Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

470 results about "Hexanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexanol may refer to any of the following isomeric organic compounds with the formula C₆H₁₃OH:

Fuels for internal combustion engines

InactiveUS6858048B1Emission reductionSafer land environmentLiquid carbonaceous fuelsFuel additivesKeroseneOctanol

Mixed alcohols can be used as a fuel additive in gasoline, diesel, jet fuel or as a neat fuel in and of itself. The mixed alcohols can contain C1-C5 alcohols, or in the alternative, C1-C8, or higher, alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with amounts of hexanol, heptanol and octanol. A gasoline-based fuel includes gasoline and the mixed alcohols. A diesel based fuel includes diesel and the mixed alcohols. A jet fuel includes kerosene and the mixed alcohols. The neat fuel of the mixed alcohols has an octane number of at least 109 and the Reid Vapor Pressure is no greater than 5 psi. The gross heat of combustion is at least 12,000 BTU's / lb.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

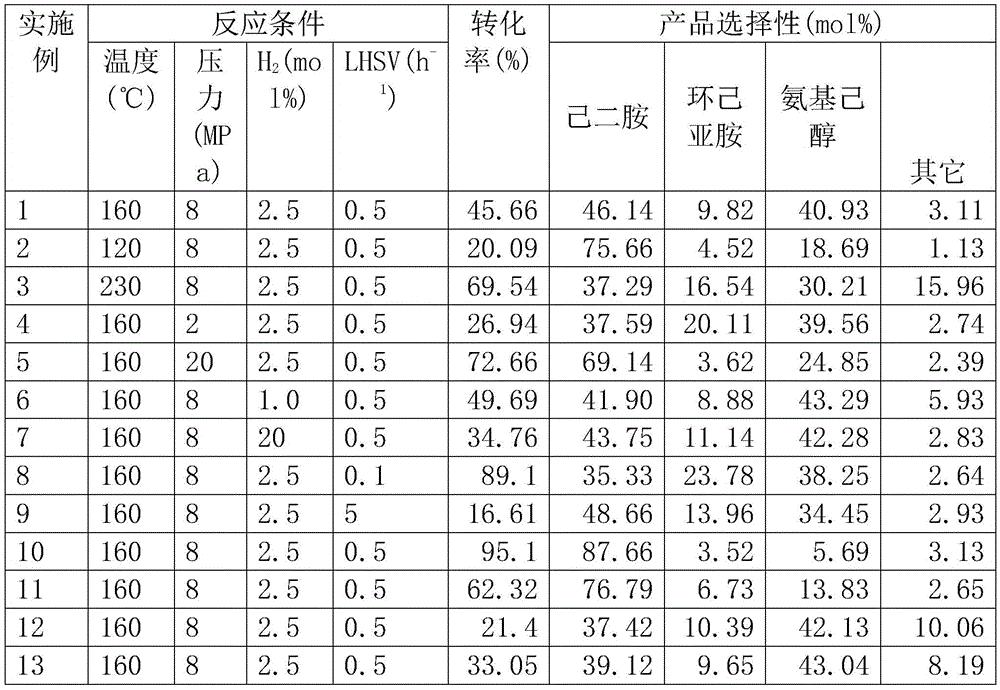

Catalyst for synthesizing hexamethylenediamine

InactiveCN106807377APromote productionReduce the likelihood of aggregationOrganic compound preparationAmino compound preparationHydrogenHexamethylenediamine

The invention relates to a catalyst for synthesizing hexamethylenediamine. The catalyst is composed of three parts, namely a main active ingredient, aids and a carrier subjected to ammoniated treatment, wherein the main active ingredient is Ni or Co; the aids refer to one or more ofmetals such as Fe, Cu, Ru, Re, K, Zn and B or oxides; and the carrier subjected to ammoniated treatment is selected from SiO2 or Al2O3 subjected to ammoniated treatment. In the total weight of the catalyst, the main active ingredient accounts for 1-40%, and the aids account for 0.1-20%. The catalyst disclosed by the invention has the characteristic that the adopted carrier needs special ammoniated treatment. According to the catalyst disclosed by the invention, an ammonolysis reaction of hexanediol or amino hexanol or a hexanediol / amino hexanol mixture is implemented, the hexamethylenediamine product is synthesized under a hydrogen present condition, and the catalyst has high activity, high selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

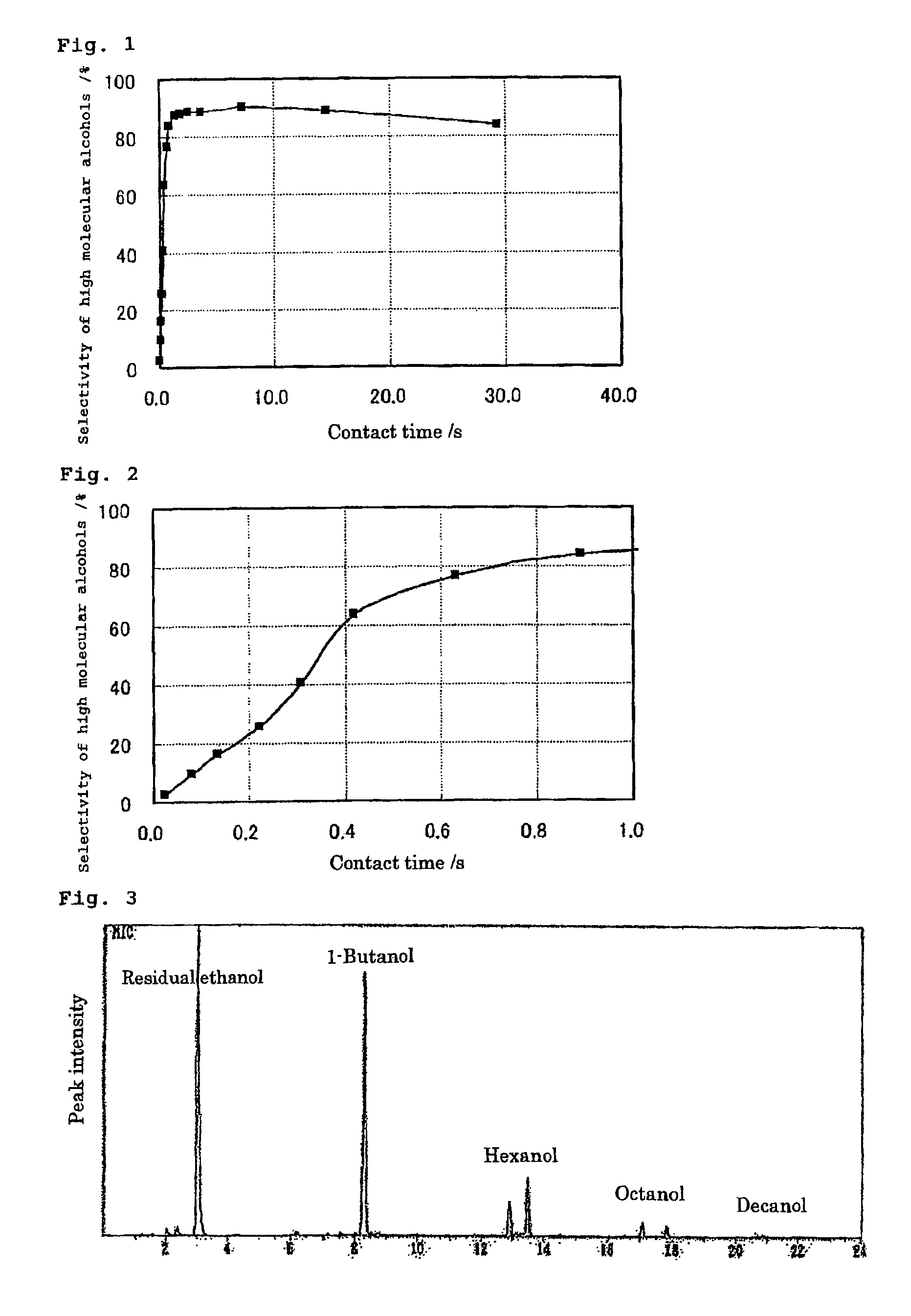

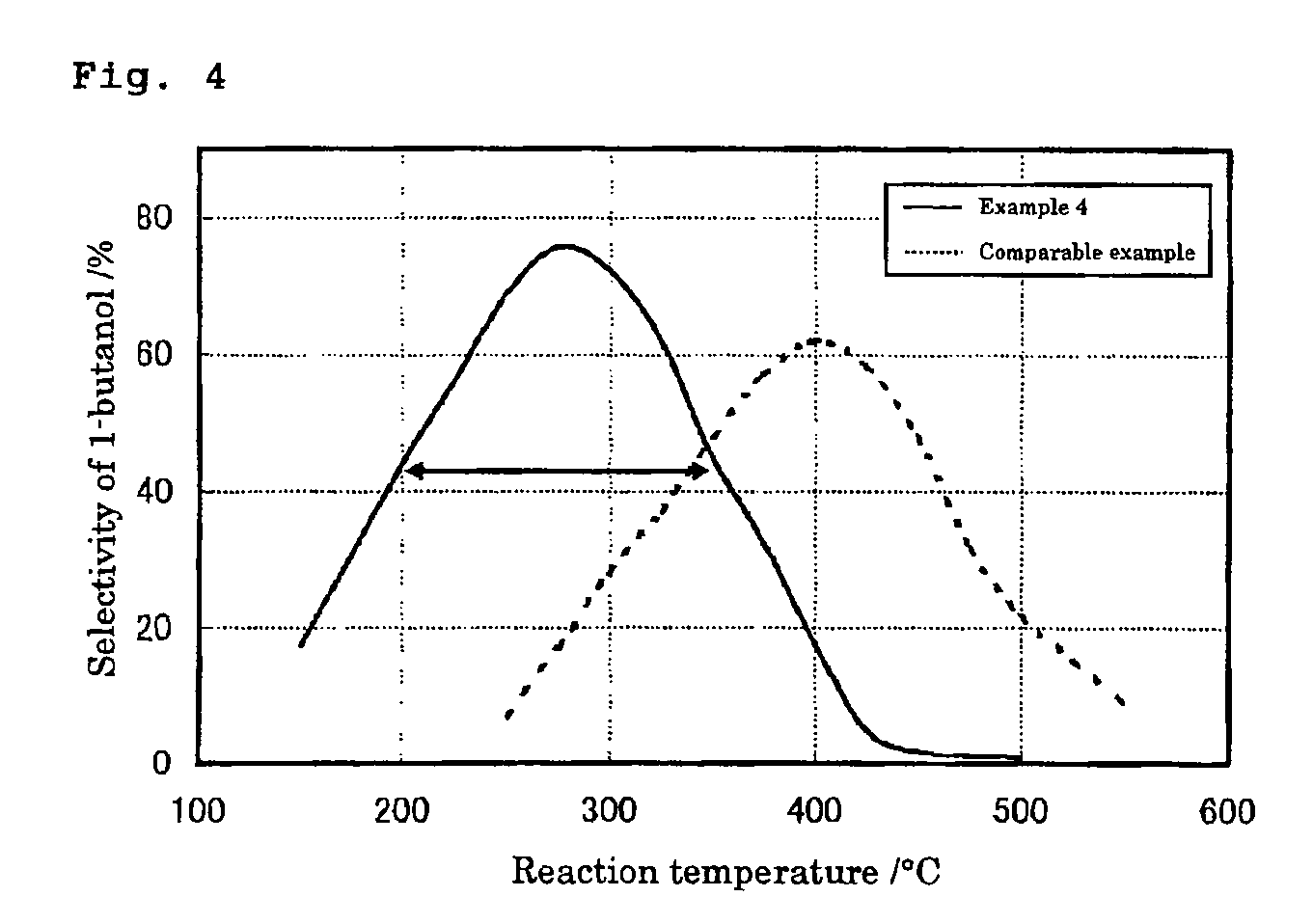

Method of Synthesizing Higher-Molecular Alcohol

ActiveUS20070255079A1Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationOctanolSynthetic Polymeric Macromolecules

