Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "Good seawater resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

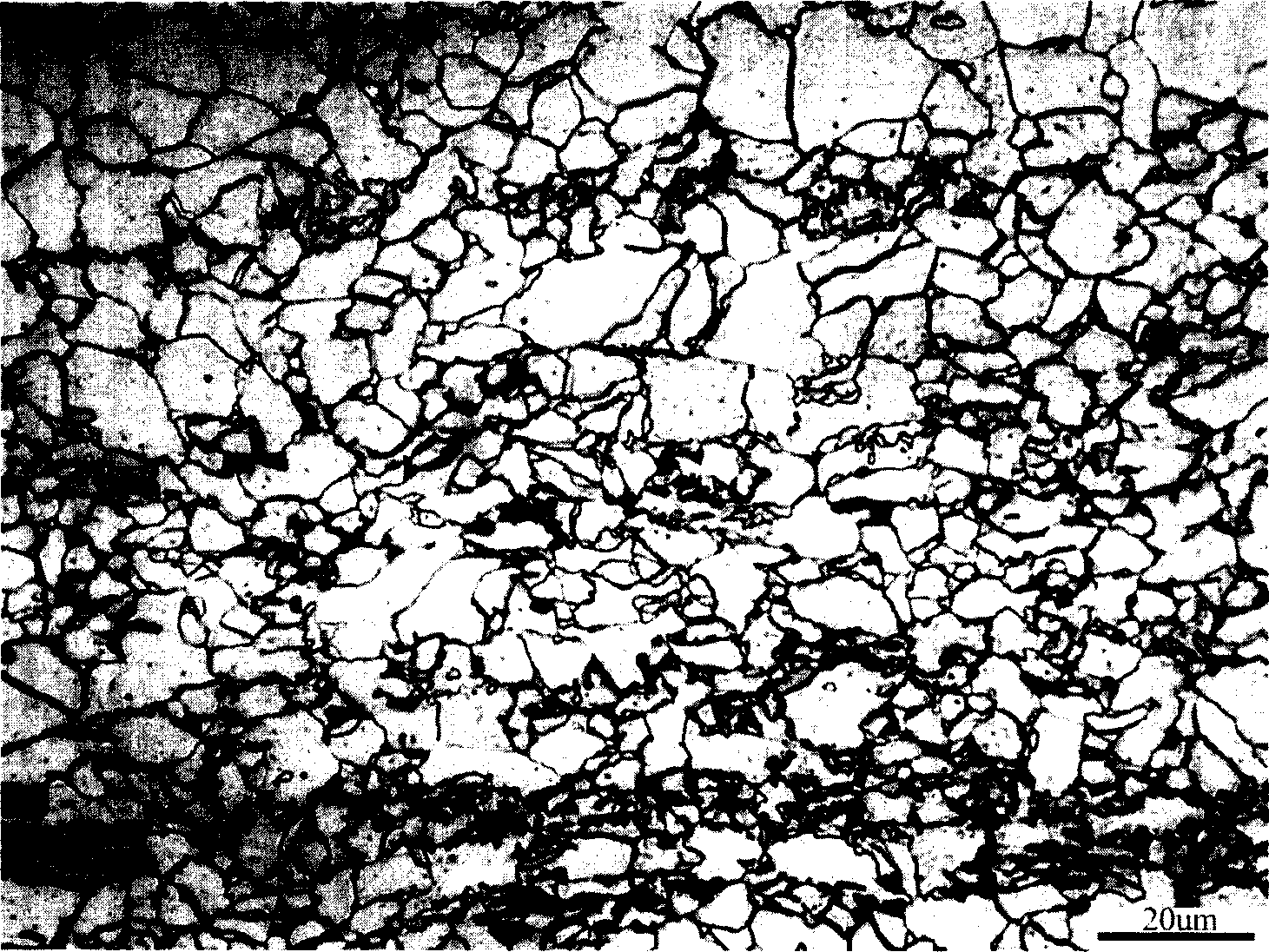

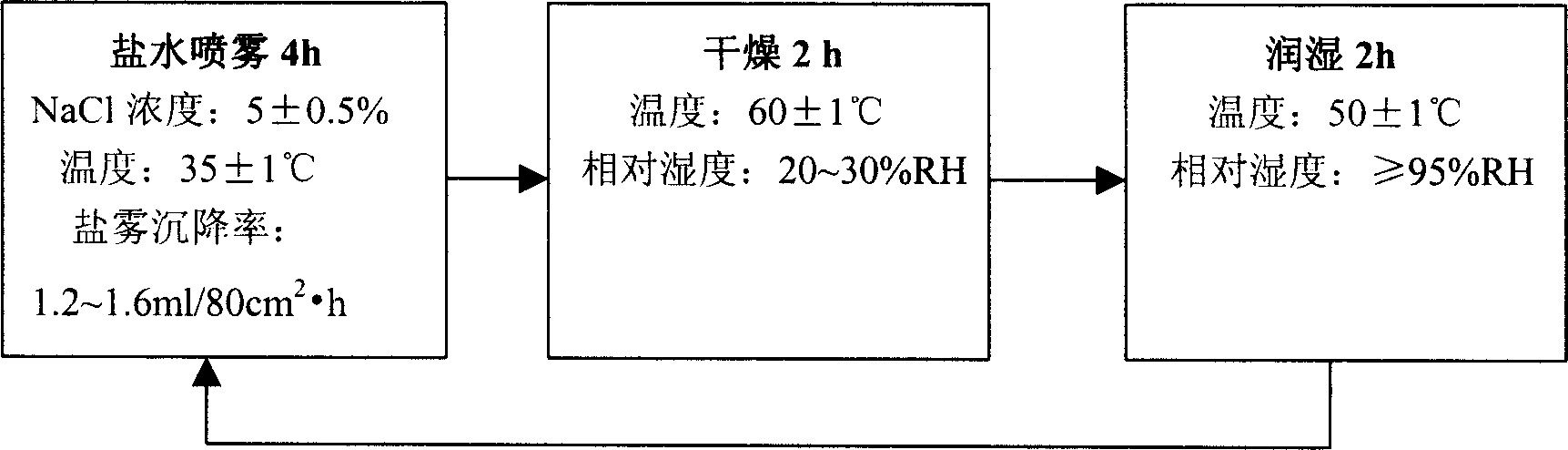

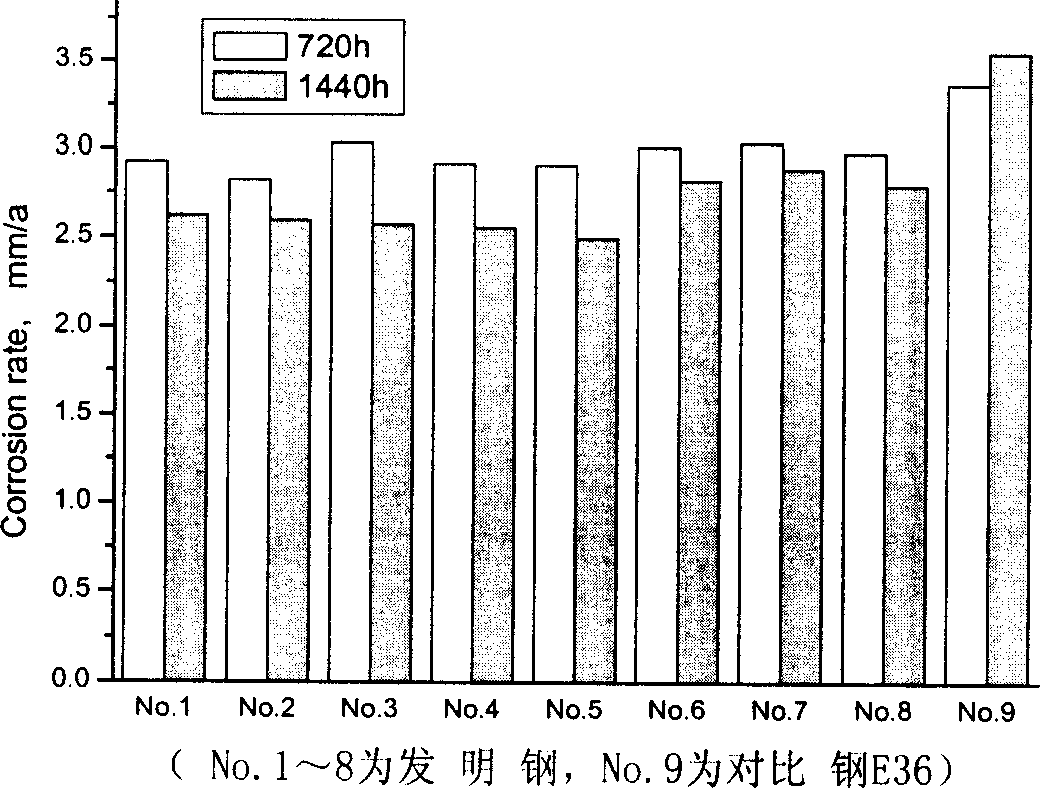

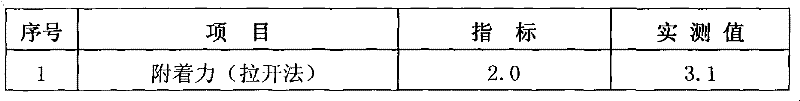

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

Novel anti-skidding coating for deck and preparation method thereof

ActiveCN102504679AStrong adhesionImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWeather resistanceFoaming agent

The invention provides a novel anti-skidding coating for a deck, which is composed of the following components in parts by weight: 30-45 parts of latex, 2-5 parts of film forming accessory ingredient, 15-25 parts of titanium pigment, 5-20 parts of filler, 0.2-1.0 part of wetting dispersant, 5-15 parts of anti-skidding agent, 0.1-0.5 part of de-foaming agent, 0.5-1.0 part of age inhibitor, 0.5-2.0 parts of thickening agent, 0.5-1.0 part of anti-mildew corrosion-protection agent, and 10-25 parts of water. The coating of the invention has very high wearing resistance and anti-skidding degree; the formed coat has good adhesive ability, wearing resistance, weather resistance, light-proof aging resistance, seawater resistance and salt mist resistance, wherein the artificial weathering aging test (ultraviolet UVB-313 resistance) is 4000 h, and the wearing resistance (1000g / 1000r) is not more than 30mg; the coating is applied to the corrosion prevention of the decks and the iron surfaces of the sea apparatus of boats and ocean platforms, wherein the decks and the iron surfaces require to have weather resistance, anti-skidding property, wearing resistance, and seawater corrosion resistance. The preparation method of the anti-skidding coating for the deck is simple in technology, low in cost and is performed without special apparatus.

