Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Heptanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heptanol may refer to any of four isomeric chemical compounds: 1-Heptanol 2-Heptanol 3-Heptanol 4-Heptanol

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Salts of alkyl esters of sulfonated dicarboxylic acids and compositions containing same

A salt of a mono- and / or dialkyl ester of a sulfonated dicarboxylic acid is provided, where the dicarboxylic acid contains 4 to 8 carbon atoms and the alkyl groups are derived from 2-propylheptanol. A composition including (a) one or more salt(s) of a mono- and / or dialkyl ester(s) of a sulfonated dicarboxylic acid(s), where the dicarboxylic acid contains 4 to 8 carbon atoms and the alkyl groups are derived from 2-propylheptanol; and (b) one or more organic solvents liquid at 20° C. with a boiling point above 250° C. at 1 bar is also provided.

Owner:COGNIS IP MANAGEMENT GMBH

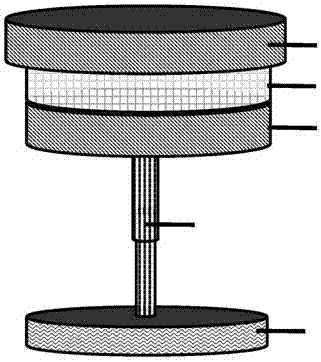

Preparation of polystyrene-divinylbenzene microspheres for blood purification

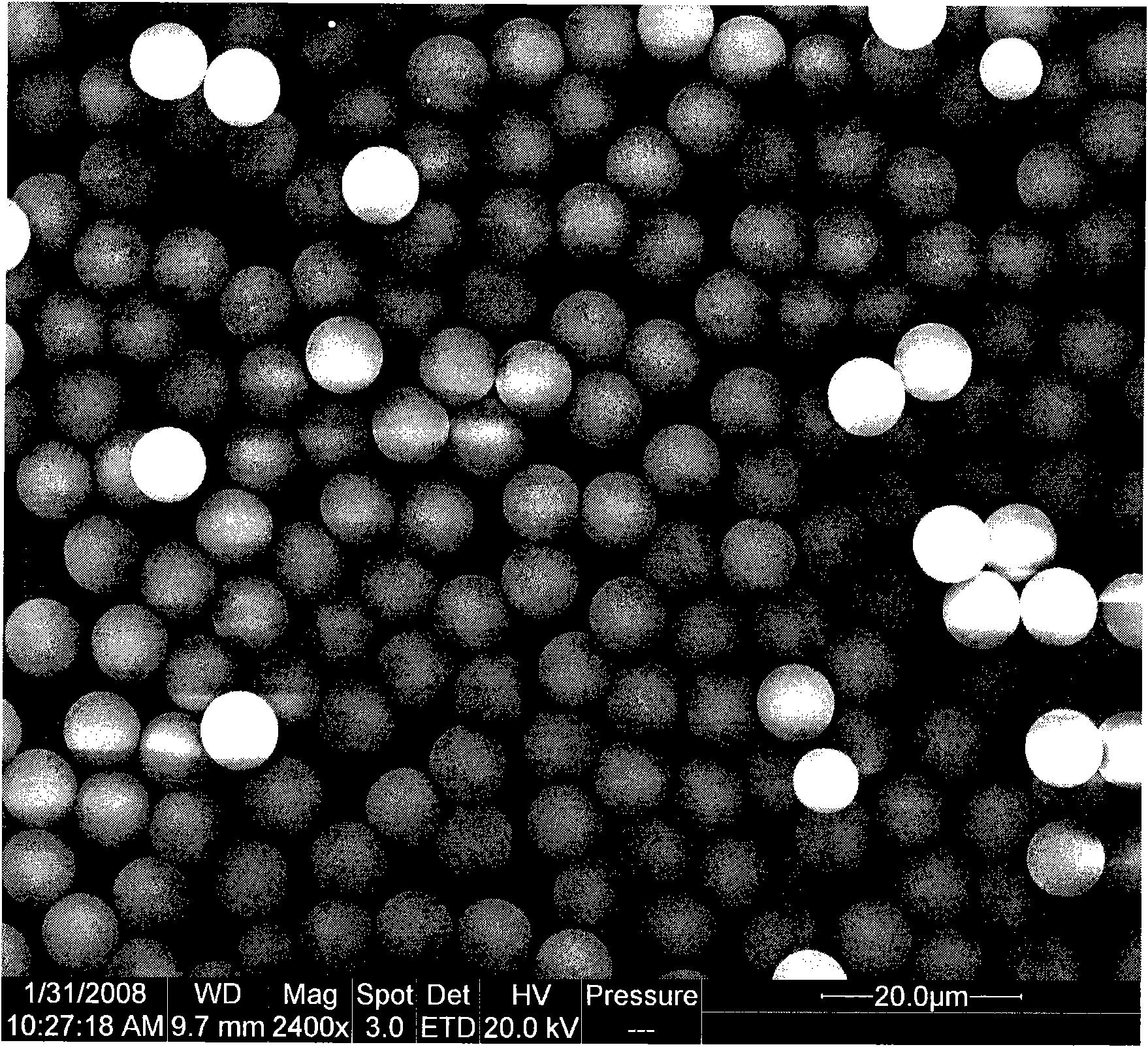

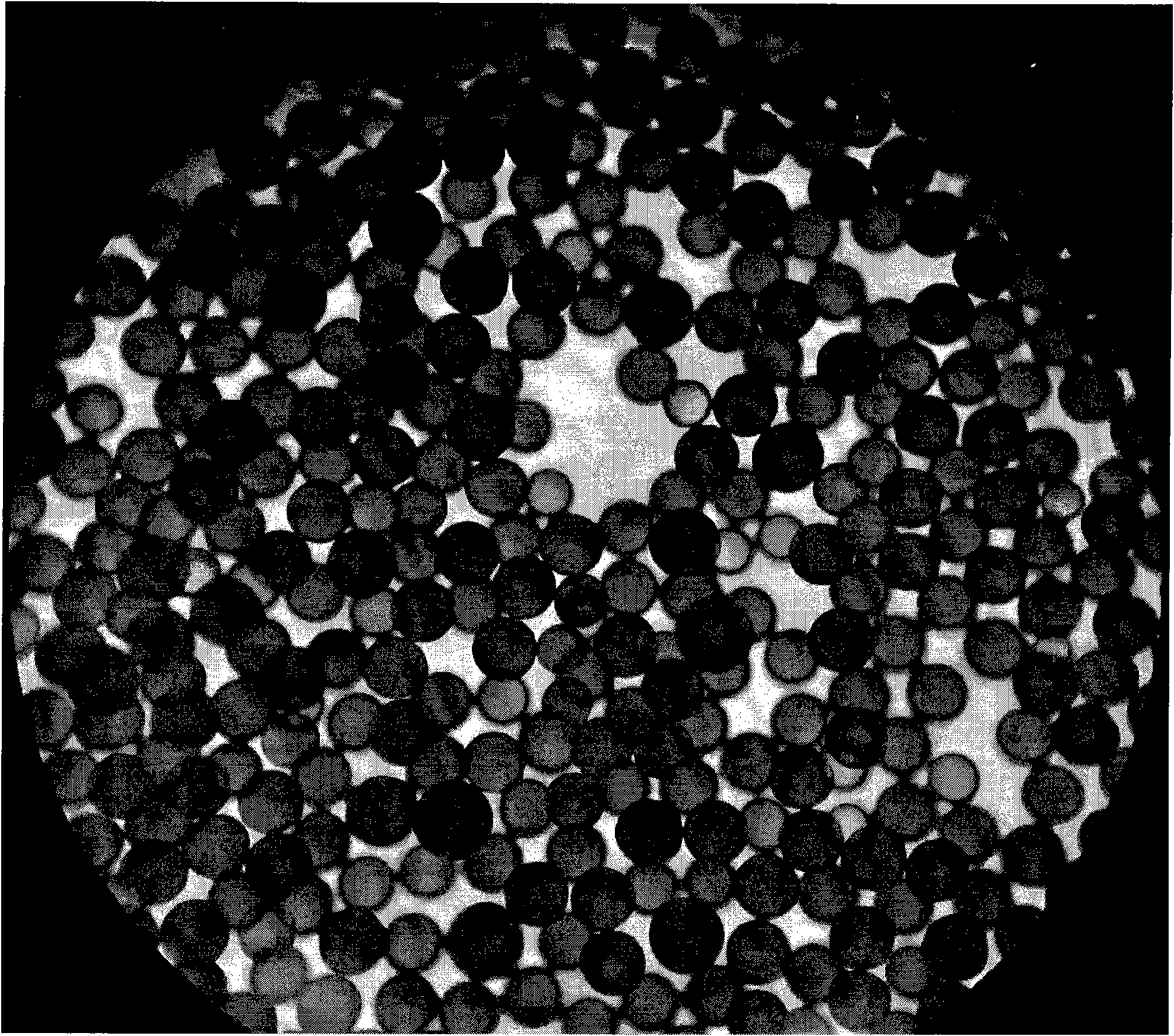

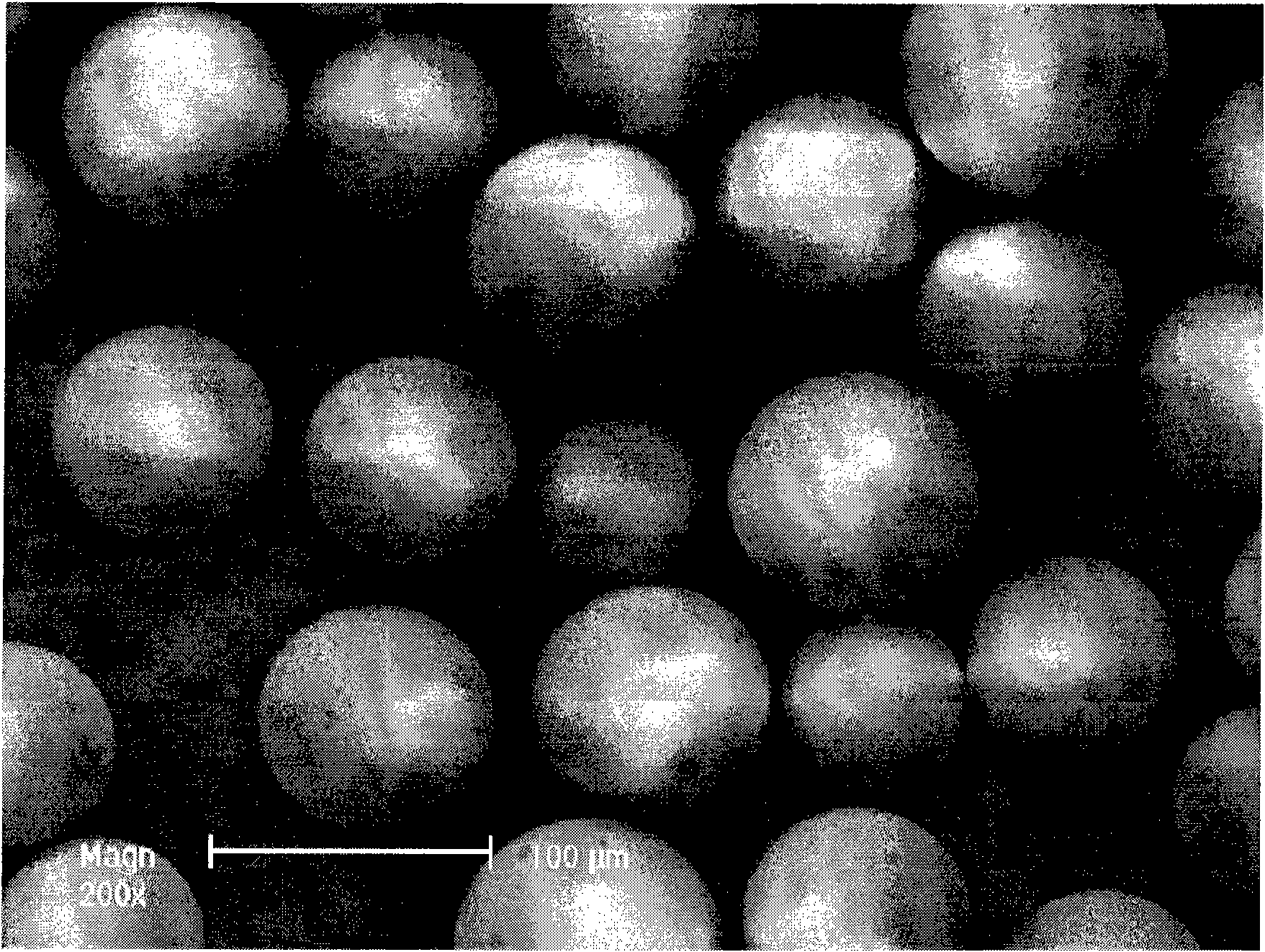

InactiveCN101612543AEvenly distributed diameterGood repeatabilityMicroballoon preparationSuction devicesLipid formationCross-link

