Polyurethane ultrafine fiber leather with high light aging resistance and preparation method and application thereof

A microfiber leather and aging performance technology, applied in transportation and packaging, textiles and papermaking, vehicle parts, etc., can solve the problems of material aging and damage, and achieve the effect of improving light resistance, excellent color development, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

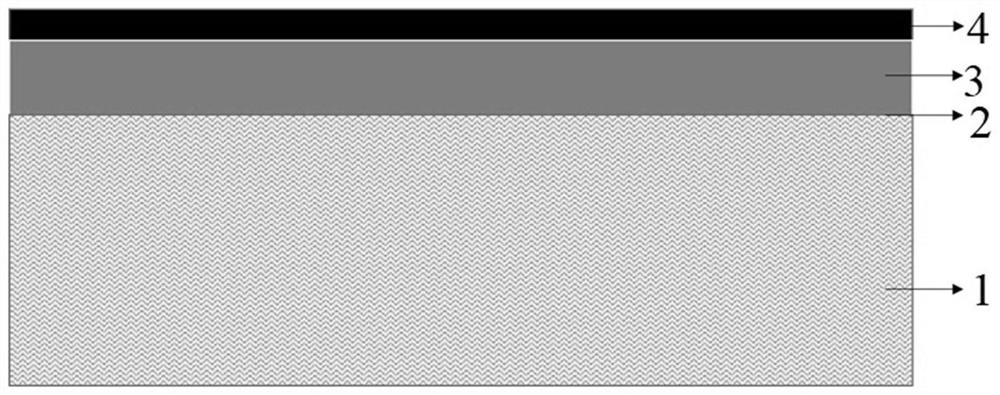

[0043] In order to better realize the technical purpose of the present invention, the present invention also discloses a preparation method of a polyurethane microfiber leather with high light aging resistance, the polyurethane microfiber leather includes an adhesive layer sequentially stacked on the surface of the base cloth layer, And the cortex and epidermis with polyurethane resin as the main raw material, specifically include the following steps:

[0044] 1) Configure the skin layer slurry, skin layer slurry and adhesive layer slurry according to the corresponding formula, and select the base cloth and release paper;

[0045] 2) Coat the skin layer slurry on the surface of the release paper and dry at 70-160°C; the skin layer slurry includes the following components in parts by mass: polyurethane resin: 100 parts, solvent: 20-20 100 parts, wetting and dispersing agent: 0.01-2 parts, infrared light-transmitting pigment: 1-20 parts;

[0046] 3) Coat the cortex slurry on th...

Embodiment 1

[0060] This embodiment discloses a preparation method of polyurethane microfiber leather with high light aging resistance, including the following preparation process:

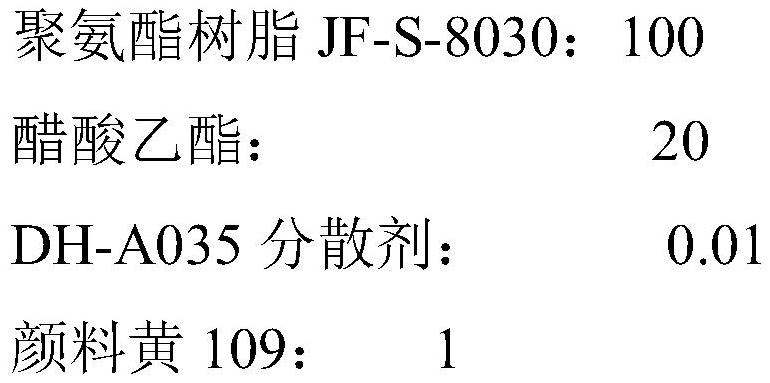

[0061] (1) Prepare the skin layer, wherein the skin layer slurry is composed of the following components in parts by mass:

[0062]

[0063] Add the above components into the batching barrel in turn, stir evenly, configure the skin layer slurry, coat the skin layer slurry on DE-7C release paper, and dry it at a temperature of 70°C to obtain a product with good infrared Light-transmissive epidermis;

[0064] (2) Prepare the cortex, wherein the cortex slurry is composed of the following components in parts by mass:

[0065] Polyurethane resin JF-S-8030: 100

[0066] Ethyl acetate: 20

[0067] Altiris 550: 40

[0068] Add the above-mentioned components into the batching tank in turn, stir evenly, configure the cortex slurry, coat the cortex slurry on the epidermis, and dry it at a temperature of 70°C to ob...

Embodiment 2

[0072] This embodiment discloses a preparation method of polyurethane microfiber leather with high light aging resistance, including the following preparation process:

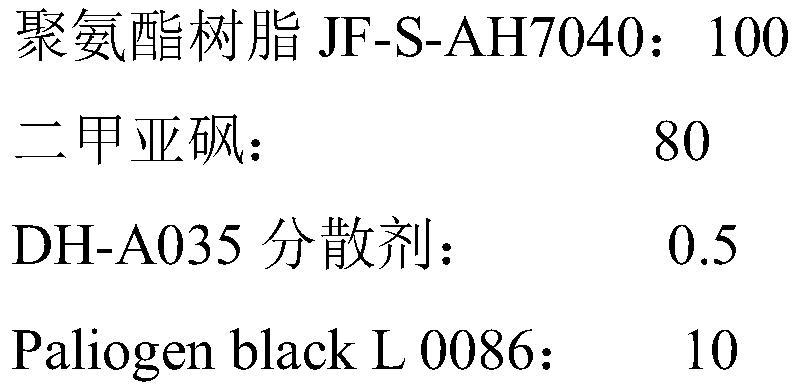

[0073] (1) Prepare the skin layer, wherein the skin layer slurry is composed of the following components in parts by mass:

[0074]

[0075] Add the above components into the batching barrel in turn, stir evenly, configure the skin layer slurry, coat the skin layer slurry on DE-7C release paper, and dry it at 160 ° C to obtain a good infrared Light-transmissive epidermis;

[0076] (2) Prepare the cortex, wherein the cortex slurry is composed of the following components in parts by mass:

[0077] Polyurethane resin JF-S-AH7040: 100

[0078] Dimethyl sulfoxide: 80

[0079] Black: 20

[0080] Add the above-mentioned components into the batching barrel in turn, stir evenly, and prepare a cortex slurry, coat the cortex slurry on the epidermis, and dry at a temperature of 160°C to obtain a cortex with good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com