Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1298results about "Molybdenum sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating Composition Containing Ashfree Antiwear Agent Based on Hydroxypolycarboxylic Acid Derivative and a Molybdenum Compound

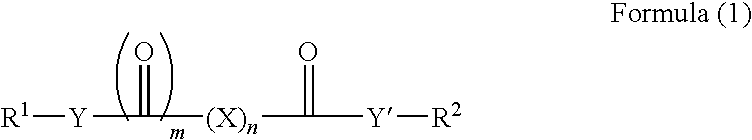

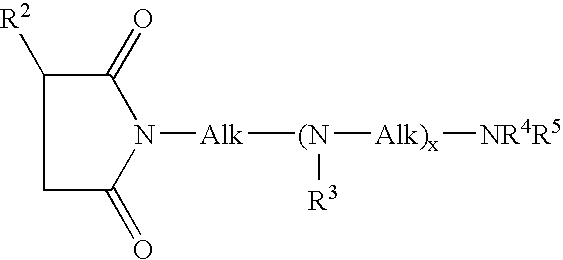

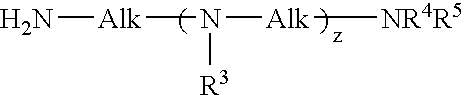

InactiveUS20100197536A1Reducing and preventing emissionImprove fuel economyAdditivesMolybdenum sulfidesAntioxidantAcid derivative

The invention provides a lubricating composition containing an oil of lubricating viscosity, an oil soluble molybdenum compound, and an ashless antiwear agent. The invention further provides for a new antioxidant. The lubricating composition is suitable for lubricating an internal combustion engine.

Owner:THE LUBRIZOL CORP

Joint for steel pipe having high galling resistance and surface treatment method thereof

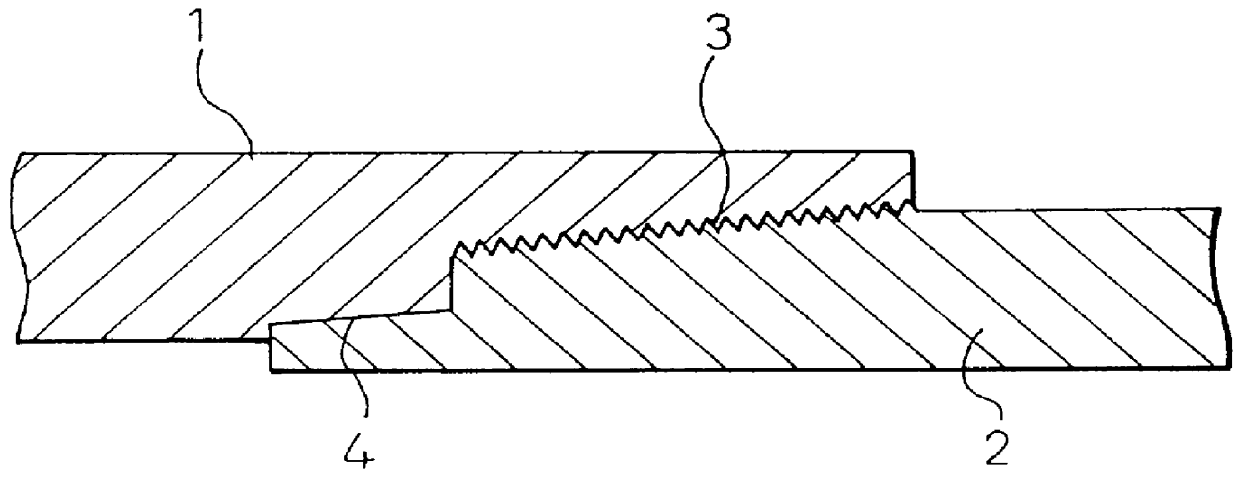

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

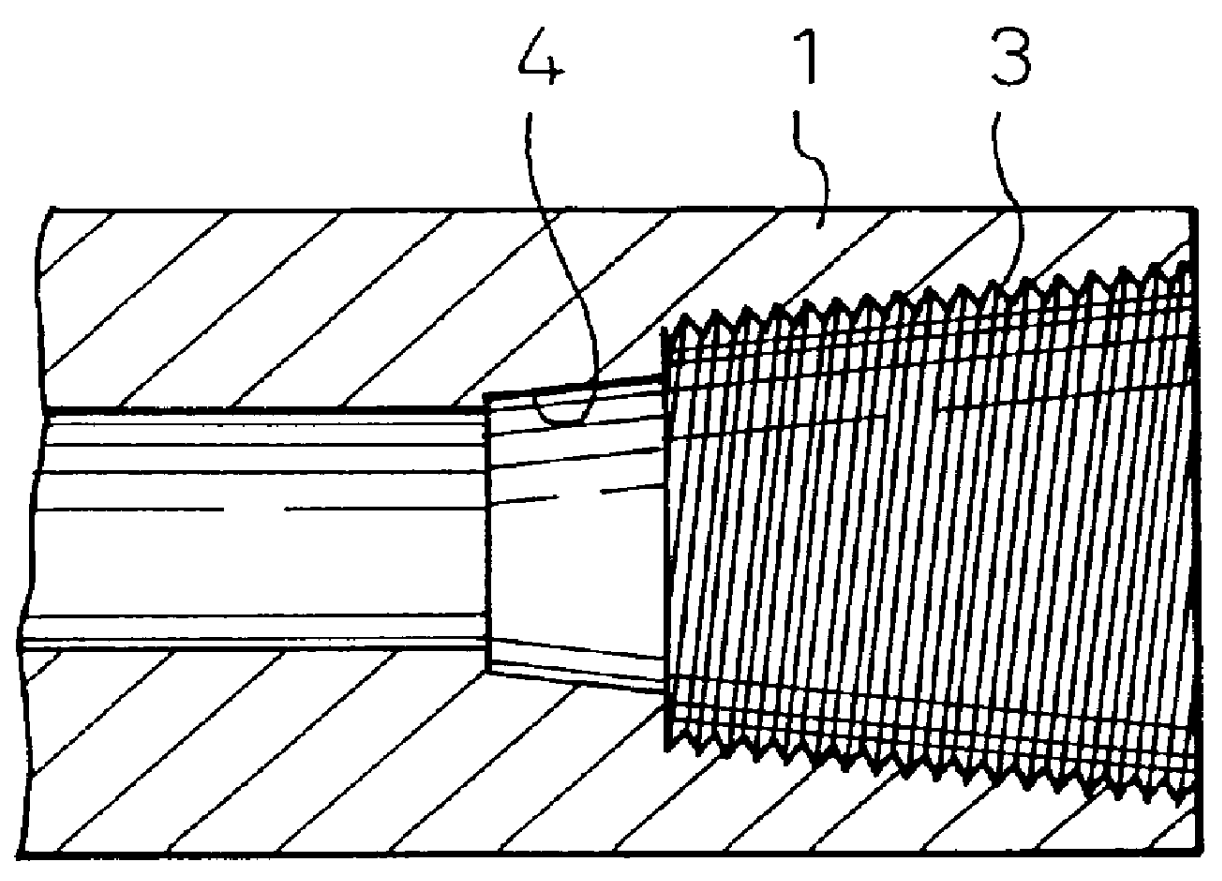

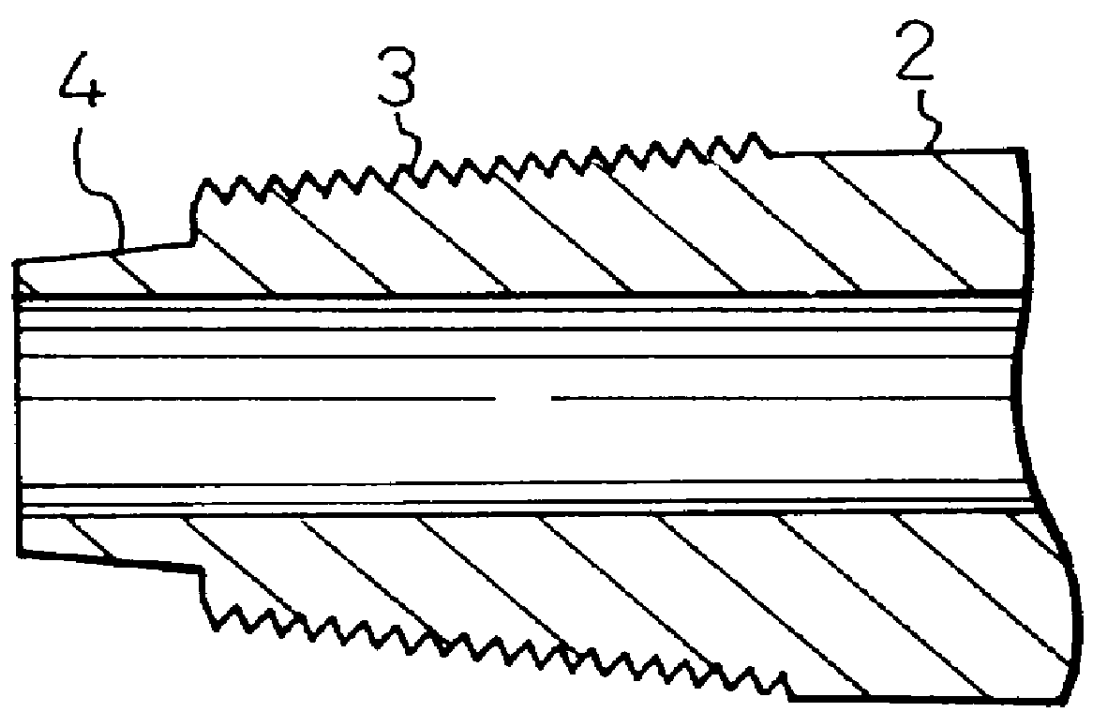

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

Lubricant and additive formulation

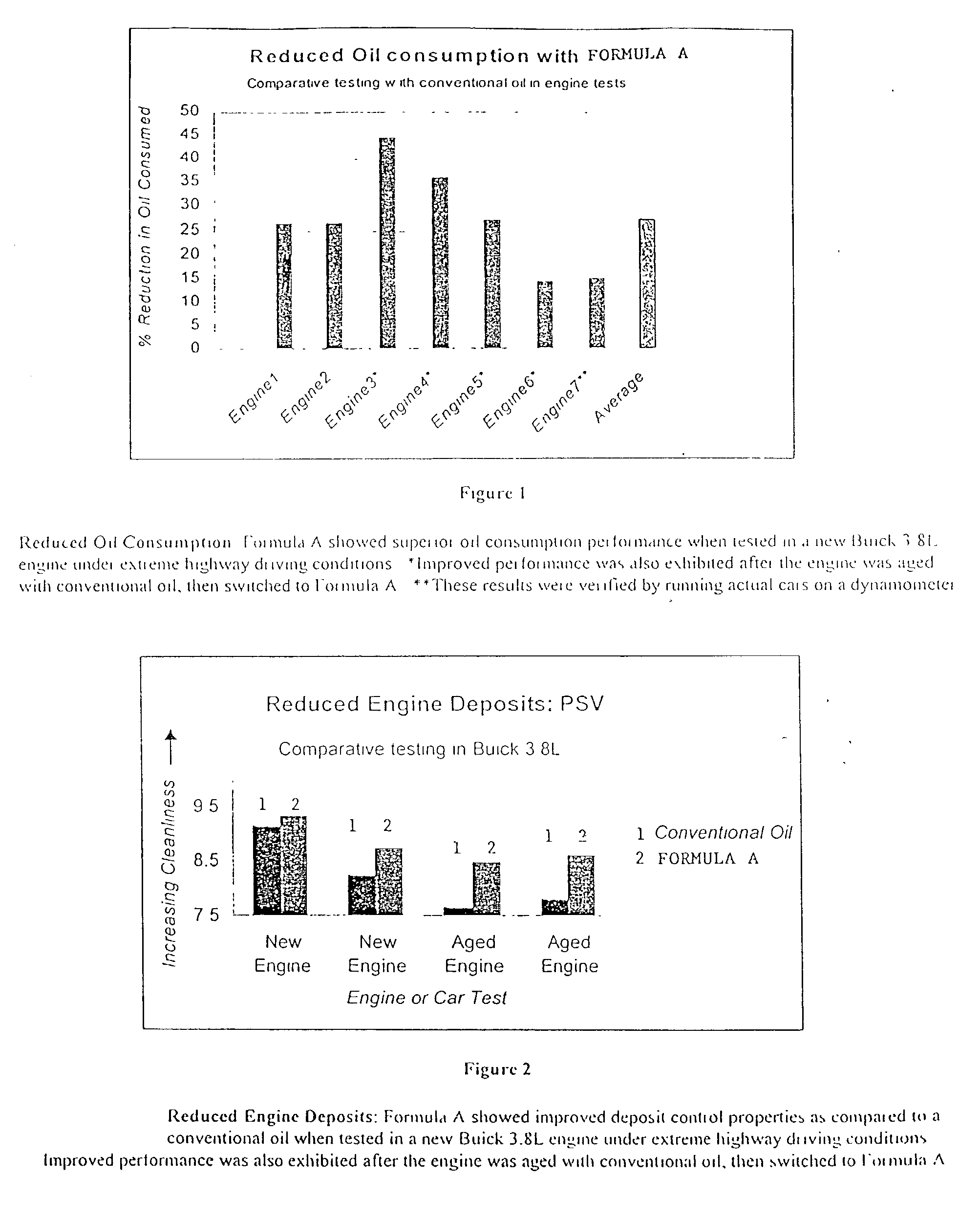

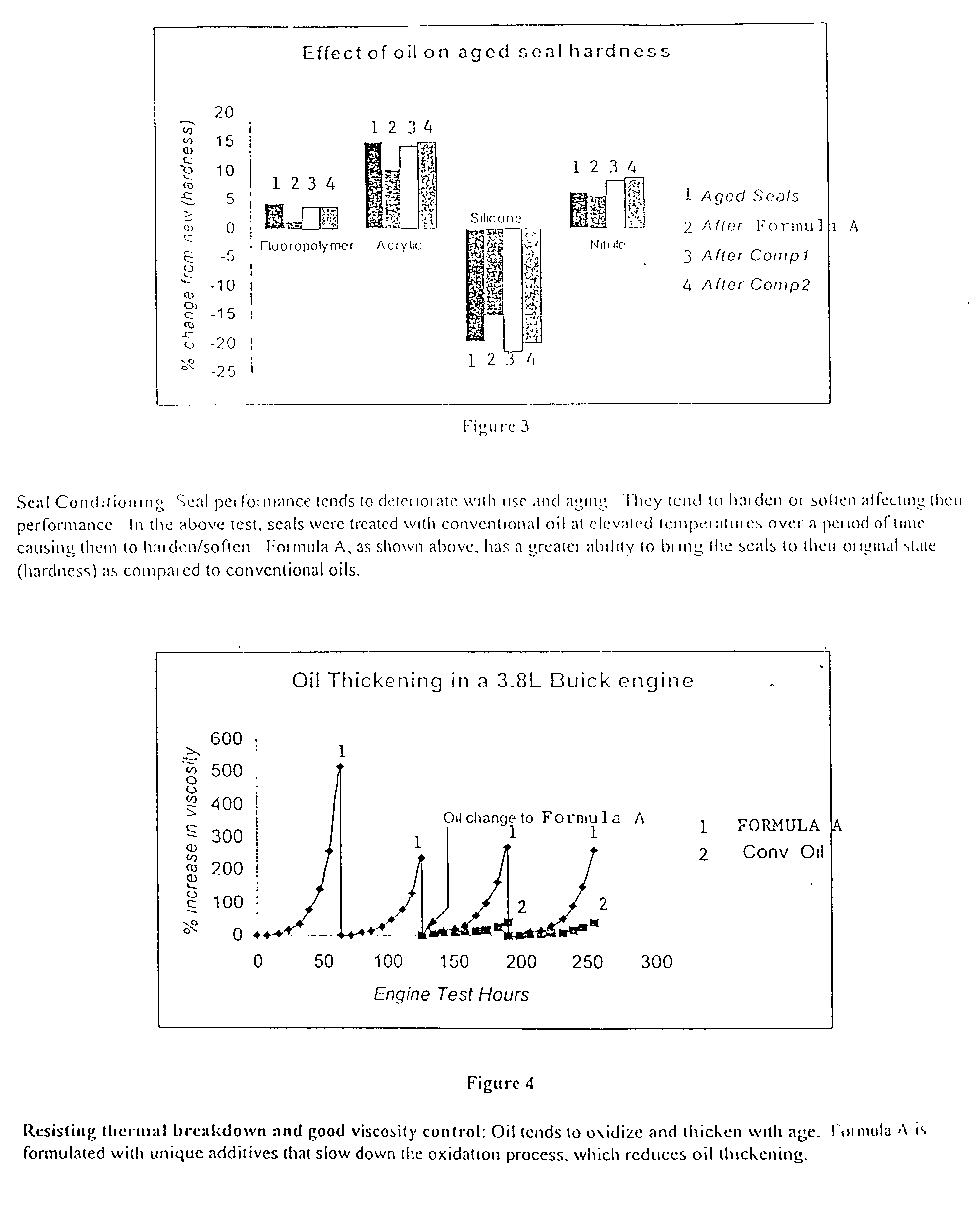

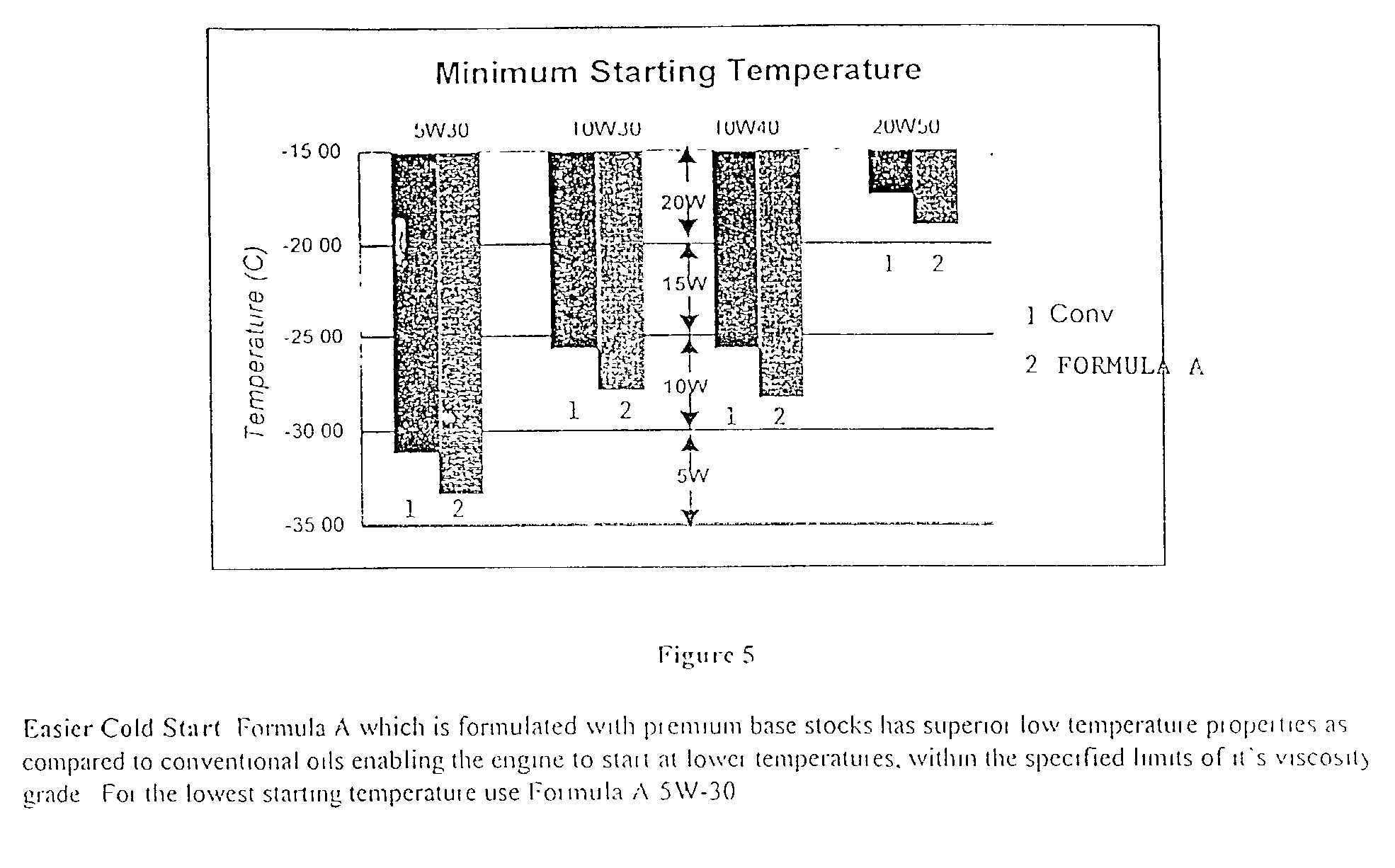

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

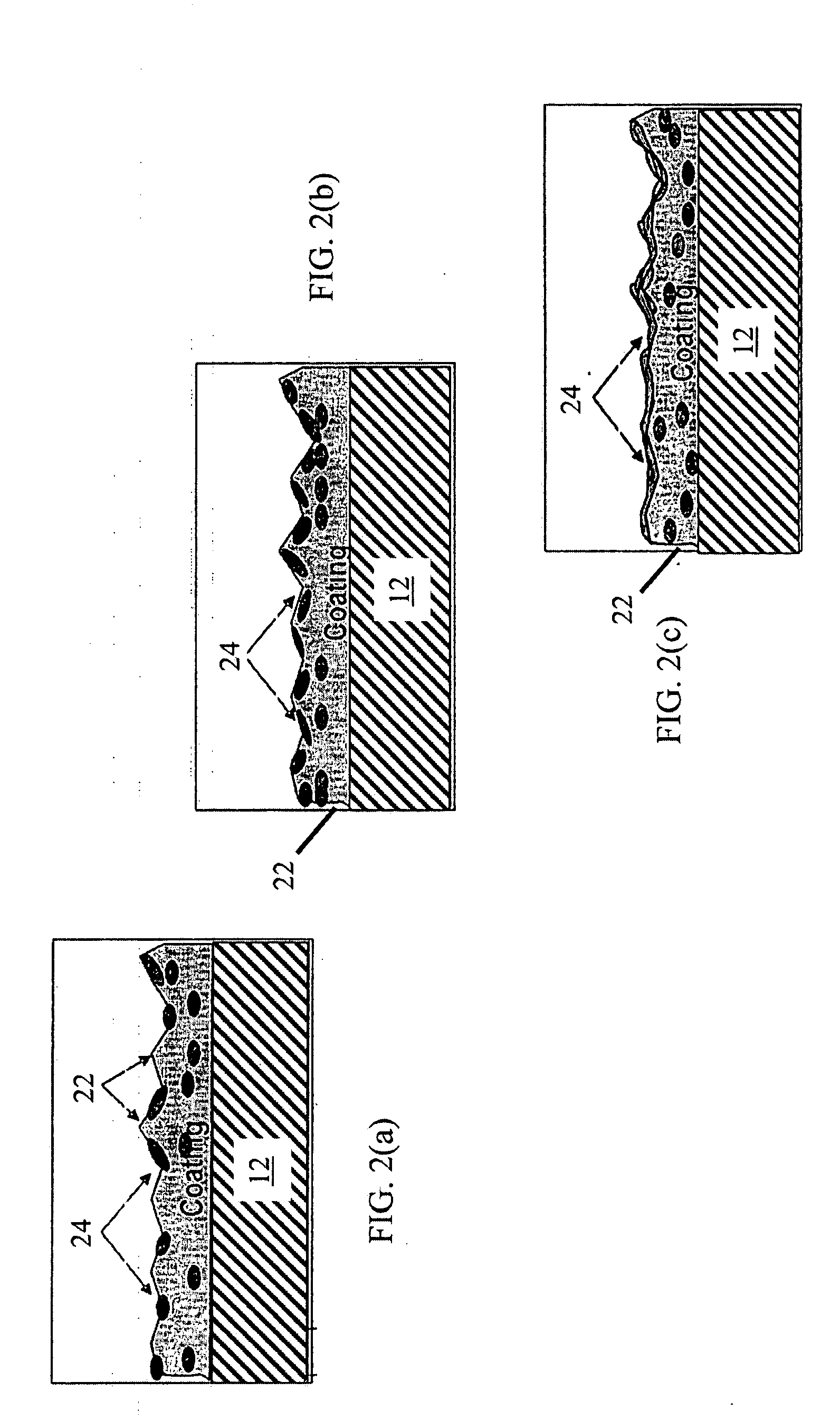

Lubricant-hard-ductile nanocomposite coatings and methods of making

InactiveUS20090155479A1Liquid surface applicatorsMolten spray coatingNanocomposite coatingWear resistance

Lubricant-hard-ductile composite coating compositions and methods of making the same are provided. In embodiment, a composite coating composition comprises: a lubricant phase for providing lubrication to a surface; a hard ceramic phase for providing structural integrity and wear resistance to the surface; and a ductile metal phase for providing ductility to the surface.

