Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Excellent light aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel anti-skidding coating for deck and preparation method thereof

ActiveCN102504679AStrong adhesionImprove wear resistanceAntifouling/underwater paintsPaints with biocidesWeather resistanceFoaming agent

The invention provides a novel anti-skidding coating for a deck, which is composed of the following components in parts by weight: 30-45 parts of latex, 2-5 parts of film forming accessory ingredient, 15-25 parts of titanium pigment, 5-20 parts of filler, 0.2-1.0 part of wetting dispersant, 5-15 parts of anti-skidding agent, 0.1-0.5 part of de-foaming agent, 0.5-1.0 part of age inhibitor, 0.5-2.0 parts of thickening agent, 0.5-1.0 part of anti-mildew corrosion-protection agent, and 10-25 parts of water. The coating of the invention has very high wearing resistance and anti-skidding degree; the formed coat has good adhesive ability, wearing resistance, weather resistance, light-proof aging resistance, seawater resistance and salt mist resistance, wherein the artificial weathering aging test (ultraviolet UVB-313 resistance) is 4000 h, and the wearing resistance (1000g / 1000r) is not more than 30mg; the coating is applied to the corrosion prevention of the decks and the iron surfaces of the sea apparatus of boats and ocean platforms, wherein the decks and the iron surfaces require to have weather resistance, anti-skidding property, wearing resistance, and seawater corrosion resistance. The preparation method of the anti-skidding coating for the deck is simple in technology, low in cost and is performed without special apparatus.

Owner:QINGDAO AIR NEW MATERIALS

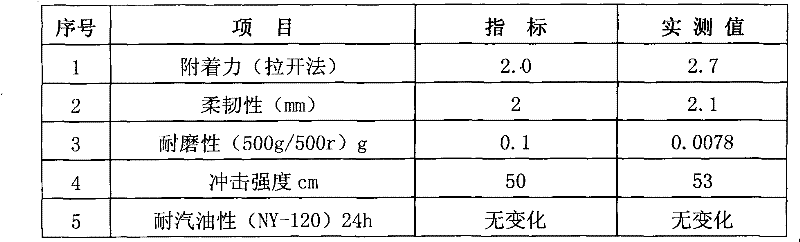

Light aging resistant photodiffusion polycarbonate composite material and preparation method thereof

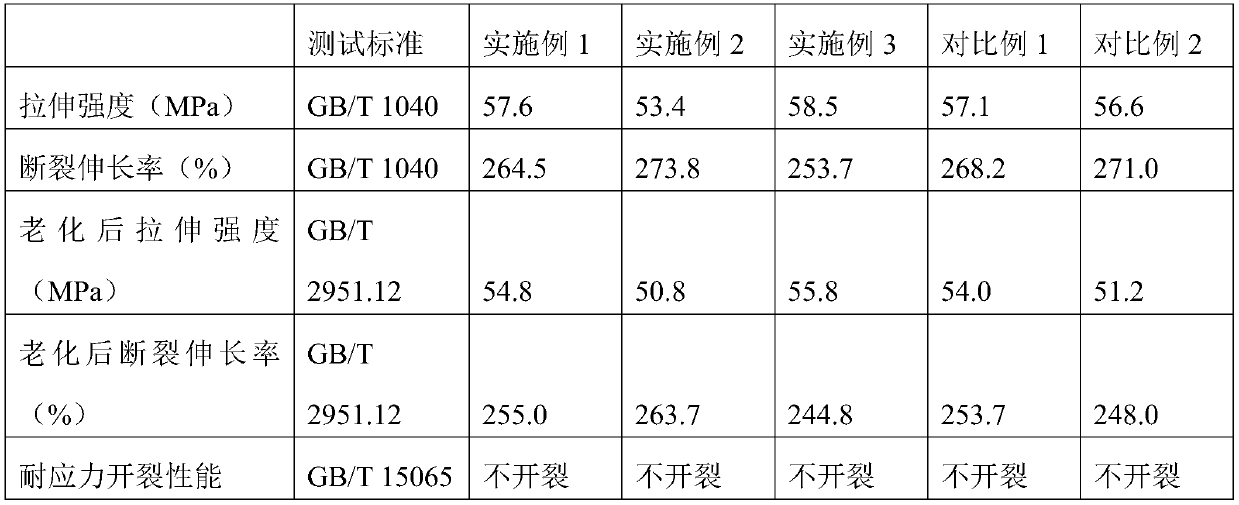

The invention relates to a light aging resistant photodiffusion polycarbonate composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 700-900 parts of polycarbonate aggregate, 100-300 parts of polycarbonate powder, 0.5-5 parts of photodiffusion agent, 2-8 parts of light stabilizer, 1-5 parts of antioxidant and 0.5-2 parts of processing agent. The light aging resistant photodiffusion polycarbonate composite material is prepared from the raw materials in high-speed mixing, extruding and pelletizing manners. The light aging resistant photodiffusion polycarbonate composite material disclosed by the invention has the advantages of being good in processing formability, good in light aging resisting performance, good in light transmittance and haze, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Wear-resistant nonskid polyurethane deck paint, and manufacture method thereof

InactiveCN102190954AGood chemical stabilityImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsGas phaseWear resistant

The invention relates to a wear-resistant nonskid polyurethane deck paint, and a manufacture method thereof. The manufacture method comprises the following steps of: adding a hydroxyl acrylic resin, polyether polyol, hydroxyl-containing fluorocarbon acrylic resin, a polyacrylate copolymer solution, poly(methyl alkyl siloxane) solution and [b-[3-(2-H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropyl]-hydroxypoly(oxo-1,2-ethanediyl) to a mixed solvent of xylene, n-butyl acetate, methyl isobutyl ketone and butanone for high-speed stirring; adding rutile titanium white powder, talcum powder, aluminum oxide ceramic powder, sericite powder, silicon micropowder, carbon black and gas-phased silicon dioxide; milling with a sand mill while controlling fineness of a mixture not higher than 60 mu m to obtain a liquid A; and forming a liquid B by a mixed solution of 1,6-hexamethylene diisocyanate tripolymer, anhydrous xylene and n-butyl acetate, and mixing 1 weight part of the liquid A with 0.2-1.0 weight part of the liquid B for use. The obtained wear-resistant nonskid polyurethane deck paint can be used for the corrosion protection of the steel surfaces of deck and ocean facilities.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

Modified chlorosulphonated polyethylene rubber paint for steel storage tank and preparation method thereof

InactiveCN101294016AImprove dispersion efficiencyHigh viscosityLarge containersEpoxy resin coatingsSodium BentoniteN-Butanol

The invention relates to a modified chlorosulfonated polyethylene rubber coating used for steel storage tanks and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A is composed of chlorosulfonated polyethylene rubber, dimethylbenzene, trimethylbenzene, titanium white powder, talc powder, fluorocarbon-modified polyacrylamide and organic bentonite; and the component B is composed of bisphenol-A epoxy resin, dimethylbenzene, n-butanol, diphenyl guanidine (manufactured by Dongbei Auxiliary general factory, Shenyang) and ethylenethiourea. The component A and the component B are mixed and cured to form a coating film before application. The coating is excellent in physical property, chemical resistance, salt spray resistance and light fastness, and can be used for the surface protection and coating of steel storage tanks in various corrosive environments.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

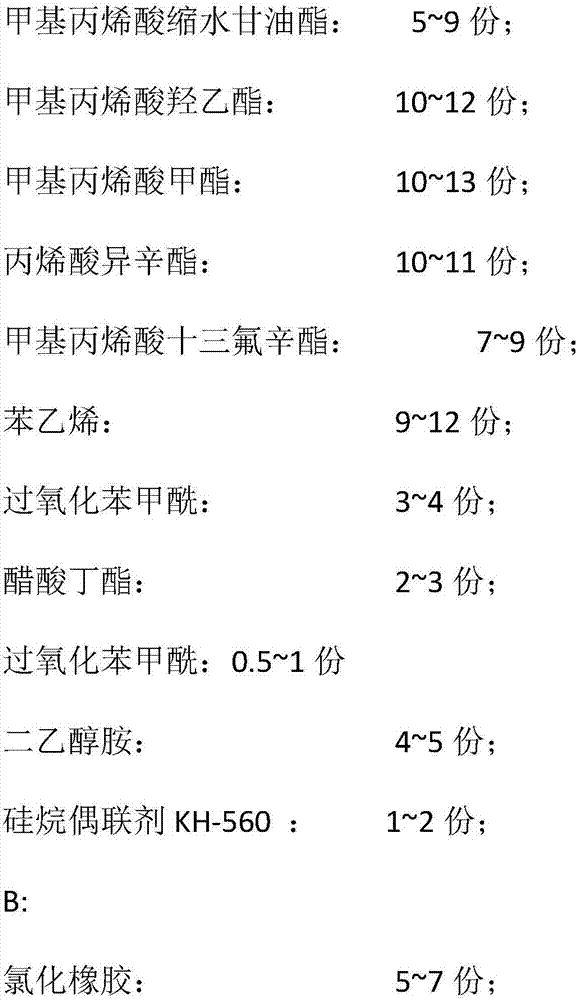

Acrylic acid modified chlorinated rubber waterborne coating suitable for marine environment and preparation method of acrylic acid modified chlorinated rubber waterborne coating

ActiveCN107245293AGood physical and mechanical propertiesGood chemical resistanceChloropene polymer coatingsAnti-corrosive paintsPolymer scienceEmulsion

The invention relates to an acrylic acid modified chlorinated rubber waterborne coating suitable for a marine environment and a preparation method of the acrylic acid modified chlorinated rubber waterborne coating. The coating composition is prepared from a modified acrylic acid modified chlorinated rubber waterborne emulsion component and a color paste component, wherein the modified acrylic acid emulsion component is prepared from the following components in parts by weight: 34-40 parts of modified acrylic acid resin, 15-17 parts of closed type aliphatic isocyanate curing agent and 44-52.2 parts of deionized water. The coating provided by the invention is a waterborne double-component coating, is convenient to coat and environmentally friendly to use and is safe; a board surface is smooth and bright and is good in decorative effect; a coating layer has the advantages of excellent mechanical performance, acid resistance performance and alkaline resistance performance, very excellent weather resistance performance and corrosion resistance performance and can be used for protecting and coating the surface of a steel structure in a marine corrosion environment; the prepared coating is simple in preparation operation technology, uniform in dispersion of various components and good in stability.

