Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

466results about How to "Self-lubricating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

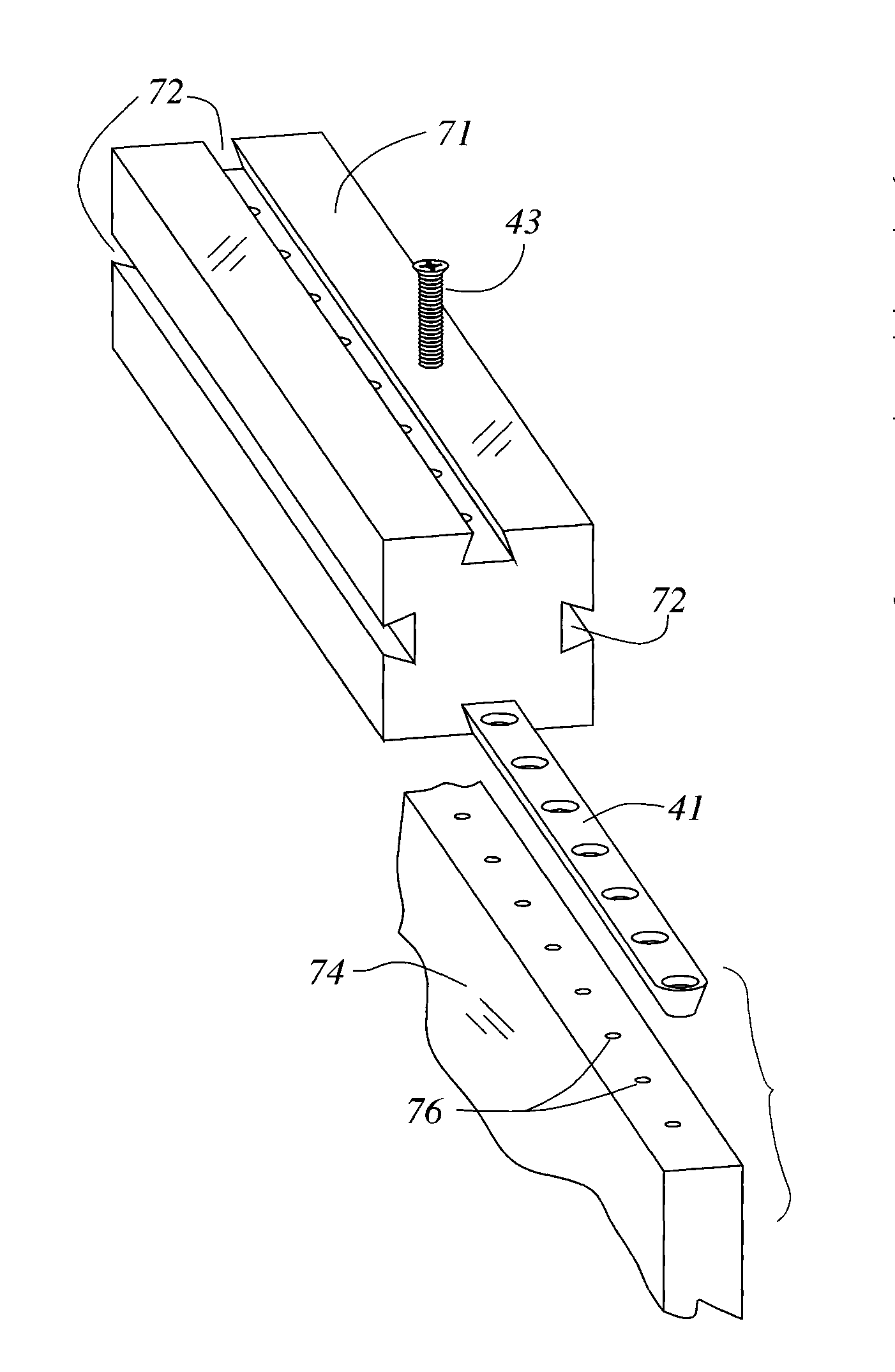

Furniture component joining system

InactiveUS20140294498A1Easy to cutEasy to modifyFurniture joining partsRod connectionsEngineeringMechanical engineering

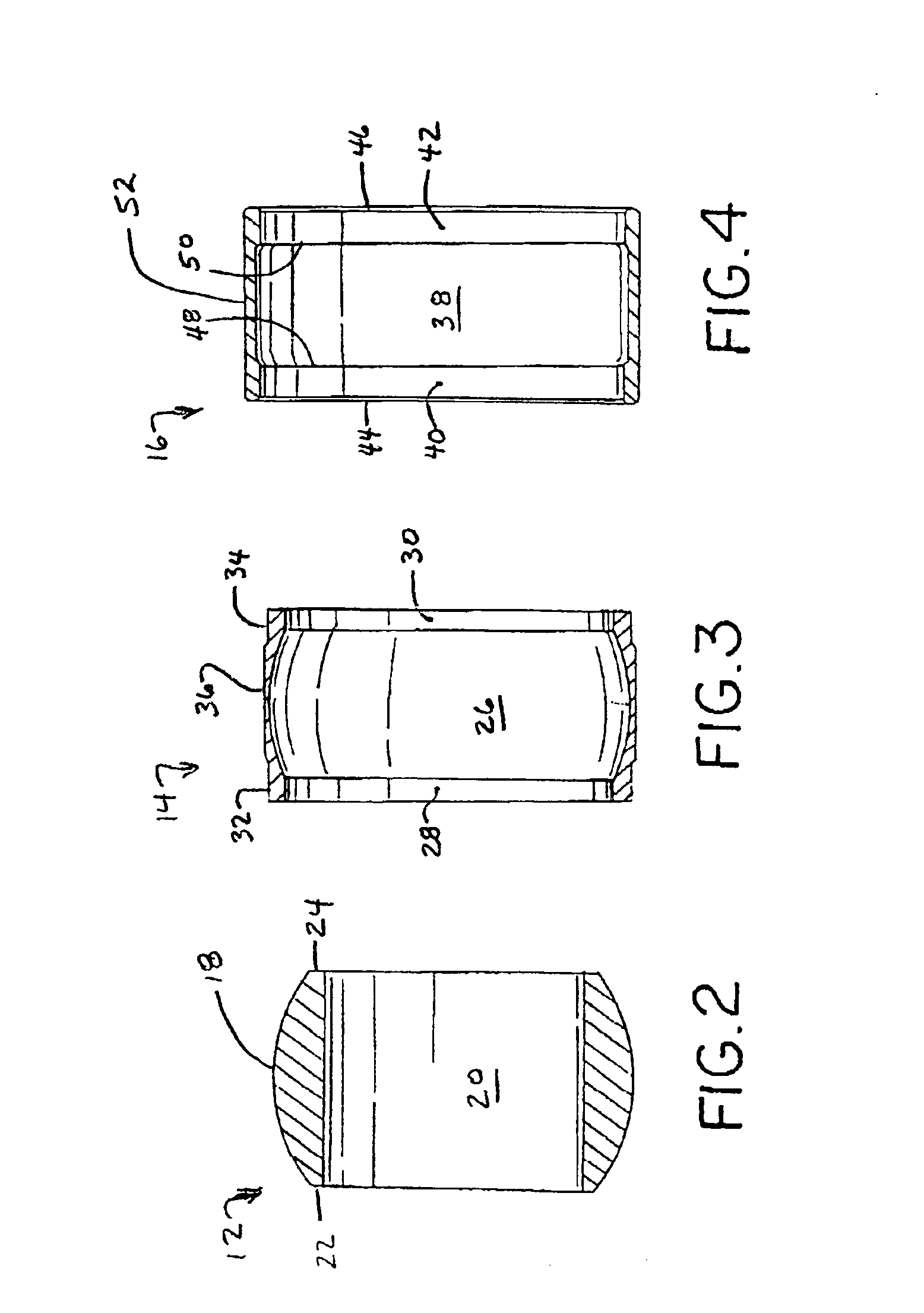

A dovetail joining system for furniture provides hardware components that embody the male and / or female components of the dovetail joint, and these components are secured to structural components using standard screws. Male dovetail fittings have a cross-sectional profile complementary to a dovetail groove, and are secured to furniture components with screws, and range in length from a bar with a large plurality of screw holes, to a short component having a single screw hole. A block fitting comprises a rectangular solid tube with each surface having a female dovetail channel dimensioned to receive a male dovetail fitting. A male right angle dovetail fitting has orthogonal arms, each arm slidably secured in a dovetail channel formed in a separate furniture component.

Owner:LOGAN WILLIAM ROBERT

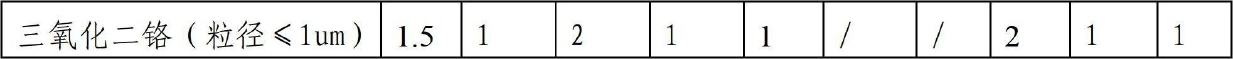

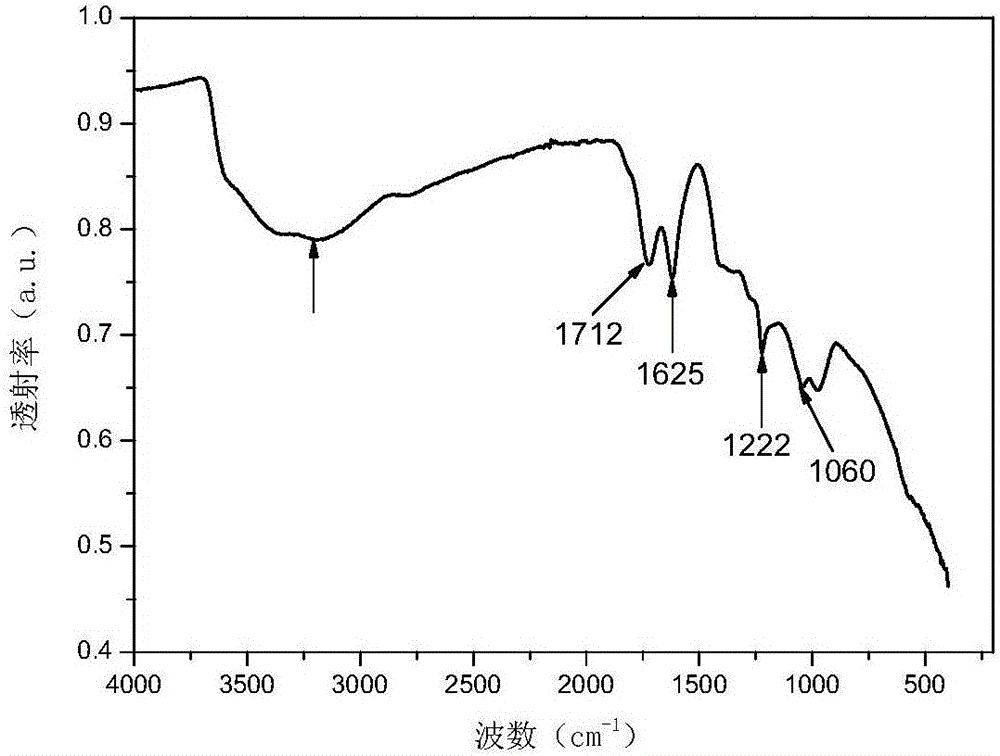

Infrared energy-saving coating with anti-corrosion and anti-coking functions and preparation method thereof

InactiveCN102585571AStress reliefLow shrinkageAnti-corrosive paintsInorganic adhesivesBoron nitrideManganese(III) oxide

The invention relates to an infrared energy-saving coating with anti-corrosion and anti-coking functions, which is prepared from a component A and a component B according to the weight ratio of 1: 1-2. The particle size of powder materials in the component A is not less than 280 meshes and the component A is prepared from the following powder materials according to the weight ratio: 40-60 parts of spinel structure infrared composite darkening agent, 10-30 parts of corundum powder and 3-10 parts of high-temperature binding agent. The component A further comprises an anti-coking agent, and the anti-coking agent is prepared from the following powder materials according to the weight ratio: 3-10 parts of graphite, 0-10 parts of boron nitride and 1-5 parts of manganese sesquioxide. The component B is of a film-forming substance and prepared from the following raw materials according to the weight ratio: 60-80 parts of water glass, 10-30 parts of silica sol and 0-20 parts of water-borne resin solution. The invention further discloses a preparation method of the coating. The coating provided by the invention has the advantages: corrosion prevention, capability of reducing coking, high temperature resistance and excellent infrared radiation performance.

Owner:KING STRONG MATERIAL ENG LTD

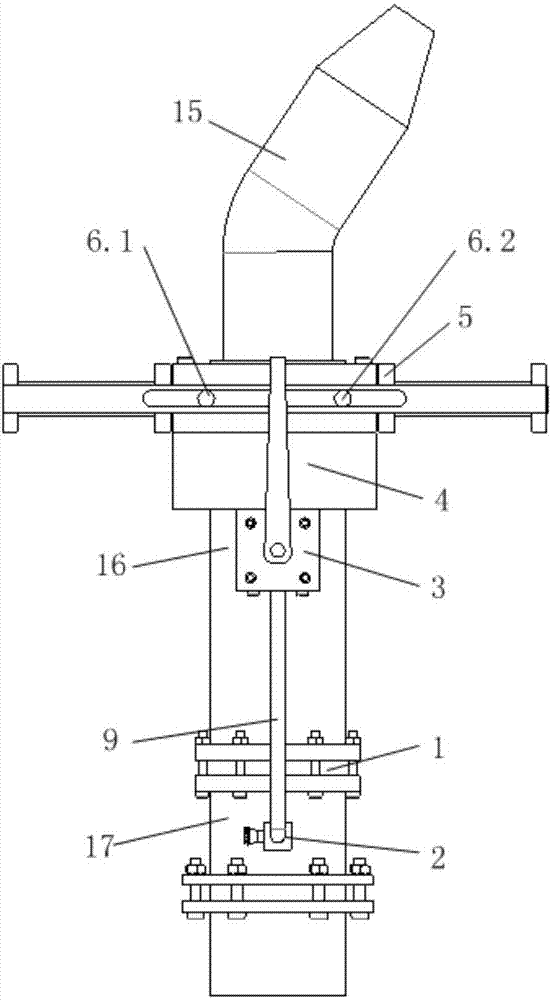

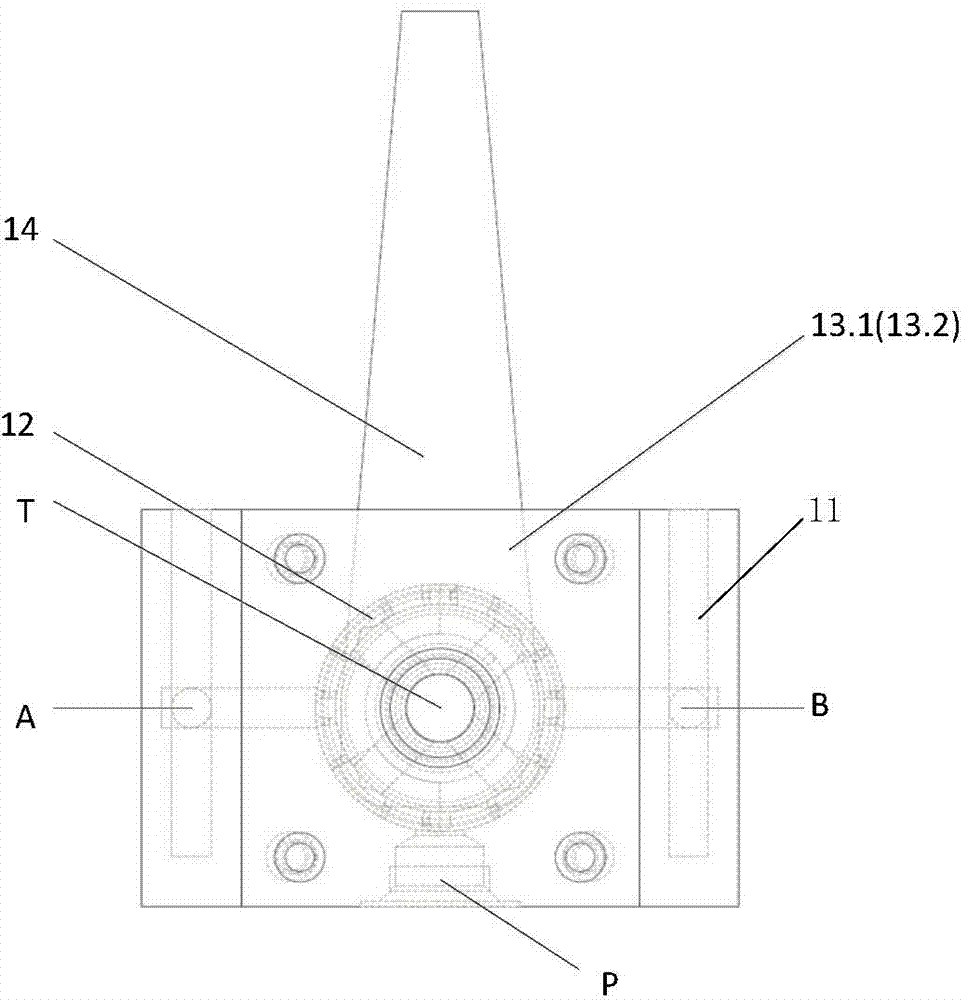

Watering spray gun with automatically rotating shower nozzle

InactiveCN104841582AImprove securityWide range of applicationsMovable spraying apparatusReversing valveShower

The invention discloses a watering spray gun with an automatically rotating shower nozzle. The watering spray gun with the automatically rotating shower nozzle comprises an upper spray gun body, a lower spray gun body, a throttling device, a speed regulating device, a steering device and the shower nozzle; the lower spray gun body is connected through the throttling device; one end of the speed regulating device is connected to the lower spray gun body through one end of a pipeline and the other end of the speed regulating device is connected to a P opening of the reversing valve through a water inlet pipe; the reversing device which is installed on the upper spray gun body comprises a water inlet pipe, a reversing valve, a valve block, a hydraulic cylinder, a reversing blocking block, a rack and a pinion; a first reversing blocking block and a second reversing blocking block are installed on the valve block; the end portion of a shifting rod of the reversing valve is arranged between the first reversing blocking block and the second reversing blocking block; the nozzle is installed on the upper spray gun body through a bearing. According to the watering spray gun with the automatically rotating shower nozzle, an electric element is avoided, the safety is high, and application occasions are wide; the valve block which is adopted plays a role as a pipeline for flowing between the reversing valve and the hydraulic cylinder, the hydraulic pipeline is simplified, and the device structure is compact.