Owner:INFRAMAT CORPORATION

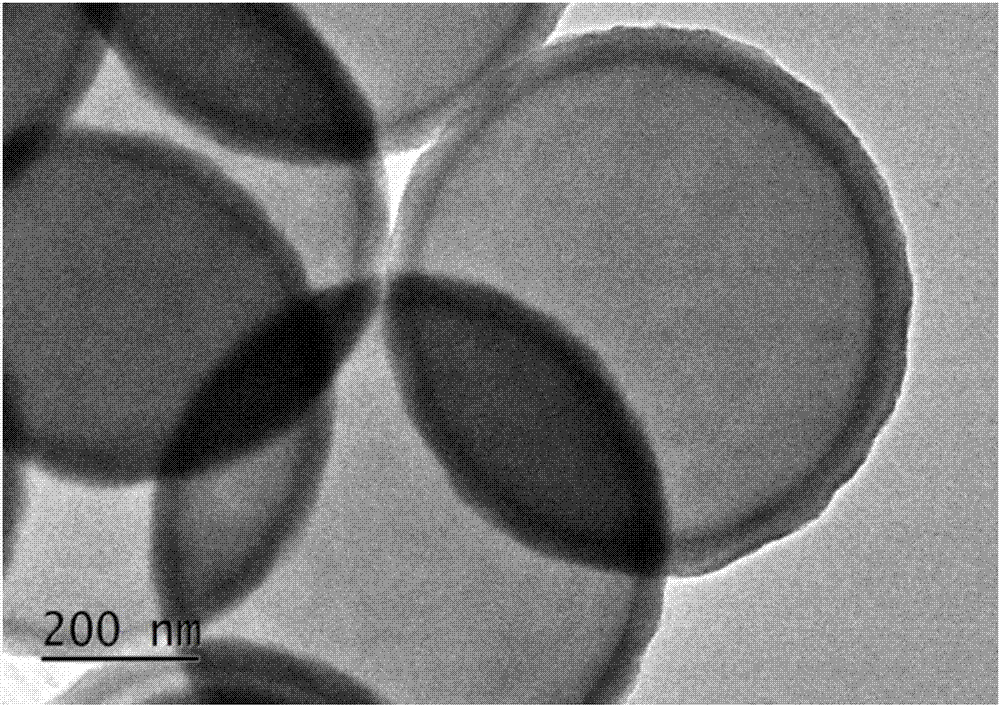

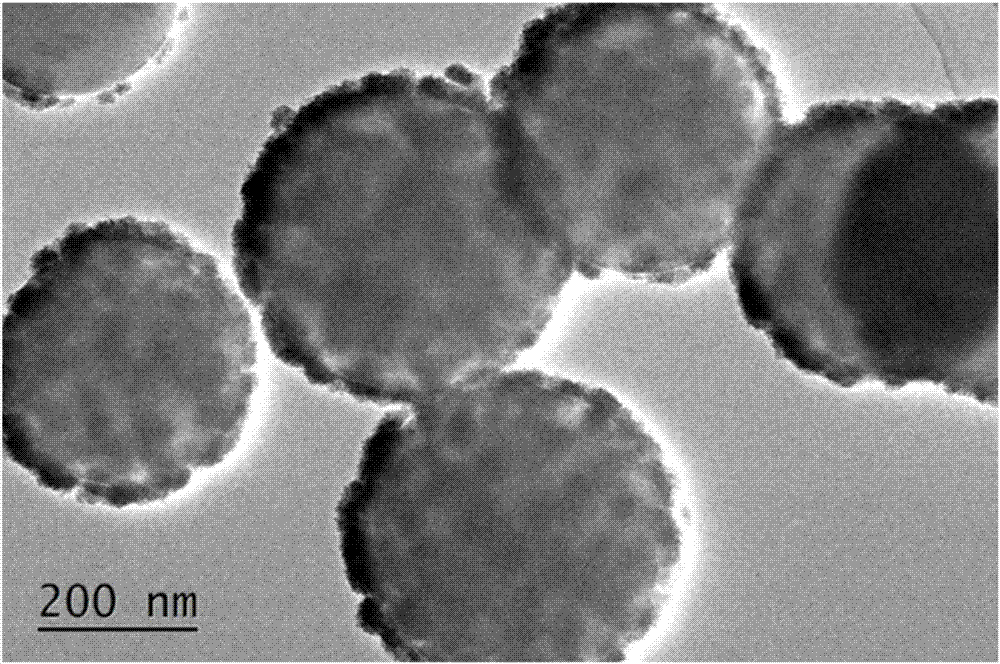

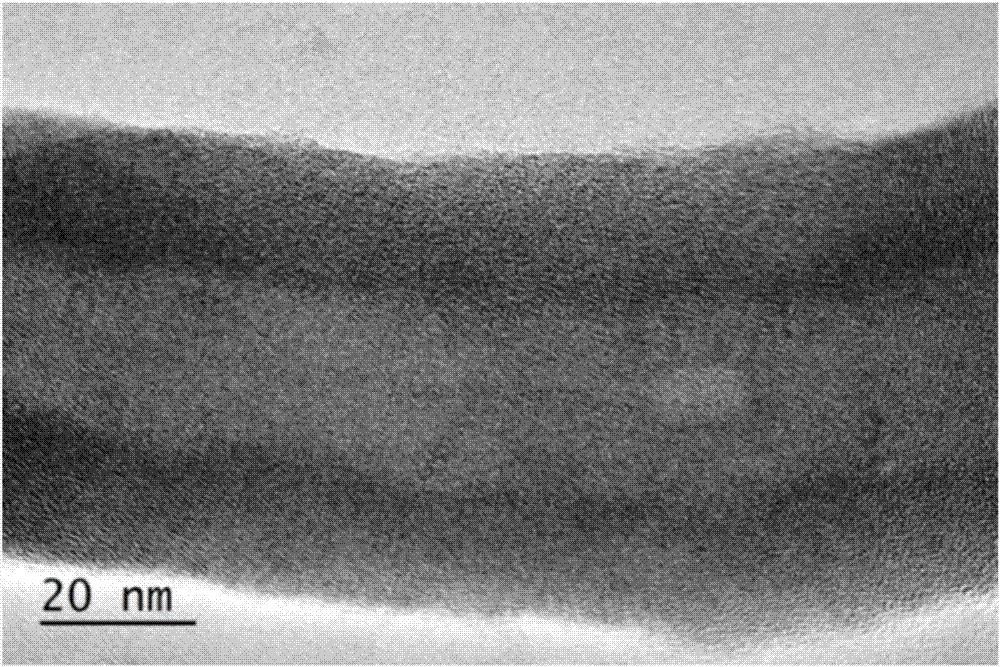

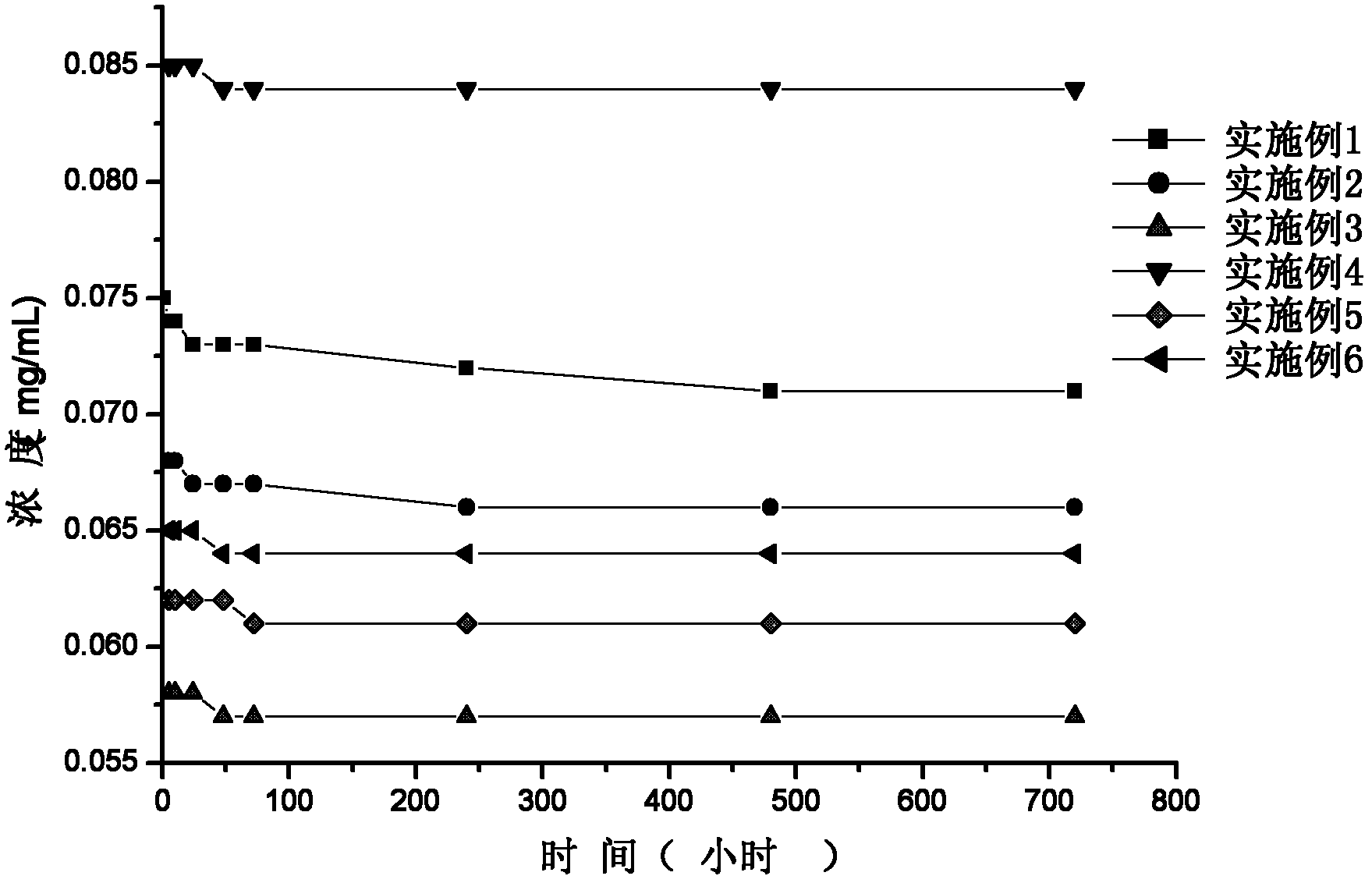

Sulfide coated particle as well as preparation method and application thereof

InactiveCN107983272AUniform thicknessThickness is easy to controlCobalt sulfidesZinc sulfidesMetallic sulfideLithium-ion battery

The invention discloses a sulfide coated particle as well as a preparation method and an application thereof. The sulfide coated particle comprises a core and a shell coating the core, wherein the core is prepared from at least one of metal, oxide, metal hydroxide, metal inorganic salt, elemental carbon or oxysome thereof, carbide, nitride, semiconductor and organic matter; the shell is prepared from metal sulfide. The to-be-coated core is mixed with the metal salt, a reducing agent and a sulfur source with a liquid phase method, metal sulfide is precipitated to the particle surface through in-situ reduction, and uniform, continuous and controllable coating of the core surface with metal sulfide is realized. The coating method is simple, reaction conditions are mild, universality is high,a coating layer is controllable in thickness, complete and uniform, and the sulfide coated particle has quite broad practical application prospect in the fields of electrocatalysis, lithium ion batteries, biomedicine and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

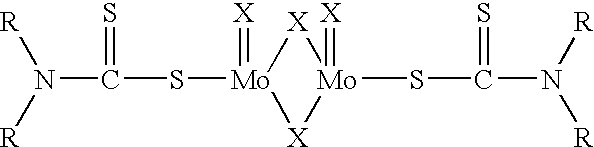

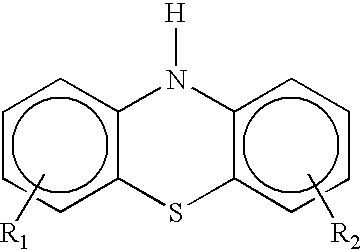

Antioxidant combination for oxidation and deposit control in lubricants containing molybdenum and alkylated phenothiazine

InactiveUS6797677B2Easy to controlPromote oxidationLiquid carbonaceous fuelsAdditivesAntioxidantOxidation resistant

The invention relates to a lubricating oil composition having improved antioxidant properties, and which contains a molybdenum compound and an alkylated phenothiazine. Further, it may also include a secondary diarylamine, preferably an alkylated diphenylamine. This combination of additives provides improved oxidation control and friction modifier performance to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant, or a transmission lubricant, including low levels and zero levels of phosphorus.

Owner:AFTON CHEMICAL +1

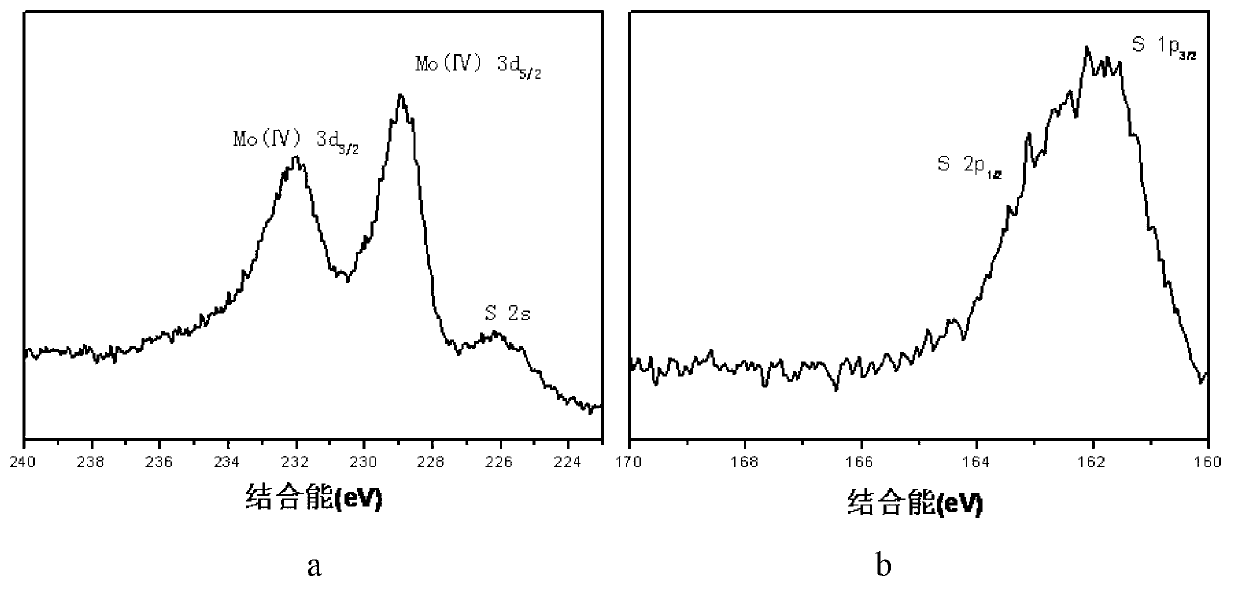

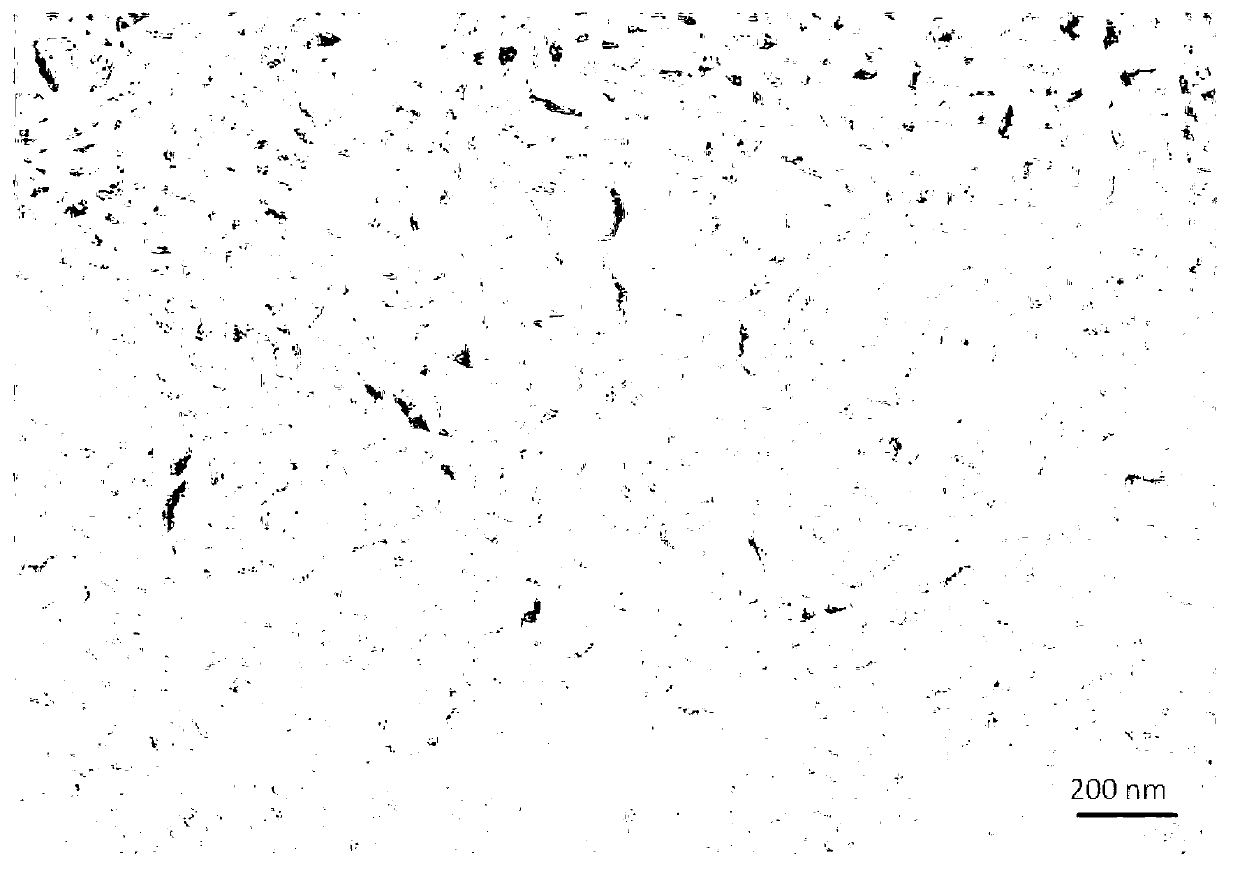

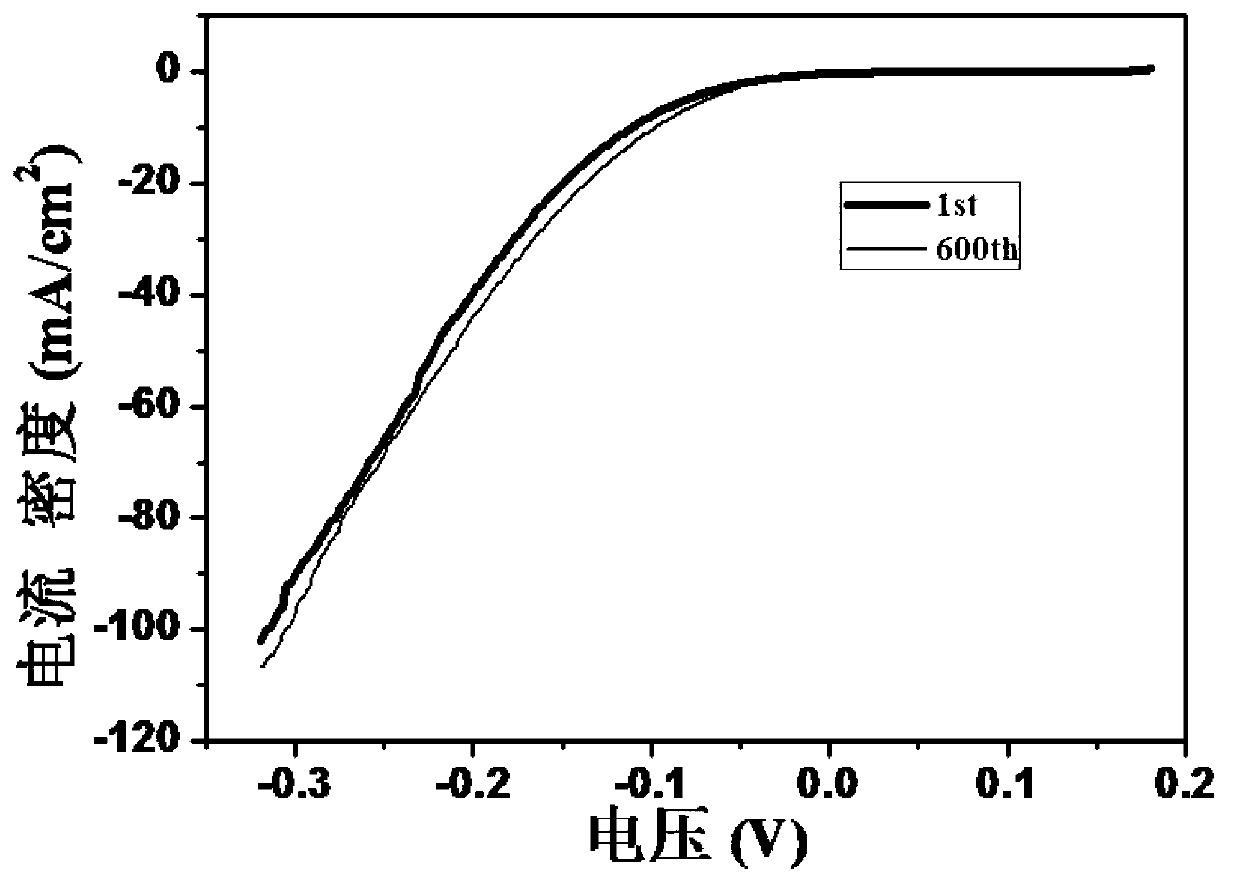

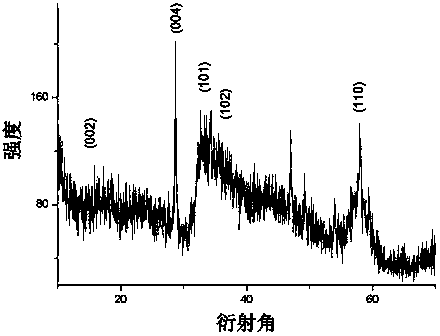

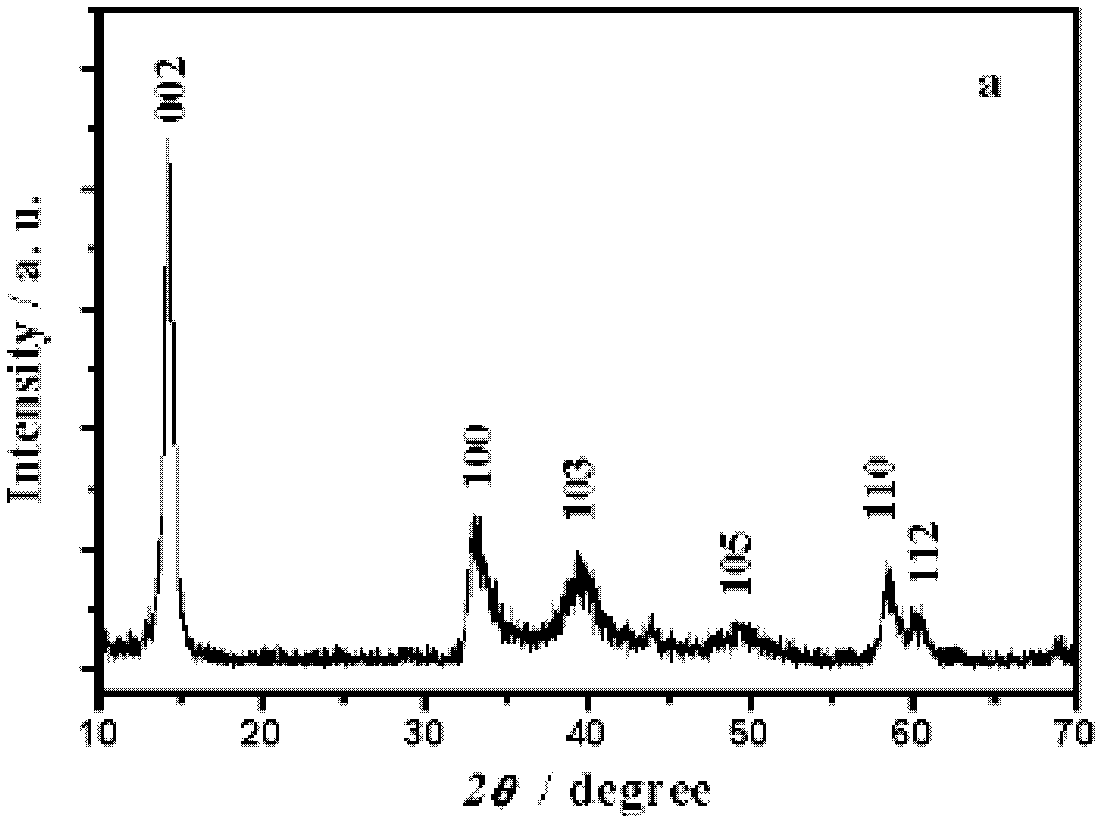

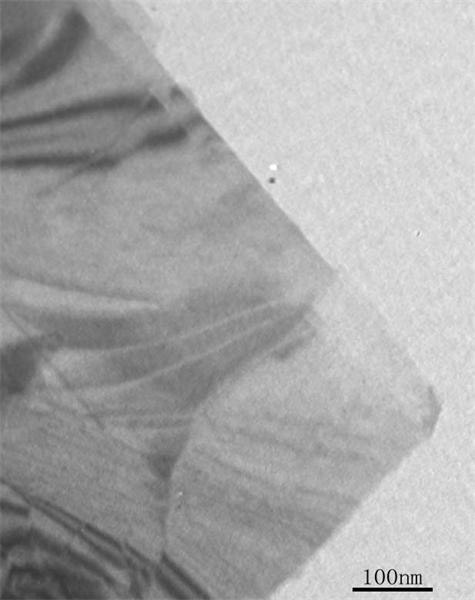

Molybdenum disulfide nano-sheet film material and its preparation methods

ActiveCN102849798AImprove hydrogen evolution performanceShape is easy to controlMaterial nanotechnologyCable/conductor manufactureThioureaFilm material

The invention discloses a molybdenum disulfide (MoS2) nano-sheet film material and its preparation methods. The film material is characterized in that MoS2 nano-sheets vertically and sequentially grow on a conductive substrate, and the diameters and the thicknesses of the MoS2 nano-sheets are 0.05-2mum and 2-30nm respectively. There are two preparation methods of the film material. One preparation method comprises the following steps: a substrate which can be a copper sheet, a silver sheet, a titanium sheet, a tungsten sheet, a molybdenum sheet or carbon is placed in a solution comprising a molybdate and sulfur-containing compounds (comprising thiourea, thioacetamide and L-cysteine); and the sulfur-containing compounds undergo a hydrothermal reaction to grow the compactly-grown and uniformly-sequential MoS2 nano-sheet films on the substrate. Another method comprises the following steps: the molybdenum sheet is directly placed in a solution of the sulfur-containing compounds (comprising thiourea, thioacetamide and L-cysteine); and the sulfur-containing compounds undergo a sulfuration reaction under a hydrothermal condition to form the compact and uniform MoS2 nano-sheet ordered films. The film has a low hydrogen evolution overpotential (-30mv), a small Tafel slope (52mV / dec) and a high electrochemical stability, and is a hydrogen evolution electrode material extremely having an application prospect.

