Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Precipitation complete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

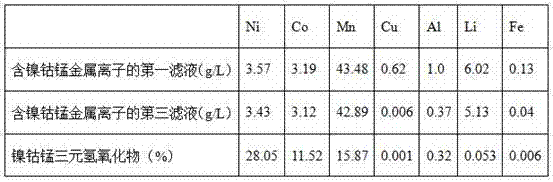

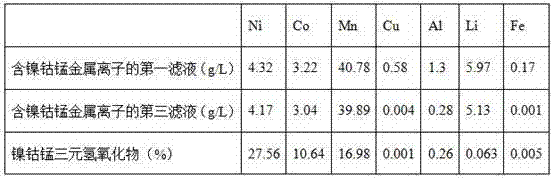

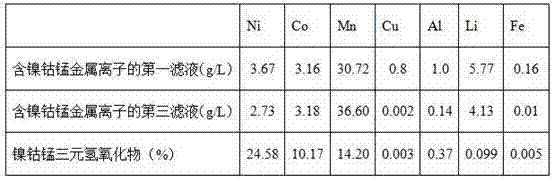

Method for preparing ternary hydroxide from nickel cobalt manganese recycled from waste lithium ion batteries through liquid phase method

ActiveCN107117661ALabor savingEasy to industrializeWaste accumulators reclaimingNickel oxides/hydroxidesManganeseSlurry

