Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

296 results about "Molybdenum compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Commonly used molybdenum-oxygen compounds are molybdenum trioxide, MoO3, sodium molybdate, Na2MoO4.2H2O, ammonium dimolybdate, (NH4)2 Mo2O7, and ammonium heptamolybdate, (NH4)6Mo7O24.4H2O. Molybdenum is used mainly as an alloying element in steel, cast iron, and superalloys and in the electronics industries.

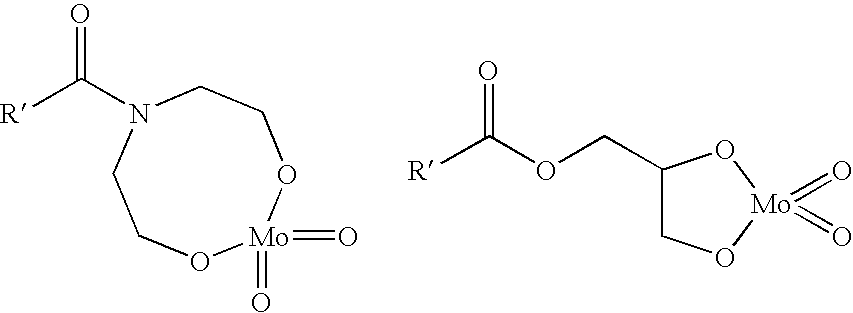

Lubricating Composition Containing Ashfree Antiwear Agent Based on Hydroxypolycarboxylic Acid Derivative and a Molybdenum Compound

InactiveUS20100197536A1Reducing and preventing emissionImprove fuel economyAdditivesMolybdenum sulfidesAntioxidantAcid derivative

The invention provides a lubricating composition containing an oil of lubricating viscosity, an oil soluble molybdenum compound, and an ashless antiwear agent. The invention further provides for a new antioxidant. The lubricating composition is suitable for lubricating an internal combustion engine.

Owner:THE LUBRIZOL CORP

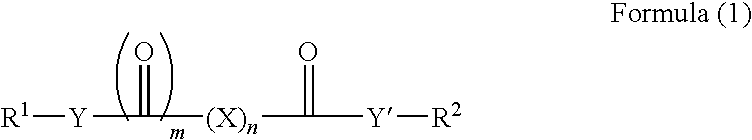

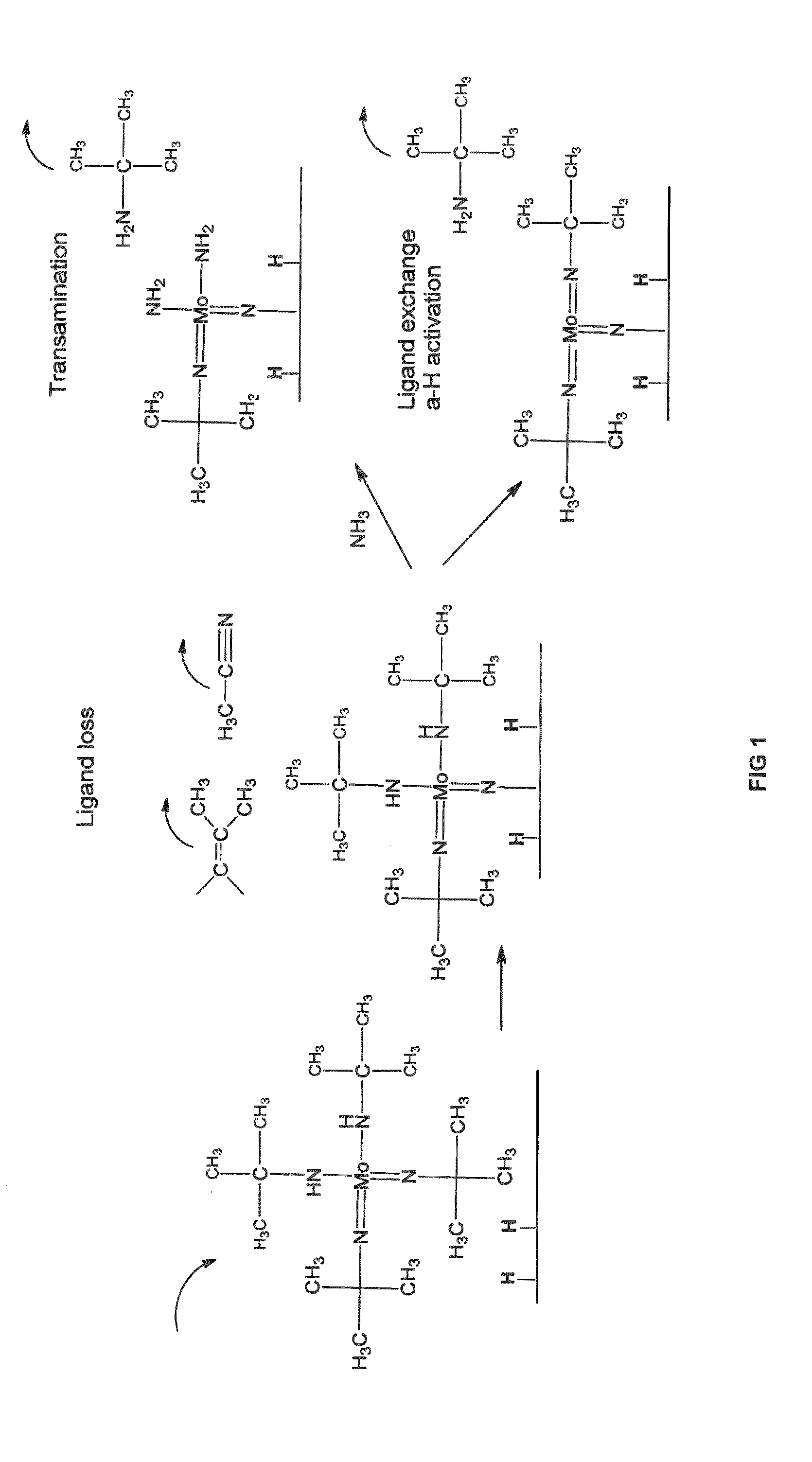

Bis(alkylimido)-bis(alkylamido)molybdenum molecules for deposition of molybdenum-containing films

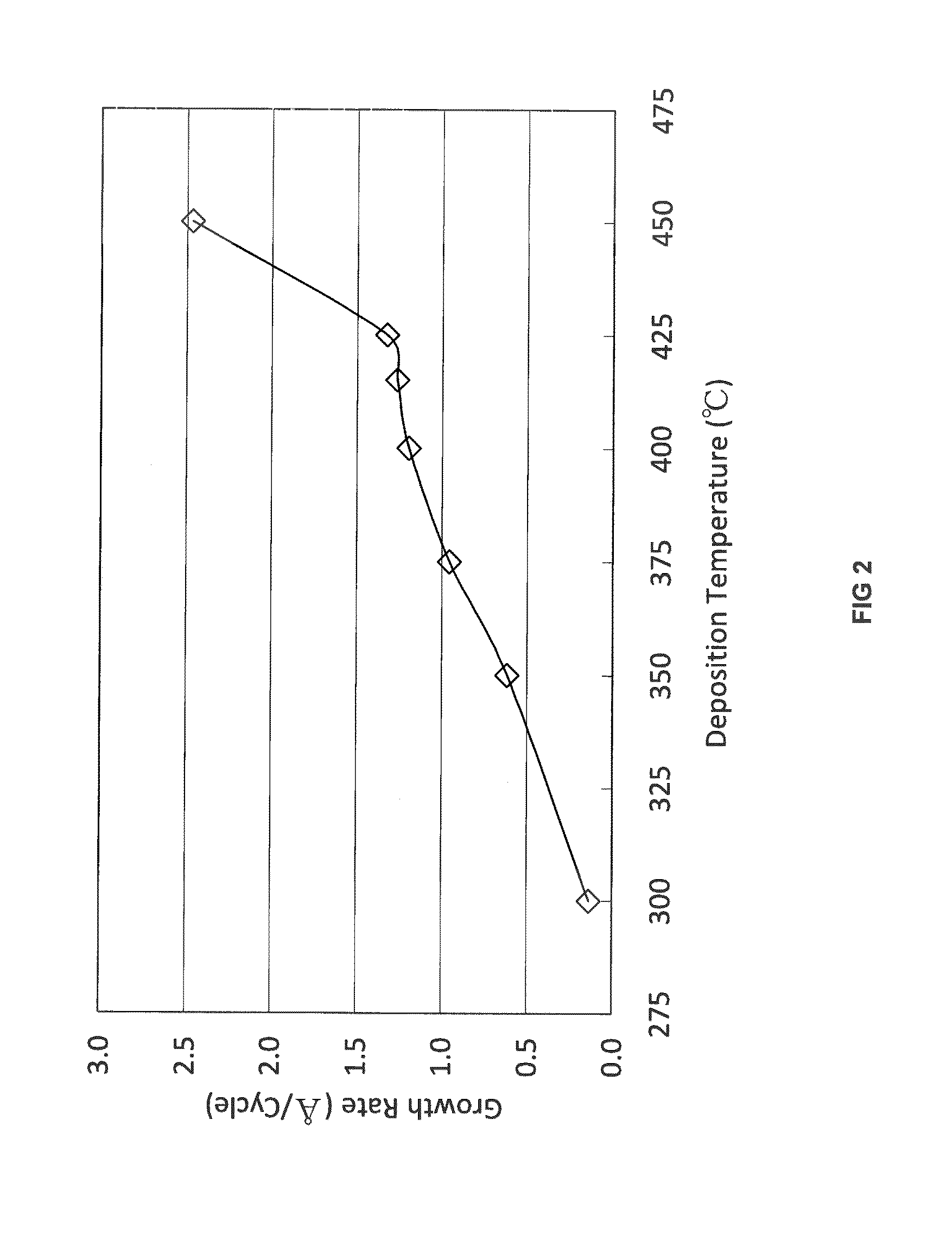

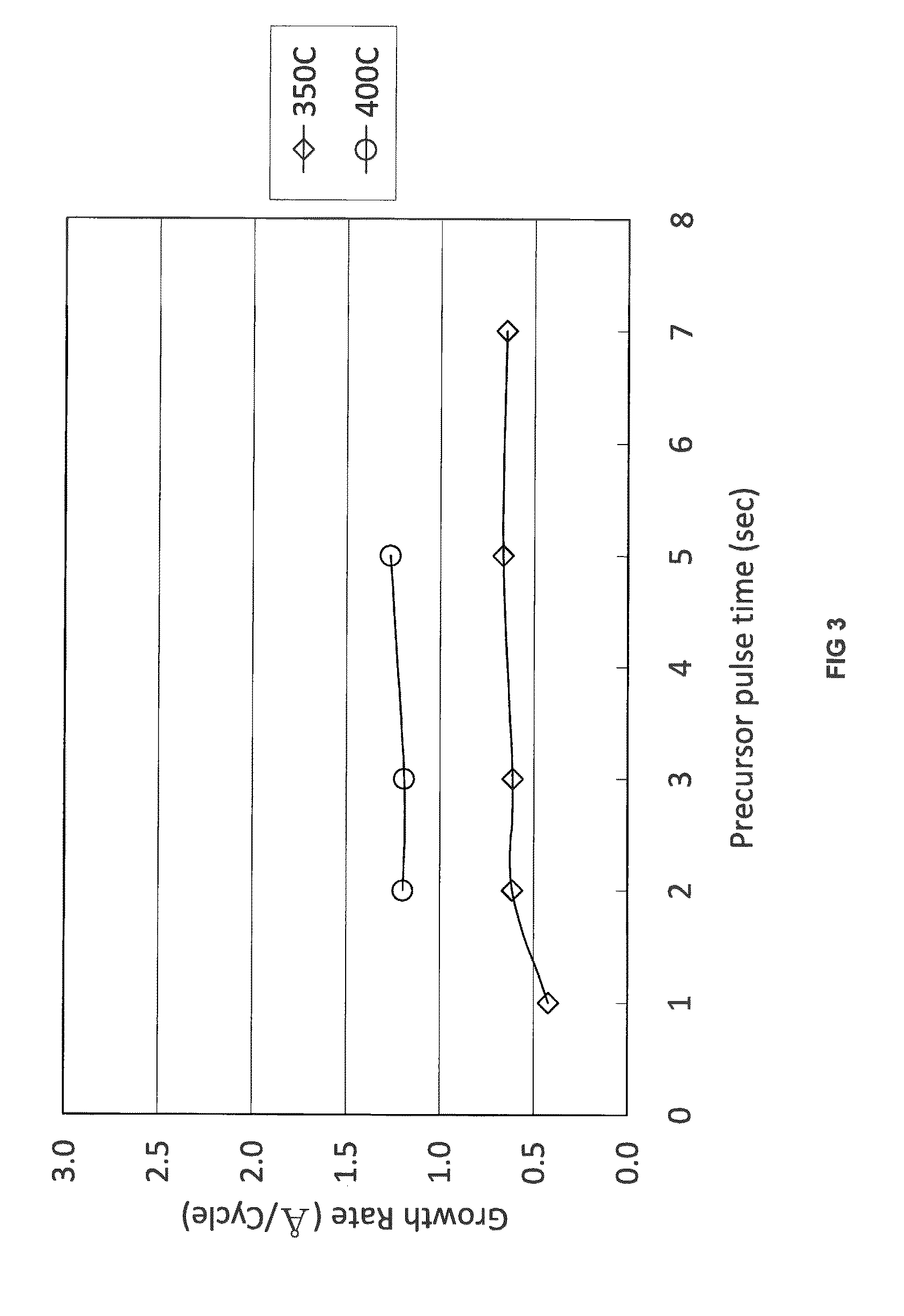

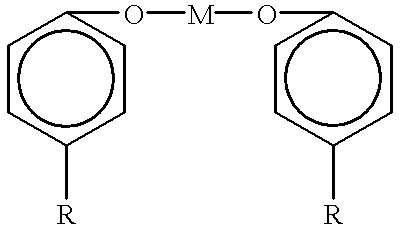

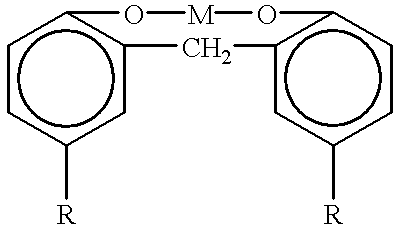

InactiveUS20160002786A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingMolybdenum compoundsPhotochemistry