Owner:深圳海氢科技有限公司

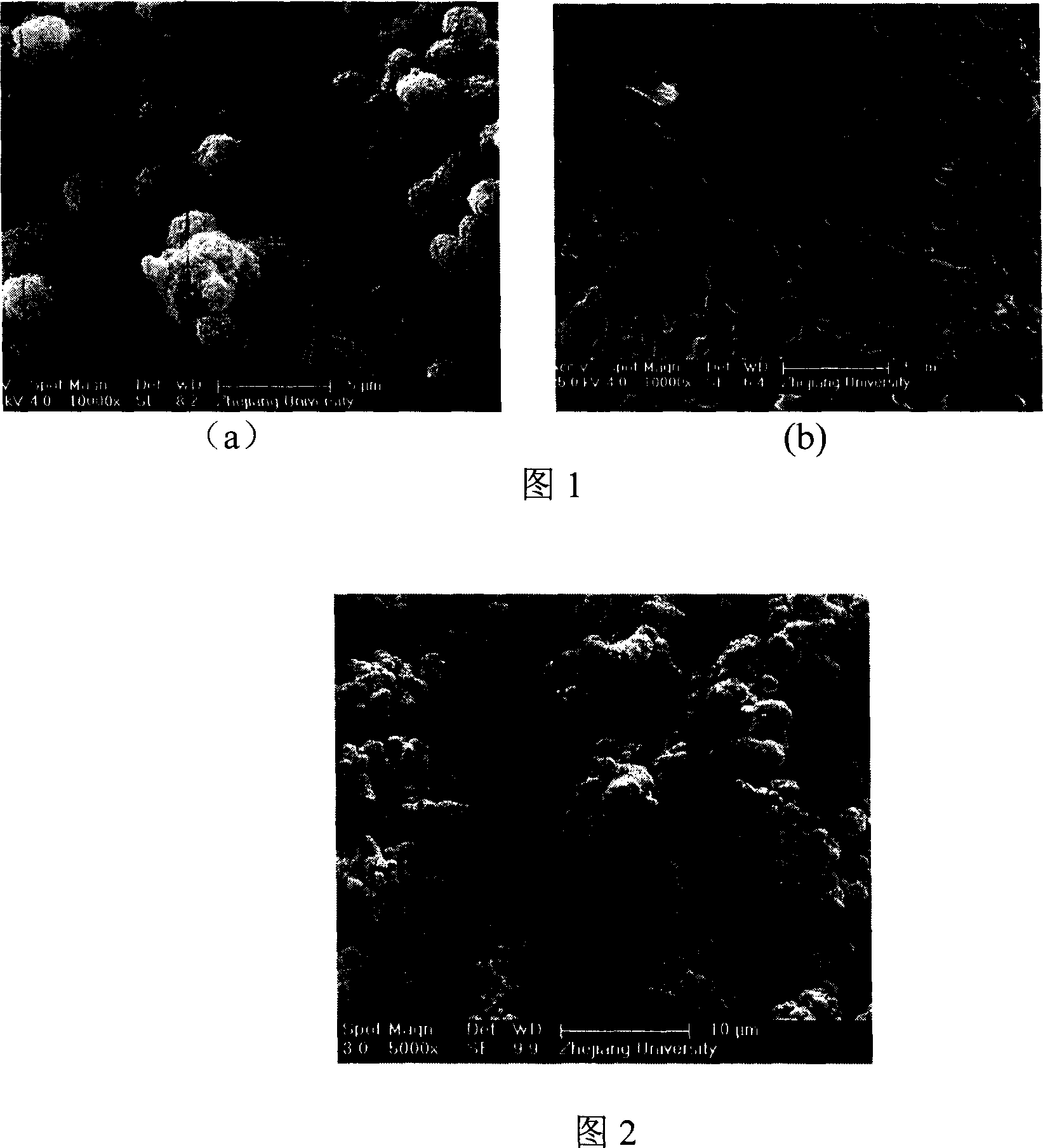

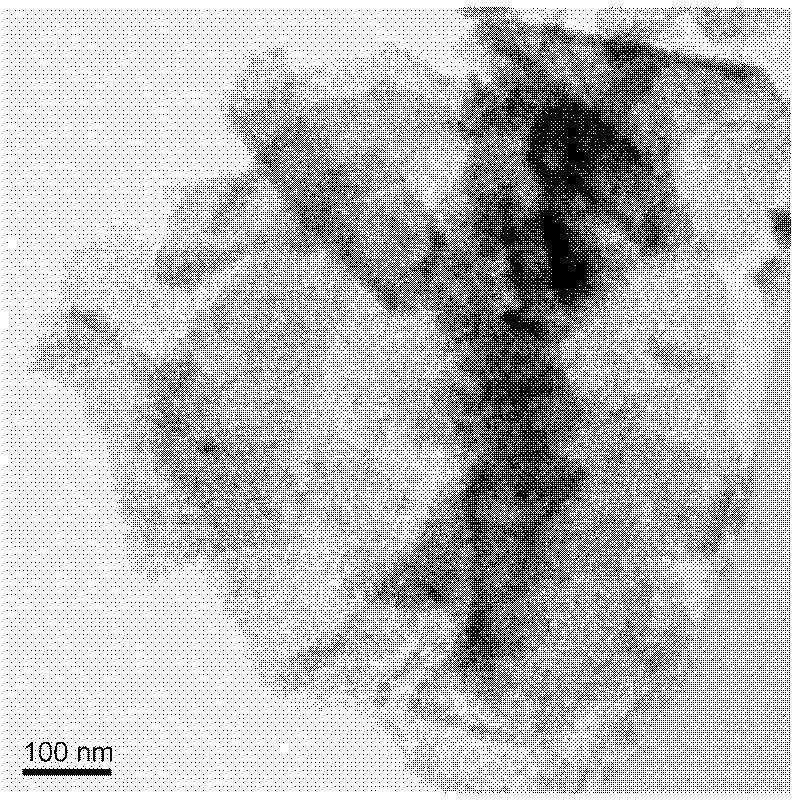

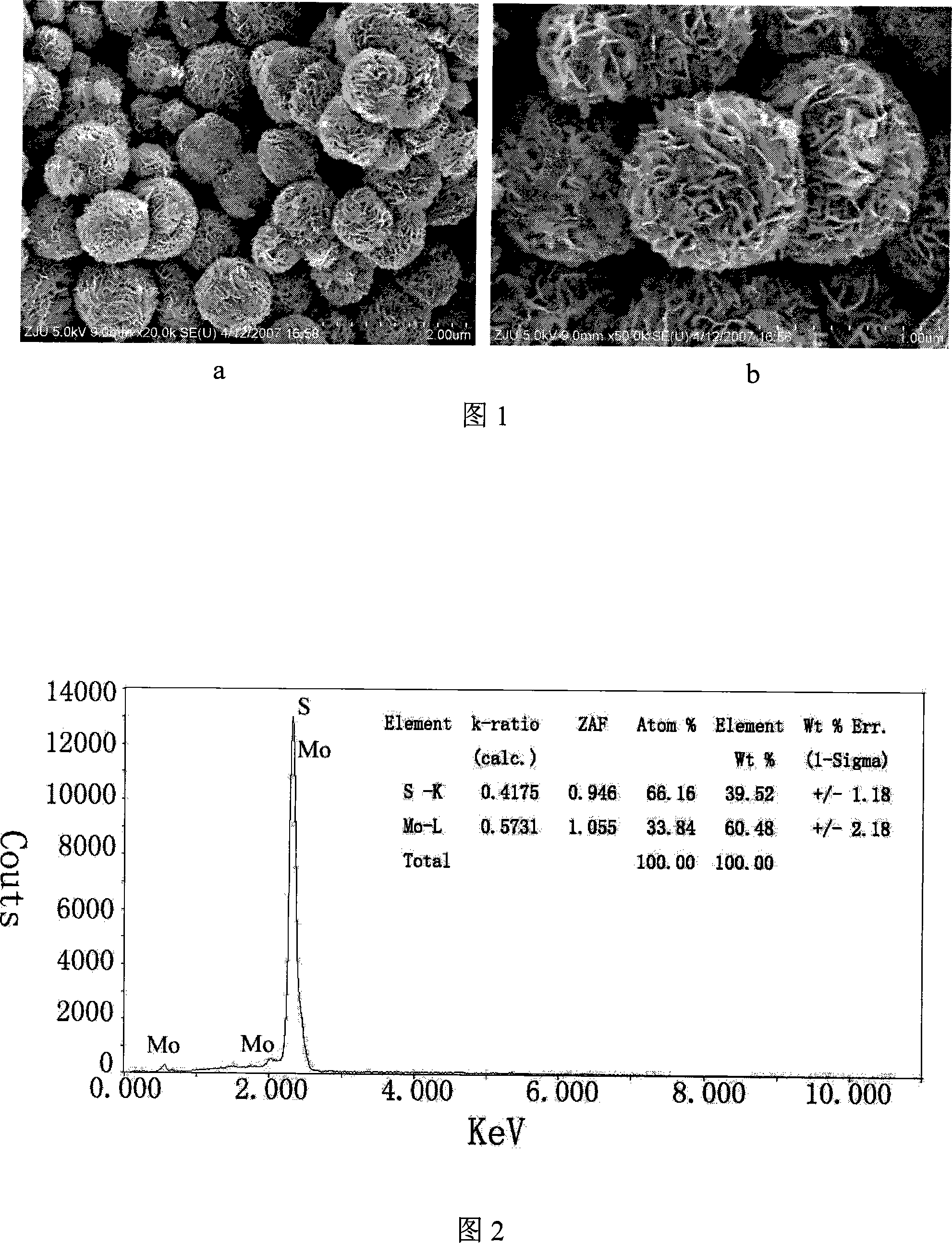

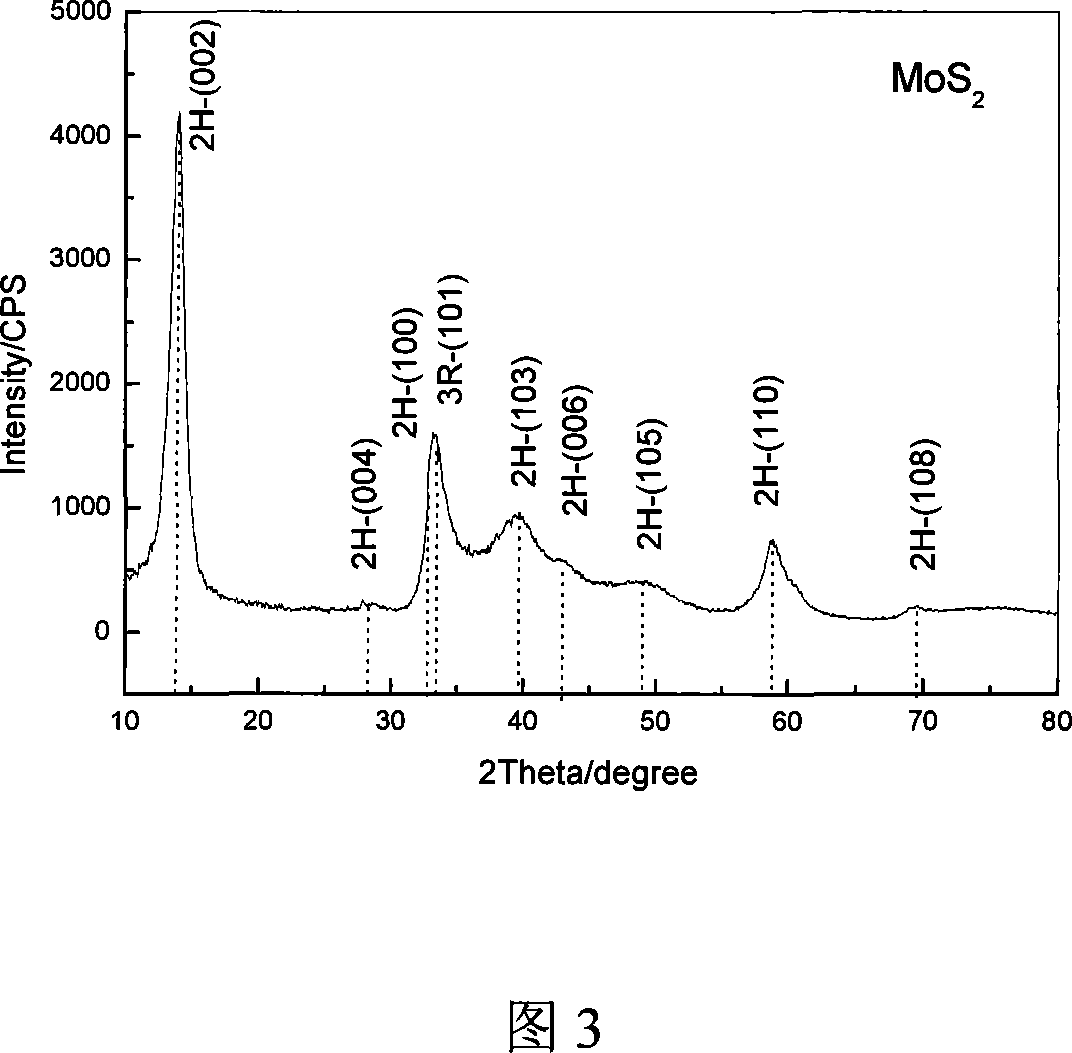

Preparation method of one-step hydrothermal synthesis of carbon/molybdenum disulfide composite microsphere

InactiveCN1994896AUniform particle sizeSimple methodVanadium oxidesMolybdenum sulfidesSucroseMicrosphere

The invention discloses a making method of carbon / molybdenum disulfide composite microball through water heat method, which comprises the following steps: dissolving molybdate in the deionized water to form 0.02-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding glucose or sucrose as carbon source with the molar rate of glucose or sucrose and molybdate at 51-251; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

