Fluorine-containing metal coating on surface of NdFeB rare-earth permanent magnet and preparation method of fluorine-containing metal coating

A rare-earth permanent magnet and metal coating technology, which is applied to the device for coating liquid on the surface, the coating, and the pre-treated surface, etc., can solve the problem of affecting the anti-corrosion effect of the electroplating layer, the decrease of the bonding force of the electroplating layer, and the easy occurrence of pinholes in the coating And other problems, to achieve the effect of low friction coefficient, improve surface bonding force, improve anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The volume of the NdFeB magnet in this embodiment is 30×30×3mm 3 .

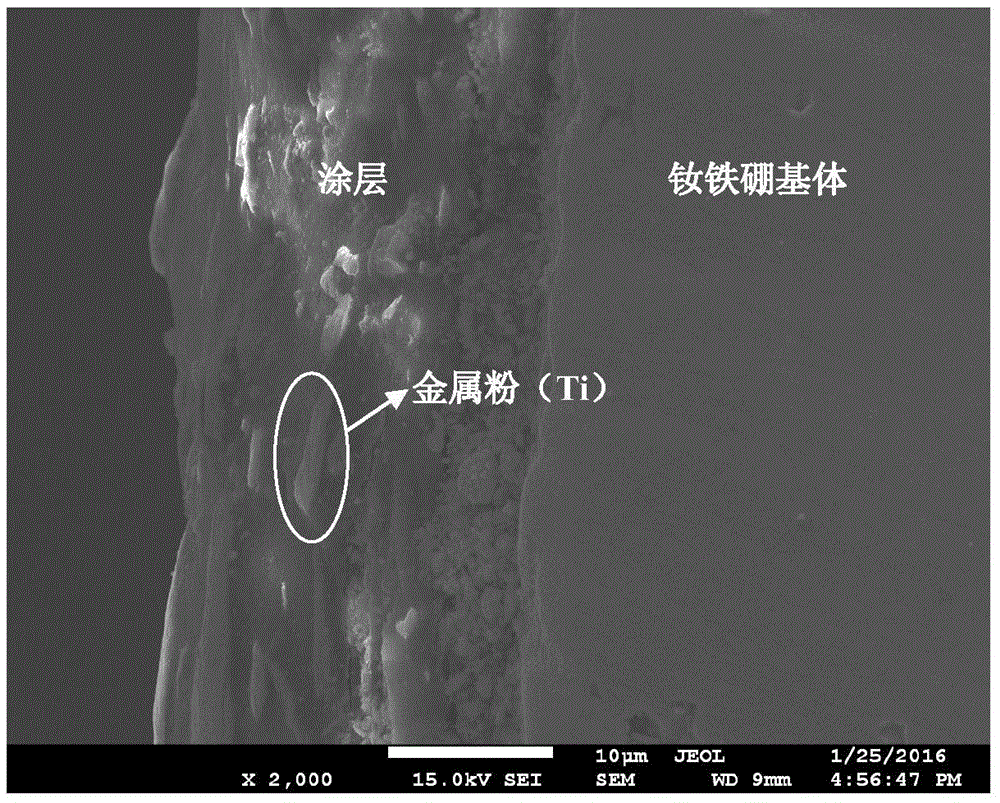

[0040] The fluorine-containing metal coating on the surface of the NdFeB rare earth permanent magnet has a thickness of 20 μm, and the composition is based on the mass ratio, polytetrafluoroethylene: solid powder: binder = 10:25:30; wherein, the particle size of polytetrafluoroethylene is 3-10 μm; the solid powder is Ti powder with a particle size of 1-20 μm; the binder is epoxy resin.

[0041] A method for preparing a fluorine-containing metal coating on the surface of an NdFeB rare earth permanent magnet, comprising the following steps:

[0042] Step 1, surface pretreatment of NdFeB rare earth permanent magnets:

[0043] Use a spray gun to spray sand particles with a particle size of 400 mesh on the surface of the NdFeB rare earth permanent magnet, remove the oxide layer on the surface of the NdFeB rare earth permanent magnet, and expose the fresh off-white surface; wherein, the spray pressure is 15M...

Embodiment 2

[0055] The volume of the NdFeB magnet in this embodiment is 40×20×3mm 3 .