Owner:YANSHAN UNIV

Refractory far infrared radiation ceramics coating

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

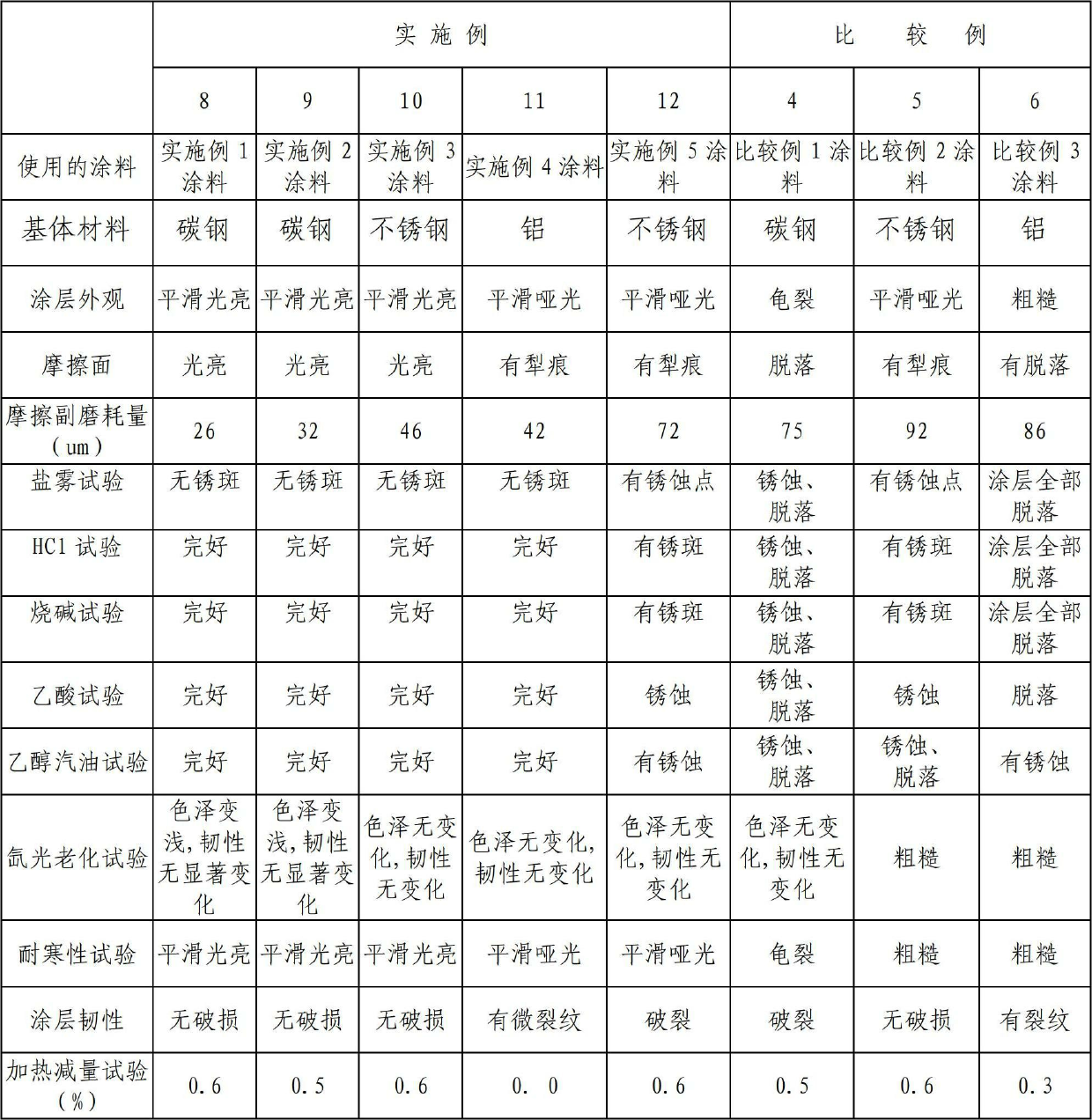

Modified polyphenylene sulfide coating and application thereof

ActiveCN102676048AImprove corrosion resistanceSelf-lubricatingAnti-corrosive paintsWear resistantCorrosion

The invention discloses a modified polyphenylene sulfide coating and the application thereof. The modified polyphenylene sulfide coating consists of the following components by weight percentage: 60-90 percent of polyphenylene sulfide resin, 3-25 percent of poly-perfluorinated ethylene propylene resin, 3-20 percent of ethylene-tetrafluoroethylene copolymer resin, 1-5 percent of molybdenum disulfide, 1-5 percent of graphite and the balance of filler, wherein the filler is any one of or a mixture of zinc oxide, aluminum oxide, silicon carbide and chromium sesquioxide. The modified polyphenylene sulfide coating disclosed by the invention has the advantages that the compatibility among the components is good; a prepared coating layer has higher corrosion resistance, higher self-lubricity and strong wear-resistant ability, is resistant to high temperature, is highly insulated, has good toughness, can bear impact force capable of being borne by a metal surface, has excellent bond performance with a metal material and is particularly suitable for the using and working condition of cold / hot sudden changes which cannot be borne by glass lining equipment; and through spraying the coating disclosed by the invention on the surface of the metal matrix material, a manufactured work piece has excellent physical-chemical performance, a long service life and a wide application range.

Owner:CHENGDU LETIAN PLASTICS

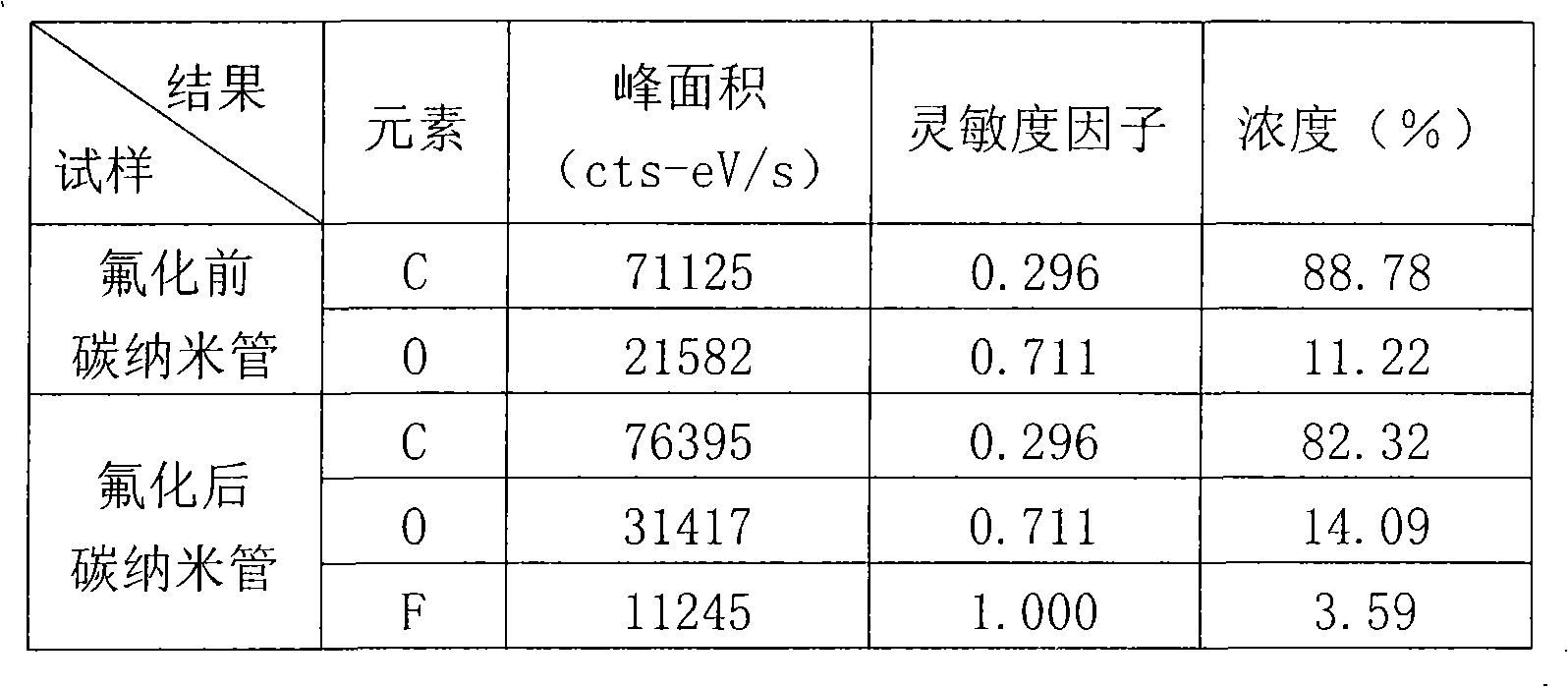

Carbon fluoride nanotube and method for making same

InactiveCN101284659AImprove securityExtended service lifeNanostructure manufacturePolyvinylidene fluorideMuffle furnace

The invention relates to a perfluorocarbon nanotube and a preparation method thereof. The method is technically characterized in that the nanotube and organic fluorine are mechanically ground, fully and evenly mixed, then placed in a reactor, sealed and then immediately put into a muffle furnace; the heating temperature is maintained at 100 to 600 DEG C; the heating is stopped after the reaction time for 1 to 10 hours; then the reactor is opened after being cooled to the room temperature; and then the perfluorocarbon nanotube is obtained after grinding. The nanotube is a multi-walled carbon nanotube or a single-walled carbon nanotube. The organic fluoride is the organic fluoride of solid powders or liquids such as polyfluortetraethylene, fluorinated ethylene propylene, polyvinylidene fluoride, ethylene-tetrafluoroethylene copolymer, tetrafluoroethylene and perfluoroalkyl vinyl ether copolymer, dodecafluoroheptyl heptanol or derivants of dodecafluoroheptyl heptanol. The method overcomes the shortcomings of low safety, short apparatus service life and high product cost of the prior fluorization methods, and has the advantages of long service life, simple process, low production cost and no pollution, so as to be suitable for mass production.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

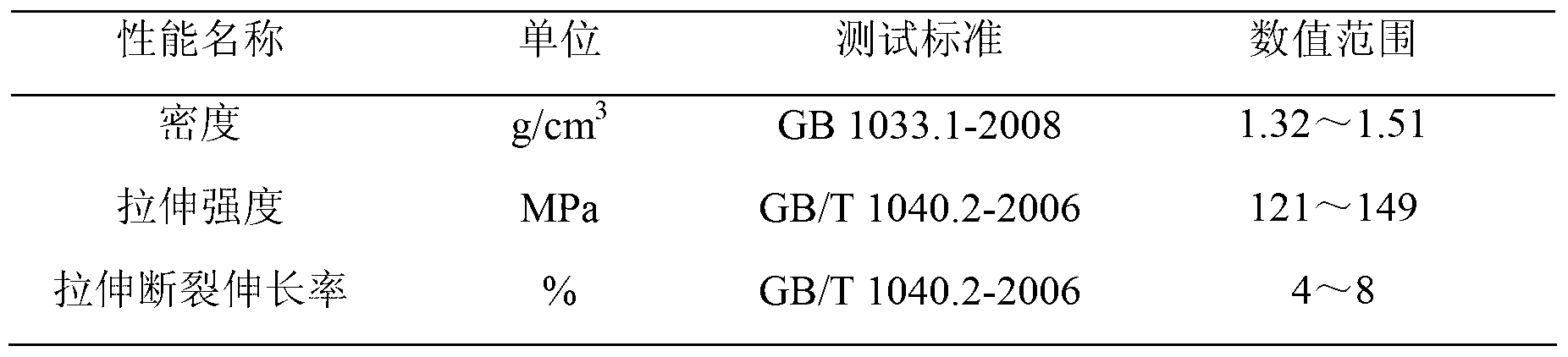

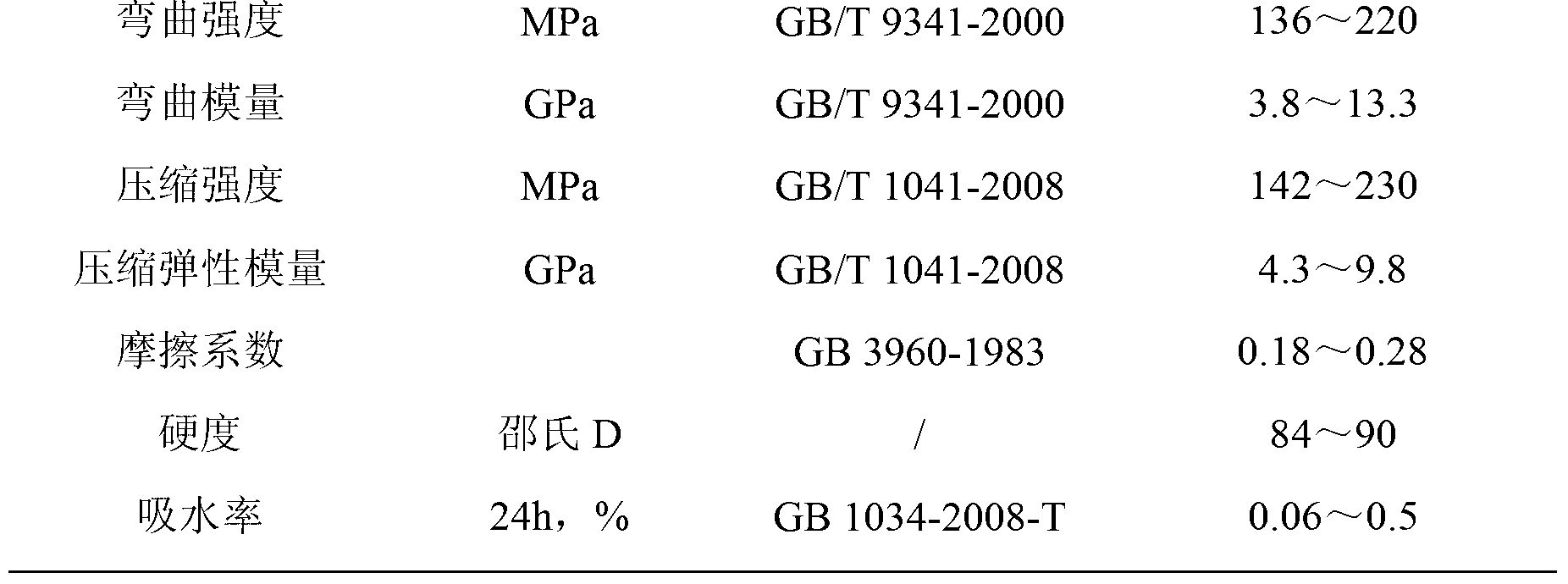

Wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material

The invention discloses a wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material. The poly (ether-ether-ketone) composite material comprises the following raw materials in parts by weight: 71-83 parts by weight of poly (ether-ether-ketone) resin, 5-10 parts by weight of suspension polytetrafluoroethylene resin, 7-12 parts by weight of carbon fiber powder and 5-7 parts by weight of aluminum oxide powder, as well as a silane coupling agent with the adding quantity of 0.8-1.5% of the weight of the aluminum oxide powder. The poly (ether-ether-ketone) composite material disclosed by the invention has the performance characteristics of wear resistance, high strength, self-lubrication, light weight, corrosion resistance and the like, is used for replacing a hard alloy and a metal framework to assemble a novel sliding bearing, effectively reduces the cost and weight of a bearing product (the weight is reduced by 30%) under the situation of meeting the requirements for service life, and can obviously reduce the power consumption and noise of a pump and achieve the purposes of saving energy and reducing consumption.