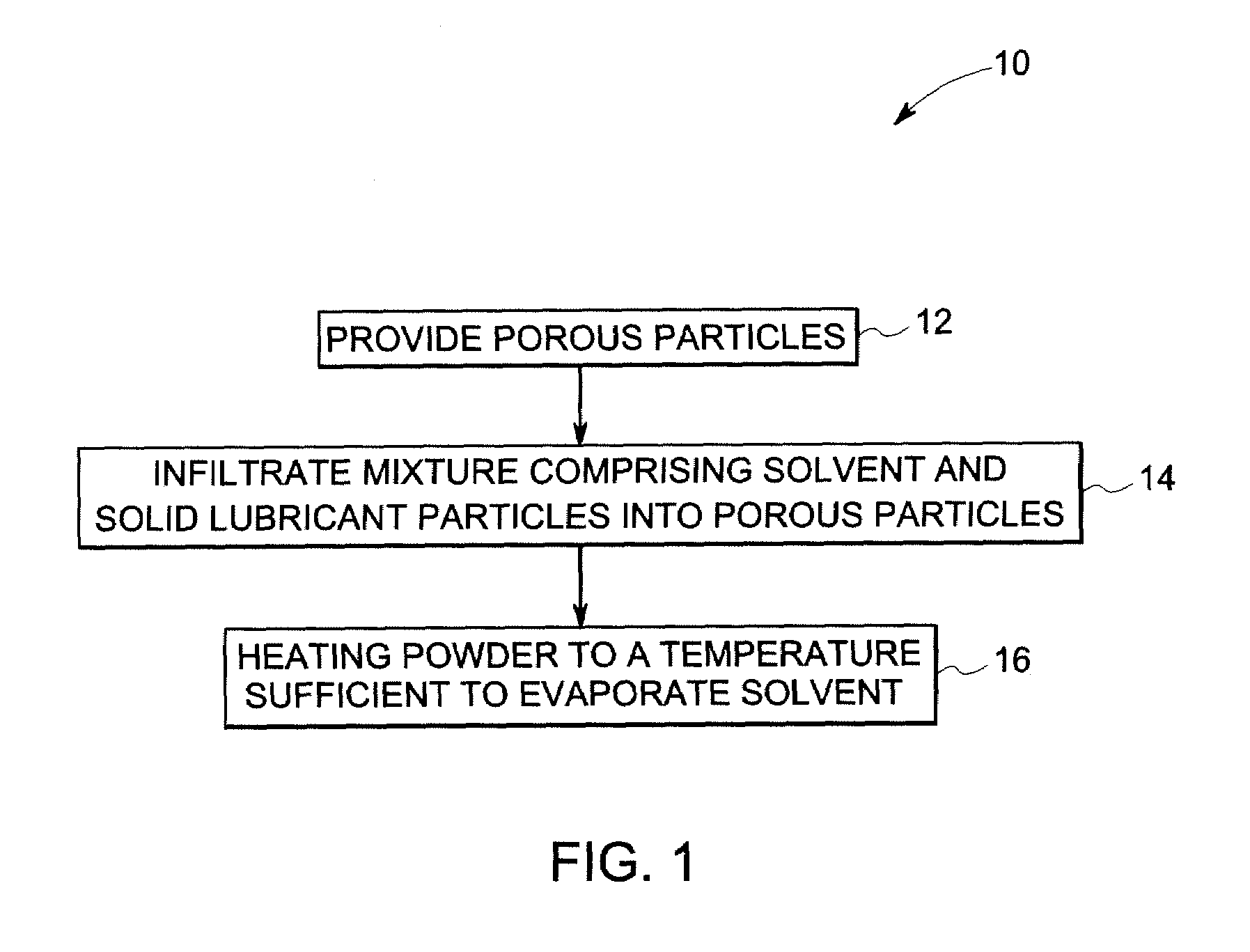

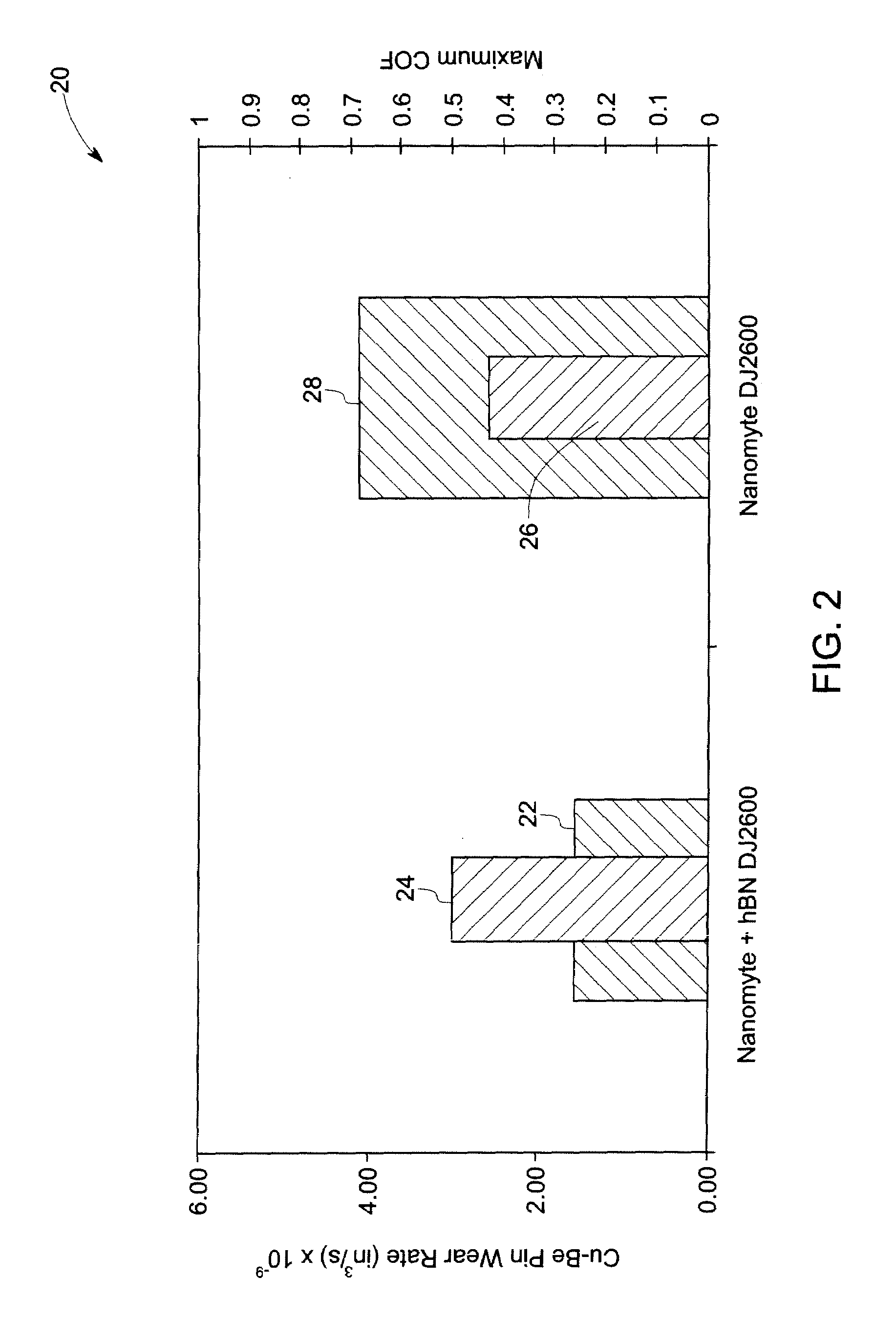

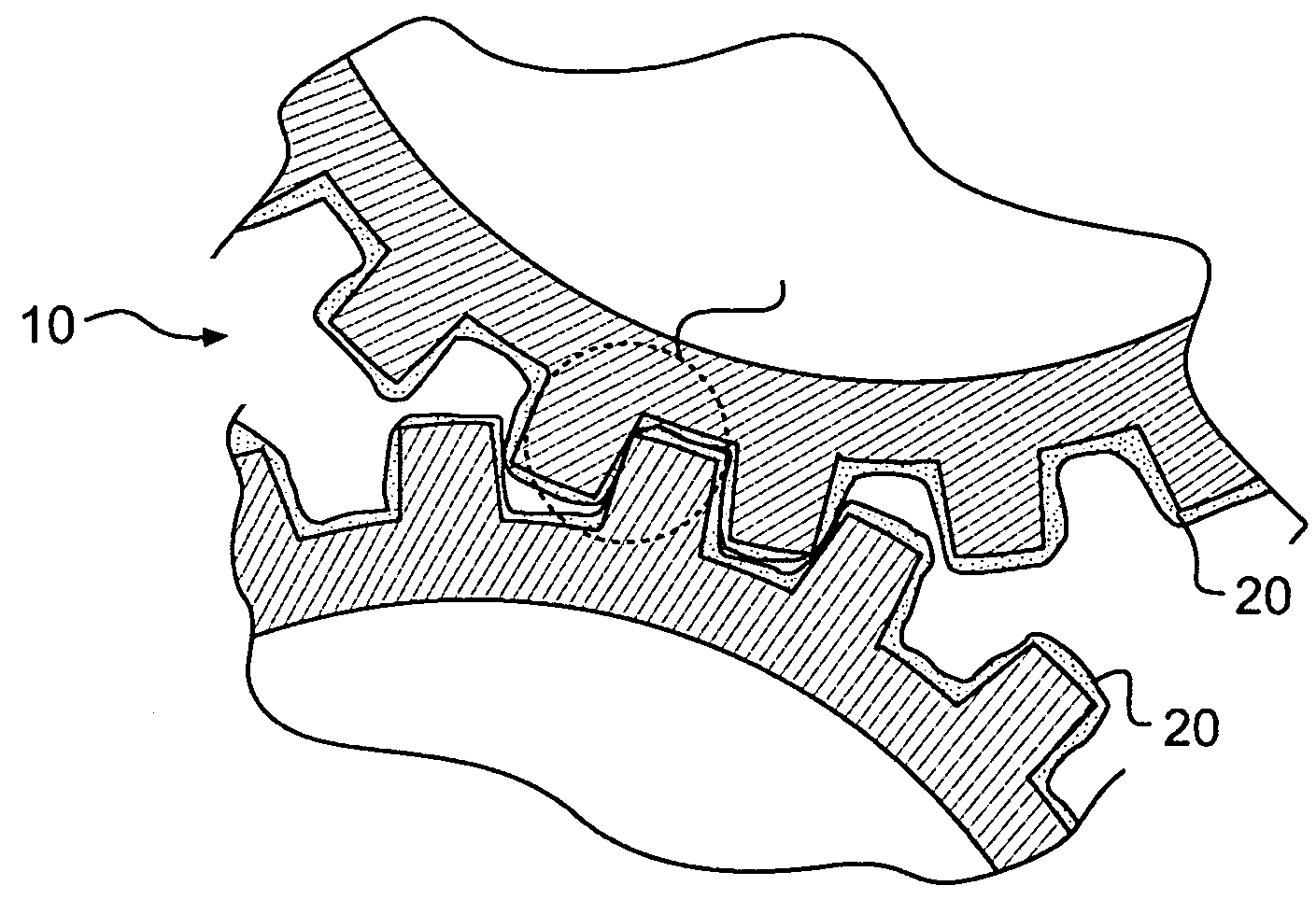

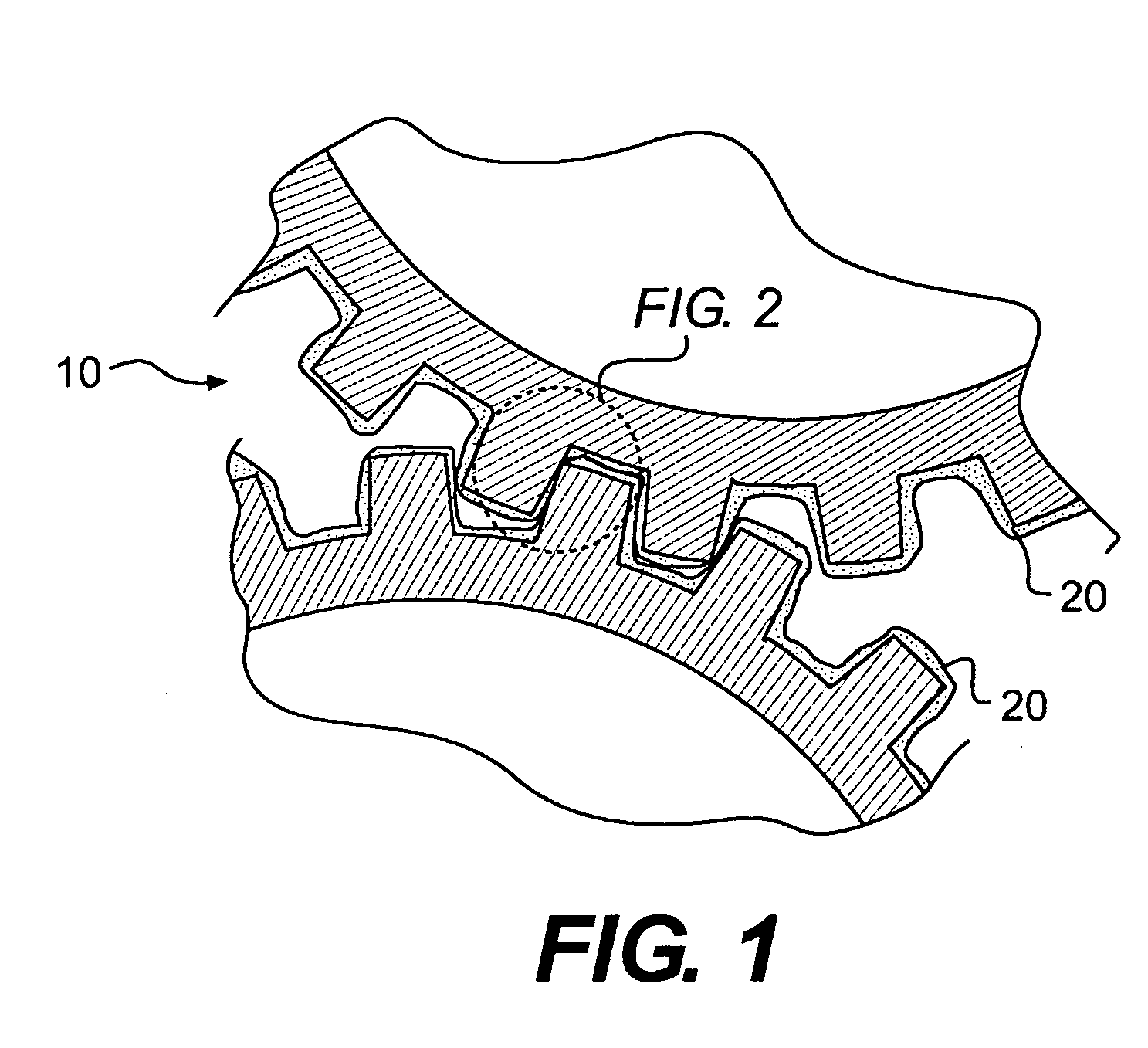

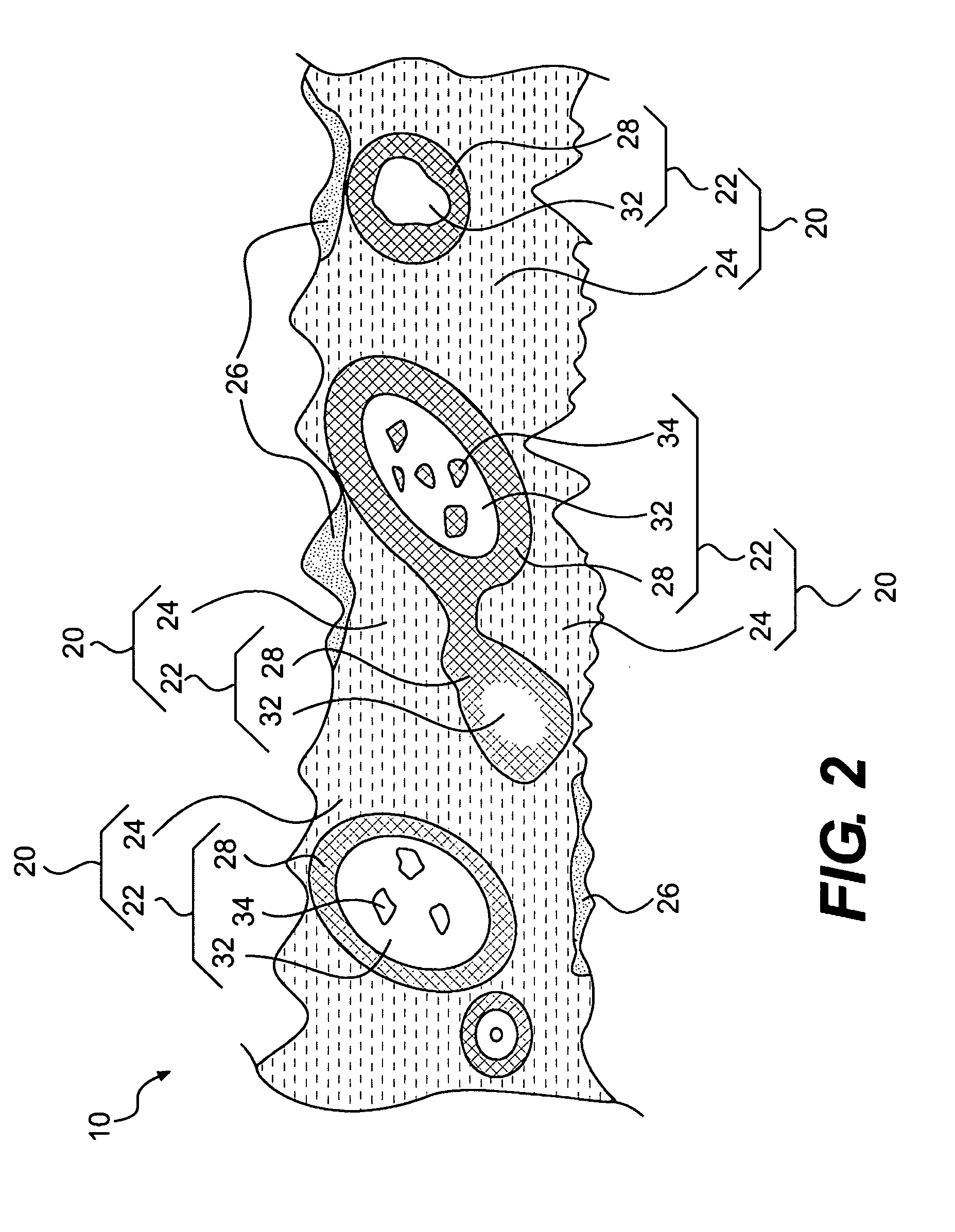

Thermal spray powders for wear-resistant coatings, and related methods

InactiveUS20080145554A1High solid lubricant loadingUniform solid lubricant dispersionLiquid surface applicatorsMolten spray coatingThermal sprayingWear resistant

A method of making a thermal spray powder is provided. The method comprises: providing a powder comprising a plurality of porous particles; infiltrating a mixture comprising a solvent and a plurality of solid lubricant particles into the porous particles; and heating the powder to a temperature sufficient to evaporate the solvent. The method of forming a wear-resistant coating is provided. The method comprises: providing a thermal spray powder; heating the thermal spray powder; and accelerating the thermal spray powder from a thermal spray gun onto the substrate, to form a deposit. Yet another embodiment provides a wear resistant coating. The wear resistant coating is formed by thermally spraying the thermal spray powder.

Owner:GENERAL ELECTRIC CO

Nanoparticulate based lubricants

A method of making a nanoparticulate based lubricant is disclosed. The method includes providing solid lubricant material with particles having a size less than or equal to about 500 nanometers, and treating the particles to create composite nanoparticles. The composite nanoparticles includes the solid lubricant material and at least a second material.

Owner:CATERPILLAR INC

Hydrothermal synthesis method of molybdenum disulfide nano flowers

InactiveCN103613137AAvoid direct exposureGuaranteed purityNanotechnologyMolybdenum sulfidesAir exposureSulfur

The invention discloses a hydrothermal synthesis method of molybdenum disulfide nano flowers. The hydrothermal synthesis method mainly comprises the following steps: adding an inorganic molybdenum source, an organic sulfur source and a proper amount of reducing agent into deionized water, uniformly mixing the ingredients, transferring the mixture into a high pressure reaction kettle, and then heating the mixture at a high temperature for 24 hours; washing and centrifugally separating the obtained solution for multiple times, and finally drying the solution to obtain black solid powder, namely, the molybdenum disulfide nano flowers. The hydrothermal synthesis method disclosed by the invention has the beneficial effects that the whole reaction and drying process is carried out in a sealed environment to avoid direct air exposure so as to ensure the product purity; since the reducing agent adopted by the hydrothermal synthesis method disclosed by the invention can be both used as the sulfur source and as a catalyst, no impurity is generated, and thus, the product purity is further improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

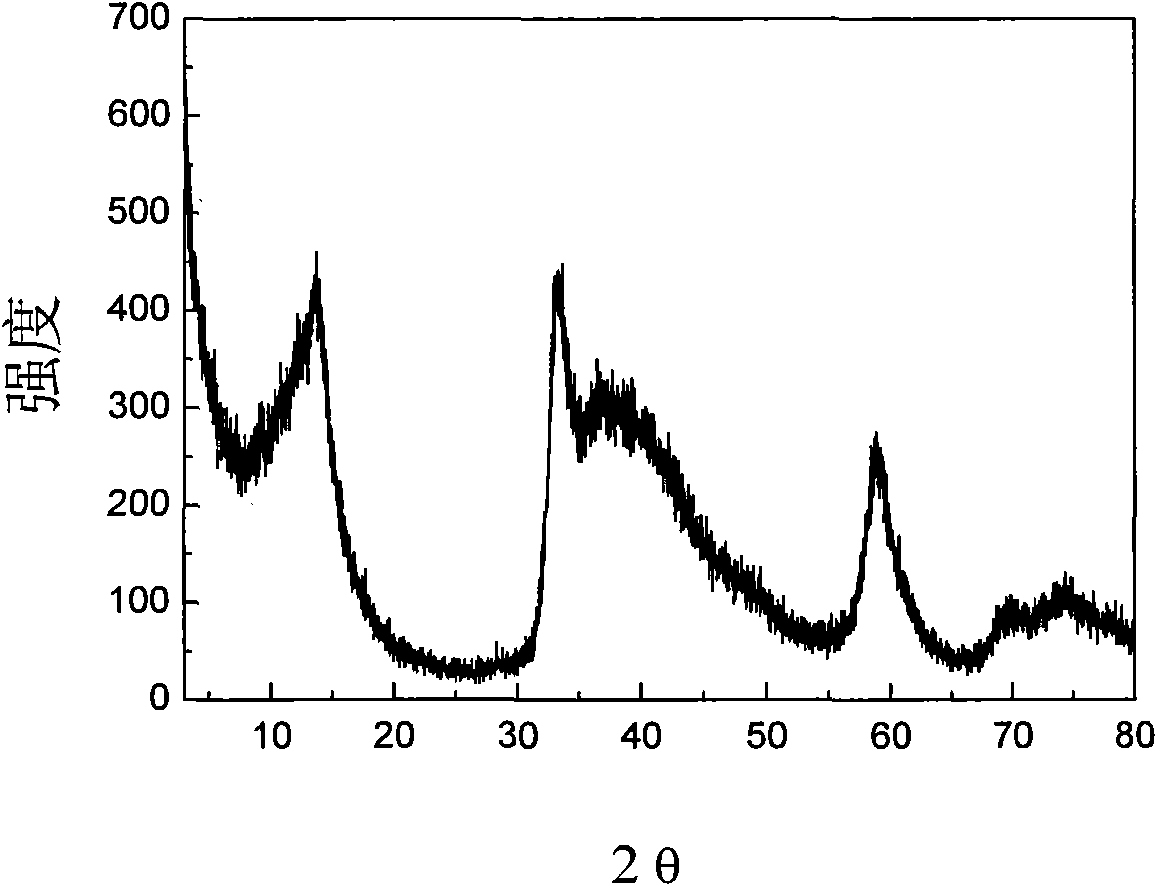

Method for preparing MoS2 microspheres by solvent hot method

InactiveCN101851006AMild reaction conditionsGood reproducibilityMolybdenum sulfidesAlcoholHigh volume manufacturing

The invention relates to a method for preparing MoS2 microspheres by a solvent hot method, which comprises the following preparation steps: 1) mixing molybdenum source compounds and sulfur source compounds into an alcohol solvent, sufficiently stirring the mixture, and carrying out ultrasonic processing for sufficiently dispersing the mixture; 2) then, transferring the uniformly dispersed mixture into a reaction kettle for carrying out constant-temperature reaction; and 3) carrying out natural cooling, separation, washing and drying on reacting substances to obtain black MoS2 microspheres. The invention has the advantages of mild reaction condition, good reaction reproduction quality, simple preparation process, low preparation cost and high product yield and purity, and is hopeful to realize mass production. The MoS2 products prepared by the solvent hot method of the invention have very important application prospects in all aspects of energy storage, catalysts, solid lubricating agents and the like.

Owner:NANKAI UNIV

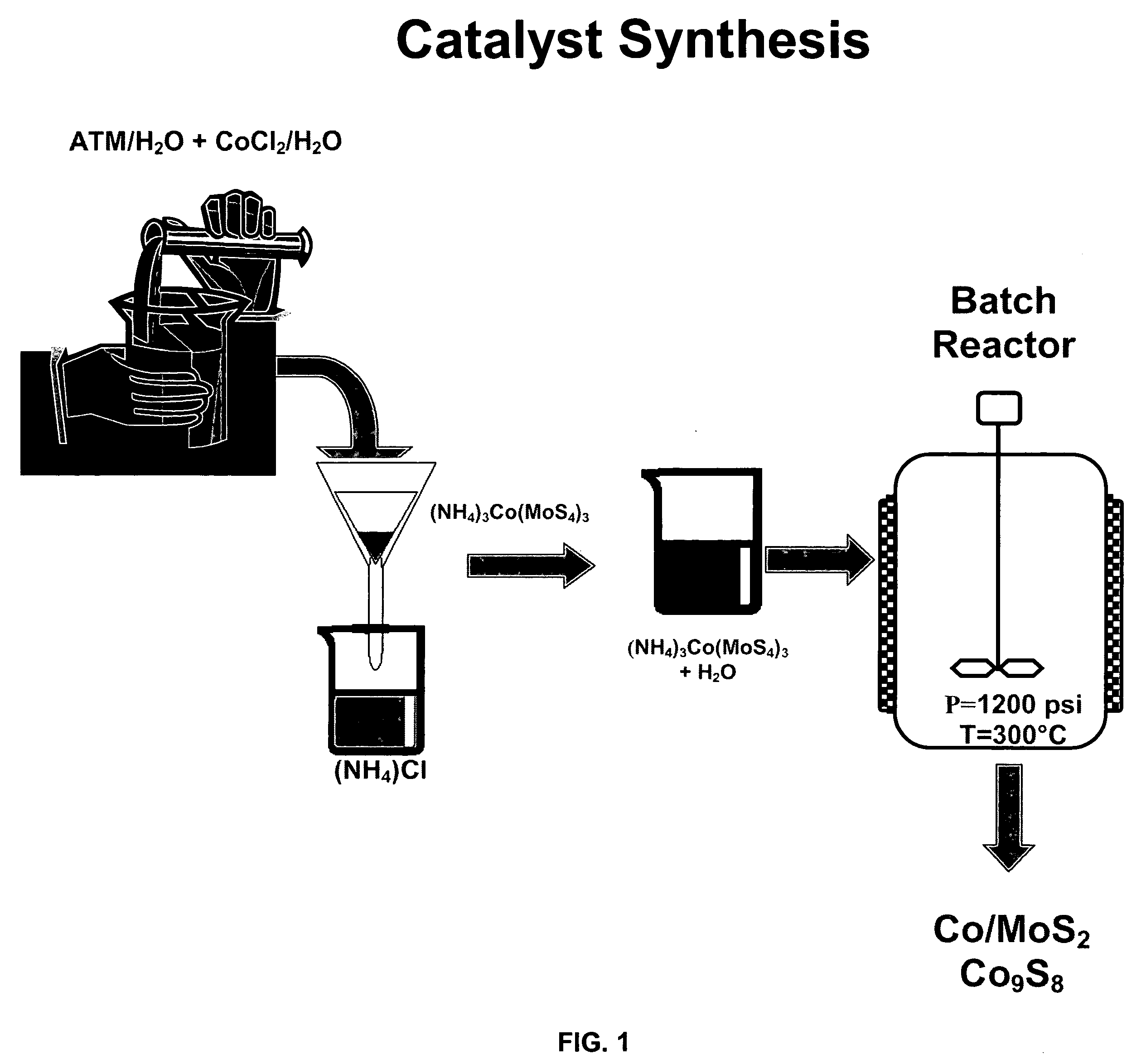

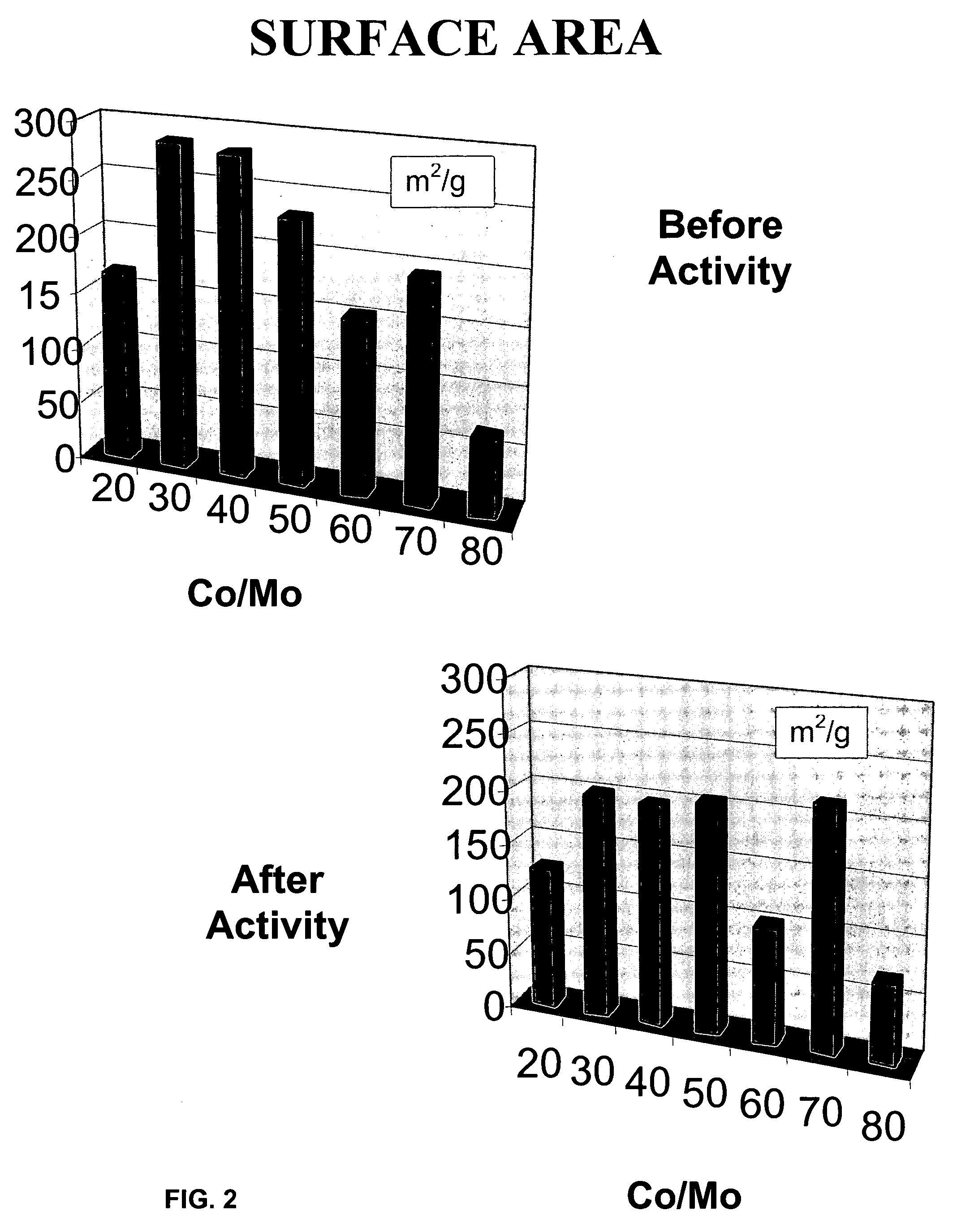

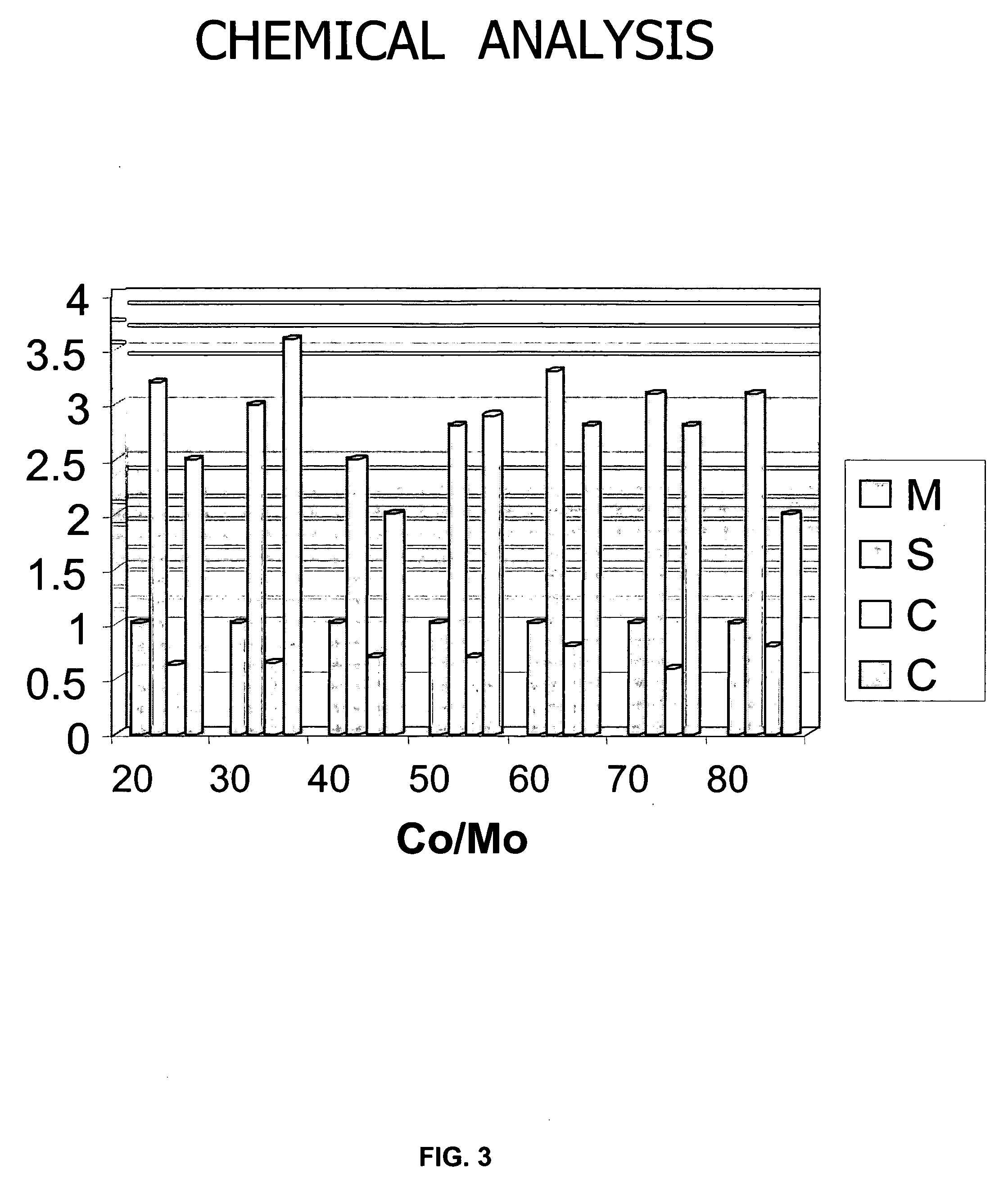

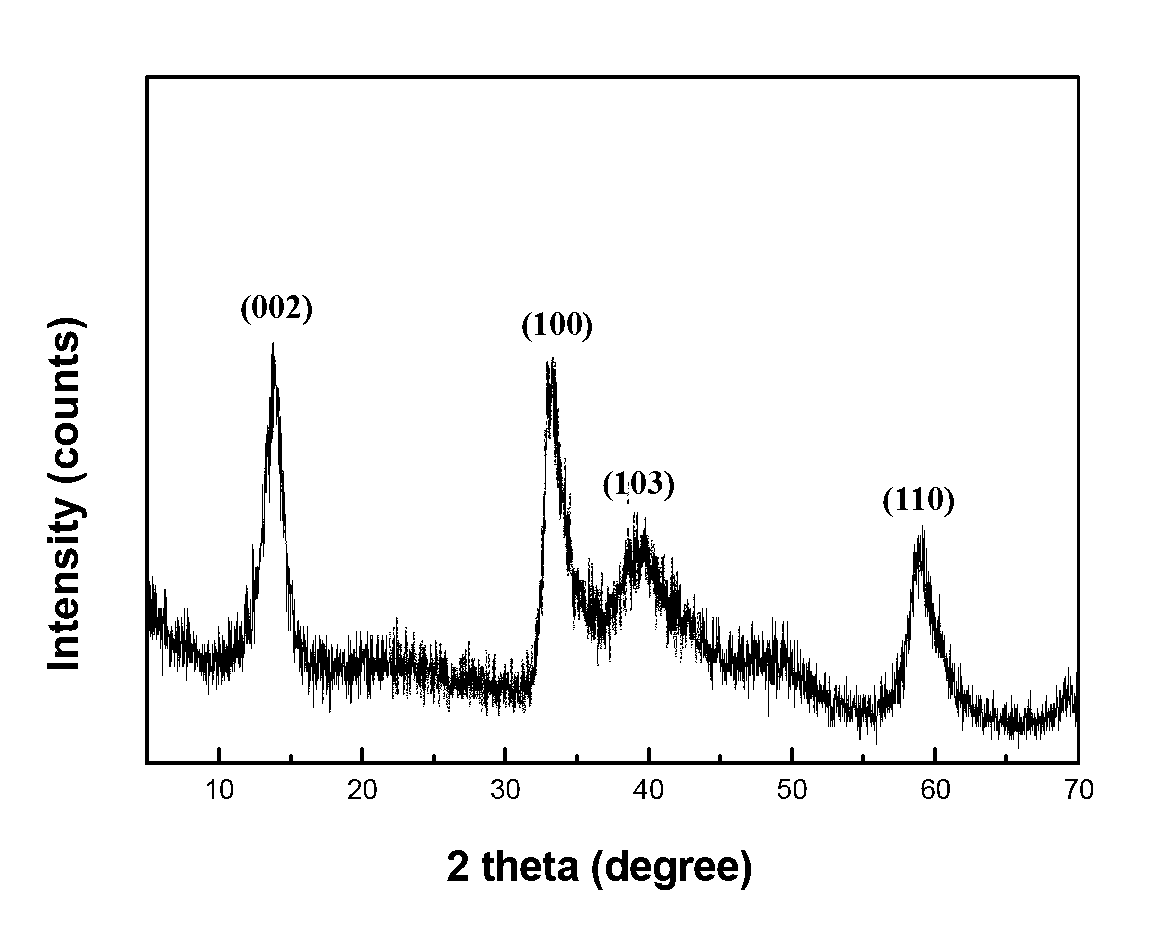

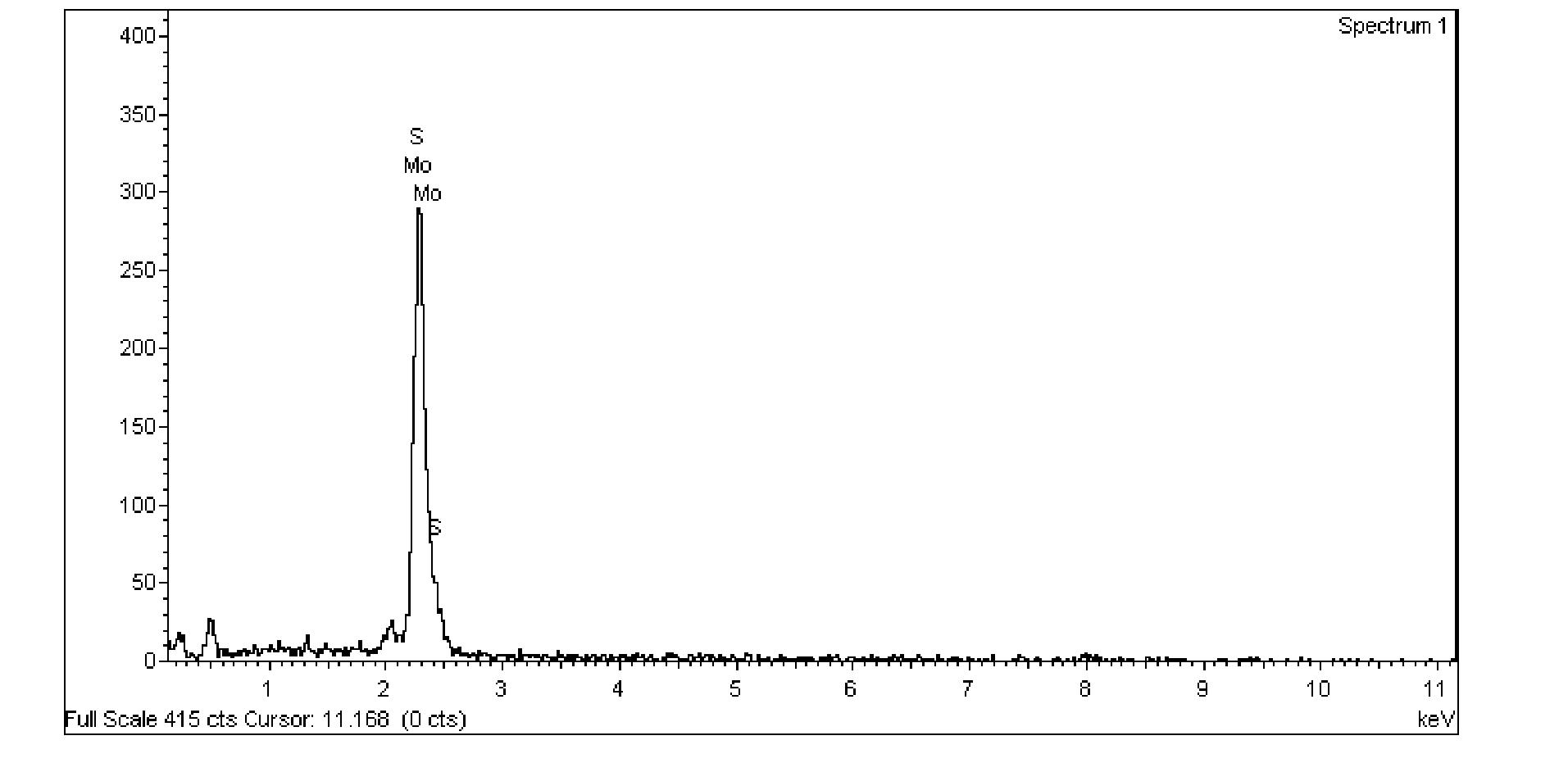

Molybdenum sulfide/carbide catalysts

InactiveUS7223713B2High activityImprove stabilityCell electrodesCatalyst activation/preparationMolybdateNitrogen

The present invention provides methods of synthesizing molybdenum disulfide (MoS2) and carbon-containing molybdenum disulfide (MoS2-xCx) catalysts that exhibit improved catalytic activity for hydrotreating reactions involving hydrodesulfurization, hydrodenitrogenation, and hydrogenation. The present invention also concerns the resulting catalysts. Furthermore, the invention concerns the promotion of these catalysts with Co, Ni, Fe, and / or Ru sulfides to create catalysts with greater activity, for hydrotreating reactions, than conventional catalysts such as cobalt molybdate on alumina support.