Owner:QINGDAO AIR NEW MATERIALS

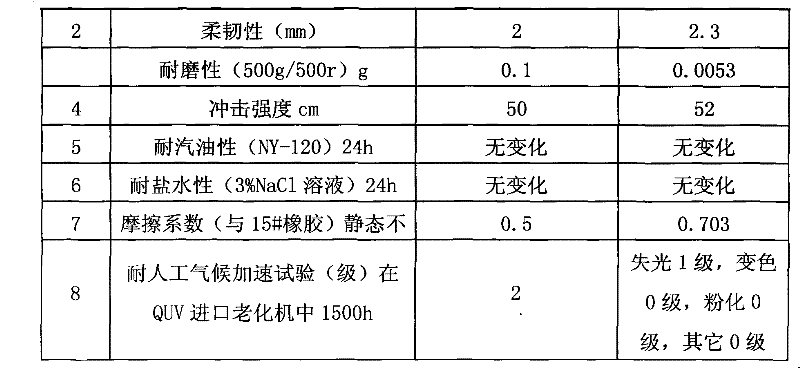

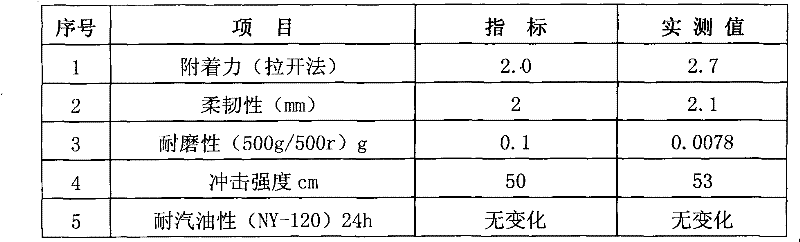

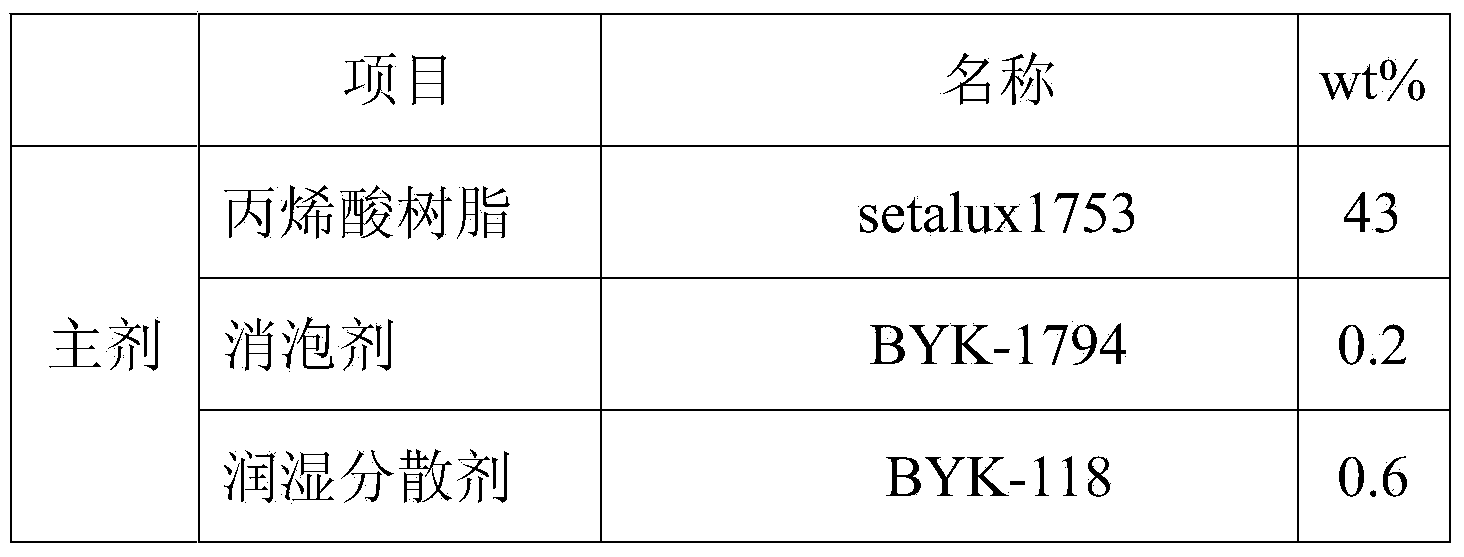

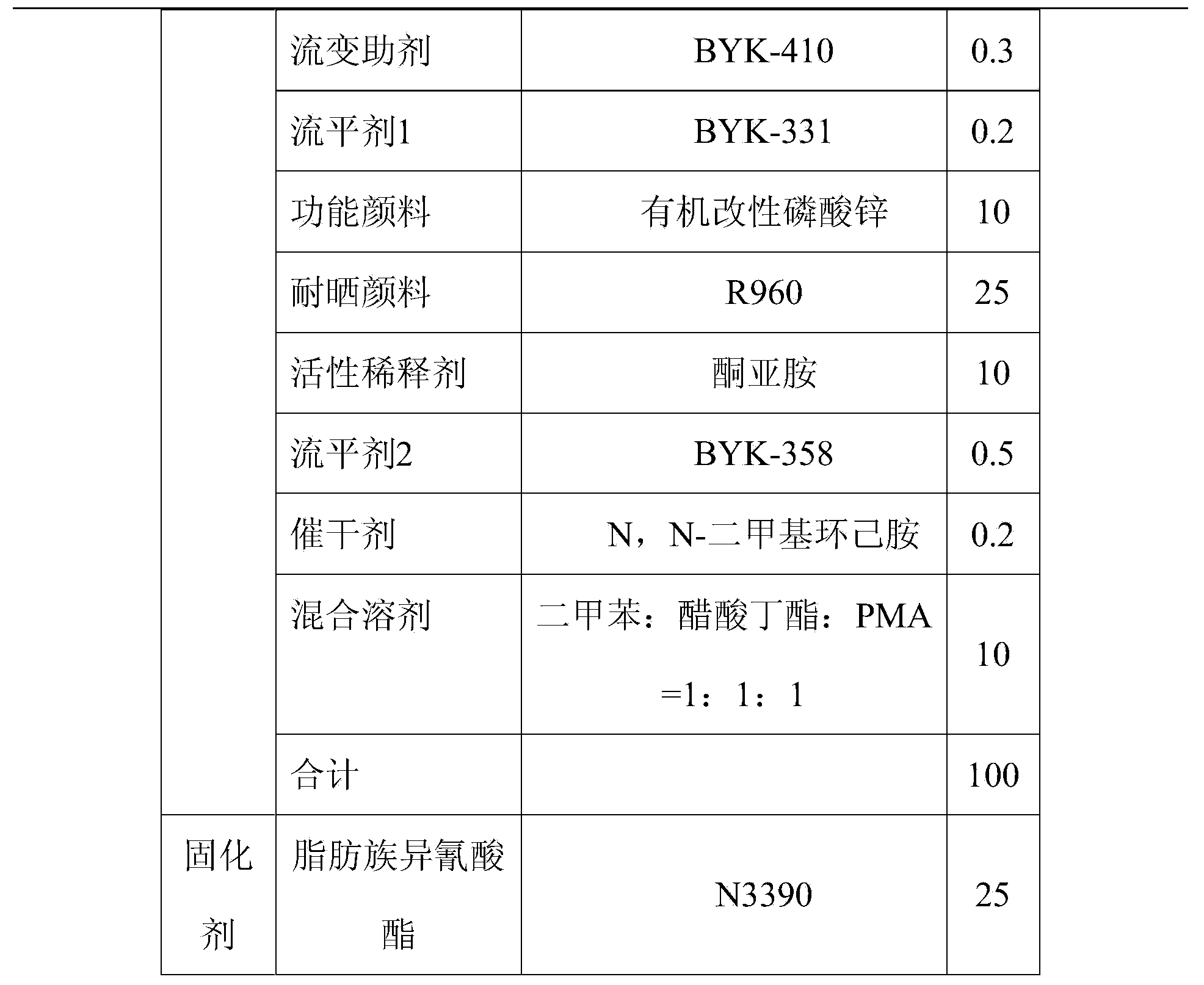

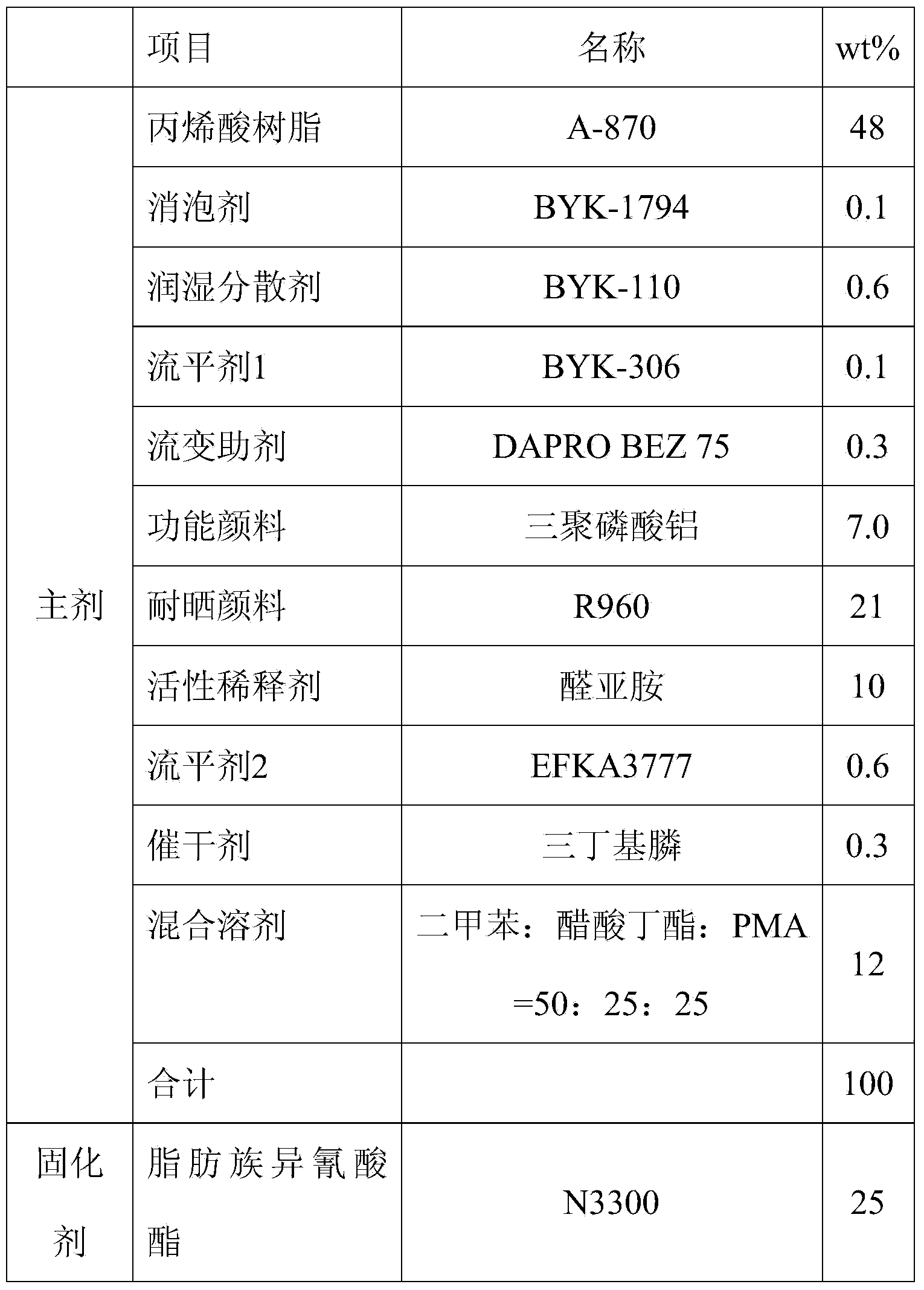

High solid coating for container and preparation method of high solid coating

ActiveCN103666229APromote environmental protectionImprove efficiencyAnti-corrosive paintsPolyurea/polyurethane coatingsChemical industryAcrylic resin

The invention discloses a high solid coating for a container and a preparation method of the high solid coating, and relates to the field of the coating chemical industry. The high solid coating comprises a host and a curing agent; the mass ratio of the host to the curing agent is 4:1; the host comprises the following components by mass: 40-60 percent of high solid low viscosity hydroxy acrylic resin, 1-5 percent of a rheological agent, 1-10 percent of a functional pigment, 20-25 percent of a sunproof pigment, 0-1 percent of an antifoaming agent, 1-3 percent of a wetting dispersant, 0.1-0.5 percent of a flatting agent I, 0.1-0.5 percent of a flatting agent II, 1-10 percent of a reactive diluent, 0.1-5 percent of a drier, and 1-5 percent of a mixed solvent. The coating has the advantages that the content of volatile organic compounds is low, the one-step film formation thickness is 150 microns, the surface dry purpose is achieved within 15 min, the film abrasion resistance is low to 40 mg, the coating is saved, the emission and coating time of volatile organic compounds are reduced, and the corrosion resistance, the abrasion resistance and the weathering resistance meet the requirement for anticorrosion outside the container, and adapt to the rapid production requirement of the container production line.