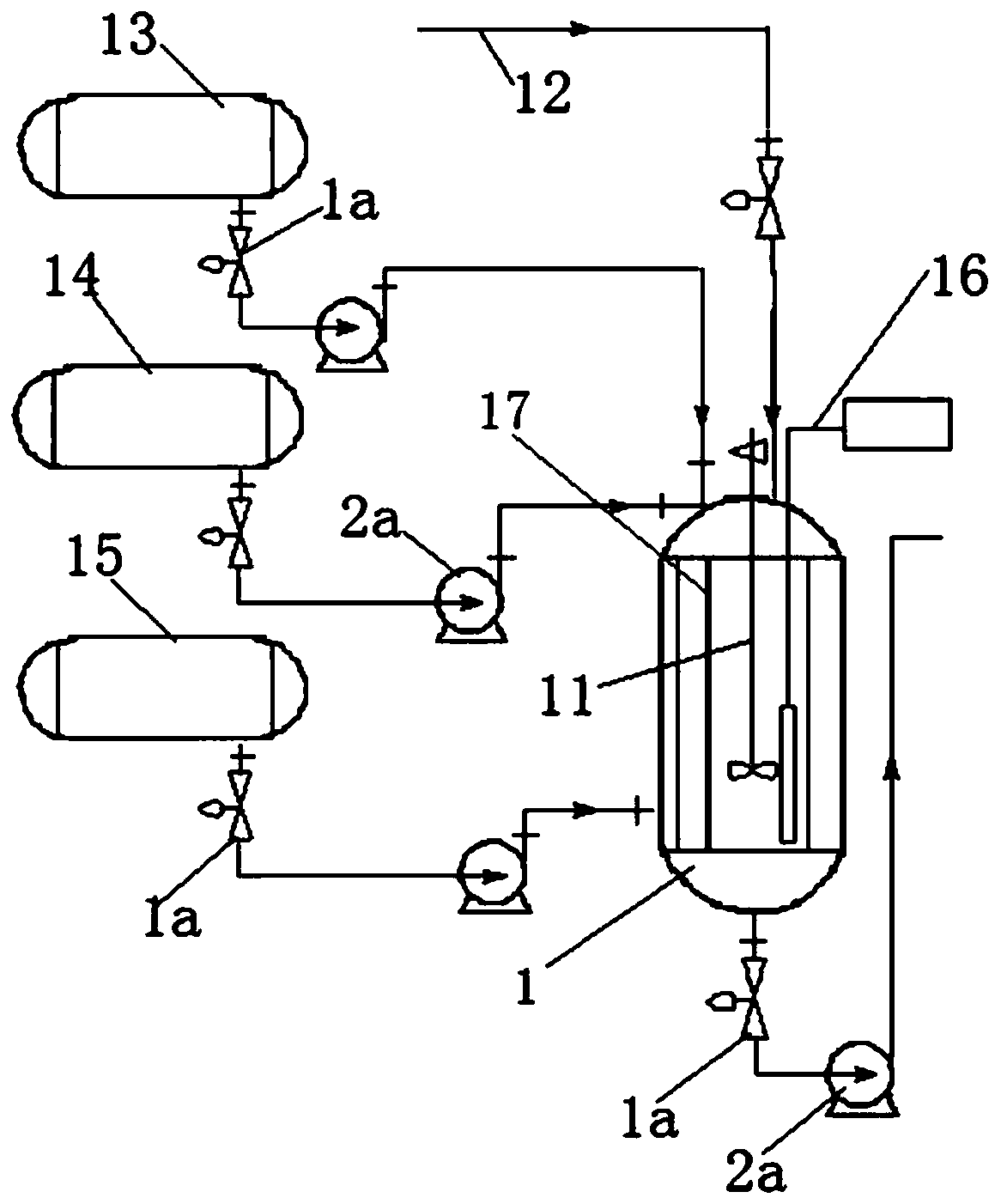

The invention discloses a method for preparing ternary hydroxide from nickel, cobalt and manganese in waste lithium ion batteries recovered by a liquid phase method, belonging to the technical field of metallurgical recovery of valuable metals, and solves the increasingly prominent problem of recycling waste lithium ion batteries. question. The invention uses waste lithium ion batteries as raw materials, and the main production steps include: dismantling and crushing, pulping, leaching, copper removal by extraction, iron and aluminum removal by precipitation, and preparation of nickel-cobalt-manganese ternary hydroxide. In the invention, the whole battery is crushed and then processed, no harmful gas is generated in the whole process of recovery and preparation, and green recovery is realized from the root. Raw material requirements, the entire production process is more convenient to operate, and the product is more pure, suitable for industrialization.