Bis(alkylimido)-bis(alkylamido)molybdenum compounds, their synthesis, and their use for the deposition of molybdenum-containing films are disclosed.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Lubricants containing molybdenum compounds, phenates and diarylamines

There is disclosed a lubricating oil composition which contains from about 50 to 1000, preferably 50 to 500 parts per million of molybdenum from a molybdenum compound which is oil-soluble and substantially free of reactive sulfur, about 1,000 to 20,000, preferably 1,000 to 10,000 parts per million of a diarylamine and about 2,000 to 40,000 parts per million of a phenate. This combination of ingredients provides improved oxidation control and improved deposit control to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant.

Owner:AFTON CHEM INTANGIBLES

Lubricant containing molybdenum compound and secondary diarylamine

InactiveUSRE38929E1Low treat levelLow costLiquid carbonaceous fuelsAdditivesSulfurMolybdenum compounds

Owner:AFTON CHEM INTANGIBLES

Lubricant containing molybdenum compound and secondary diarylamine

InactiveUSRE40595E1Lower levelSupplemental oxidation protection and frictional propertiesOrganic chemistryLiquid carbonaceous fuelsSulfurMolybdenum compounds

There is disclosed a lubricating oil composition which contains from about 100 to 450 parts per million of molybdenum from a molybdenum compound which is substantially free of active sulfur and about 750 to 5,000 parts per million of a secondary diarylamine. This combination of ingredients provides improved oxidation control and friction modifier performance to the lubricating oil. The composition is particularly suited for use as a crankcase lubricant.

Owner:AFTON CHEM INTANGIBLES

High performance non-zinc, zero phosphorus engine oils for internal combustion engines

A substantially zinc and phosphorous free lubricating oil meeting engine performance requirements contain an additive system containing metal detergents, at least one borated ashless dispersant, at least an amine antioxidant and a trinuclear molybdenum compound. The lubricant contains a minimum of 120 ppm boron and a minimum of 80 ppm molybdenum.

Owner:FARNG L OSCAR +4

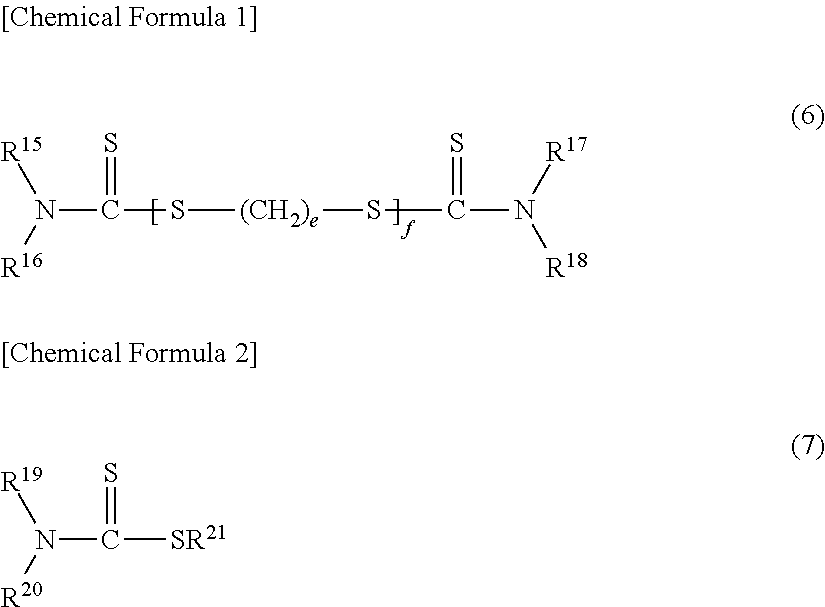

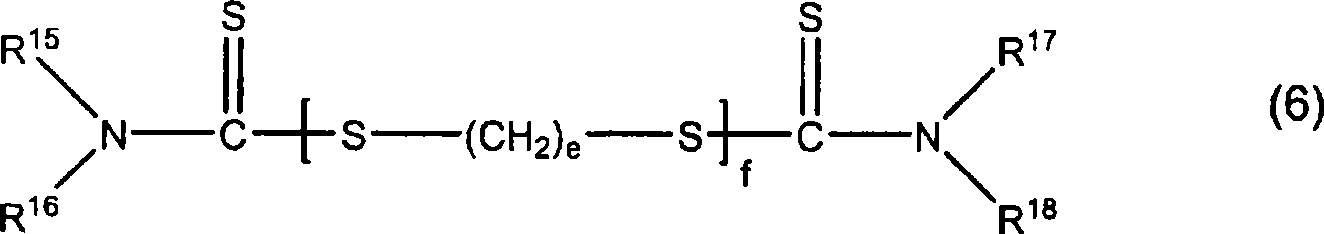

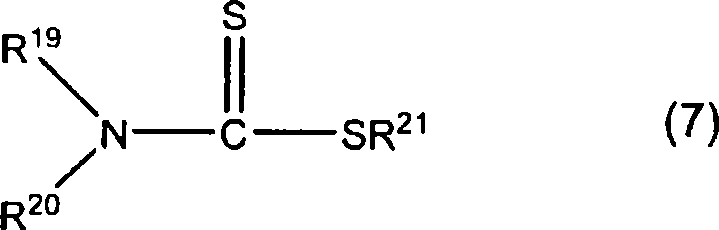

Antioxidant additive compositions and lubricating compositions containing the same

InactiveUS6806241B2Low levelImprove corrosion inhibition and friction propertyOrganic chemistryLiquid carbonaceous fuelsAntioxidantDithiocarbamate

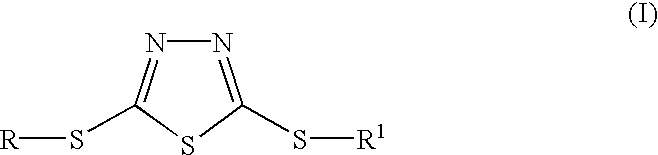

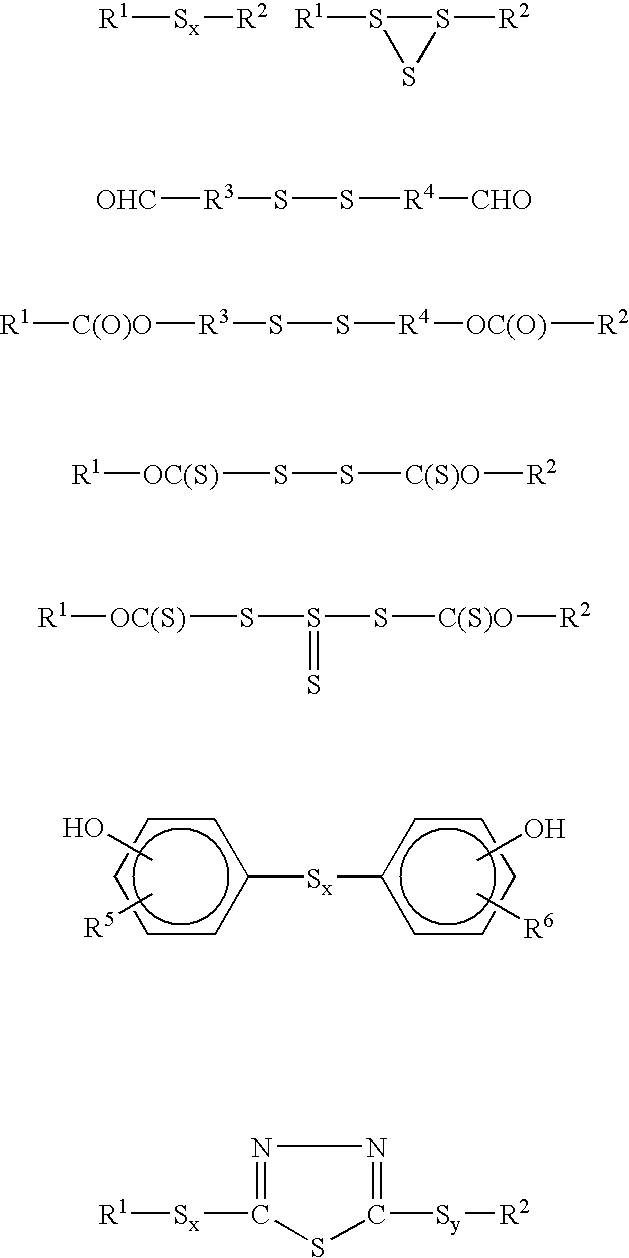

Disclosed are antioxidant compositions comprising of: (1) an organomolybdenum compound; (2) an alkylated diphenylamine; and (3) a sulfur compound selected from the group consisting of: (a) thiadiazole; (b) dithiocarbamate; and (c) mixtures of (a) and (b).