Owner:洛阳双瑞防腐工程技术有限公司

Method for producing basalt fibre reinforcing composite material and application in producing boat hull

The invention provides a method for making a basalt fiber enhanced composite material and the application of the method on making ship bodies. The formula of the method comprises vinyl ester resin or unsaturated polyester resin, a peroxide initiator and a promoter; the resin is injected and solidified and molded under the condition of vacuum aid resin transfer molding by raw material mixing. The method for making the basalt fiber enhanced composite material is characterized in that the raw material contains 30 to 70 percent mass of the basalt fiber as the enhancing material. The technique is used for making the ship bodies of army auxiliary ship and high speed ships, the ship bodies have outstanding aging resistant property, creep resistant property and anti-explosion impact property in addition to excellent mechanical property, ocean environment resistant property and high temperature resistance property, meanwhile, the method for making the basalt fiber enhanced composite material can lower the building cost of ship bodies and prolong the service life of ships.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Epoxy resin coating in marine steel pipe 3PE anticorrosive coating and preparation method thereof

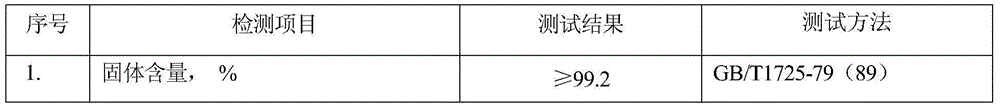

InactiveCN104449249AReduce dosageAvoid crackingAnti-corrosive paintsEpoxy resin coatingsEpoxyShrinkage rate

The invention discloses an epoxy resin coating in a marine steel pipe 3PE anticorrosive coating and a preparation method thereof. The epoxy resin anticorrosive coating comprises the following components in percentage by weight: 55-65 percent of epoxy resin, 23.5-36 percent of filler and pigments and 10.4-15.3 percent of aids, wherein the epoxy resin comprises the following components in percentage by weight: 39-47 percent of E-12 epoxy resin and 16-23 percent of novolac epoxy resin. Talcum powder, mica powder, bentonite and titanium dioxide are properly added into the epoxy resin to serve as partial fillers. The use amount of the resin can be relatively reduced, the cost is reduced, the physical and mechanical properties can be improved; particularly, the elasticity modulus is increased, the cure shrinkage rate is reduced, the seawater impact resistance is increased, and the seawater resistance is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Anticorrosive coating for water ballast tank and preparing method thereof

ActiveCN104341967AGood mechanical propertiesSimple manufacturing methodAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention relates to anticorrosive coating for a water ballast tank and a preparing method thereof. The preparing method includes: adding bisphenol A epoxy resin, novolac epoxy resin, bisphenol F epoxy resin and petroleum resin into a mixed solvent of xylene and n-butyl alcohol; adding wet-process sericite powder, silica powder, barite powder, titanium dioxide, fumed silica, bentonite, an active epoxy toughening diluting agent, a silane coupling agent, a polyacrylate co-polymer and polyether-modified polymethyl alkylsiloxane; mixing; stirring; grinding to obtain an A component of the high-solid anticorrosive coating of the water ballast tank; mixing modified phenolic amine and modified amine to obtain a B component; and mixing the A component and the B component when the coating is to be used. The coating has characteristics of good mechanical performance, flexibility, sea water resistance and chemical resistance, and can be used as the coating for the water ballast tank. The preparing method is simple, low in cost and low in VOC content and meets requirements on environment protection.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

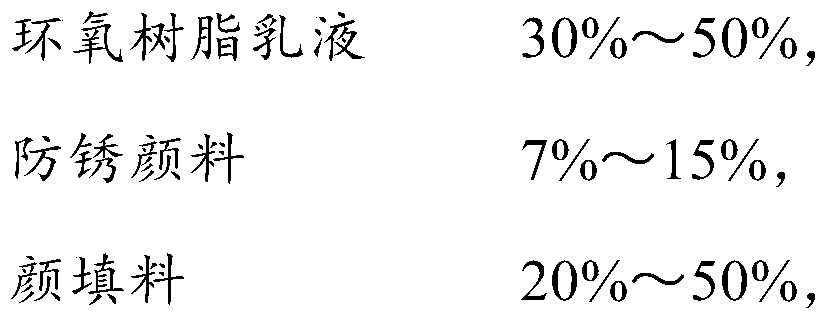

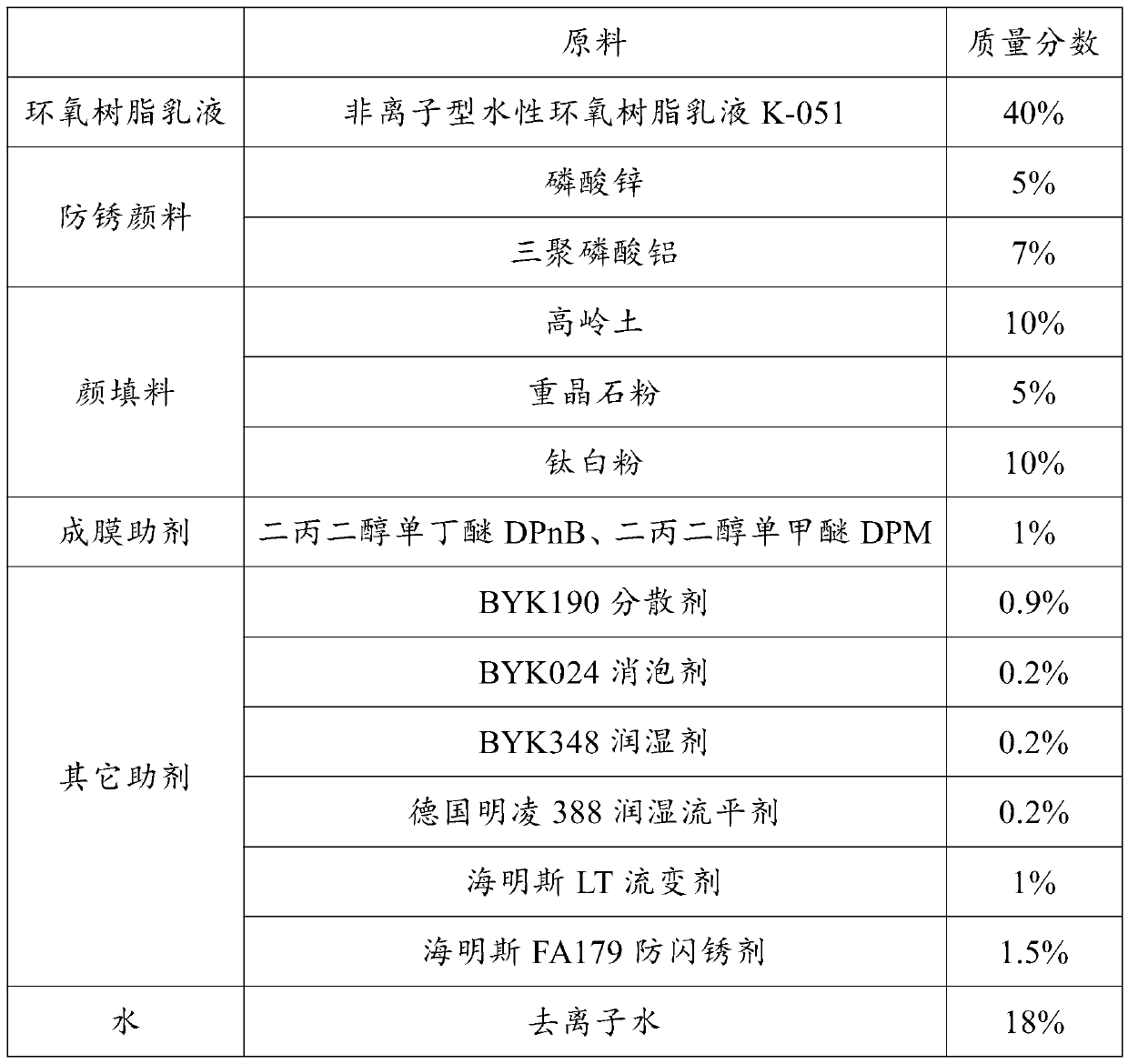

Waterborne epoxy resin cabin coating and preparation method thereof

InactiveCN110982380AStrong adhesionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention provides a waterborne epoxy resin cabin coating. The coating comprises a component A and a component B in a weight ratio of (8-5): 1. The component A comprises the following components in percentage by mass: 30%-50% of an epoxy resin emulsion, 7%-15% of an antirust pigment, 20%-50% of a pigment filler, 1%-2% of a coalescing agent, 5%-8% of other auxiliaries and 5%-30% of water. The component B is a water-based epoxy amine curing agent with a solid content of 45-55% and with a solvent being water. According to the waterborne epoxy resin cabin coating, the VOC content of a cured paint film meets the environmental protection standard that the VOC content is smaller than or equal to 80 g / L, the adhesive force between the paint film and a substrate is larger than or equal to 5 MPa, the water contact angle of the paint film reaches 100 degrees or above and is kept stable, and recoating is easy; and the waterborne epoxy resin cabin coating has excellent salt spray resistance andcorrosion resistance.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

Wear-resistant nonskid polyurethane deck paint, and manufacture method thereof

InactiveCN102190954AGood chemical stabilityImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsGas phaseWear resistant

The invention relates to a wear-resistant nonskid polyurethane deck paint, and a manufacture method thereof. The manufacture method comprises the following steps of: adding a hydroxyl acrylic resin, polyether polyol, hydroxyl-containing fluorocarbon acrylic resin, a polyacrylate copolymer solution, poly(methyl alkyl siloxane) solution and [b-[3-(2-H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropyl]-hydroxypoly(oxo-1,2-ethanediyl) to a mixed solvent of xylene, n-butyl acetate, methyl isobutyl ketone and butanone for high-speed stirring; adding rutile titanium white powder, talcum powder, aluminum oxide ceramic powder, sericite powder, silicon micropowder, carbon black and gas-phased silicon dioxide; milling with a sand mill while controlling fineness of a mixture not higher than 60 mu m to obtain a liquid A; and forming a liquid B by a mixed solution of 1,6-hexamethylene diisocyanate tripolymer, anhydrous xylene and n-butyl acetate, and mixing 1 weight part of the liquid A with 0.2-1.0 weight part of the liquid B for use. The obtained wear-resistant nonskid polyurethane deck paint can be used for the corrosion protection of the steel surfaces of deck and ocean facilities.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

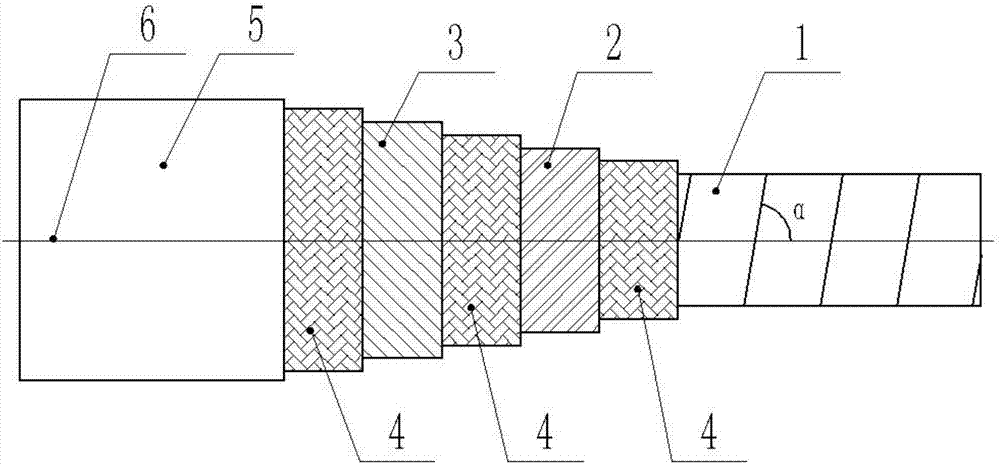

Non-sticking thermal plasticity composite material flexible pipe and preparation process thereof

The invention provides a non-sticking thermal plasticity composite material flexible pipe and a preparation process thereof. A liner skeleton layer and an outer protecting layer are arranged at an innermost layer and an outermost layer of the flexible pipe. At least one tension resisting layer and at least one compression resisting layer are arranged between the liner skeleton layer and the outer protecting layer. An abrasion resisting layer is arranged between every two arbitrary layers of the liner skeleton layer, the tension resisting layers, the compression resisting layers and the outer protecting layer. The liner skeleton layer is formed by winding, heating melting and press fit bonding of composite material belts with different fiber contents, wherein the winding angle of the composite material belts and the core mould axis is larger than or equal to 70 degrees and smaller than 90 degrees. The fiber content of the liner skeleton layer is decreased gradually from inside to outside, the winding layer number of each kind of the composite material belts is even, and the winding directions between every two adjacent layers are opposite. The non-sticking thermal plasticity composite material flexible pipe and the preparation process thereof have the beneficial effect of having the remarkable advantages that the flexibility and strength of a common steel flexible pipe are achieved, better corrosion resistance and the excellent fatigue resisting characteristic are achieved, the mass is light, and the cost performance is high.

