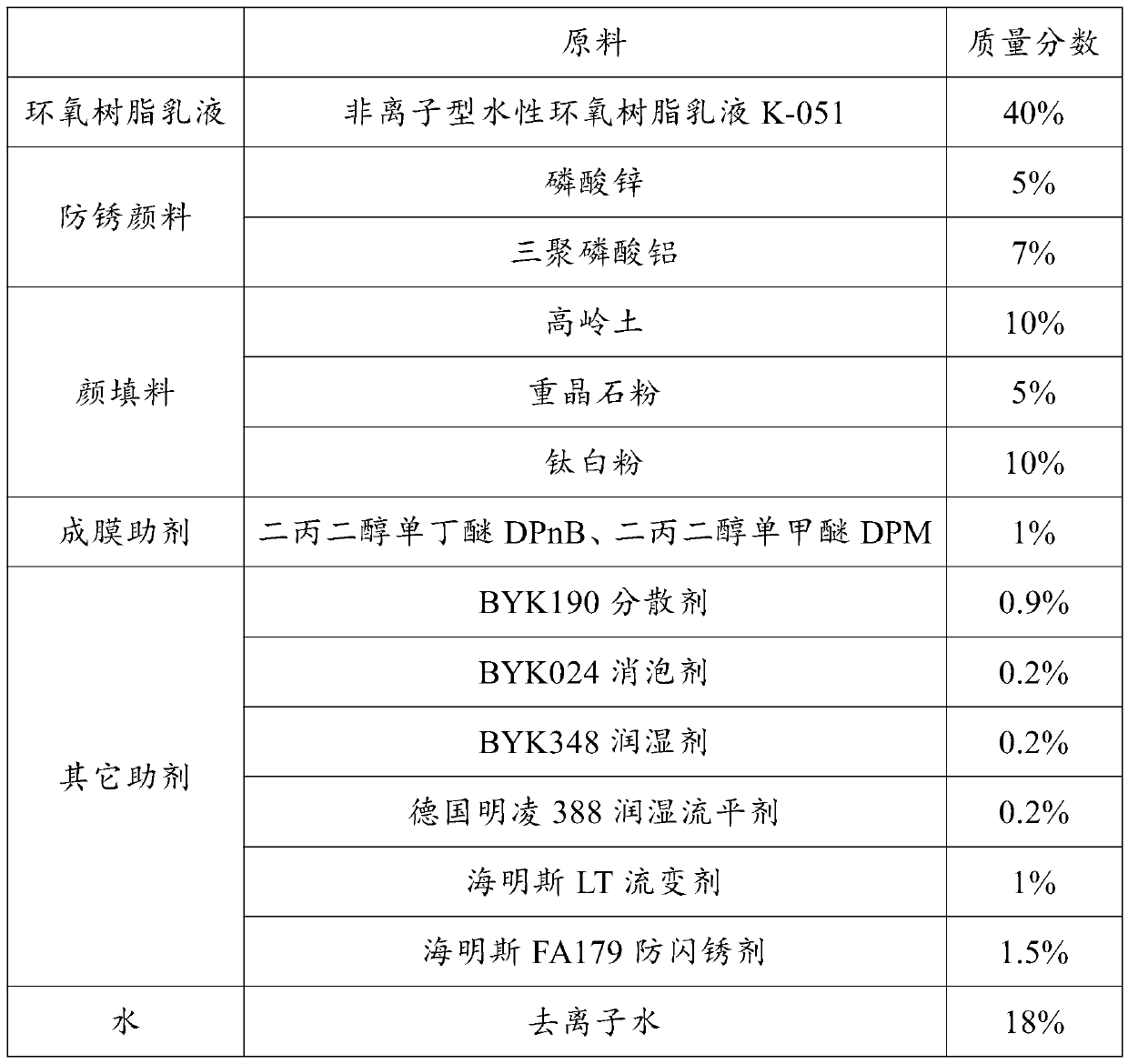

[0027]

[0028] The B component is Huntsman Aradur 3985 waterborne epoxy curing agent.

[0029] Put 15% (percentage of the total mass, the same below) of water, 0.9% of dispersant, 0.1% of defoamer and 0.1% of wetting and leveling agent into the batching tank for high-speed dispersion and stirring. Put in 5% zinc phosphate, 7% aluminum tripolyphosphate, 10% kaolin, 5% barite powder, 10% titanium dioxide, and continue to stir and disperse for 40 minutes, then grind and disperse, control the fineness and grind to ≤30μm, filter out the slurry; put 40% non-ionic water-based epoxy resin emulsion K-051 into the paint mixing tank, and then add 0.2% wetting agent, 1.5% anti-flash rust agent, 0.1% wetting agent Wet leveling agent, 1% film-forming aid, 1% LT rheological agent, 0.1% defoamer and 3% deionized water, stir for about 15 minutes, u...

Embodiment 2

[0033] A waterborne epoxy resin cabin paint, wherein the A component is calculated as a percentage of gravity and includes the following components:

[0034]

[0035]

[0036] The B component is Huntsman Aradur 38 waterborne epoxy curing agent.

[0037] Put 15% water, 0.9% dispersant, 0.1% defoamer and 0.1% wetting agent into the batching tank for high-speed dispersion and stir evenly, and put in 5% zinc phosphate and 7% tripolyphosphoric acid under stirring. Aluminum, 7% talc powder, 8% mica powder, 10% titanium dioxide and iron oxide yellow, continue to stir and disperse for 30 minutes, then grind and disperse, control the fineness to grind to ≤30μm, and filter out the slurry; Put 42% non-ionic water-based epoxy resin emulsion Epikote3510-W-60A into the paint mixing tank, then add 2% anti-flash rust agent, 0.6% substrate wetting agent, 0.7% thickener, 0.1% Stir the defoamer and 1.5% film-forming aid for about 15 minutes until it is completely uniform, and then detect the A compo...

Embodiment 3

[0041] In the marine waterborne engine room primer, the A component is calculated as a percentage of gravity and includes the following components:

[0042]

[0043] The B component is Huntsman Aradur 36 waterborne epoxy curing agent.

[0044] Put 11% water, 0.5% dispersant, 0.05% defoamer and 0.05% wetting and leveling agent into the batching tank for high-speed dispersion and stirring, and put in 6% zinc phosphate and 6% three Aluminum polyphosphate, 10% titanium dioxide, 6% talc powder and 6% precipitated barium sulfate, and accelerate the dispersion for 25 minutes, then grind and disperse, control the fineness to ≤30μm, and filter out the slurry; Put 50% non-ionic water-based epoxy resin emulsion Epikote3510-W-60A into the tank, and then add 0.1% wetting agent, 0.2% rheological agent, 2% anti-flash rust agent, 0.05% wetting agent in sequence Leveling agent, 2% film-forming aid and 0.05% defoamer, stir for about 15 minutes, until completely uniform, detect the A component of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com