Owner:VANDERBILT CHEM LLC

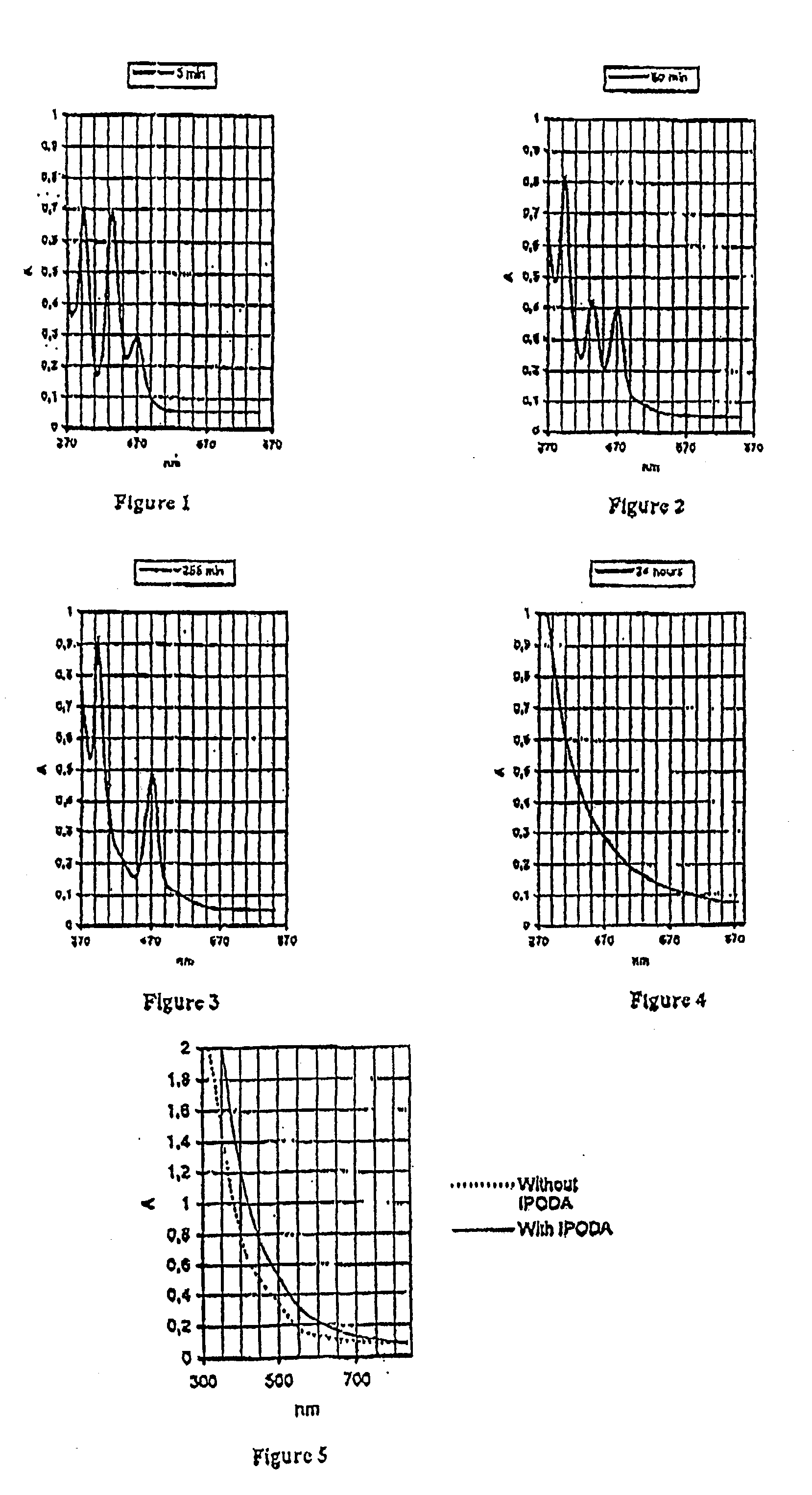

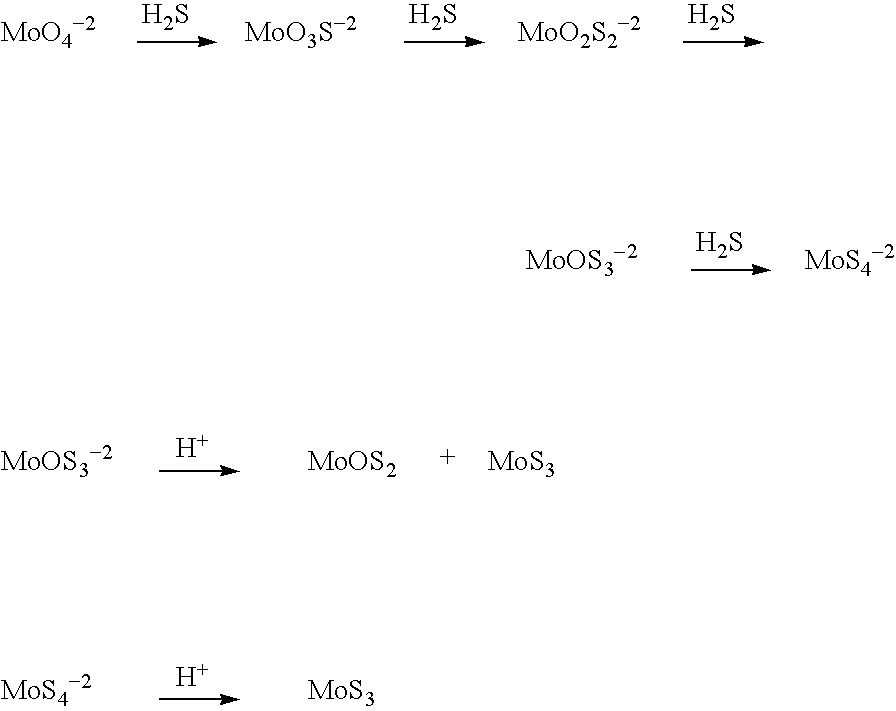

Nanosized particles of molybdenum sulfide and derivatives,method for its preparation and uses thereof as lubricant additive

InactiveUS20050065044A1Prevent coagulationProvide solubilityGroup 1/11 element organic compoundsAdditivesMolybdenum compoundsSulfidation

A lubricant composition is disclosed that comprises: (a) a lubricant and (b) at least one molybdenum-containing compound in the form of surface-capped nanosized particles of the general formula: (Z)n(X—R)m wherein Z is an inorganic moiety comprising molybdenum and sulfur in the form of particles having dimensions in the range of from about 1 to about 100 nm; (X—R) is a surface-capping reagent wherein R is a C4 to C20 straight or branched-chain alkyl or alkylated cycloalkyl radical or radicals and X is a functional group capable of specific sorption and / or chemical interaction with molybdenum / sulfur moiety; n is the number of molecules of Z in the particles; m is an integer representing the amount of surface-capping reagents relative to a single particle; and the ratio of m to n is in the range of from about 1:1 to about 10:1.

