Non-sticking thermal plasticity composite material flexible pipe and preparation process thereof

A composite material and composite material tape technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of difficult curing effect control, toxicity and pollution, repeated winding, etc., to achieve excellent anti-fatigue properties, cost-effective, good seawater resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation process of the non-bonded thermoplastic composite flexible pipe comprises the following steps:

[0059] 1) First, the composite material belt with a width of 30-50mm and a fiber content of 60-70% is lapped and wound according to the winding angle α between the composite material belt and the mandrel axis, 70°≤α<90°, adjacent composite material belts The overlapping area ranges from 3 to 10mm. Laser heating is used to heat the overlapping area of adjacent composite material tapes to melt them while winding. The temperature range of laser heating is: 180-360°C. , use a tensioning device to apply a winding tension of 300-500N to the composite material tape, and apply a pressure of 100-200N through the pressure roller to bond the overlapping area;

[0060] 2) Wrap the composite material tape with a width of 30-50 mm and a fiber content of 60-70% in the direction opposite to the winding angle of the innermost layer of the lining skeleton layer, that is, at ...

Embodiment 1

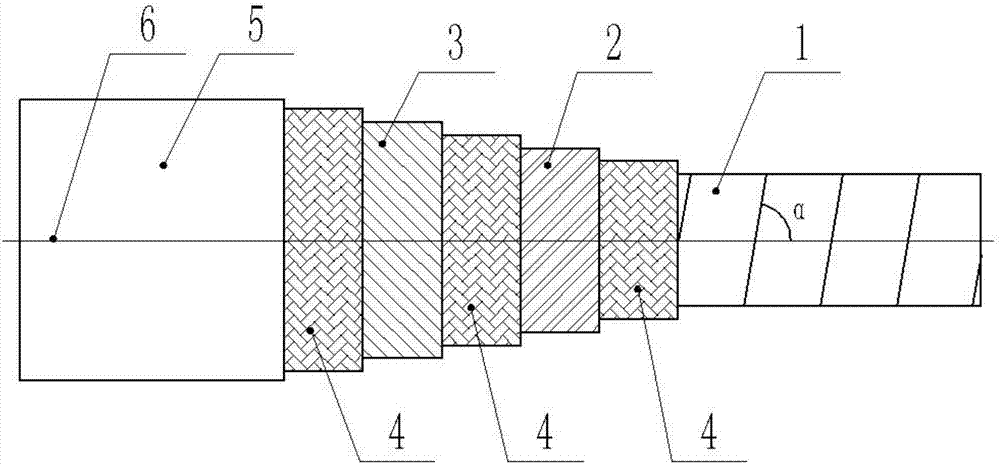

[0083] The non-bonded thermoplastic composite flexible pipe is respectively an inner lining skeleton layer 1, a wear-resistant layer 4, a tensile layer 2, a wear-resistant layer 2, a compressive layer 3, a wear-resistant layer 4, and an outer protective layer 5 from the inside to the outside. , this structure is suitable for oil and gas transportation in medium and low pressure environments.

[0084] (1) Fabrication of lining skeleton layer 1

[0085] 1) The inner lining skeleton layer adopts polyphenylene sulfide PPS glass fiber tape with a width of 50 mm, a thickness of 0.25 mm, and a fiber content of 70%, and is wound according to the winding angle of 80° between the polyphenylene sulfide PPS glass fiber tape and the mandrel axis The overlapping area of adjacent polyphenylene sulfide PPS glass fiber tapes is 10mm, and the laser heating method is used to heat the overlapping area of adjacent composite material tapes to melt them. The temperature range of laser heating is...

Embodiment 2

[0100] The non-bonded thermoplastic composite flexible pipe is respectively the lining skeleton layer 1, the wear-resistant layer 4, the tensile layer 2, the wear-resistant layer 2, the compressive layer 3, the wear-resistant layer 4, and the tensile layer 2 from the inside to the outside. , wear-resistant layer 4, pressure-resistant layer 3, wear-resistant layer, and outer protective layer 5. This structure is more suitable for oil and gas transportation in high-pressure environments.

[0101] (1) Fabrication of lining skeleton layer 1

[0102] 1) The lining skeleton layer is made of polyether ether ketone PEEK carbon fiber tape with a width of 45 mm, a thickness of 0.30 mm, and a fiber content of 70%, and is formed by winding the PEEK carbon fiber tape and the mandrel axis at an angle of 85° The overlapping area of adjacent PEEK carbon fiber tapes is 10mm, and the overlapping area of adjacent PEEK carbon fiber tapes is heated to melt by laser heating. The temperature ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com