Owner:WEIHAI NACHUAN PIPE FITTINGS

Solvent-free epoxy coating for steel sheet pile in seaport wharf and manufacture method

The invention relates to a solvent-free epoxy coating for a steel sheet pile in a seaport wharf and a manufacture method. Liquid (A) is prepared from the following components in parts by weight: 1 part of bisphenol A epoxy resin, 0.01-0.15 part of modified poly-acrylate solution containing a paint affinity base, 0.005-0.03 part of fluorine-modified acrylate copolymer, 0.005-0.01 part of mixture of a foam-breaking polymer and polysiloxane, 0.005-0.05 part of ether-modified organic silicone solution, 0.01-0.07 part of polymethacrylate solution, 0.1-0.5 part of rutile-form titanium dioxide powder, 0.002-0.01 part of carbon black, 0.1-0.3 part of talcum powder, 0.1-0.5 part of sericite powder and 0.01-0.05 part of gas-phase silicon dioxide, and liquid (B) is prepared from the following components in parts by weight: 1 part of mannich base curing agent and 0-0.015 part of polyolefin wax, reaches the salt mist resistance over 5000 h and has good adhesion to a substrate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

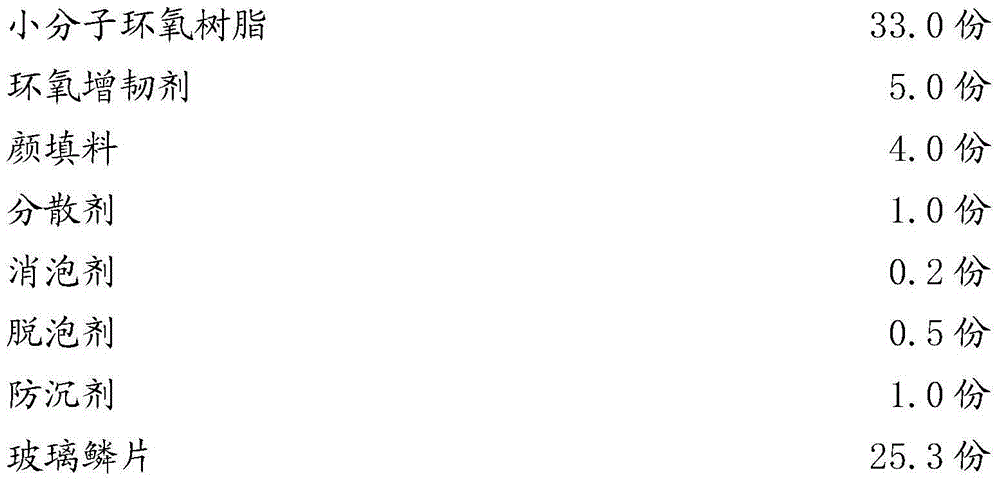

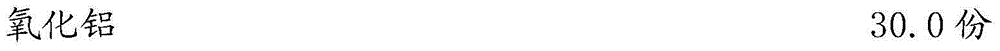

Solvent-free epoxy coating for steel pipe pile

InactiveCN104449214AGood seawater resistanceEffective protectionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention provides a solvent-free epoxy coating for a steel pipe pile, which is mainly applied to anticorrosive protection of steel pipe piles in oceanographic engineering. A main agent and a curing agent are fully mixed and cured to obtain a special heavy anti-corrosion coating, wherein the main agent comprises epoxy resin, an epoxy flexibilizer, pigments and filler, glass flakes and aluminum oxide and the curing agent comprises modified amine and a curing accelerant. Besides excellent epoxy corrosion resistance, the solvent-free epoxy coating for the steel pipe pile, provided by the invention, further has excellent seawater resistance, so that the coating particularly meets the anticorrosive requirement of the steel pipe pile in a tidal zone, further can be used for effectively protecting steel products in the fields such as corrosion prevention of storage tanks, sewage pipelines, pipelines of a chemical plant and the like, so that the steel can resist 20wt% hydrochloric acid, 20wt% sodium hydroxide and 60wt% sulfuric acid for a long time. The product has a very good film forming property and is stable to store.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

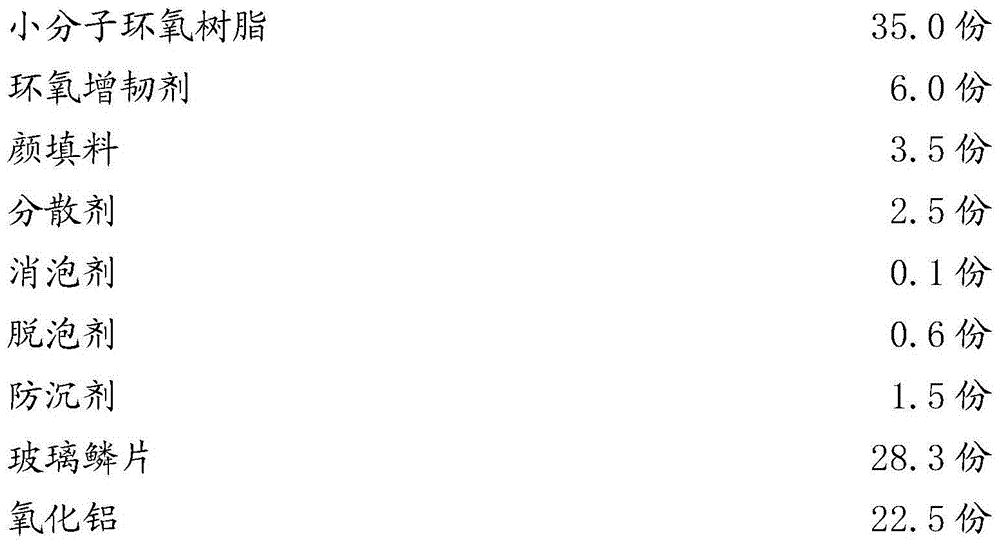

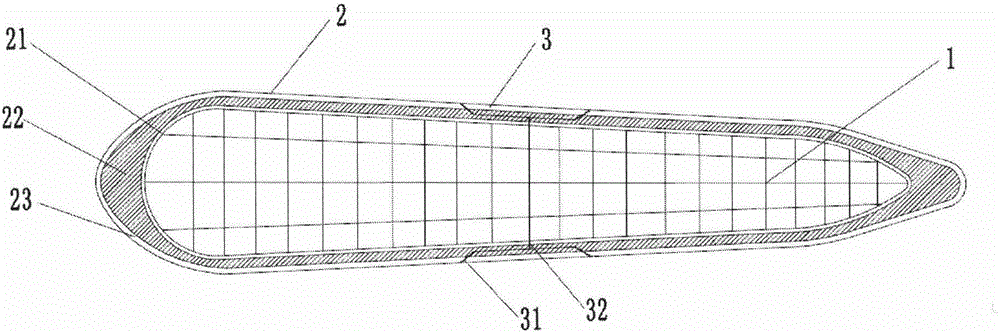

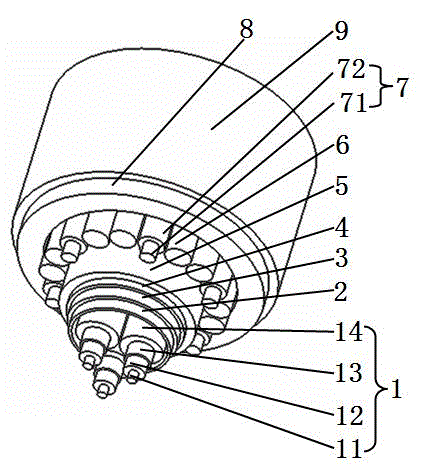

Submarine pressure shell and preparation method thereof

The invention discloses a submarine pressure shell which comprises a steel skeleton and a shell body, wherein the steel skeleton is fixed on the inner surface of the shell body; the shell body is formed by compounding a lining layer, a reinforcing layer and an outer protection layer sequentially from inside to outside; the reinforcing layer is formed by winding a bamboo skin sheet with adhered amino resin for multiple layers; and the lining layer and the outer protection layer are both formed by compounding bamboo fiber nonwoven fabric and epoxy vinyl ester resin. The invention also discloses a preparation method of the submarine pressure shell. The preparation method comprises the following steps: pretreatment of the bamboo skin sheet, resin preparation, thickness design, preparation of midship-stern shell body, preparation of a midship-bow shell body, connection of the steel skeleton and connection of the midship-stern shell body and the midship-bow shell body, wherein the steps are all carried out in a condition that the ambient humidity is lower than 40% RH. The submarine pressure shell prepared in the invention is green and environmentally friendly, light in weight and low in cost, and increases the travel speed and endurance mileage while the deformation resistance is strong and the damping property is good.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

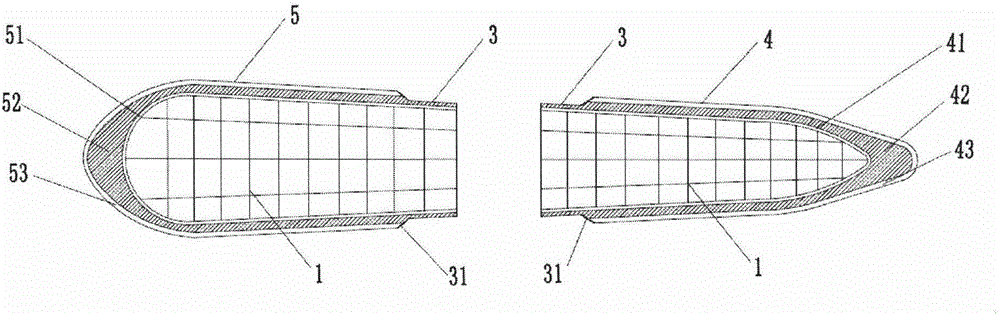

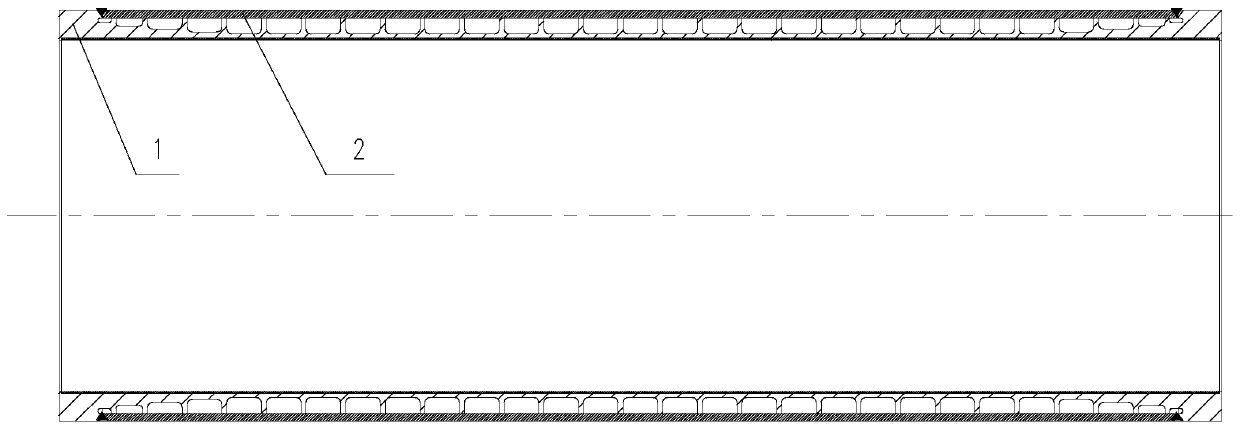

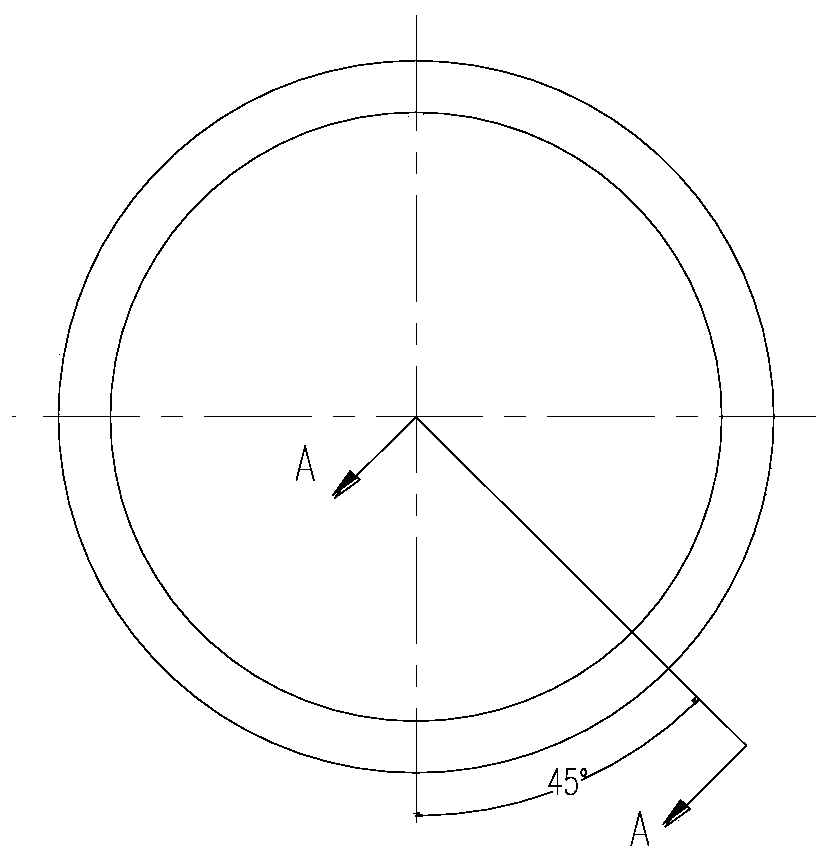

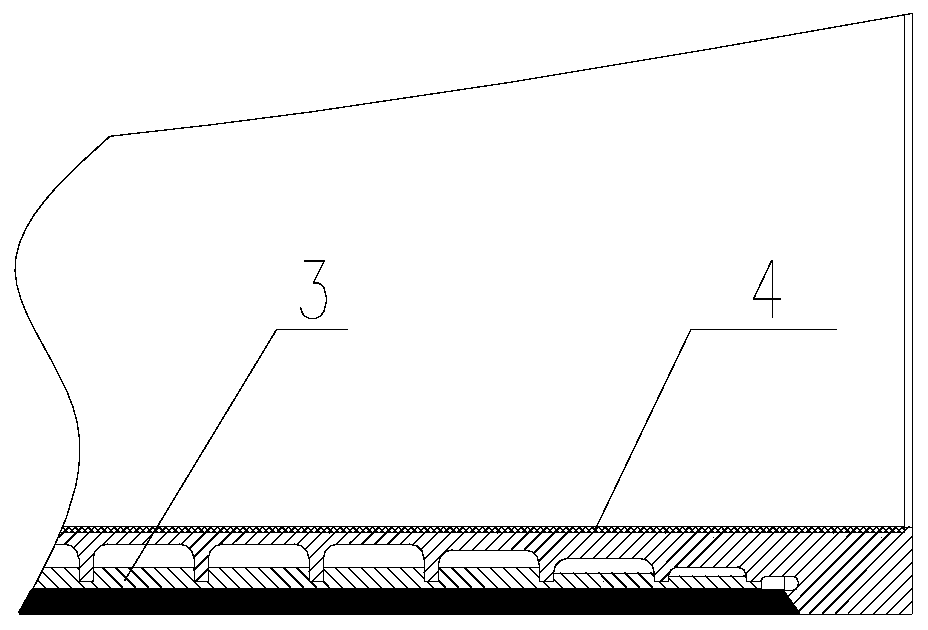

Double layer overpressure resistant cabin body of great depth underwater vehicle and molding method thereof