Owner:GABRIEL ALONSO +2

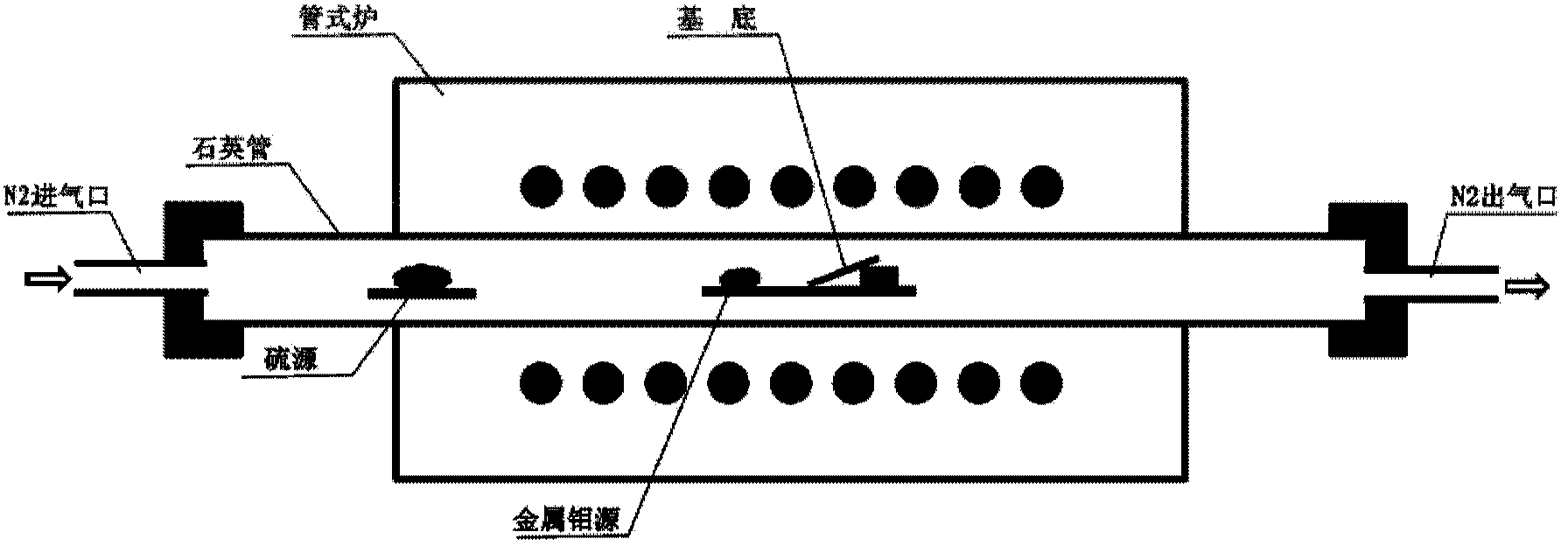

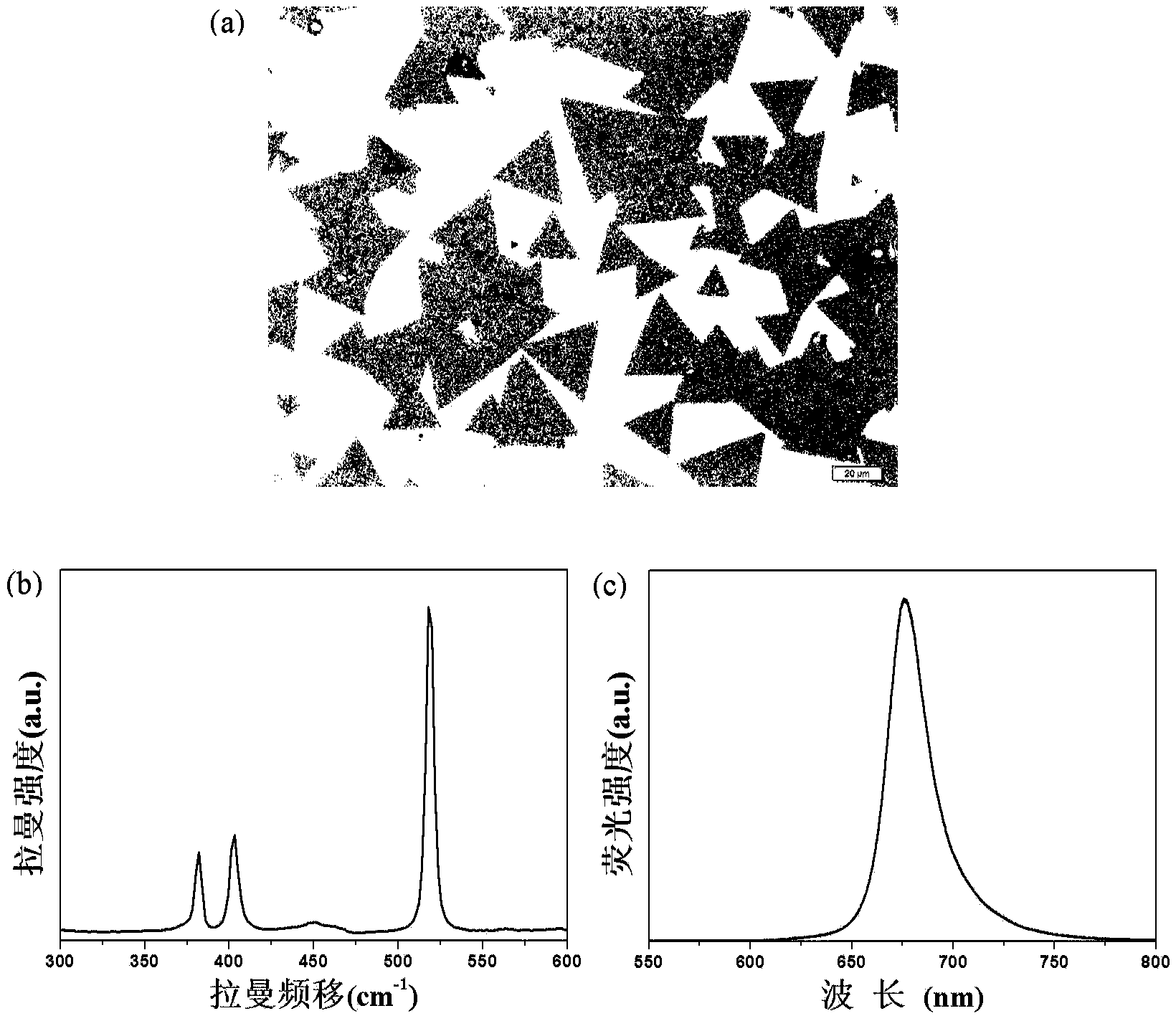

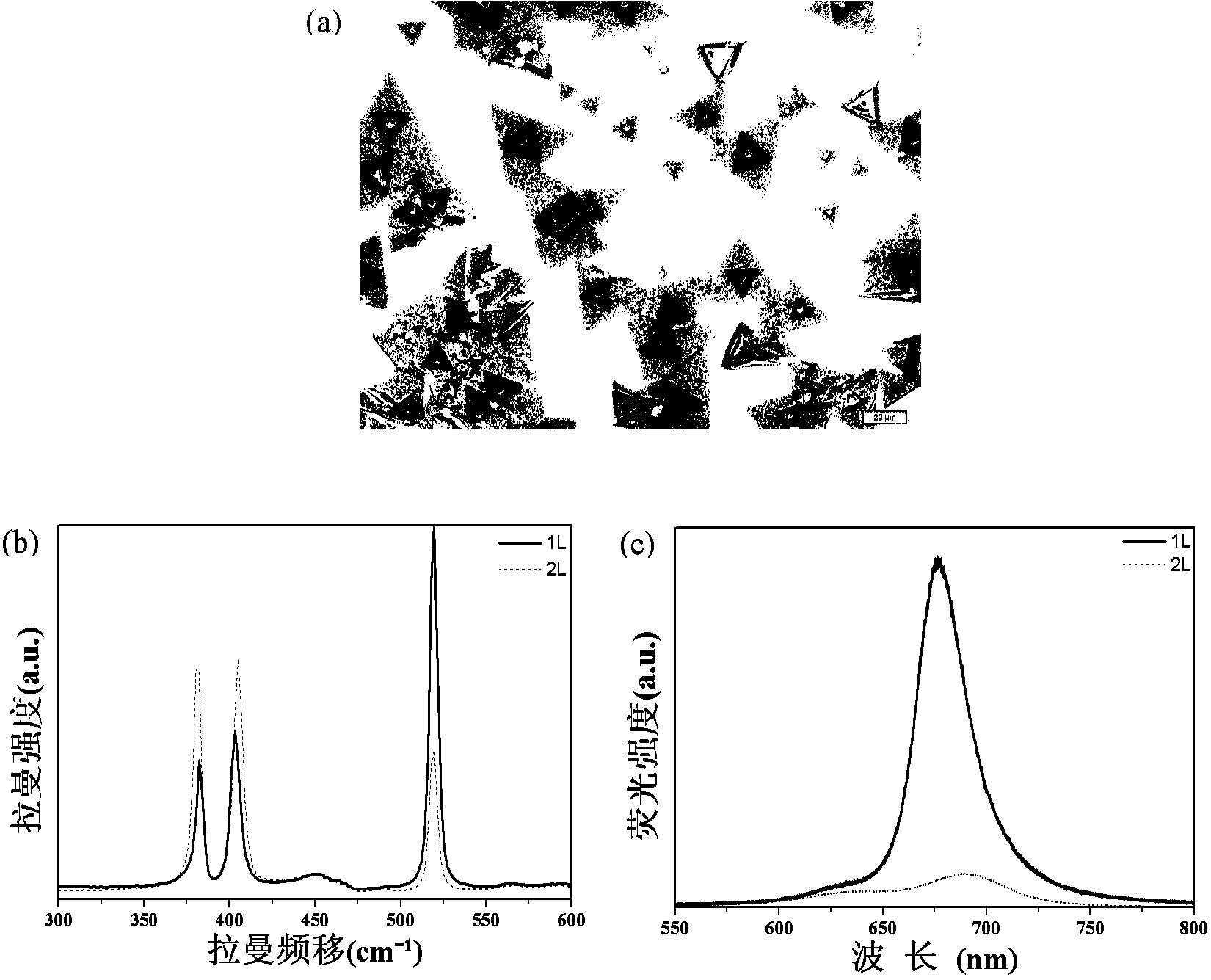

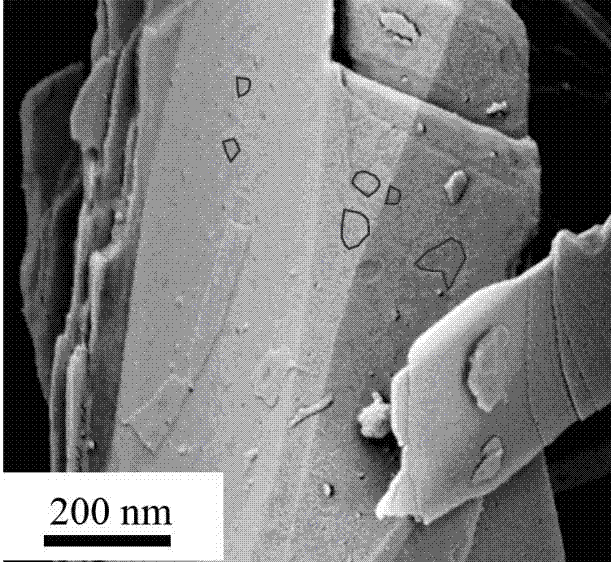

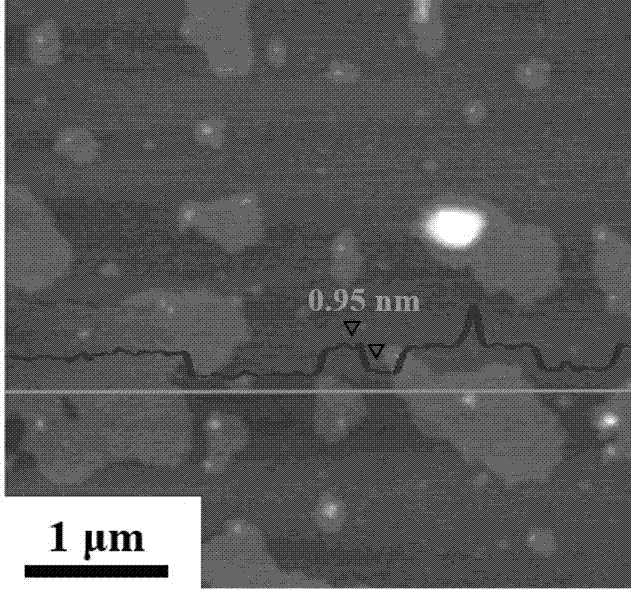

Method for preparing high-quality single/double-layer controllable molybdenum disulfide

ActiveCN104058458AQuality improvementLow equipment requirementsMolybdenum sulfidesDeposition temperatureSulfur

The invention relates to a method for preparing layered molybdenum disulfide. The layered molybdenum disulfide is in a single-layer or double-layer structure, wherein a chemical vapor deposition method is adopted, elemental molybdenum metal and powdered sulfur is taken as a source, two-dimensional molybdenum disulfide is deposited on the surface of a substrate, the preparation parameters such as deposition temperature and growth time are optimized, and controllable growth of the single-layer or double-layer structure of the high-quality molybdenum disulfide is realized.

Owner:UNIV OF SCI & TECH OF CHINA

Antiadhesive high temperature layers

ActiveUS20060159909A1Easy to slideGood adhesionFireproof paintsMaterial nanotechnologySolid particleBoron nitride

Owner:INST FUR NEUE MATERIALIEN GEMEINNUTZIGE GMBH

Preparation method of molybdenum disulfide nanosheet in stripping manner

ActiveCN104495935AReduce energy consumptionNo pollution in the processMaterial nanotechnologyMolybdenum sulfidesRoom temperatureSolvent

The invention discloses a preparation method of a molybdenum disulfide nanosheet in a stripping manner. Stirring or ultrasonic treatment is carried out in a mixed solvent containing an oxidizing agent, and a raw material, namely molybdenum disulfide, is stripped, so that the molybdenum disulfide nanosheet is formed. The preparation method of the molybdenum disulfide nanosheet has the advantages that a cheap reagent is adopted, operation is carried out at room temperature, energy consumption is low, no pollution is caused, efficiency is high, and the prepared molybdenum disulfide nanosheet can be widely applied to the fields of energy storage and conversion, catalysis, lubrication, various composite materials and the like.