Owner:HAOLISEN COATING SHANGHAI

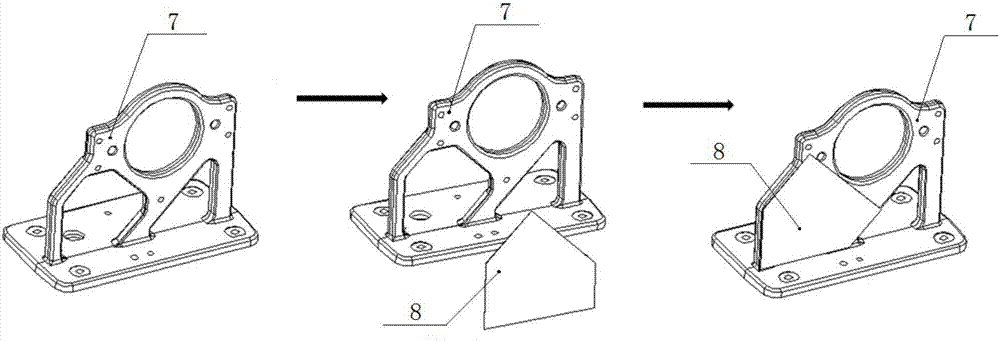

Light aging resistant fluororubber composite material, and preparation method and application thereof

ActiveCN106928601AGood heat insulationExcellent light aging resistanceAging resistanceHeat resistance

The invention discloses a light aging resistant fluororubber composite material, and a preparation method and an application thereof, and belongs to the field of laser devices. The light aging resistant fluororubber composite material is prepared by the following components in parts by weight: 100 parts of perfluoroether rubber, 3-5 parts of SiO2 hollow balls with particle sizes of 100nm to 2mu m, 2.5-3 parts of vulcanizing agent, 2-3 parts of paraffin and 0.2-0.4 part of light stabilizer. According to the light aging resistant fluororubber composite material provided by the invention, the SiO2 hollow balls are added to improve the volume of the gas in the fluororubber composite material by means of the property that the heat conductivity coefficient of the gas is relatively small, thereby reducing the heat conductivity coefficient of the fluororubber composite material and improving the heat resistance, and the fluororubber composite material has good heat-insulating property, thereby prolonging the light aging resistance time of the fluororubber composite material and ensuring the working reliability of other elements on the surrounding.

Owner:HISENSE VISUAL TECH CO LTD

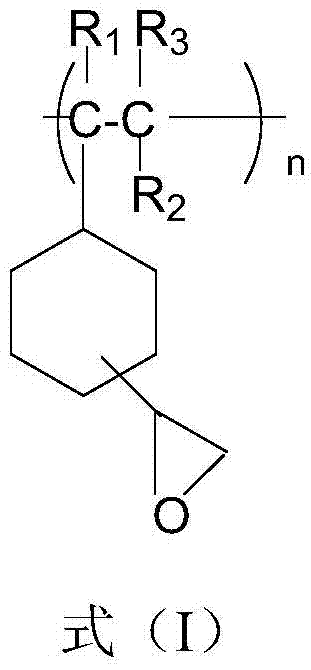

Thermosetting resin composition, prepreg containing same, metal foil-coated laminate and printed circuit board

ActiveCN106916414AExcellent resistance to heat yellowingLow water absorptionPrinted circuit detailsSynthetic resin layered productsHeat resistanceMetal foil

The invention provides a thermosetting resin composition, a prepreg containing the same, a metal foil-coated laminate, and a printed circuit board. The thermosetting resin composition comprises alicyclic epoxy resin with a structure as shown in a formula I. Through usage of the alicyclic epoxy resin with a specific structure, the prepared resin composition has excellent resistance to yellowing caused by heat, resistance to ageing caused by light and excellent drilling processability; and a laminate, the metal foil-coated laminate and the printed circuit board prepared from the composition have excellent heat resistance, excellent resistance to ageing caused by light and a water absorption rate of 0.32% or below. According to the invention, the problems of proneness to yellowing and ageing under heat and proneness to yellowing and ageing under illumination of traditional printed circuit boards are overcome; and a preparation process for the thermosetting resin composition is simple and feasible and is low in cost.

Owner:GUANGDONG SHENGYI SCI TECH

Preparation method of epoxy-modified ultra-matte acrylic acid coating

ActiveCN112266714AReduce glossReduce the abrasivenessPolyurea/polyurethane coatingsEpoxyElectrophoreses

The invention discloses a preparation method of an epoxy-modified ultra-matte acrylic acid coating. The epoxy-modified ultra-matte acrylic acid coating is specifically prepared from epoxy-modified ultra-matte acrylic emulsion and color paste in proportion. The coating product provided by the invention has good storage stability, has excellent physical and mechanical properties, chemical resistance, salt spray resistance and light aging resistance after electrophoretic coating, and can pass an artificial accelerated aging test and an artificial accelerated salt spray test for thousands of hours. The coating is suitable for protecting and coating the surface of a workpiece with chemical resistance and ultralow gloss requirements.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