The invention provides a method for preparing polystyrene-divinylbenzene microspheres 60 to 100 microns in diameter, and a use thereof for blood purification. Polymer microspheres prepared are synthesized by swelling and polymerizing seed emulsion. Seeds microspheres used are large-diameter linear polystyrene microspheres 6 to 8 microns in diameter. Monomer and cross-linking agent used are styrene and divinyl benzene respectively. Pore-forming agents used are toluene, ethylbenzene, o-phthalic acid lipids, n-heptane, n-octane, n-heptanol or a mixture of the substances. The polymer microspheres prepared are used to remove bilirubin during blood purification. The microspheres prepared have the characteristics of cross-linked multihole, high specific surface area (between 100 and 1,000 m<2> / g), stable mechanical strength, high yield of preparation process, use for blood purification and bilirubin adsorption, small pressure drop of adsorption column, high removal rate and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fuels and fuel additives comprising butanol and pentanol

Disclosed herein are fuels and / or fuel additives comprising butanol and pentanol. In particular, the fuels and / or fuel additives comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol, based on the total volume of the fuels or the fuel additive. Also disclosed herein are fuel compositions comprising fuels or fuel additives, which comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol. The fuels and / or fuel additives may also comprise minor amounts of methanol, ethnaol, propanol, hexanol, heptanol, and / or octanol.