Owner:安徽百特新材料科技有限公司

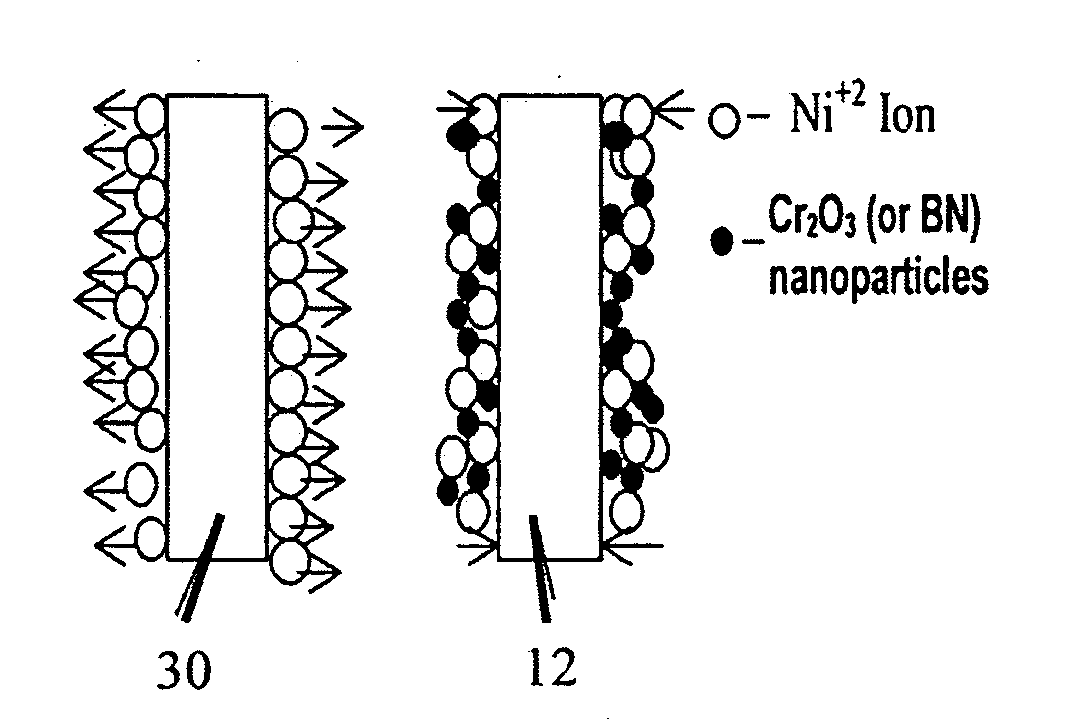

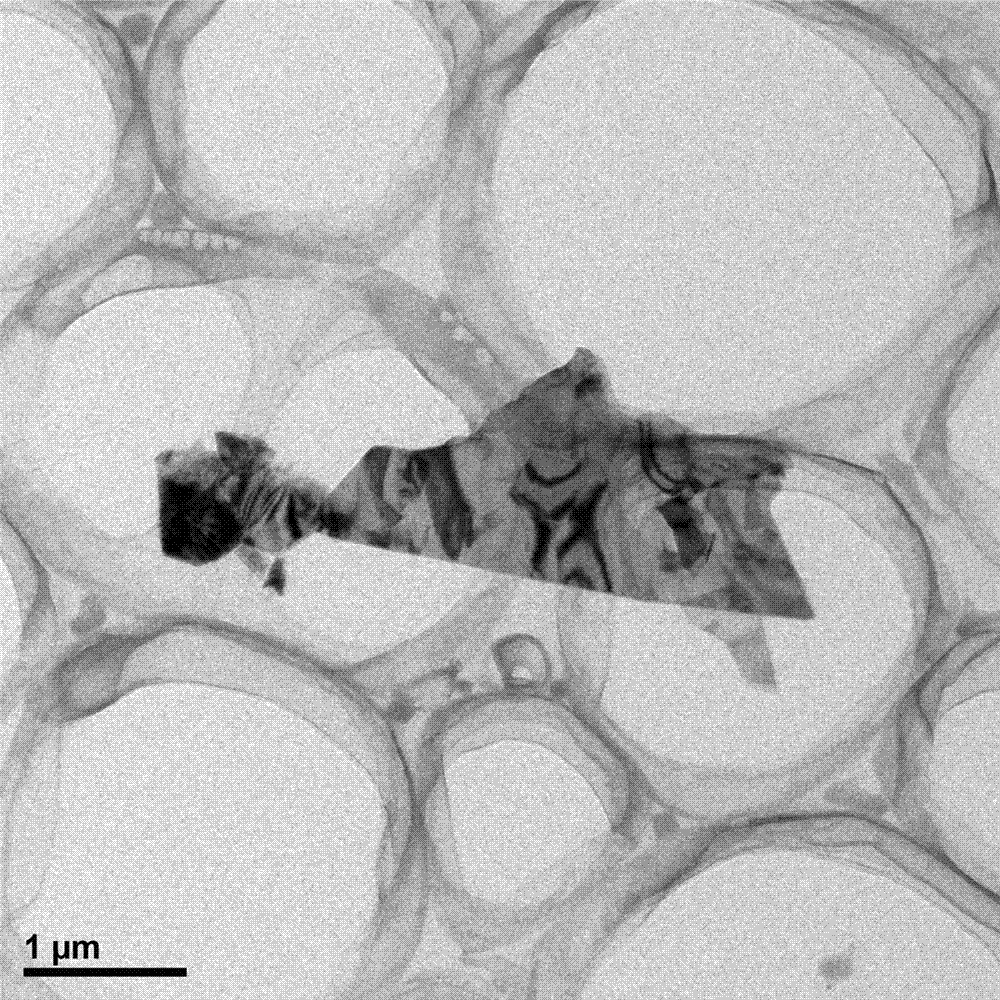

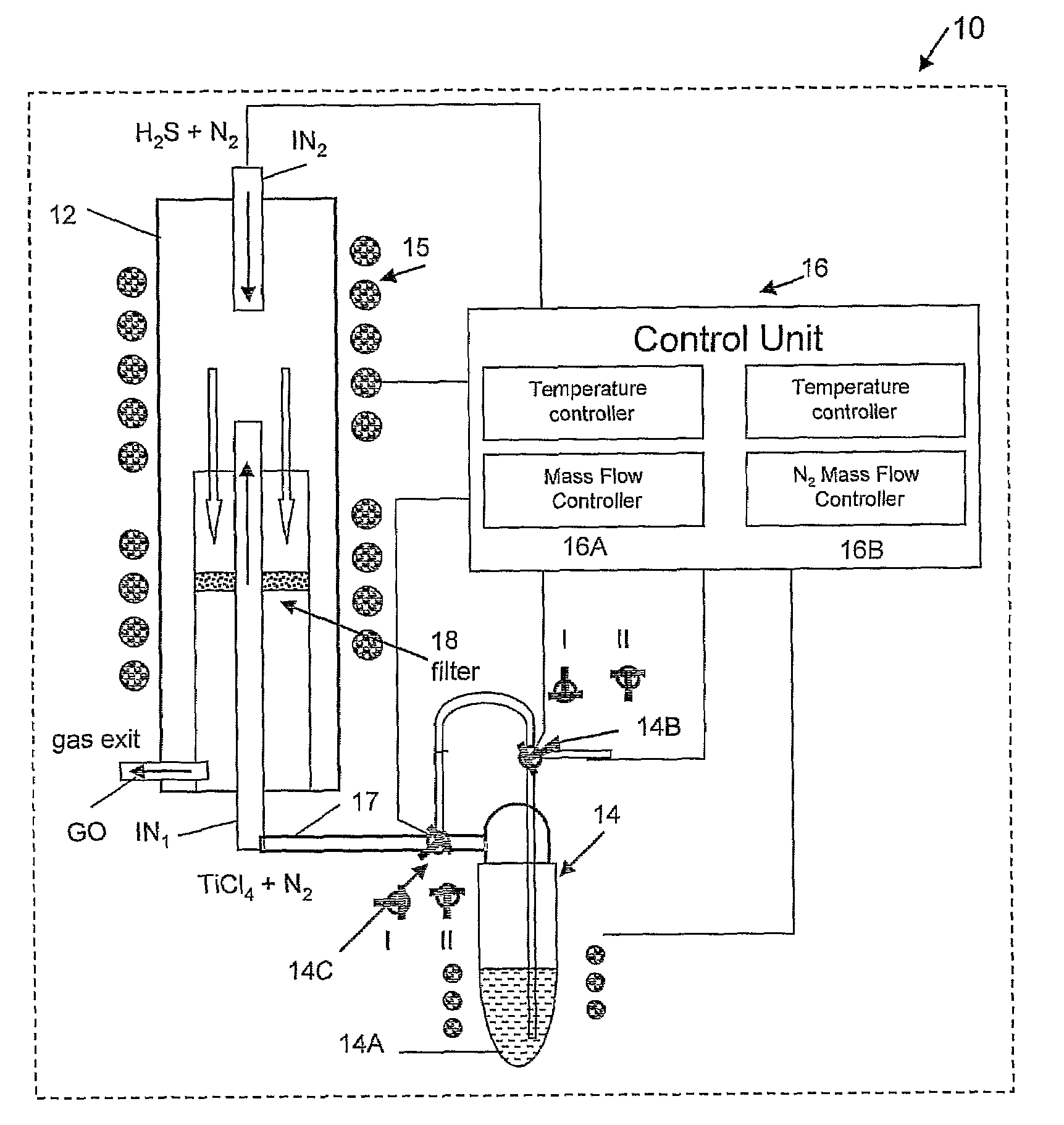

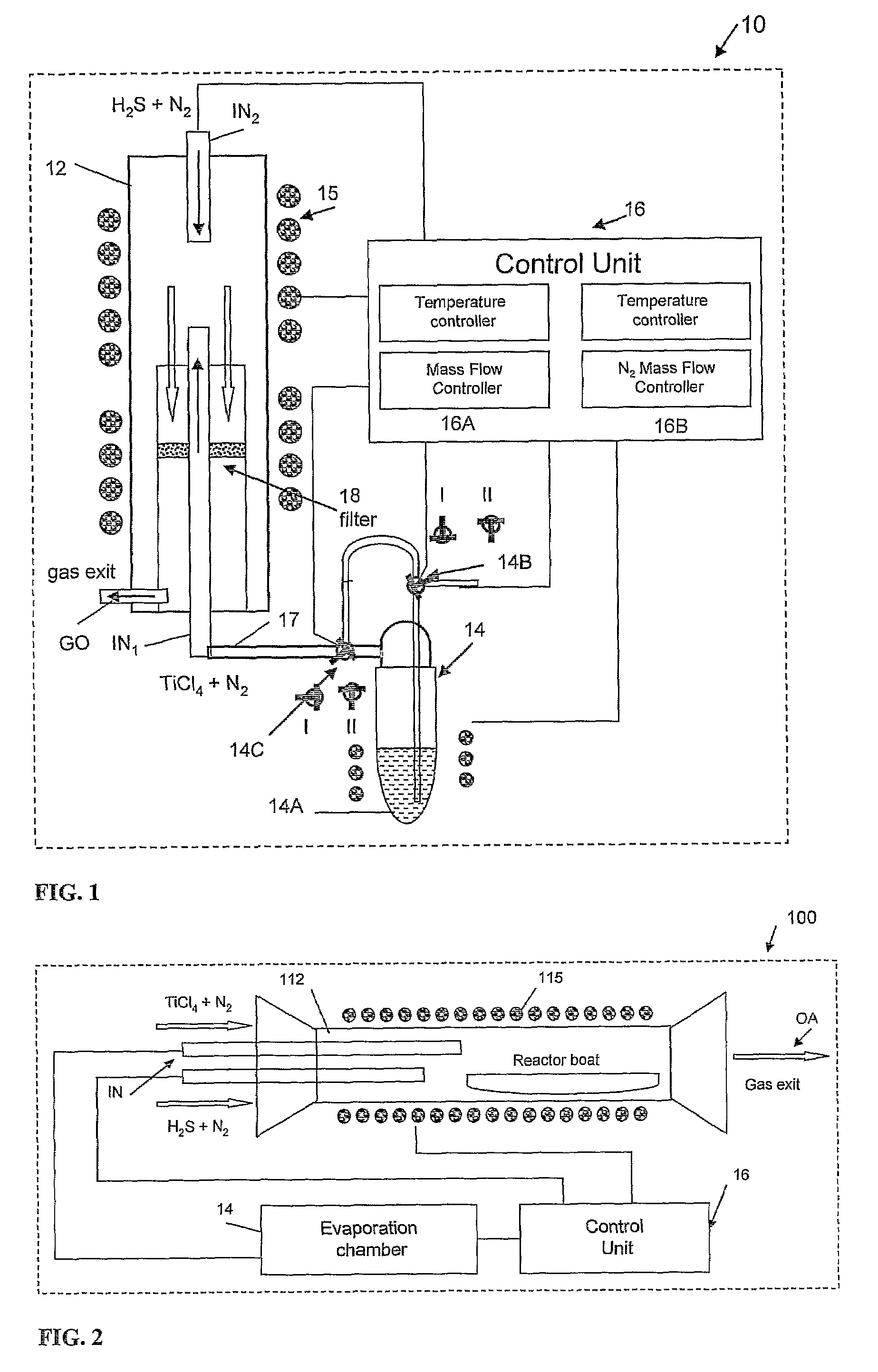

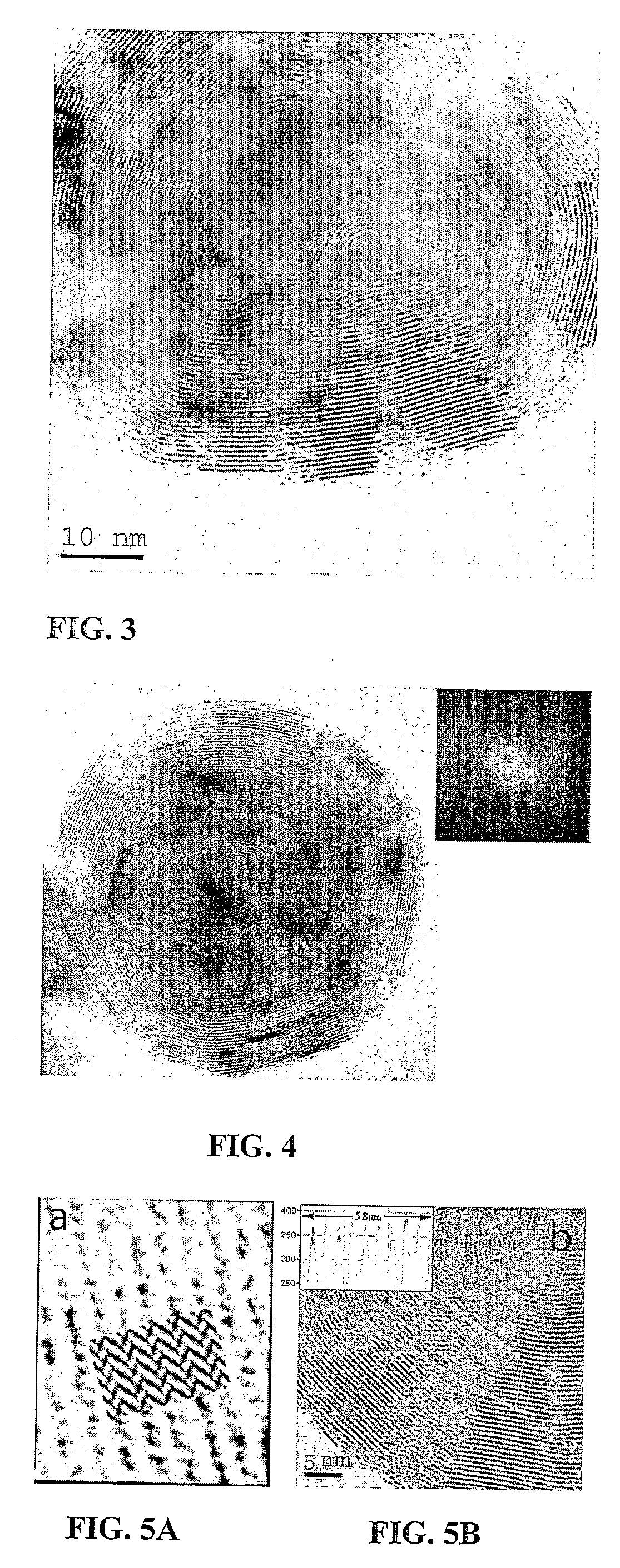

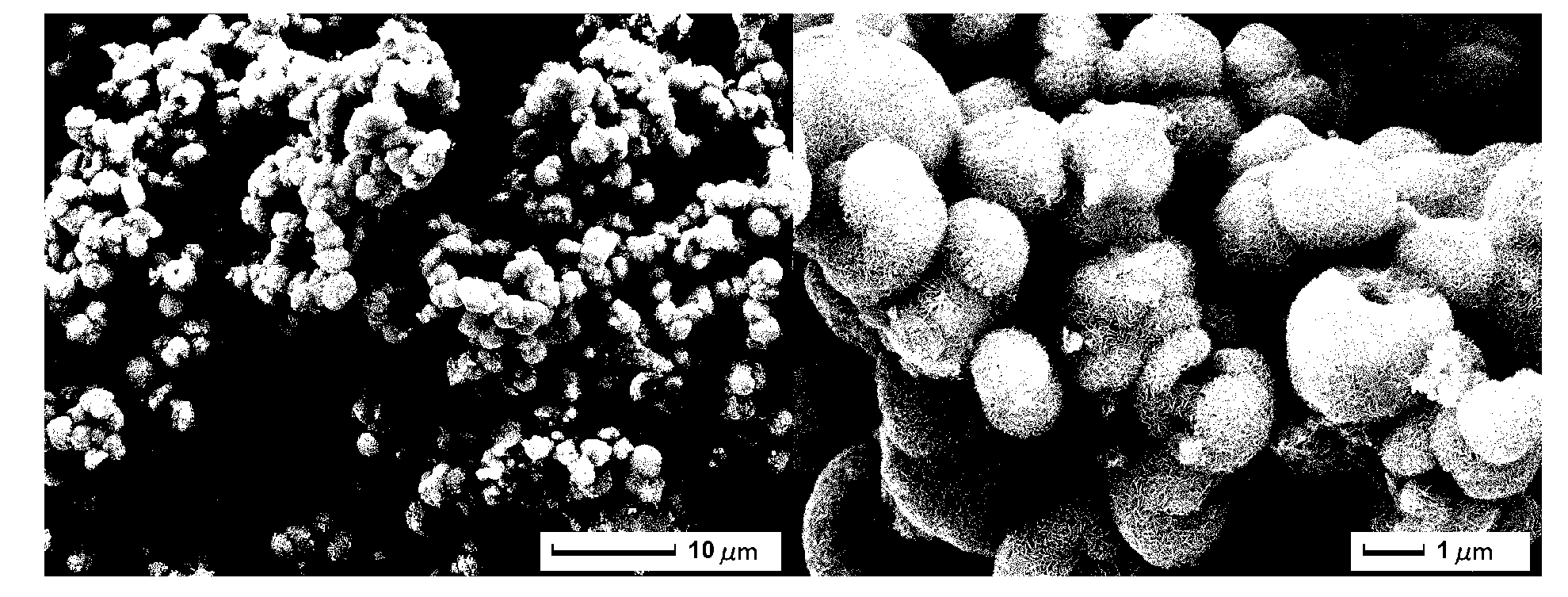

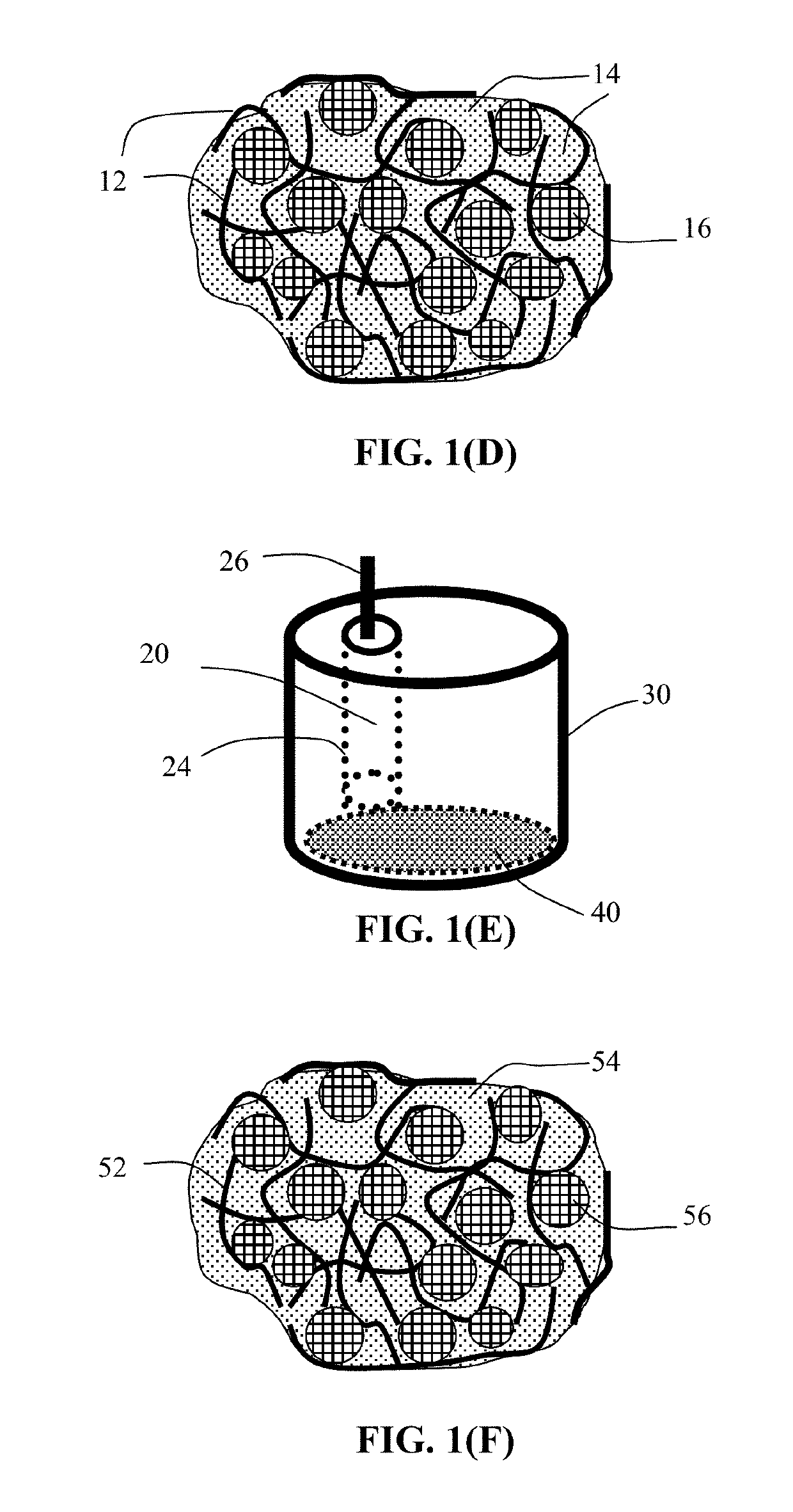

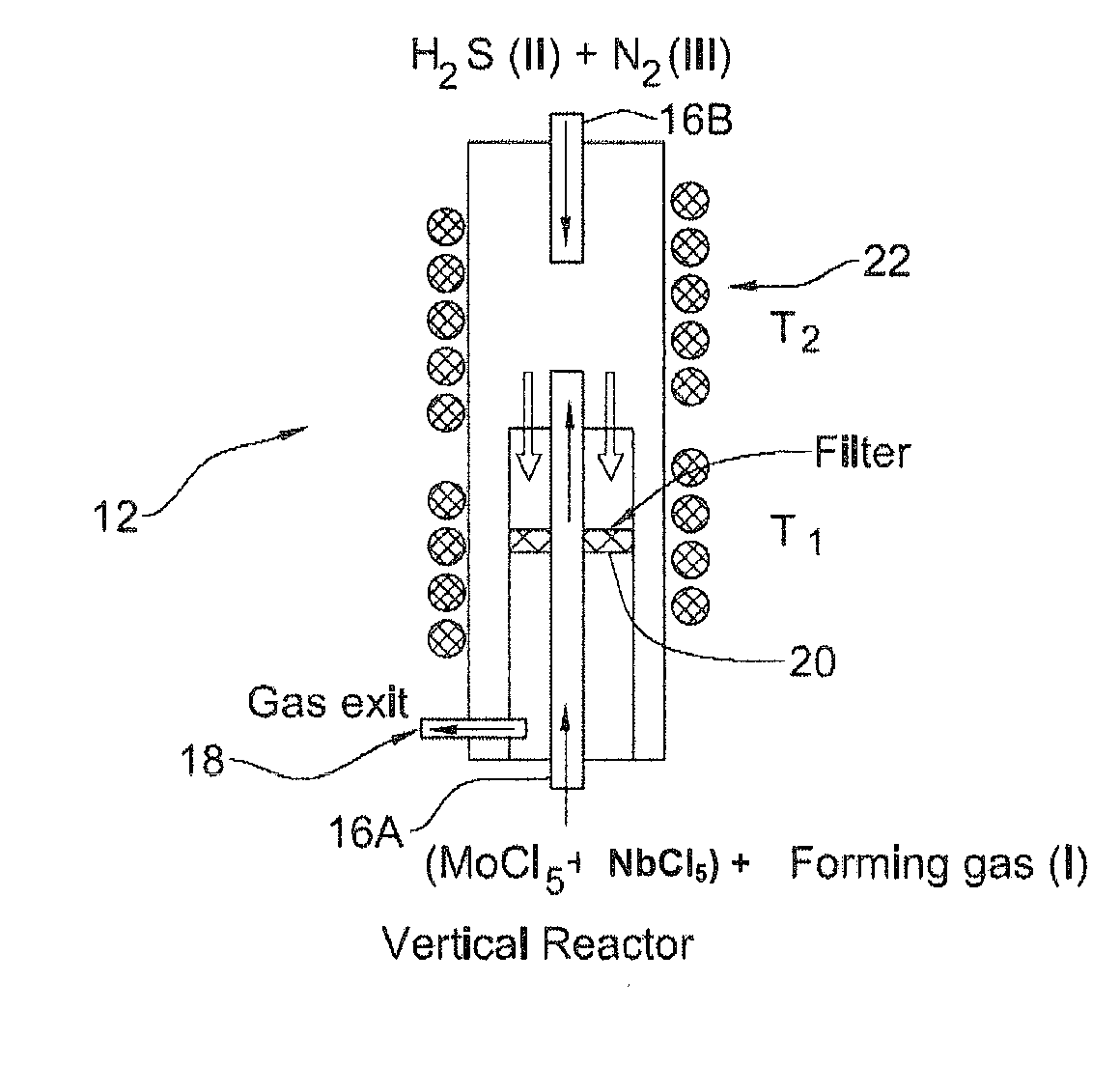

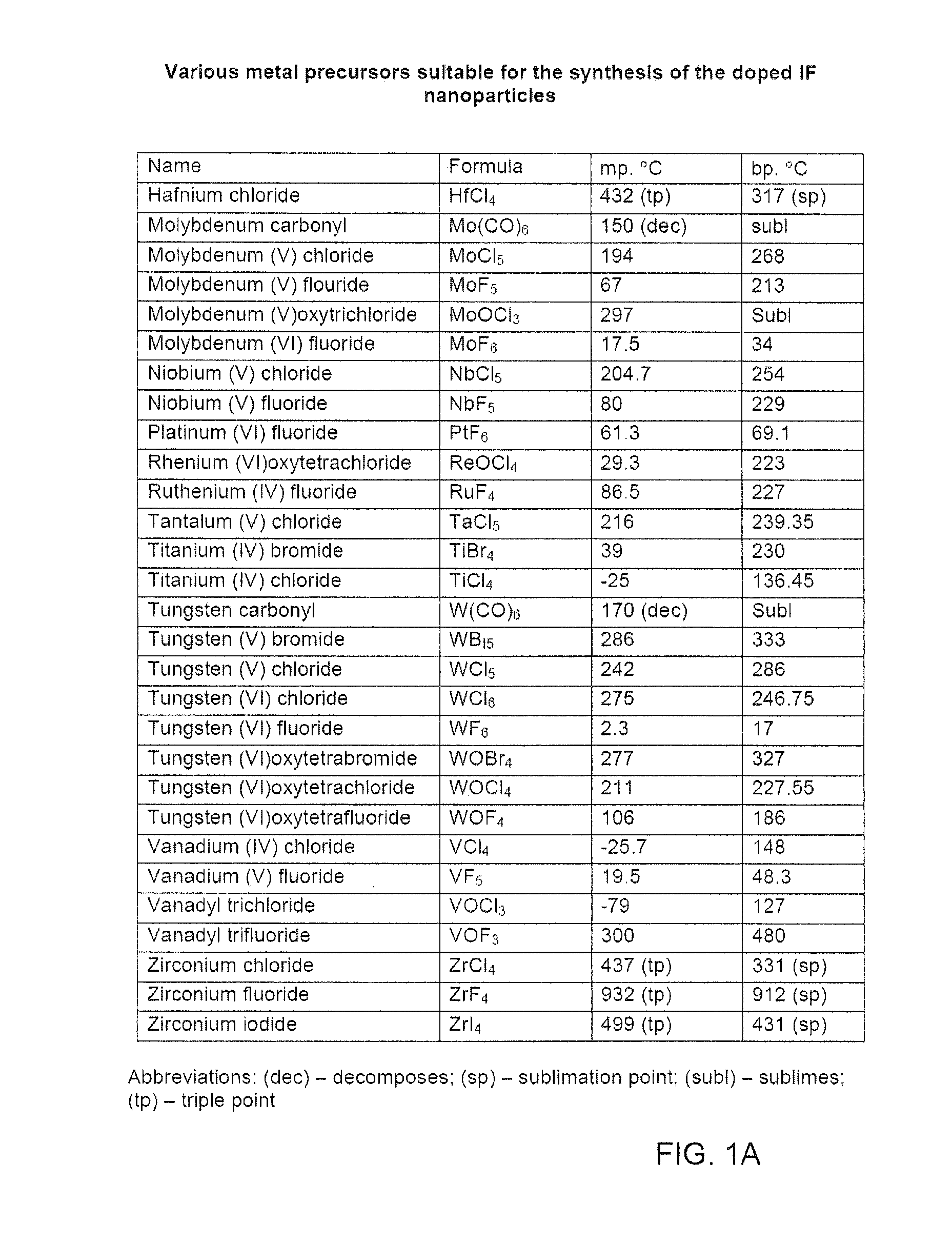

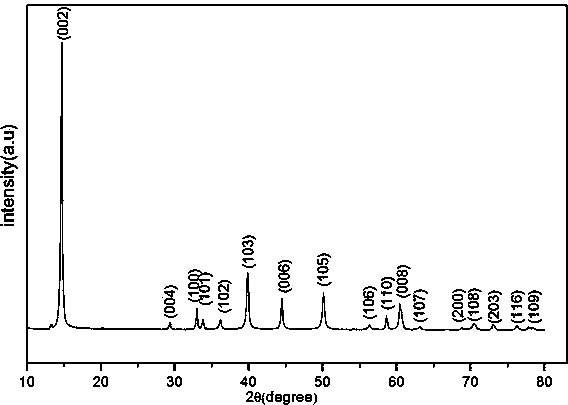

Process and apparatus for producing inorganic fullerene-like nanoparticles

ActiveUS7641886B2Easy to produceImproved propertyMaterial nanotechnologyNanostructure manufactureGas phaseMetal chalcogenides

The present invention provides a process for obtaining fullerene-like metal chalcogenide nanoparticles, comprising feeding a metal precursor (INi) selected from metal halide, metal carbonyl, organo-metallic compound and metal oxyhalide vapor into a reaction chamber (12) towards a reaction zone to interact with a flow of at least one chalcogen material (IN2) in gas phase, the temperature conditions in said reaction zone being such to enable the formation of the fullerene-like metal chalcogenide nanoparticles product. The present invention further provides novel IF metal chalcogenides nanoparticles with spherical shape and optionally having a very small or no hollow core and also exhibiting excellent tribological behavior. The present invention further provides an apparatus for preparing various IF nanostructures.

Owner:A Y Y T TECHCAL APPL & DATA UPDATE +1

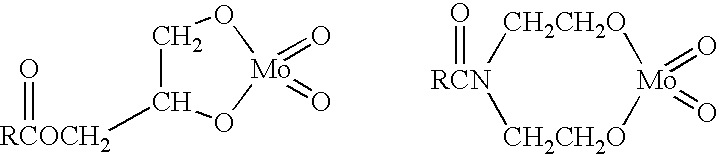

Lubricating oil composition for internal combustion engines

ActiveUS20060025313A1Improve fuel economyLow in phosphorusGroup 3/13 element organic compoundsAdditivesTotal Base NumberAlkaline earth metal

The present invention relates to a low phosphorus lubricating oil composition for internal combustion engines which demonstrates fuel economy benefits while also providing high temperature oxidation, piston deposits, and wear. The lubricating oil composition of the present invention comprises: a) major amount of a base oil of lubricating viscosity; b) from about 0.1 to 10 wt % of an overbased alkaline earth metal alkyl aryl sulfonate detergent having a total base number (TBN) of about 25 to 500; c) from about 0.02 to 10 wt % of a oxymolybdenum-containing complex; d) from about 0.1 to 5 wt % of a friction modifier; and e) from about 0.2 to 10 wt % of an antioxidant selected from the group consisting of a diphenylamine type, a sulfurized ester-containing compound and mixtures thereof; wherein the total concentration of the oxymolybdenum-containing complex and antioxidant must be at least 1.3 wt %, based on the total weight of the lubricating oil composition and wherein the phosphorus content of the total lubricating oil composition is 0.08 wt % or less, based on the total weight of the lubricating oil composition.