ActiveCN110341876AImprove performanceMaximize utilizationPretreated surfacesPlasma welding apparatusButt weldingWeld seam

The invention discloses a double layer overpressure resistant cabin body of a great depth underwater vehicle and a molding method thereof. The cabin body includes an inner shell, an outer shell, a backing plate and an insulating coating; the inner shell is in a structural form that flanges on the two ends and the middle part includes a cylinder and outer ring ribs; the flanges on the two ends canbe connected to other sections; the ring ribs of the inner shell are in equidistant distribution; the wall thickness of the inner shell close to girth weld are gradually increased, so that the increasing of the integral intensity and stiffness of the structure can be achieved, and weld positions can be ensured that the subjected stress is small when being subjected to external pressure; the outershell adopts a thin wall cylinder shell and is formed by thin-wall plates through roll welding, and the welding seam is longitudinal; and the inner shell and the outer shell of the cabin body are in connection through the abutting joint of the girth weld, and the small cavity structure on the back of the girth weld can guarantee that the structural form of butt welding can be realized easily. Thecabin body is high in underwater overpressure resistance, good in overpressure resistant stability, light in weight, high in specific strength, good in impact resistance, long in seawater corrosion resistance duration and long in service life.

Owner:NAVAL UNIV OF ENG PLA

Seawater-resistant semi-conductive copper wire shielding tape and preparation method thereof

PendingCN108831625AImprove shielding effectImprove water resistanceNon-macromolecular adhesive additivesPower cables with screens/conductive layersFiberMetal strips

The invention provides a seawater-resistant semi-conductive copper wire shielding tape and a preparation method thereof, which relate to the technical field of power cables. The seawater-resistant semi-conductive copper wire shielding tape comprises a fiber, a metal wire and a water-blocking adhesive, wherein the fibers comprise a plurality of spaced fiber strips. The metal wire comprises a plurality of metal strips crossing and arranged in a grid mode, and a plurality of metal strips crossing and arranged in a grid mode are crossed and arranged in the fiber to form a shielding tape base material; a water-stop adhesive is compounded on the base material of the shielding tape, and is used for bonding metal wires and fibers, intersections of the metal wires arranged crosswise, and filling gaps between the metal wires and the metal wires and between the metal wires and the fibers. The seawater-resistant semi-conductive copper wire shielding tape has good shielding electric field and waterblocking performance and excellent seawater-resistant performance by coating a seawater-resistant semi-conductive resistor hydrogel layer on a substrate woven by metal wires and fibers and improvingthe composition of the seawater-resistant semi-conductive resistor hydrogel.

Owner:沈阳天荣电缆材料有限公司

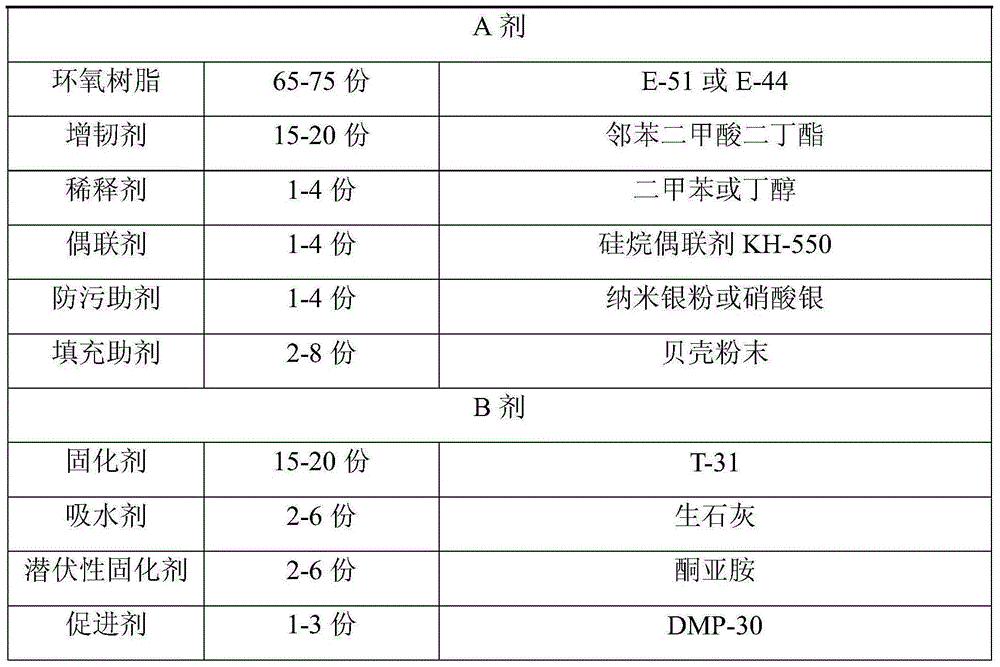

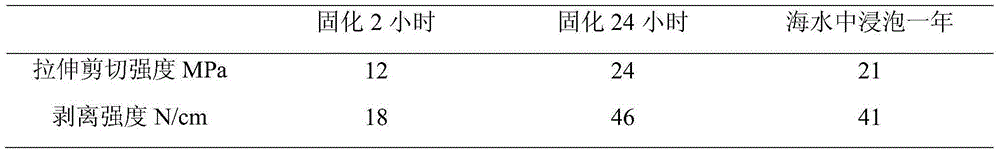

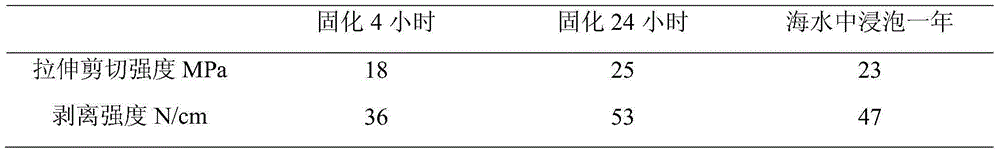

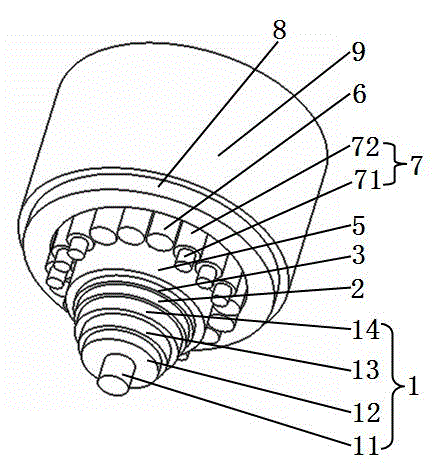

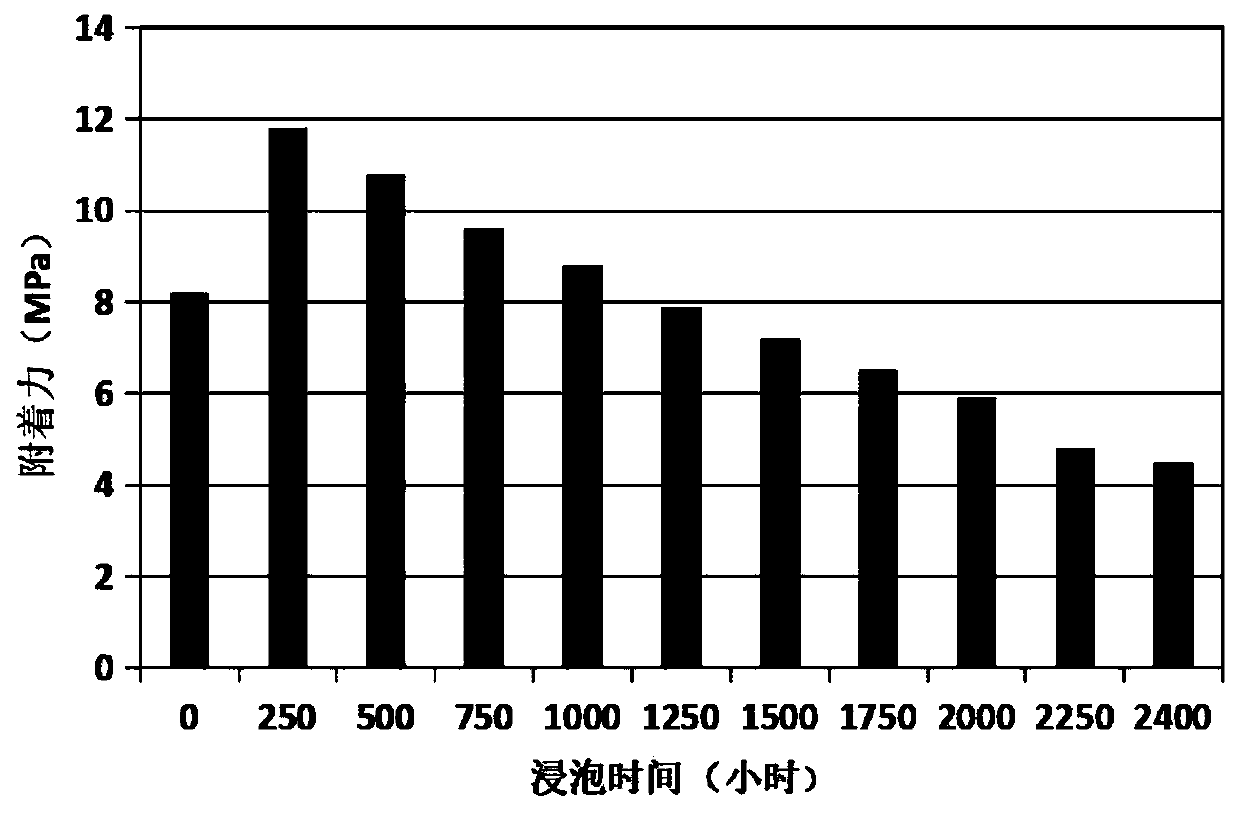

Seawater-resistant normal-temperature quickly-cured adhesive

ActiveCN105131885AHigh mechanical strengthGood seawater resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention relates to a seawater-resistant normal-temperature quickly-cured adhesive. The adhesive is formed by evenly mixing an agent A and an agent B in the weight ratio of 5:1. The agent A is prepared from, by weight, 65-75 parts of epoxy resin, 15-20 parts of flexibilizers, 1-4 parts of diluents, 1-4 parts of coupling agents, 1-4 parts of antifouling auxiliaries and 2-6 parts of filling auxiliaries. The agent B is prepared from, by weight, 15-20 parts of curing agents, 2-6 parts of water-absorbing agents, 2-6 parts of latent curing agents and 1-3 parts of promoters. The adhesive can be quickly cured in the normal-temperature and moist marine environment. Besides, after being socked by seawater for a long time, the adhesive still keeps good mechanical properties and chemical stability. The adhesive has good flexibility, and can improve fatigue resistance of marine equipment and flexibility of marine instrument design. In addition, the adhesive has the function of preventing biological adhesion in seawater.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