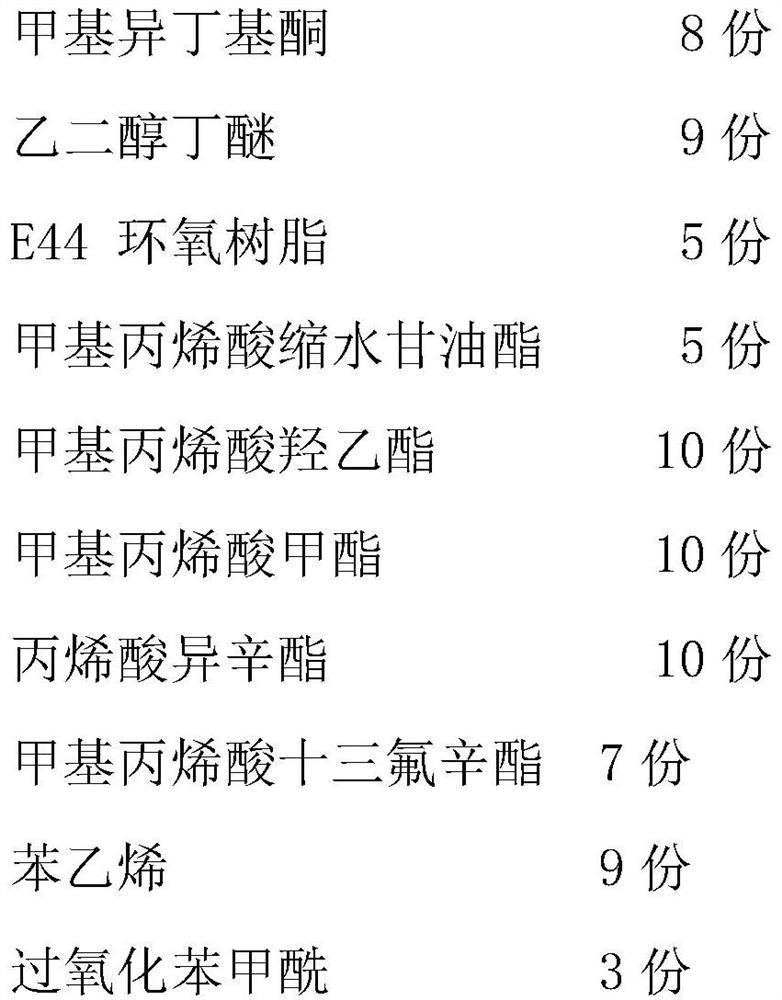

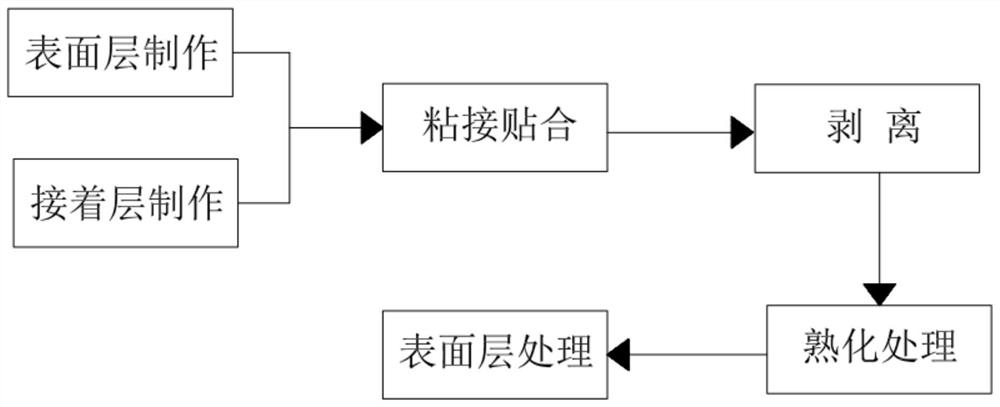

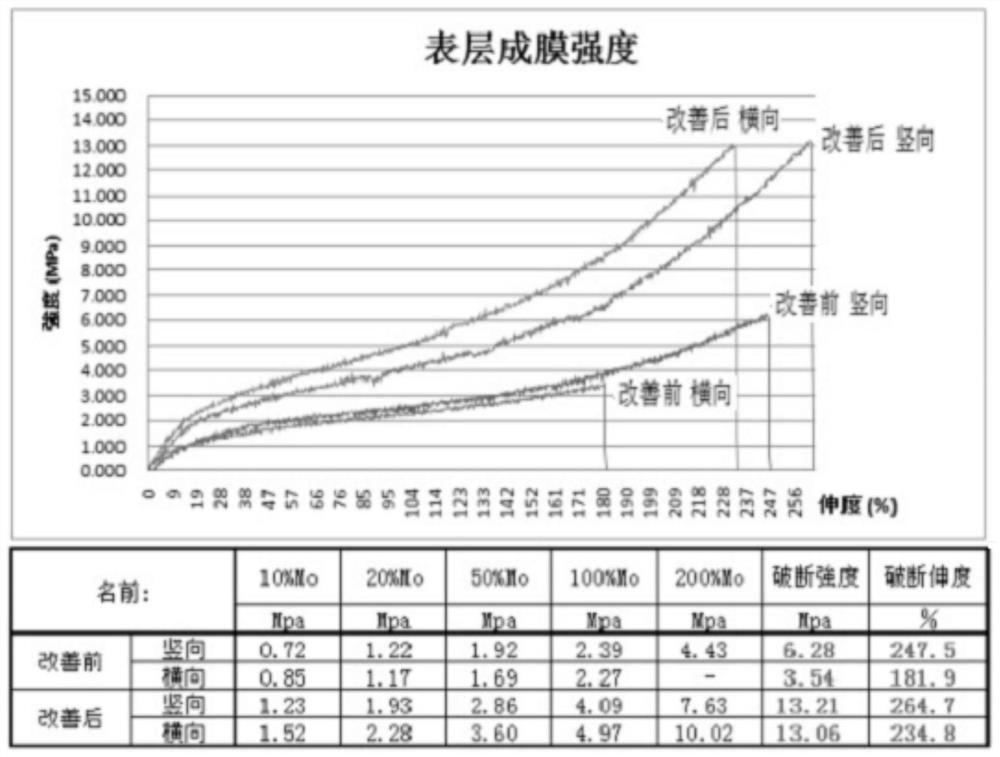

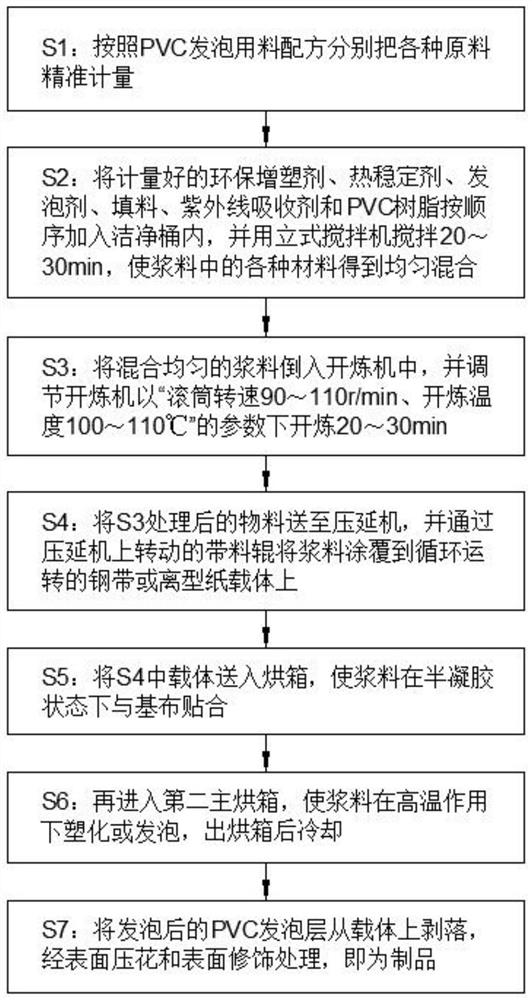

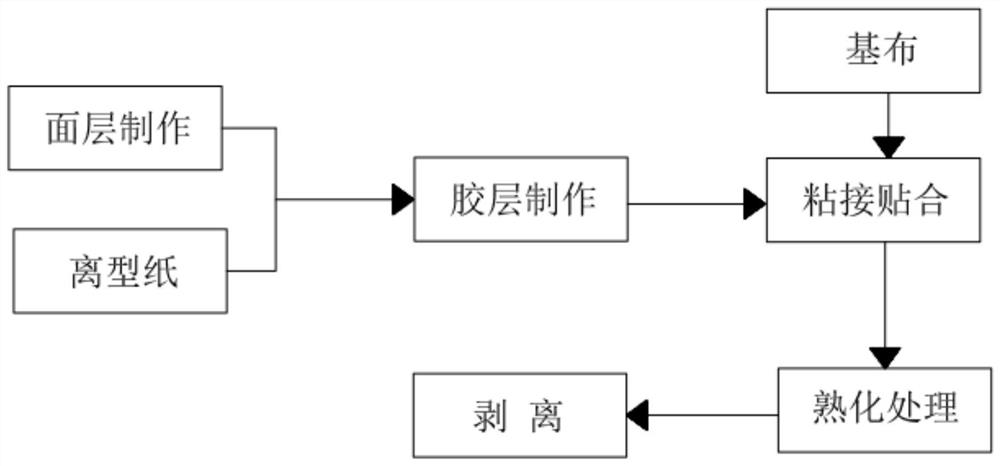

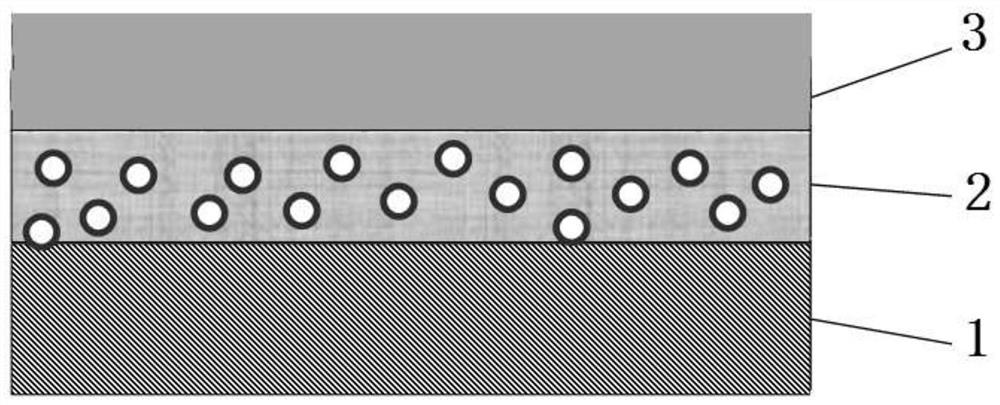

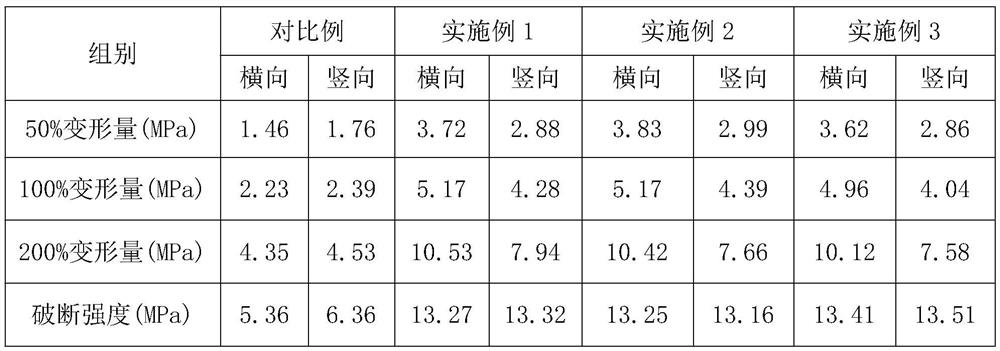

Waterborne polyurethane composite leather and preparation method thereof

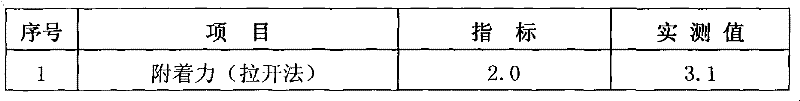

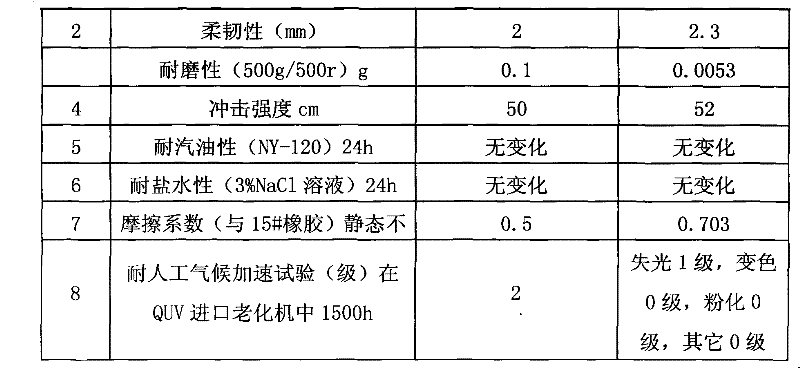

PendingCN111809404AExcellent light aging resistanceExcellent abrasion resistanceTextiles and paperPolymer scienceTackifier

The invention provides waterborne polyurethane composite leather. The waterborne polyurethane composite leather comprises a base cloth layer, an adhesion layer, a surface layer and a surface treatmentlayer, wherein the surface treatment layer comprises polyurethane, a bridging agent, a tackifier and a smoothing agent, the surface layer comprises polyurethane, a bridging agent, a tackifier, a pigment and a dissolving medium, and the adhesion layer comprises polyurethane, a hardening agent, a catalyst, a solvent, a flame retardant and a pigment. The invention further provides a preparation method of the composite leather. The preparation method comprises the steps of manufacturing the surface layer, manufacturing the adhesion layer, bonding the surface layer, the adhesion layer and the basecloth layer together, carrying out stripping, carrying out curing treatment, treating the surface layer and the like. According to the waterborne polyurethane composite leather and the preparation method thereof, the surface layer of the waterborne polyurethane composite leather can enhance surface film formation, abrasion resistance and flexibility by improving the components of all the layers and adopting the preparation method; and meanwhile, various strengths such as abrasion resistance, breaking property, tension and cracking of the waterborne polyurethane composite leather are enhanced,and the phenomena of peeling, cracking and the like of a product after long-term solarization are avoided.