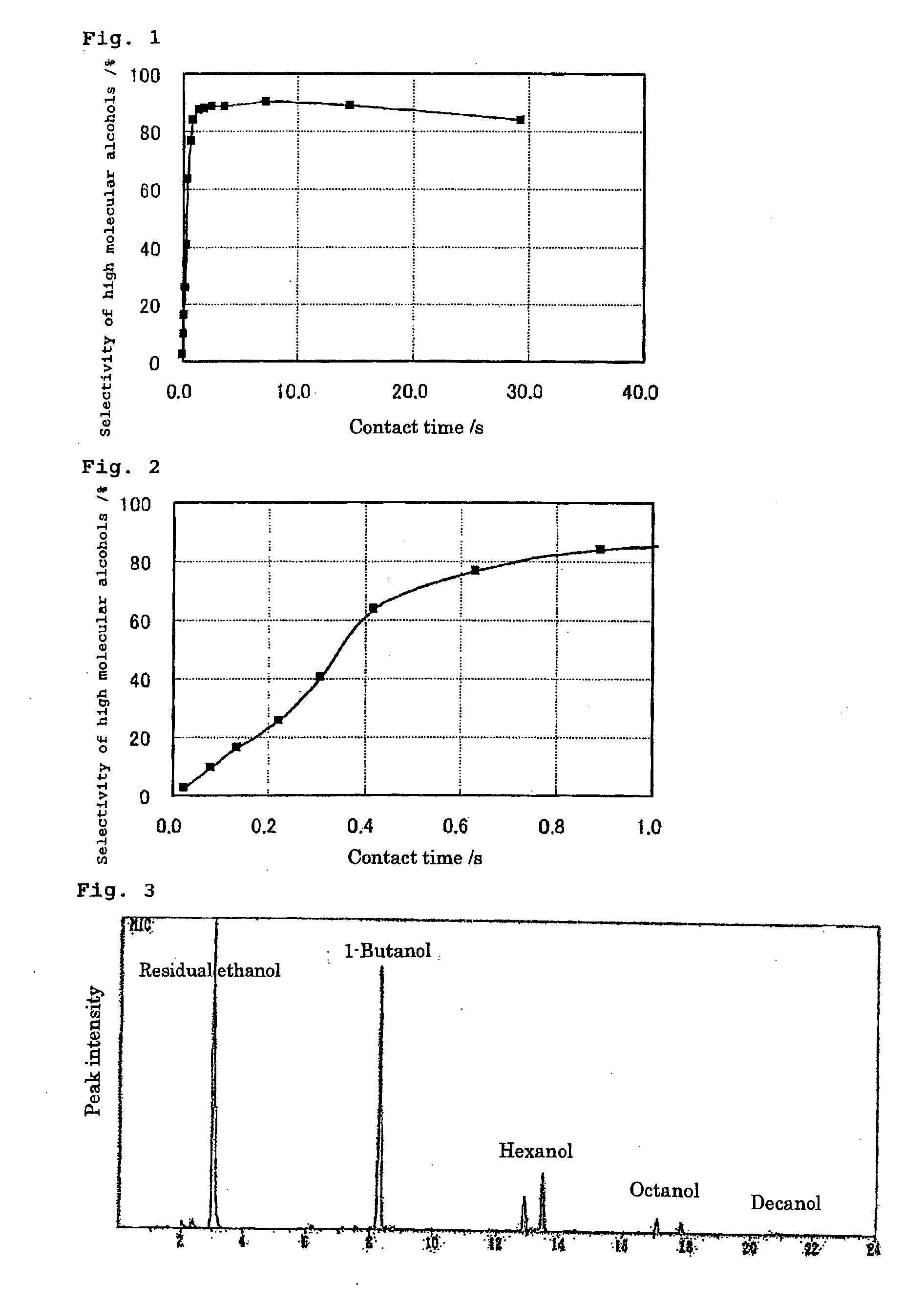

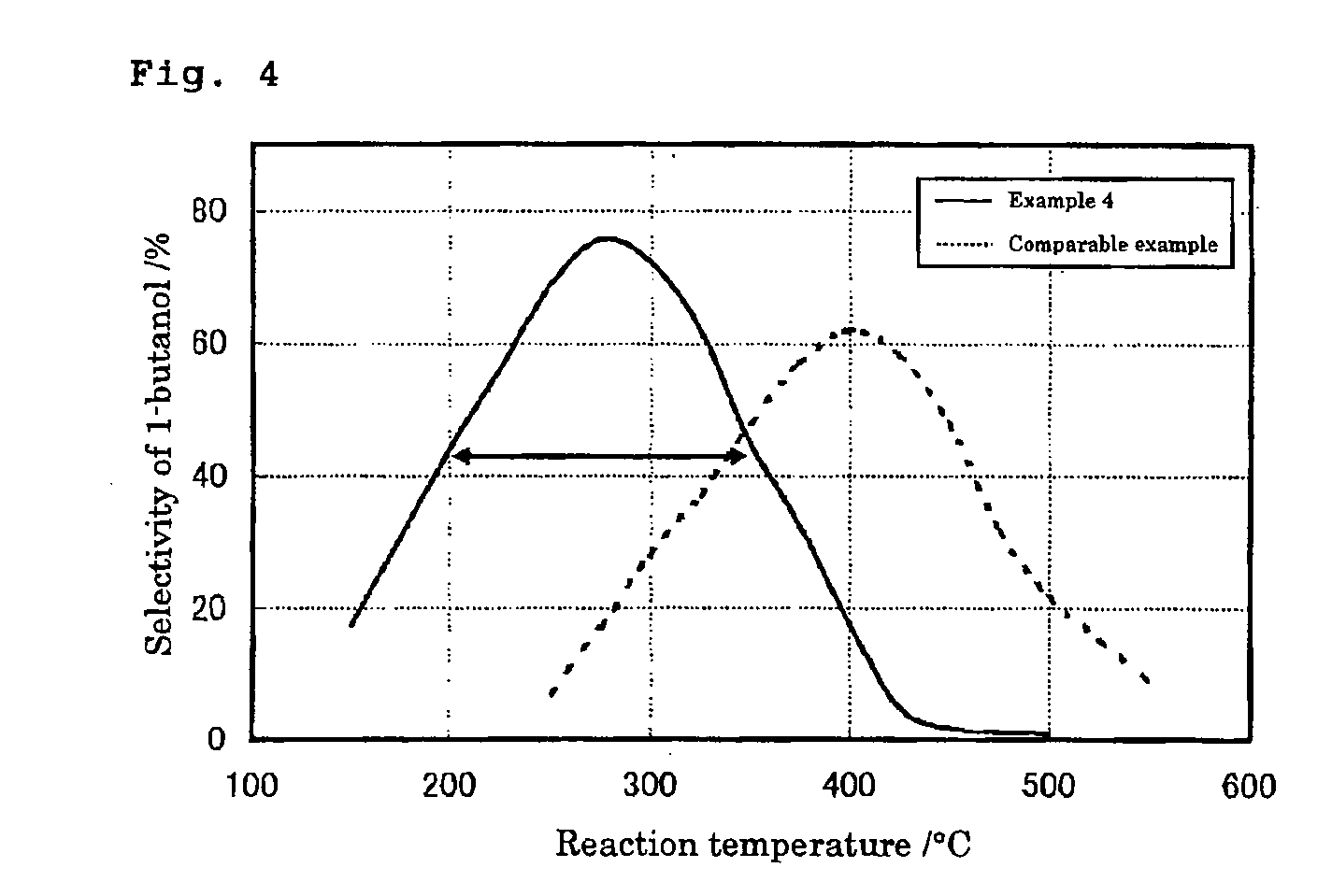

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2.nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

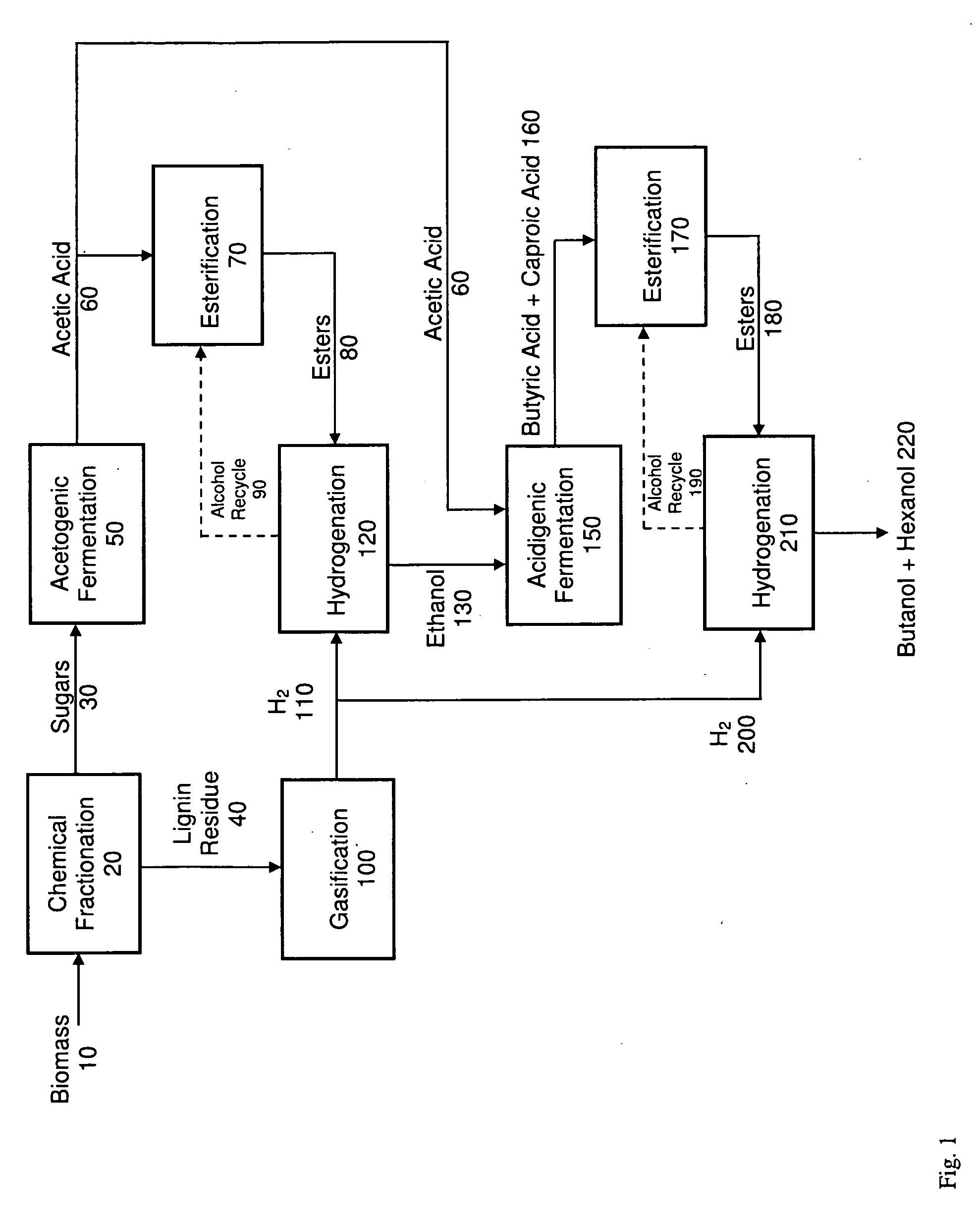

Indirect production of butanol and hexanol

InactiveUS20090203098A1Organic compound preparationHydroxy compound preparationAcetic acidButyric acid

A process for the conversion of carbohydrates from any of a number of sources into butanol and hexanol for fuel or chemical use is disclosed. The process includes conducting a homoacetogenic fermentation to produce an acetic acid intermediate which is chemically converted to ethanol. The ethanol and a remaining portion of the acetic acid intermediate are used as a substrate in an acidogenic fermentation to produce butyric and caproic acid intermediates which are then chemically converted to butanol and hexanol.

