Wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material

A polyether ether ketone and composite material technology, applied in the field of polyether ether ketone composite materials, can solve the problems of limiting the application of multi-stage centrifugal pumps, increasing pump power consumption and noise, and high density of cemented carbide, and achieving excellent physical properties. Mechanical properties, reduced power consumption and noise, improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

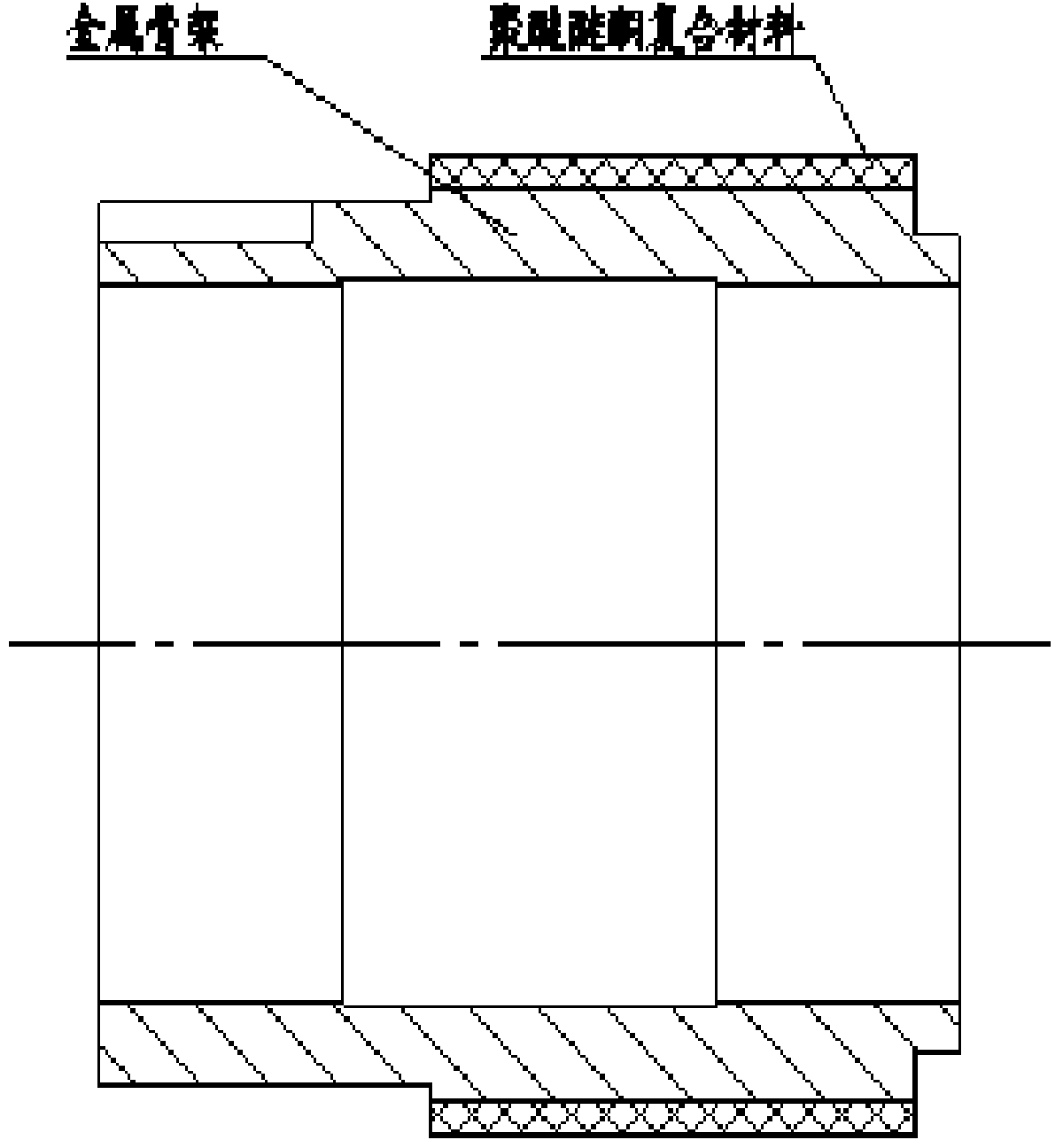

Image

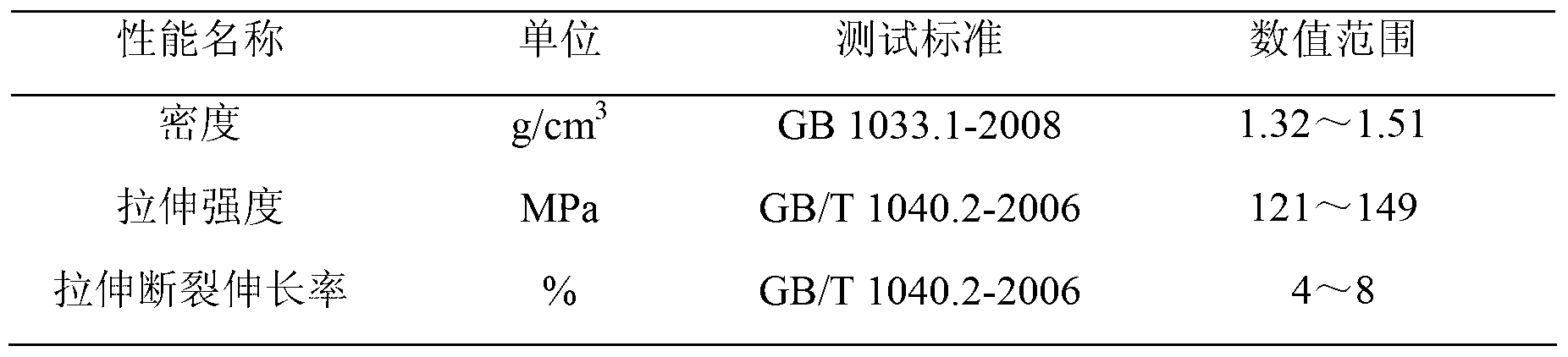

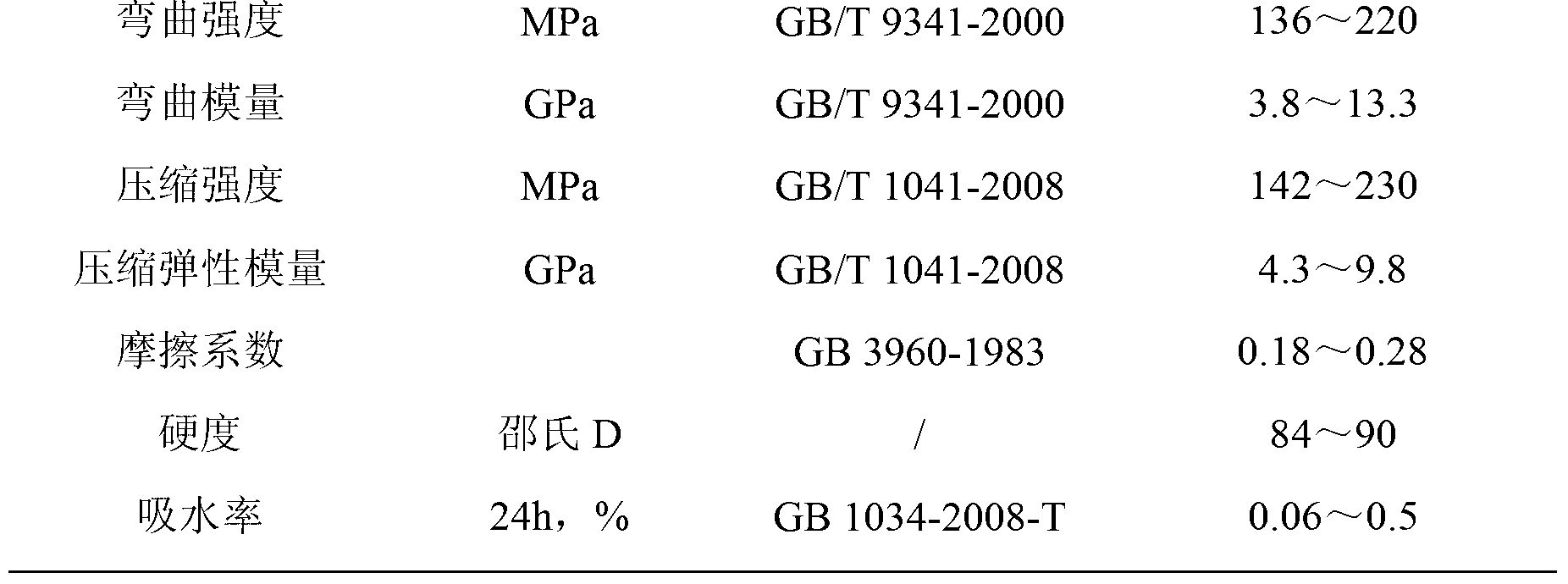

Examples

Embodiment 1

[0042] 1. Surface treatment

[0043] Get the aluminum oxide powder of 5 mass parts, stir in mixer, spray KH550 solution simultaneously, the consumption of KH550 is 1wt% of aluminum oxide powder quality, the mass percentage of KH550 is 20wt% in the KH550 solution, and the mass percentage of ethanol is 72wt%, and the mass percentage of water is 8wt%; take it out after stirring for 15-20 minutes, dry at 130°C for 2 hours, pass through a 200-300 mesh standard sieve after pulverization, and obtain surface-treated aluminum oxide powder. use.

[0044] 2. mix