Owner:SEIREN SUZHOU CO LTD

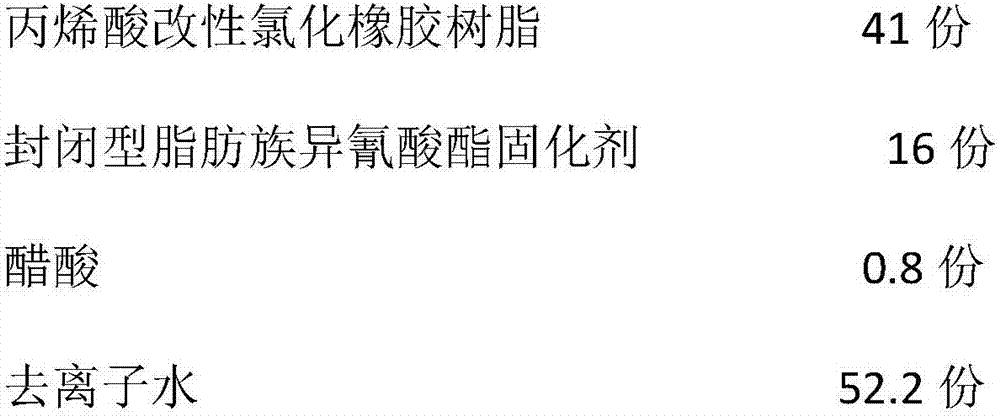

Composite deck coated with anticorrosive paint

InactiveCN103373019AStrong adhesionImprove wear resistanceHull decksSynthetic resin layered productsWear resistantAcrylic resin

The invention discloses a composite deck coated with anticorrosive paint, and relates to the field of shipbuildings. A deck coating and a wear-resistant coating are respectively applied to the upper and lower layers of outer layer of a steel plate, wherein the deck coating consists of hydroxyl acrylic resin, polyether polyol, olefine resin, an antifoaming agent, a flatting agent and a pigment / filler, and the wear-resistant coating is composed of aluminum oxide ceramic powder, silica powder, carbon black, a polyacrylate copolymer solution and anhydrous dimethylbenzene. The composite deck coated with the anticorrosive paint, due to excellent adhesion, abrasive resistance, weather fastness, light aging resistance, seawater resistance and salt fog resistance of the coatings thereof, is applicable to corrosion prevention for decks of ships and ocean platforms which require weather fastness, skid and wear resistance, and seawater corrosion resistance as well as steel and iron surfaces of other ocean facilities. The preparation method of the composite deck coated with the anticorrosive paint is simple in process, free from special equipment and relatively cheap in price.

Owner:DALIAN GANGXIN MACHINERY

Dedicated material for full-biodegradation mulching film special for peanuts and preparation method thereof

The invention discloses a dedicated material for a full-biodegradation mulching film special for peanuts. The dedicated material is characterized by being prepared from the following ingredients in parts by weight: 100 parts of PLA, 70 to 90 parts of PBAT, 0.5 to 1.0 part of nucleating agent, 5 to 10 parts of compound anti-hydrolysis agent, 0.5 to 1.5 parts of compound anti-ultraviolet agent, 3 to6 parts of molecular weight modifier and 20 to 30 parts of flexibility modifier. The mulching film prepared from the dedicated material disclosed by the invention has the advantages of excellent anti-hydrolysis performance, excellent light aging resistance, good flexibility performance, good mulching film anti-blocking property (saving mulching film laying time) and high light transmittance. Under the composting condition, the dedicated material can be completely and biologically degraded into carbon dioxide and water; thus, pollution to soil and environment is avoided, and the dedicated material is suitable for being utilized as peanut mulching films.

Owner:山东天野生物降解新材料科技有限公司

Water-based fluorocarbon coating for communication iron tower and preparation method thereof

InactiveCN110804349AGood dispersionGood combinationAntifouling/underwater paintsPaints with biocidesFluorocarbon ResinsChemistry

The invention discloses a water-based fluorocarbon coating for communication towers and a preparation method thereof. The water-based fluorocarbon coating is prepared from the following raw materialsin parts by weight: 25-35 parts of water-based fluorocarbon resin, 8-16 parts of hydrophilic graphene dispersion, 15-25 parts of hydroxyl acrylic resin, 0.5-1 part of alcohol ester, 5-8 parts of alkydresin, 5-8 parts of water-based polyurethane, 0.5-1.5 parts of an environment-friendly water-based flash rust inhibitor, 5-10 parts of superfine wollastonite powder, 5-10 parts of modified nano calcium carbonate and 5-15 parts of deionized water. The water-based fluorocarbon coating uses water-based film-forming raw materials and uses water as a dispersion medium, can effectively avoid environmental pollution caused by toxic solvents in the oily coating, and at the same time may not cause harm to the health of construction personnel. Moreover, the prepared coating has excellent water resistance, salt fog resistance, weather resistance and physical and mechanical properties, and when used on iron towers, the service life of the iron towers can be effectively prolonged.

Owner:广西凯威铁塔有限公司

Preparation method of water-soluble varnish containing Ag-carrying sepiolite

ActiveCN104725967AExcellent light aging resistanceImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesDefoaming AgentsEthanol

The invention relates to the technical field of water-soluble varnish and discloses a preparation method of water-soluble varnish containing Ag-carrying sepiolite. The preparation method comprises the following steps: (1) preparing Ag-carrying sepiolite; (2) compounding silane coupling agent modified Ag-carrying sepiolite with a water-soluble resin liquid A and a water-soluble resin liquid B and then compounding a mixed resin liquid with deionized water, ethanol, tea saponin, water-soluble wax emulsion, a defoaming agent, a levelling agent and a buffer agent, thus preparing the water-soluble varnish containing Ag-carrying sepiolite. The preparation method has the beneficial effects that containing various antibacterial components, such as nano-silver, titanium dioxide and tea saponin, the water-soluble varnish prepared by the preparation method has strong bactericidal broad-spectrum property; the bactericidal components have synergistic effects, so that the bactericidal effects are greatly enhanced; the dispersibility of the bactericidal components in the water-soluble varnish is quite outstanding.

Owner:长兴艾飞特科技股份有限公司

Modified chlorosulphonated polyethylene rubber paint for steel storage tank and preparation method thereof

InactiveCN100582178CGood physical and mechanical propertiesGood chemical resistanceLarge containersEpoxy resin coatingsBisphenolPolyacrylamide

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

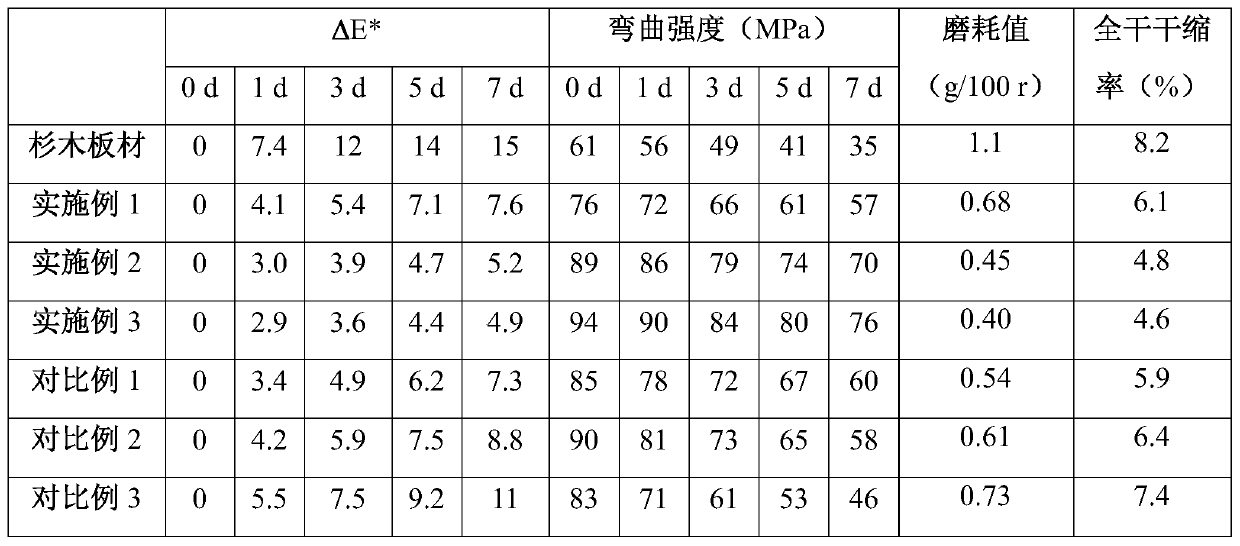

High-weather-resistant fir plate preparation method

ActiveCN110722653AGood dispersionAvoid reunionWood treatment detailsPressure impregnationAqueous solutionAnti oxidant

The invention discloses a high-weather-resistant fir plate preparation method, and belongs to the technical field of wood anti-aging treatment. The preparation method comprises: carrying out a reaction on 2,4-dihydroxybenzophenone and nanometer titanium dioxide to prepare 2,4-dihydroxybenzophenone grafted nanometer titanium dioxide, carrying out first modification treatment on a fir plate by usinga mixed dispersion liquid of the 2,4-dihydroxybenzophenone grafted nanometer titanium dioxide and antioxidant, and carrying out second modification treatment on the fir plate by using a polyurethaneaqueous solution. According to the invention, the prepared fir plate has advantages of excellent weather resistance, good wear resistance, good dimensional stability and remarkable economic value andsocial benefit.