Owner:HEFEI GENERAL MACHINERY RES INST

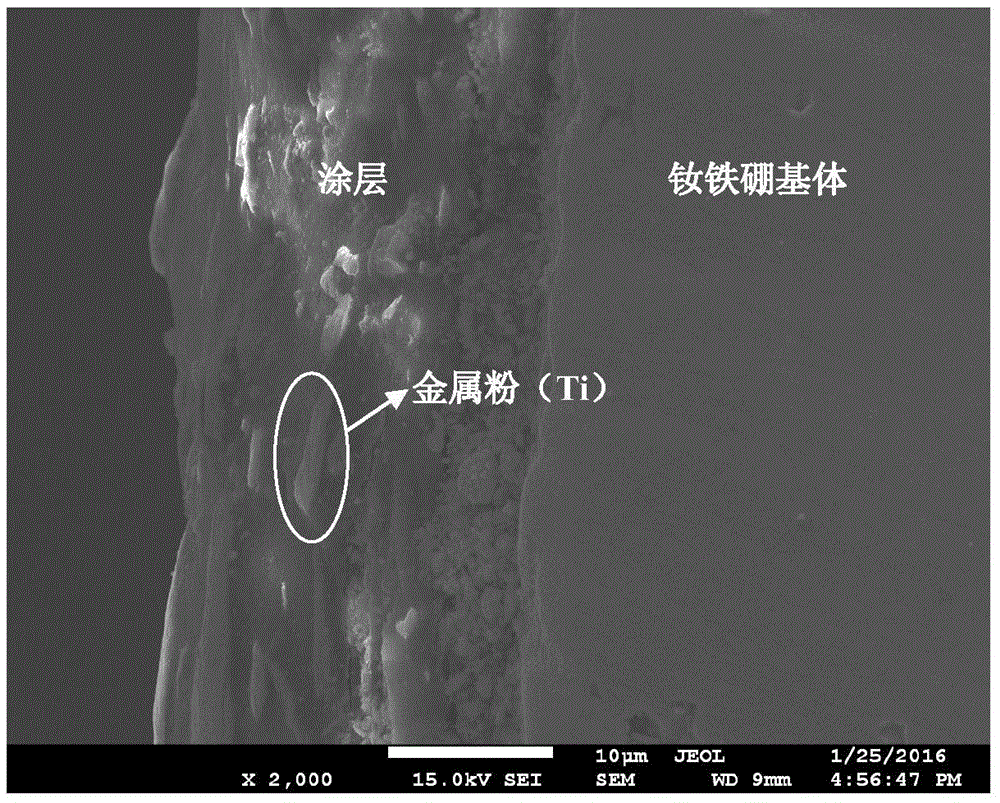

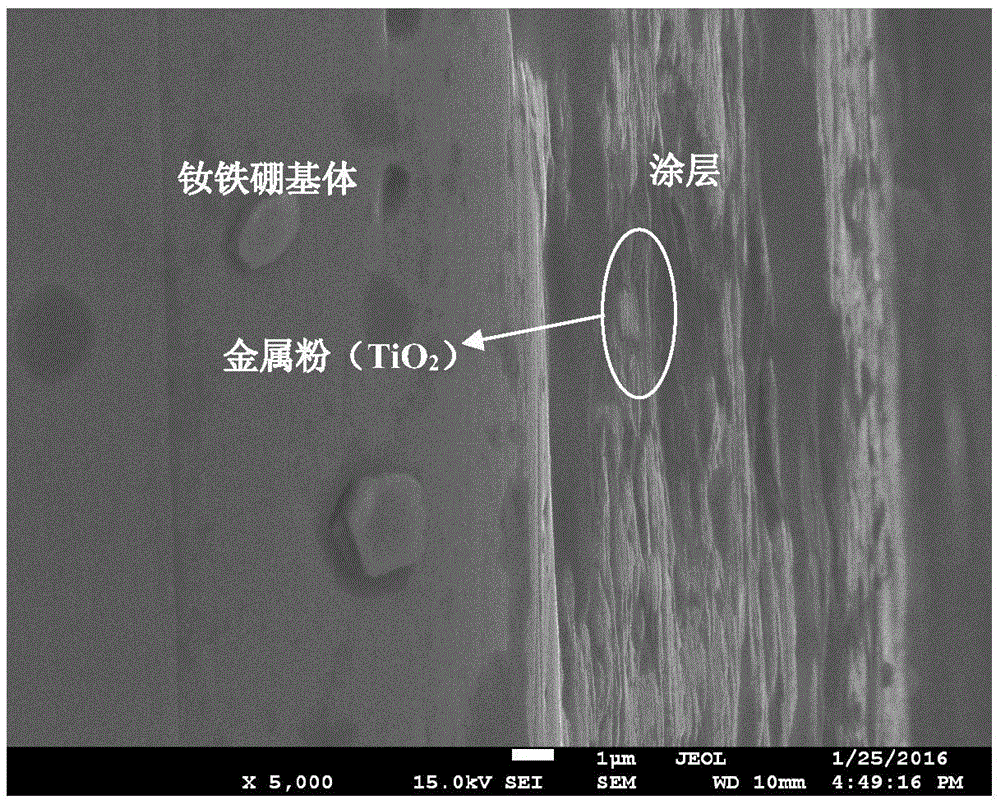

Fluorine-containing metal coating on surface of NdFeB rare-earth permanent magnet and preparation method of fluorine-containing metal coating

The invention discloses a fluorine-containing metal coating on the surface of an NdFeB rare-earth permanent magnet and a preparation method of the fluorine-containing metal coating, and belongs to the technical field of anticorrosion surface treatment. The fluorine-containing metal coating has the thickness of 5-40 microns and is prepared from polytetrafluoroethylene, solid powder and adhesive according to the mass ratio of (1-30):(2-30):(20-40). The preparation method includes the steps of firstly, preprocessing the surface of the NdFeB rare-earth permanent magnet through an oil removal and acid pickling or sand blasting method; secondly, preparing the coating through a centrifugal soaking and throwing or spraying method. Polytetrafluoroethylene contained in paint for preparing the coating has excellent corrosion resistance, and the corrosion resistant capacity of the surface of the NdFeB rare-earth permanent magnet can be improved; in the coating process, no acid bath is used, the fresh surface of the magnet is not damaged after preprocessing, and the surface adhesion force between the coating and the magnet can be effectively improved; no acid waste liquid exists, the environment is not polluted, and the preparation method belongs to the green and environment-friendly coating process.

Owner:NORTHEASTERN UNIV

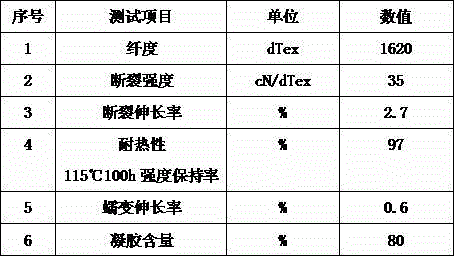

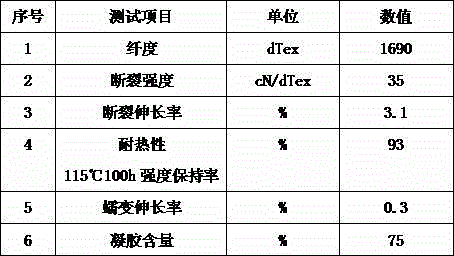

Heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber and preparation method thereof

InactiveCN104695038AHeat resistantHeat resistance and creep resistance haveMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCross-link

The invention discloses a heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The fiber comprises ultra-high molecular weight polyethylene powder, graphene, a cross-linking agent, a curing agent, an initiator and an anti-oxidant. The preparation method comprises the following steps: swelling the ultra-high molecular weight polyethylene powder by a solvent so as to form pores; then adding a composite modifying agent wetted by the cross-linking agent, the curing agent, the initiator, the anti-oxidant, the graphene and the solvent together; penetrating the composite modifying agent evenly into the ultra-high molecular weight polyethylene powder pores, and mixing evenly; and finally, carrying out irradiation crosslinking to obtain the heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber. The heat-resisting creep-resisting ultra-high molecular weight polyethylene constant-strength fiber has the comprehensive performances of heat resistance, creep resistance, abrasion resistance, impact resistance, self lubrication, corrosion resistance, low temperature resistance, hygiene, no toxicity, difficulty in adhesion and water absorption and relatively low density, is wide in applicability, and is long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

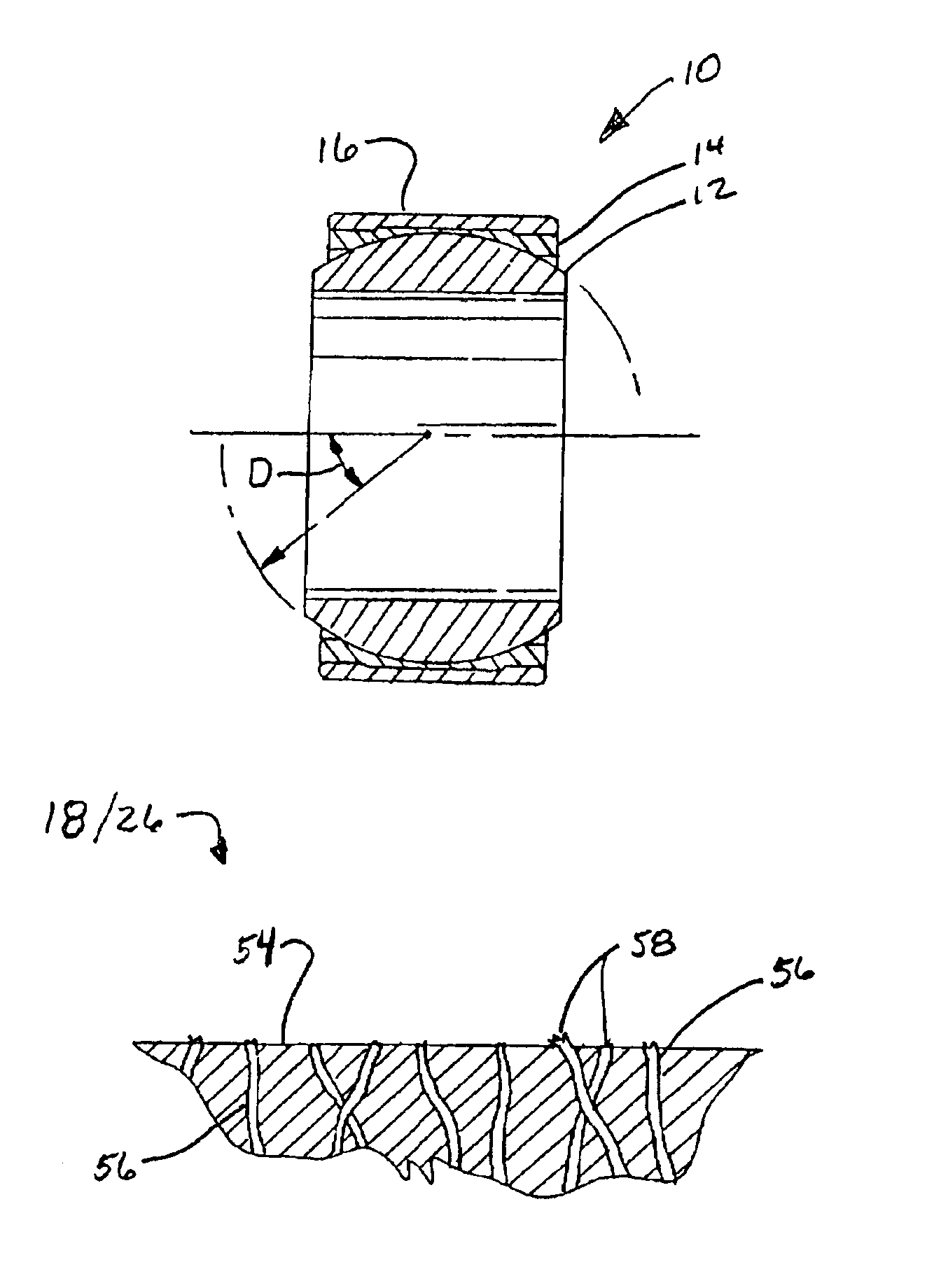

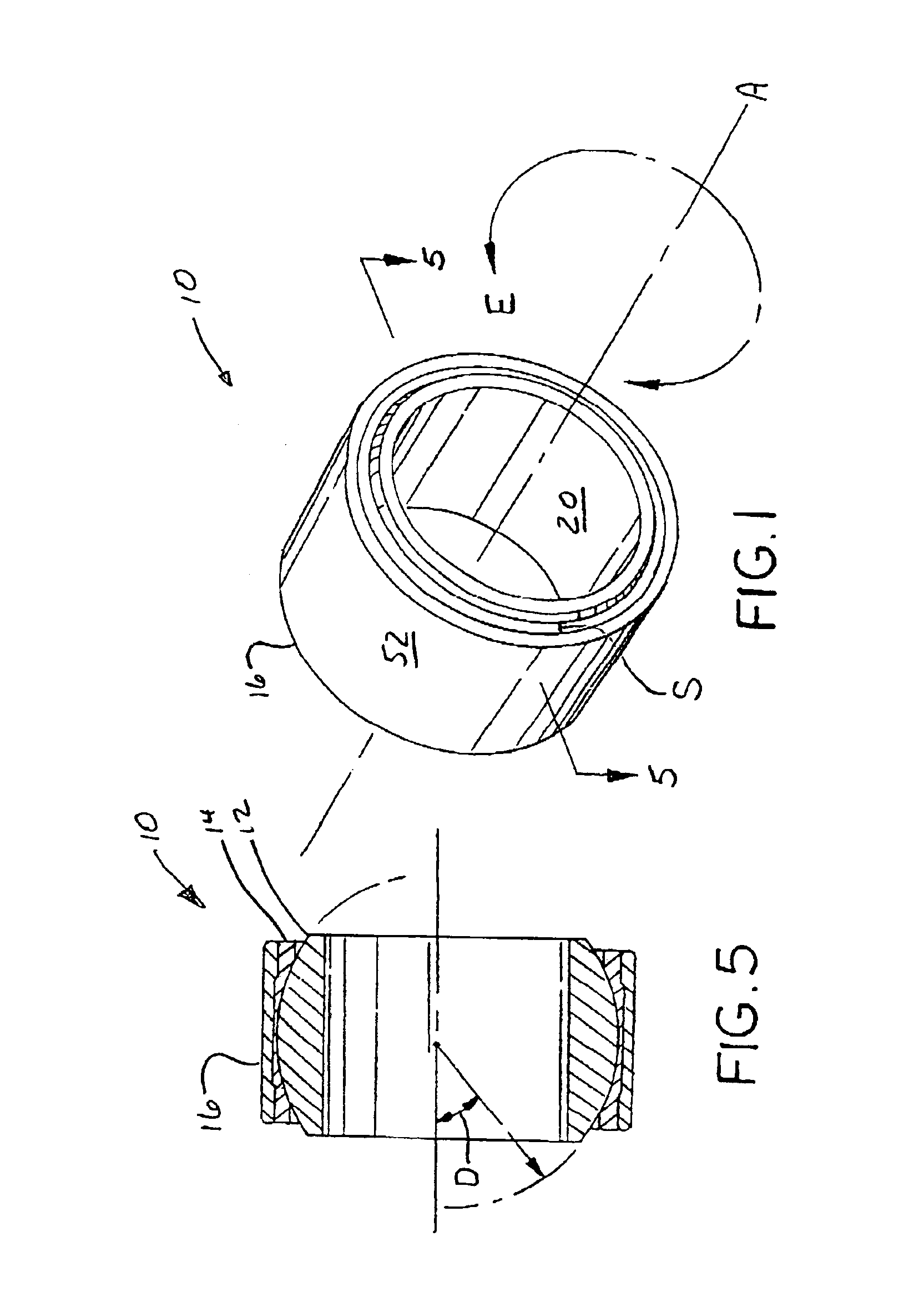

Spherical bearing

A spherical bearing including a generally annular first portion having at least a partial substantially spherical outer surface and a generally annular second portion having at least a partial substantially concave surface, the outer surface at least partially engaging the concave surface, at least one of the outer surface and the concave surface having a plurality of frayed polytetraflouroethylene fibers exposed therefrom.