Owner:IGP ENERGY

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Composition for hard article surface cleaning liquid

InactiveUS7030070B2Organic detergent compounding agentsEssential-oils/perfumesSurface cleaningDamascone

A fragrant compound or fragrant composition stable for a long period of time in an acidic hard article surface cleaning liquid adjusted so as to be acidic, particularly to pH 2.0 to 3.0 with an organic acid. One or more of fragrant compounds selected from the group consisting of 2,6-dimethyl-2-heptanol, 3,3-dimethylcyclohexyl methyl ketone, o-tert-butylcyclohexanol, α-amylcinnamic aldehyde, α-damascone, γ-octalactone, γ-nonalactone, γ-decalactone, anethole, ethyl benzoate, ethyl 2,2,6-trimethylcyclohexanecarboxylate, 2,2,6-trimethyl-1-crotonylcyclohexane, 6-acetyl-1,1,2,4,4,7-hexamethyltetrahydronaphthalene, isoamyl phenylethyl ether, methyl octin carbonate, 6,7-dihydro-1,1,2,3,3-pentamethyl-4(5H)-indanone, tricyclodecenyl acetate, undecyl aldehyde, fenchyl acetate, dihydrojasmone, cedryl methyl ether, p-cresol, hexyl aldehyde, and rosephenone are stable.

Owner:TAKASAGO INTERNATIONAL CORPORATION

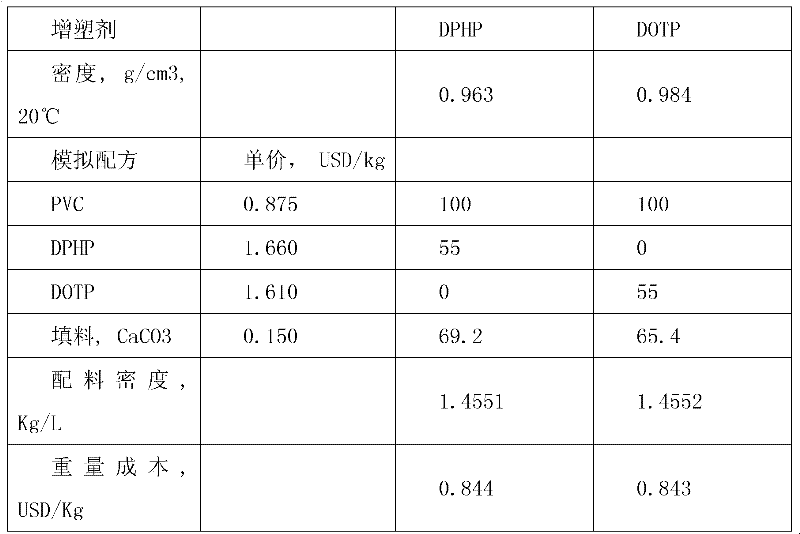

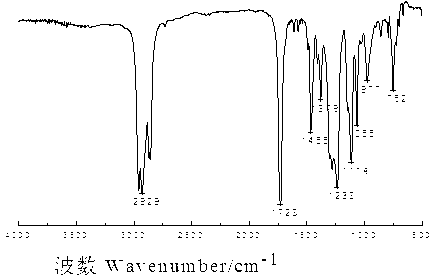

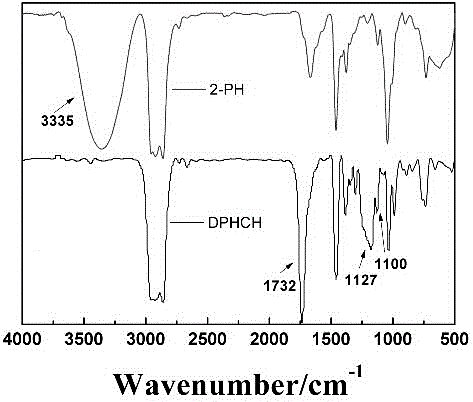

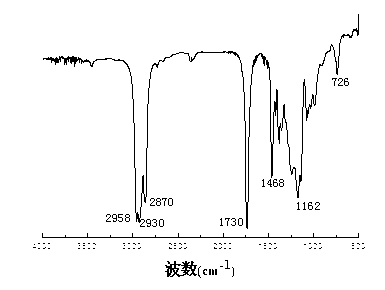

Preparation method and application of phthalic acid diester (2-propyl group heptanol)

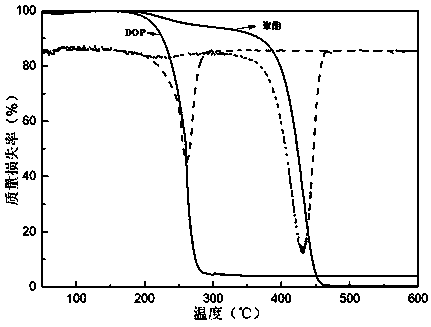

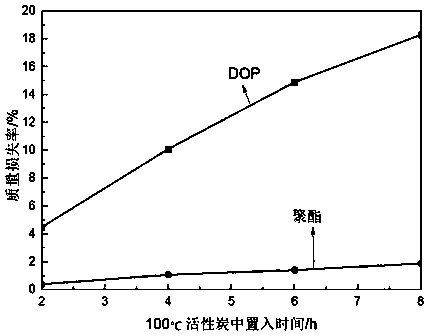

InactiveCN102531903AImprove stabilityImprove migration resistanceOrganic compound preparationCarboxylic acid esters preparationThermal ageingPlasticizer

The invention provides a preparation method and application of phthalic acid diester (2-propyl group heptanol), which obtain the phthalic acid diester (2-propyl group heptanol) (DPHP) through a one-step reaction with phthalic anhydride and the 2-propyl group heptanol serving as raw materials. The raw materials selected by in the preparation method and the application are easy to obtain and mild in reaction condition, the postprocessing after reaction is simple, operation is simple and convenient, chemical yield coefficient is high and the like. The preparation method is convenient in operation, saves energy, and is less in environmental contamination. Obtained products have low volatility, good thermal ageing performance, good weather fastness and good anti-mobility, and can serve as a plasticizer in the polrvinyl chloride processing process.