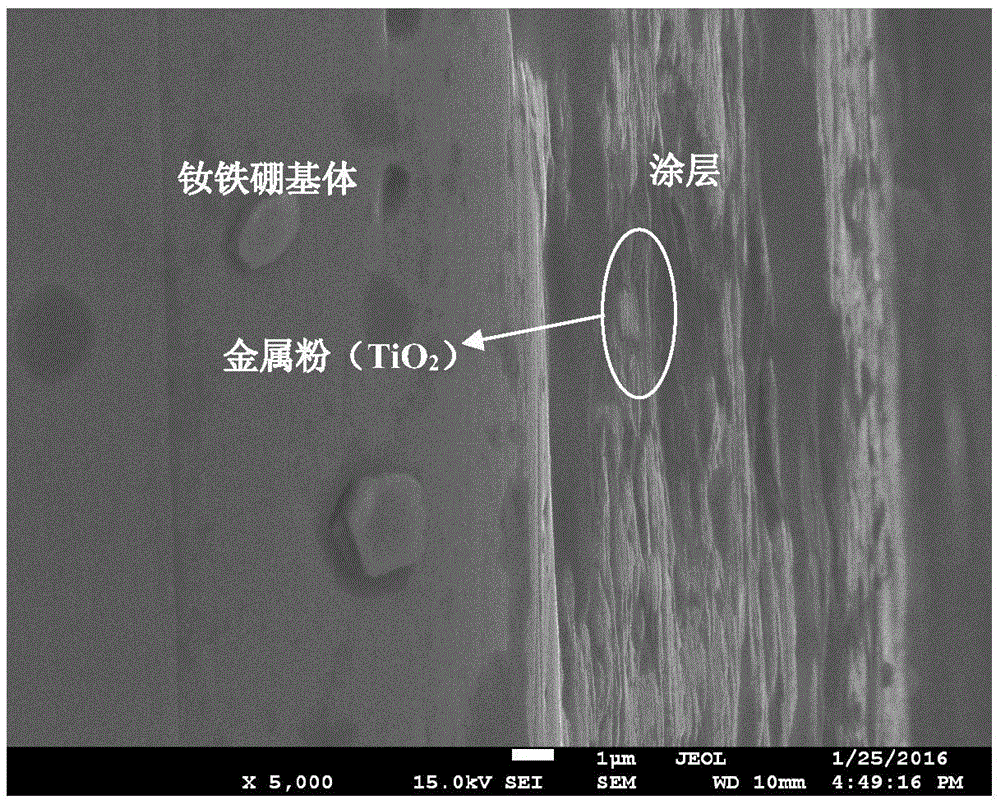

[0056] The fluorine-containing metal coating on the surface of the NdFeB rare earth permanent magnet has a thickness of 5 μm, and the composition is by mass ratio, polytetrafluoroethylene: solid powder: binder = 5: 15: 35; wherein, the particle size of polytetrafluoroethylene is 0.1~5μm; solid powder is TiO 2 powder, the particle size is 10-50μm; the binder is mixed resin P-200.

[0057] A method for preparing a fluorine-containing metal coating on the surface of an NdFeB rare earth permanent magnet, comprising the following steps:

[0058] Step 1, surface pretreatment of NdFeB rare earth permanent magnets:

[0059] Use a spray gun to spray sand particles with a particle size of 1000 mesh on the surface of the NdFeB rare earth permanent magnet, remove the oxide layer on the surface of the NdFeB rare earth permanent magnet, until the fresh gray surface is exposed; wherein, the spray pressure is 1MPa;...

Embodiment 3

[0071] The volume of the NdFeB magnet in this embodiment is 20×20×10mm 3 .

[0072] The fluorine-containing metal coating on the surface of the NdFeB rare earth permanent magnet has a thickness of 20 μm, and the composition is based on the mass ratio, polytetrafluoroethylene: solid powder: binder = 15:30:31; wherein, the particle size of polytetrafluoroethylene is 10-20μm; solid powder composition by mass ratio, Al powder: Zn powder = 1:2, particle size 3-15μm; binder is phenolic resin.

[0073] A method for preparing a fluorine-containing metal coating on the surface of an NdFeB rare earth permanent magnet, comprising the following steps:

[0074] Step 1, surface pretreatment of NdFeB rare earth permanent magnets:

[0075] Use a spray gun to spray sand particles with a particle size of 600 mesh on the surface of the NdFeB rare earth permanent magnet, remove the oxide layer on the surface of the NdFeB rare earth permanent magnet, and expose the fresh off-white surface; where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com