Owner:POLYGON

Waterproof high-hardness waterborne polyurethane coating

InactiveCN104312411AImprove thermal stabilityHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesCarbon nanotube

The invention discloses a waterproof high-hardness waterborne polyurethane coating which is characterized by comprising the following components in parts by weight: 65-80 parts of modified waterborne polyurethane, 20-35 parts of waterborne polyaniline, 3-6 parts of polyisocyanate, 5-20 parts of nano-silica, 3-9 parts of isopropanol, 5-10 parts of ethylene glycol propyl ether, 0.5-1.6 parts of dipentaerythritol, 15-20 parts of polydimethylsiloxane, 3-8 parts of gamma-isocyanate propyl triethoxy silane, 3-8 parts of polytetrafluoroethylene, 0.5-3 parts of modified carbon nanotubes, 5-20 parts of precipitated barium sulphate, 2-6 parts of amino resin, 3-8 parts of zinc powder and 30-60 parts of water. The waterproof high-hardness waterborne polyurethane coating is good in water resistance, high in harness and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Preparation method for high-strength high-density isotropic impregnation silver carbon/graphite composite material

InactiveCN105215331AExcellent electrochemical resistanceImprove corrosion resistanceEnergy inputHigh intensityHigh density

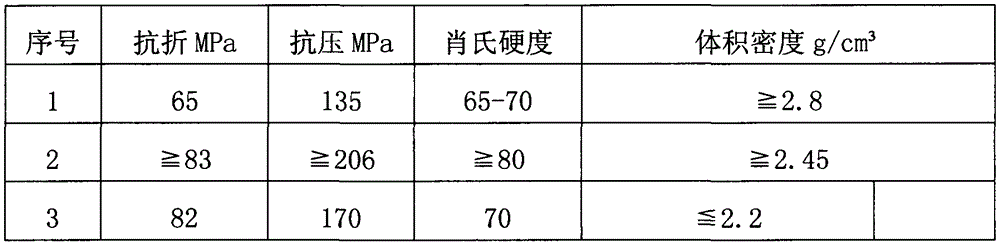

The invention provides a preparation method for a high-strength high-density isotropic impregnation silver carbon / graphite composite material and is aimed at providing a preparation method for a stable high-strength long-service-life carbon graphite material. According to the technical scheme, firstly, a carbon graphite substrate material matched with impregnation silver is prefabricated, and an isotropic graphite material substrate is prepared through an isostatic pressing forming method; then the isotropic graphite material substrate reaches performance parameters matched with an impregnation silver process through continuous impregnation, roasting, impregnation angle changing and other processes; and afterwards silver is impregnated under the circumstances of high temperature and high pressure, so that the silver penetrates the network structure of the carbon graphite substrate, and the high-strength long-service-life carbon graphite / silver composite material with carbon graphite as the substrate is formed. According to the preparation method, the mechanical strength of the carbon graphite / silver composite material can be significantly improved; the carbon graphite / silver composite material is good in friction coefficient, thermal conductivity, radiation resistance and low in abrasion loss, and the requirement for the service life of the material above 60 years is met.

Owner:CHENGDU ZHONGCHAO CARBON SCI & TECH

Self-lubricating wear-resistant eutectic graphitic steel and preparation method thereof

The invention discloses self-lubricating wear-resistant eutectic graphitic steel and a preparation method thereof, and relates to the field of ferrous materials. The eutectic graphitic steel is different from ordinary isothermal quenching nodular cast iron in the preparation method, graphite shape and engineering service response behavior. Sectionoal materials are drawn through a continuous casting method with the rapid cooling ability, the composition of molten iron is strictly controlled at the eutectic point, and thus eutectic graphite nodules with the spheroidization rate of 100% are obtained; in addition, the fine graphite nodules are in dispersed distribution, the peripheries of the graphite nodules are coated with layers of amorphous mechanical impurities, impurity elements in the molten iron are collected, and the grain boundary of a matrix is purified; and tiny high-frequency elastic deformation of the materials in service can appear rings of 'strain aging and heat aging' softening structures around the graphite nodules, initiation of fatigue cracks is effectively inhibited, and the fatigue life is prolonged. In summary, the eutectic graphite steel has excellent mechanicalperformance of quenched steel and physical properties of self-lubrication, sound absorption and noise reduction, shock absorption and friction reduction of cast iron materials.

Owner:XIAN UNIV OF TECH

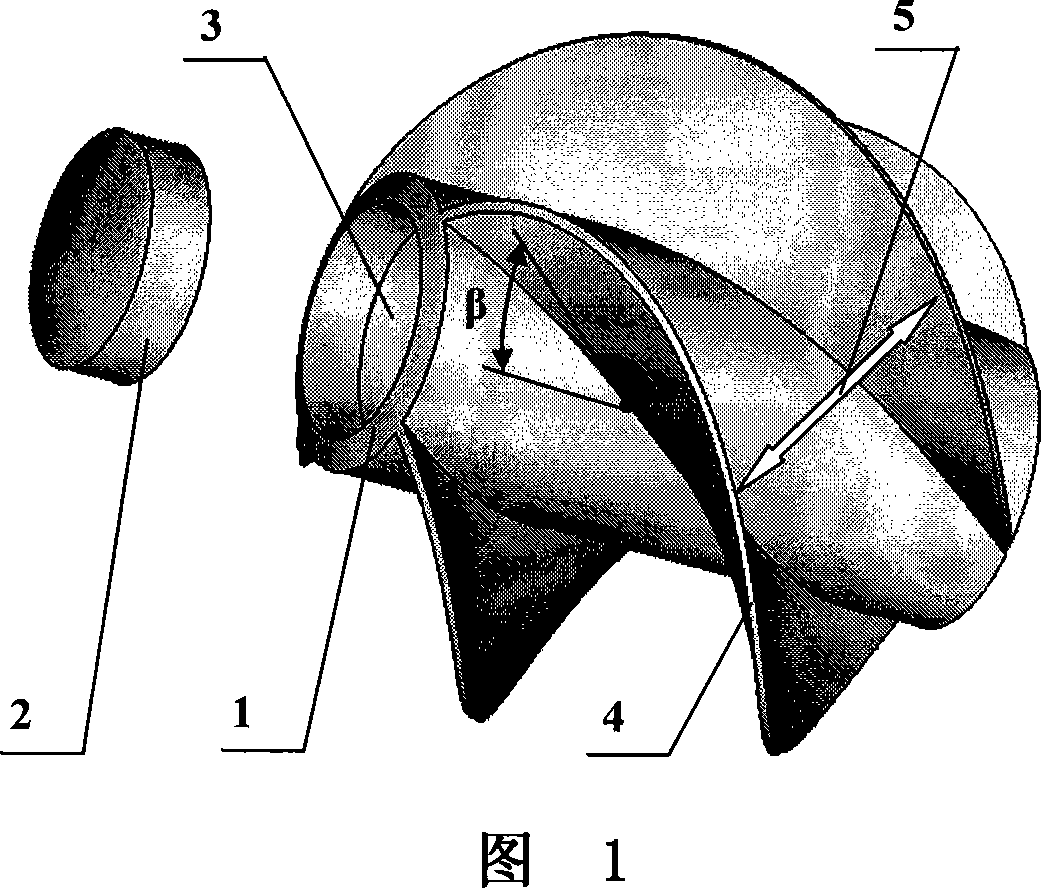

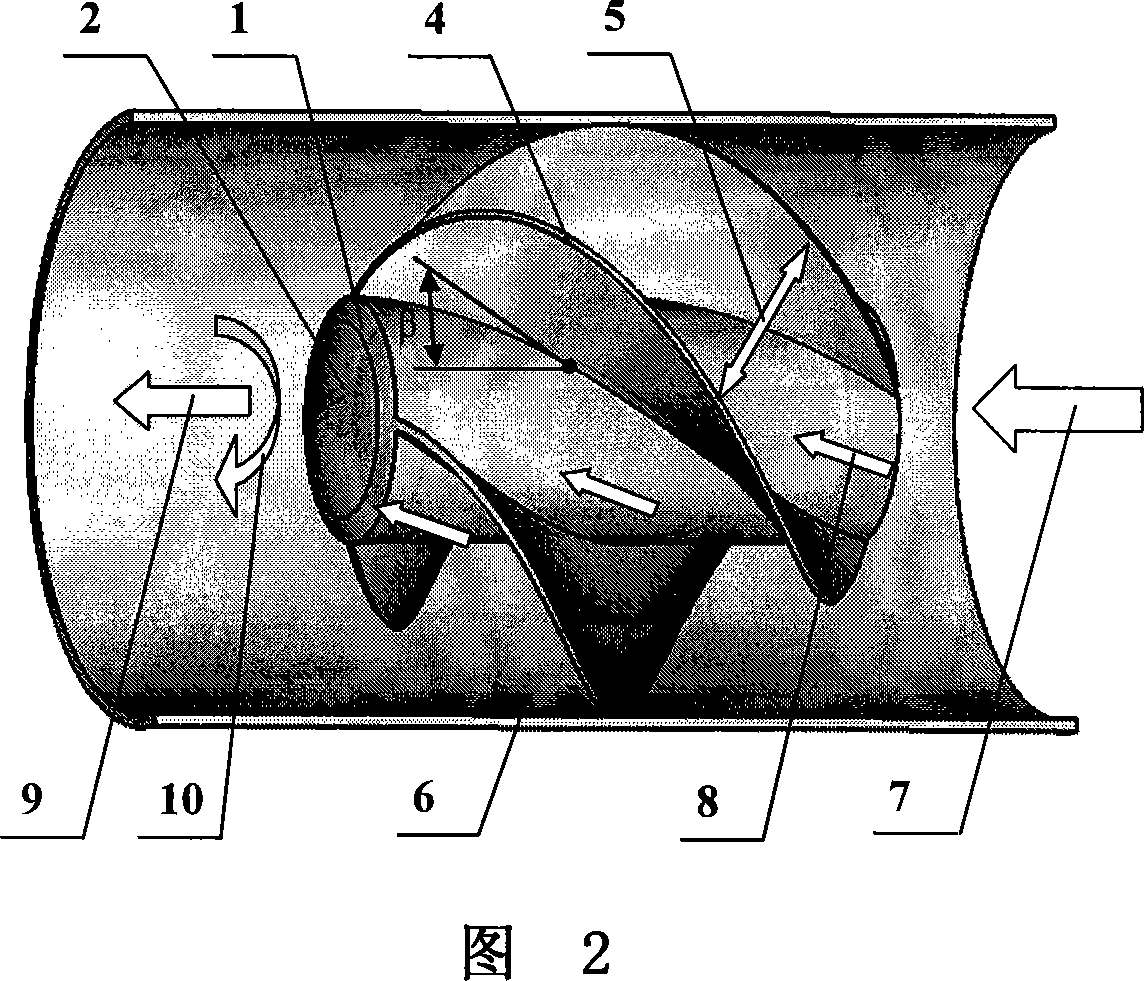

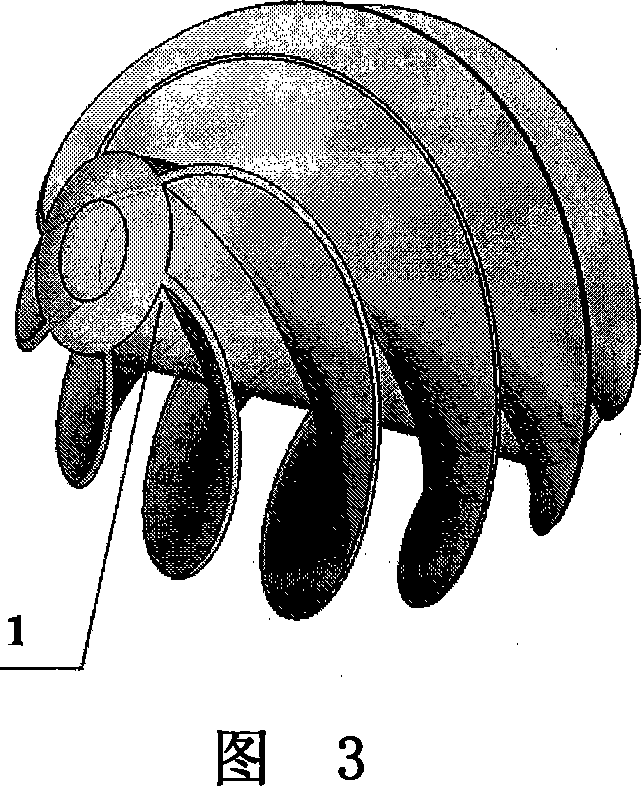

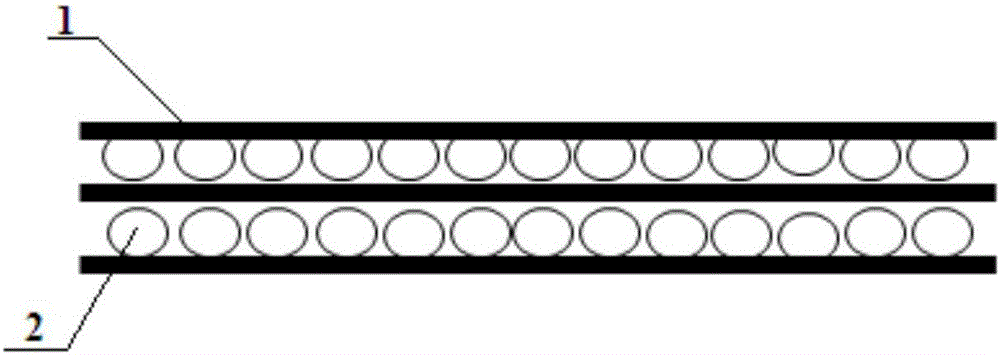

Member for online cleaning and removing scale of heat exchange tube

The invention discloses an element that heat exchange tube cleans and releases contaminant; it is characterized in that it includes a global element which has some. Roundness space of global element are separated by screwing or inclining heave to form the flow passages; The change of the global element's external diameter due to immergence is smaller than 2%, The of due to immergence is smaller than 5%, the error of the global element's density and transporting fluid's density is smaller than 10%. The most biggest outer contour of the element cleaning and releasing contaminant appears spherical or elliptical or appears approximate, possesses flow passages screwing or inclining to a rotating axis, when fluid flows in the flow passage, it drives the global element at liberty in the heat exchange tube prepared for cleaning and releasing contaminant. Therefore it has the characteristics in that the cleanout is effectual, flowing resistance is small and not apt to jam the heat exchange tube.

Owner:TSINGHUA UNIV

Modified ultra-high molecular weight polyethylene resin

The invention discloses a production formula and a manufacturing method of a modified ultra-high molecular weight polyethylene resin. The modified ultra-high molecular weight polyethylene resin comprises an ultra-high molecular weight polyethylene resin, molybdenum disulfide, nano graphite, superfine talcum powder, ethylene bis stearamide, polytetrafluoroethylene and benzoyl peroxide. The modified ultra-high molecular weight polyethylene resin has ultra high wear resistance and favorable temperature tolerance and self-lubricating property. Compared with the resin before the modification, the modified resin has the advantages that the heat distortion temperature is increased by 38 DEG C, the Shore hardness is improved by 20 degrees, the friction factor is decreased by 40%, and the expansion factor is decreased by 30%. The modified resin is widely used for producing products such as gears, valves, artificial joints, skis, oil field transfer pipelines and the like.