Owner:福建省顺昌县升升木业有限公司

Special full-biodegradable material for peanut mulching film and preparation method of special full-biodegradable material

InactiveCN107868420AImprove hydrolysis resistanceExcellent light aging resistanceAdditive ingredientTransmittance

The invention discloses a special full-biodegradable material for a peanut mulching film. The special full-biodegradable material is characterized by being prepared from the following ingredients: 100parts of PLA, 70-90 parts of PBAT, 0.5-1.0 part of a nucleating agent, 5-10 parts of a compound hydrolysis resisting agent, 0.5-1.5 parts of a compound anti-ultraviolet agent, 3-6 parts of a molecular weight modifier, and 25-35 parts of a compound flexibility modifier. The mulching film prepared from the special material is excellent in hydrolysis resistance, lightproof aging property and flexibility, the opening property of the mulching film is good (the time for paving the mulching film is saved), the transmittance of light is high, and the special material can be completely biodegraded into carbon dioxide and water under the composting condition, does not pollute the soil and the environment, and is suitable for serving as the peanut mulching film.

Owner:山东天野生物降解新材料科技有限公司

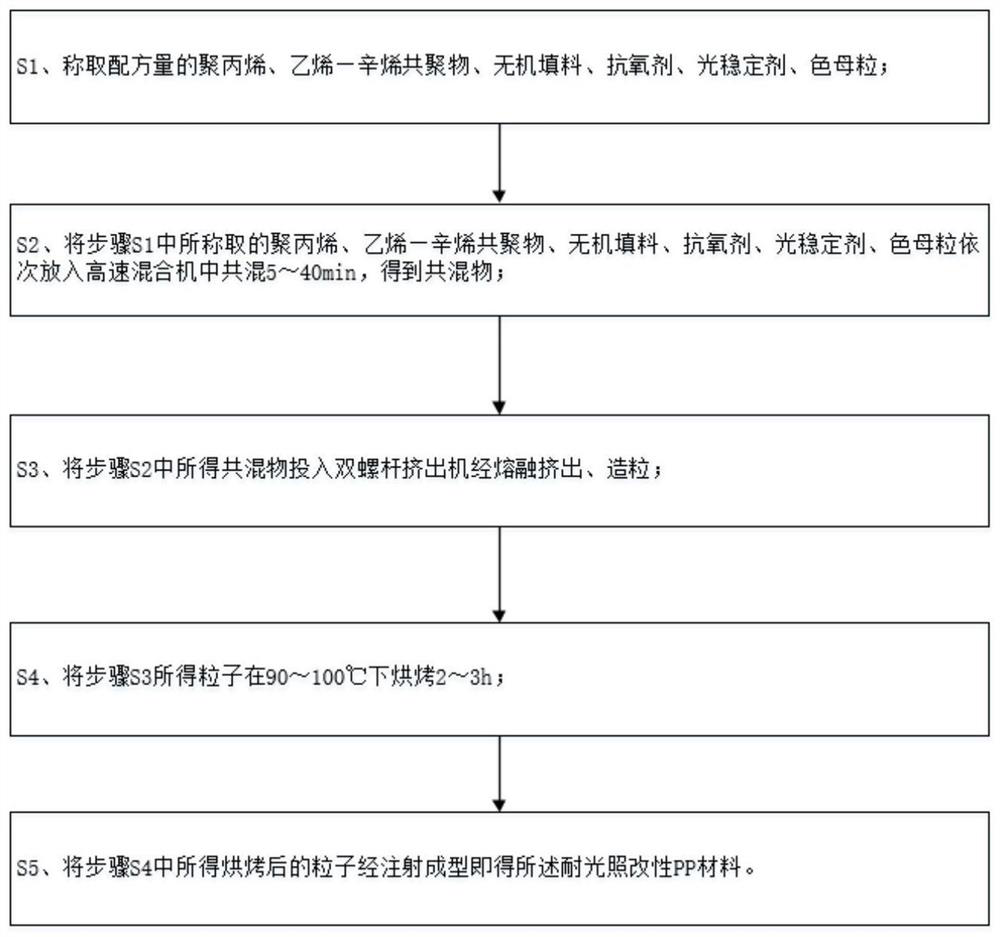

Light-resistant modified PP material and preparation method thereof

The invention discloses a light-resistant modified PP material and a preparation method thereof. The light-resistant modified PP material is prepared from the following raw materials in parts by weight: 65-85 parts of polypropylene, 5-20 parts of ethylene-octene copolymer, 5-20 parts of inorganic filler, 0.1-3 parts of an antioxidant, 0.1-3 parts of a light stabilizer and 0-4 parts of color masterbatch. The light stabilizer in the light-resistant modified PP material disclosed by the invention can capture active free radicals generated in macromolecules, so that the photooxidation process isinhibited, and the light stabilizer and the antioxidant have a synergistic effect to form a light-stable antioxidant system, meanwhile, under the reasonable compatibility of the components, the modified polypropylene material keeps excellent insulating property and mechanical property, is easy to process and form, has excellent light aging resistance, and the application range of the polypropylenematerial is expanded. The preparation method of the light-resistant modified PP material is simple, easy to control, wide in raw material source, low in cost and convenient for realizing industrial production, and has a wide application prospect.

Owner:上海奉坤新材料有限公司

Novel deck antiskid coating

The invention discloses a novel deck antiskid coating prepared from the following raw materials in parts by weight: 30-45 parts of an emulsion; 2-5 parts of a film forming additive; 15-25 parts of titanium dioxide; 5-20 parts of a filler; 5-12 parts of an organic solvent; 5-15 parts of a nano oxide particle enhancing agent; 1-5 parts of a levelling agent; 1-5 parts of an epoxy solidification promoter; 10-15 parts of a defoaming agent; 0.5-2.0 parts of a thickening agent; 0.5-1.0 part of an antiseptic antimildew agent; and 10-25 parts of water. The novel deck antiskid coating has quite high wear resistance and antiskid degree, a coating layer has the advantages of excellent adhesion, wear resistance, weather resistance, light aging resistance, seawater resistance and salt fog resistance, the process is simple, special equipment is not required, and the price is low.

Owner:QINGDAO UWELL INFORMATION TECH

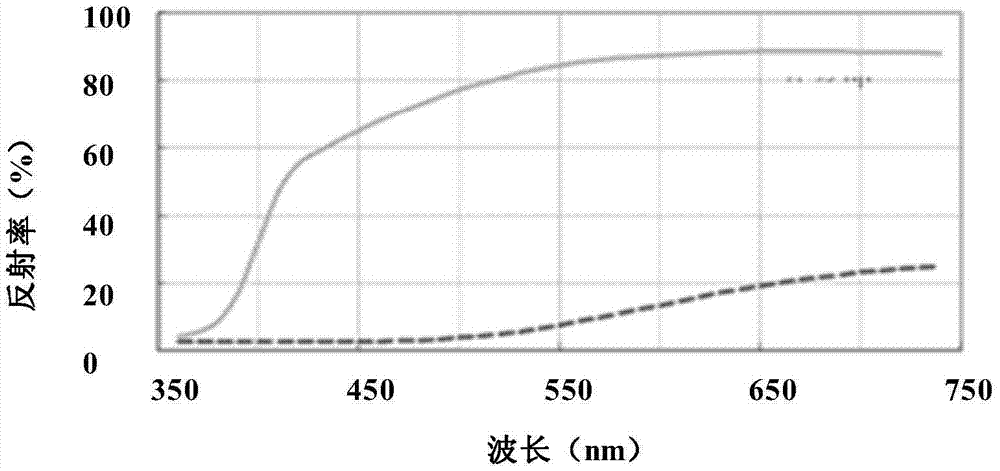

Polyurethane ultrafine fiber leather with high light aging resistance and preparation method and application thereof

InactiveCN111607975AExcellent infrared light reflection abilityAvoid destructionVehicle componentsTextiles and paperPolymer scienceAntioxidant

The invention discloses polyurethane ultrafine fiber leather with high light aging resistance and a preparation method and application thereof, and belongs to the technical field of polymer materials.The polyurethane ultrafine fiber leather comprises a skin layer and a surface skin layer, the skin layer and the surface skin layer uses polyurethane resin as main raw materials and are sequentiallyarranged on the surface of a base fabric layer in a stacked mode, wherein the skin layer contains infrared light reflecting fillers and infrared light transmitting pigments are dispersed in the surface skin layer. Ultraviolet light absorbers and antioxidants are not required to be added in the polyurethane ultrafine fiber leather, and the polyurethane ultrafine fiber leather has excellent light aging resistance, effectively avoids the adverse effects caused by migration of small molecular substances such as the ultraviolet light absorbers and the antioxidants during use of the ultrafine fiberleather. The polyurethane ultrafine fiber leather has good applications in automotive interior products.

Owner:DONGFENG MOTOR CORP HUBEI +1

Special material for 5G optical fiber sheath and preparation method of special material

The invention belongs to the technical field of optical fiber sheath materials, and particularly relates to a special material for a 5G optical fiber sheath and a preparation method of the special material. The special material is prepared from PBT resin slices, an alpha-methylstyrene-acrylonitrile copolymer, aluminum silicate fibers, a titanate coupling agent, polyether, a light stabilizer, an ultraviolet light absorber and an antioxidant. According to the special material of the invention, the alpha-methylstyrene-acrylonitrile copolymer and the polyether are introduced into the PBT resin slices at the same time, so that the alpha-methyl styrene-acrylonitrile copolymer still can significantly increase the softening point of the PBT resin when being used at a low dosage, the heat resistance of the PBT resin is improved, and the problem of cost increase caused by a condition that that the heat resistance of the PBT resin is improved by adopting high-content alpha-methyl styrene-acrylonitrile copolymer in the prior art is solved; the polyether is doped into the PBT resin slices, so that the melt rheological property of the PBT resin slices in a melting processing process is improved,and the good processability of the PBT resin slices is ensured.