Owner:CHEVRON ORONITE CO LLC

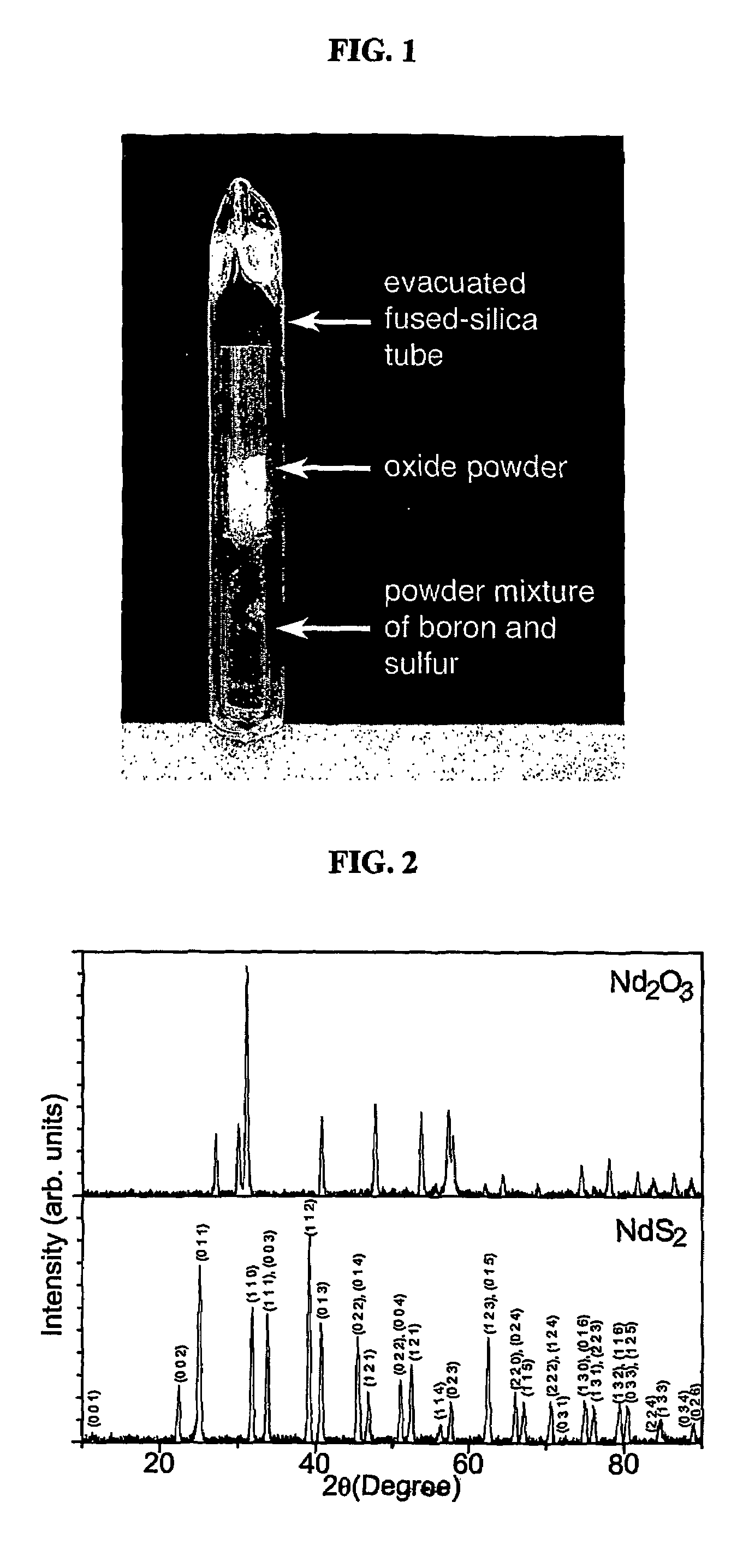

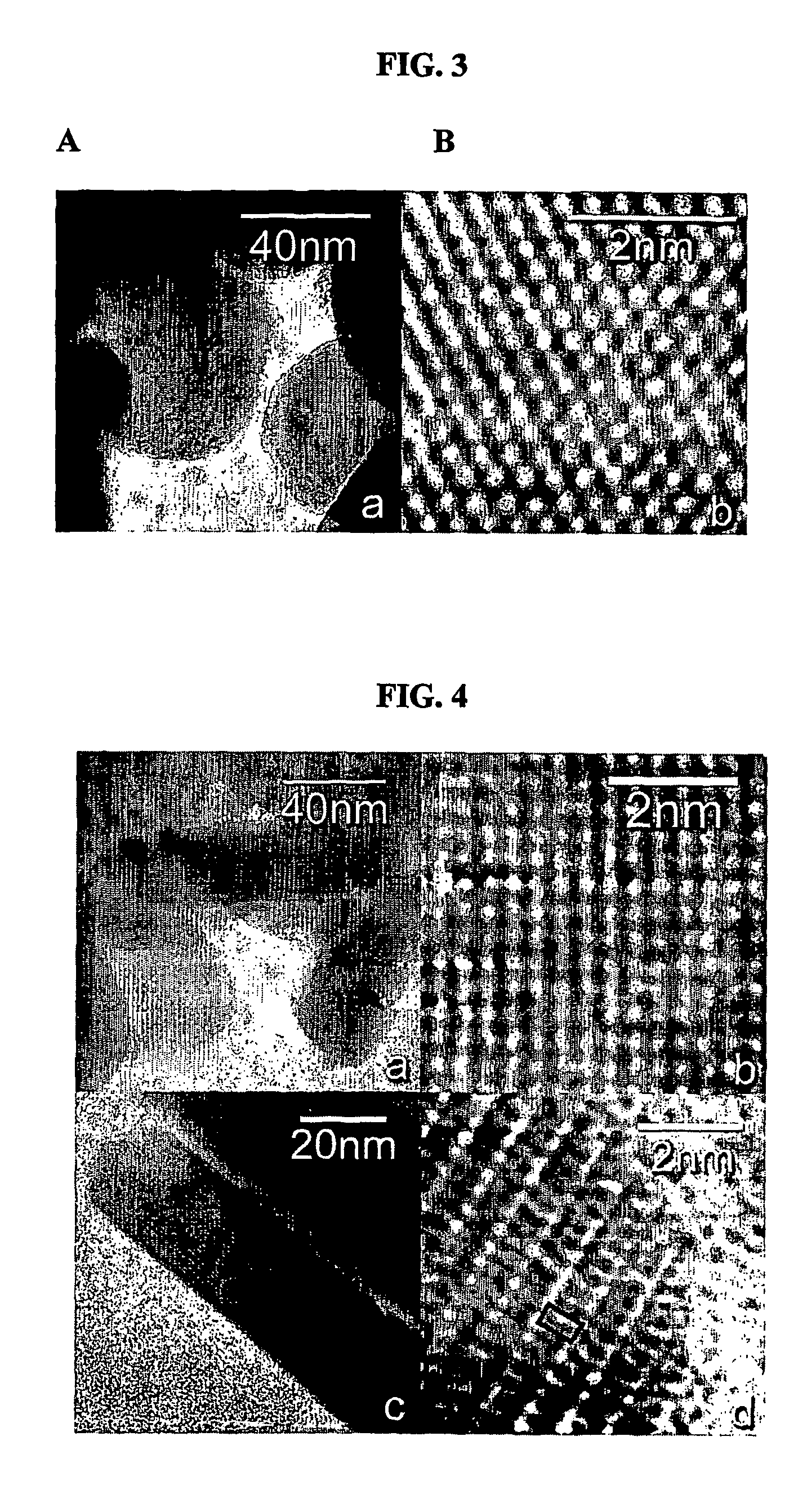

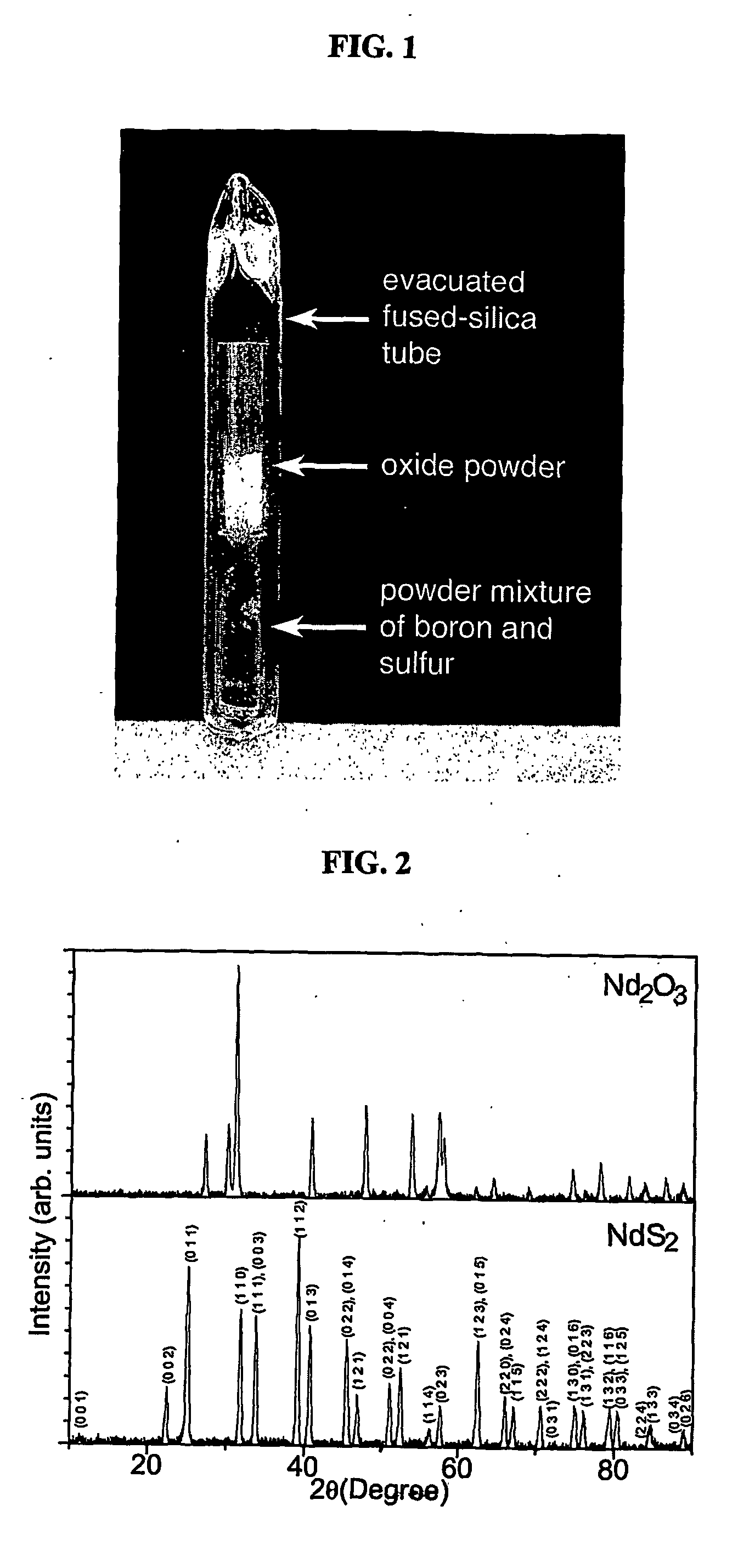

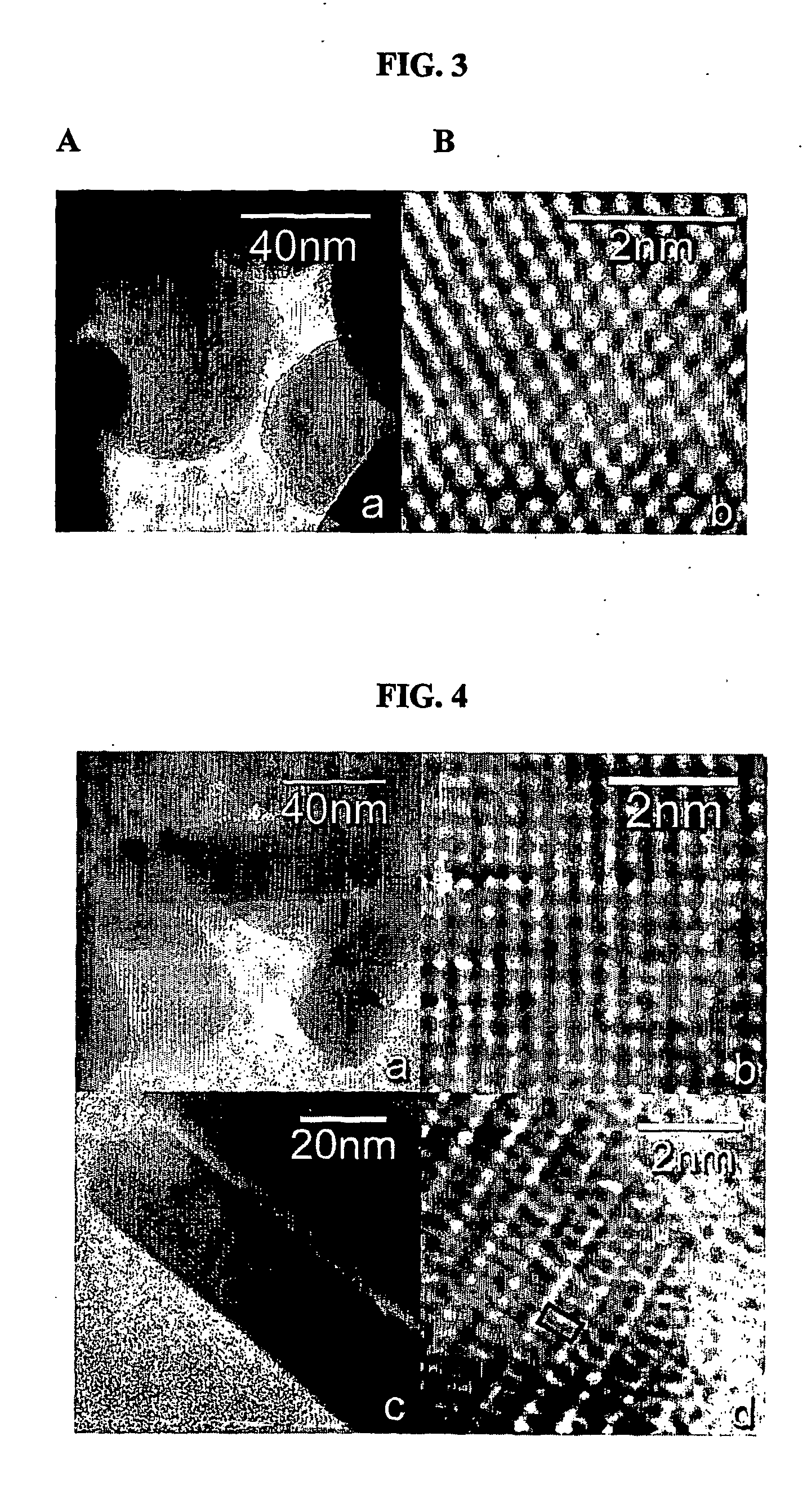

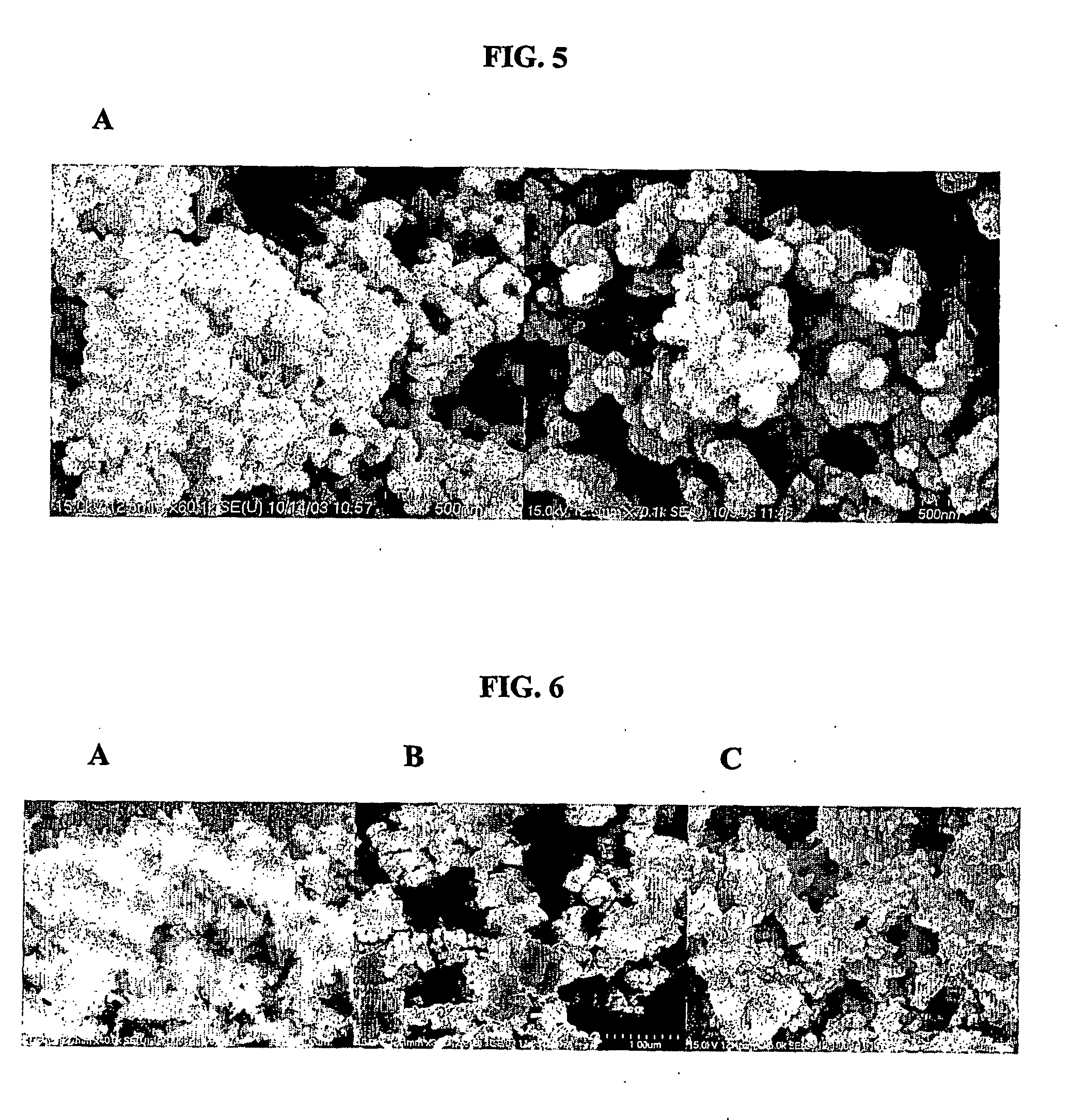

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

Preparation method of flower-shaped hollow molybdenum disulfide microspheres

InactiveCN102701281ASimple processLow costNanotechnologyMolybdenum sulfidesMaterials preparationMicrosphere

The invention relates to a preparation method of flower-shaped hollow molybdenum disulfide microspheres, belonging to the technical field of nanometer material preparation. The method provided by the invention comprises the following steps of: (1) solution preparation: dissolving (NH4)2MoO4, CS(NH2)2, NH2OH.HCl and a surfactant into water, dissolving to obtain the solution, and then adjusting the pH value to 5-6.5 by acid; (2) agitating the solution obtained in step (1), and then transferring to a reaction kettle, sealing and reacting at a constant temperature, and then cooling to the room temperature to obtain the reaction product; (3) separating the reaction product, washing and drying to obtain the flower-shaped hollow molybdenum disulfide microspheres. The shape of the flower-shaped hollow molybdenum disulfide microspheres prepared by the method provided by the invention is controllable. The method provided by the invention is simple in process and low in cost; the prepared product is high in purity and high in yield, has an important application in the field of tribology and photochemistry, and is expected to be applied to large-scale industrial production.

Owner:无锡润鹏复合新材料有限公司

Preparation method for ion liquid assisted hydrothermal synthesis of MoS2 microsphere

InactiveCN1994895AImprove performanceMild reaction conditionsMolybdenum sulfidesTetrafluoroborateMolybdate

The invention discloses a making method of MoS2 microball synthesized by ionic liquid auxiliary water, which comprises the following steps: dissolving molybdate in the deionized water to form 0.05-0.1m solution; adding thioacetamide or sulfourea as sulfur source with molar rate of thioacetamide or sulfourea and molybdate at 31-51; stirring evenly; adding 1-butyl-3-methyl imidazole tetrafluoride borate as ionic liquid with the bulk rate of ionic liquid and synthetic solution at 1300-1 50; stirring completely; transmitting solution into water heat reacting autoclave to react under 200-240 deg. c for 20-24h; cooling naturally; separating; washing; drying to obtain the product.

Owner:ZHEJIANG UNIV

Preparation method of monolayer MoS2 nano-sheet solution

InactiveCN102583547AImprove solubilityGood dispersionNanotechnologyMolybdenum sulfidesLithiumOrganic solvent

The invention discloses a preparation method of a monolayer MoS2 nano-sheet solution. The preparation method provided by the invention comprises the following steps of weighing MoS2 powder, putting the MoS2 powder into a pyrrolidone solvent, carrying out magnetic stirring of the mixture, transferring the stirred mixture to a hydrothermal reactor, carrying out hydrothermal pre-treatment, adding a surfactant into the mixture subjected to hydrothermal pre-treatment, carrying out ultrasonic stripping by an ultrasonic destrustor, carrying out centrifugation treatment, and collecting a supernatant liquor, wherein the supernatant liquor is the monolayer MoS2 nano-sheet solution. Compared with the prior art for preparing a monolayer MoS2 nano-sheet solution by a reaction of MoS2 and alkyl lithium and ultrasonic stripping, the preparation method provided by the invention has the advantages of the adopted organic solvent is not sensitive to the environment; a whole preparation period is short; and the obtained monolayer MoS2 nano-sheets have better dispersibility and stability and a lower cost.

Owner:CHANGAN UNIV

Preparation of metal chalcogenides from reactions of metal compounds and chalcogen

InactiveUS20060239882A1Rare earth metal sulfidesSelenium/tellurium compundsSufficient timeNanoparticle

A method of preparing metal chalcogenides from elemental metal or metal compounds has the following steps: providing at least one elemental metal or metal compound; providing at least one element from periodic table groups 13-15; providing at least one chalcogen; and combining and heating the chalcogen, the group 13-15 element and the metal at sufficient time and temperature to form a metal chalcogenide. A method of functionalizing the surface of semiconducting nanoparticles has the following steps: providing at least one metad compound; providing one chalcogenide having a cation selected from the group 13-15 (B, Al, Ga, In, Si, Ge, Sn, Pb, P, As, Sb and Bi); dissolving the chalcogenide in a first solution; dissolving the metal compound in a second solution; providing and dissolving a functional capping agent in at least one of the solutions of the metal compounds and chalcogenide; combining all solutions; and maintaining the combined solution at a proper temperature for an appropriate time.

Owner:ARIZONA STATE UNIVERSITY

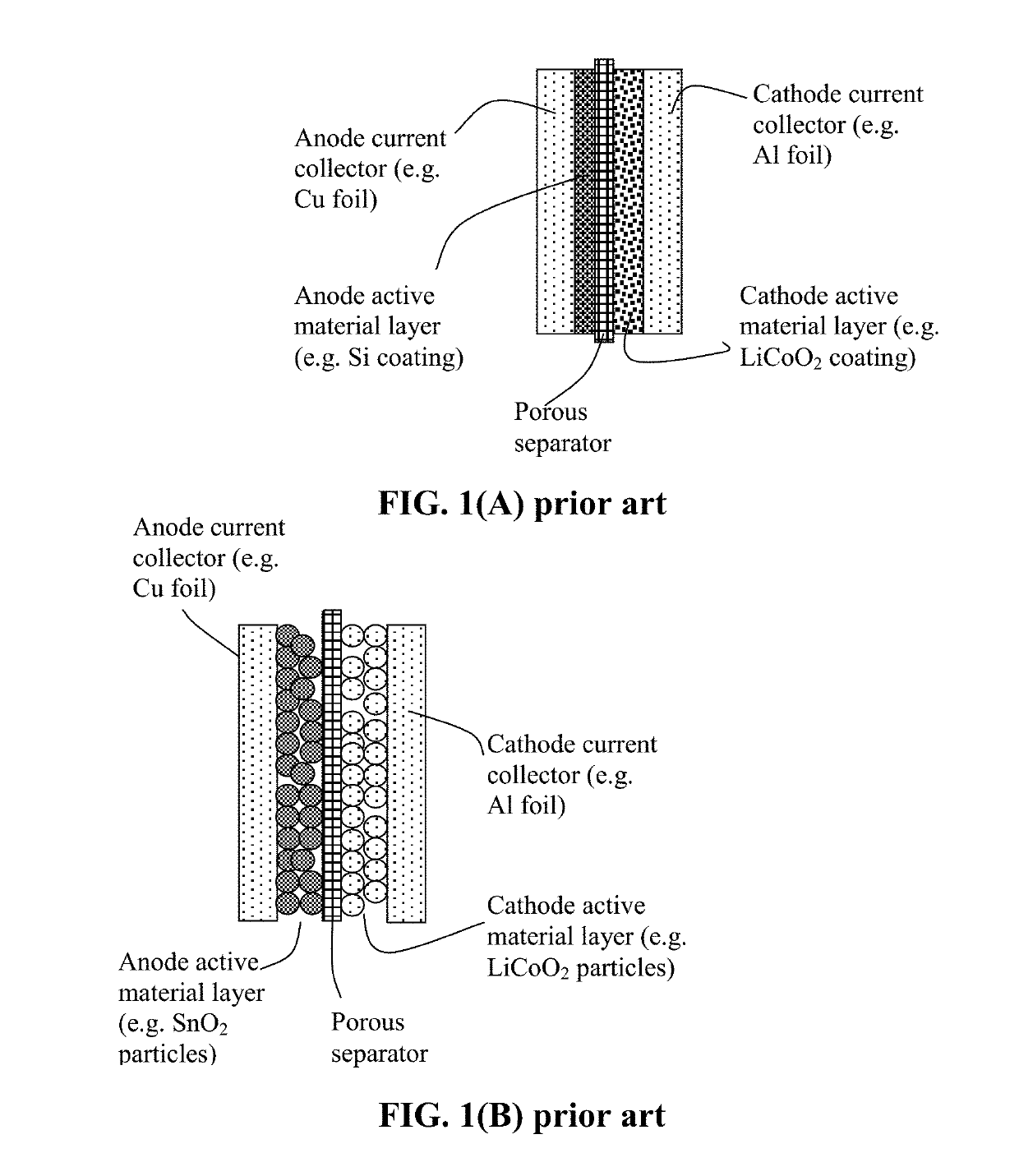

Anode Particulates or Cathode Particulates and Alkali Metal Batteries Containing Same

Provided is an anode particulate, having a dimension from 10 nm to 100 μm, for use in an alkali metal battery, the particulate comprising (i) an anode active material capable of reversibly absorbing and desorbing lithium ions or sodium ions, (ii) an electron-conducting material, and (iii) a lithium ion-conducting or sodium ion-conducting electrolyte, wherein the electron-conducting material forms a three dimensional network of electron-conducting pathways in electronic contact with the anode active material and the electrolyte forms a three dimensional network of lithium ion- or sodium ion-conducting channels in ionic contact with the anode active material. The particulate can be of any shape, but preferably spherical or ellipsoidal in shape. Also provided is a cathode in a particulate form containing a cathode active material, an electron-conducting material forming a three dimensional network of electron-conducting pathways, and a lithium ion-conducting or sodium ion-conducting electrolyte forming a three dimensional network of ion-conducting channels.