Owner:王崇高

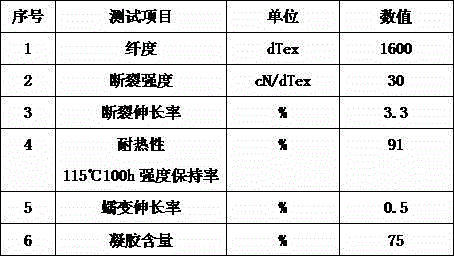

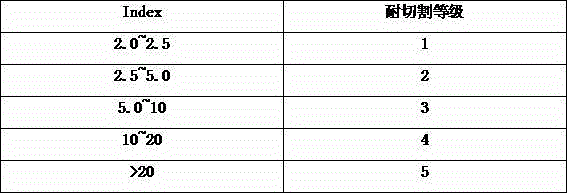

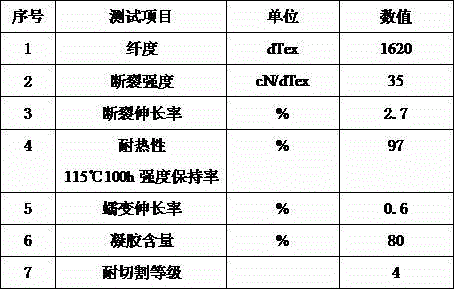

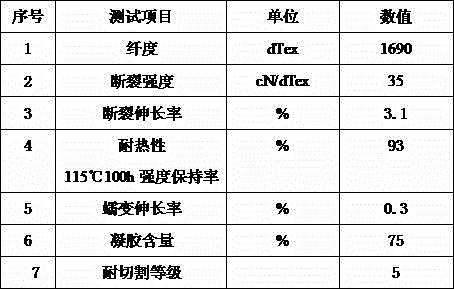

Thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber and preparation method thereof

InactiveCN104695039AHeat resistantHeat and cut resistant withPhysical treatmentMonocomponent polyolefin artificial filamentFiberCross-link

The invention discloses a thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber which comprises ultra-high molecular weight polyethylene powder, inorganic nanoparticles, a cross-linking agent, a curing agent, an initiator and an antioxidant. The preparation method of the thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber comprises the following steps: swelling the ultra-high molecular weight polyethylene powder by using a solvent to form pores, adding a composite modifier formed by common infiltration of the cross-linking agent, the curing agent, the initiator, the antioxidant, the inorganic nanoparticles and the solvent are moistened by one another, enabling the components to uniformly permeate into the pores of the ultra-high molecular weight polyethylene powder, uniformly mixing, extruding and spinning through a screw extruder, removing the solvent, drawing so as to obtain the ultra-high molecular weight polyethylene fiber, and finally performing irradiation crosslinking, thereby obtaining the thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber. The thermal-resistant anti-cutting ultra-high molecular weight polyethylene fiber is wide in application and long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

Fluoro polymer synergistic coating treatment process for iron and steel material

InactiveCN1616713AGood bindingGood wear resistanceHot-dipping/immersion processesMolten spray coatingNickel coatingHardness

The iron and steel material treating process with synergistic fluoropolymer coating features the first chemical nickel plating of iron and steel material to form the base layer of the synergistic coating, the subsequent pore creating treatment of the nickel coating, the introducing of fluoropolymer to the pores and surface and the heat treatment under vacuum state for the fluoropolymer to fuse with the chemical coating to form the synergistic coating. The said technological process has the advantages of high coating hardness, high wear resistance, the self-lubricating performance and increased wear resistance caused by the fluoropolymer as friction reducing matter, resistance to most harmful matters of the fluoropolymer, and self-lubricating function of the dry coating.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

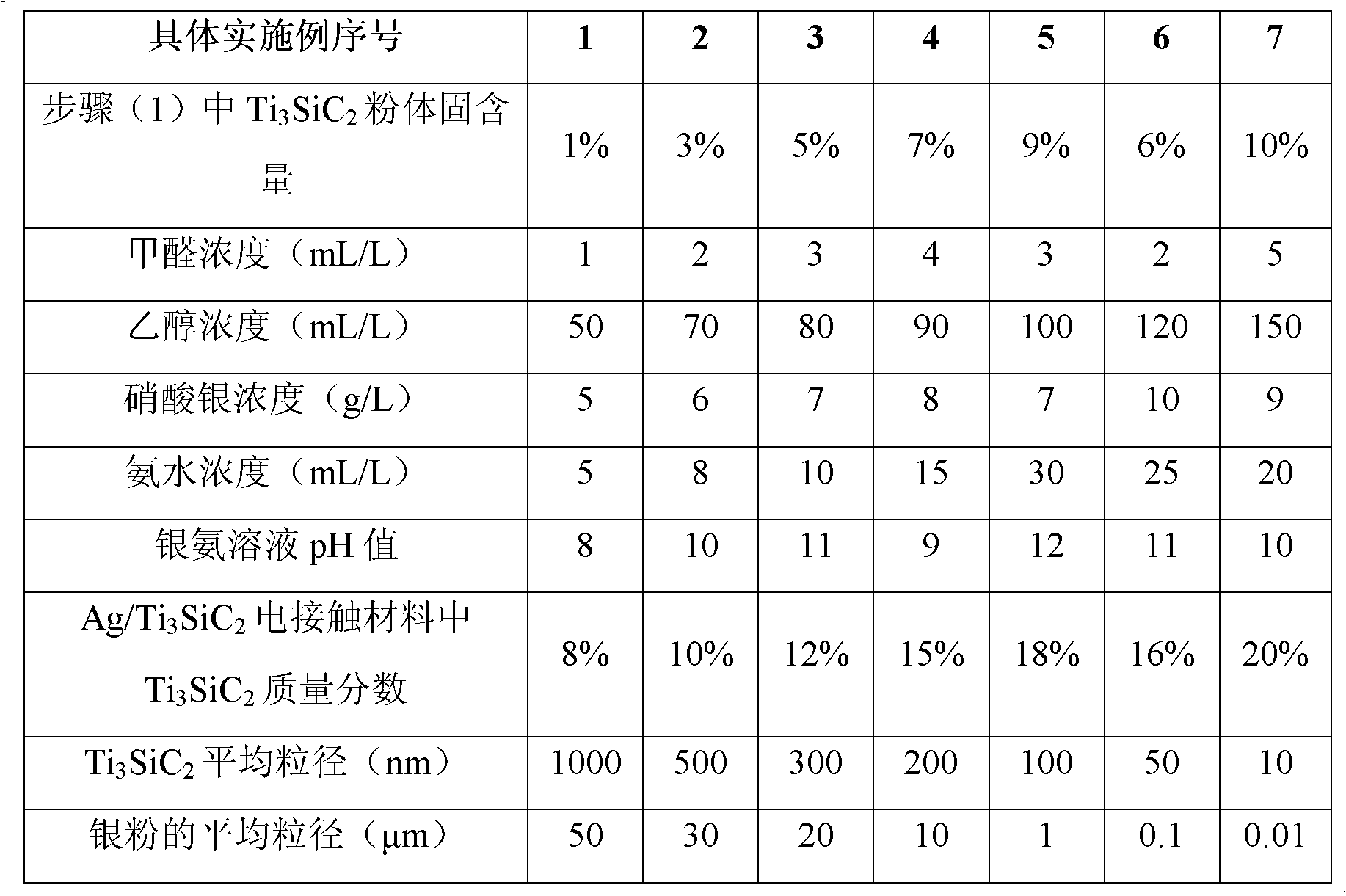

Preparation method of Ag / Ti3SiC2 electric contact composite material

InactiveCN102312150AImprove wettabilityHigh thermal conductivity at room temperatureContactsAlcoholDistilled water

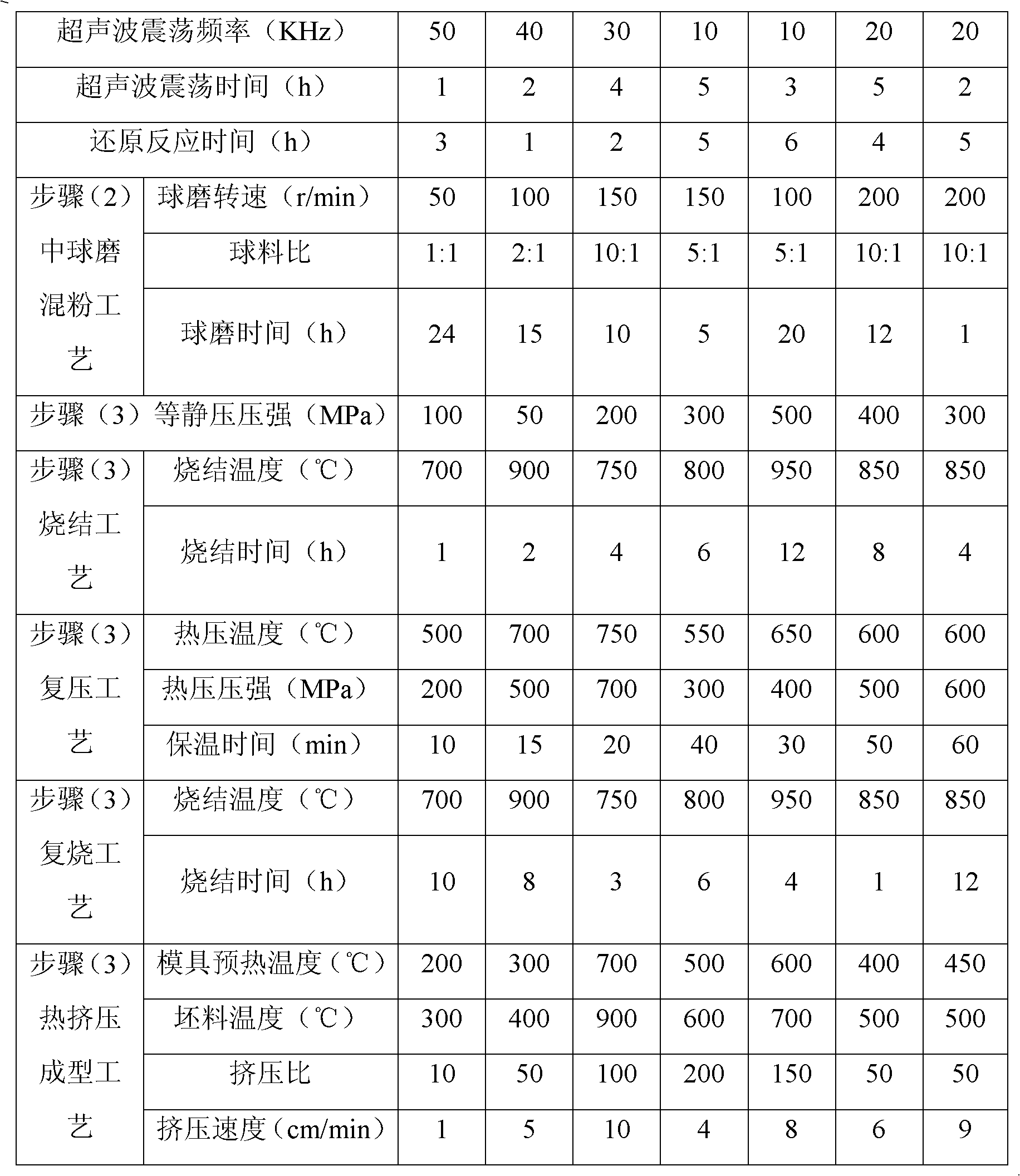

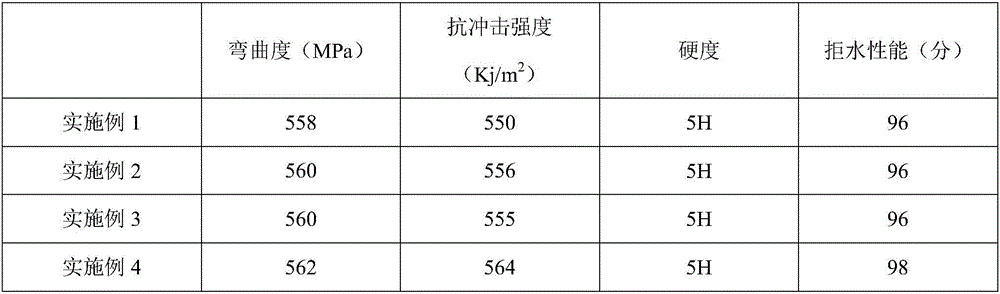

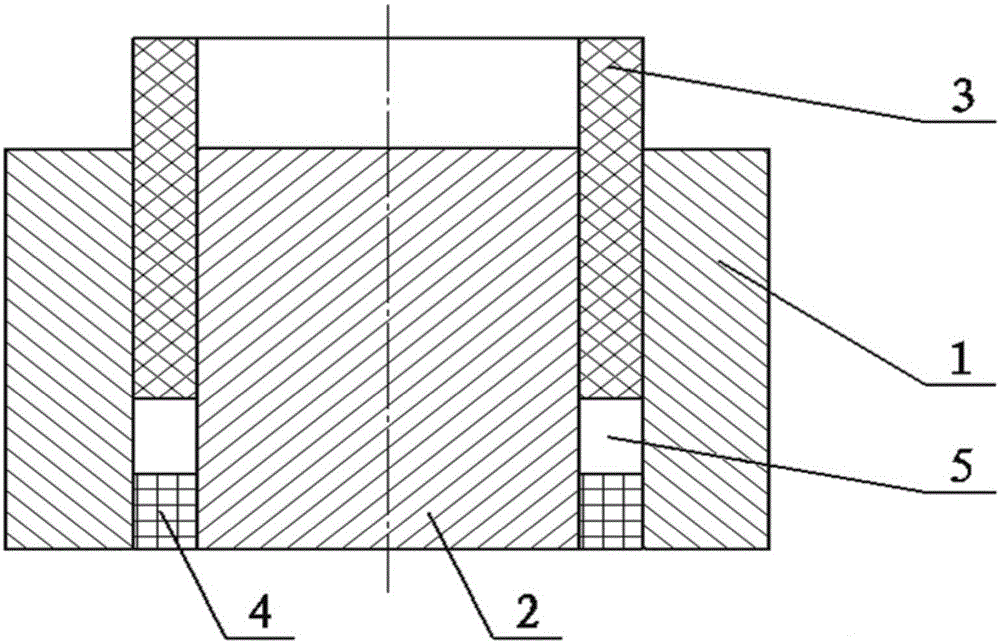

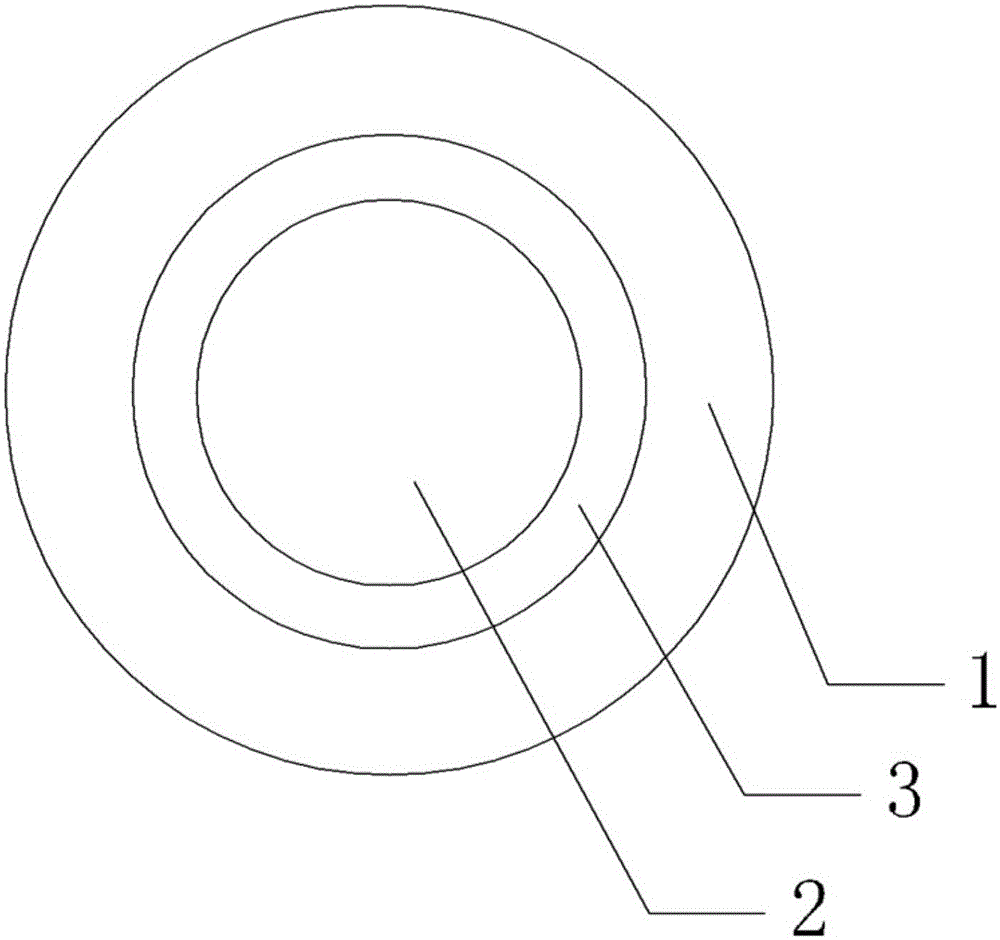

The invention relates to a preparation method of a novel electric contact composite material, and provides a preparation method of an Ag / Ti3SiC2 electric contact composite material. The preparation method comprises the following steps of: preparing silver coated Ti3SiC2 powder by a Tollen reagent chemical silvering method, then cleaning the powder with distilled water to neutral, washing with alcohol and drying in vacuum; carrying out ball milling on dried powder and silver powder and mixing uniformly; compacting the uniformly mixed powder into a green body through isostatic pressing, then carrying out sintering, repressing and re-sintering, and finally moulding through hot extrusion to obtain a finished product. According to the invention, wetabilities of a reinforcing phase and a silver matrix are improved through a silver loaded surface technology; severe clustering will not occur on a surface of the material eroded by arc; and contact resistance keeps at a low and stable range; meanwhile, material surface temperature rise can be maintained at a low level. A mixing amount of the reinforcing phase in the composite material can be increased substantially, and silver can be saved by 5-10%, compared with an Ag / SnO2 material.