Owner:ZEACHEM

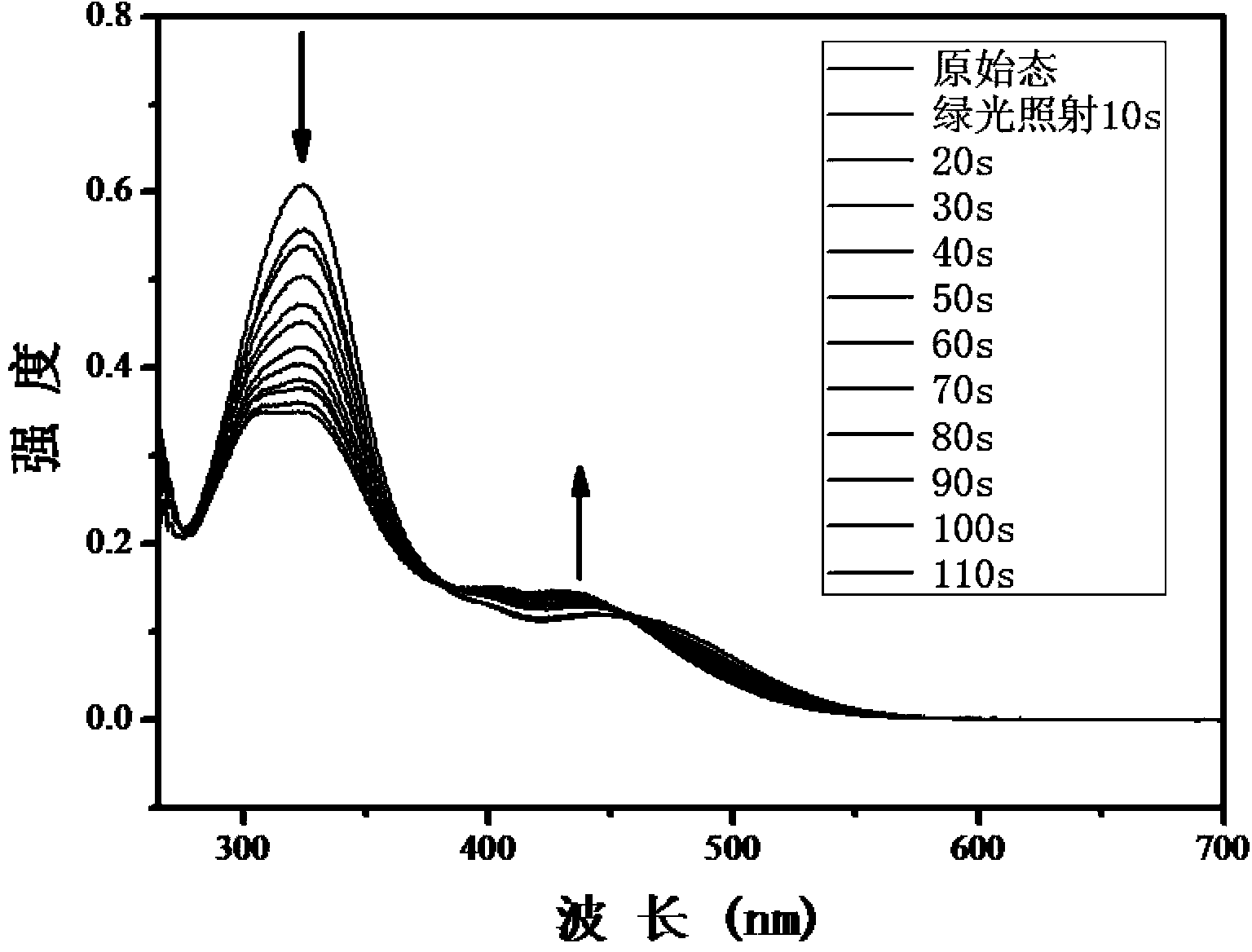

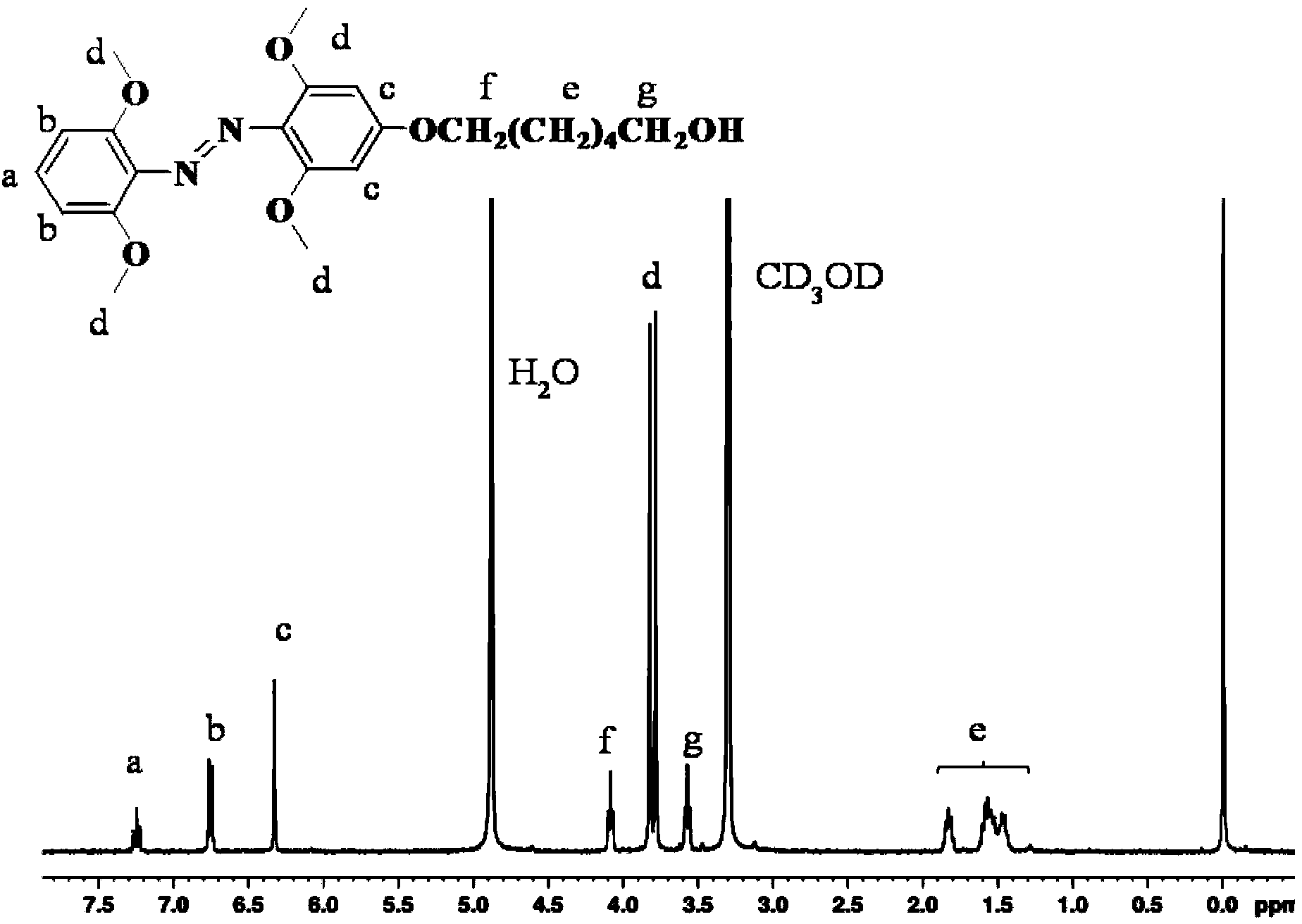

Method for synthesizing visible-light response type azobenzene polymer

The invention relates to a method for synthesizing a visible-light response type azobenzene polymer. The method comprises the following steps: preparing tetramethoxy dihydroxyazobenzene from 2,6-dimethoxyaniline and 3,5-dimethoxy phenol through diazo-reaction, reacting tetramethoxy dihydroxyazobenzene as a raw material with 6-bromohexane alcohol to prepare tetramethoxy-4-ethanol oxyl azobenzene, grafting azobenzene onto a polypropylene acyl chloride framework through alcoholysis reaction of acyl chloride groups, and converting unreacted acyl chloride groups into carboxyl through hydrolysis, thereby finally obtaining the visible-light response type azobenzene polymer, namely, a 2-(2,6,2',6'-tetramethoxy-4-hexyloxy azobenzene phenoxy) crylic acid ethyl ester acrylic copolymer. The method has the advantages that the method is simple and feasible, the synthesized polymer has visible-light response type azobenzene groups, trans / cis-form conversion is achieved under the radiation of green light (520nm), reverse conversion can be achieved under radiation of blue light (420nm), and compared with conventional azobenzene molecules, the azobenzene polymer has the most remarkable advantage that bidirectional conversion of isomer can be achieved without ultraviolet light.

Owner:UNIV OF SCI & TECH BEIJING

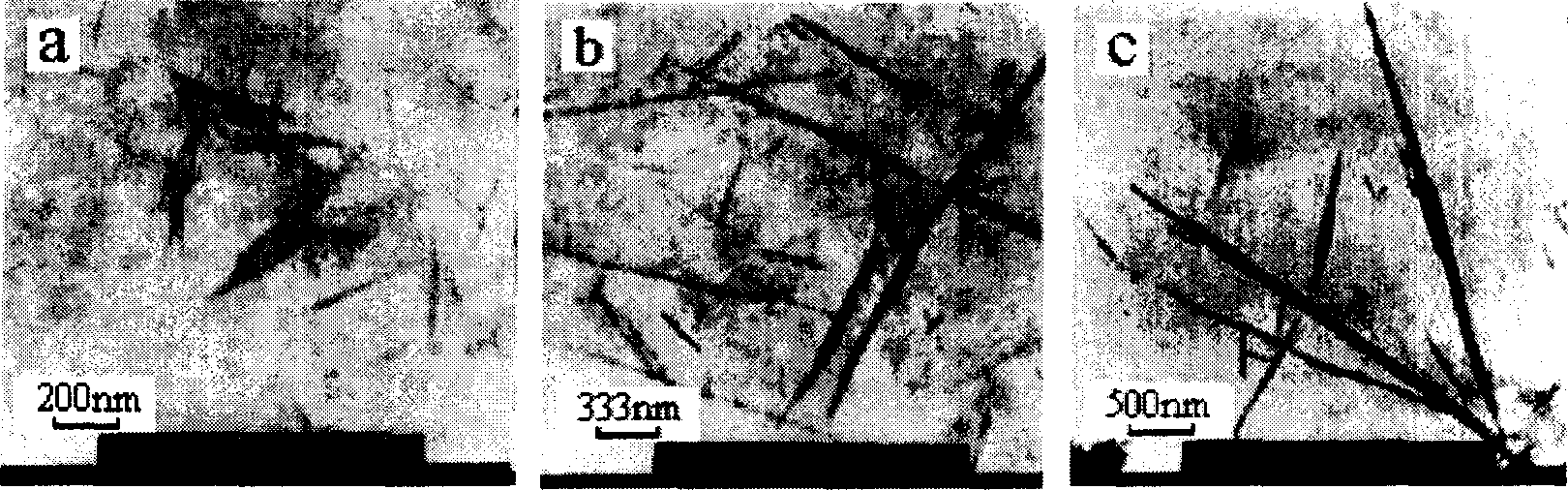

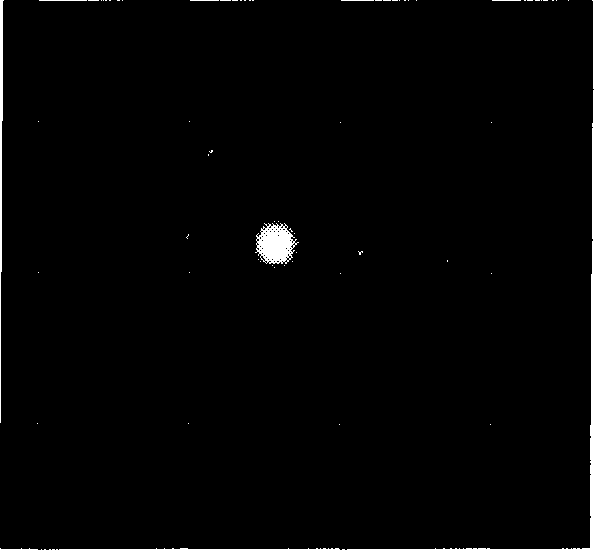

Process for prepairng granularity controllable nm-class zirconium oxide

A process for preparing nm-class zirconium oxide with controllable size (less than 30 nm) includes preparing two portions of microsuspension containing non-ionic surfactant, n-hexanol, cyclohexane and zirconium salt solution or amminia water, mixing, hydrolysis reaction, centrifuging or filtering, washing with alclohol and water several times, drying and calcining. It features that its size can be controlled by controlling the content of zirconium solution or ammonia water, the ratio of water to surfactant and reaction temp.

