Special material for 5G optical fiber sheath and preparation method of special material

A technology for optical fiber sheathing and special materials, which is applied in the field of special materials for 5G optical fiber sheathing and its preparation, can solve the problems of poor heat resistance and light aging resistance, lack of effective and stable improvement, etc., and achieve excellent heat resistance and light aging resistance. , Good machinability, the effect of improving softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

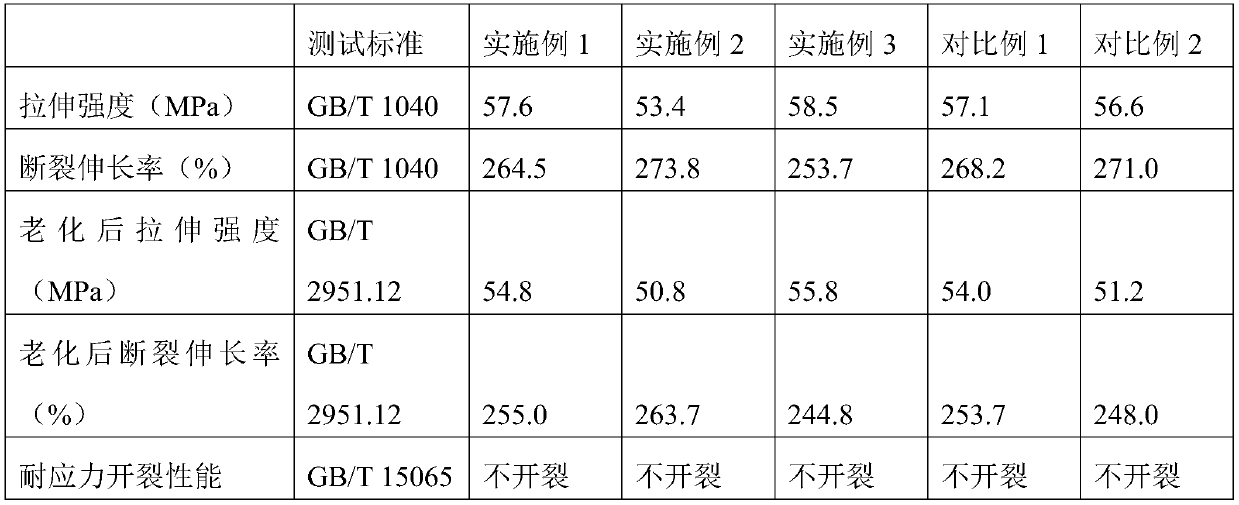

Examples

Embodiment 1

[0041] A special material for optical fiber sheath, prepared from the following raw material components in parts by weight:

[0042] PBT resin chips (intrinsic viscosity 0.86dl / g ISO1628 / 5) 100 parts by weight

[0043] 0.8 parts by weight of α-methylstyrene-acrylonitrile copolymer

[0044] Aluminum silicate fiber (length is 40nm, diameter is 3μm) 15 parts by weight

[0045] 8 parts by weight of isopropyl trioleate acyloxy titanate

[0046] Polyethylene glycol (PEG2000, purchased from Jiangsu Dana Chemical Co., Ltd.) 7 parts by weight

[0047] 0.5 parts by weight of hindered amine light stabilizer (CH944, produced by BASF)

[0048] Ultraviolet absorber 2-hydroxyl-4-n-octyloxybenzophenone 0.3 parts by weight

[0049] Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol 0.24 parts by weight

[0050] Antioxidant tris(2,4-di-tert-butylphenyl) phosphite 0.16 parts by weight

[0051] The preparation method of above-mentioned optical fiber ...

Embodiment 2

[0056] This embodiment is basically the same as the special material for optical fiber sheath and its preparation method described in Example 1. The difference is that the raw material components of the special material for optical fiber sheath are:

[0057] PBT resin chips (intrinsic viscosity 0.86dl / g ISO1628 / 5) 100 parts by weight

[0058] 0.5 parts by weight of α-methylstyrene-acrylonitrile copolymer

[0059] Aluminum silicate fiber (length is 40nm, diameter is 3μm) 12 parts by weight

[0060] 4 parts by weight of isopropyl trioleate acyloxy titanate

[0061] Polyethylene glycol (PEG2000, purchased from Jiangsu Dana Chemical Co., Ltd.) 5 parts by weight

[0062] Hindered amine light stabilizer (CH944, produced by BASF) 0.1 parts by weight

[0063] Ultraviolet absorber 2-hydroxyl-4-n-octyloxybenzophenone 0.1 parts by weight

[0064] Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol 0.04 parts by weight

[0065] Antioxidant tris...

Embodiment 3

[0068] This embodiment is basically the same as the special material for optical fiber sheath and its preparation method described in Example 1. The difference is that the raw material components of the special material for optical fiber sheath are:

[0069] PBT resin chips (intrinsic viscosity 0.86dl / g ISO1628 / 5) 100 parts by weight

[0070] 1 part by weight of α-methylstyrene-acrylonitrile copolymer

[0071] Aluminum silicate fiber (length is 40nm, diameter is 3μm) 20 parts by weight

[0072] 10 parts by weight of isopropyl trioleate acyloxy titanate

[0073] Polyethylene glycol (PEG2000, purchased from Jiangsu Dana Chemical Co., Ltd.) 10 parts by weight

[0074] Hindered amine light stabilizer (CH944, produced by BASF) 1 part by weight

[0075] Ultraviolet absorber 2-hydroxyl-4-n-octyloxybenzophenone 0.5 parts by weight

[0076] Antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol 0.32 parts by weight

[0077] Antioxidant tris(2,4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com