Novel anti-skidding coating for deck and preparation method thereof

A deck anti-slip coating, a new technology, applied in the field of coatings, can solve the problems of easy aging, poor weather resistance, uneven sand grains, etc., and achieve the effect of high wear resistance and anti-slip, excellent adhesion, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

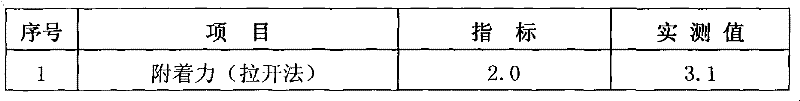

Examples

Embodiment 1

[0019] The anti-skid coating for decks of the present embodiment, the formula of parts by weight of each component consists of: 30 parts of aqueous polyurethane emulsions, 15 parts of fluorocarbon emulsions; 10 parts of heavy calcium powder, 10 parts of precipitated barium sulfate; anti-slip agent (120 mesh polyurethane particles) 15 parts; 5 parts of film-forming aid (U.S. Eastman Chemical Company, Taxanol); 1.0 part of wetting agent (Guangzhou Guanzhi Chemical Co., Ltd., PE-100); antioxidant (Zhejiang Huangyan Zhedong Rubber Auxiliary Co., Ltd. , ketamine anti-aging agent AW), 0.8 parts; defoamer (German BYK Chemical Company, BYK-055) 0.5 parts; antifungal agent (Beijing Jinyuan Hengtai Fine Chemical Co., Ltd., Huake-108) 0.5 parts; preservative (Beijing Jinyuan Hengtai Fine Chemical Co., Ltd., Huake-088) 0.5 parts; water 10 parts; thickener (Rohm and Haas Company, DR-73) 1 part; rutile titanium dioxide 25 parts.

[0020] The method of above-mentioned novel deck antiskid coa...

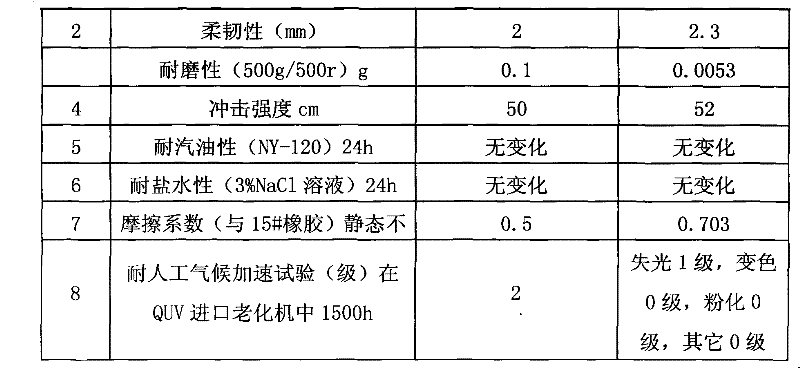

Embodiment 2

[0029] The deck anti-slip coating of the present embodiment, the formula of each component by weight consists of: 15 parts of silicon acrylic emulsion, 15 parts of fluorocarbon emulsion; 5 parts of heavy calcium powder, 10 parts of precipitated barium sulfate, 3 parts of talcum powder; Antiskid agent ( 200 mesh waste tire particles) 5 parts; film-forming aid (U.S. Eastman Chemical Company, Taxanol) 2 parts; wetting agent (Guangzhou Guanzhi Chemical Co., Ltd., PE-100) 0.1 part; antioxidant (Guangzhou Liben Rubber Raw Materials Co., Ltd., anti-aging agent D), 0.5 parts; defoamer (German BYK Chemical Company, BYK-053) 0.1 part; antifungal agent (Beijing Jinyuan Hengtai Fine Chemical Co., Ltd., Huake-108) 0.3 part; dispersant (Shanghai Coating Research Institute, P-19) 0.1 part; water 25 parts; thickener (Shanghai Yuhao Chemical Technology Co., Ltd., 250HBR) 2.0 parts; 15 parts of rutile titanium dioxide.

[0030] The method of above-mentioned novel deck antiskid coating is made ...

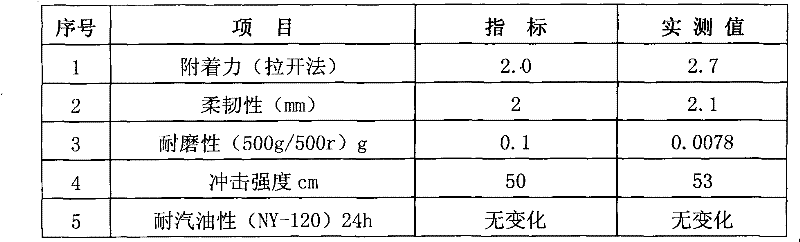

Embodiment 3

[0039] The deck anti-skid coating of the present embodiment, the formula of weight part of each component consists of: 15 parts of aqueous polyurethane emulsions, 10 parts of silicon acrylic emulsions, 15 parts of fluorocarbon emulsions; 1.5 parts of mica powders, 1.5 parts of heavy calcium powders, precipitated barium sulfate 2 parts; 9 parts of anti-slip agent (150 mesh waste rubber particles); 4 parts of film-forming aid (Eastman Chemical Company, USA, Taxanol); 0.5 part of wetting agent (Shanghai Auxiliary Factory Co., Ltd. Part; Dispersant (Shanghai Paint Research Institute, P-19), 0.2 part; Anti-aging agent (Guangzhou Liben Rubber Raw Material Co., Ltd., anti-aging agent D), 1.0 part; Defoamer (German BYK Chemical Company, BYK-053 ), 0.3 part; preservative (Fuzhou Banglian Chemical Co., Ltd., MB-16), 0.25 part; antifungal agent (Fuzhou Banglian Chemical Co., Ltd., MB-11), 0.25 part; water 15 parts; Menhas Company, DR-01), 0.5 parts; 20 parts of rutile titanium dioxide. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com