Owner:TSINGHUA UNIV

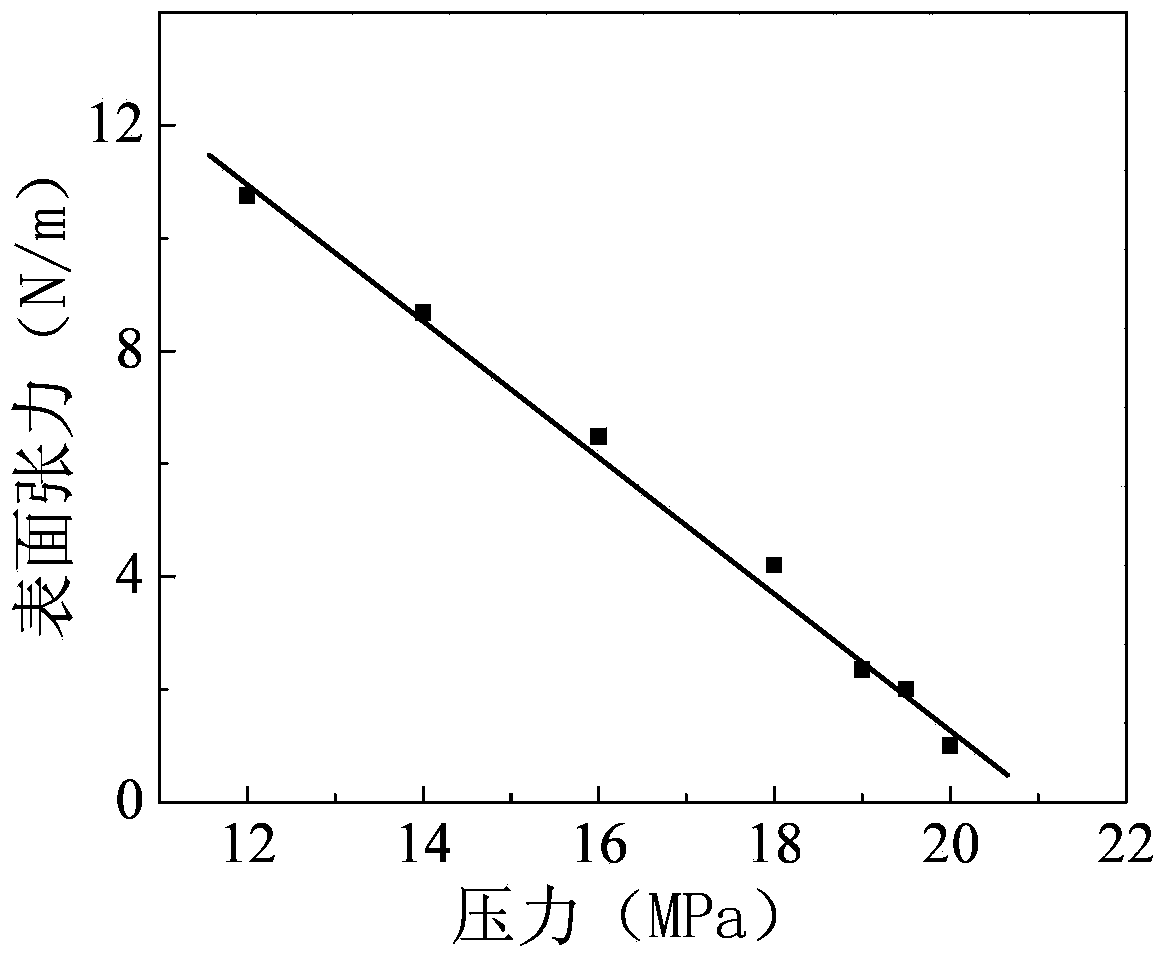

Supercritical CO2 microemulsion and method for improving oil recovery factor

InactiveCN104194762AReduce the minimum miscibility pressureEnhanced overall recoveryDrilling compositionBulk chemical productionPhosphatePolyethylene glycol

The invention provides a supercritical CO2 microemulsion and a method for improving an oil recovery factor. The supercritical CO2 microemulsion comprises the following raw materials in percentages by weight: 4.5*10<-3>wt% to 16.5*10<-3>wt% of a surfactant, 12.0wt% to 14.5wt% of a cosurfactant, 0.2wt% to 1.8wt% of water, and 83.7wt% to 87.8wt% of CO2, wherein the surfactant is one of 2-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate or a homolog of 2-(1-ethyl-2-methyl-1-pentyl) sodium sulfosuccinate, polyethylene glycol-2,6,8-trimethyl-4-nonyl ether, perfluorinated alkyl polyoxyethylene, polyacrylic acid 1,1-perfluorooctyl dihydrogen phosphate, polydimethylsiloxane, and polyacrylic acid 1,1-dihydrogen perfluorinated octyl methyl ester-b-polyoxyethylene; and the cosurfactant is ethanol, propyl alcohol, butanol, pentanol or hexyl alcohol. The invention also provides a method for improving an oil recovery factor. The method comprises a step of improving the oil recovery factor by adopting the supercritical CO2 microemulsion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Fuels and fuel additives comprising butanol and pentanol

Disclosed herein are fuels and / or fuel additives comprising butanol and pentanol. In particular, the fuels and / or fuel additives comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol, based on the total volume of the fuels or the fuel additive. Also disclosed herein are fuel compositions comprising fuels or fuel additives, which comprise from about 45 vol. % to about 90 vol. % of butanol and from about 10% to about 55% of pentanol. The fuels and / or fuel additives may also comprise minor amounts of methanol, ethnaol, propanol, hexanol, heptanol, and / or octanol.

Owner:IGP ENERGY

Preparation method of ferro-doped TiO2/SiO2 aerogel microball

InactiveCN1966141AWide variety of sourcesLow priceMetal/metal-oxides/metal-hydroxide catalystsMicrosphereOil phase

The invention relates to a method for preparing TiO2 / SiO2 aerogel micro ball doping with iron, wherein it dissolves TiOSO4 and FeCl3 into deionized water, adjusts pH value to 7-8, to obtain deposits; washes deposits, adds nitric acid solution, mixes at 50-90Deg. C to obtain TiO2 sol doping with iron; adds nitric acid into silicasol and absolute ethyl alcohol to prepare SiO2 alcohol sol; then mixes titanium sol with SiO2 alcohol sol at 1:3-8 volume ratio, adds formamide, mixes to obtain TiO2 / SiO2 composite sol; mixes skellysolve C / skellysolve B, siban 80, tuwen 85, butanol / hexanol at 1000:1-10:0.1-1:25-100, to obtain the oil phase; then adds TiO2 / SiO2 composite sol into oil phase, to make pH at 7-10, to obtain the TiO2 / SiO2 gel micro ball; washes with acetone and dries, to obtain the TiO2 / SiO2 aerogel micro ball at 10-200micrometer diameter. The invention has simple process and low cost.

Owner:TONGJI UNIV

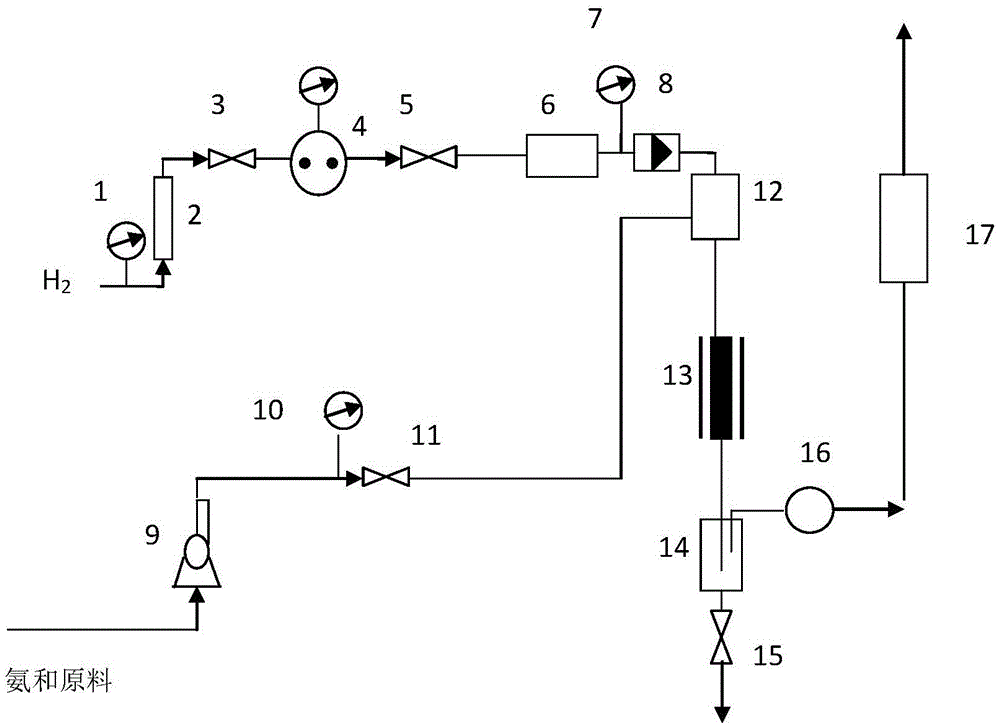

Method for preparing hexamethylene diamine

InactiveCN106810454AImprove performanceHigh selectivityOrganic compound preparationAmino compound preparationHydrogenHexamethylenediamine

The invention relates to a method for preparing hexamethylene diamine by using hexanediol, or amino hexanol or a hexanediol / amino hexanol mixture as a raw material. The method comprises the following steps: mixing the hexanediol, or the amino hexanol or the hexanediol / amino hexanol mixture with liquid ammonia according to a certain proportion, pumping the mixture into a reactor, and reacting under the existence of a catalyst and hydrogen. According to the method disclosed by the invention, a novel catalyst is adopted, the catalytic performance is excellent, and long-time operation is easy; production of a hexamethylene diamine product by carrying out hydro-amination on the hexanediol, or the amino hexanol or the hexanediol / amino hexanol mixture can be realized under lower reaction pressure, compositions of the product can be flexibly changed by changing reaction conditions, the selectivity of a target product is increased, a reaction process is simple, the one-time investment and the production cost of a production device are reduced, separation of a reaction product and the catalyst is simple, and large-scale continuous industrial production can be easily realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing TiO2/SiO2 aerogel microsphere

InactiveCN1868581AThe process is simple and easy to controlLow costPhysical/chemical process catalystsMicrosphereOil phase

A process for preparing microspheres of TiO2 / SiO2, aerogel includes such steps as dissolving TiOSO4 in deionized water, adding ammonia water to make pH=7-8, depositing, washing deposit, adding nitric acid, stirring to obtain TiO2 sol, mixing Si sol with nitric acid, adding alcohol to obtain SiO2 alcohol sol, mixing it with said TiO2 sol, adding formamide and epoxy propane, mixing to obtain TiO2 / SiO2 sol, mixing heptane or hexane, Span-80, tween-85 and butanol or hexanol, stirring to obtain oil phase, adding TiO2 / SiO2 sol, adding ammonia water to make pH=7-1, centrifugal separation of target microspheres, washing and drying.