Owner:ANHUI GUANHONG PLASTIC IND

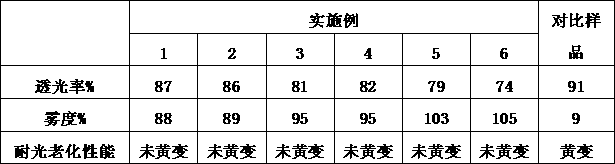

Anti-cracking leather and production method thereof

InactiveCN112080942AEfficient and stable surface performanceExcellent light aging resistanceTextiles and paperSurface modificationPolymer chemistry

The invention discloses a production method of anti-cracking leather. The leather comprises a base cloth layer, a PVC foaming layer and a surface modification layer, wherein the PVC foaming layer is arranged between the base cloth layer and the surface modification layer, and the PVC foaming layer is particularly prepared from the following raw materials in parts by weight: 110-130 parts of PVC resin, 80-90 parts of an environment-friendly plasticizer, 3-4 parts of a heat stabilizer, 4-5 parts of a foaming agent, 8-10 parts of filler and 3-4 parts of an ultraviolet absorber. According to the anti-cracking leather, PVC is adopted as a main material and matched with base cloth, the novel environment-friendly foaming agent and the heat stabilizer, a coating calendering attachment method is used, efficient and stable surface performance of the artificial leather is guaranteed, the ultraviolet absorber is added into the PVC foaming layer, therefore the leather has an excellent light aging resistance effect, the peeling strength, the low-temperature buckling resistance and the like after long-term solarization are improved, and the phenomena of peeling, cracking and the like of a productin the daily use process are effectively reduced.

Owner:QINGYUAN TENGXIANG LEATHER CO LTD

A light-diffusing polycarbonate composite material resistant to light aging and its preparation method

The invention relates to a light-diffusing polycarbonate composite material resistant to light aging and a preparation method thereof. The composite material consists of 700-900 parts of polycarbonate pellets, 100-300 parts of polycarbonate powder, and 0.5-5 parts of a light-diffusing agent , 2-8 parts of light stabilizer, 1-5 parts of antioxidant and 0.5-2 parts of processing aid are made by weight. It is a light-diffusing polycarbonate composite material with light aging resistance and high-speed mixing and extrusion granulation of raw materials. The light-aging resistant light-diffusing polycarbonate composite material of the invention has the advantages of good processability, good light-aging resistance, good light transmittance, haze and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Wear-resistant nonskid polyurethane deck paint, and manufacture method thereof

InactiveCN102190954BStrong adhesionImprove wear resistancePolyurea/polyurethane coatingsGas phaseWear resistant

The invention relates to a wear-resistant nonskid polyurethane deck paint, and a manufacture method thereof. The manufacture method comprises the following steps of: adding a hydroxyl acrylic resin, polyether polyol, hydroxyl-containing fluorocarbon acrylic resin, a polyacrylate copolymer solution, poly(methyl alkyl siloxane) solution and [3-[3-(2-H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropyl]-hydroxypoly(oxo-1,2-ethanediyl) to a mixed solvent of xylene, n-butyl acetate, methyl isobutyl ketone and butanone for high-speed stirring; adding rutile titanium white powder,talcum powder, aluminum oxide ceramic powder, sericite powder, silicon micropowder, carbon black and gas-phased silicon dioxide; milling with a sand mill while controlling fineness of a mixture not higher than 60 mu m to obtain a liquid A; and forming a liquid B by a mixed solution of 1,6-hexamethylene diisocyanate tripolymer, anhydrous xylene and n-butyl acetate, and mixing 1 weight part of the liquid A with 0.2-1.0 weight part of the liquid B for use. The obtained wear-resistant nonskid polyurethane deck paint can be used for the corrosion protection of the steel surfaces of deck and ocean facilities.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

A kind of anti-aging fluorine rubber composite material and its preparation method and application

ActiveCN106928601BGood heat insulationExcellent light aging resistanceHeat resistanceAging resistance

Owner:HISENSE VISUAL TECH CO LTD

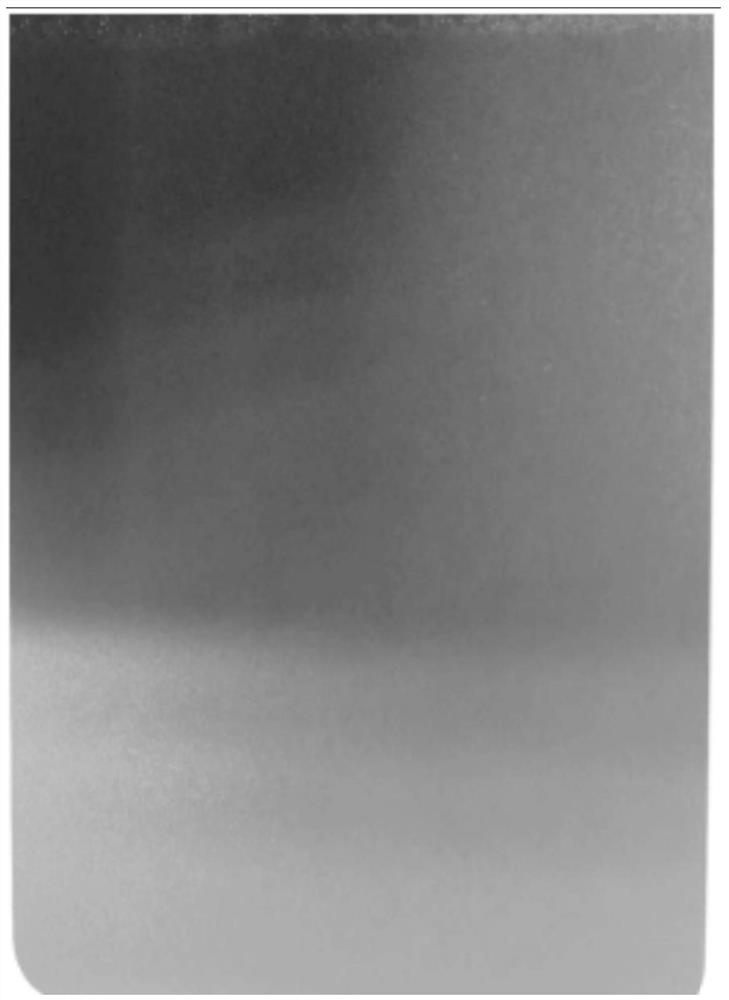

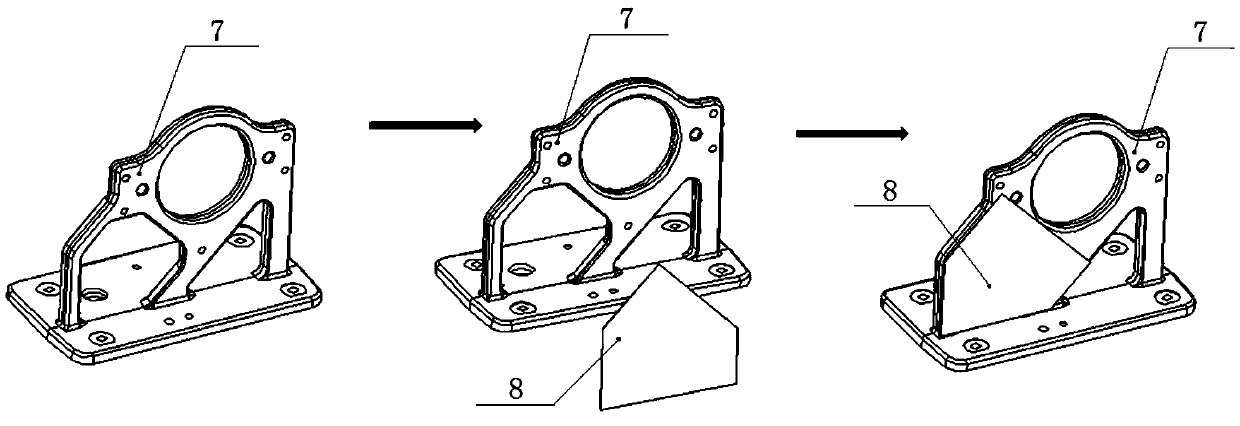

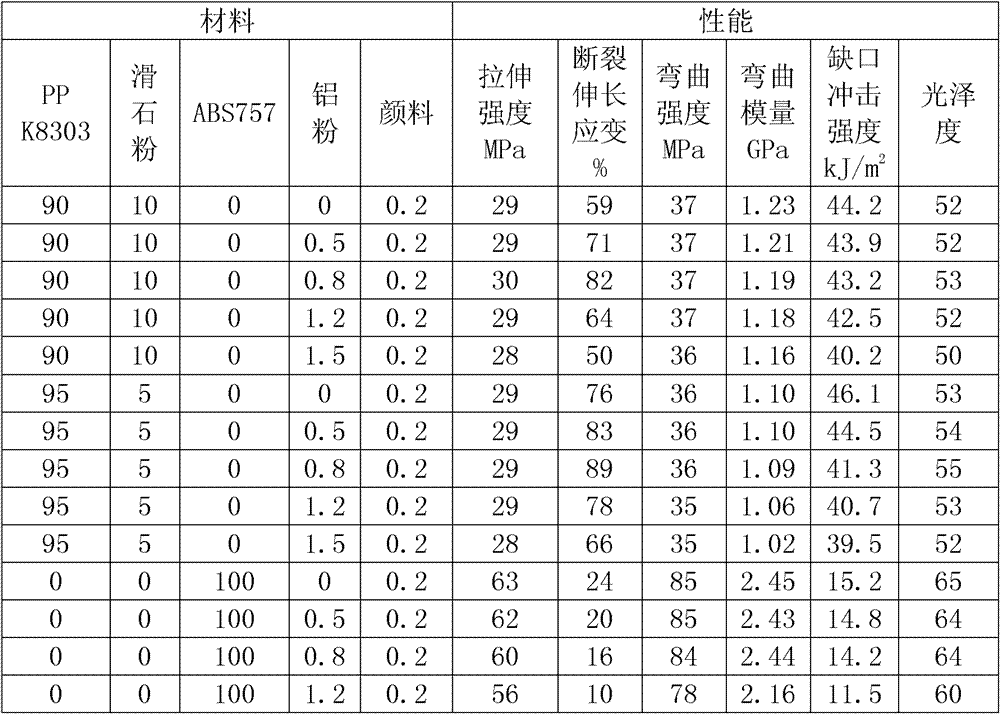

Formula of non-painted automobile spoiler with metal luster and production process thereof

The invention provides a non-painted automobile spoiler with metal luster and a production process thereof. The automobile spoiler is prepared from the following components in part by weight: 90 to 100 parts of PP, 5 to 10 parts of talcpowder and 0.5 to 3.5 parts of aluminum powder; or 90 to 100 parts of ABS and 0.5 to 1.5 parts of aluminum powder. The automobile spoiler produced by blending the aluminum powder and the PP or ABS; by using the PP or ABS as a raw material to produce the automobile spoiler, the surface of the automobile spoiler can obtain the metal luster without spraying treatment, and the metal luster is not lost or fades, the inner part of the product still obtains the metal luster even if the surface of the product is scratched or damaged, the surface treatment process of spraying the metal flashing paint on the surface of the product is unnecessary, and the metal luster is high in durability, particularly excellent in light ageing resistance; and in addition, the paint-spraying process step in a process of producing the automobile spoiler adopting the formula is saved, so that the production flow is simplified, and the production cost is greatly lowered.