Owner:CROMPTON CORP

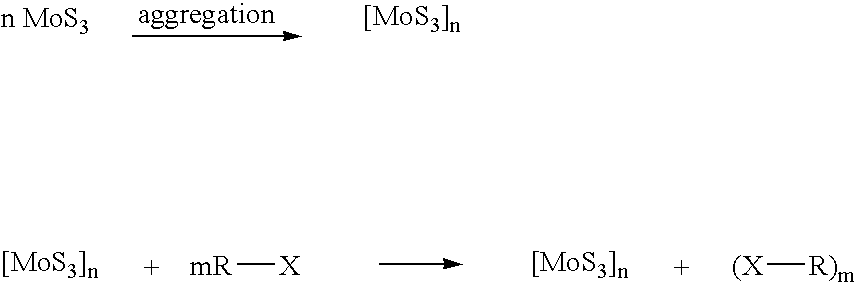

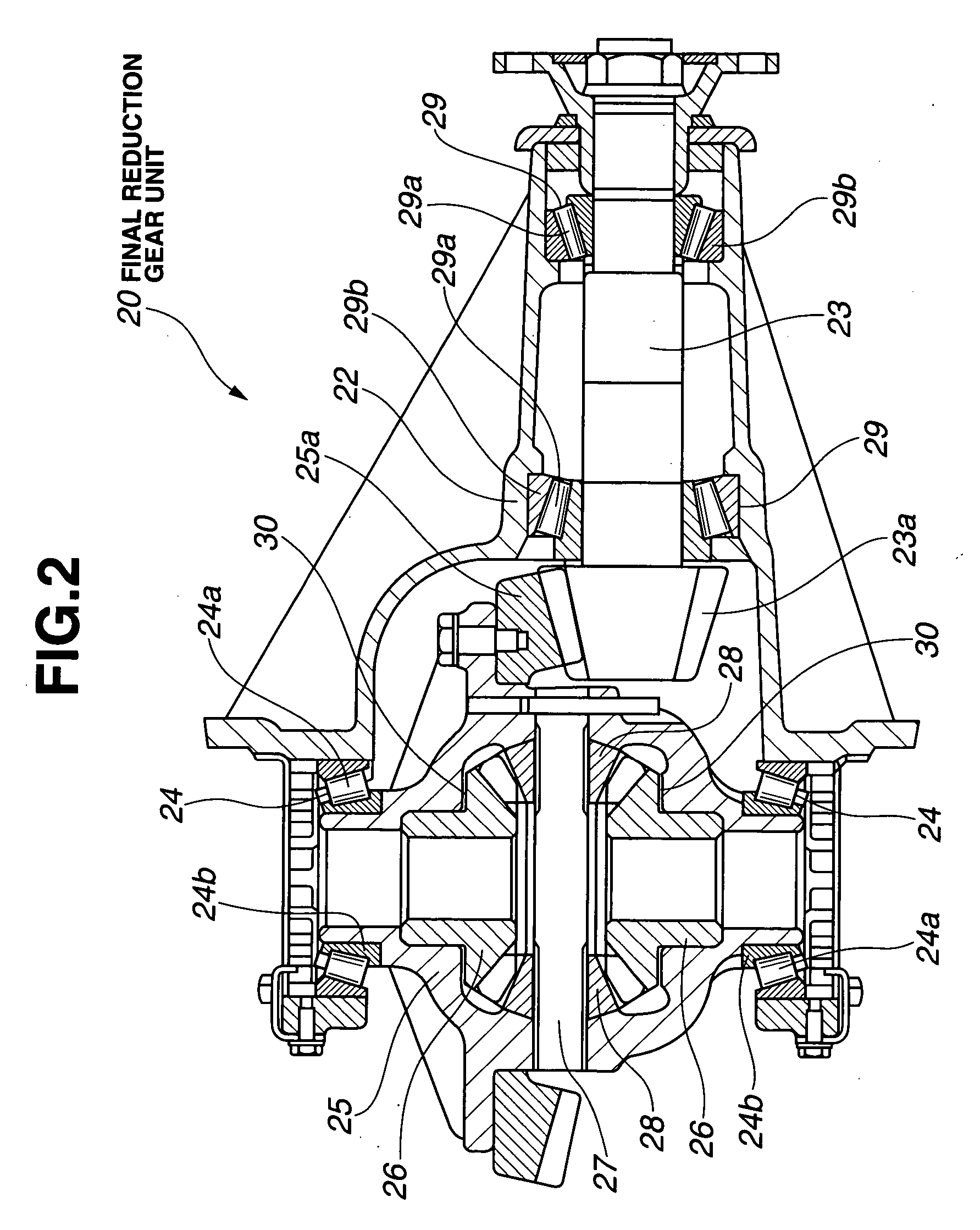

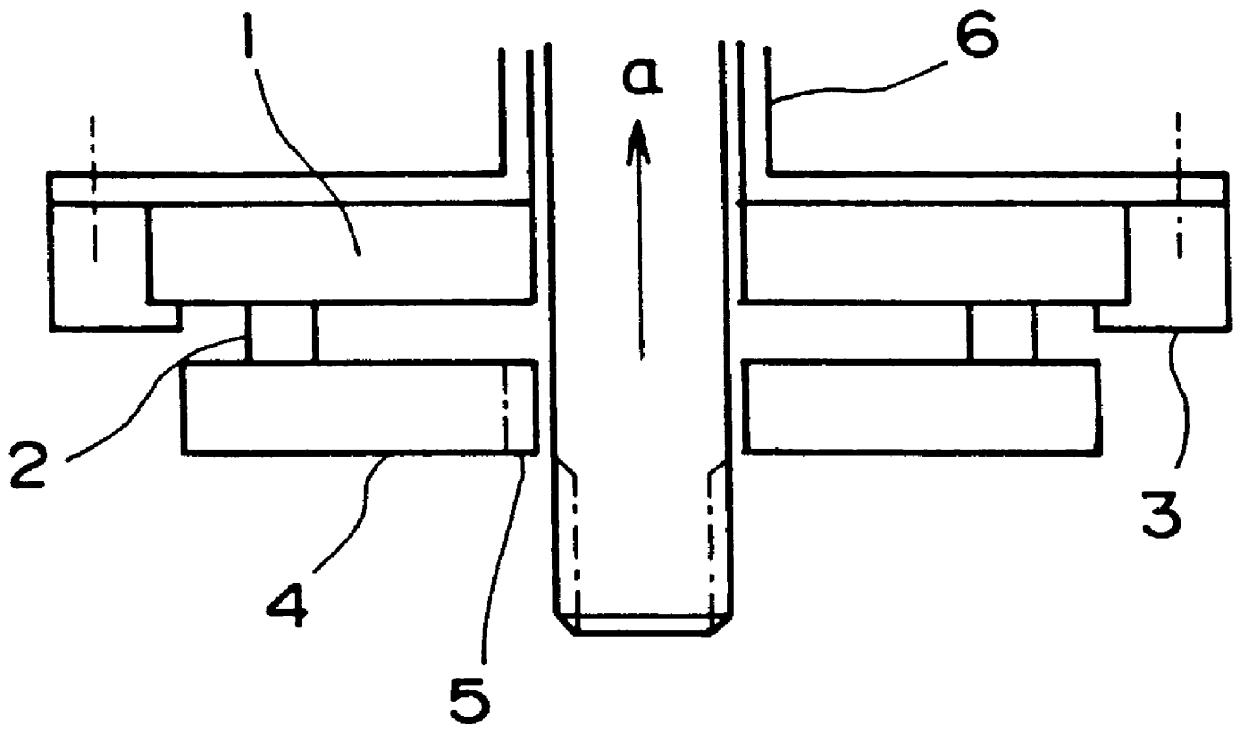

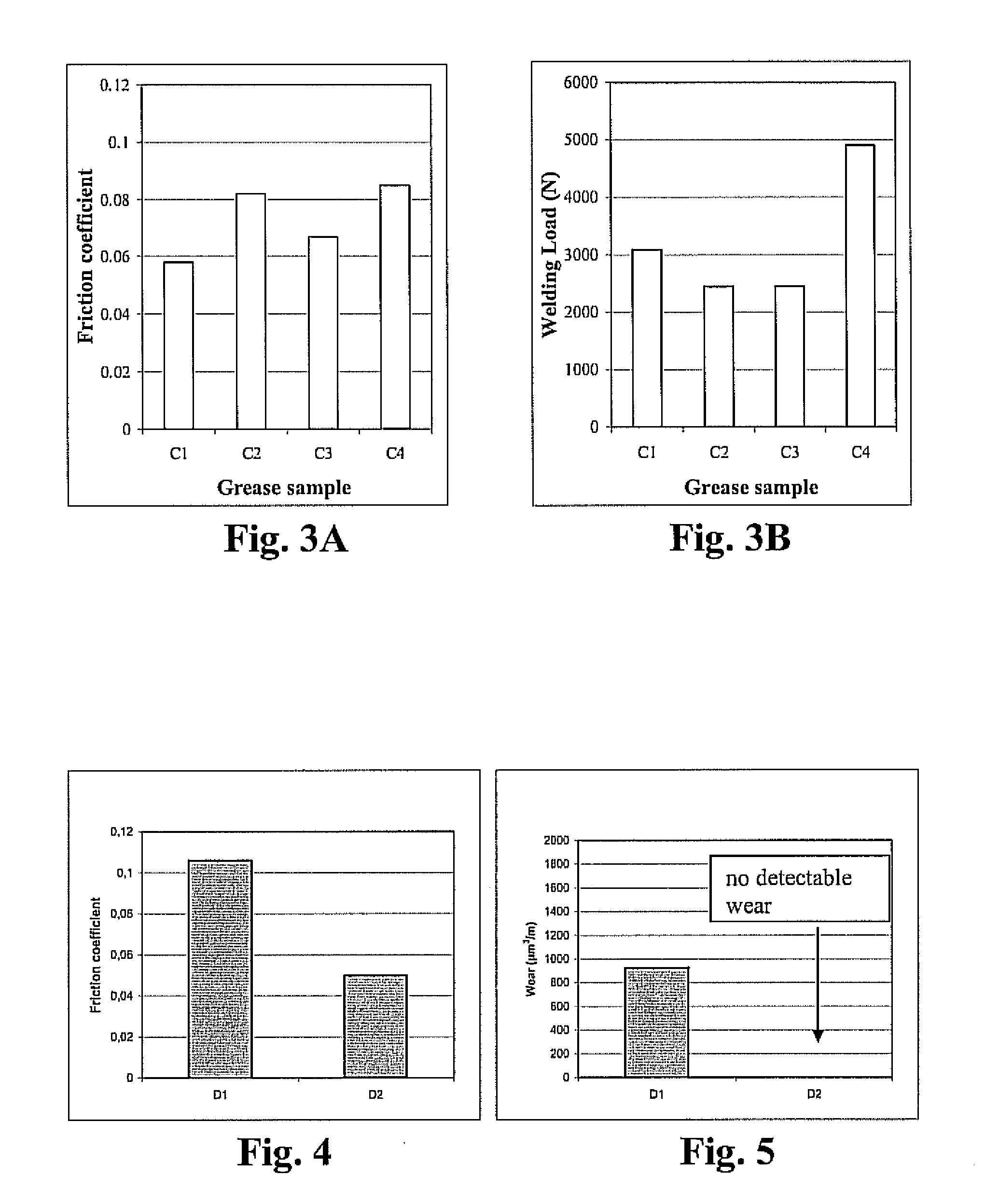

Low-friction sliding mechanism, low-friction agent composition and method of friction reduction

ActiveUS20060263604A1Reduce coefficient of frictionImprove fuel efficiencyCrankshaftsGear lubrication/coolingSimple Organic CompoundsFriction reduction

The invention provides a low-friction sliding mechanism, a low-friction agent composition, a friction reduction method, a manual transmission and a final reduction gear unit that can exert very excellent low friction characteristics to sliding surfaces present under various applications, and, in particular, that have more excellent low friction characteristics than that of a combination of an existing steel material and an organic Mo compound. The low-friction sliding mechanism has an oxygen-containing organic compound or an aliphatic amine compound interposed between sliding surfaces that a DLC coated sliding member and a sliding member form. The low-friction agent composition contains an oxygen-containing organic compound or an aliphatic amine compound. The friction reduction method includes supplying the low-friction agent composition between sliding surfaces that a DLC coated sliding member and a sliding member form. The manual transmission includes, as at least one of sliding members, a DLC coated sliding section. The final reduction gear unit includes, as at least one of sliding members, a DLC coated sliding section.

Owner:NISSAN MOTOR CO LTD +2

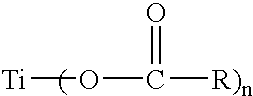

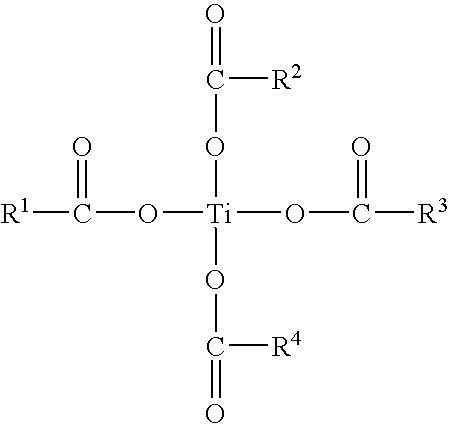

Titanium-containing lubricating oil composition

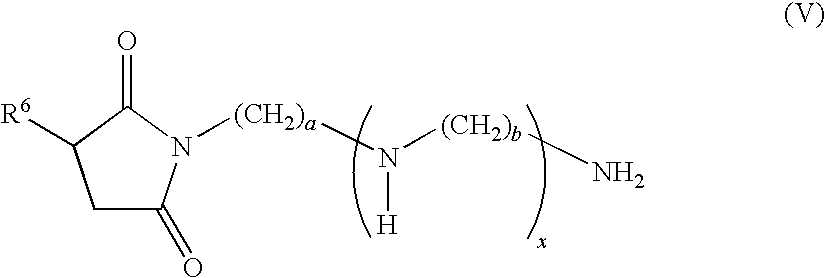

ActiveUS20070111908A1Improved performance characteristicsImprove featuresMixingAdditivesImideMolybdenum compounds

A fully formulated lubricating oil, lubricated surface, and lubricant additive concentrates for lubricants providing reduced sludge formation. The fully formulated lubricating oil composition has therein at least one succinimide dispersant derived from a polyalkylene compound having from about 50 to about 85% vinylidene double bonds in the compound, a metal containing detergent, at least one wear reducing agent, at least one antioxidant, and a hydrocarbon soluble titanium compound as a friction modifier. The lubricating oil composition is also substantially free of molybdenum compounds.

Owner:AFTON CHEMICAL

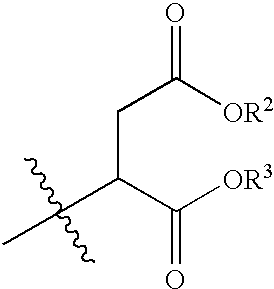

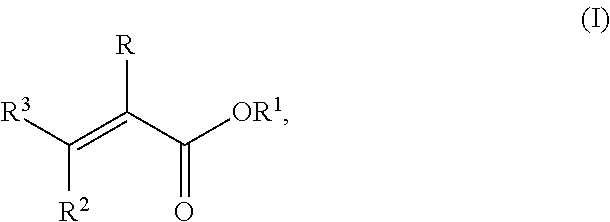

Fuel efficient lubricating oils

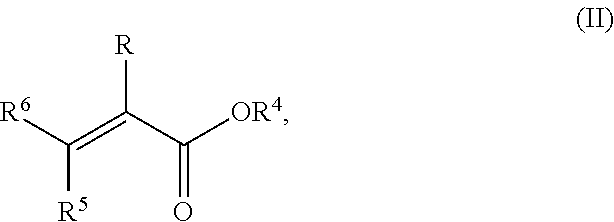

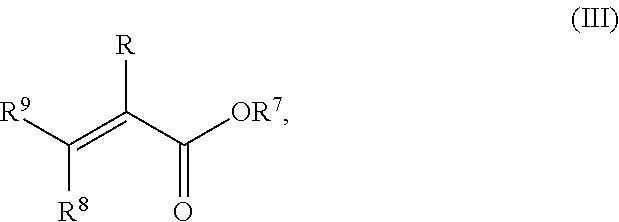

ActiveUS20150133352A1Reduce the amount requiredImprove fuel economyAdditivesBase-materialsMeth-Turbocharger

The present invention relates to an engine oil lubricant composition for use in internal combustion engines comprising one or more molybdenum containing compounds that deliver 1-1000 ppm molybdenum to the finished oil, one or more phosphorus containing compounds that deliver 25-650 ppm phosphorus to the finished oil, and one or more poly(meth)acrylate viscosity index improvers (VI improvers) that may or may not be functionalized, for improved fuel economy and turbocharger related deposits. In addition, the composition comprises an antioxidant system which is carefully balanced to provide improved fuel economy, comprising an aminic antioxidant, a phenolic antioxidant and an ashless dithiocarbamate. Additionally, the formulated oil may contain a dispersant poly(meth)acrylate, in addition to the PAMA VI improver, to reduce the amount of traditional succinimide dispersants.