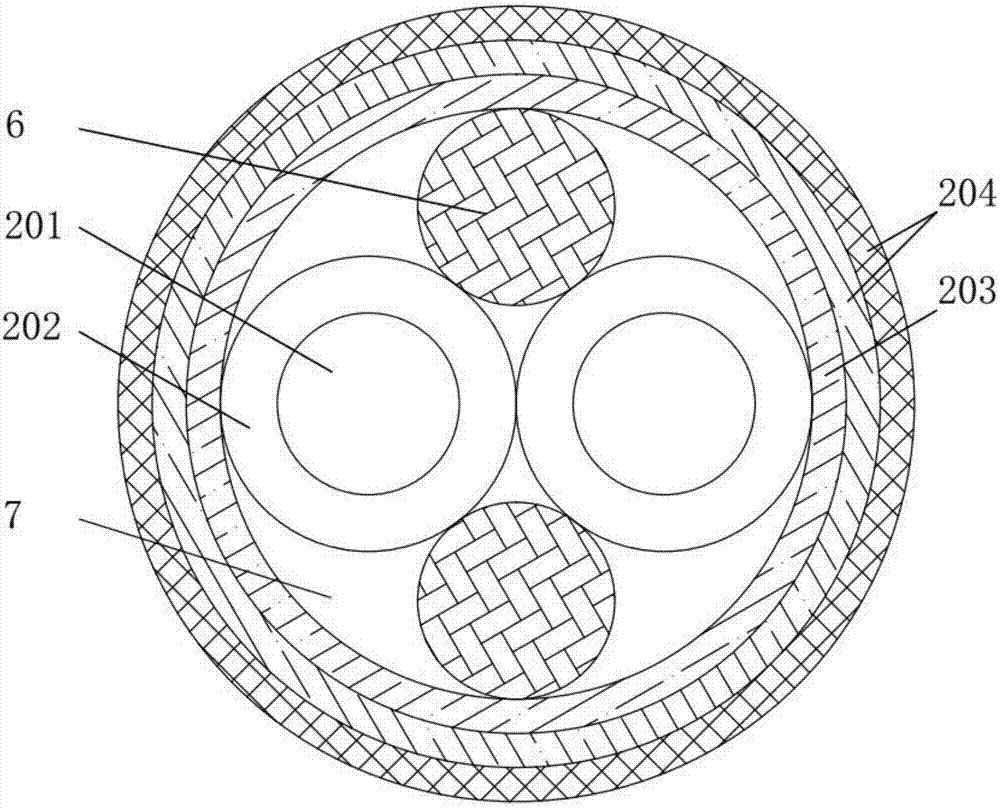

Water tight cable for beach

InactiveCN103400646AIncrease the compression factorEnsure vertical waterproof performanceInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention discloses a water tight cable for a beach, which comprises a cable core positioned in the middle of the cable, the cable core is formed by hinging a plurality of wire cores, and each wire core is composed of a conductor and a conductor screen layer, an insulating layer, an insulating screen layer, a semi-conductive belting layer and a metal screen layer arranged outside the conductor in sequence; a packing layer is arranged between the cable cores, and a belting layer, a metal armor layer, a water proof inner protecting sleeve and a water proof outer protecting sleeve are arranged outside the cable core in sequence. The cable adopting the structure provided by the invention is provided with better water blocking performance, better corrosion resisting performance, and higher safety performance, and the cable is used for power transporting line in beach area.

Owner:夏航

Submarine high-voltage cable and production method for same

InactiveCN104700934ASave resourcesImprove wear resistanceClimate change adaptationPower cables with screens/conductive layersPolyamideElectrically conductive

The invention belongs to the technical field of cables and particularly relates to a submarine high-voltage cable. The cable comprises a conductive unit, a metal shielding layer, a waterproof layer, an inner sheath, an armor layer, an outer sheath and an outer sheath protection layer. The conductive unit comprises a conductor, an insulation layer, an insulation shielding layer and a conductor protection layer. On any one cross section, the circular center of the conductor and the circular center of the insulation layer coincide, the diameter of the insulation layer is 1.5 times to 5 times of that of the conductor, and the minimum insulation layer thickness is 1.5mm. Filling rope layers and reinforcing elements are distributed on the outside of the inner sheath alternately and are attached to the inner sheath. The outer sheath protection layer is made of polyamides, and the insulation layer is made of silane crosslinked polyethylene or special materials. The invention further discloses a production method for the cable. The cable and the production method have the advantages of being appropriate in mechanical performance redundancy is, capable of saving resources, anti-abrasion, anti-water-seepage, anti-seawater, good in shielding performance and capable of transmission high voltages.

Owner:沈群华

Vinyl anticorrosion coating material and manufacturing method thereof

InactiveCN104177990AImprove compactnessImprove acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsKetoneSolution composition

The invention relates to a vinyl anticorrosion coating material and a manufacturing method thereof. The method includes: adding bisphenol A type epoxy vinyl ester resin into styrene, a co-polymerization solution containing an acid group, silicone oil, a polyacrylate solution and aminopropyltriethoxysilane, dispersing, dissolving, stirring at a high speed, adding fumed silica, titanium dioxide, barite, silica powder and carbon black under stirring, grinding by a sand mill to prepare a liquid mixture, adding glass flakes into the liquid mixture, dispersing at a high speed, and adding a modified urea solution during the dispersion step. A B solution comprises cobalt naphthenate and a styrene mixed solution. A C solution comprises methyl ethyl ketone peroxide, methyl ethyl ketone and a phthalate mixed solution. When the coating material is to be used, an A solution, the B solution and the C solution are mixed. A coating of the coating material has excellent adhesive force, impact resistance, wear resistance, resistance to heat and humidity, resistance to sea water and salt fog resistance and long working lifetime, and is suitable for splashing-zone and underwater corrosion resistance of ocean platforms, marine work steel structures, and the like.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Submarine high voltage cable and manufacturing method thereof

ActiveCN104376904ASave resourcesImprove wear resistancePlastic/resin/waxes insulatorsClimate change adaptationInsulation layerElectrical conductor

The invention belongs to the technical field of cables and particularly relates to a submarine high voltage cable which is formed by a conducting unit, a metal shielding layer, a water-resistant layer, an inner sheath, an armoring layer, an outer sheath and an outer sheath protective layer which are arranged sequentially from inside to outside. The conducting unit is formed by a conductor, an insulation layer, an insulation shielding layer and a conductor protective layer. On one of any cross sections, the circle center of the conductor coincides with the circular center of the insulation layer, the diameter of the insulation layer is 1.5 to 5 times that of the conductor, and the minimum value of the thickness of the insulation layer is 1.5mm. Filling rope groups and reinforcing part groups are distributed outside the inner sheath in an alternating mode and cling to the inner sheath. The outer sheath protective layer is made of polyamide. The insulation layer is made of organosilane crosslinked polyethylene or special materials. The invention further discloses a manufacturing method of the submarine high voltage cable. The submarine high voltage cable mainly has the following advantages of being proper in mechanical performance redundancy, capable of saving resources, high in abrasion resistance, water seepage resistance, sea water resistance and shielding performance and good in high voltage transmission.

Owner:海悦电缆制造有限公司

High-seawater-resistant epoxy coating suitable for ocean platforms and ships as well as preparation method and application method of high-seawater-resistant epoxy coating

InactiveCN104194558AReduce dock repairsStrong adhesionAntifouling/underwater paintsPaints with biocidesHydrophobic silicaSilicon dioxide

The invention relates to a high-seawater-resistant epoxy coating suitable for ocean platforms and ships as well as a preparation method of the high-seawater-resistant epoxy coating. A liquid A is composed of bisphenol A liquid epoxy resin, C9 petroleum resin, an epoxystearic acid alkyl ester, a polyurethane modified high-molecular compound, a modified hydrogenated castor oil, a silicone polyether, a nonionic surfactant, a mixture of dimethyl polysiloxane and hydrophobic silica, aerosol, micaceous iron oxide gray, quartz powder, silica micropowder, titanium dioxide powder, carbon black and aluminium triphosphate. A liquid B is a phenolic aldehyde amine curing agent with an amine value of 305 to 335. When the epoxy coating is used, the liquid A and the liquid B are mixed to form a coating layer which has a good adhesive force with a steel base material and is excellent in seawater resistance, salt spray resistance and cathodic disbonding resistance, so that the anticorrosion quality of ocean steel structures is effectively improved. Thus, the dock repairing of the ocean platforms, the ships and the like due to the failure of the coating layers is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Phenolic epoxy powder coating for anticorrosion in seawater desalination pipeline, and preparation method thereof

InactiveCN110205000AStrong adhesionImprove anti-agingAnti-corrosive paintsEpoxy resin coatingsEpoxyAging resistance

The invention discloses a phenolic epoxy powder coating for anticorrosion in a seawater desalination pipeline. The phenolic epoxy coating is composed of a component A and a component B according to amass ratio of (5-7):1; the component includes, by mass, 30-50 parts of epoxy resin, 20-35 parts of a pigment and filler, 3-12 parts of an assistant and 5-15 parts of a solvent; and the component B includes, by mass, 40-60 parts of an amine curing agent, 2-10 parts of the solvent and 0.5-3 parts of a coupling agent. The phenolic epoxy coating of the invention has the advantages of good adhesion, good seawater corrosion resistance, good aging resistance and good application property.