Owner:JINCHUAN GROUP LIMITED

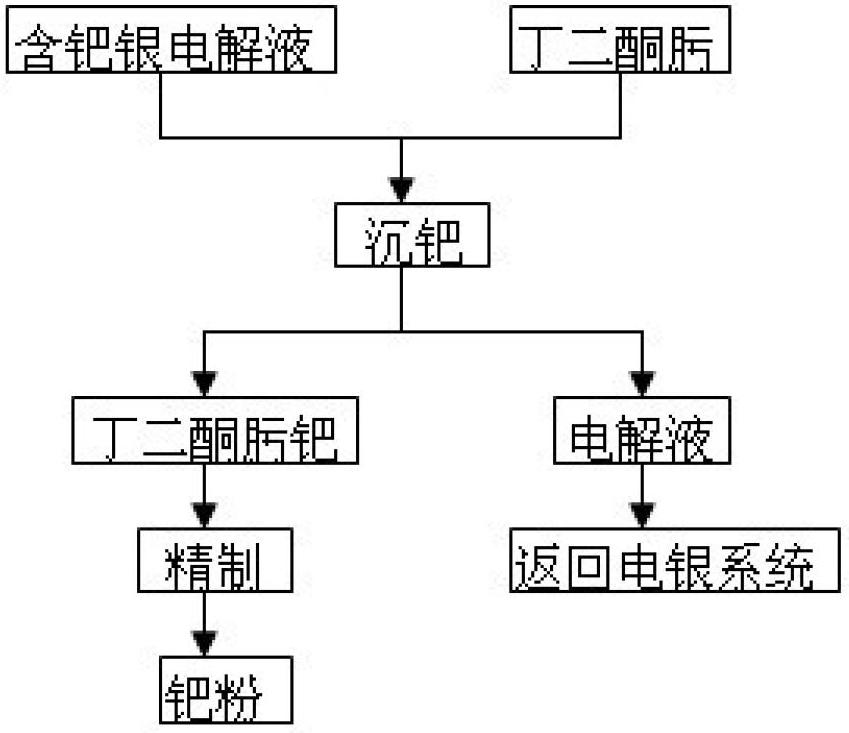

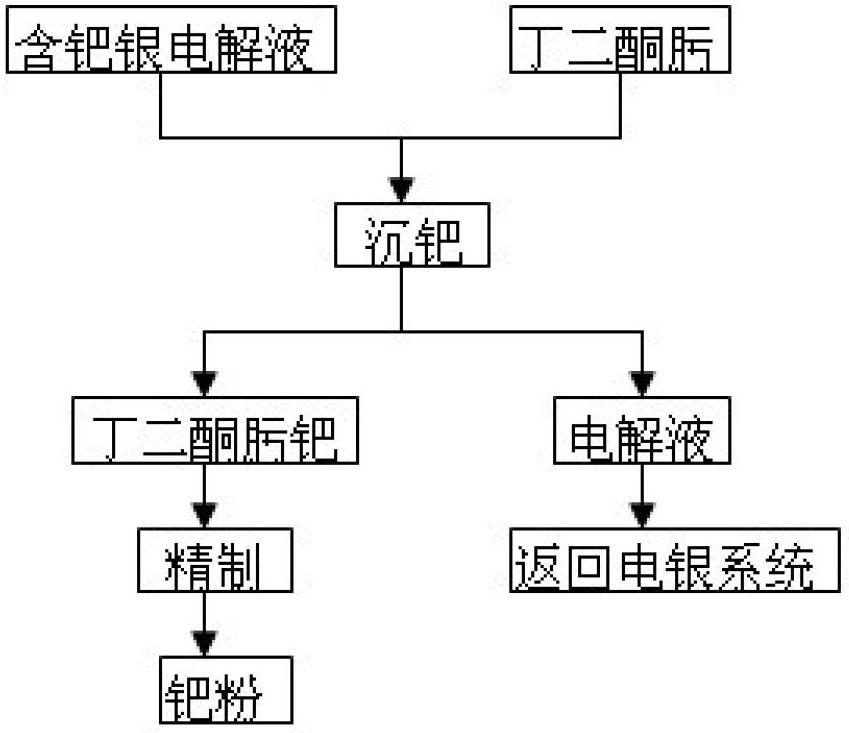

Method for recycling palladium from silver electrolyte by using dimethylglyoxime

InactiveCN102676837ANo heating requiredSimplify operating proceduresProcess efficiency improvementElectrolyteEthanol

The invention discloses a method for recycling palladium from a silver electrolyte by using dimethylglyoxime. The method comprises the following steps: adding dimethylglyoxime into a palladium-containing electrolyte for precipitating palladium; performing solid-liquid separation, returning filtrate as an electrolyte, and eluting filter residue with nitric acid acidification water to obtain a dimethylglyoxime palladium crude product; dissolving the dimethylglyoxime palladium crude product with aqua regia, and then precipitating palladium with ammonium chloride; eluting an obtained ammonium chloropalladate precipitate with an ammonium chloride solution until filtrate is colorless; and adding water, heating, and dissolving; filtering, and cooling filtrate; adding ammonia water, complexing and dissolving; cooling, filtering, and eluting the filter residue with ammonia water; adding hydrochloric acid for acidifying filtrate; filtering to obtain a diammonium dichloropalladite precipitate; and reducing the precipitate by hydrazine hydrate to obtain palladium sponge with the grade of 99.99%. Heating and pH regulation are not required, and only quantitative precipitation of palladium is required; the selectivity is good; and the precipitated dimethylglyoxime palladium can achieve a very high purity after simple eluting, so that the palladium purifying process is greatly shortened and the palladium recycling rate is improved; the using amount of dimethylglyoxime is low; and except a small amount of ethanol, other ions are not brought, so that the reuse of the electrolyte is not affected.