Owner:CHAOHU XIANGFENG PLASTIC AIDS

Method for preparing plasticizer 1, 2, 4-benzenetricarboxylicacid tris(2-propyl heptyl) ester

InactiveCN103012150ALow costNo decolorization step requiredOrganic compound preparationCarboxylic acid esters preparationPolyesterChemical synthesis

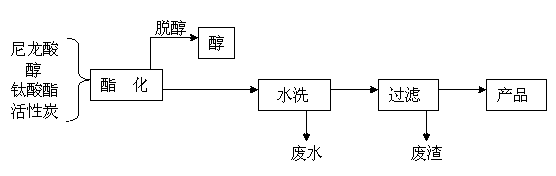

A method for preparing a plasticizer 1, 2, 4-benzenetricarboxylicacid tris(2-propyl heptyl) ester belongs to the technical field of chemical synthesis. The method comprises the steps: by adopting trimellitic anhydride and 2-propyl heptanol as main reaction raw materials, mixing and heating in the presence of a titanate catalyst, activated carbon and attapulgite to esterify to obtain a 1, 2, 4-benzenetricarboxylicacid tris(2-propyl heptyl) ester crude product after reaction is finished; and carrying out neutralizing, alkali washing and washing on the crude product in turn, distilling at reduced pressure to remove the excessive alcohol, and filtering to obtain the 1, 2, 4-benzenetricarboxylicacid tris(2-propyl heptyl) ester finished product. The method has the advantages of available and low price selected raw materials, small catalyst usage, no obvious corrosiveness, small environmental pollution and the like, and is convenient for operation and energy-saving. The obtained product has small volatility, extraction resistance and transfer resistance and has advantages which are similar to those of a polyester catalyst; and moreover, the compatibility, processability and lower temperature performance of the obtained product are comparable to those of phthalic acid ester, and the obtained product has a wide application.

Owner:JIANGNAN UNIV +1

Fischer-tropsch derived turbine fuel and process for making same

InactiveUS7785378B2Increase pointsIncrease productionLiquid carbonaceous fuelsHydrocarbons1-PentanolOxygen

The present invention is directed to a Fischer-Tropsch derived distillate suitable for use as a turbine fuel having a flash point 38° C. minimum measured by ASTM D 56 and a freeze point of −40° C. or less and further containing not less than 0.01 wt. % oxygen in each of 1-pentanol, 1-hexanol, and 1-heptanol and not more than about 0.01 wt. % oxygen in C8+ linear alcohols. Preferably, the Fischer-Tropsch derived distillate will have a freeze point of at least −47° C., and more preferably the freeze point of the Fischer-Tropsch derived distillate will be not less than −50° C. All the wt. % oxygen amounts are on a water free basis.

Owner:CHEVROU USA INC

Preparation method of heat-resistant migration-resistant environment-friendly polyether plasticizer

A preparation method of a heat-resistant migration-resistant environment-friendly polyether plasticizer. The invention belongs to the field of fine chemical synthesis and plastic additive application.The method includes steps of: with glutaric acid, 1,4-cyclohexane dimethanol and 2-propyl heptanol as main raw materials, performing esterification condensation polymerization to modify molecular structures and convert functional groups, thus producing a crude product, environment-friendly polyether plasticizer; and then performing water-carrying agent removal and alcohol removal separation to purify the product 1,4-cyclohexane dimethanol polyglutarate. The target molecule has a structure of a straight-chain low polymer in which the cyclohexyl group, having a ring structure, is combined witha linear molecule, so that the product has the features of both the ring molecules and linear molecules. The polyether plasticizer has moderate viscosity and light color, is free of o-benzene and benzene ring structure, has good compatibility with PVC, is heat-resistant and migration-resistant and is suitable for industrial production. The novel environment-friendly polyether plasticizer may replace conventional phthalic acid-type plasticizers.

Owner:JIANGNAN UNIV

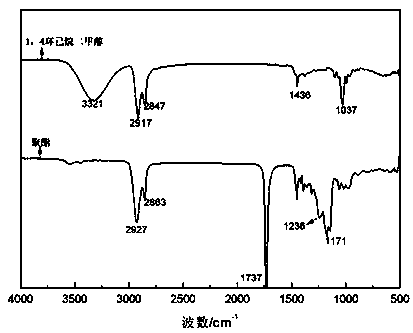

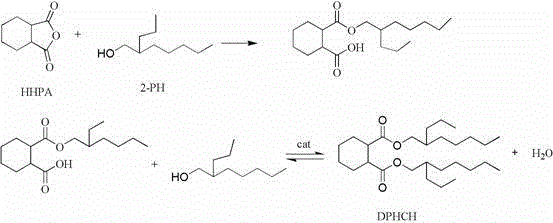

Preparation method of di(2-propylheptyl) cyclohexyl-1,2-diformate

InactiveCN104478722AImprove product qualityMeet the requirements of green environmental protectionOrganic compound preparationCarboxylic acid esters preparationSodium bisulfatePhthalate

The invention relates to a preparation method of di(2-propylheptyl) cyclohexyl-1,2-diformate, belonging to the field of synthesis of fine chemical engineering products. The preparation method comprises the following steps: carrying out esterification reaction on hexahydrophthalic anhydride and 2-propyl heptanol by using non-protonic acid as a catalyst; and after the esterification reaction finishes, neutralizing, washing with water, dealcoholizing, and drying to obtain the di(2-propylheptyl) cyclohexyl-1,2-diformate, wherein the esterification rate is up to 99% above. The non-acid catalyst is a composite catalyst composed of tetrabutyl titanate, sodium bisulfate monohydrate or tetrabutyl titanate and sodium bisulfate monohydrate, and accounts for 0.2-4 wt% of the acid anhydride; the raw material alcohol / acid mole ratio is (2.2-3.0):1; the esterification reaction temperature is controlled at 140-230 DEG C, and the reaction time is 3-12 hours; and when the acid number is lower than 1mg KOH / g, the reaction is finished, thereby obtaining the product with nearly no color and higher esterification rate. The method has the advantages of high utilization ratio of the raw materials, high product quality, high efficiency and environment friendliness; and the di(2-propylheptyl) cyclohexyl-1,2-diformate is free of benzene ring structure, can be substituted for the phthalate-type novel environment-friendly plasticizer product, and has broad market prospects.

Owner:JIANGNAN UNIV

Fuels and fuel additives comprising butanol and pentanol

Disclosed herein are fuels and / or fuel additives comprising butanol and pentanol. In particular, the fuels and / or fuel additives comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol, based on the total volume of the fuels or the fuel additive. Also disclosed herein are fuel compositions comprising fuels or fuel additives, which comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol. The fuels and / or fuel additives may also comprise minor amounts of methanol, ethanol, propanol, hexanol, heptanol, and / or octanol.