Owner:TONGJI UNIV

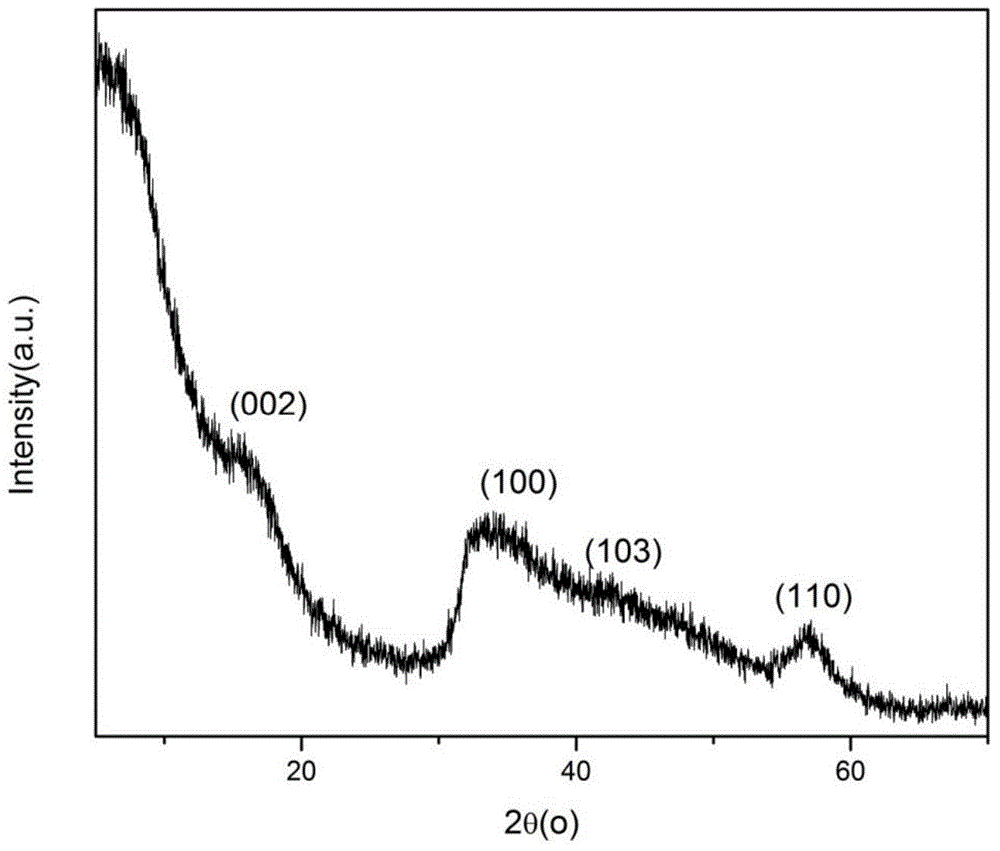

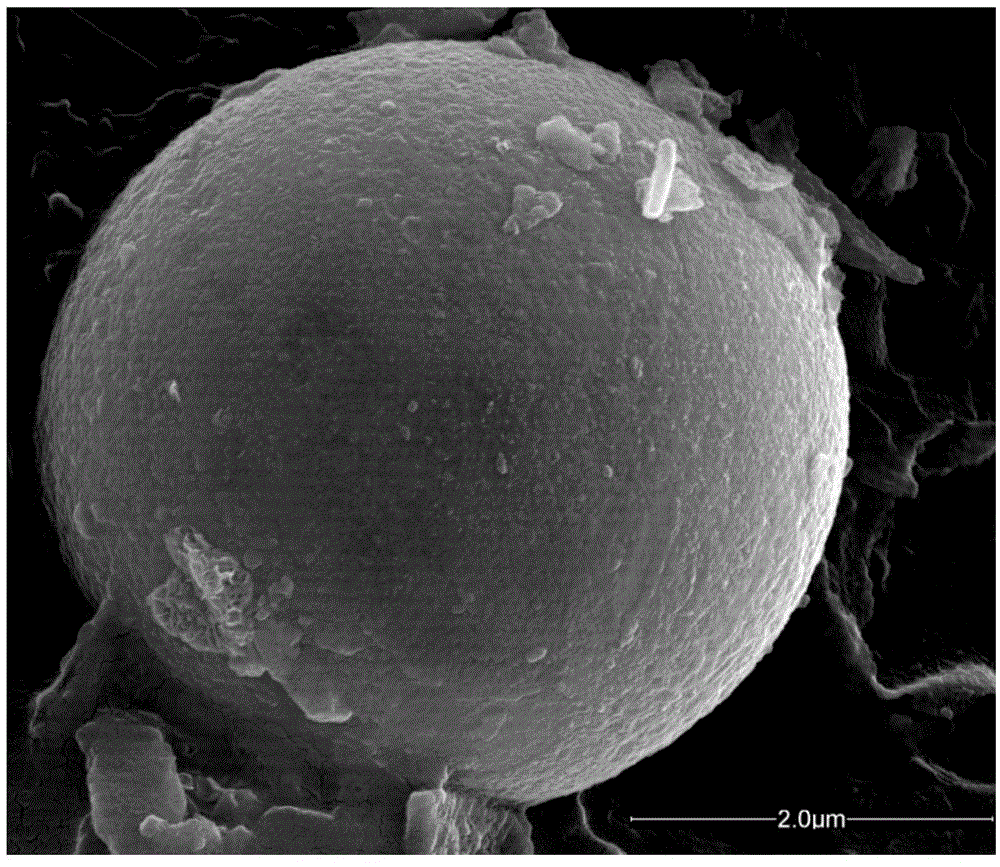

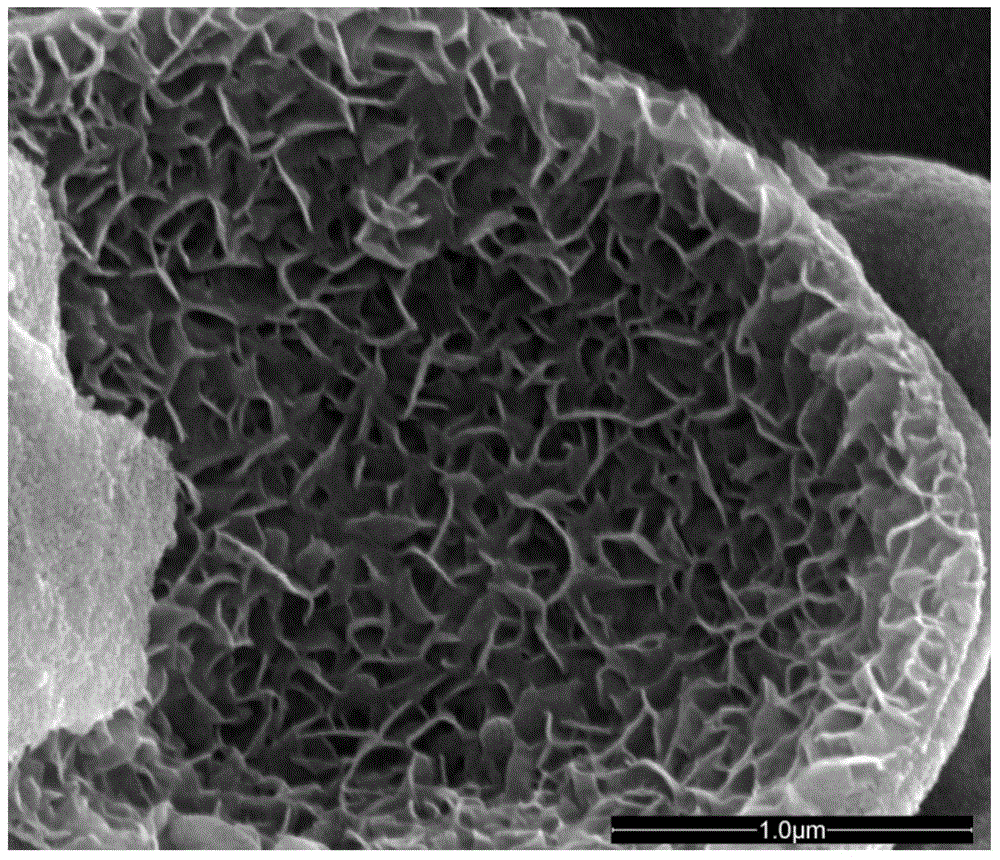

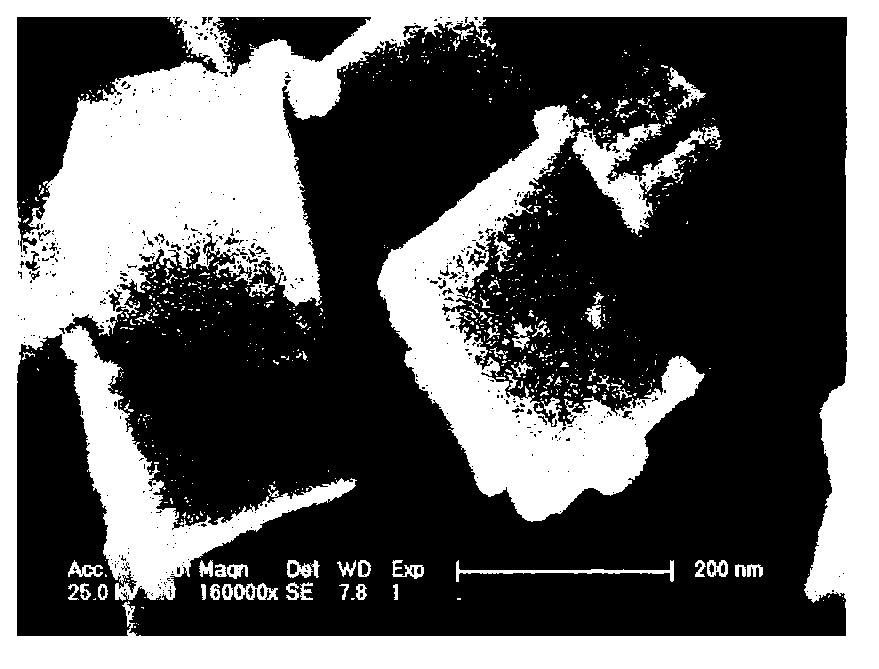

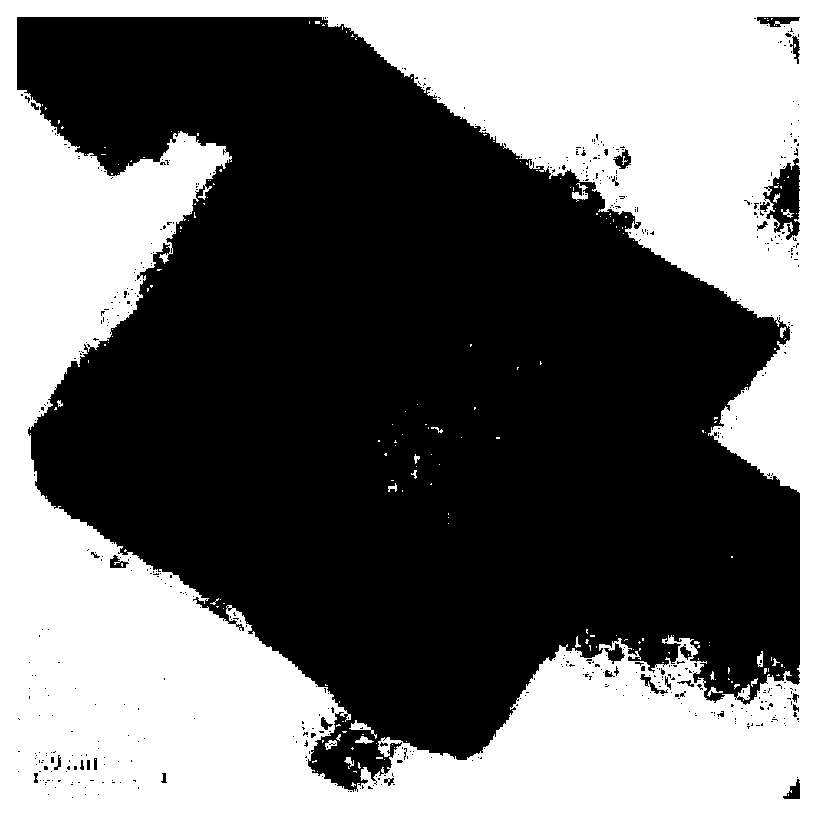

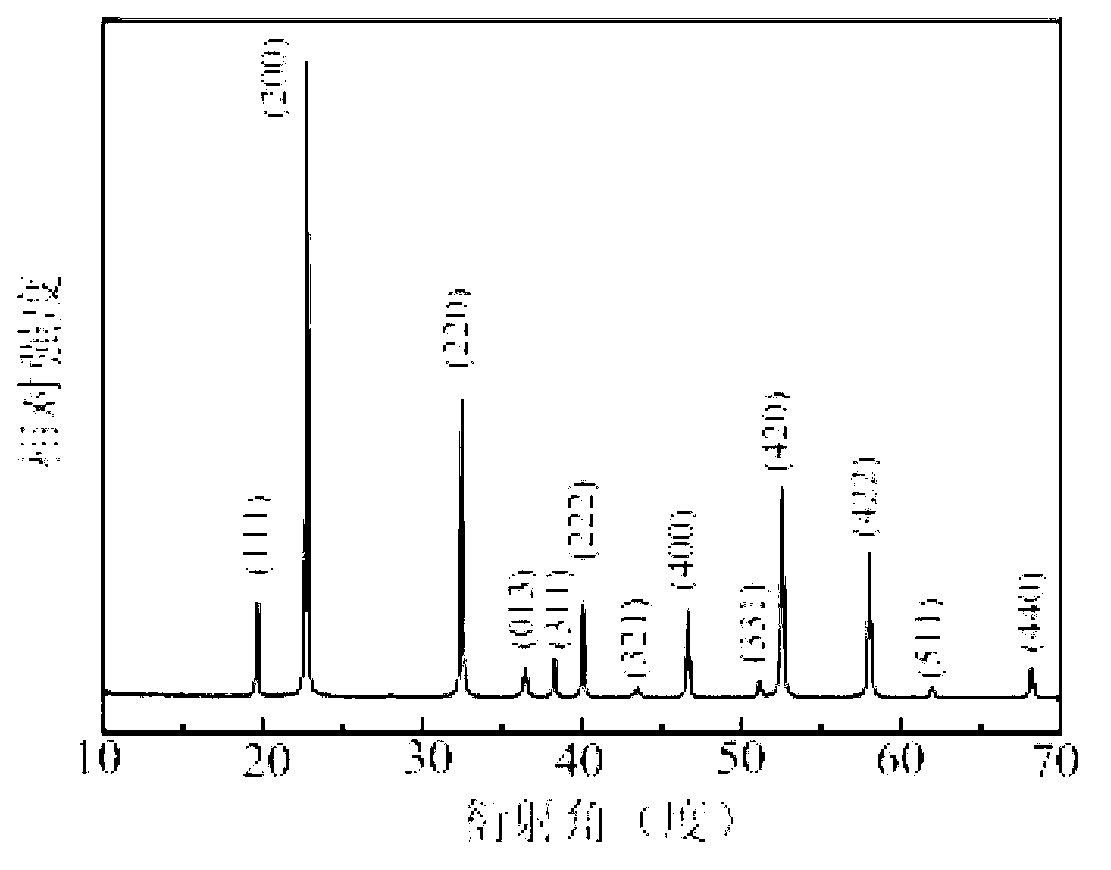

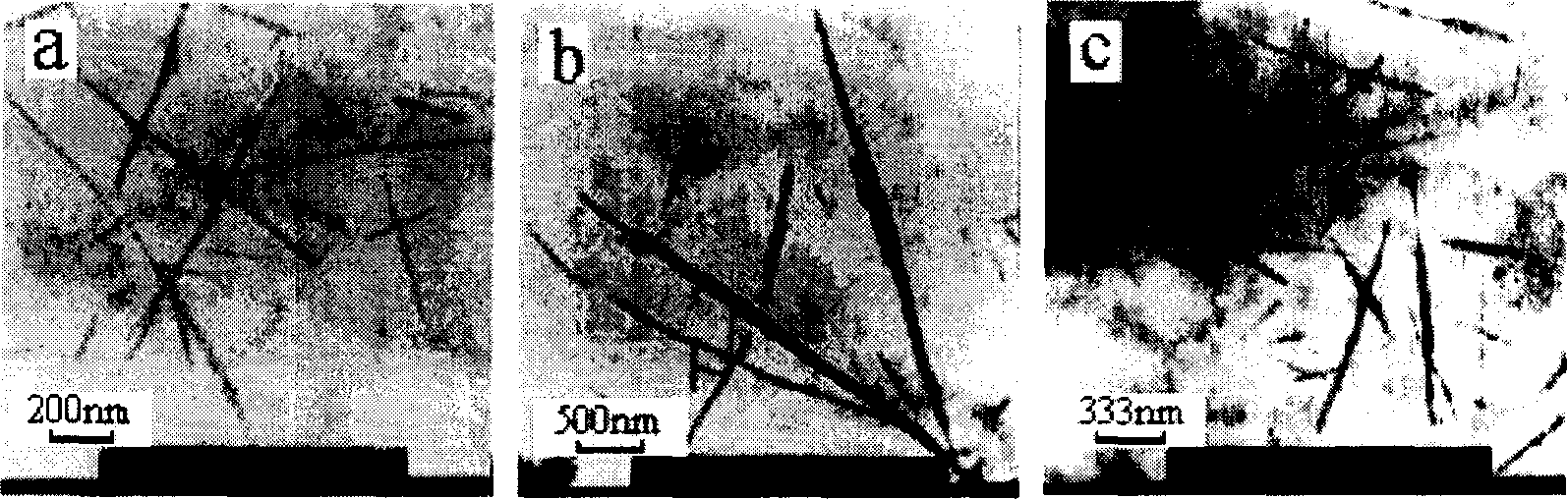

A method of preparing molybdenum disulfide microspheres in a reversed-phase microemulsion system

The invention provides a method of preparing molybdenum disulfide microspheres through sulfurizing and reducing a soluble molybdenum source in a reversed-phase microemulsion system. The method includes a) a step of preparing a reversed-phase microemulsion A through adopting polyethylene glycol octylphenol ether (Triton X-100), n-hexanol, cyclohexane and an aqueous solution of the soluble molybdenum source as a surfactant, a cosurfactant, an oil phase and a water base respectively, b) a step of adding an aqueous solution containing a sulfur source and a reductant into the reversed-phase microemulsion A to obtain a reversed-phase microemulsion B, and c) a step of transferring the reversed-phase microemulsion B to a hydrothermal reactor, performing crystallization thermal treatment at a certain temperature for a certain period of time, separating, washing, and drying the reaction product to obtain the molybdenum disulfide microspheres. The method is simple and mild in reaction conditions. Through characterization by a scanning electron microscope and a transmission electron microscope, the molybdenum disulfide microspheres have the characteristics of being solid or hollow, smooth or wrinkled in surface, and the like.

Owner:PETROCHINA CO LTD +1

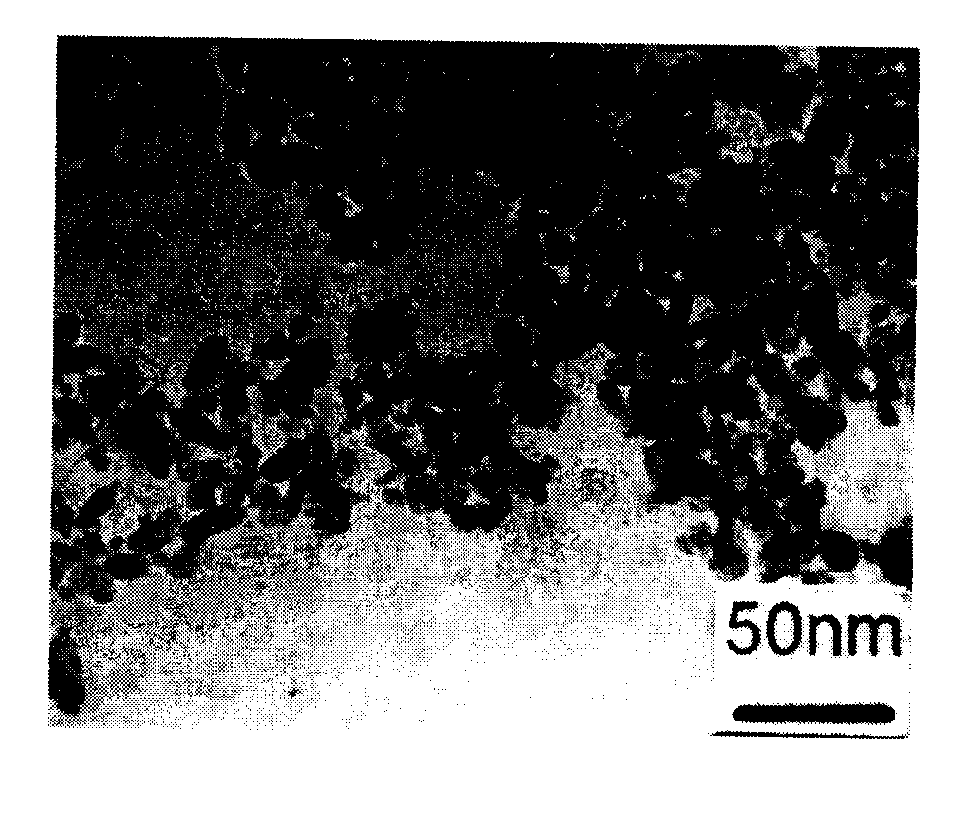

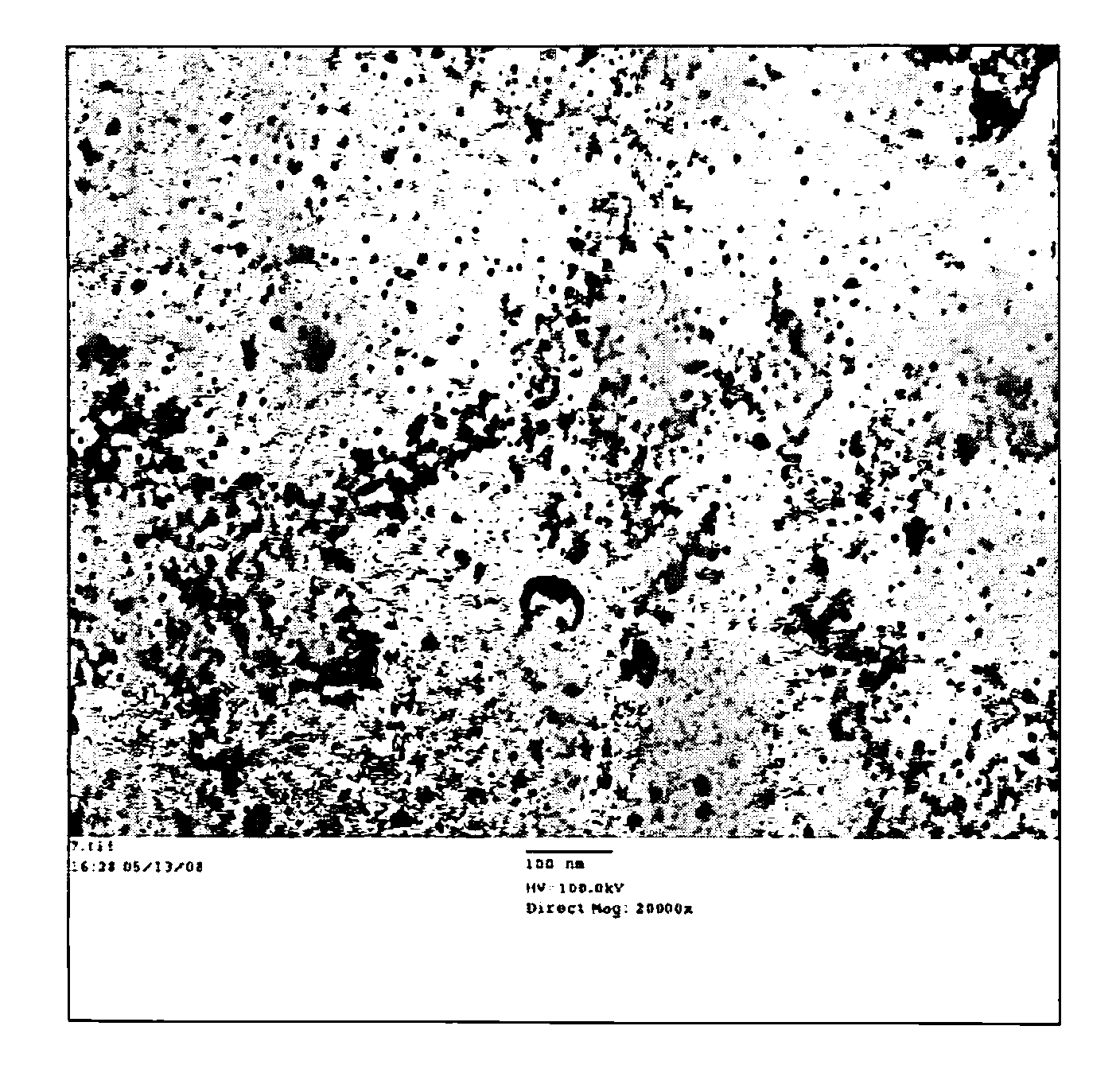

Copper-based nano catalyst for preparing high-carbon alcohol from synthetic gas as well as preparation method and application thereof

ActiveCN102500374ASmall particle sizeLarger than surfaceOrganic compound preparationHydroxy compound preparationNano catalystSyngas

The invention discloses a copper-based nano catalyst for preparing high-carbon alcohol from synthetic gas as well as a preparation method and application thereof. The catalyst is a copper-based polymetallic nano catalyst, which is composed of copper and at least one Fischer-Tropsch component. The preparation method is selected from one of replacement reaction method, step-by-step reduction method and simultaneous reduction method. The catalyst disclosed by the invention is small in particle size, large in specific surface and high in utilization rate; the preparing process is simple and convenient for operation; and when the catalyst is used for the synthesis of high-carbon alcohol from synthetic gas, by controlling the component and ratio of the catalyst, the selectivity of the alcohols higher than ethanol in the obtained alcohols is up to 95wt% and the selectivity of high-carbon alcohols higher than hexanol reaches more than 80wt%.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +2

