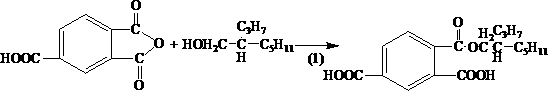

Method for preparing plasticizer 1, 2, 4-benzenetricarboxylicacid tris(2-propyl heptyl) ester

A technology of trimellitic acid tris and trimellitic anhydride, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of industrial production level, low output, high raw material price, and restricted application, and achieve Reduce production costs, reduce raw material costs, and achieve superior low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

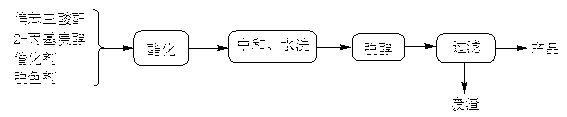

Method used

Image

Examples

Embodiment 1

[0031] Add 4.8kg of trimellitic anhydride, 25.3kg of 2-propylheptanol (the molar ratio of trimellitic anhydride to 2-propylheptanol is 1:3.2), 0.0192kg of tetra-n-butyl titanate, 0.0075kg of activated carbon, and attapulgite in the reaction kettle 0.0075kg, used to absorb oxygen and decolorize, stir and raise the temperature to 200℃~220℃, the reaction time is 4h, the esterification rate reaches 99.1%; the crude product is washed with neutralization alkali and water, and the mass fraction of neutralization alkali washing is 5 % sodium bicarbonate aqueous solution at a temperature of 50°C to 70°C, washed with deionized water or distilled water at a temperature of 60°C to 90°C; dealcoholized by vacuum distillation at a temperature of 170°C and a vacuum of 0.09MPa. After extraction again, it is finally filtered to obtain a light yellow product, tris(2-propylheptyl) trimellitate.

Embodiment 2

[0033] Add 4.8kg of trimellitic anhydride, 31.66kg of 2-propylheptanol (the molar ratio of trimellitic anhydride to 2-propylheptanol is 1:4), 0.0288kg of tetraisopropyl titanate, 0.029kg of activated carbon, and attapulgite in the reaction kettle 0.029kg, used to absorb oxygen and decolorize, stir and heat up to a temperature of 200°C~220°C, reaction time 4h, esterification rate reaches 99.6%; the crude product is washed with neutralization alkali and water, and the mass fraction of neutralization alkali washing is 5 % sodium bicarbonate aqueous solution at a temperature of 50°C to 70°C, washed with deionized water or distilled water at a temperature of 60°C to 90°C; dealcoholized by vacuum distillation at a temperature of 170°C and a vacuum of 0.09MPa. After extraction again, it is finally filtered to obtain a light yellow product, tris(2-propylheptyl) trimellitate.

Embodiment 3

[0035] Add 4.8kg of trimellitic anhydride, 35.62kg of 2-propylheptanol (the molar ratio of trimellitic anhydride to 2-propylheptanol is 1:4.5), 0.0288kg of titanate (of which 0.0192kg of tetraisopropyl titanate, Tetra-n-butyl titanate 0.0096kg), activated carbon 0.0404kg, attapulgite 0.0404kg, used to absorb oxygen and decolorize, stir and heat up to a temperature of 200 ° C ~ 220 ° C, the reaction time is 6 hours, and the esterification rate reaches 99.4%; the crude product Carry out neutralization alkali washing and water washing, neutralization alkali washing uses sodium bicarbonate aqueous solution with a mass fraction of 5%, the temperature is 50 ° C ~ 70 ° C, water washing uses deionized water or distilled water, the temperature is 60 ° C ~ 90 ° C; decompression Dealcoholization by distillation at a temperature of 170°C and a vacuum of 0.09MPa. After the alcohol no longer comes out, filter at last to obtain a light yellow product, tris(2-propylheptyl)trimellitate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com