Owner:IGP ENERGY

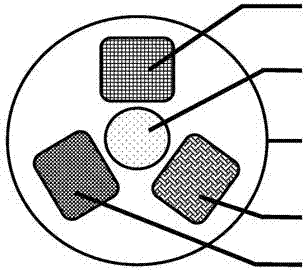

Rice brown planthopper pest monitoring method and device

PendingCN106908488AEarly warning is accurateGood timelinessMaterial resistanceAgainst vector-borne diseasesVolatile organic compoundLinalool

The invention provides a rice brown planthopper pest monitoring method and device. The monitoring method comprises the steps that one or more of linalool, monoterpene-beta-ocimene and 2-heptanol which are released by rice and are used for seducing brown planthoppers are monitored through chemical sensors, and when it is detected that one or more of the linalool, the monoterpene-beta-ocimene and the 2-heptanol exceed a preset threshold, an alarm is given. The chemical sensors are a linalool sensor, a monoterpene-beta-ocimene sensor and a 2-heptanol sensor. By the usage of the rice brown planthopper pest monitoring method and device, a volatile organic compound which is released by the rice in different growth periods and used for seducing brown planthopper pests can be automatically and continuously monitored in real time, and an early warning is issued in time. Compared with methods such as an image processing technology, an early-warning model and bibliometrics which are adopted by current paddy field pest early-warning, the rice brown planthopper pest monitoring method and device have superior timeliness.

Owner:AGRI INFORMATION INST OF CAS

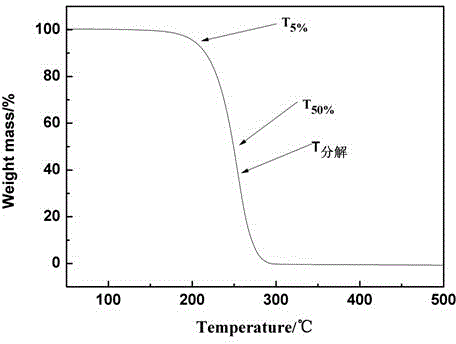

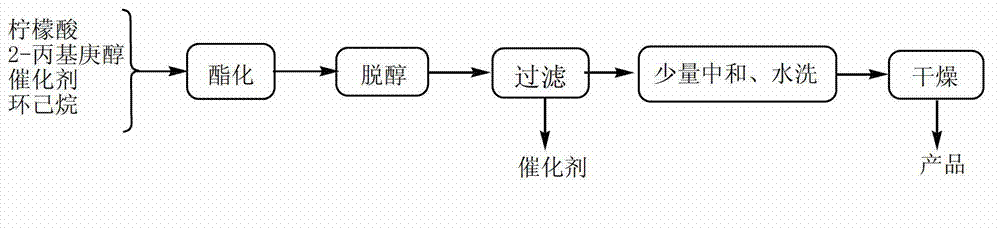

Preparation technology of citric acid tri-2-propylheptanol ester

InactiveCN102633643AAnti-mildewImprove plasticizing effectOrganic compound preparationCarboxylic acid esters preparationPlasticizerEsterification reaction

The invention discloses a preparation technology of citric acid tri-2-propylheptanol ester and belongs to the field of a citric acid plasticizer. The preparation technology comprises the following steps: esterifying citric acid monohydrate or anhydrous citric acid and 2-propyl heptanol in the presence of a catalyst H2SO4 to synthetize citric acid tri-2-propylheptanol ester; cyclohexane is used as water-carrying agent in reaction, wherein in the reaction, cyclohexane is used as a water carrying agent, the temperature of the esterification reaction is 120-160 DEG C, the reaction time is 2-3 hours, the molar ratio of citric acid monohydrate or anhydrous citric acid to 2-propyl heptanol is 1: (3-7); neutralizing with a sodium carbonate solution after the esterification reaction is finished; then washing to obtain a citric acid tri-2-propylheptanol ester crude product; and carrying out steam stripping on the crude product to remove excessive 2-propyl heptanol, drying and filtering so as to obtain a tri-2-propylheptanol ester finished product. The technology is high in esterification rate, economic and environment-friendly and suitable for industrial production. The obtained citric acid tri-2-propylheptanol ester has the advantages of non-toxic property, mildew resistance, good plasticizing effect, cold resistance, light fastness, water resistance, small volatility and the like.

Owner:江苏雷蒙新材料有限公司

Black soybean milk flavor and preparation method and application thereof

The invention discloses a black soybean milk flavor and a preparation method and an application thereof. The flavor comprises isovaleric aldehyde, methyl alcohol, isopentyl alcohol, hexanal, 2-methylpyrazine, furfural, trans-2-hexenal, furfuryl alcohol, hexyl alcohol, 2-heptanone, heptanal, 2-acetylfuran, 2, 5-methylpyrazine, 2, 3-dimethyl pyrazine, trans-2-heptenal, 5-methyl-furfural, benzaldehyde, heptanol, 1-octen-3-alcohol, 2-pentyl-furan, caprylaldehyde, 2-acetyl thiazole, trans-2-octenyl aldehyde, octanol, nonanal, capraldehyde, trans,trans-2,4-nonadienal, trans-2-decenal, 2-undecanone,trans,trans-2,4-heptadienal, trans-2-undecenal and propylene glycol. The method comprises the following steps: evenly mixing the above constituents, stewing and curing for 15 days, subpackaging to obtain the black soybean milk flavor. The flavor has convenient raw materials sources, mild fragrance and high naturalness, and is applied to preparing the beans products, is especially used for preparing black soybean milk beverage, not only can enhance mouthfeel, but also can better cover soil mildewed flavor brought by beans in basic materials.

Owner:广州市凯虹香精香料有限公司

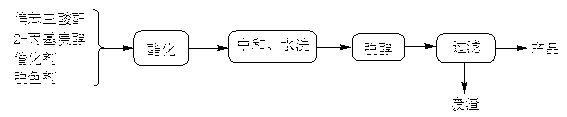

Novel synthetic process of tris (2-propylheptyl) trimellitate

InactiveCN103694121AIncrease the color numberQuick responseOrganic compound preparationCarboxylic acid esters preparationTrimellitic acidReaction system

The invention discloses a novel synthetic process of tris (2-propylheptyl) trimellitate. The process comprises the following steps: (1) taking raw materials according to a molar ratio of trimellitic anhydride to heptanol being 1:2.7-2.9, and taking a catalyst isopropyl titanate accounting for 0.3-0.35% of the total weight of trimellitic anhydride and heptanol; (2) taking raw materials according to a molar ratio of trimellitic anhydride to heptanol being 1:2.5-2.6, adding 80% of the catalyst into the reactor and heating for reaction; (3) continuing to heat the reaction materials to 200-220 DEG C, and adding the remaining heptanol and the catalyst isopropyl titanate into the reaction kettle for reaction; (4) decolorizing the reaction materials to obtain a crude product, and adding hydrogen peroxide accounting for 1-1.2 wt% of the whole reaction system in the decolorization process; and (5) conducting neutralization washing on the crude product with neutralization washing temperature at 105-110 DEG C, dealcoholizing and filtering to obtain a finished product of tris (2-propylheptyl) trimellitate. The process provided by the invention not only can reduce the production energy consumption but also can improve the color and grade of the finished product.