[0045] Add 80 parts by mass of copolyetheretherketone resin (brand name: 021P, manufacturer: Panjin Zhongrun Special Plastic Co., Ltd.) and 7 parts by mass of carbon fiber powder to the mixer, and then add 8 parts by mass of suspended polytetrafluoroethylene Vinyl resin and the surface-treated aluminum oxide powder obtained in step 1 are stirred evenly to obtain a mixture, which is taken out for use.

[0046] 3. Dry

[0047...

Embodiment 2

[0051] 1. Surface treatment

[0052] Get the aluminum oxide powder of 8 mass parts, stir in mixer, spray KH550 solution simultaneously, the consumption of KH550 is 1wt% of aluminum oxide powder quality, the mass percentage of KH550 is 20wt% in the KH550 solution, and the mass percentage of ethanol is 72wt%, and the mass percentage of water is 8wt%; take it out after stirring for 15-20 minutes, dry at 130°C for 2 hours, pass through a 200-300 mesh standard sieve after pulverization, and obtain surface-treated aluminum oxide powder. use.

[0053] 2. mix

[0054] Add 75 parts by mass of copolyether ether ketone resin (brand name: 021P, manufacturer: Panjin Zhongrun Special Plastic Co., Ltd.) and 9 parts by mass of carbon fiber powder to the mixer, stir well and then add 8 parts by mass of suspended polytetrafluoroethylene Vinyl resin and the surface-treated aluminum oxide powder obtained in step 1 are stirred evenly to obtain a mixture, which is taken out for use.

[0055] 3. ...

Embodiment 3

[0060] 1. Surface treatment

[0061] Get the aluminum oxide powder of 3 mass parts, stir in mixer, spray KH550 solution simultaneously, the consumption of KH550 is 1wt% of aluminum oxide powder quality, the mass percentage of KH550 is 20wt% in the KH550 solution, and the mass percentage of ethanol is 72wt%, and the mass percentage of water is 8wt%; take it out after stirring for 15-20 minutes, dry at 130°C for 2 hours, pass through a 200-300 mesh standard sieve after pulverization, and obtain surface-treated aluminum oxide powder. use.

[0062] 2. mix

[0063] Add 83 parts by mass of copolyetheretherketone resin (brand name: 021P, manufacturer: Panjin Zhongrun Special Plastic Co., Ltd.) and 7 parts by mass of carbon fiber powder to the mixer, stir well and then add 7 parts by mass of suspended polytetrafluoroethylene Vinyl resin and the surface-treated aluminum oxide powder obtained in step 1 are stirred evenly to obtain a mixture, which is taken out for use.

[0064] 3. Dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com