Method for preparing flower-shaped molybdenum disulfide micro-balloon

A technology of molybdenum disulfide and microspheres, applied in the direction of molybdenum sulfide, etc., can solve the problems of complex process and high cost, and achieve the effect of high product purity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

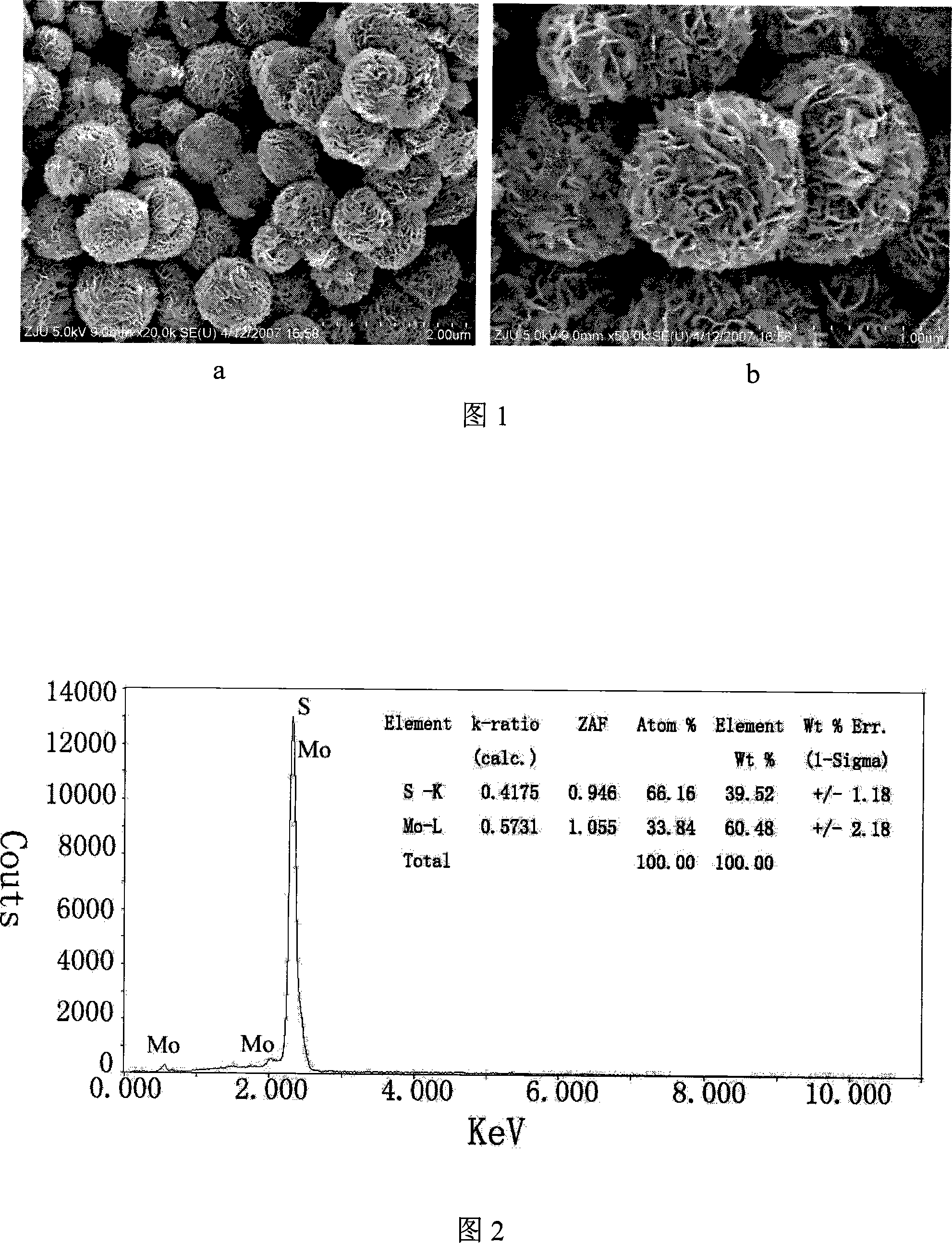

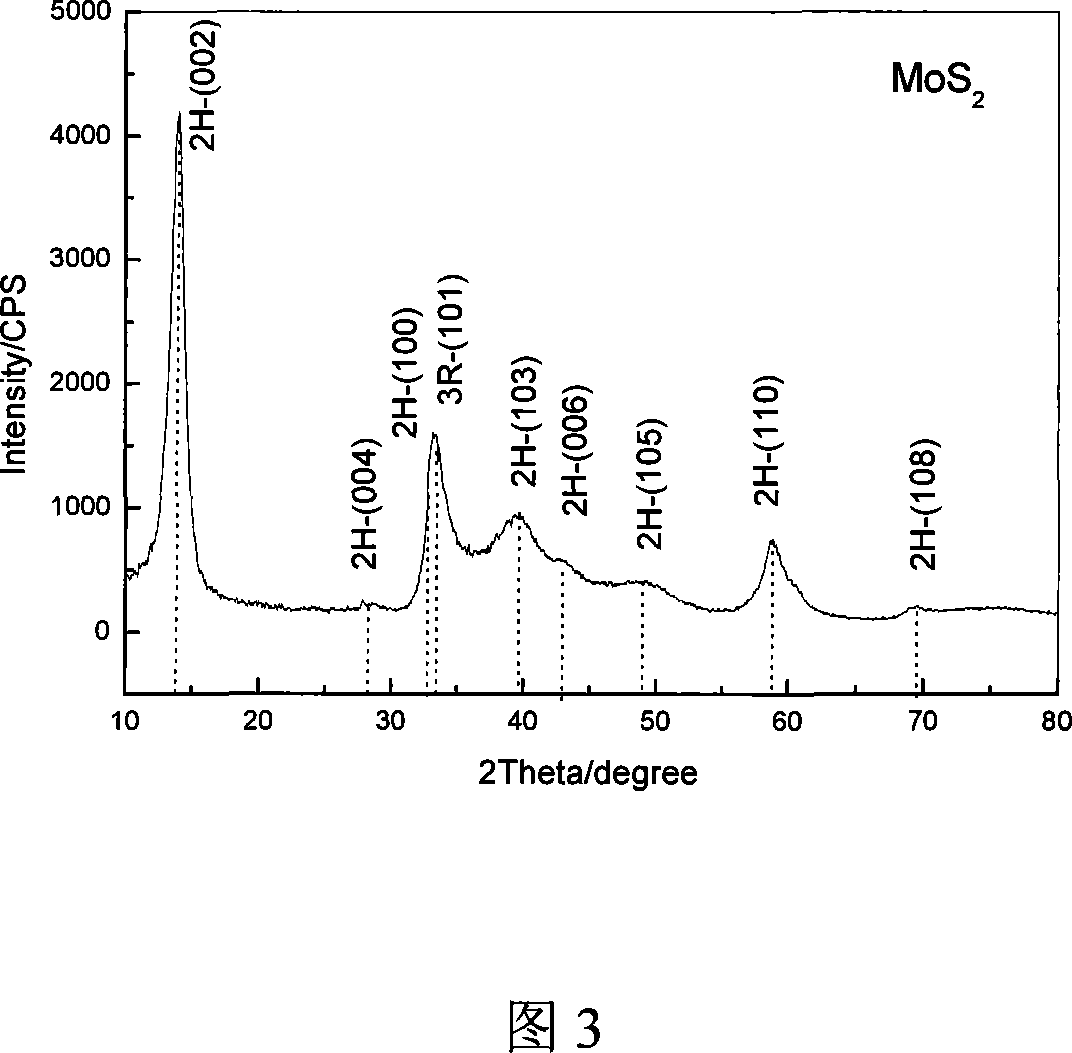

[0016] 0.2g Na 2 MoO 4 , 0.2g CS(NH 2 ) 2 Put 0.1g of tungstic acid in a 50ml reactor, after ultrasonication for 30min, seal the reactor and put it in an oven at 180°C, keep it warm for 16h, cool to room temperature, and centrifuge and wash the product with deionized water until the pH value is Neutral, black powder product after oven drying at 60°C. Directly observed under the field emission scanning electron microscope as shown in Figure 1 (a, b), it can be found that a large number of flower-like microspheres are formed, with a purity of 95%. These microspheres are composed of lamellar thin layers with a thickness of about 8-30 nm, and the diameter of the microspheres is 500-700 nm. The EDX analysis of Figure 2 shows that only Mo and S exist in the sphere, and the atomic ratio of Mo and S is 1:1.96, which is different from that of MoS 2 The atomic ratio is close. The XRD diffraction in Figure 3 further confirmed that the product is MoS2 microspheres, and the phase com...

Embodiment 2

[0018] 0.2g Na 2 MoO 4 , 0.2g CS(NH 2 ) 2 Put 0.1g of titanium oxide in a 50ml reactor, after ultrasonication for 30min, seal the reactor and place it in an oven with a temperature of 150°C. Neutral, black powder product after oven drying at 60°C. The morphology and structure of the product after drying are the same as in Example 1.

Embodiment 3

[0020] 0.2g Na 2 MoO 4 , 0.4g CS(NH 2 ) 2 Put 0.04g of titanic acid in a 50ml reactor, after ultrasonication for 30min, seal the reactor and put it in an oven with a temperature of 200°C, keep it warm for 24h; cool to room temperature, and centrifuge the product with deionized water until the pH value is Neutral, black powder product after oven drying at 60°C. The morphology and structure of the product after drying are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com