Owner:ZHEJIANG HAILIYE TECH

Novel synthesis technology of adipic acid (2-propyl heptyl) ester

InactiveCN103664597AProcess stabilityQuick responseOrganic compound preparationCarboxylic acid esters preparationAdipic acidEnergy consumption

The invention discloses a novel synthesis technology of adipic acid (2-propyl heptyl) ester. The technology comprises the following steps: (1) taking adipic acid and heptanol according to the molar ratio of 1:(2.3-2.5) as raw materials, and taking a catalyst with the mass of 0.18%-0.22% of the total mass of the adipic acid and heptanol, wherein the catalyst is a mixture of isopropyl titanate and tetrabutyl titanate with the ratio of 2:1; (2) taking adipic acid and heptanol according to the molar ratio of 1:(1.8-1.9) as raw materials, placing the raw materials into a reaction kettle, adding the catalyst, and heating for an reaction for 2-3 hours; (3) heating the reaction liquid in the step (2) to be at 200-220 DEG C, and adding the remaining heptanol for complete reaction to obtain a crude product; (4) performing water washing, decoloring, and filtering on the crude product to obtain the finished product of the adipic acid (2-propyl heptyl) ester. The novel synthesis technology provided by the invention can reduce production energy consumption, and hardly generates waste water with a high COD value, thereby meeting the requirement of environment protection.

Owner:ZHEJIANG HAILIYE TECH

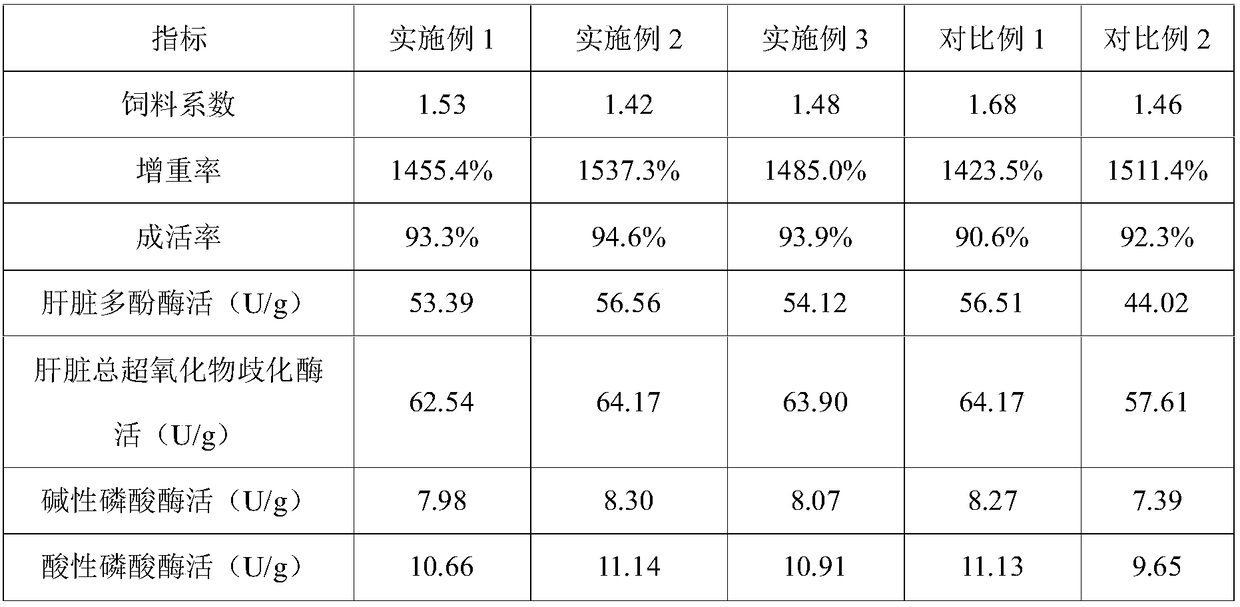

Crab feed added with marine red yeast extract

InactiveCN109275801APromote growthImprove immunityFood processingClimate change adaptationBiotechnologyNutritive values

The invention discloses a crab feed added with a marine red yeast extract. The crab feed comprises the following nutritional components in percentage by weight: 38-65% of protein source raw materials,3-11% of fat source raw materials, 20-35% of sugar source raw materials, 2% -6% of the marine red yeast extract, 1% -3% of fermented aloes, 0.4% -1.5% of compound vitamins and 1-1.5% of composite mineral salt. A preparation method of the marine red yeast extract comprises the following steps: taking marine red yeast dry powder, adding distilled water, 2-phenoxy ethanol and citric acid, performingultrasonic wall breaking, adding papain for enzymolysis, centrifuging, and carrying out freeze drying on supernate to obtain the marine red yeast extract. The preparation of the fermented aloes comprises the following steps: pretreating the aloes, wherein the extraction rates of vitamin, aloin and aloe polysaccharides can be improved by 4-Methyl heptanol and phenyl salicylate; preparing a fermentation strain; and preparing the fermented aloes. The feed has the beneficial effects that the feed is high in nutritive value, promotes the growth of crabs, and has the effect of improving the immunity.

Owner:兰溪市普润斯水产养殖技术有限公司

Method for producing cold-resistant plasticizer through industrial byproduct nylon acid

InactiveCN103012128ASimple production processReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationPolyvinyl chlorideProduct processing

The invention provides a method for producing a cold-resistant plasticizer through industrial byproduct nylon acid, and belongs to the technical fields of comprehensive utilization of the nylon acid and preparation of plasticizers. According to the method, the industrial byproduct nylon acid is used for replacing the expensive long-chain fatty acid to be used as the raw material to react with novel alcohol, namely 2-propyl heptanol, for high-molecular plasticizer to realize the preparation, thus the byproduct can be reasonably recycled, the problem due to pollution of the wastes to the environment can be solved, and the cost can be greatly reduced. The method adopts the process of dealcoholizing firstly and water washing secondly, so that the production process can be simplified, the energy consumption can be saved, and the production period can be shortened. The method is remarkable in economic benefit and social benefit; and the cold-resistant plasticizer has the advantages of being high in compatibility with PVC (Polyvinyl Chloride) and excellent in plasticity and cold resistance, and meets the requirements of product processing and application.