Owner:国家复合改性聚合物材料工程技术研究中心

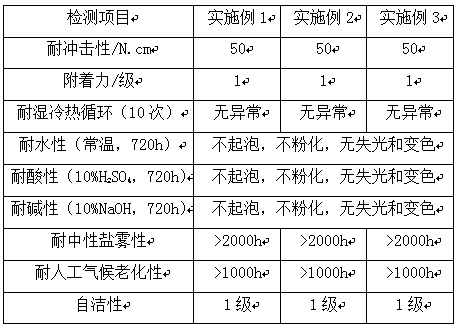

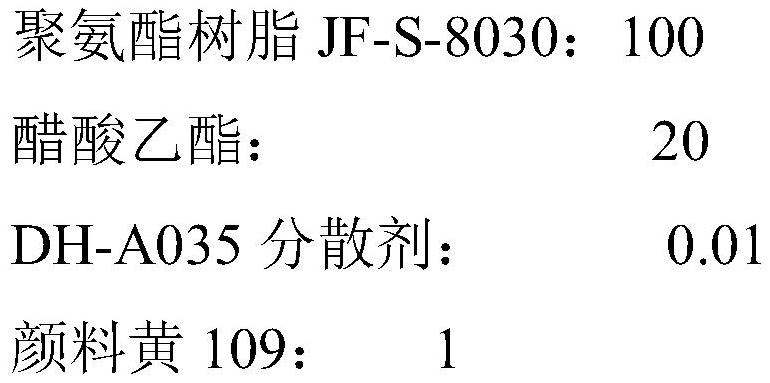

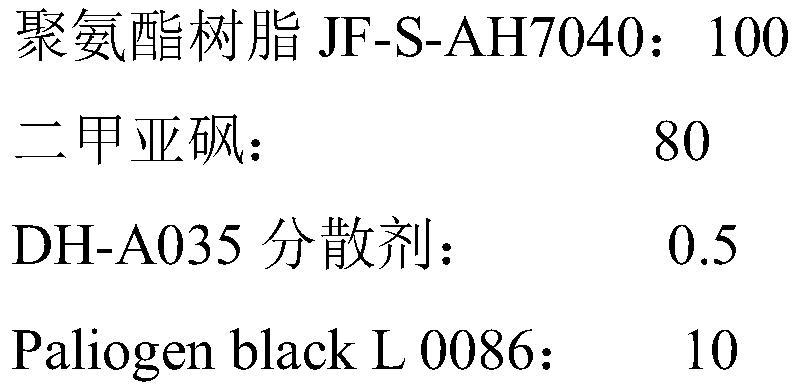

Soft transparent polyurethane surface film and preparation method thereof

PendingCN111979789AExcellent light aging resistanceExcellent abrasion resistanceTextiles and paperPhoto agingPolymer science

The invention provides a soft transparent polyurethane surface film. The surface film comprises base cloth, an adhesive layer and a surface layer, wherein the adhesive layer is arranged between the base cloth and the surface layer, and the base cloth and the surface layer are bonded together through the adhesive layer, and each of the surface layer and the adhesive layer contains polyurethane, a bridging agent, a thickener, a leveling agent and a defoamer; and meanwhile, the invention further provides a preparation method of the light, thin and flexible polyurethane surface film, wherein the method comprises the steps of manufacturing the surface layer, manufacturing the adhesive layer, bonding the adhesive layer and the base cloth together, curing and stripping, and by improving components of all the layers, the abrasion resistance, the breaking resistance and the transparency of the surface film are enhanced. In addition, the surface film also has an excellent light aging resistanceeffect, so that the phenomena of aging, peeling, cracking and the like of a product after long-term solarization are avoided.