Owner:GLOBAL GRAPHENE GRP INC

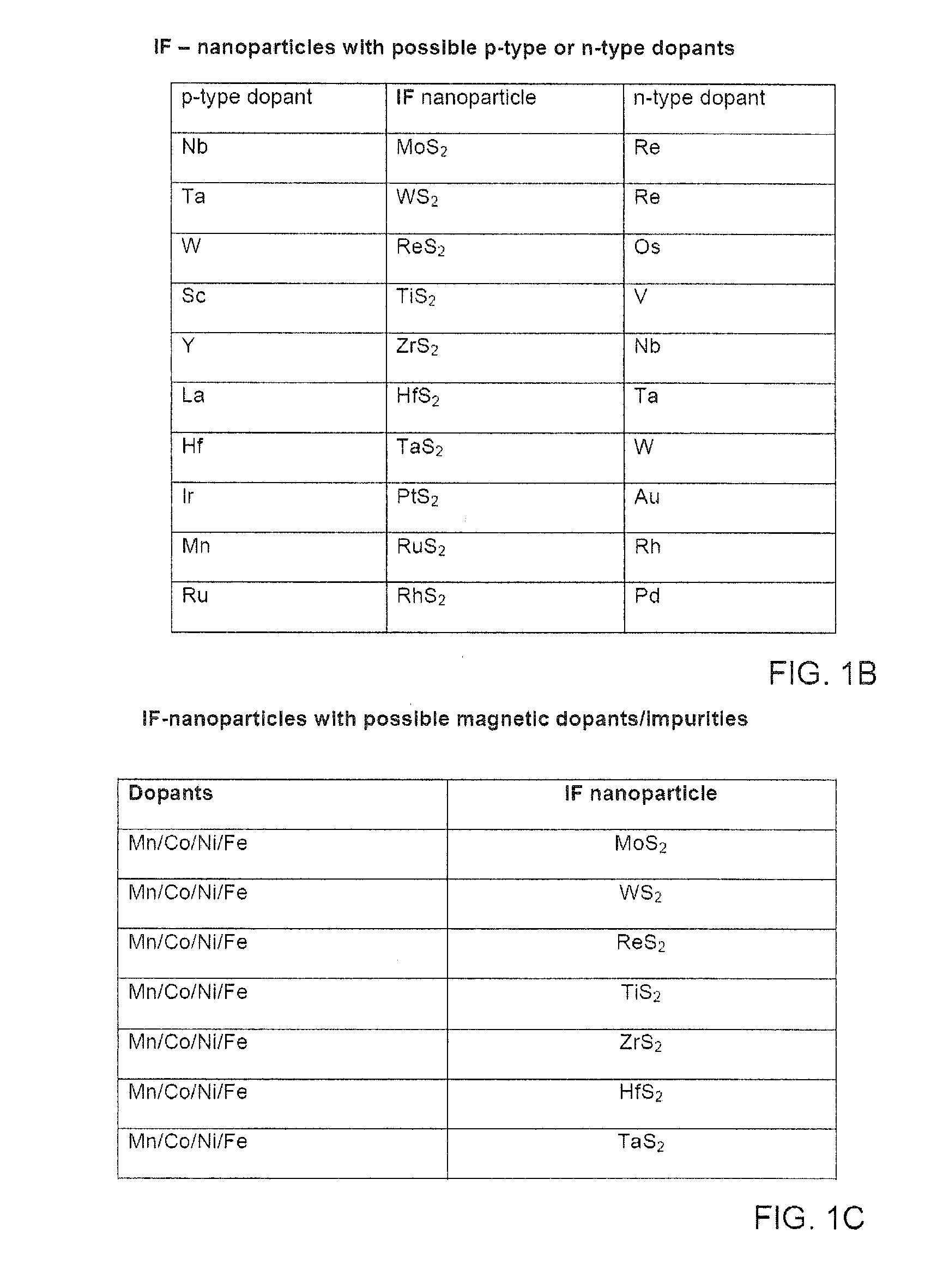

Fullerene-like nanostructures, their use and process for their production

ActiveUS20100227782A1Improve conductivityMaterial nanotechnologyConductive materialAlloyElectronic properties

A nanostructure, being either an Inorganic Fullerene-like (IF) nanostructure or an Inorganic Nanotube (INT), having the formula A1−x-Bx-chalcognide are described. A being a metal or transition metal or an alloy of metals and / or transition metals, B being a metal or transition metal B different from that of A and x being ≦0.3. A process for their manufacture and their use for modifying the electronic character of A-chalcognide are described.

Owner:YEDA RES & DEV CO LTD

Method for preparing flower-shaped molybdenum disulfide micro-balloon

InactiveCN101113021ASimple processEasy to operateMolybdenum sulfidesNeutral phHigh volume manufacturing

The invention discloses a method which adopts hydrothermal compound method for preparing flower-shaped microsphere of molybdenum disulfide. The invention comprises the steps: Na2MoO4, CS (NH2)2 and inorganic additives are added to a reactor and deionized water of 60 percent of the reactor column is also added and then the reactor is sealed and kept in a constant temperature case with a temperature ranging from 150 DEG C to 250 DEG C at least for 12 hours to be cooled in ambient temperature; obtained objects are washed by deionized water eccentrically to a neutral pH value; the flower-shaped microsphere of molybdenum disulfide is obtained after the objects are dried. The method of the invention has simple technique, easy operation, low cost and the products prepared has high purity and is promising for large-scaled production.

Owner:ZHEJIANG UNIV

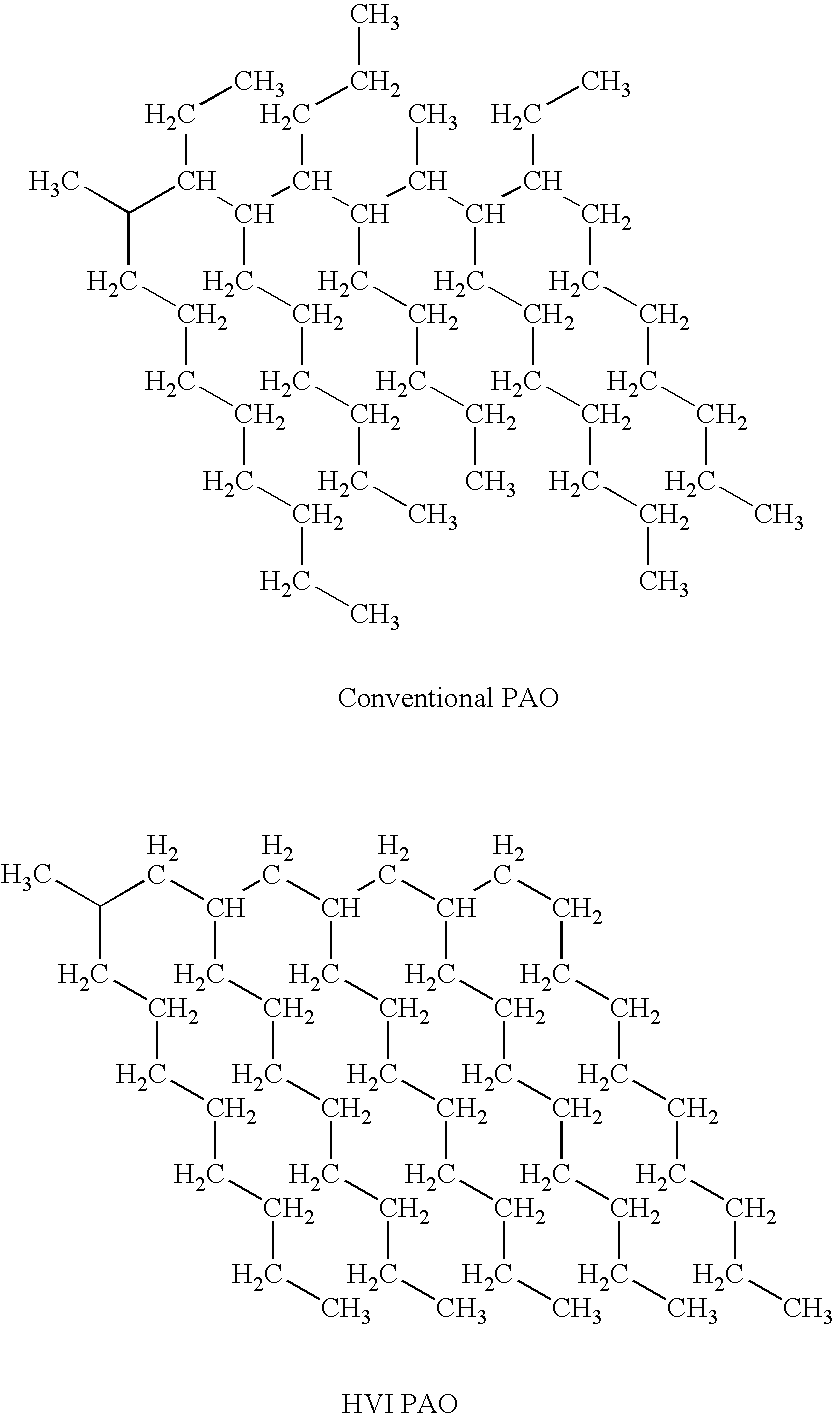

Rock bit grease composition

InactiveUS7312185B2Minimizes scoring and galling and wearGood thermal and oxidative stabilityTransportation and packagingHydrocarbon purification/separationViscosity indexLubrication

A grease for rock bit lubrication and other high temperature bearing applications is provided comprising a high viscosity index polyalphaolefin synthetic base fluid in combination with an alkylated naphthalene base fluid.

Owner:TOMLIN SCI

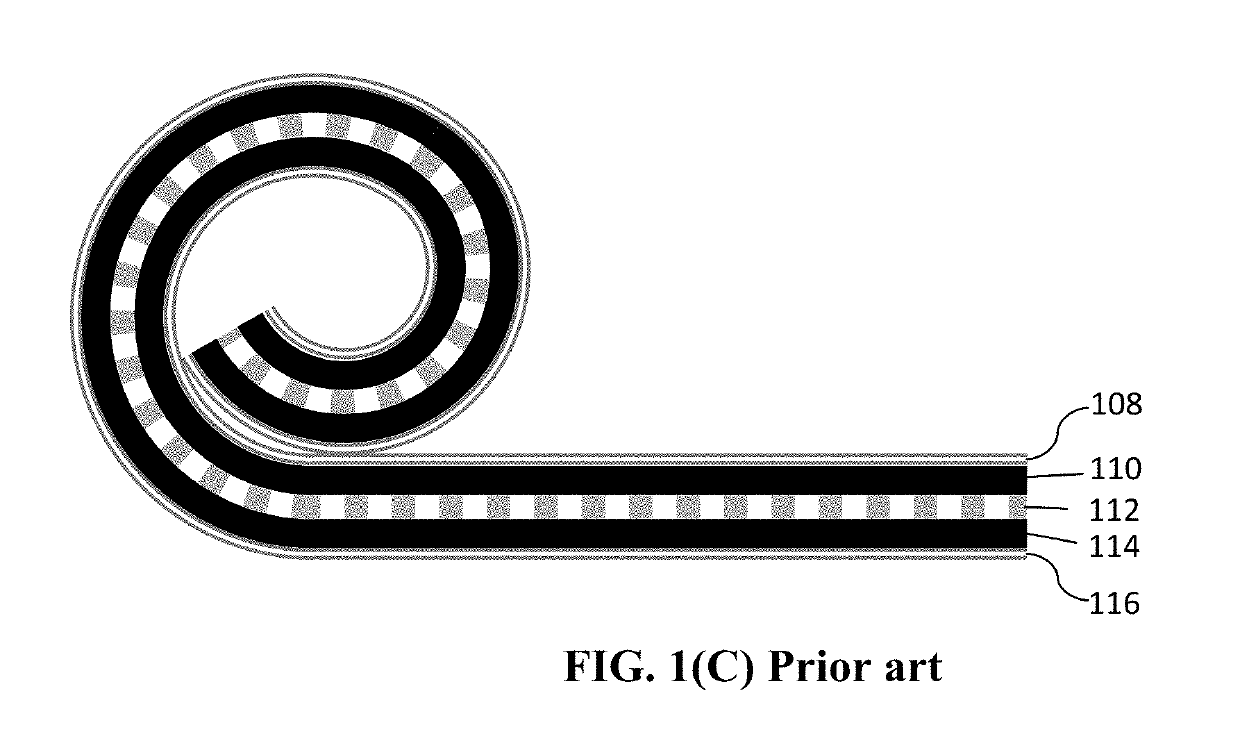

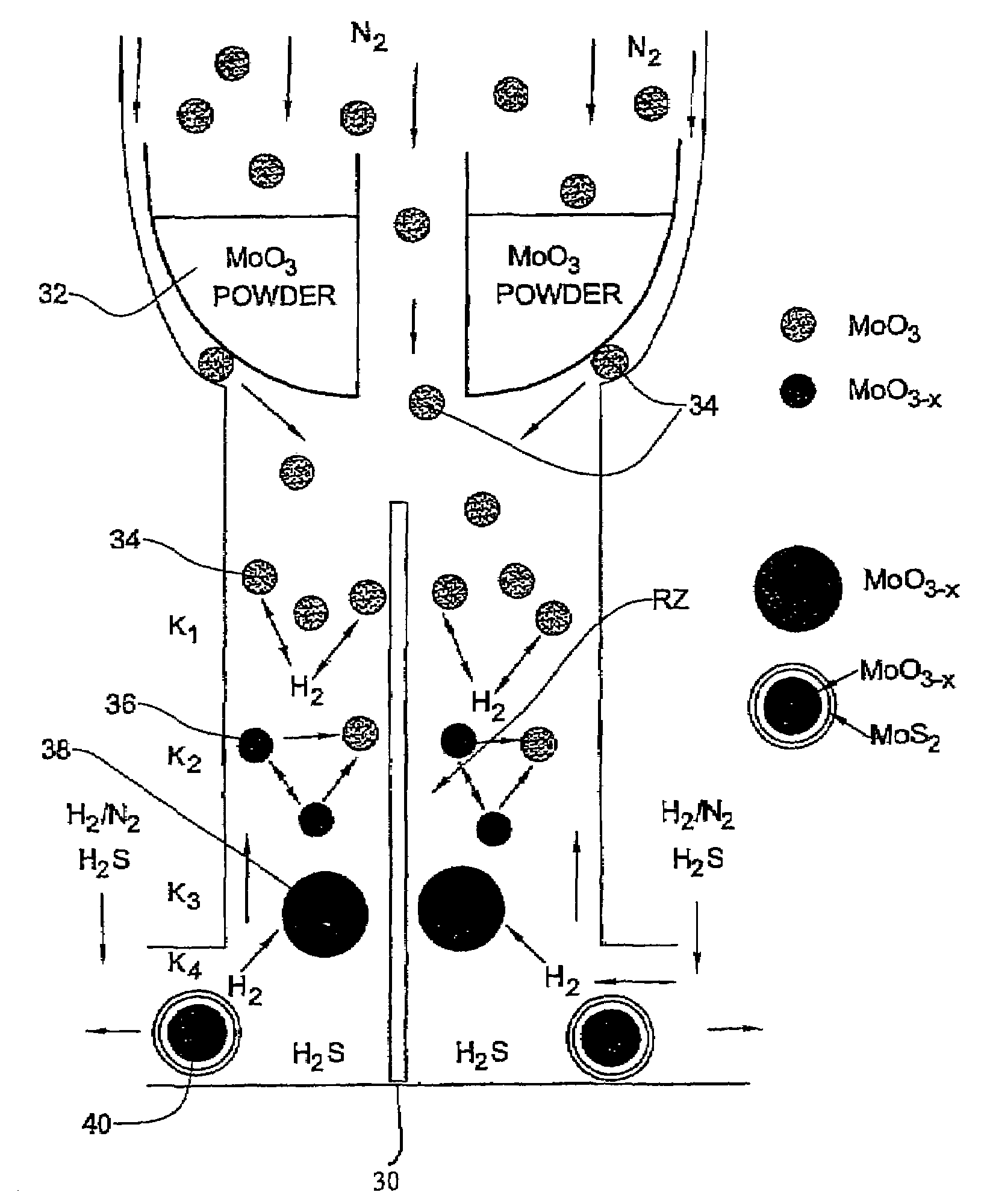

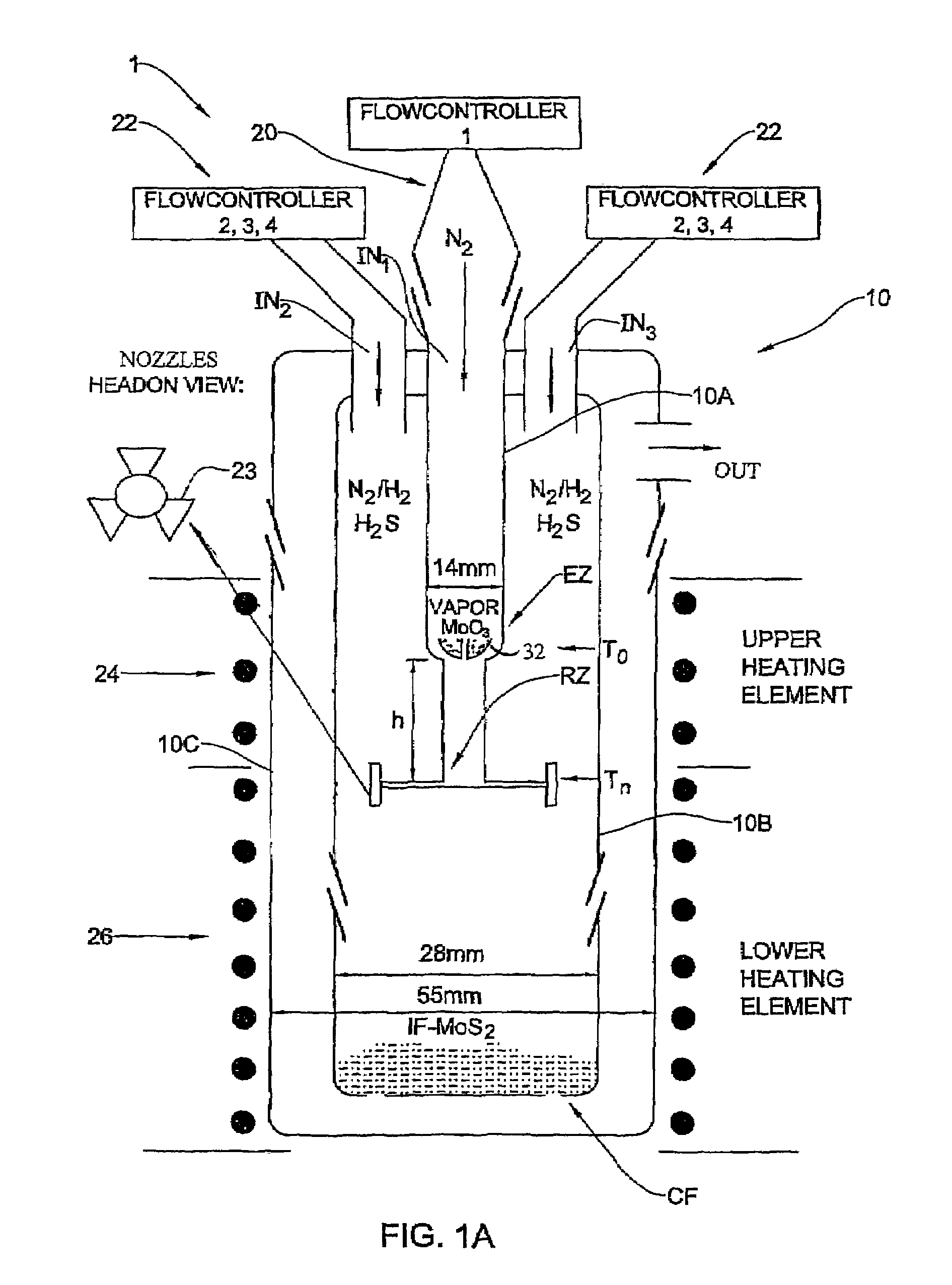

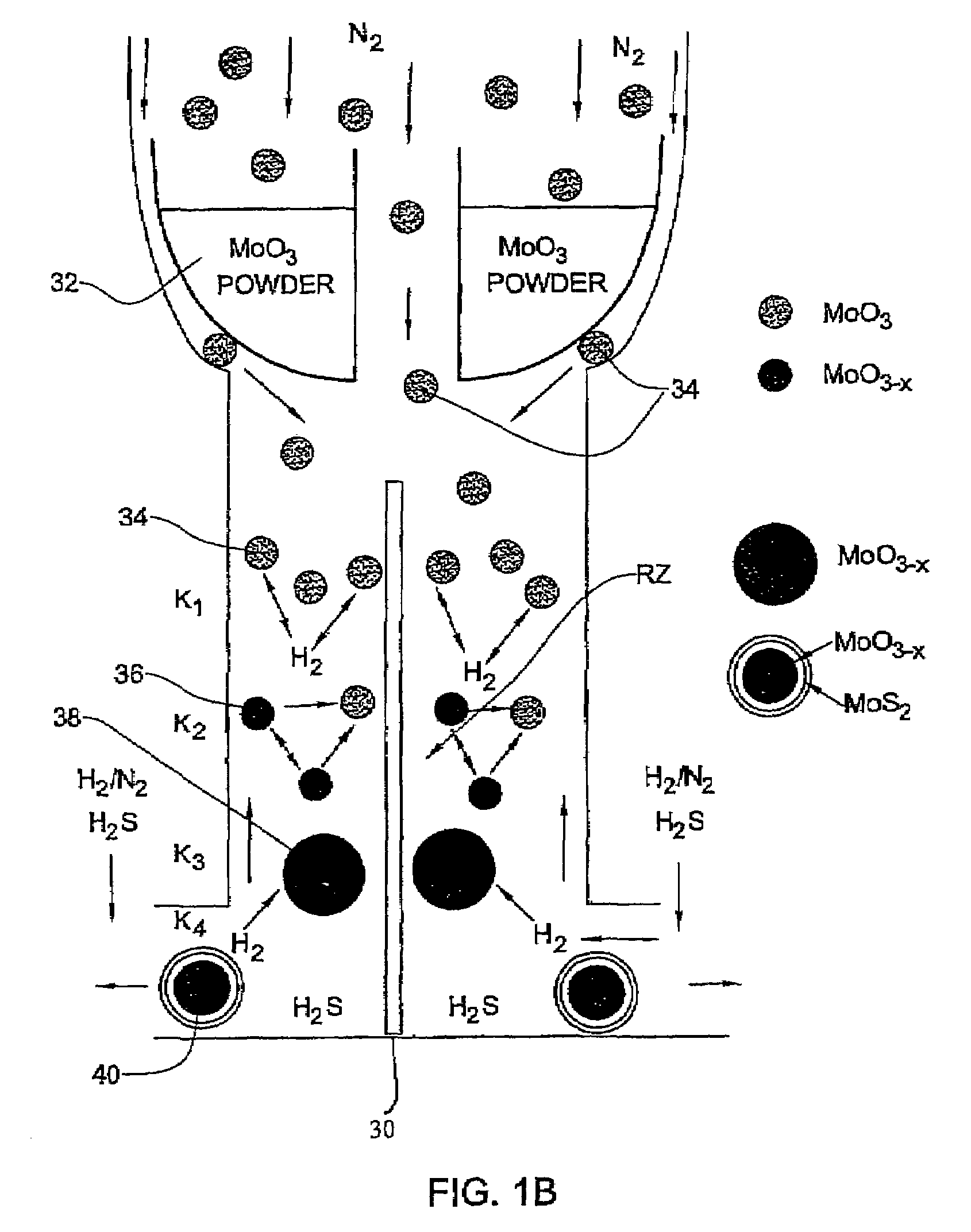

Method and apparatus for producing inorganic fullerene-like nanoparticles

InactiveUS7018606B2Easy to produceMaterial nanotechnologyNanostructure manufactureNanoparticleGas phase

A process and apparatus are presented for obtaining inorganic fullerene-like nanostructures. A metal oxide is evaporated at predetermined temperature conditions, and is swept towards a reacting zone, to which first and second gas phase reacting agents are concurrently swept. The evaporated metal oxide thus interacts with the first reacting agent and is converted into metal suboxide nanoparticles in the gas phase. The condensing metal suboxide nanoparticles interact with the second reacting agent in the gas phase resulting in substantially pure phase of the inorganic fullerene-like nanoparticles.

Owner:YEDA RES & DEV CO LTD

Stripping method of stratified materials

The invention discloses a stripping method of stratified materials. The stripping method comprises the following steps of: weighing 30-70% of stratified materials, 0.2-5% of an organic intercalation agent, and the balance of a solvent, and mixing and stirring the weighed stratified materials, the weighed organic intercalation agent and the weighed solvent so as to obtain paste; placing the paste in a closed container, and performing static steeping; heating the steeped paste under the condition of continuously stirring, filtering the paste, washing the filtered paste, drying the washed paste so as to obtain a filter cake; placing 10-50% of filter cake, 0.5-30% of an inorganic intercalation agent, and the balance of a solvent into a closed container, uniformly mixing the filter cake, the inorganic intercalation agent and the solvent so as to obtain paste; performing static steeping; heating the closed container with the paste under the condition of 50-200 DEG C for 2-8h; cooling the heated closed container with the paste to room temperature; performing repeated heating and cooling; performing filtering; performing cleaning so as to obtain a secondary filter cake and a filtrate agent; adding the secondary filter cake and the filtrate agent in the solvent for ultrasonic stripping so as to obtain a dispersion liquid; filtering the dispersion liquid; washing the filtered dispersion liquid with deionized water; and performing vacuum drying so as to obtain the stratified materials. The stripping method disclosed by the invention solves the problems that the prior art for preparing the two dimensional crystal materials is low in efficiency, small in yield, high in environmental pollution, and the like. Defects and impurities are not led in the two-dimensional crystal materials.

Owner:HUNAN UNIV

Method for preparing molybdenum disulfide (MoS2) nanosheet

The invention discloses a method for preparing a molybdenum disulfide (MoS2) nanosheet by two steps, namely a hydrothermal method and a liquid phase ultrasonic stripping method. The method disclosed by the invention is realized by the following technological steps: evenly mixing the bought MoS2 powder with lithium carbonate according to the molar ratio of 1: 42, putting the mixture into a high pressure kettle filled with 40ml of benzyl alcohol, and sealing; maintaining for 48 hours at the temperature of 200 DEG C; carrying out natural cooling and vacuum drying to obtain an intermediate product; putting 0.2-0.6g of intermediate product into mixed liquid of 20ml of dimethyl formamide and 10ml of water, and carrying out ultrasonic dispersion for 12 hours; centrifuging the obtained dispersed liquid for 30-45 minutes at the speed of 500-600rpm (revolutions per minute), and then centrifuging the supernatant liquid for 6 minutes at the speed of 6000-8000rpm; cleaning the product by 3% HCl for twice, and then cleaning the product by deionized water until the product is neutral; and finally, carrying out vacuum drying on the product to obtain the nano MoS2 sheet. The MoS2 nanosheet is stripped by the method disclosed by the invention. The method has the characteristics of being simple, easy to realize and popularize and suitable for large-scale industrial production.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com