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Method for extracting polygahatous polysaccharides from traditional Chinese medicine rhizoma polygonati

The invention discloses a method for extracting polygahatous polysaccharides from traditional Chinese medicine rhizoma polygonati. The method comprises the steps of cleaning, drying and grinding the rhizoma polygonati; performing secondary microwave auxiliary extraction on rhizoma polygonati powder through hexanol serving as a solvent, filtering and combining secondary extraction liquid; recycling the hexanol from the combined extraction liquid, then concentrating the extraction liquid, adding ethyl alcohol, performing uniform stirring, putting into an ultrasonic oscillator for ultrasonic oscillation, standing, performing centrifugal filtration to obtain precipitates, and drying the precipitates to obtain coarse polygahatous polysaccharides; removing proteins from the coarse polygahatous polysaccharides through an ethanol solution, recycling ethanol, concentrating to concentrated paste, dissolving the concentrated paste into a Tris-HCl buffering solution, and purifying the polygahatous polysaccharides twice through DE-52 cellulose column chromatography; performing third-time purification through distilled water by SephadexG-100 sephadex gel filtration chromatography, concentrating and carrying out freeze drying to obtain a refined polygahatous polysaccharides product. The extraction method disclosed by the invention is simple and feasible; the production efficiency is high; the quality of the prepared product is high; the yield is over 90 percent, and the purity is over 99 percent; the method is suitable for industrial large-scale production.

Owner:XUANCHENG BAICAO PLANT IND & TRADE CO LTD

Method of synthesizing higher-molecular alcohol

ActiveUS8080695B2Efficient collectionIncreased ethanol productionOxygen-containing compound preparationOrganic compound preparationSynthetic Polymeric MacromoleculesOctanol

The present invention provides a production method with which high molecular alcohols having an even number of carbon atoms such as 1-butanol, hexanol, octanol and decanol, and a mixture of these are efficiently collected through clean processes with the use of ethanol as a raw material. High molecular alcohols are produced from ethanol by using calcium phosphate-based compounds such as hydroxyapatite Ca10(PO4)6(OH)2, tricalcium phosphate Ca3(PO4)2, calcium monohydrogen phosphate CaHPO4.(0˜2)H2O, calcium diphosphate Ca2P2O7, octacalcium phosphate Ca8H2(PO4)6.5H2O, tetracalcium phosphate Ca4(PO4)2O or amorphous calcium phosphate Ca3(PO4)2. nH2O as a catalyst, using ethanol as a starting material, and setting a contact time at 0.4 second or longer.