Owner:SEIREN SUZHOU CO LTD

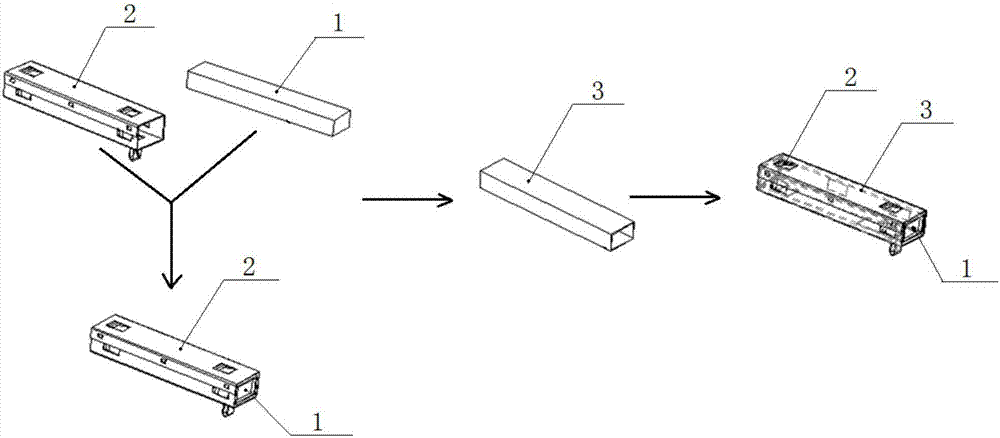

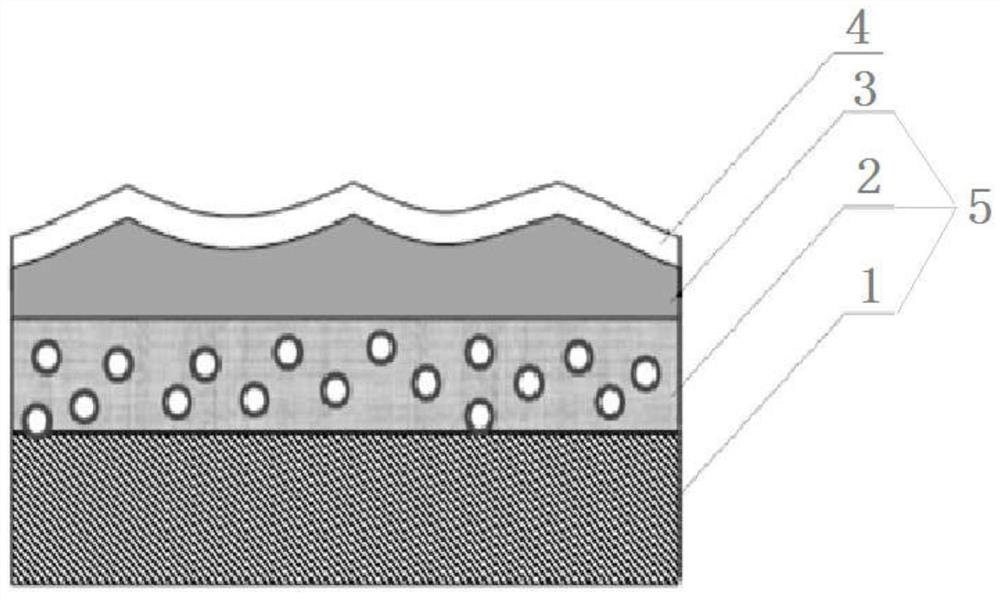

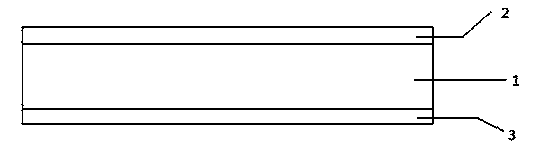

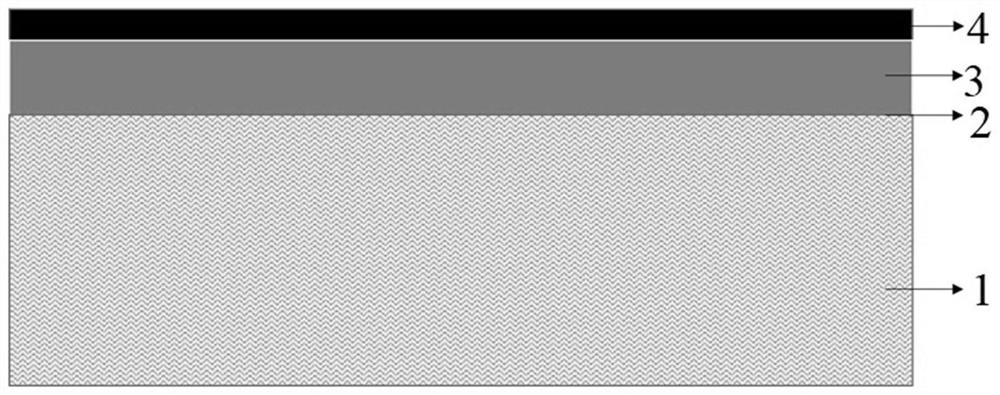

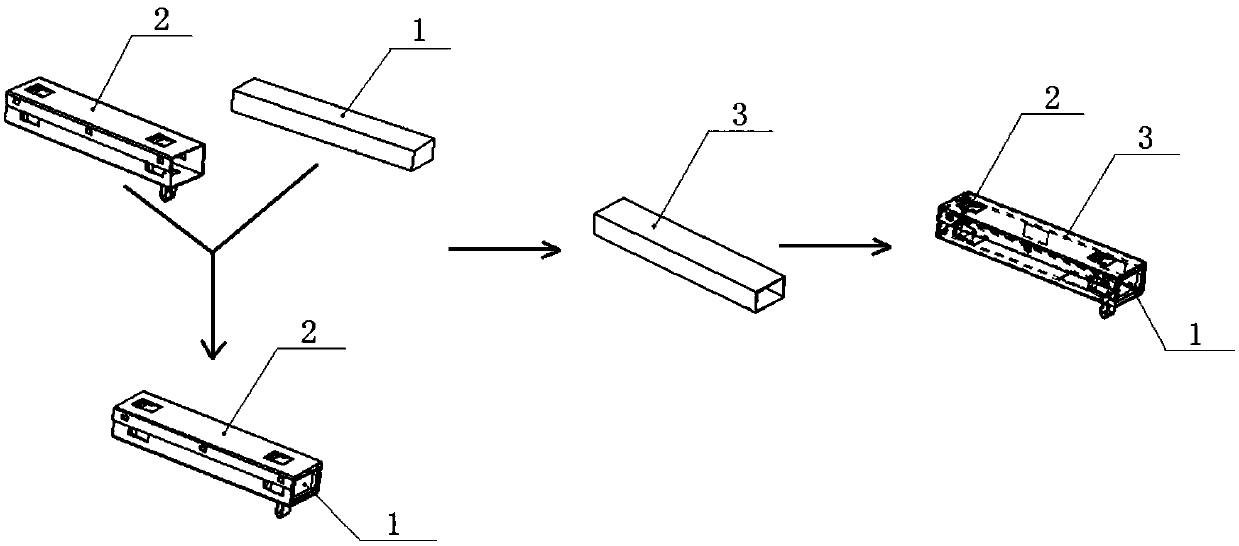

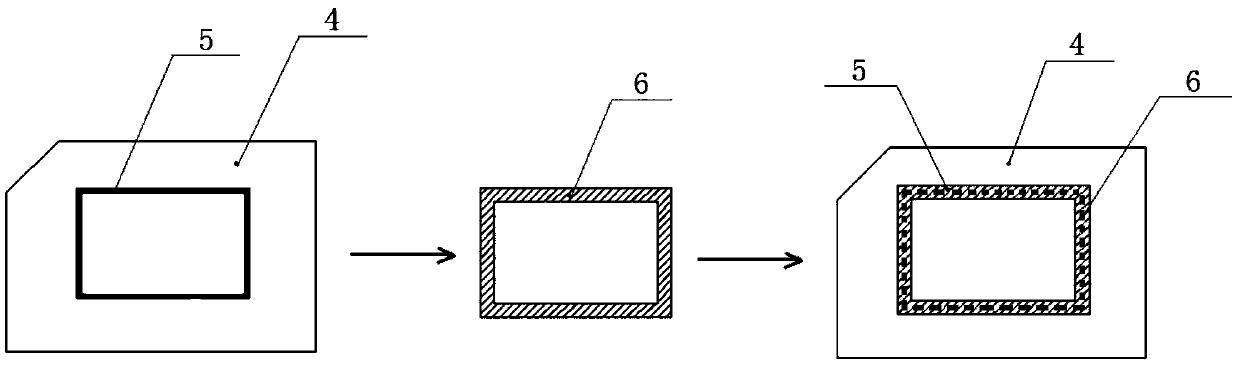

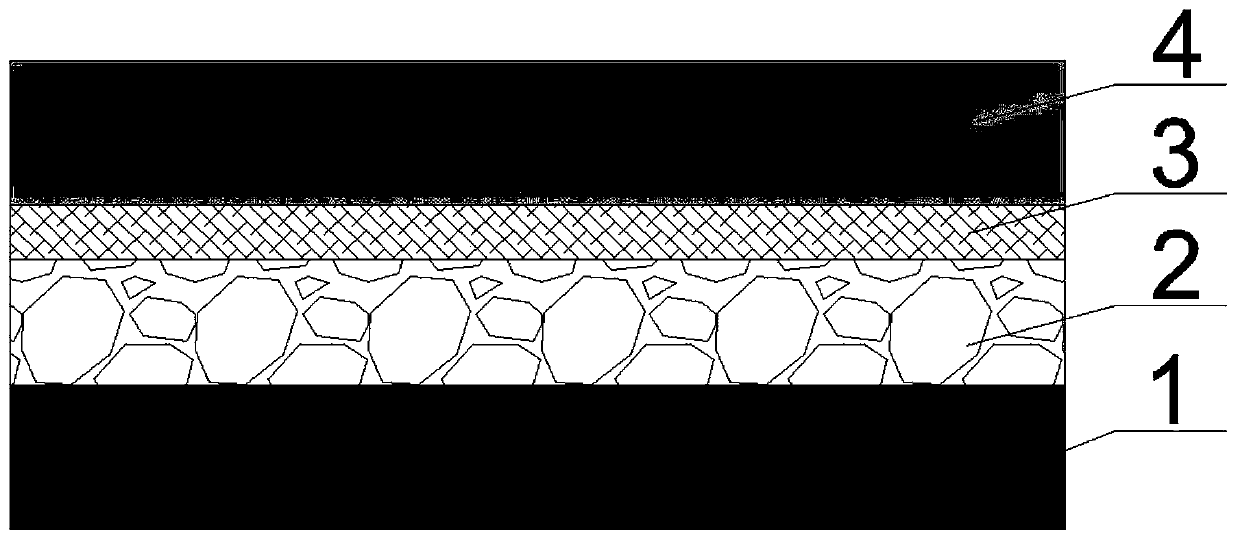

Synthesized leather

PendingCN109826022AExcellent light aging resistanceHigh peel strengthTextiles and paperSurface layerUltraviolet

The invention discloses synthesized leather. The synthesized leather comprises a basic cloth layer (1), a surface layer (4) and a foaming bonding layer (2) which is located between the basic cloth layer (1) and the surface layer (4), and further comprises an ultraviolet adsorption coating (3) which is arranged between the surface layer (4) and the foaming bonding layer (2); the ultraviolet adsorption coating (3) includes an ultraviolet adsorption agent, wherein the ultraviolet adsorption agent is titanium dioxide ultra-fine powder formed by mixing rutile titanium dioxide and anatase titanium dioxide. According to the synthesized leather, a layer of the ultraviolet adsorption coating is additionally arranged in a conventional synthesized leather structure, so that the synthesized leather has an excellent light-proof aging effect, performance such as the peel strength and the low temperature buckling resistance of the synthesized leather after the synthesized leather is aired for a longtime are improved, phenomena such as peeling and cracking of the products during daily use are effectively reduced, and the hand feeling of the synthesized leather can also be improved.

Owner:SEIREN SUZHOU CO LTD

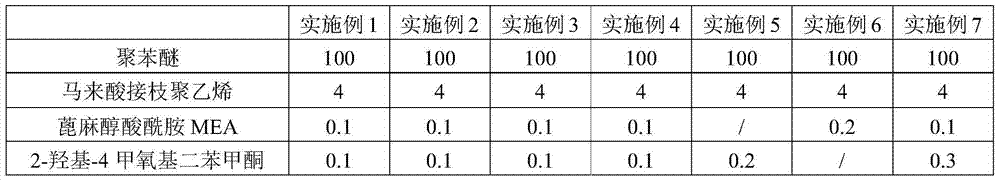

A kind of environment-friendly modified polyphenylene ether material for automotive interior parts

Owner:SHANGHAI HAN MOLDING SHAPE CO LTD

A high-strength coating resistant to marine climate and its preparation process

ActiveCN103725127BStrong adhesionImprove wear resistanceAntifouling/underwater paintsPaints with biocidesAcrylic resinWear resistant

The invention discloses marine climate resistant high-strength coating which comprises the following components of acrylic resin, polyether polyol, nano-silica, a hydrophilic acrylate dispersing agent, a polyether modified siloxane foam breaking agent, a composite mildewproof and bactericidal agent, a polyurethane thickening agent, a wetting agent, titanium dioxide, kaolinite, coarse whiting and deionized water. The coating has excellent adhesive force, wearing resistance, weather resistance, light aging resistance, sea water resistance and salt fog resistance, and can be used for corrosion protection of the surface of iron steel of decks, required to be weather-proof, anti-skid and wear-resistant, and seawater corrosion resistant, of ships, ocean platforms and the like and other marine facilities. According to the invention, a preparation method of the marine climate resistant high-strength coating is simple in technology, special equipment is not required, and the price is lower.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Long-term corrosion resistance coating for ocean platform steel structure in atmospheric region and manufacture method thereof

ActiveCN102816521BExcellent long-term salt spray corrosion resistanceExcellent light aging resistanceAnti-corrosive paintsDiacetone alcoholPolyester

The invention relates to a long-term corrosion resistance coating for an ocean platform steel structure in an atmospheric region and a manufacture method thereof. The long-term corrosion resistance coating comprises, by weight, 1 part of epoxy modified organic silicon resin EF type HG-41, 0.2-0.3 part of acrylic acid organic silicon resin AS-04, 0.15-0.3 part of dimethylbenzene, 0.1-0.2 part of diacetone alcohol, 0.1-0.2 part of tetraethoxysilane, 0.01-0.1 part of ultraviolet absorber UV5050, 0.01-0.1 part of modified polysiloxane deuchem 5500, 0.01-0.1 part of polymer polysiloxane copolymer tego450, 0.01-0.1 part of polyether polysiloxane copolymer tego245, 0.1-0.2 part of 2500-mesh titanium dioxide, 0.1-0.3 part of 6000-mesh alumina powder, 0.01-0.05 part of 1250-mesh fumed silica and 0.01-0.05 part of T-4 carbon black. The coating is resistant to salt mist corrosion and light aging and good in adhesion.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com