Owner:ZHEJIANG UNIV

High-abrasion-resisting glass fiber fabric and preparation method thereof

The invention discloses a high-abrasion-resisting glass fiber fabric and a preparation method thereof. The preparation method comprises the steps that 1, glass fiber monofilaments are plain-woven to obtain a basic glass fiber fabric; 2, the basic glass fiber fabric is put in a sizing agent to be dipped for 2-3 hours; 3, the excessive sizing agent on the basic glass fiber fabric is extruded out, and air bubbles are removed to obtain a preformed glass fiber fabric; 4, the glass fiber monofilaments are parallelly concentrated to obtain protofilaments, the protofilaments are cut according to the length of 60-70 mm and are randomly and uniformly laid on the preformed glass fiber fabric, then a bonder is applied, and heating and curing are performed to obtain a basic material; 5, the sizing agent in the step 2 is uniformly applied to two sides of the basic material in a coated mode, and then ultraviolet curing is conducted on the basic material to obtain the high-abrasion-resisting glass fiber fabric. The high-abrasion-resisting glass fiber fabric has high hardness, good mechanical strength and a high water-repellency performance value, and good abrasion resistance is reflected. The curvature and anti-impact strength are ideal, and it is indicated that the high-abrasion-resisting glass fiber fabric has good water repellency.

Owner:嘉兴杰特新材料股份有限公司

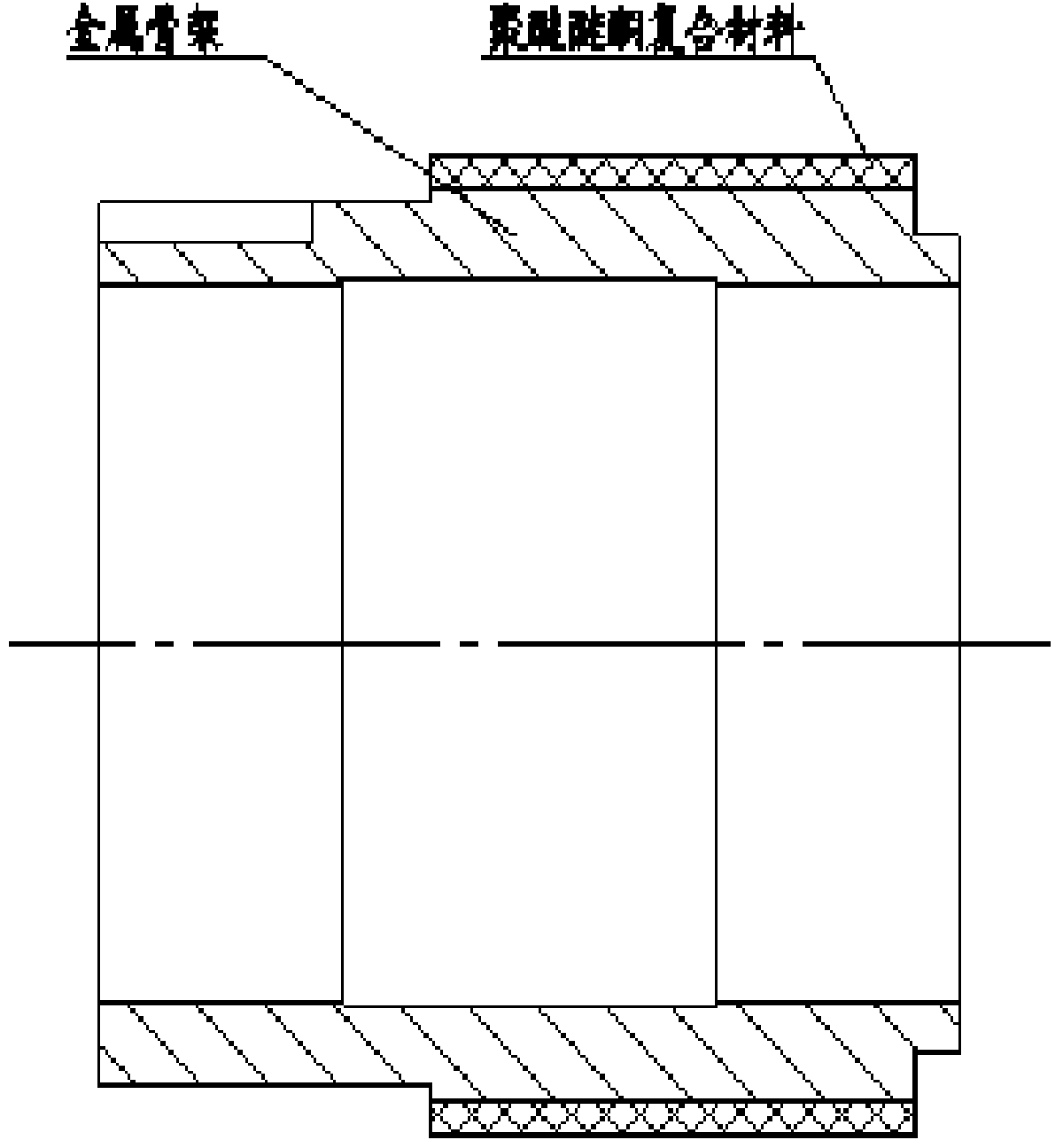

Polyether-ether-ketone modified polytetrafluoroethylene composite material, bearing retainer and making method of bearing retainer

ActiveCN105061956AGood temperature resistanceReduce coefficient of frictionBearing componentsRolling resistance optimizationHeat deflection temperaturePoly ether ether ketone

The invention discloses a polyether-ether-ketone modified polytetrafluoroethylene composite material, a bearing retainer and a making method of the bearing retainer. The composite material comprises, by mass, 18-25% of polyether ether ketone, 5-8% of tungsten disulfide, and the balance of polytetrafluoroethylene. The composite material comprises polytetrafluoroethylene, polyether-ether-ketone and tungsten disulfide. Polyether-ether-ketone has good temperature resistance, hydrolysis resistance, compression strength and corrosion resistance, has a low friction coefficient and has wear fastness, tungsten disulfide has high compression strength and high oxidation resistance, and very low friction coefficient, and polyether-ether-ketone and tungsten disulfide are used to modify polytetrafluoroethylene as fillers, so the obtained composite material reserves the lubrication performance of polytetrafluoroethylene, improves the dimension stability, the compression strength and the wear resistance of polytetrafluoroethylene, and has a greatly higher thermal deformation temperature than a pure polytetrafluoroethylene material, thereby requirements of the material of the retainer by long life bearings are met.

Owner:LUOYANG BEARING RES INST CO LTD

Tin titanium carbide granule reinforced copper base composite material and its preparation method

The invented composite material consists of wild phase of Ti2SnC granule and copper base with percentage of volume as 5-50%. The preparing procedures are as follows. The Ti2SnC granule and Cu powder are mixed evenly by use of physical and mechanical method. Then, under condition of vacuum or in protection of inert gases, the sinter of hot pressing or sinter of isostatic pressing in temperature at750-900 deg.C, pressure at 20-50 MPa and agglomeration time as 0.5-2 hr. carries out to obtain the composite material. The prepared composite material possesses the synthetical capabilities of high intensity, high electrical conductivity, high temperature resistant and self lubricating.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

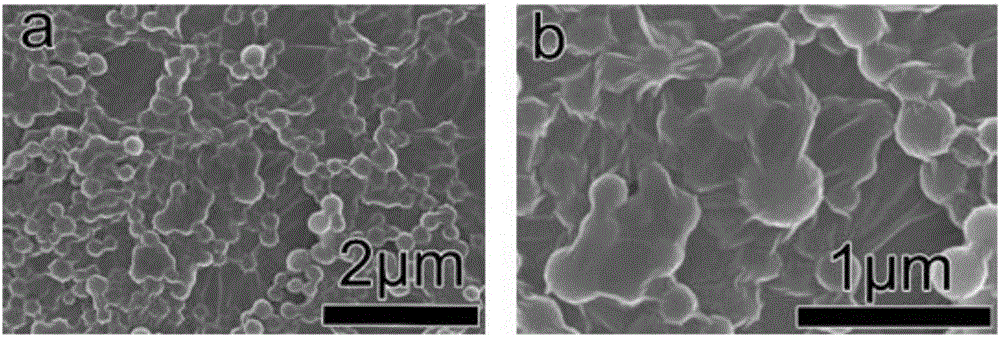

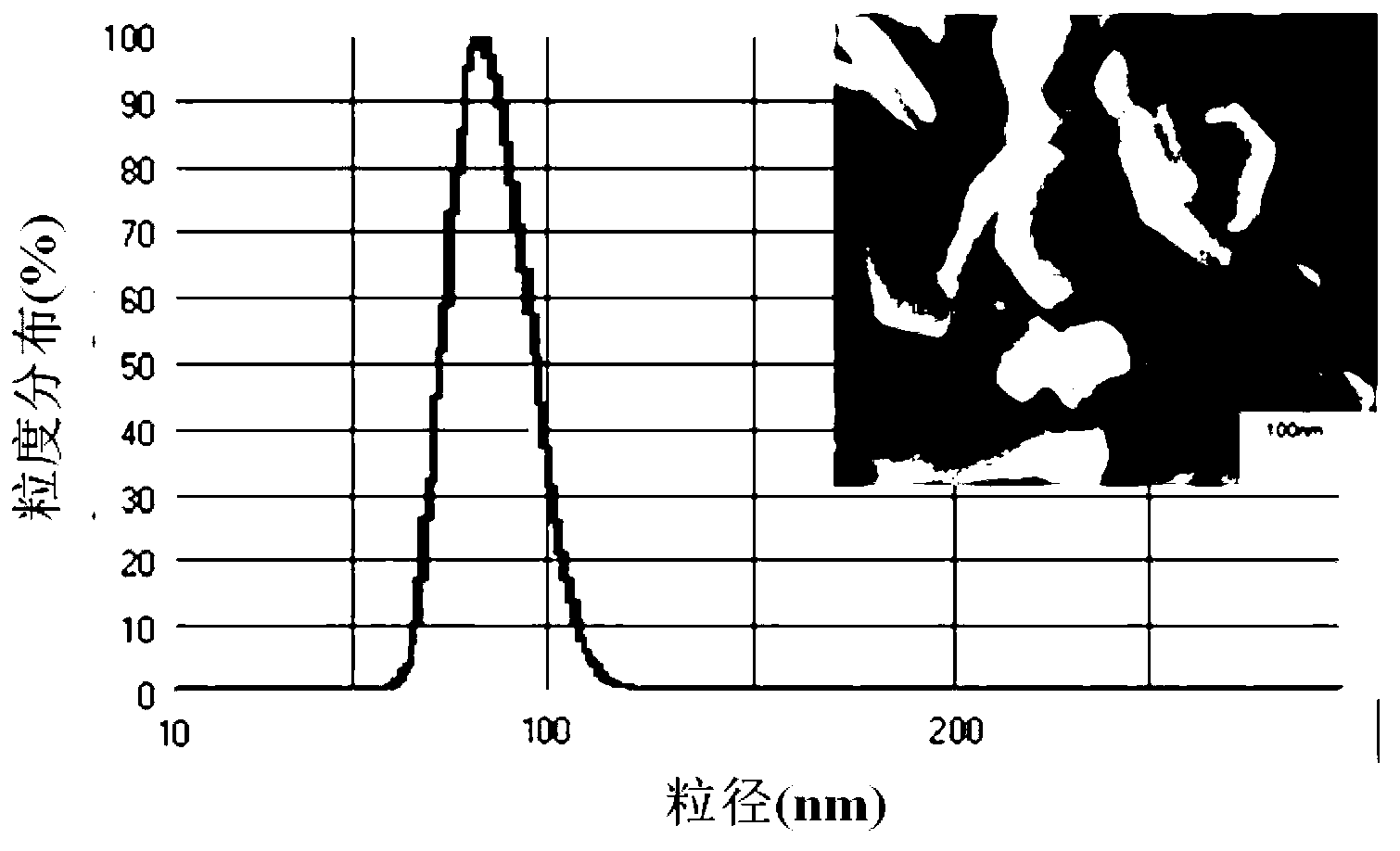

Graphene oxide-polymeric microsphere water-based lubricant additive and preparation method thereof

The invention belongs to the field of lubricant additives, and particularly relates to a graphene oxide-polymeric microsphere water-based lubricant additive as well as a preparation method of the lubricant additive. The preparation method comprises the following steps: preparing graphene oxide powder and a polymeric microsphere emulsion, wherein the polymeric microsphere emulsion is the polyacrylate microsphere emulsion or polystyrene microsphere emulsion; adding the graphene oxide powder into the polymeric microsphere emulsion, conducting ultrasonic vibration until the graphene oxide powder is completely dispersed to obtain a graphene oxide-polymeric microsphere compound emulsion, and diluting the graphene oxide-polymeric microsphere compound emulsion to be with the mass fraction of 0.1-2% through the deionized water, so as to obtain the graphene oxide-polymeric microsphere water-based lubricant additive. The graphene oxide-polymeric microsphere water-based lubricant additive is adopted to replace the conventional oil-based lubricant, so that the friction coefficient can be reduced, the abrasion resistance can be improved, the environmental pollution can be reduced, the cost can be reduced, the use stability can be improved, and meanwhile, various efficacies of cooling, rust prevention, corrosion inhibition and the like can be achieved.

