Lubricating Composition Containing Ashfree Antiwear Agent Based on Hydroxypolycarboxylic Acid Derivative and a Molybdenum Compound

a technology of hydroxypolycarboxylic acid and molybdenum compound, which is applied in the direction of lubricant composition, molybdeum compound, chemistry apparatus and processes, etc., can solve the problems of reducing the performance of said catalysts, zddp is believed to have a detrimental impact on fuel economy and efficiency, and interferes with each other's respective functions, so as to reduce or prevent phosphorus emissions, reduce or prevent sulphur emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

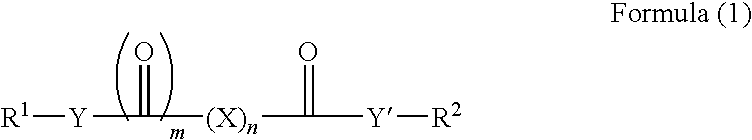

Method used

Image

Examples

example 1 (

EX1)

[0124]A lubricating composition is prepared containing 1 wt % of di-2-ethylhexyl tartrate, 0.6 wt % of other antiwear agents, 7.9 wt % of dispersants, 1.5 wt % of detergents, 3.6 wt % of antioxidants including an effective amount of molybdenum dithiocarbamate, 6.1 wt % of viscosity modifier, 0.1 wt % of corrosion inhibitor, and 0.1 wt % of friction modifier. The lubricating composition has a sulphated ash content of 0.6 wt %, a phosphorus content of about 570 ppm, and a sulphur content of 0.17 wt %.

example 2 (

EX2)

[0125]A lubricating composition is prepared containing 1 wt % of a C12-14-alkyl tartrate, 4.1 wt % of dispersants, 1.4 wt % of detergents, 2.5 wt % of antioxidants including 0.7 wt % of molybdenum dithiocarbamate (commercially available as Sakuralube™515, manufactured by Asahi Denka), 0.56 wt % of antiwear agents, 0.1 wt % of corrosion inhibitor, and 0.1 wt % of friction modifier. The lubricating composition has a phosphorus content of about 560 ppm.

example 3 (

EX3)

[0131]A lubricating composition is designed to meet Euro 4 and Euro 5 emission standards and containing 1 wt % of C8-10 alkyl tartrate. The lubricating composition has a phosphorus content of 900 ppm or less, 0.3 wt % or less of sulphur, and 0.9 wt % or less of sulphated ash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com