Owner:VANDERBILT CHEM LLC

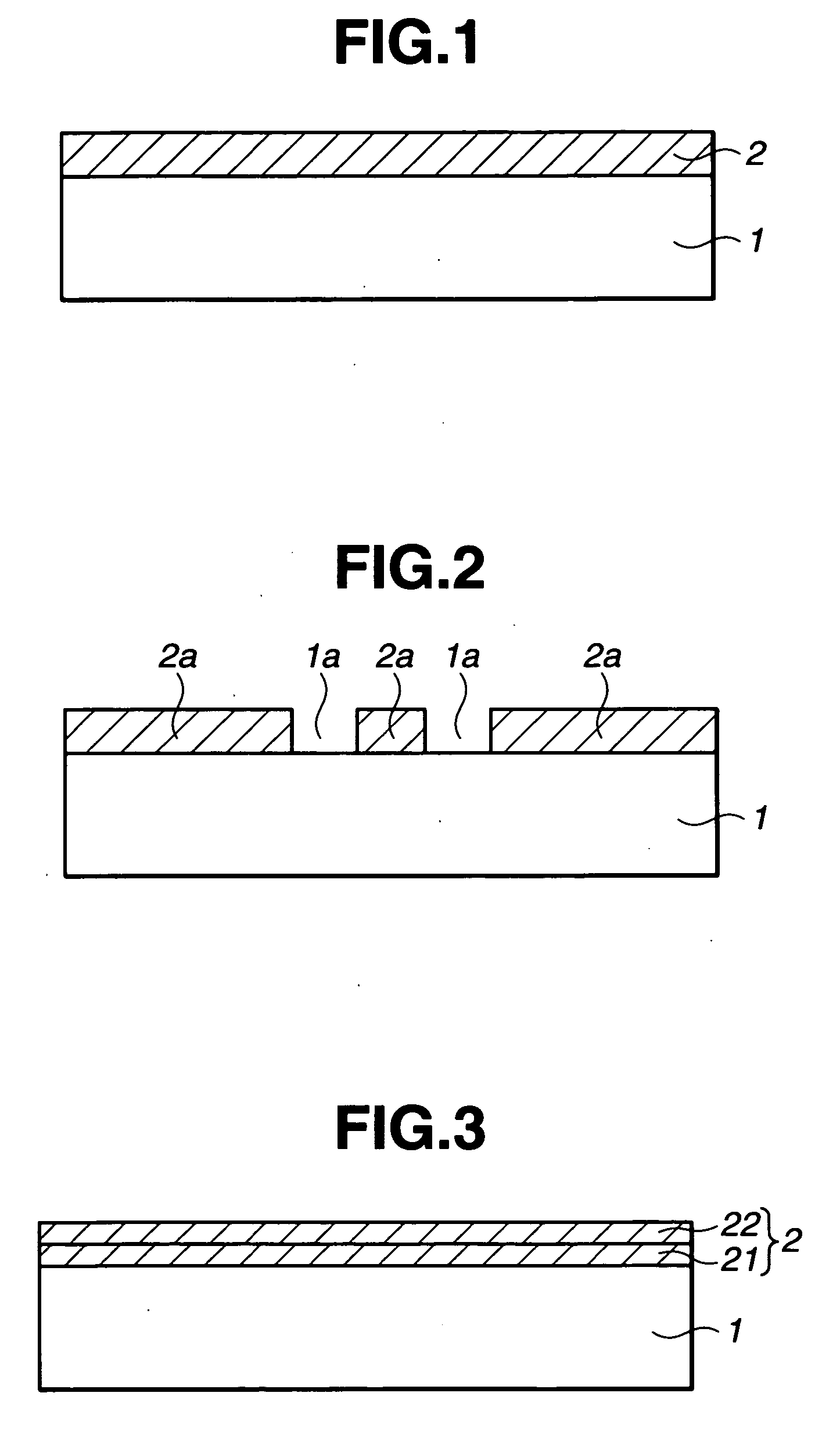

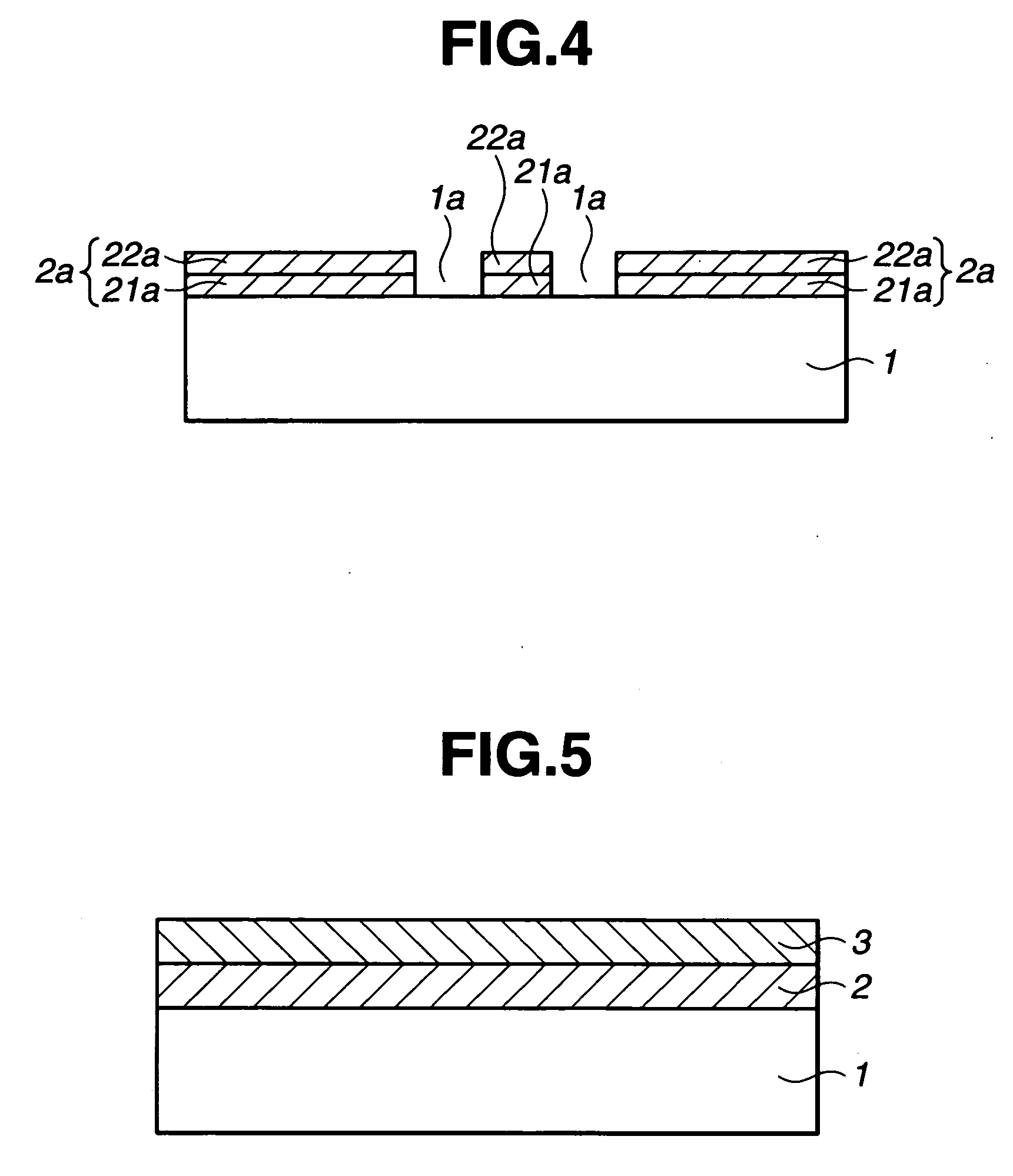

Photomask blank, photomask, and method of manufacture

A photomask blank comprising a multilayer film including at least four layers of different compositions, wherein the interface between the layers is moderately graded in composition; a phase shift mask blank comprising a phase shift film of at least two layers including a surface layer of a composition based on a zirconium silicide compound and a substrate adjacent layer of a composition based on a molybdenum silicide compound, and a further layer between one layer and another layer of a different composition, the further layer having a composition moderately graded from that of the one layer to that of the other layer; a phase shift mask blank comprising a phase shift film including a plurality of layers containing a metal and silicon in different compositional ratios which are stacked in such order that a layer having a higher etching rate is on the substrate side and a layer having a lower etching rate is on the surface side. The invention provides a photomask blank, typically a phase shift mask blank, which satisfies optical properties such as transmittance, reflectance and refractive index at an exposure wavelength of interest, and has an etched pattern with a minimal line edge roughness, and a photomask, typically a phase shift mask obtained therefrom.

Owner:SHIN ETSU CHEM IND CO LTD

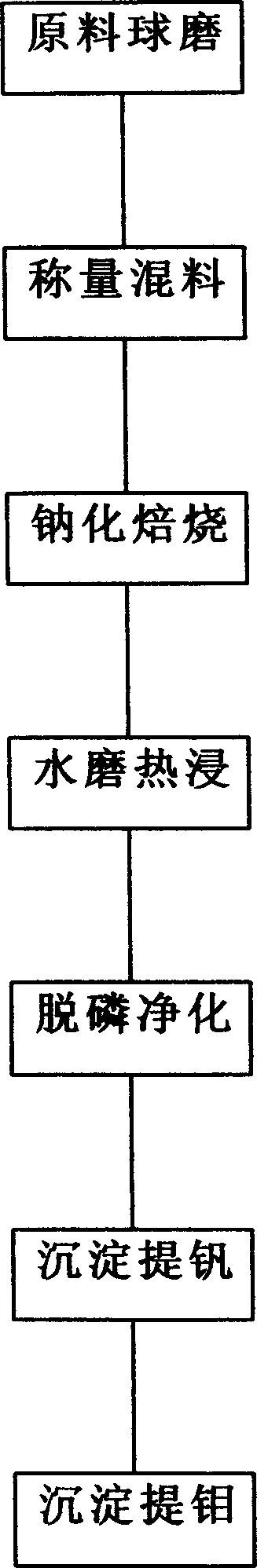

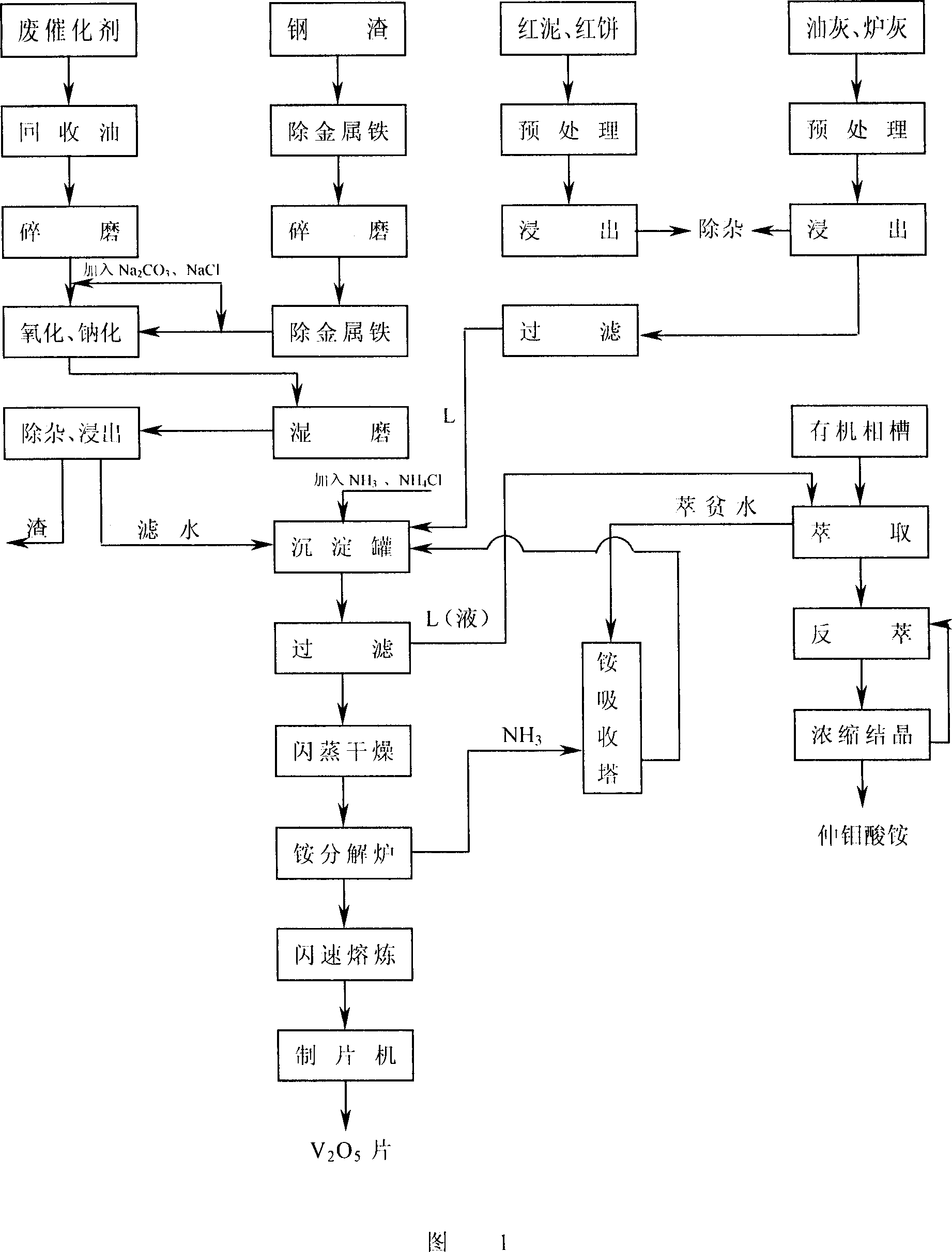

Production technology for extracting vanadium and molybdenum from spent aluminum base molybdenum catalyzer using wet method

The wet production process of extracting vanadium and molybdenum from waste aluminum-base molybdenum catalyst includes successively ball milling material, mixing material, roasting to sodidize, wet milling and hot soaking, dephoshorization to purify, deposition to extract vanadium and molybdenum successively. The present invention is developed on the basis of weight vanadiuim extracting process and apparatus and realizes the simultaneous extraction of valuable vanadium and molybdenum.

Owner:四川川投峨眉铁合金(集团)有限责任公司

Low sulfur and low phosphorus lubricating oil composition

The present invention is directed to a low sulfur and low phosphorus lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity and (b) one or more dispersants (c) one or more anti-oxidants and (d) one or more detergents, wherein the lubricating oil composition is essentially free of zinc di-alkyl di-thiophosphates and contains no more than 0.1 weight percent sulfur and provided the lubricating oil composition does not contain alkylated and non-alkylated aromatic amines and tri-nuclear molybdenum compounds. The present invention is also directed to a low sulfur and low phosphorus lubricating oil composition comprising (a) an oil of lubricating viscosity (b) a borated dispersant and a non-borated dispersant (c) a molybdenum anti-oxidant and a phenolic anti-oxidant and (d) a high overbased and a low overbased calcium sulfonate, wherein the lubricating oil composition is essentially free of zinc di-alkyl di-thiophosphates and contains no more than 0.1 weight percent sulfur and provided the lubricating oil composition does not contain alkylated and non-alkylated aromatic amines and tri-nuclear molybdenum compounds. The present invention is also directed to method for lubricating internal combustion engines, which comprises lubricating the engine with a low sulfur and low phosphorus lubricating oil compositions of the present invention.