Owner:ZHEJIANG JIANYE CHEM +1

Novel efficient energy-saving environment-friendly flotation reagent

The invention discloses a novel efficient energy-saving environment-friendly flotation reagent, and belongs to the technical field of coal washing. The flotation reagent comprises, by weight, 30-70 parts of diesel, 10-50 parts of octanol, 25-45 pars of heptanol, and 15-35 parts of 2-ethyl hexanol. The flotation reagent is nontoxic, efficient, high in safety, and high in foaming and collecting performance, has no irritating smell, saves energy, is 0.1-0.5 kg in per ton of coal slime, is low in using amount, saves coal dressing cost, and improves clean coal productivity.

Owner:泰安远东化工科技有限公司

Catalyst for preparation of heptanol by hydrogenation of hyptyl aldehyde

InactiveCN1456388AHigh activityHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsPreparation by oxygen reductionHydrogenAlloy

A hydrocatalyst for preparing heptanol from heptanal by hydrogenation is an efficient low-Ni one composed of non-crystal Ni-B alloy (1-15 wt.%) and carrier (85-99 wt.%). It is applied at 100-300 deg.C and 0.1-4.0 / hr for space speed of liquid under 0.5-4.0 MPa and (5-80):1 for hydrogen / aldehyde ratio. Its advantages are high transform rate and high selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Novel synthesis process of octyl 2-propylheptyl phthalate

InactiveCN103664618APrevent oxidationGood pungent colorOrganic compound preparationCarboxylic acid esters preparationActivated carbonAlcohol

The invention discloses a novel synthesis process of octyl 2-propylheptyl phthalate. The process comprises steps as follows: (1), raw materials are taken in a molar ratio of phthalate to alcohol of 1: (2.5-2.7), a catalyst, namely, titanium, is taken according to the amount accounting for 0.3%-0.35% of the total mass of phthalate and alcohol, and alcohol is a mixture of heptanol and octanol in a molar ratio of 1:1; (2), all phthalate, all heptanol and 50% of the catalyst are put into a reaction kettle, nitrogen is fed into the reaction kettle, and the reaction kettle is heated to the temperature of 200-220 DEG C for reaction; (3), all octanol and the residual catalyst are put into the reaction kettle, the reaction continues, and a crude product is obtained until a complete reaction is finished; and (4) after the crude product is washed with water and dealcoholized, activated carbon is used for decoloration, and a finished product is obtained after impurities are filtered. According to the process, nitrogen is used for protection, the condition that an esterification reaction is oxidized at the high temperature is prevented, the chroma grade of octyl 2-propylheptyl phthalate synthetized with the process is better, and the product quality is more stable.

Owner:ZHEJIANG HAILIYE TECH

Biodegradable lubricant oil

The present invention discloses biodegradable lubricant oil which mainly comprises 3.0-5.0 parts by weight of montmorillonite and 1.6-2.0 parts by weight of zirconium oxide, and further comprises 35-40 parts by weight of rapeseed oil, 30-35 parts by weight of tridecyl diacid iso-heptanol, 20-25 parts by weight of castor oil, 1.5-1.8 parts by weight of an antioxidant agent, 0.8-1.0 part by weight of a viscosity modifier and 0.6-1.0 part by weight of an antifoamer, by use of the castor oil, the tridecyl diacid iso-heptanol, the castor oil and other biodegradable base oil, the prepared biodegradable lubricant oil can be biodegradable in a short time, and may not cause pollution and harm to the environment. The biodegradable lubricant oil is simple in production process, low in cost, safe and environmentally-friendly, and has market use prospects.

Owner:大庆市加通石油化工有限公司

Catalyst for preparation of heptanol by hydrogenation of hyptyl aldehyde and use

InactiveCN1212890CHigh activityHigh selectivityPreparation by oxygen reductionMetal/metal-oxides/metal-hydroxide catalystsHydrogenAlloy

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

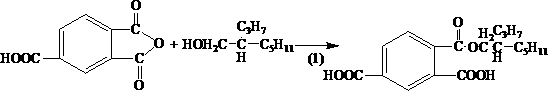

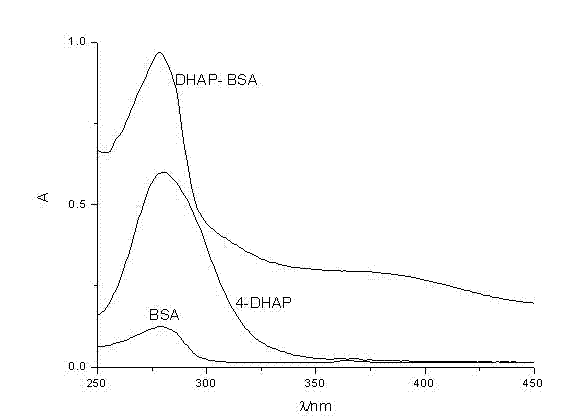

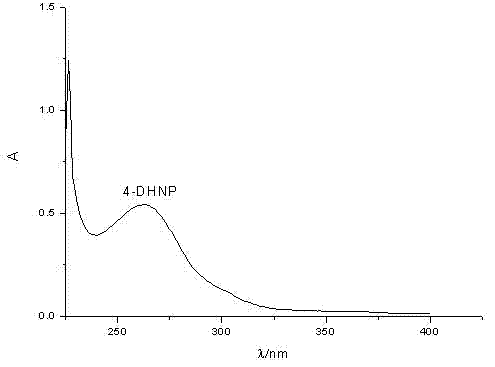

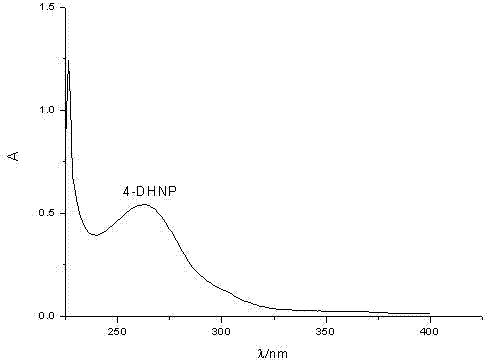

Synthesis method of 4- nitro diheptyl phthalate

InactiveCN102225898AThe synthetic route is simpleLow costOrganic chemistryOrganic compound preparationIce waterSynthesis methods

The invention discloses a synthesis method of 4- nitro diheptyl phthalate, comprising the following steps: adding heptanol in 4-nitro phthalic acid, adding a catalyst with stirring, stirring at 115-125 DEG C and refluxing, reducing pressure to distill off unreacted heptanol and water generated by the reaction, adding ice water while hot, dripping sodium carbonate solution with stirring until the PH value of the water layer is in the range of 6.5-7.2, separating grease and subsequently processing to obtain a yellowish oily liquid, 4- nitro diheptyl phthalate. The method has the advantages of simple process and low cost, and is convenient for application.