Owner:SANGI CO LTD

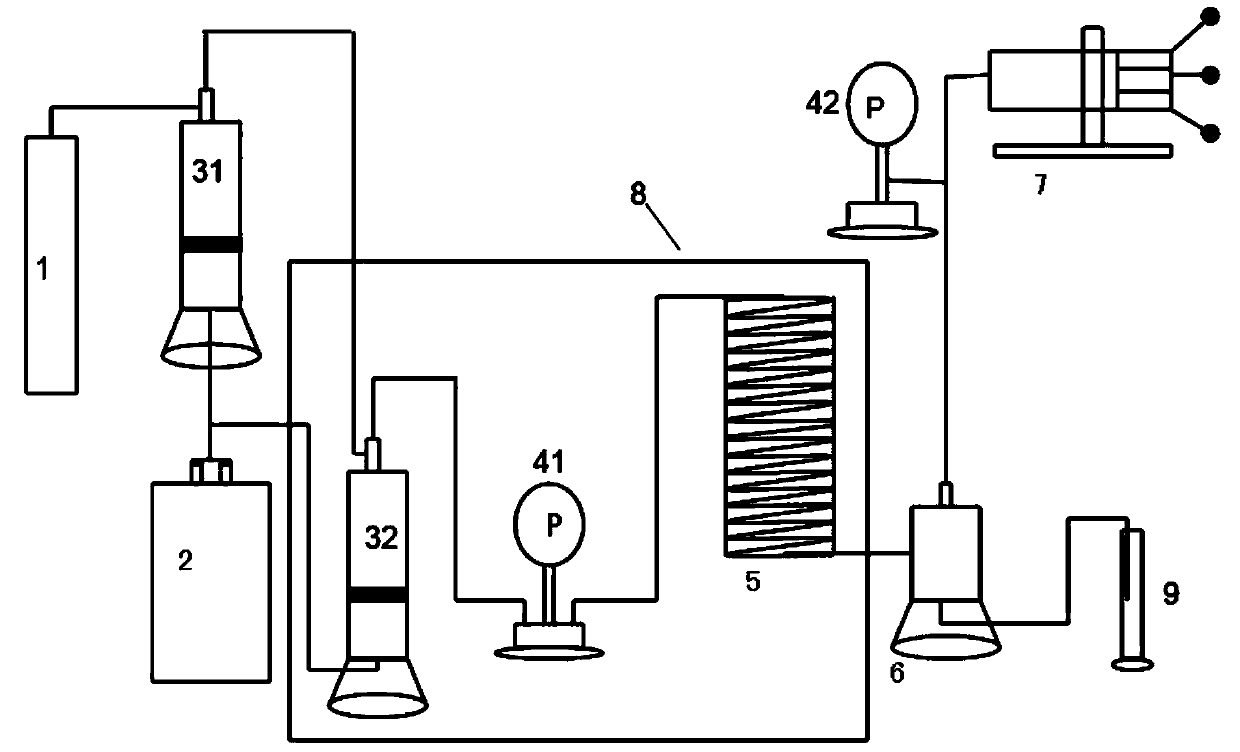

Hydrothermal synthesis method of micro-emulsion of nano lithium titanate

InactiveCN103274454AHigh crystallinityEffective control of particle sizeCell electrodesTitanium compoundsLithium hydroxideHigh pressure

The invention discloses a hydrothermal synthesis method of a micro-emulsion of nano lithium titanate. According to the method disclosed by the invention, the micro-emulsion is prepared from cetyltrimethylammonium bromide, n-hexanol, cyclohexane and a water phase, and tetrabutyl titanate and lithium hydroxide are used as reaction materials. The method comprises the steps of: (1) preparing the 0.02-2.0 mol / L lithium hydroxide micro-emulsion and 0.025-2.5 mol / L titanium tetraisopropoxide micro-emulsion respectively; and (2) mixing the micro-emulsions in two concentrates, stirring for 5-120 minutes at the room temperature, then transferring a mixture into a 50 ml high-pressure reactor which is lined with polytetrafluoroethylene, carrying out hydrothermal reaction at the temperature of 60-240 DEG C for 1-70 hours, and then carrying out centrifugal separation, washing, drying and thermal treatment on a reactant to obtain spinel type lithium titanate. The method has the characteristics of controllable grain size, controllable morphology, simple process, simple equipment and the like.

Owner:JILIN UNIV

Preparation method of submicron hydroxy zinc stannate cubic material

The invention discloses a preparation method of a submicron hydroxy zinc stannate cube, the size of which is 100-300 nanometers. According to the preparation method, raw materials, including cetyl trimethyl ammonium bromide, n hexanol, cyclohexane and deionized water, are selected to form a microemulsion; the microemulsion reacts with zinc sulfate and sodium stannate which are used as reactants to respectively prepare a microemulsion containing zinc sulfate and a microemulsion containing sodium stannate; the two microemulsions are mixed to react and undergo aging, centrifugation, washing and drying so as to obtain submicron hydroxy zinc stannate cubic particles, which can be used as photocatalysis, gas-sensitive and flame retardation materials and the like. The method can be adopted to synthesize the size-controllable hydroxy zinc stannate cubic material at room temperature. The production technology is simple, requires low cost and causes no environmental pollution.

Owner:JILIN UNIV

Ultra-small chitosan nanoparticles useful as bioimaging agents and methods of making same

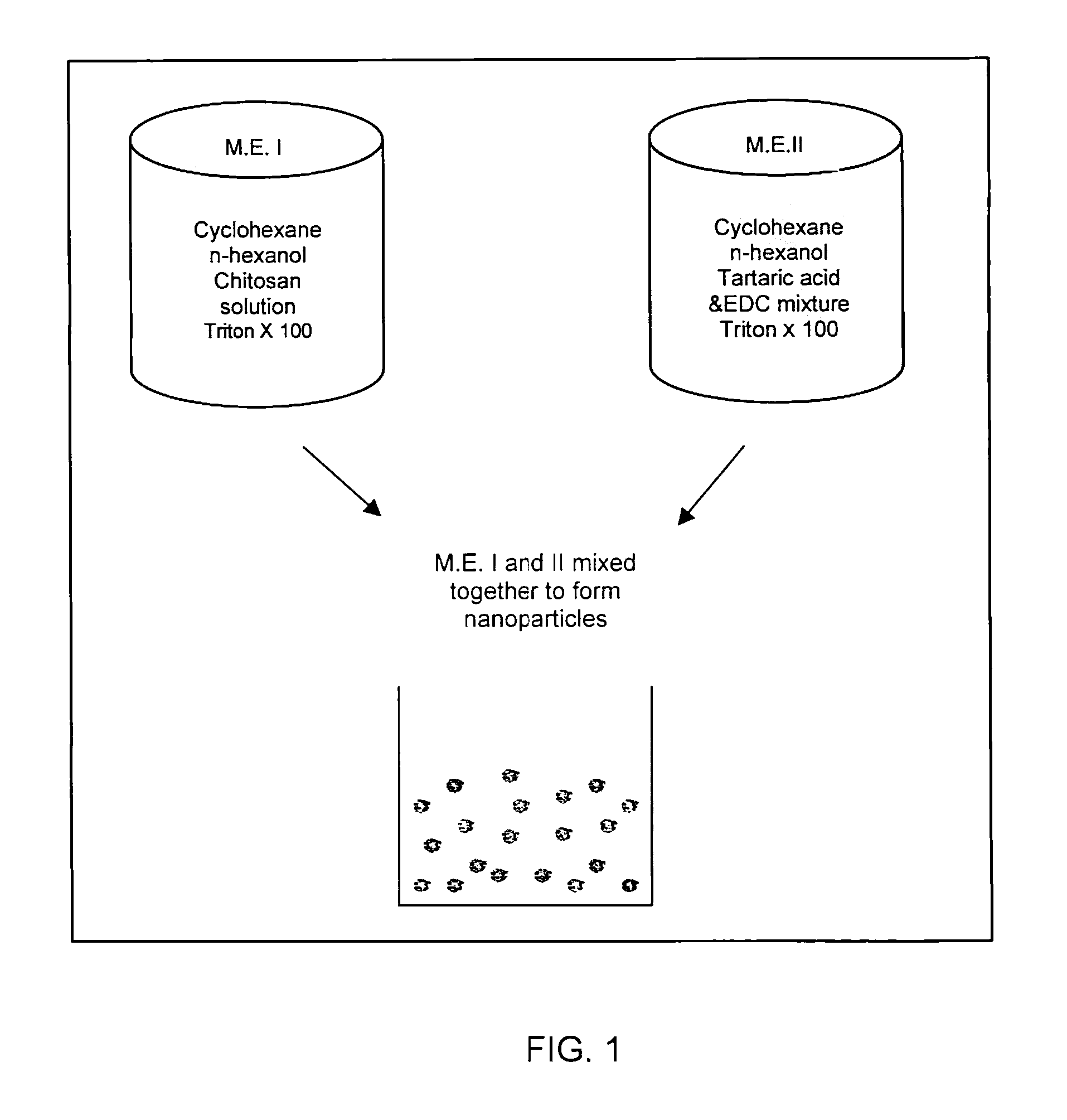

InactiveUS20110021745A1Powder deliveryGeneral/multifunctional contrast agentsChitosan nanoparticlesFluorescence

A method of making ultra-small chitosan nanoparticles having a size range of approximately 10-20 nm, includes preparing a first microemulsion containing effective amounts of cyclohexane, n-hexanol, chitosan polymer and a nonionic surfactant. A second microemulsion is prepared containing effective amounts of cyclohexane, n-hexanol, tartaric acid, EDC, n-hydroxysuccinimide, and a nonionic surfactant. The method continues by reacting the first and second microemulsions for a time sufficient to form the ultra-small chitosan nanoparticles and recovering the nanoparticles from the reacted microemulsion. The chitosan polymer may be crosslinked and may also be tagged with a fluorescent compound, a radio-opaque compound, a paramagnetic ion, a ligand specific for a predetermined biologic target, a drug, and combinations thereof.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Separation and refining method of 1,3-methyl glycol in ferment liquor

ActiveCN1880290AReduce energy consumptionNo cloggingOrganic compound preparationHydroxy compound preparation1-PentanolFiltration

This invention relates to a method for separating and purifying 1,3-dihydroxypropane from microbial fermentation liquor, comprising: after the sterilization and dehydration of fermentation liquor, add in 1-pentanol or isoamyl alcohol, n-butanol and n-hexanol, then remove the sediment in the fermentation liquor by filtration or settlement followed by washing; add in appropriate amount of glycerol or 1,4-butylene glycol to the supernatant to recover 1-pentanol or isoamyl alcohol, n-butanol and n-hexanol, by decompression or normal pressure distillation, so as to produce high-purity 1,3-dihydroxypropane, with more than 95% recovering rate. This invention is characterized of simple separation process, mature technique, low separation cost, and little additional introduced agent with easy recovery. Besides, the crystallization sediment in the fermentation liquor can be efficiently separated, which overcomes the problems of foaming, agglomerating and pipe clogging during distillation, so as to realize continuous operation.

Owner:PETROCHINA CO LTD

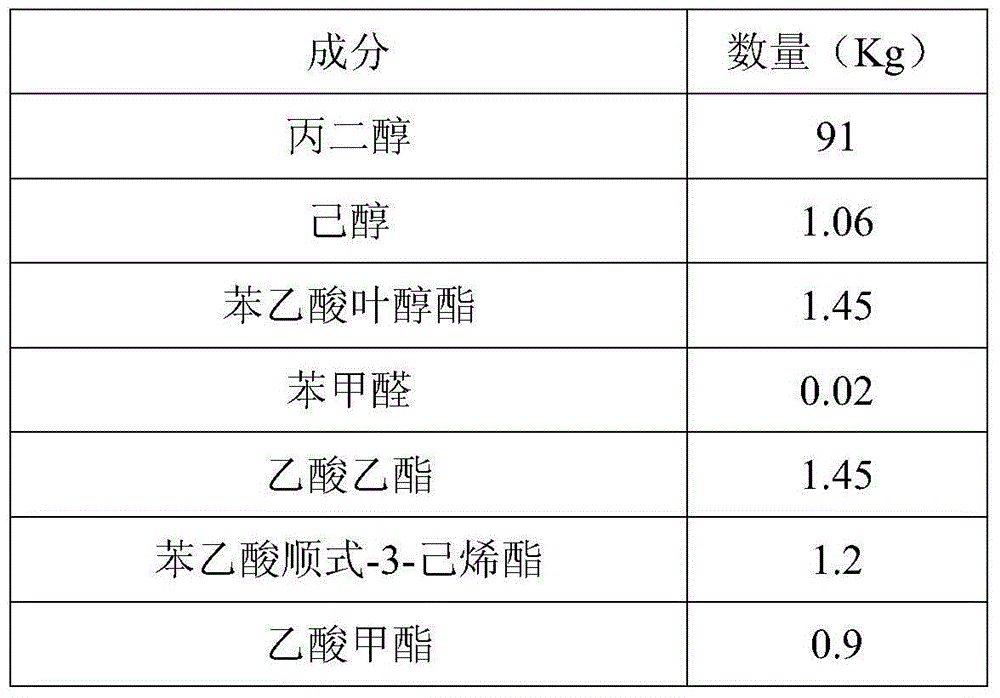

Peach essence

ActiveCN104957584AReduce manufacturing costBroad sales marketFood ingredientsFood preparationAdditive ingredientPhenylacetic acid

The invention discloses a peach essence. The peach essence consists of the following ingredients: propanediol, hexanol, hexenyl phenylacetate, benzaldehyde, ethyl acetate, phenylacetic acid cis-3-ester hexane, methyl acetate, hexyl acetate, hexyl trans-2-ester hexane, ethyl maltol, leaf alcohol, hexanal, acetic acid, linalool, gamma-caprylolactone, theta-decalactone, gama-decalactone, gamma-undecalactone, 8-mercaptomenthone, 2-isopropyl-4-methylthiazole, beta- damascenone, ethyl caprate and ethyl benzoate. The peach essence is moderate in fragrance, saturated, thick, stable in quality, natural in flavor and approximat to the natural fragrance of peach.