Owner:CHEVRON ORONITE CO LLC

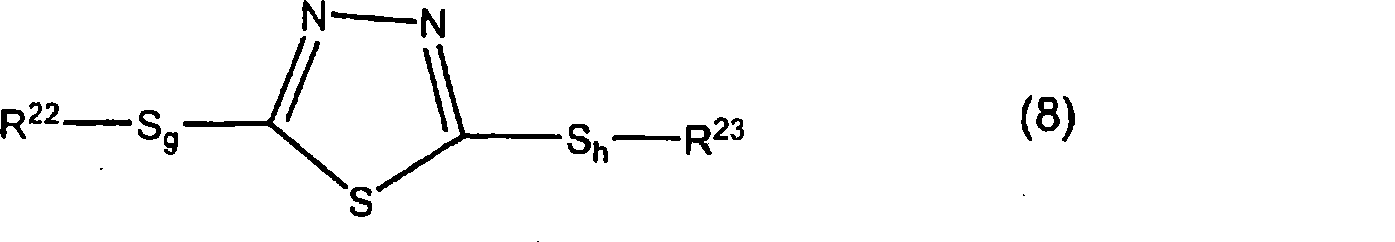

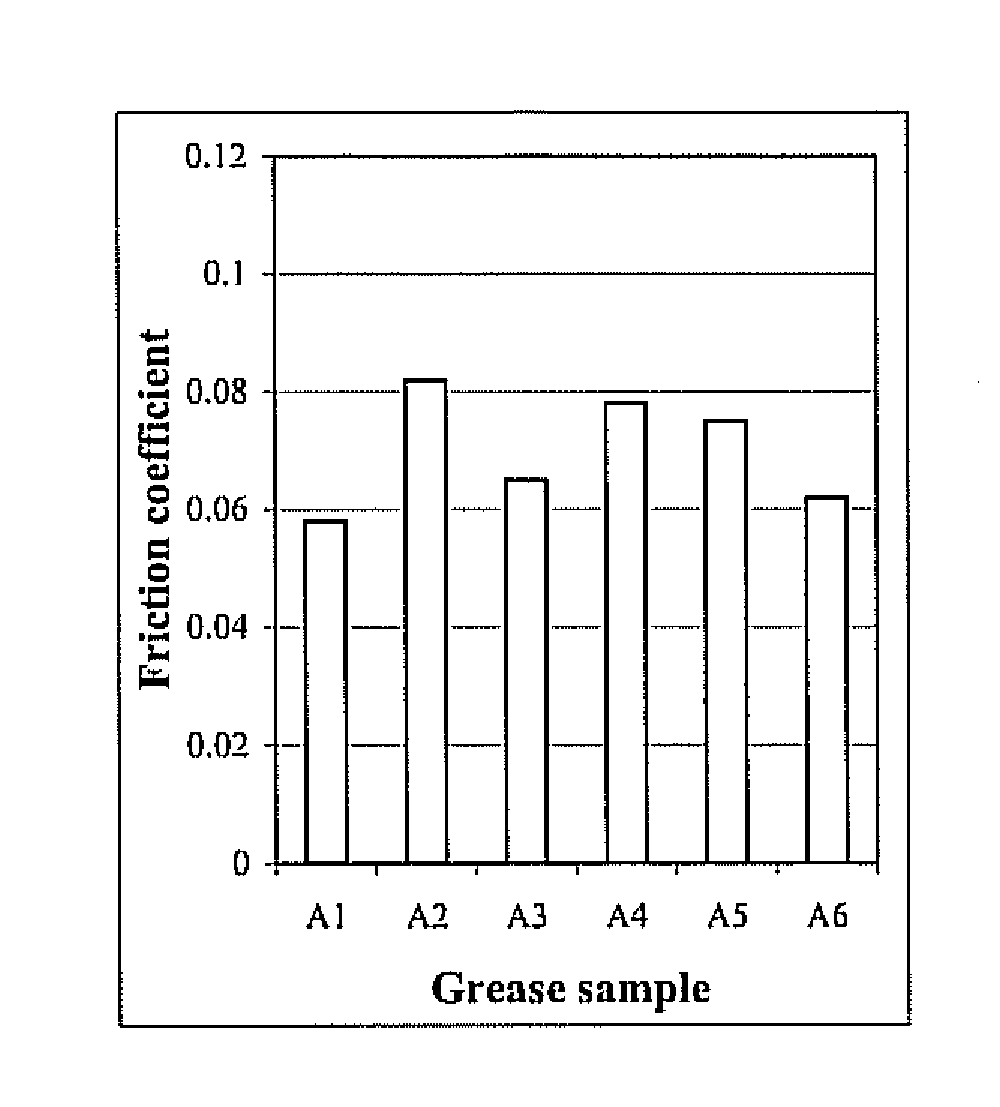

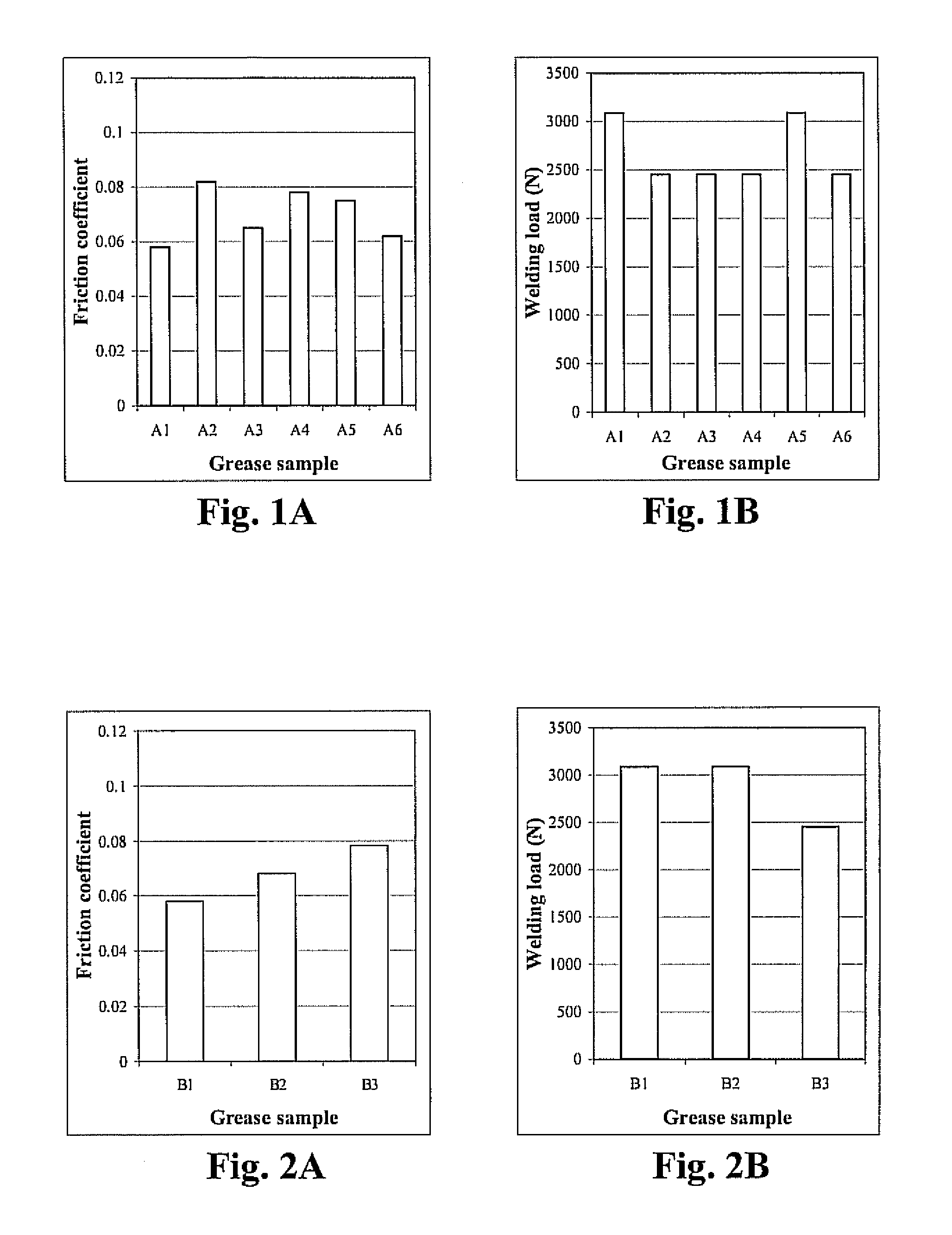

Lubricating compositions containing synthetic ester base oil, molybdenum compounds and thiadiazole-based compounds

ActiveUS20060035791A1Good for wear protectionImprove anti-wear performanceOrganic chemistryAdditivesCompound aEther

A lubrication composition providing excellent anti-wear protection for corrosion-resistant materials which comprises a major amount of a synthetic ester base oil, and a minor amount of a molybdenum compound and an anti-wear additive selected from the group consisting of 1,3,4-thiadiazole derivative as an anti-wear additive, the reaction products of 2,5-dimercapto-1,3,4-thiadiazole dimers and poly(ether)glycols, and 2,5-dimercapto-1,3,4-thiadiazole monomer and mixtures thereof. Also described is a method for imparting anti-wear properties to a corrosion resistant material, comprising using the lubricating composition of the invention.

Owner:VANDERBILT CHEM LLC

Method for regenerating molybdenum-containing oxide fluidized-bed catalyst

InactiveUS6559085B1Improve catalytic performanceOther chemical processesCatalyst regeneration/reactivationCeriumLanthanum

A method for regeneration of a molybdenum-containing oxide fluidized bed catalyst which comprises impregnating a fluidized catalyst of a metal oxide containing molybdenum, bismuth and iron which has been deteriorated by being used for a reaction in production of acrylonitrile by ammoxidation of propylene, with a solution of a molybdenum compound and a solution of at least one compound containing at least one element selected from the group consisting of iron, chromium, lanthanum and cerium which are prepared separately or with a previously prepared mixed solution of the above compounds, drying the resulting catalyst and, then, firing the catalyst at a temperature of 500-700° C.

Owner:MITSUBISHI CHEM CORP

Phosphonic acid and polyvinyl alcohol conversion coating

Compositions for preparing coatings on metal substrates include a phosphonic acid, polyvinyl alcohol, an optional catalyst, and optionally an organo-functional silane. The catalyst may be a group IV-B compound, a boron compound, a vanadium compound, or a molybdenum compound. The compositions may be applied from an aqueous carrier to a metal surface and then dried to form a coating imparting good paint adhesion and corrosion resistance to the metal substrate.

Owner:BULK CHEM

Lubricant oil composition for internal combustion engine

ActiveUS20110065618A1Improve the heating effectPromote oxidationTin organic compoundsAdditivesSulfurAntioxidant

The lubricating oil composition for an internal combustion engine of the invention comprises a lubricating base oil having a urea adduct value of not greater than 4% by mass and a viscosity index of 100 or greater, an ash-free antioxidant containing no sulfur as a constituent element, and at least one compound selected from among ash-free antioxidants containing sulfur as a constituent element and organic molybdenum compounds.

Owner:JX NIPPON OIL & ENERGY CORP

Low sulfur and low phosphorus heavy duty diesel engine lubricating oil composition

ActiveUS20070111905A1Reduce the temperatureGuaranteed low temperature fluidityAdditivesAnti oxidantHeavy duty diesel

The present invention is directed to a low sulfur and low phosphorus heavy duty diesel engine lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity and (b) one or more dispersants (c) one or more anti-oxidants and (d) one or more ash-containing detergents, wherein the lubricating oil composition is essentially free of zinc di-alkyl di-thiophosphates and contains no more than 0.175 weight percent sulfur and provided the lubricating oil composition does not contain alkylated and non-alkylated aromatic amines and tri-nuclear molybdenum compounds. The present invention is also directed to a low sulfur and low phosphorus heavy duty diesel engine lubricating oil composition comprising (a) an oil of lubricating viscosity (b) a borated dispersant and a non-borated dispersant (c) a molybdenum anti-oxidant and a phenolic anti-oxidant and (d) a low overbased calcium sulfonate and a high overbased calcium phenate, wherein the lubricating oil composition is essentially free of zinc di-alkyl di-thiophosphates and contains no more than 0.175 weight percent sulfur and provided the lubricating oil composition does not contain alkylated and non-alkylated aromatic amines and tri-nuclear molybdenum compounds. The present invention is also directed to method for lubricating a heavy duty diesel engines, which comprises lubricating the engine with a low sulfur and low phosphorus heavy duty diesel engine lubricating oil compositions of the present invention.

Owner:CHEVRON ORONITE CO LLC

Lubricant composition and antioxidant composition

ActiveUS20110077181A1Sufficient long drain intervalIncrease the number ofTin organic compoundsLiquid carbonaceous fuelsAromatic solventMolybdenum compounds

The lubricating oil composition of the present invention comprises at least one species of aromatic constituent selected from the following (a1) to (a5):(a1) a lubricating base oil comprising a polycyclic aromatic content of 0.01% by mass or more based on the total amount of base oil(a2) a lubricating base oil comprising a total aromatic content of 20 to 100% by mass based on the total amount of base oil(a3) an aromatic solvent(a4) at least one species of polycyclic aromatic compound selected from alkyl naphthalene and compounds having three or more aromatic rings, and(a5) an aromatic compound having a nitrogen atom, an oxygen atom or a sulfur atom;and an organic molybdenum compound.