Owner:上海泰梧科技有限公司

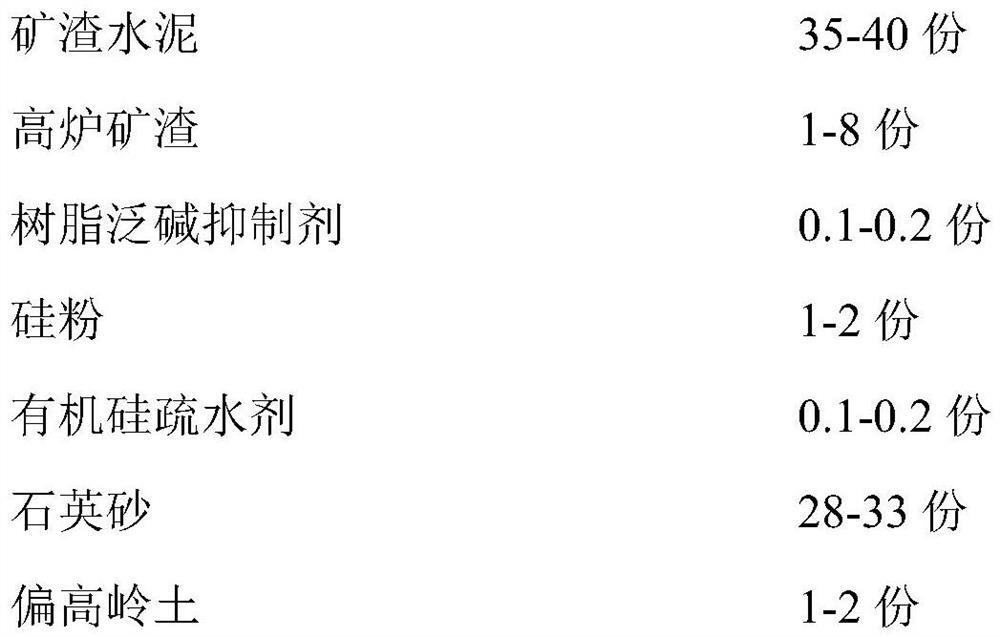

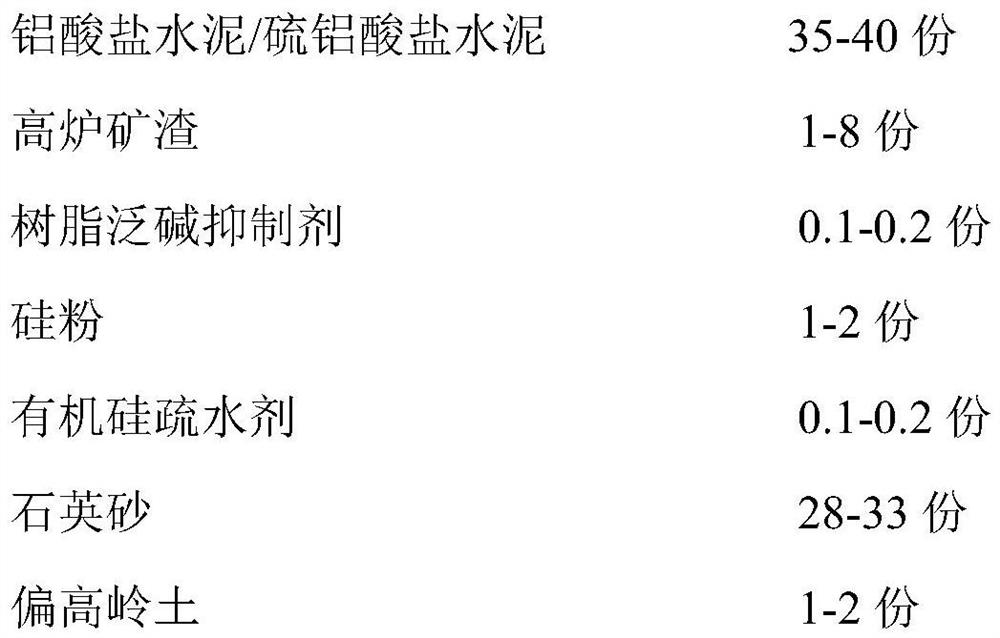

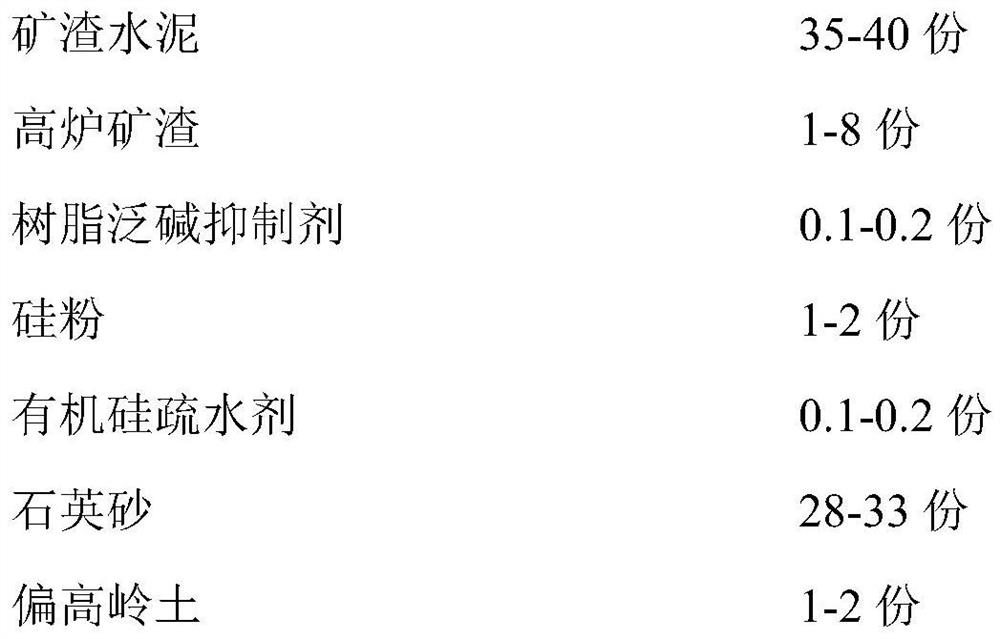

Alkali-resistant impermeable waterproof slurry and construction process thereof

The invention relates to an alkali-resistant impermeable waterproof slurry, which comprises a surface layer slurry and a bottom layer slurry, wherein the bottom layer slurry comprises powder A and a liquid agent, and the surface layer slurry comprises powder B and a liquid agent; the powder A comprises slag cement, a resin efflorescence inhibitor, blast furnace slag, silicon powder and an organicsilicon water repellent agent; the powder B comprises aluminate cement, a resin efflorescence inhibitor, blast furnace slag, silicon powder and an organic silicon water repellent agent; and the liquidagent comprises a silicon resin emulsion. The invention further provides a waterproof material with salt and alkali resistance and a construction process of the waterproof material. The waterproof slurry prepared in the invention has the characteristics of wet base surface construction, high early strength and good impermeability, and has excellent efflorescence resistance compared with other traditional wall waterproof materials.

Owner:广东嘉宝莉科技材料有限公司

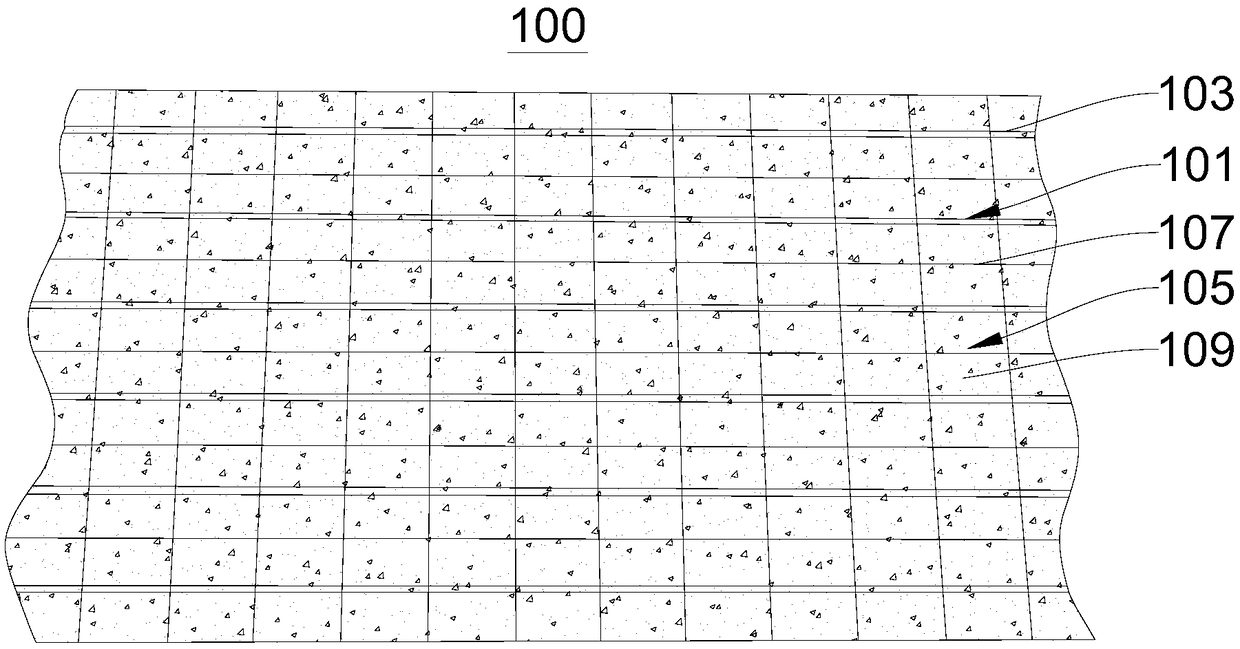

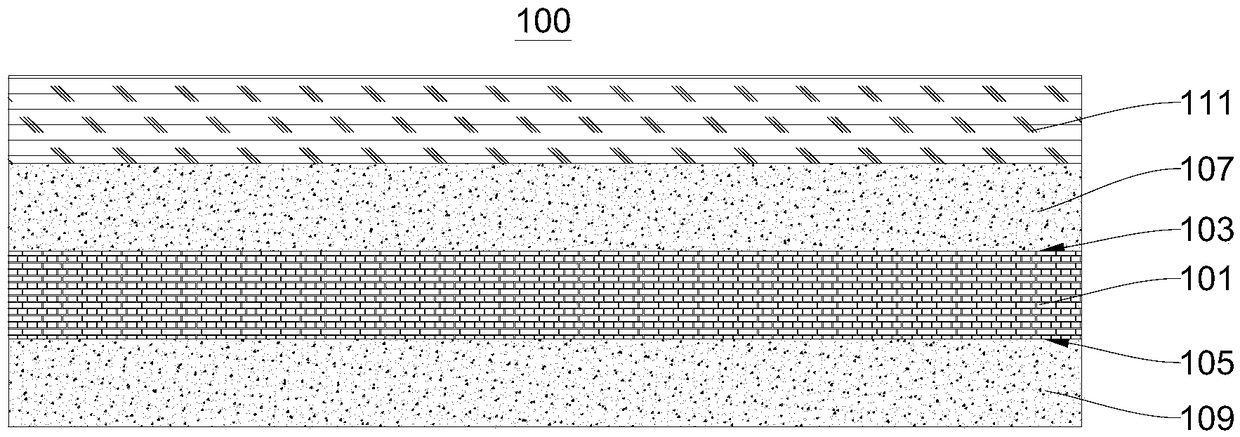

Composite deck coated with anticorrosive paint

InactiveCN103373019AStrong adhesionImprove wear resistanceHull decksSynthetic resin layered productsWear resistantAcrylic resin

The invention discloses a composite deck coated with anticorrosive paint, and relates to the field of shipbuildings. A deck coating and a wear-resistant coating are respectively applied to the upper and lower layers of outer layer of a steel plate, wherein the deck coating consists of hydroxyl acrylic resin, polyether polyol, olefine resin, an antifoaming agent, a flatting agent and a pigment / filler, and the wear-resistant coating is composed of aluminum oxide ceramic powder, silica powder, carbon black, a polyacrylate copolymer solution and anhydrous dimethylbenzene. The composite deck coated with the anticorrosive paint, due to excellent adhesion, abrasive resistance, weather fastness, light aging resistance, seawater resistance and salt fog resistance of the coatings thereof, is applicable to corrosion prevention for decks of ships and ocean platforms which require weather fastness, skid and wear resistance, and seawater corrosion resistance as well as steel and iron surfaces of other ocean facilities. The preparation method of the composite deck coated with the anticorrosive paint is simple in process, free from special equipment and relatively cheap in price.

Owner:DALIAN GANGXIN MACHINERY

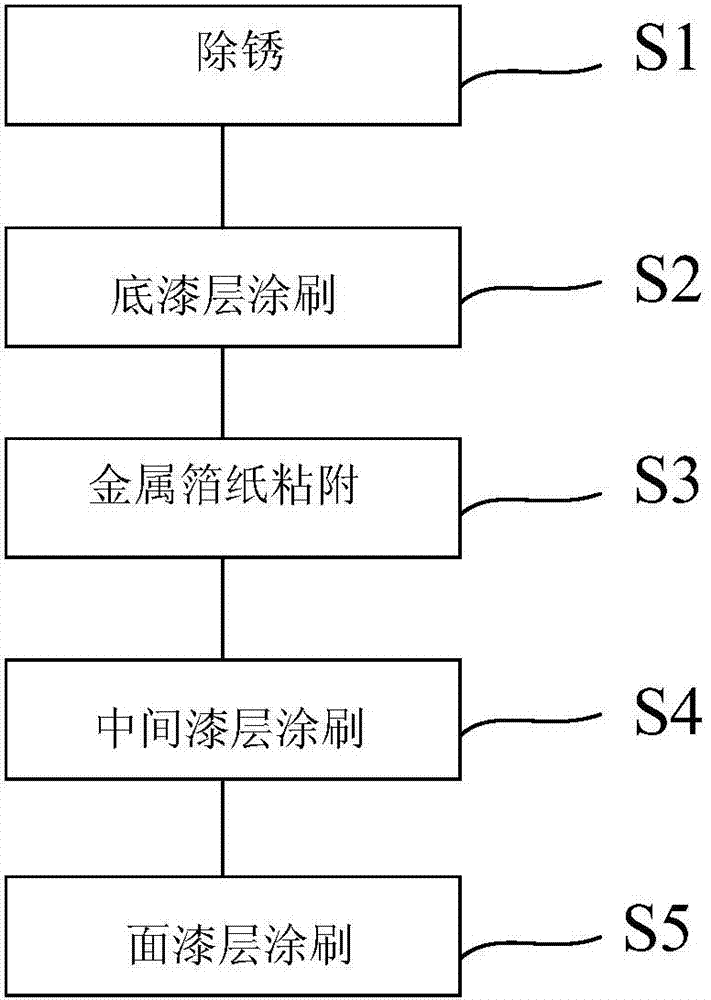

Heavy-duty anti-corrosion coating and painting method thereof

InactiveCN104231865AStrong resistance to seawater corrosionExtended use timeAnti-corrosive paintsEpoxy resin coatingsEpoxyGas phase

The invention discloses a heavy-duty anti-corrosion coating. The heavy-duty anti-corrosion coating comprises, by weight, no less than 80% of main ingredient, no more than 10% of additive and no more than 10% of accelerator, wherein the main ingredient comprises epoxy resin, phenolic resin, epoxy diluent, epoxy hardener, phenolic diluent and phenolic hardener, the epoxy resin and the phenolic resin account for 70-80% of the main ingredient, the diluent accounts for10-15% of the main ingredient and the hardener accounts for 10-15% of the main ingredient; the addictive comprises 200-400 mesh quartz powder and teflon, and the accelerator comprises dibutyl phthalate and fumed silica. The heavy-duty anti-corrosion coating can effectively improve the seawater resistant performance of devices and enables the devices to be utilized for a long time and reduces printing frequency of the heavy-duty anti-corrosion coating. The invention further discloses a heavy-duty anti-corrosion printing method utilizing the heavy-duty anti-corrosion coating.

Owner:YANTAI ZHONGTAI PIPE IND ENG

Top coating as well as preparation method thereof

InactiveCN103509426AStrong adhesionGood seawater resistancePolyamide coatingsEpoxy resin coatingsEpoxyWeather resistance

The invention discloses a top coating as well as a preparation method thereof. The top coating comprises a main agent and a hardener, wherein the main agent is refined by epoxy resin in combination with special pigments such as phthalocyanine blue, barium sulfate, talcum powder and xylene, and the hardener is a modified polyamide resin. The main agent is 24KG in mass, and the hardener is 3.4KG in mass. The top coating disclosed by the invention can be coated on various models of coatings or be coated by various models of coatings, and is used on ships, bridges and common steel concrete members. The top coating is flexible in film, strong in adhesion, and excellent in water-proof and seawater-proof performances. The thickness can reach 150 mu m by coating at one time. The top coating can be hardened at temperatures above -10 DEG C, and is easy to construct and good in weather resistance.