Owner:WUHAN UNIV OF TECH

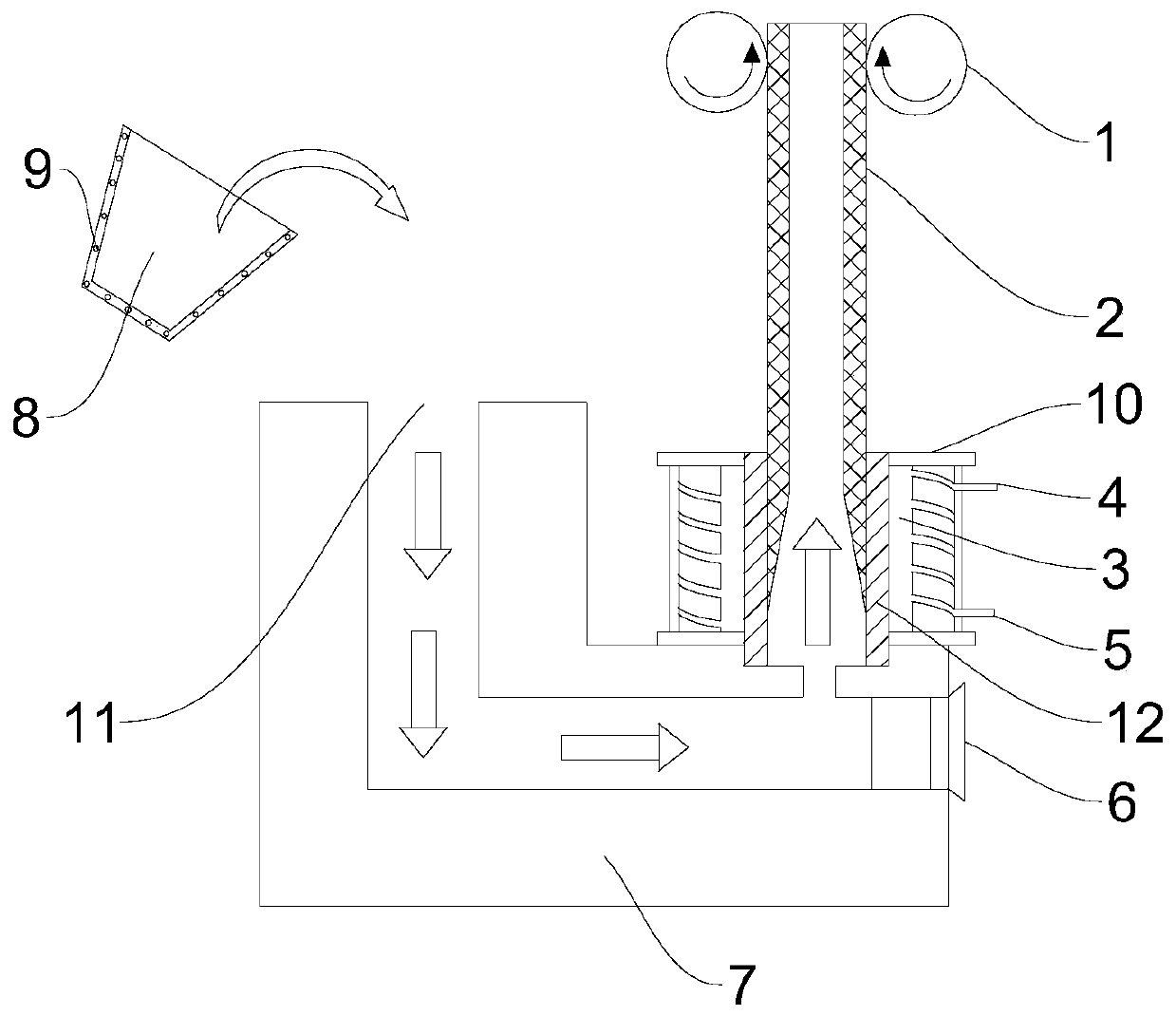

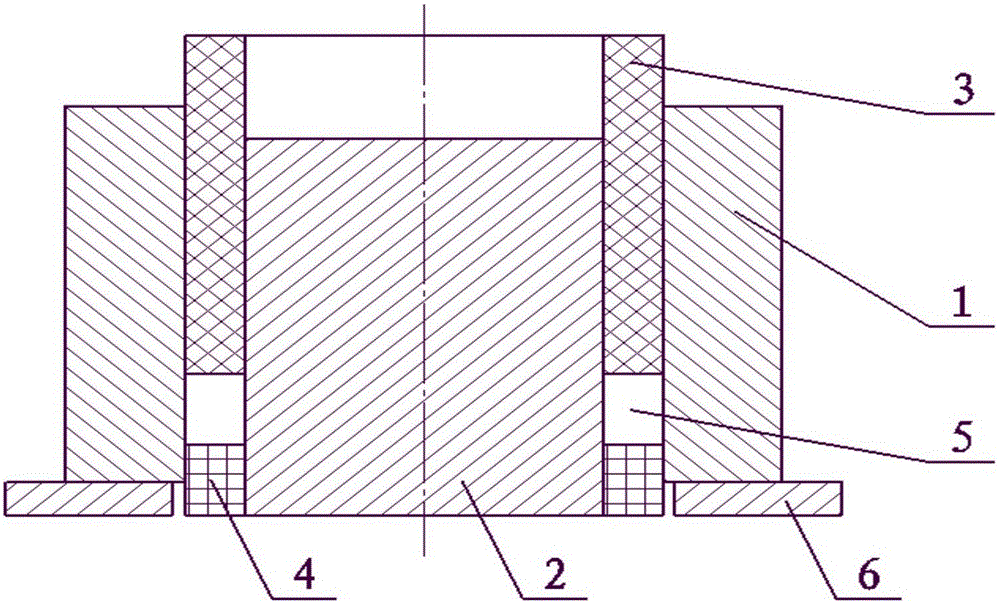

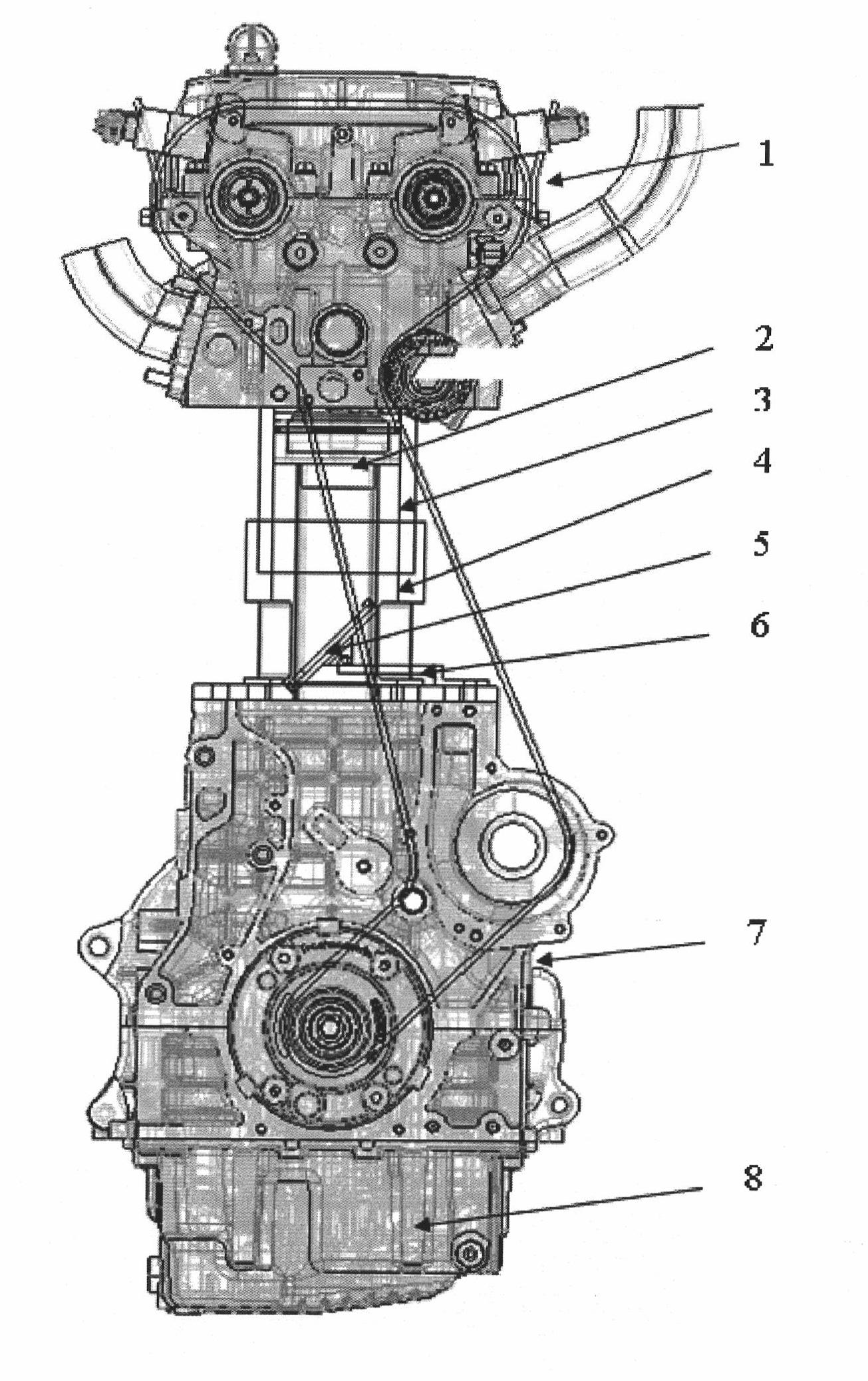

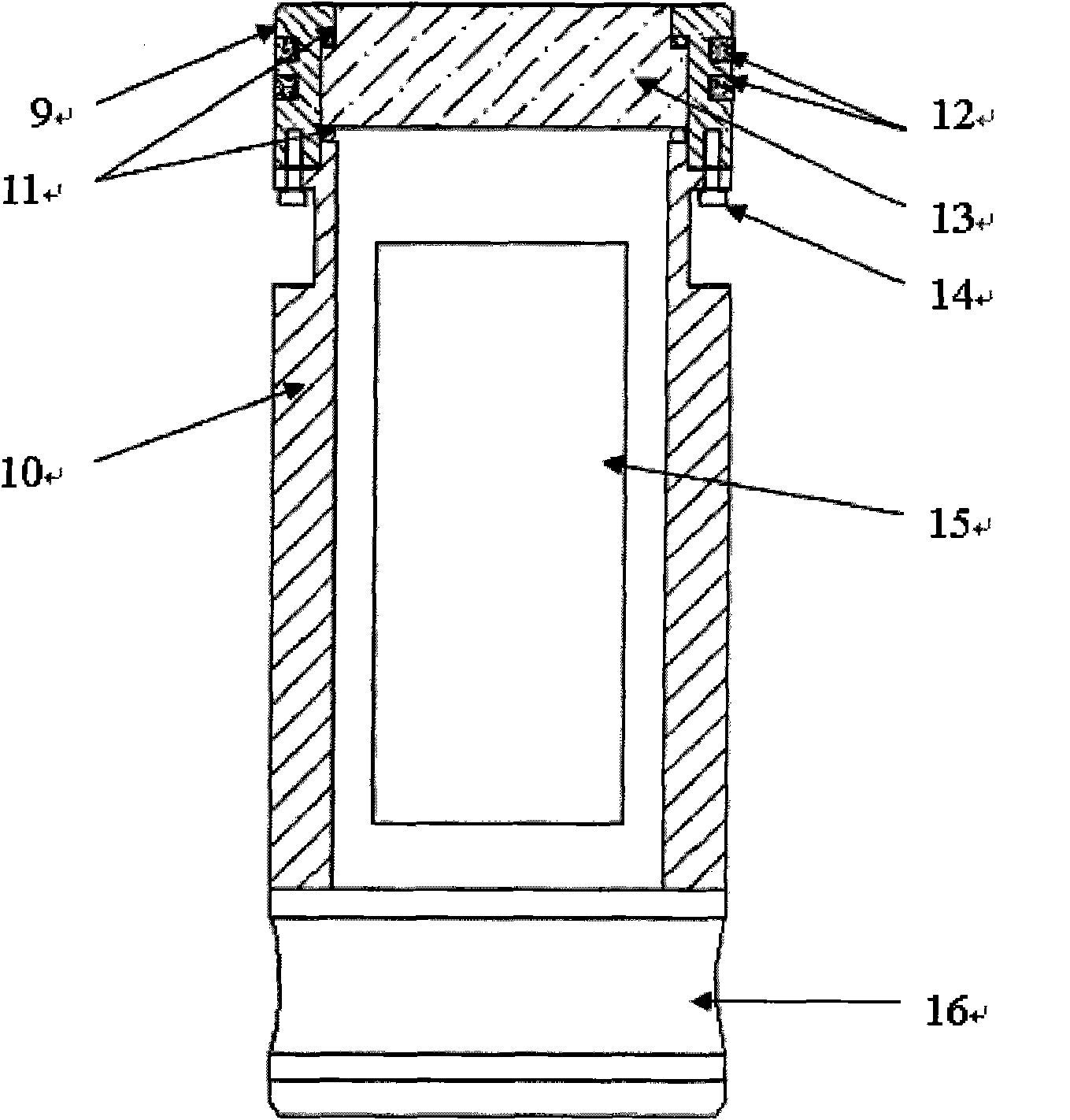

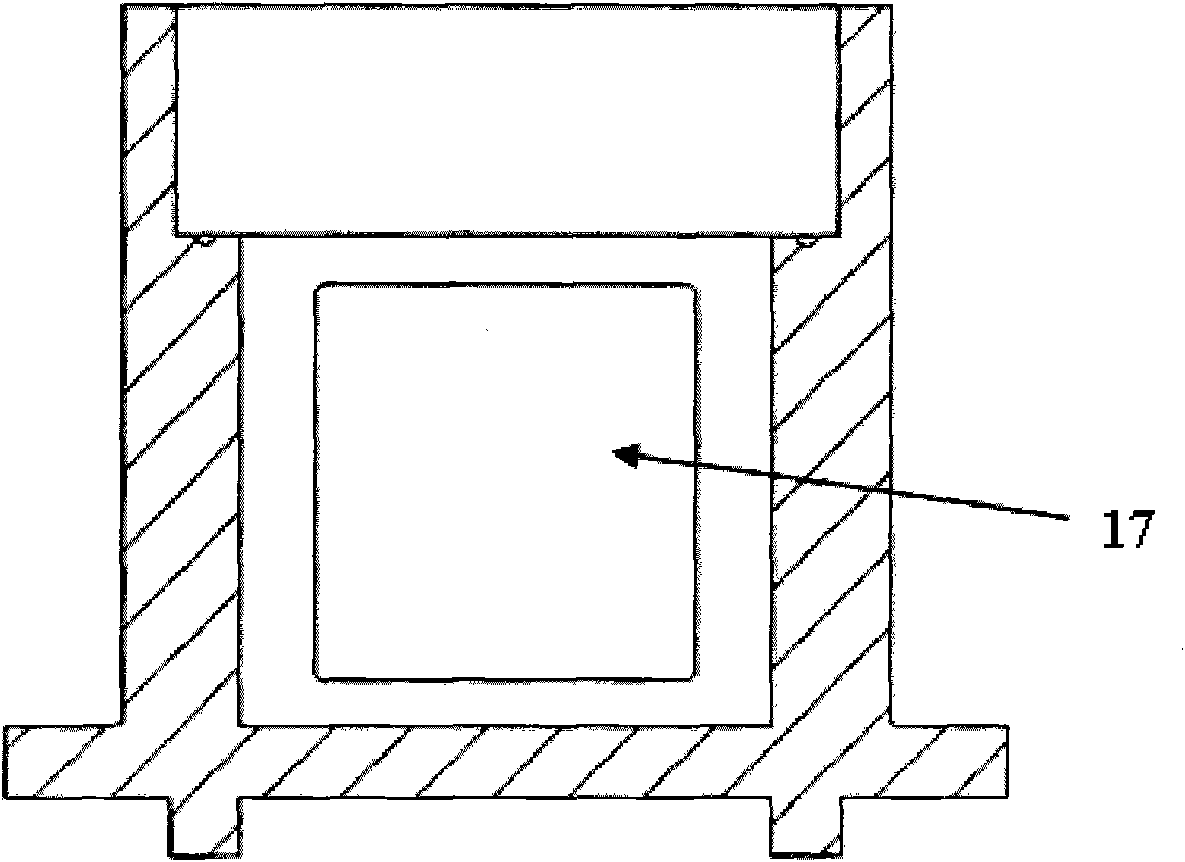

Optical engine

The invention relates to an optical engine which comprises a cylinder cover, an original cylinder casing and a piston; a transparent quartz glass cylinder casing is arranged between the cylinder cover and the original cylinder casing; the piston is an extended piston; the top of the extended piston is provided with a round window; transparent quartz glass is arranged in the round window; the length of the transparent quartz glass cylinder casing is more than the sum of the stroke of the engine and the distance between a ring at the bottommost of the piston and the top surface of the piston; and an engine cylinder body, the original cylinder casing, the cylinder cover and the transparent quartz glass cylinder casing are fixedly connected by bolts.