Owner:NIPPON OIL CORP

Extraction of vanadium and molybdenum compound from refused materials containing vanadium and molybdenum etc. multiple elements

InactiveCN1940096APrecipitation completeStable pHVanadium oxidesProcess efficiency improvementSodium molybdateMolybdenum compounds

Extraction of vanadium and molybdenum from waste materials is carried out by physically or chemically pre-treating for raw materials by recovered oil, leaching out at a certain pH value, generating soluble sodium metavanadate and sodium molybdate, removing impurities, filtering, solid-liquid separating, precipitating ammonium metavanadate by amine salt, filtering, drying, decomposing, tabletting by smelting furnace to obtain sheeted vanadic anhydride, precipitating ammonium metavanadate filtrate, pouring it into vanadium extraction tank, extracting by organic phase, cleaning by saturated organic phase, reversed extracting, concentrating and crystallizing. It has better vanadium recovery rate and quality and more product yield.

Owner:HUARUI VANADIUM IND SHENYANG

Lubricating oil compositions

InactiveUS20100152072A1High deposit reductionHigh wearBearing componentsAdditivesPhysical chemistryMolybdenum compounds

A lubricating oil composition having a sulfur content of up to about 0.4 wt. % and a sulfated ash content of up to about 0.5 wt. % as determined by ASTM D874 is disclosed which comprises (a) a major amount of an oil of lubricating viscosity; (b) at least one oil-soluble or dispersed oil-stable boron-containing compound having greater than 400 ppm of boron, based upon the total mass of the composition; and (c) at least one oil-soluble or dispersed oil-stable molybdenum-containing compound having at least about 1100 ppm of molybdenum, based upon the total mass of the composition; wherein the lubricating oil composition has a ratio of sulfur to molybdenum of less than or equal to about 4:1.

Owner:CHEVRON ORONITE CO LLC +1

Lube base oil, lubricating oil composition for internal combustion engine, and lubricating oil composition for drive transmission device

InactiveCN101379171AExcellent viscosity-temperature characteristicsReduce energy lossBase-materialsMeth-Chemical composition

A lube base oil satisfying at least one of the following requirements (a) and (b). A lubricating oil composition for internal combustion engines is provided which comprises the lube base oil, an ash-free antioxidant containing no sulfur as a constituent element, and at least one member selected among ash-free antioxidants containing sulfur as a constituent element and organ omolybdenum compounds. Also provided is a lubricating oil composition for drive transmission devices which comprises the lube base oil, a poly(meth)acrylate-type viscosity index modifier, and a phosphorus compound. (a) The content of saturated matters is 90 mass% or higher and the proportion of cyclic saturated matters in those saturated matters is 10-40 mass%. (b) The lube base oil satisfies the relationship represented by the following expression (1). 1.440=n20-0.002OEv100=1.453 (1) [In the expression, n20 indicates the refractive index at 20 DEG C of the lube base oil and kv100 indicates the dynamic viscosity (mm2 / s) at 100 DEG C of the lube base oil].

Owner:NIPPON OIL CO LTD +1

Complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and preparation method thereof

InactiveCN101905155AHigh catalytic activityImprove catalytic performanceCatalyst activation/preparationPreparation from organic carbonatesCoprecipitationTitanium

The invention discloses a complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and a preparation method thereof. The catalyst basically consists of a molybdenum-titanium complex oxide, wherein the weight ratio of the molybdenum to the titanium is 100:10-100; the roasting temperature is between 300 and 600 DEG C; base raw materials for preparing the catalyst are a molybdenum compound and a titanium compound; and the preparation method adopts a coprecipitation method or mechanical grinding method. The catalyst has high catalytic activity and good selectivity for the reaction of synthesizing the diphenyl carbonate by ester exchange, and particularly has the advantages of simple preparation method, easy separation and recycling, no environmental pollution, no corrosion to equipment and the like, so the catalyst can be widely applied to production of the diphenyl carbonate.

Owner:CHANGZHOU INST OF CHEM

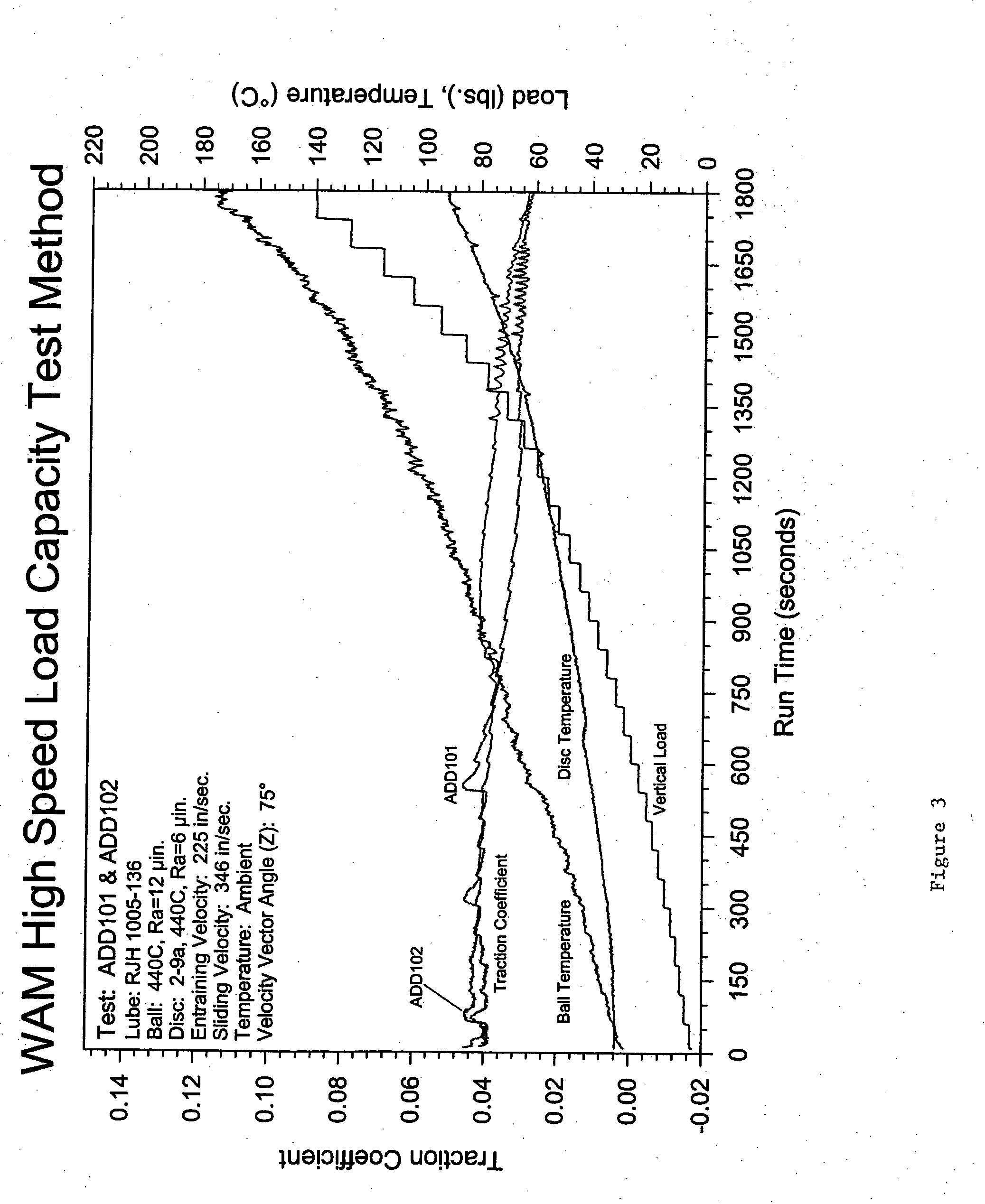

Oil composition for continuously variable transmissions

An oil composition for continuously variable transmissions (CVT) comprising a base oil, (A) a sulfonate, (B) an ashless dispersant, (C) an acid amide, (D) an organomolybdenum compound, and (E) an amine antioxidant. The oil composition for CVT prevents the scratching phenomenon while the transmitted power is kept large in CVT of a belt type used for automatic transmissions of automobiles. The gradient in the mu -V characteristic can be kept positive for a long time.

Owner:IDEMITSU KOSAN CO LTD

Method for extracting nickel and molybdenum from nickel-molybdenum ore

InactiveCN102140576AHigh recovery rateWon't happenProcess efficiency improvementSodium chlorateMolybdenum compounds

The invention discloses a method for extracting nickel and molybdenum from nickel-molybdenum ore, comprising the following steps of: (a) in the presence of an oxidizing agent, leaching the finely-ground nickel-molybdenum ore from an acid solution and filtering to obtain a leachate, wherein the oxidizing agent is sodium chlorate or potassium chlorate; (b) adding a first alkaline compound in the leachate, adjusting the pH value of the leachate to be 1.5-3.5 and filtering to respectively obtain a precipitation and a supernate; (c) adding a second alkaline compound in the supernate, adjusting thepH value of the supernate to be 5-7 and filtering to obtain a nickel-containing compound; and (d) leaching the precipitation in an alkali liquor, filtering to obtain a molybdenum-containing leachate,and extracting and re-extracting the molybdenum-containing leachate to obtain a molybdenum-containing compound. By using the method, the sodium chlorate or potassium chlorate is used as the oxidizingagent, the higher leaching rate of the nickel and molybdenum and the higher recovery rate of the nickel and molybdenum can be obtained.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

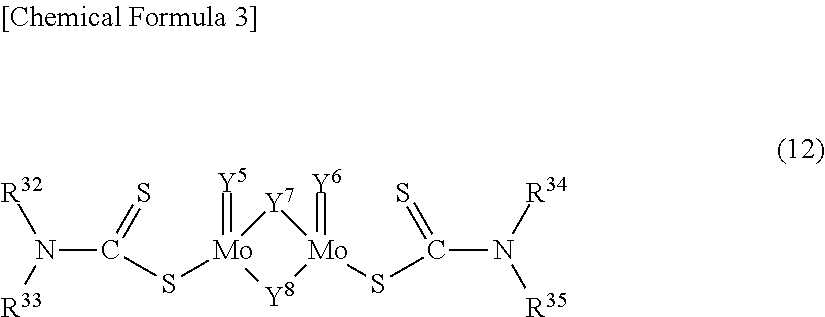

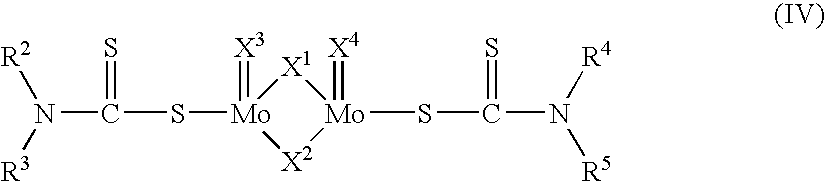

Grease Composition For Use In Constant Velocity Joints

InactiveUS20080176776A1Improve compatibilityReduce wearThickenersAdditivesAlcoholThermoplastic elastomer

In order to provide for a grease composition which has a good compatibility with boots made of rubber or thermoplastic elastomer, and which also gives low wear and low friction, a grease composition for use in constant velocity joints is suggested, comprisinga) a base oil composition;b) at least one tri-nuclear molybdenum compound of the formulaMo3SkLnQz,wherein L are independently selected ligands having organo groups with a sufficient number of carbon atoms to render the compound soluble or dispersible in the oil, n is from 1 to 4, k varies from 4 though 7, Q is selected from the group of neutral electron donating compounds such as amines, alcohols, phosphines, and ethers, and z ranges from 0 to 5 and includes non-stoichiometric values;c) at least one urea derivative thickener.

Owner:GKN DRIVELINE INT GMBH +1

Lubricant formulations with dispersancy retention capability (law684)

InactiveUS6150309AImproves dispersion retention capabilityHigh retention rateAdditivesPhenolic antioxidantCrankcase

The use of oil soluble organo molybdenum compounds in combination with phenolic or amenic antioxidants has been found to improve the dispersancy retention capability of crankcase lubricants. Thus in one embodiment the present invention comprises improving dispersancy retention of a crankcase lubricant by including in the crankcase lubricant composition an oil soluble organomolybdenum compounds and at least one of a phenolic or aminic antioxidant. Particularly preferred organomlybdenum compounds are molybdenum dithiocarbamates while a mixture of a diarylamine and two phenolic antioxidants are preferred.

Owner:EXXON RES & ENG CO

Resist composition excellent in flame resistance

InactiveUS6528552B1Improve flame retardant performanceGood self-extinguishingLactams stabilisationSemiconductor/solid-state device detailsResistStannate

A resist composition for permanent protective coating of a printed wiring board, which resist composition is excellent in flame resistance and is obtained by incorporating as essential components a flame retardant containing 100 to 140 parts by weight of (a) aluminum hydroxide, 0.1 to 15 parts by weight of (b) a molybdenum compound and 0.1 to 10 parts by weight of (c) a zinc stannate type compound into 100 parts by weight of a resin.