Owner:永记造漆工业(昆山)有限公司

Seawater-resistant semiconductive water stopping strapping tape and preparation method thereof

PendingCN108666014AImprove shielding effectImprove water resistanceConductive layers on insulating-supportsClimate change adaptationPower cableEngineering

The invention provides a seawater-resistant semiconductive water stopping strapping tape and a preparation method thereof, and relates to the technical field of power cables. The seawater-resistant semiconductive water stopping strapping tape comprises a base material layer, a first semiconductive adhesive layer, a second semiconductive adhesive layer and a semiconductive seawater-resistant adhesive layer. The base material layer is provided with a first face and a second face which are arranged oppositely; the first semiconductive adhesive layer is arranged on the first face of the base material layer, and the second semiconductive adhesive layer is arranged on the second face of the base material layer. The semiconductive seawater-resistant adhesive layer is arranged on the upper portionof the first semiconductive adhesive layer. The seawater-resistant semiconductive water stopping strapping tape and the preparation method thereof have the advantages of good performance of shieldingelectric fields and blocking water and excellent seawater-resistant performance.

Owner:沈阳天荣电缆材料有限公司

Fast curable environment friendly epoxy paint for drilling water tanks and making method thereof

InactiveCN104449245AFast curingEasy constructionAnti-corrosive paintsEpoxy resin coatingsFatty acidAdduct

Belonging to the technical field of paint and making methods, the invention relates to a fast curable environment friendly epoxy paint for drilling water tanks and a making method thereof. The method includes: in a stainless steel charging basket, adding bisphenol A low viscosity type epoxy resin, bisphenol F type epoxy resin, bisphenol A and bisphenol F mixed type epoxy resin and a cashew oil modified monoglycidyl ether epoxy active diluent, mixing the materials, under stirring, adding an anionic compound containing fatty acid and rosin acid, a hydrophobic particle containing organosilicon polymer and a modified urea solution, controlling the temperature at 25+ / -2DEG C, performing high speed stirring, and under stirring, adding zinc chrome, aluminum triphosphate, superfine silica powder and talcum powder, conducting high speed stirring for 0.25h, then carrying out grinding for 0.5-1h by a sand mill so as to obtain an A solution in the paint; and in another stainless steel charging basket, adding a phenolic aldehyde amine curing agent, linear aliphatic amine and an adduct epoxy curing agent, conducting high-speed stirring to mix the materials evenly to obtain a B solution in the paint.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

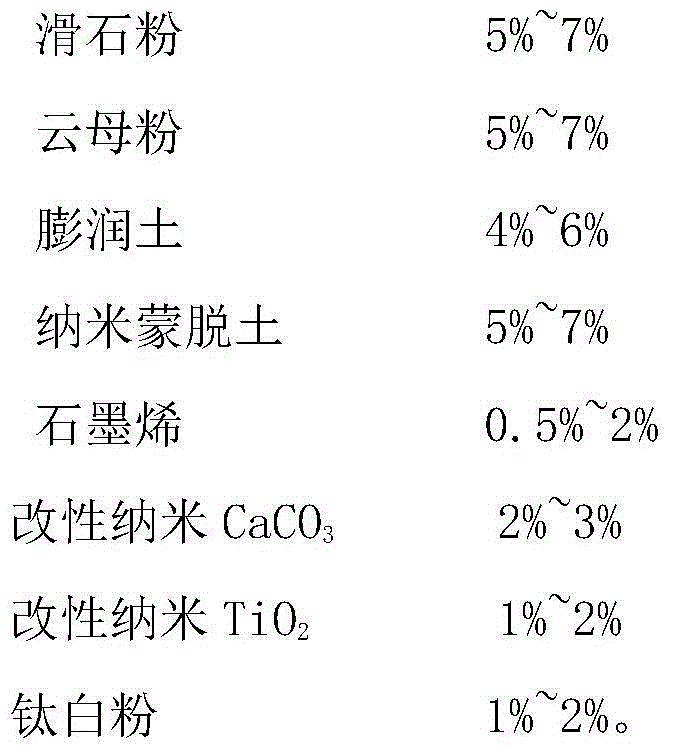

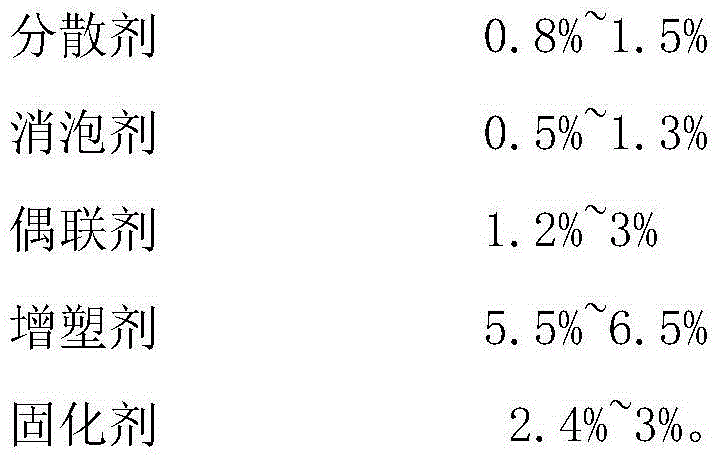

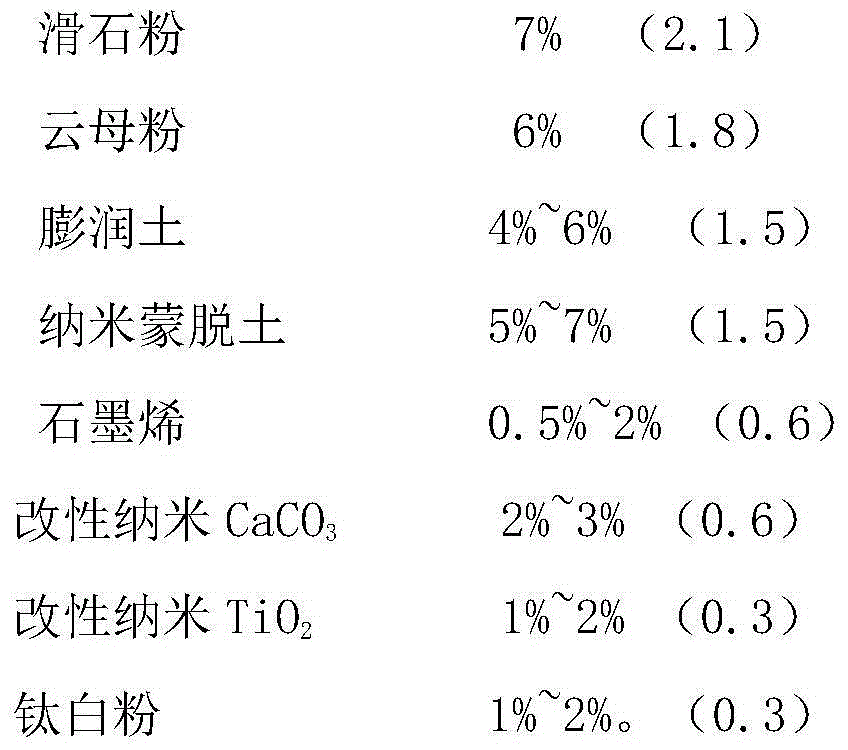

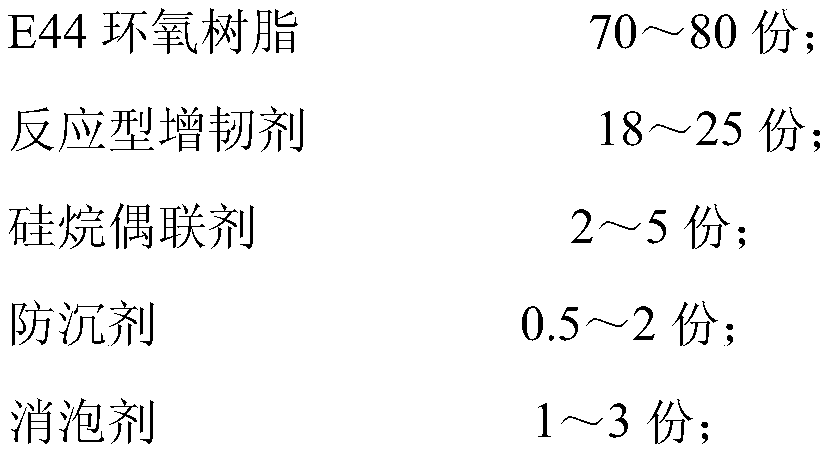

Solvent-free ultra-thick paste organic-inorganic hybrid nano-modified heavy-duty coating and preparation method thereof

ActiveCN111303727AStrong adhesionImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to a solvent-free ultra-thick paste organic-inorganic hybrid nano-modified heavy-duty coating and a preparation method thereof, and belongs to the technical field of heavy-duty coatings. The nano-modified heavy-duty coating is prepared by mixing a component A, a component B and a component C according to a mass ratio of 100: (15-30): (80-300), wherein the component A is silane modified epoxy resin sol, the component B is a phenolic aldehyde amine curing agent, and the component C is nano modified composite inorganic powder. The thickness of a single-channel coating layerof the nano-modified heavy-duty coating can reach 500-1000 microns, and the nano-modified heavy-duty coating has excellent adhesion, wear resistance, seawater resistance and chemical corrosion resistance, has good compatibility with cathodic protection and can be widely applied to the field of corrosion protection in marine environments.

Owner:洛阳双瑞防腐工程技术有限公司

Bi-component long-acting-corrosion-resistant epoxy coal tar pitch anticorrosive coating material

InactiveCN105647334AExcellent film-forming performance and anti-corrosion performanceSolve high temperature flowAnti-corrosive paintsEpoxy resin coatingsCoal Tar PitchesCorrosion resistant

The invention relates to a bi-component long-acting-corrosion-resistant epoxy coal tar pitch anticorrosive coating material. The coating material is prepared from a component A and a component B which are in the weight ratio of 6: 1; the component A is prepared from the following ingredients: dimeric acid modified epoxy resin, coal tar pitch, anticorrosive pigments / fillers, a variety of adjuvants and a special mixed diluent for anticorrosive coating materials; the component B is an epoxy curing agent containing an imide structure; and the epoxy coal tar pitch anticorrosive coating material is obtained through mixing the component A and the component B. The bi-component long-acting-corrosion-resistant epoxy coal tar pitch anticorrosive coating material disclosed by the invention has excellent seawater resistance, durability, adhesive power, toughness, resistance to chemical corrosion and aging resistance; the film forming speed for coatings is high, and brush-coating is carried out at low temperature; and the bi-component long-acting-corrosion-resistant epoxy coal tar pitch anticorrosive coating material is applied to general buried pipelines, steel storage tanks and the like.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

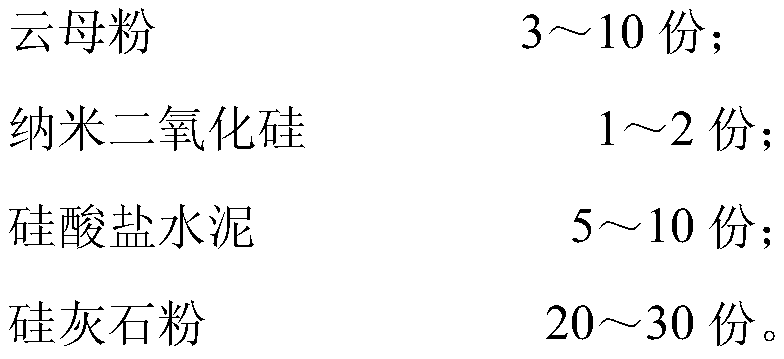

Multi-core photoelectric composite watertight cable used for deep sea system

ActiveCN107358997AHigh precisionReduce signal interferenceClimate change adaptationPower cables with screens/conductive layersPolyurethane elastomerElectricity

The invention discloses a multi-core photoelectric composite watertight cable used for a deep sea system. The multi-core photoelectric composite watertight cable comprises an inner layer optical unit, an outer layer electrical unit, a wrapping layer and an outer sheath which are arranged from inside to outside in sequence; the electrical unit consists of multiple shielded twisted pairs; the optical unit and the electrical unit are stranded in the same direction; the wrapping layer is formed by spirally winding the periphery of the outer layer electrical unit with a two-sided water-blocking band with thickness of 0.20-0.50mm; the outer sheath is prepared from a water-blocking sealant and a polyurethane elastomer by adopting a two-layer co-extrusion process; a tensile layer is additionally arranged between the outer sheath and the wrapping layer; the gap is filled with low-smoke halogen-free filling strips and water-blocking ointment; and the tensile layer is formed by winding the exterior of the wrapping layer with water-blocking aramid fiber beams. The cable can work for a long time in a position of 3,000m underwater, and the maximum tensile strength can reach 30KN; and meanwhile, the cable has excellent tensile, water blocking and wear resisting properties and can satisfy requirements of feed and signal transmission at the same time.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com