Owner:ZHEJIANG GREEN CRYSTAL FLAVOR

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

Process for preparing barium titanate nano-rod

InactiveCN1800030ASimple production processControllable size and shapeCalcium/strontium/barium compoundsTitanium compoundsCyclohexanoneBarium titanate

The invention discloses a making method of barium titanate nanometer bar, which comprises the following steps: selecting polyoxyethylated alkyl (10) phenol (OP-10), positive hexanol, cyclohexanone and water to form microemulsion; taking the titanic butonat and Ba (OH) 2 as reactant; mixing each composition of inversed-phase microemulsion; stirring the mixture strongly in the magnetic stirrer; producing the inversed-phase microemulsion of even transparency and stable property; dripping the titanic butonat solution; producing the barium titanate nanometer bar with 15-85 nm diameter and 300-4000 nm length through reacting, aging, centrifugal separating and cleaning by waterless alcohol. The invention can control the particle dimension and shape of barium titanate nanometer bar, which can be used in the inorganic functional material equipment.

Owner:XIANGTAN UNIV

Method of preparing 1,2-epoxycyclohexane using cyclohexane

ActiveCN1724524ARaw materials are cheap and easy to getLow costOrganic chemistryCyclohexeneWastewater

The invention provides a process for preparing 1,2-epoxycyclohexane by using cyclohexane as the main raw material and air as the oxygen source, which comprises oxidizing cyclohexane into cyclo-hexyl hydrogen peroxide, then charging cyclo-hexene for epoxidation reaction, thus obtaining 1,2-epoxycyclohexane and cyclo-hexanol, wherein the cyclo-hexanol can be dehydrated to produce cyclo-hexene to be put into circulated use as raw material for epoxidation reaction. The invention can solve the problem of large displacement of waste water.

Owner:昌德新材科技股份有限公司

Environment-friendly transparent dewaxing liquid, preparation method thereof and application of environment-friendly transparent dewaxing liquid in preparing pathological section

The invention belongs to the field of pathological detection reagents, and particularly relates to environment-friendly transparent dewaxing liquid, a preparation method thereof and application of the environment-friendly transparent dewaxing liquid in preparing a pathological section. The environment-friendly transparent dewaxing liquid is prepared from the following raw materials by a mass ratio: 20-60% of white oil, 12-45% of nonane, 6-35% of octane, 5-20% of heptane, 4-25% of castor oil, 3-18% of pentanol and 2-9% of hexanol. The dewaxing liquid disclosed by the invention is simple in formula and reasonable in collocation, and can serve as a clarifier and a dewaxing agent used during preparation of the pathological section, so that a pathological section process is completely free from a xylene reagent.

Owner:河南新大阳生物技术有限公司

Novel esterase as well as coding gene and application of esterase

InactiveCN104140959AImprove qualityMild reaction conditionsHydrolasesMicroorganism based processesPropanoic acidNucleotide

The invention discloses a novel esterase as well as a coding gene and an application of esterase. The esterase EST04211 has an amino acid sequence shown in SEQ ID NO. 2. The amino acid sequence of the gene of the esterase EST04211 is shown in SEQ ID NO. 1. The novel esterase disclosed by the invention is obtained by cloning Bacillus SCSIO15121 derived from deep sea of the Indian Ocean. The esterase has the largest characteristic that the esterification rate is 97% in catalytic synthesis of ethyl isobutyrate, and under similar conditions, the esterase can also catalyze propionic acid, butyric acid, valeric acid, caproic acid and ethanol, propanol, butanol, pentanol and hexanol to synthesize corresponding short-chain aromatic ester flavors, such as ethyl propionate, propyl propionate and butyl propionate, the esterification rate mostly reaches 85%-95%. The esterase can be applied in the industrial bio-manufacturing of the short-chain aromatic flavors, such as ethyl isobutyrate and the ester flavors are high in quality, belongs to natural products and can be applied in production industries, such as foods, cigarettes and daily chemical products.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

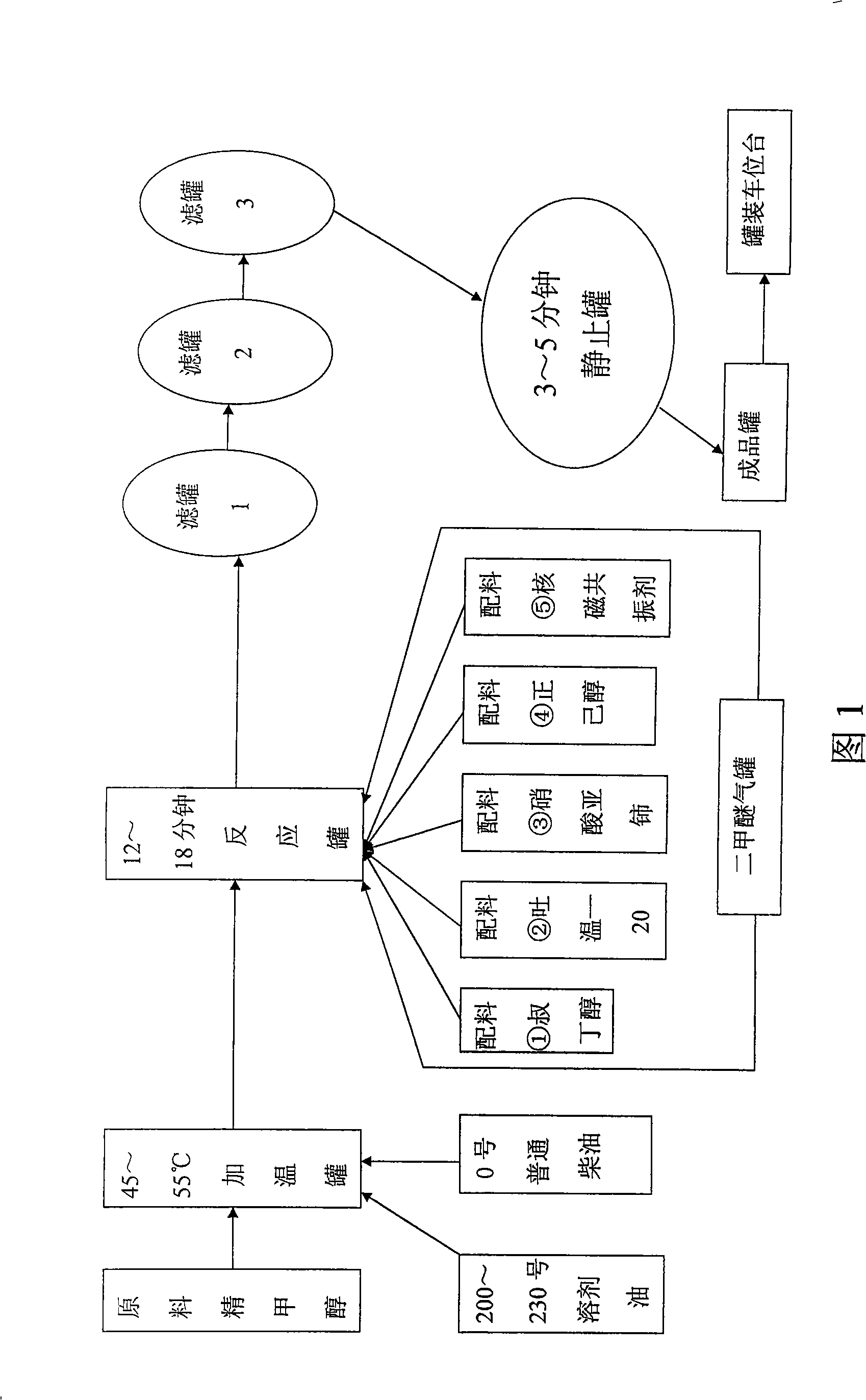

Alcohol ether fuel for diesel of vehicle and marine, and gas-liquid synthesizing method

InactiveCN101294109AReduce dosageImprove fuel economyLiquid carbonaceous fuelsCerium nitrateSynthesis methods

The invention discloses an alcohol-ether fuel for diesel engines of ships and vehicles as well as the gas-liquid synthesis method thereof. The alcohol-ether fuel comprises the following components (by weight): methanol 36 parts, diesel oil No.0 30 parts, solvent oil 31 parts, additives 2.5 parts, and dimethyl ether 0.5parts, wherein the additives include tert-butyl alcohol, tween-20, cerium nitrate, n-hexanol and nuclear magnetic resonance agent. The systhesis method comprises the following steps: sequentially adding methanol, diesel oil and solvent oil into a reaction tank, heating to 45 to 55 DEG C, stirring under a pressure of 0.2 kg for 12 to 18 min, adding the additives and dimethyl ether, mixing, stirring for 3 to 5 min, fine-filtering, and standing to obtain the final product. The alcohol-ether fuel has the advantages of no pollution, simple process, rich raw materials, low cost, no lead, high cetane number, and good anti-knock property, safety and stability, and can be used alone or mixed with common diesel oil for alcohol-ether ships and vehicles. The alcohol-ether fuel is an ideal product to substitute for the diesel oil No.0.

Owner:张元盛

Polyolefin Drag Reducing Agents Produced by Multiple Non-Cryogenic Grinding Stages

InactiveUS20110319520A1Small sizeImprove efficiencyOther chemical processesPipeline systemsPolyolefinModal particle

Fine particulate polymer drag reducing agents (DRAs) in bi-modal or multi-modal particle size distributions may be produced simply and efficiently without cryogenic temperatures. The grinding or pulverizing of polymer, e.g. non-porous poly(alpha-olefin) suitable for reducing drag in hydrocarbons may be achieved by the use of at least one liquid grinding aid and at least two grinding processors in series. The blades of the stators of the grinders are of different configuration so that granulated polymer fed to the first processor having relatively larger gaps between blades is ground to an intermediate size which is fed to the second processor having relatively smaller gaps between blades which grinds the polymer to a second, smaller size. A non-limiting example of a suitable liquid grinding aid includes a blend of propylene glycol, water and hexanol. Particulate DRA may be produced at a size of 300 microns or less in only two passes.

Owner:BAKER HUGHES INC

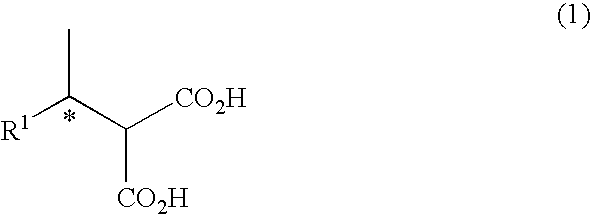

Method For Producing Alcohol and Carboxylic Acid Having Optical Activity

InactiveUS20080233621A1High optical purityProduced inexpensively and efficientlyOrganic compound preparationOrganic chemistry methodsCarboxylic acidMethyl group

It is an object of the present invention to provide an inexpensive and efficient industrial method for obtaining (S)-2-pentanol, (S)-2-hexanol, 1-methylalkyl malonic acid and 3-methyl carboxylic acid at a high optical purity. The present invention provides a method of producing (S)-2-pentanol or (S)-2-hexanol which comprises allowing certain types of microorganisms or transformed cells, a product obtained by treating said microorganisms or cells, a culture solution of said microorganisms or cells, and / or a crude purified product or purified product of a carbonyl reductase fraction obtained from said microorganisms or cells, to act on 2-pentanone or 2-hexanone.

Owner:API CORP (JP)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com