Owner:MITSUBISHI GAS CHEM CO INC

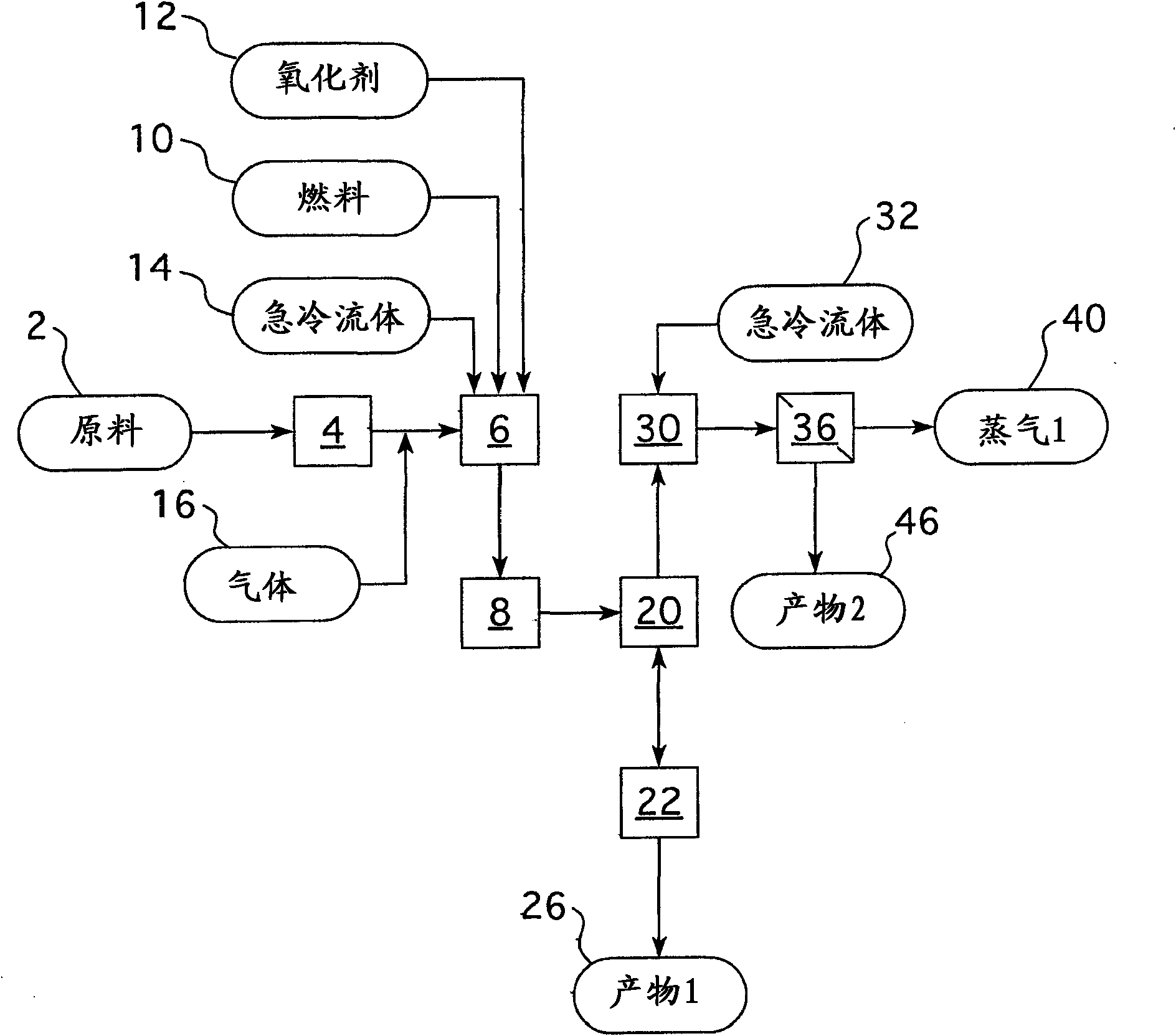

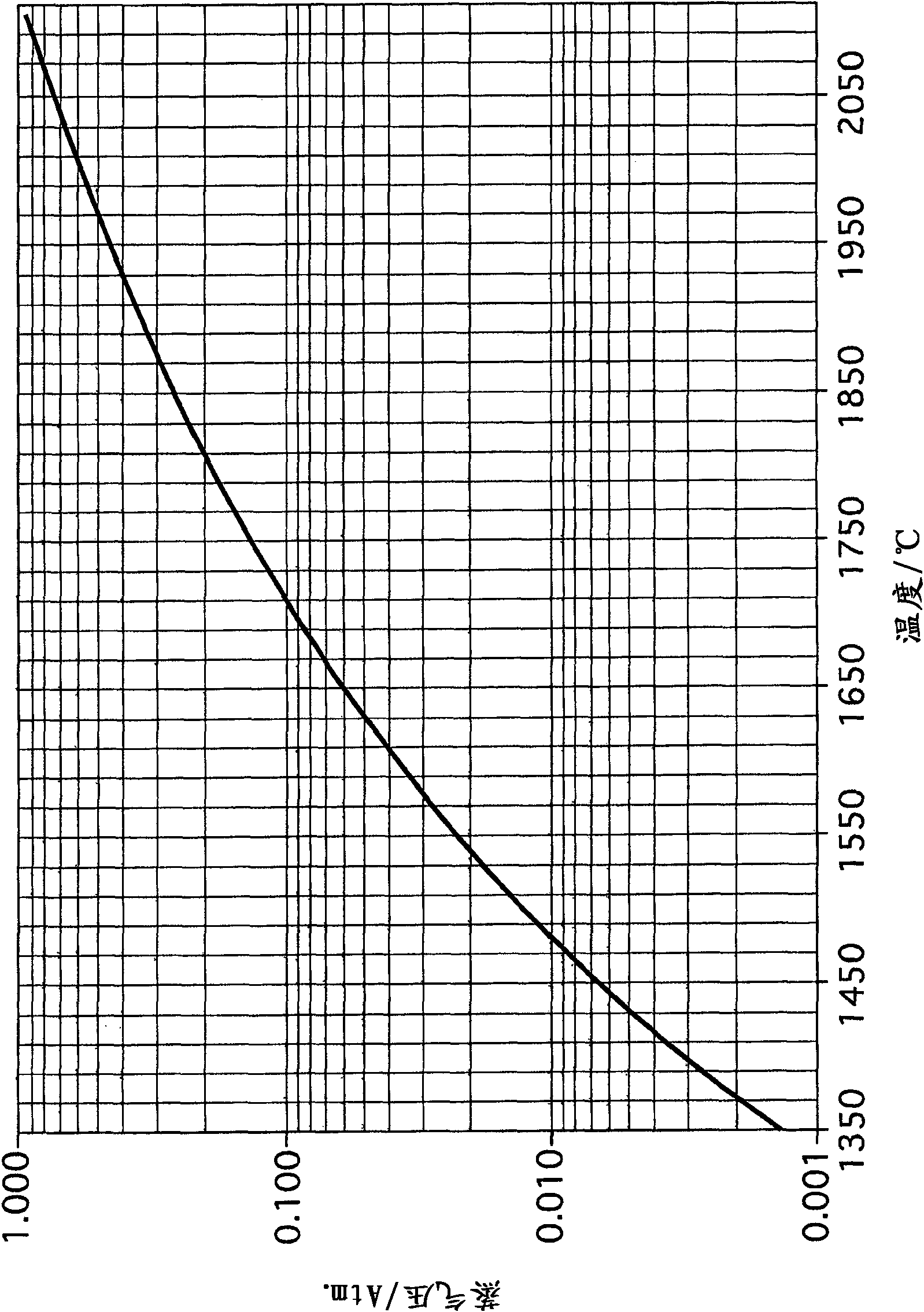

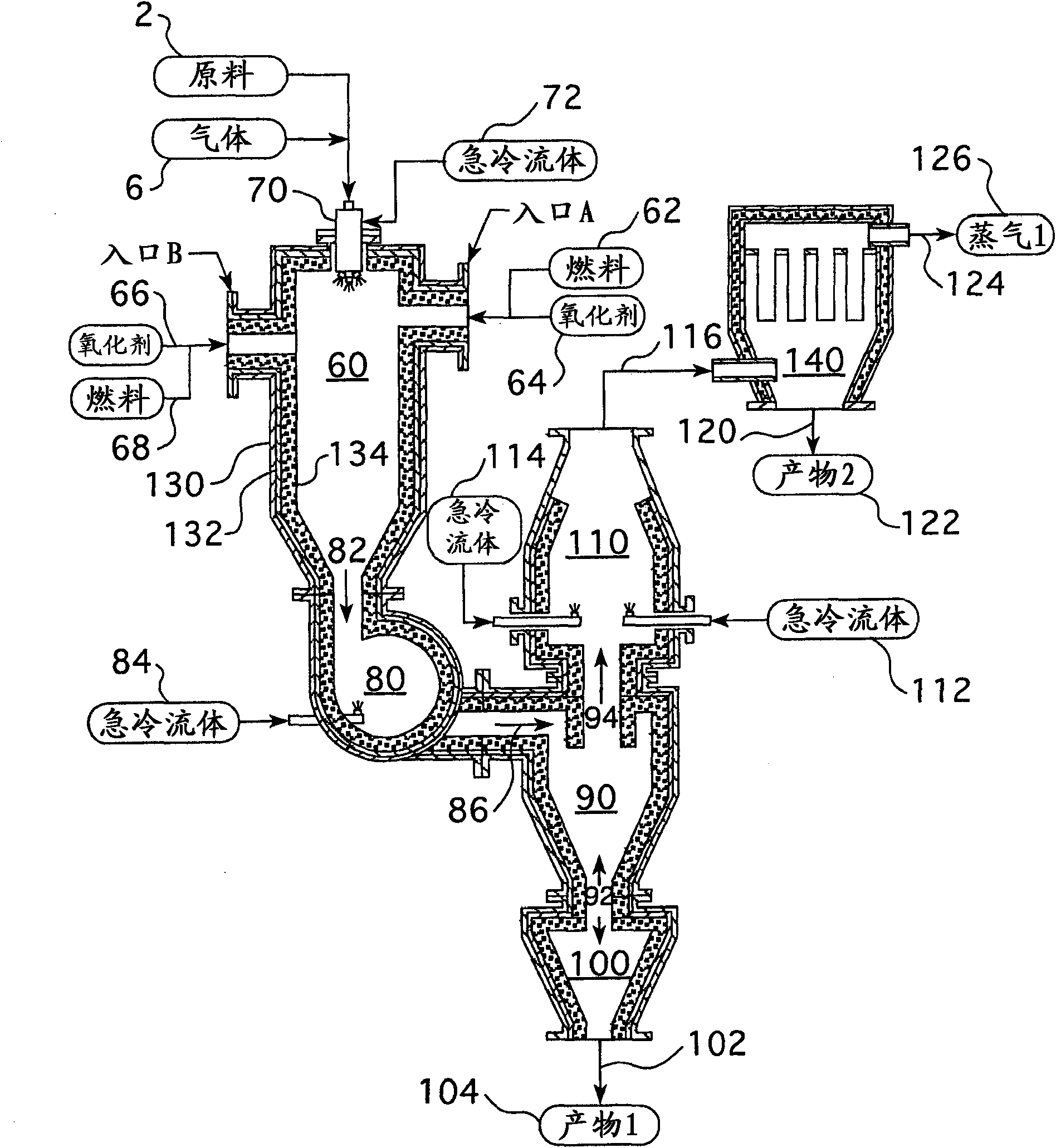

Method and apparatus for recovery of molybdenum from spent catalysts

InactiveCN102159292AAchieve separationSolvent extractionProcess efficiency improvementCycloneFiltration

This invention relates to an apparatus and process that utilizes high-temperature oxidation and sublimation for recovery of molybdenum from spent catalysts or other feedstocks that contain molybdenum. One embodiment uses a counter-rotating vortex reactor and a cyclonic entrained-flow reactor to rapidly heat and oxidize the spent catalyst feedstock, such as carbon, sulfur, and molybdenum compounds, at temperatures in the range of about 2100 DEG F to 2900 DEG F, resulting in a gas-solid stream containing molybdenum trioxide vapor. A high-temperature cyclone separator is utilized to separate the residue from this stream before this stream is rapidly quenched to a temperature sufficient to effect condensation of solid molybdenum trioxide without condensing arsenic or phosphoric oxides. The condensed molybdenum trioxide material is separated from this stream by passing through a high-temperature filtration system. The remaining gaseous stream is ducted to operations for possible further material reclamation and entailed pollution control prior to discharge to the atmosphere.

Owner:詹姆斯・G・赫纳特 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com