Owner:CHERY AUTOMOBILE CO LTD

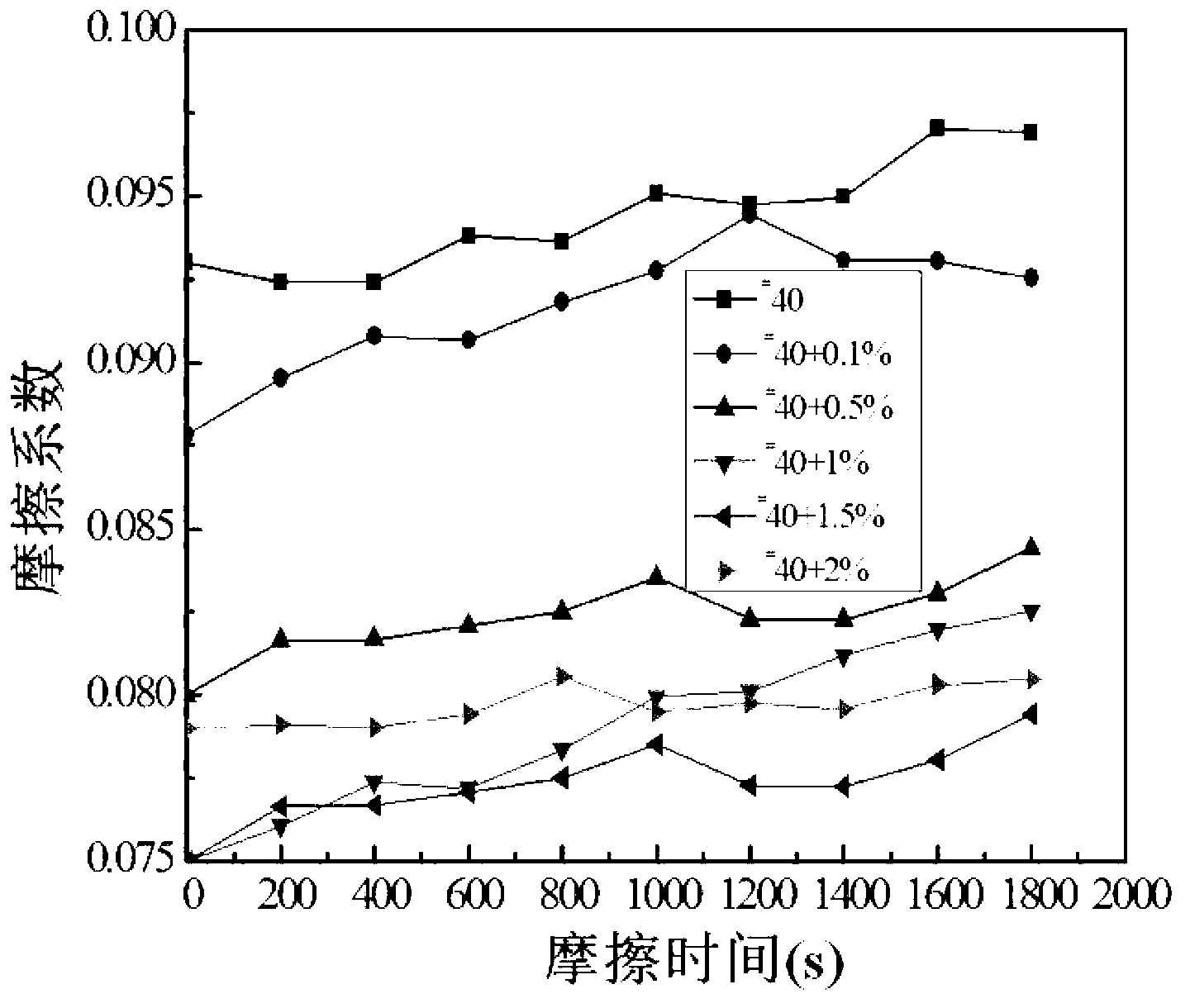

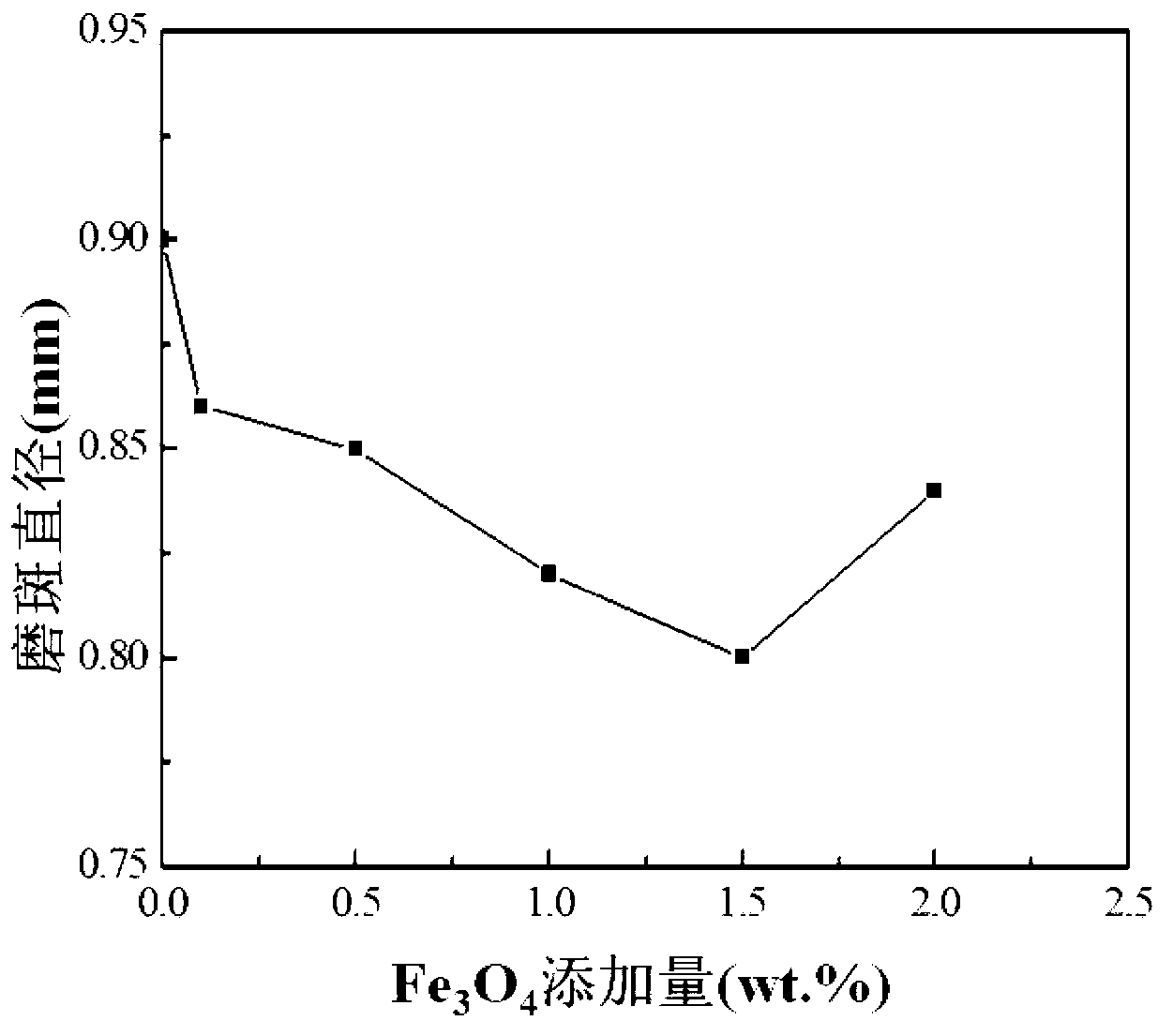

Lubricating oil containing sheet magnetic nanometer Fe3O4 particles and preparation method of lubricating oil

InactiveCN103254971AExtended service lifeUniform and stable dispersionAdditivesCarrying capacityBase oil

The invention discloses lubricating oil containing sheet magnetic nanometer Fe3O4 particles and a preparation method of the lubricating oil. The preparation method of the lubricating oil comprises the following steps of: (1), using oleic acid to clad sheet magnetic nanometer Fe3O4 particles to carry out surface modification to obtain modified Fe3O4 particles; (2), mixing the modified Fe3O4 particles with III base oil, wherein mass fraction of the modified Fe3O4 particles is 0.1%-2.0wt%, and preparing the lubricating oil containing sheet magnetic nanometer Fe3O4 particles through ultrasonic dispersion and high-speed shearing dispersion. The lubricating oil prepared by the preparation method disclosed by the invention has extremely good friction resistance and abrasion resistance, and high carrying capacity. Moreover, the prepared lubricating oil has the advantages of being stable in characteristics, capable of being stored for a long time without precipitation. Besides, the lubricating oil can be extensively applied to mechanical lubricating, can be used for saving energy consumption and prolonging service lives of mechanical parts, and therefore, the application prospect is extensive.

Owner:SOUTH CHINA UNIV OF TECH

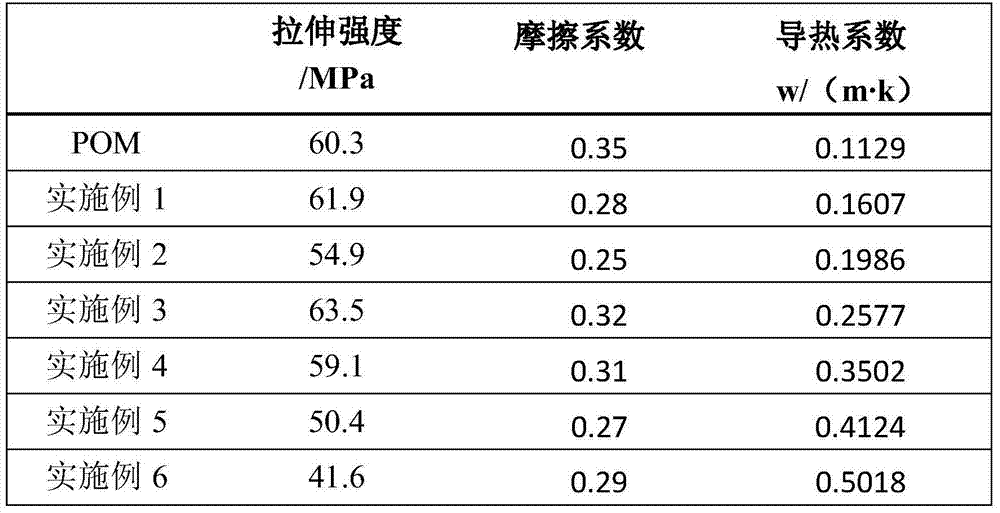

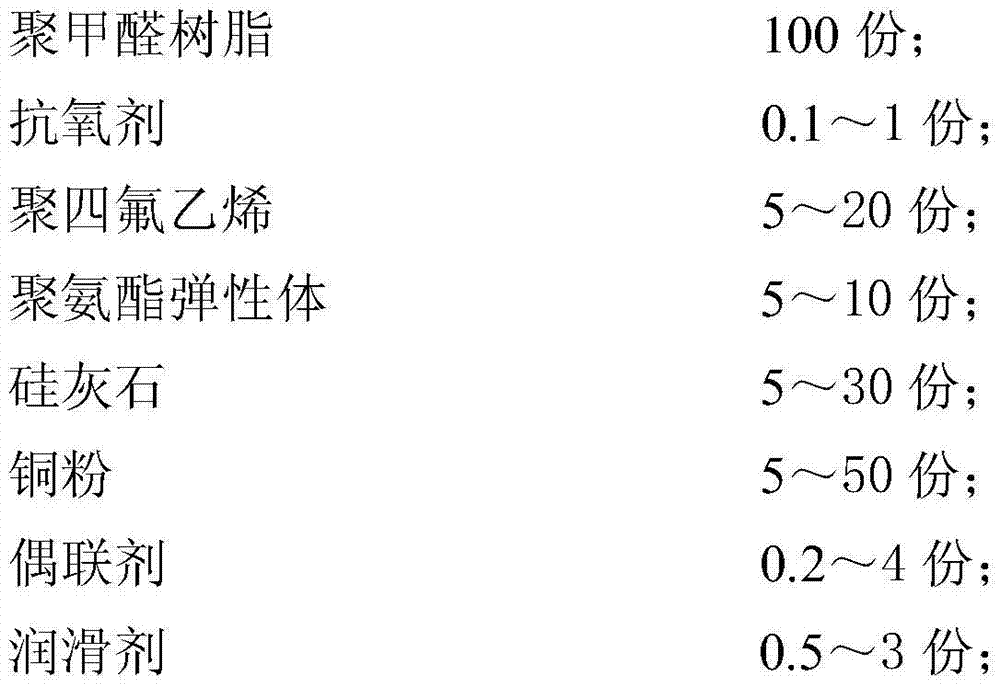

Heat-conducting friction-resistant polyformaldehyde composite material and preparation method thereof

ActiveCN103613902ALower coefficient of friction and wear rateSelf-lubricatingWear resistantPolytetrafluoroethylene

The invention belongs to the field of polymer composite materials, and relates to a heat-conducting friction-resistant polyformaldehyde composite material and a preparation method thereof. The composite material comprises the following raw materials in parts by weight: 100 parts of polyformaldehyde resin, 0.1-1 part of an antioxidant, 5-20 parts of polytetrafluoroethylene, 5-10 parts of polyurethane elastomer, 5-30 parts of wollastonite, 5-50 parts of copper powder, 0.1-2 parts of a coupling agent and 0.5-3 parts of a lubricant. The treated wollastonite and copper powder are mixed with polyformaldehyde, polytetrafluoroethylene, polyurethane, the antioxidant and the lubricant through a two-roll mixing mill, and then the mixture is subjected to tabletting in a flat vulcanizing machine to obtain the friction-resistant polyformaldehyde composite material. The composite material prepared by the method disclosed by the invention has the characteristics of low friction factor and good mechanical properties, and can be applied to preparation of wear-resistant parts including bearings, gears and the like.

Owner:大连路阳科技开发有限公司

Molding process for roller bearing retainer of railway carriage

InactiveCN101596767AShort cycleSelf-lubricatingBearing componentsGlass fiberPlastic injection molding

The invention relates to a molding process for a roller bearing retainer of a railway carriage, which comprises the following steps: taking glass fiber reinforced polyamide plastic as a raw material, and drying the raw material by a dehumidification dryer; conveying dried granular plastic into a hopper of a screw-type plastic injection molding machine, and conveying the granular plastic to a heated charging barrel through a screw to be heated and melted into a flow state; under the condition of high pressure injection, compressing the melted plastic and making the melted plastic move forward quickly; and ejecting the melted plastic by a nozzle, injecting the melted plastic into an engineering plastic retainer mold, and opening the mold to take a product out after cooling and molding. The technical proposal is simple and reasonable; the molding process has short period and can realize one-time molding; and the production process is clean and safe, saves time and protects the environment.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Metal composite ceramic cylinder sleeve and ceramic infiltration method thereof

InactiveCN103883418AStable structureWon't fall offCylinder headsCylindersComposite filmCeramic composite

The invention discloses a metal composite ceramic cylinder sleeve. Composite film ceramic is attached to the inner surface of the cylinder sleeve, and new material is formed on the metal surface through interdiffusion between the film ceramic and a cylinder sleeve base body material. A ceramic film is BN-SiN, the molecular structure of the ceramic film is of a hexagonal crystal structure and has self-lubrication performance, after ceramic infiltration, the friction coefficient of the inner surface of the cylinder sleeve is reduced to one sixth, and the hardness is improved by 41%. The thickness of the ceramic film layer is 3 micrometers -6 micrometers, and the infiltration depth is 35 micrometers-55 micrometers; and the ceramic composite film grows in the environment at the low temperature of 255 DEG C-265 DEG C. The composite film structure of the metal composite ceramic cylinder sleeve is firm and can not fall off, the inner surface of the cylinder sleeve is resistant to abrasion and high temperature and small in friction coefficient, so that engine power is improved, oil consumption is reduced, and emission pollution is reduced.

Owner:江苏爱吉斯海珠机械有限公司

Polyformaldehyde composition and preparation method thereof

The invention discloses a polyoxymethylene composition and a method for preparing the same, wherein the composition includes 20-95 percent of POM, 4-80 percent of ABS, 0.1-20 percent of compatibilizer, 0.1-1.0 percent of lubricant, and 0.1-1.2 percent of antioxidant in weight proportion ( percent). Compared with conventional TPU toughening POM system, when the POM / ABS system of the invention achieves the same impact property, the mechanical comprehensive property of the invention is obviously better than the conventional TPU toughening POM system, and the heat resistance is greatly improved. The alloy material has simple preparation technology, and has advantages of dimensional stability, good appearance, high flowability, drug resistance and easy processing forming, which can be widely used to manufacture automobile, electronic and electric components. The invention improves the POM impact toughness and greatly enriches the use of polyoxymethylene in automobile, electronic and electric components through blending with the ABS material.

Owner:SHENZHEN KEJU NEW MATERIAL

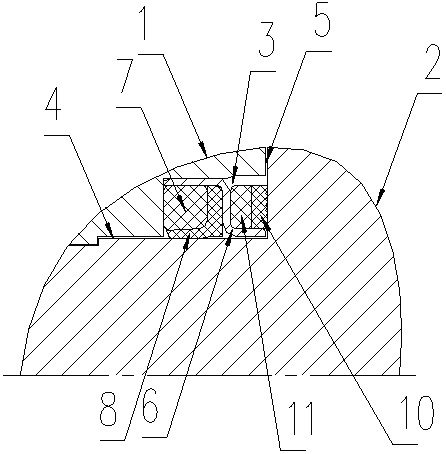

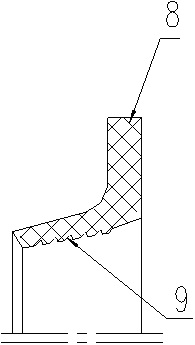

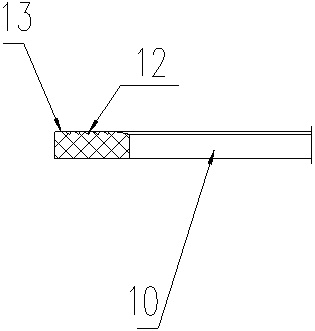

Novel roller bit sealing ring

ActiveCN102628338AReduced service lifeExtended service lifeConstructionsThermodynamicsMetal framework

The invention discloses a novel roller bit sealing ring, which belongs to the field of bearing sealing. The novel roller bit sealing ring is disposed in a sealing groove between a bearing shaft hole and a tooth palm journal. Both ends of the sealing groove are respectively communicated with an inside lubricating oil channel and an outside drilling fluid channel. The novel roller bit sealing ring comprises a metal framework fixed in the sealing groove, the metal framework separates the sealing groove into a lubricating oil sealing groove communicated with the inside lubricating oil channel and a drilling fluid sealing groove communicated with the outside drilling fluid channel. A lubricating oil sealing part is disposed in the lubricating oil sealing groove and completely seals and separates the inside lubricating oil channel together with the metal framework. A drilling fluid sealing part is disposed in the drilling fluid sealing groove and completely seals and separates the outside drilling fluid channel together with the metal framework. The novel roller bit sealing ring is more suitable for severe environment of drilling work, and capable of more effectively and simultaneously separating lubricating oil and drilling fluid, rock debris and the like. Separation of lubricating oil and separation of drilling fluid do not affect each other, and service life of a sealing device is prolonged.

Owner:CHENGDU SHENGBANG SEALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com