Owner:LIAOCHENG UNIV

Cloquintocet-mexyl synthesizing method

InactiveCN101293870AHigh yieldRaw materials are easy to getBiocideOrganic chemistryEsterification reactionToluene

The invention relates to a method for synthesizing mefenpyr-diethyl, sequentially comprising the following steps of: allowing esterification reaction of haloacetic acid and 2-heptanol in the presence of catalyst to obtain haloacetic acid-2-heptanol, and allowing condensation reaction of the haloacetic acid-2-heptanol, 5-chloro-8-hydroxyquinoline and potassium carbonate at a molar ratio of 1:(1-1.2):(1-4) in a solvent by heating, stirring and refluxing for 2.5-8 hours to obtain mefenpyr-diethyl. The solvent is toluene or a mixture of toluene and dimethyl formamide. The synthetic method has the advantages of short synthetic route, high yield, and low cost.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

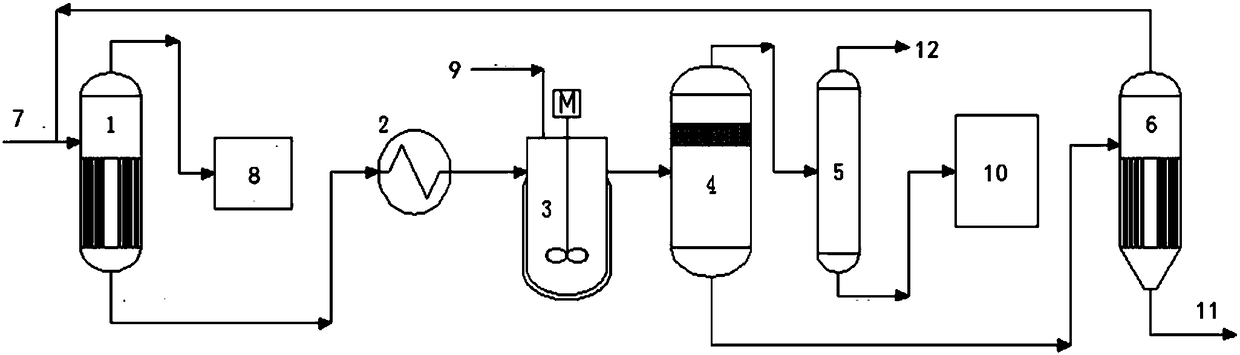

Method for treating wastewater in 2-propyl heptanol production device

InactiveCN108128982AGood added valueReduce loadWater treatment parameter controlMultistage water/sewage treatmentAdditive ingredientTower

The invention relates to a method for treating wastewater in a 2-propyl heptanol production device, and mainly solves the problem of great load of a wastewater treatment plant in the wastewater treatment process in the prior art. The method for treating wastewater in the 2-propyl heptanol production device comprises the following steps that (1) wastewater enters concentration bag equipment; concentrated liquid obtained by the concentration bag equipment is cooled by a cooler and then enters an acidification tank; water concentrated by the concentration bag equipment enters a biochemical treatment plant for biochemical treatment; (2) the concentrated liquid at an outlet of the acidification tank enters a chromatography device to obtain an organic phase and a water phase; (3) the organic phase enters a rectifying tower; valeric acid is obtained at the top of the rectifying tower; heavy ingredients of a rectification tower kettle enter an incinerator; the water phase enters an evaporativecrystallization device to obtain water and solid salts, wherein the water returns to the concentration bag equipment for reuse. The technical scheme better solves the problems, and can be used for wastewater treatment in the 2-propyl heptanol production device.

Owner:SINOPEC SHANGHAI ENG +1

Catalyzing and decoloring integrated method for synthesizing environment-friendly plasticizer triethylhexyl (2-propylheptyl) citrate

InactiveCN103030560AEasy to operateLow costOrganic compound preparationCarboxylic acid esters separation/purificationChemical synthesisP-Toluenesulfonic acid

A catalyzing and decoloring integrated method for synthesizing environment-friendly plasticizer triethylhexyl (2-propylheptyl) citrate belongs to the technical field of chemical synthesis. The method comprises: taking p-toluenesulfonic acid as an active central body, immobilizing the p-toluenesulfonic acid on an active carbon to prepare a heterogeneous catalyst, taking citric acid monohydrate or anhydrous citric acid and 2-propyl heptanol as main reaction materials, using the heterogeneous catalyst for catalyzing and decoloring, taking cyclohexane as a water carrying agent, stirring and raising the temperature to 110-150 DEG C to conduct an esterification reaction, reducing the pressure and distilling to remove excess ethanol after the reaction is over, separating the heterogeneous catalyst from a reaction system, filtering the catalyst, and neutralizing, washing with alkali, washing with water and drying a crude product, so as to obtain a finished product of the triethylhexyl (2-propylheptyl) citrate. The selected raw materials are easy to get and cheap, high in catalytic activity, good in selectivity, and high in esterification yield; the used catalyst can be recycled and is not obviously corrosive; the method integrates catalyzing and decoloring, is simple in operation and is economic and environment-friendly; in addition, the obtained product is free from toxic, good in plasticity and thermal stability and small in mobility, and is not easy to volatilize.

Owner:JIANGNAN UNIV

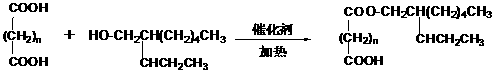

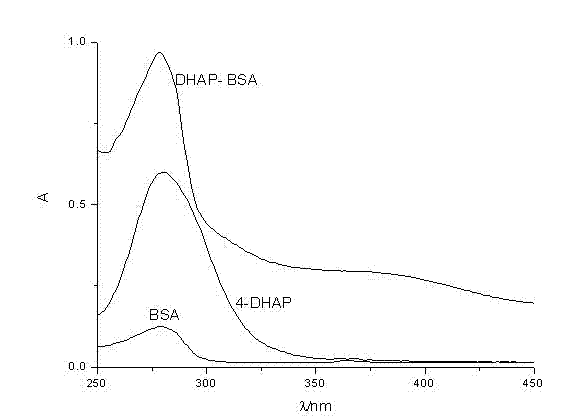

Synthetic method for 4-amino diheptyl phthalate

InactiveCN102225901AThe synthetic route is simpleLow costOrganic compound preparationAmino-carboxyl compound preparationEsterification reactionPhthalic acid

The invention discloses a synthetic method for 4-amino diheptyl phthalate. The method is characterized in that: 4-nitro phthalic acid is adopted as a raw material, and is subjected to a esterification with heptanol to prepare 4-nitro diheptyl phthalate; a nitro group is introduced into a benzene ring of the 4-nitro diheptyl phthalate, then the nitro group is subjected to a reduction reaction to obtain a active amino capable of combination with proteins to synthesize the 4-amino diheptyl phthalate. The method provided by the present invention has advantages of simple route, low cost and convenient application.

Owner:LIAOCHENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com