Owner:SIHUI CITY HONGMING PRECIOUS METALS

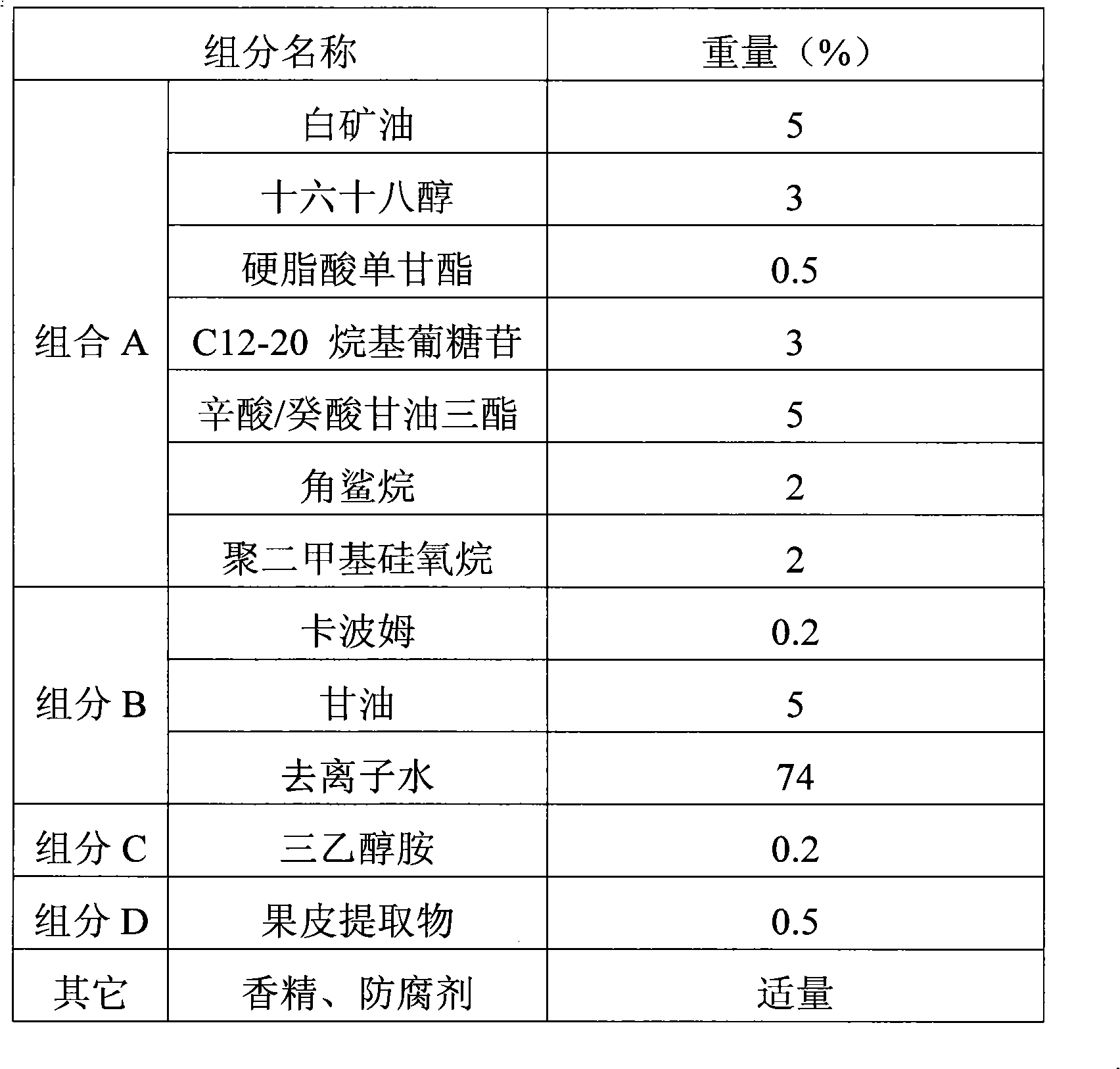

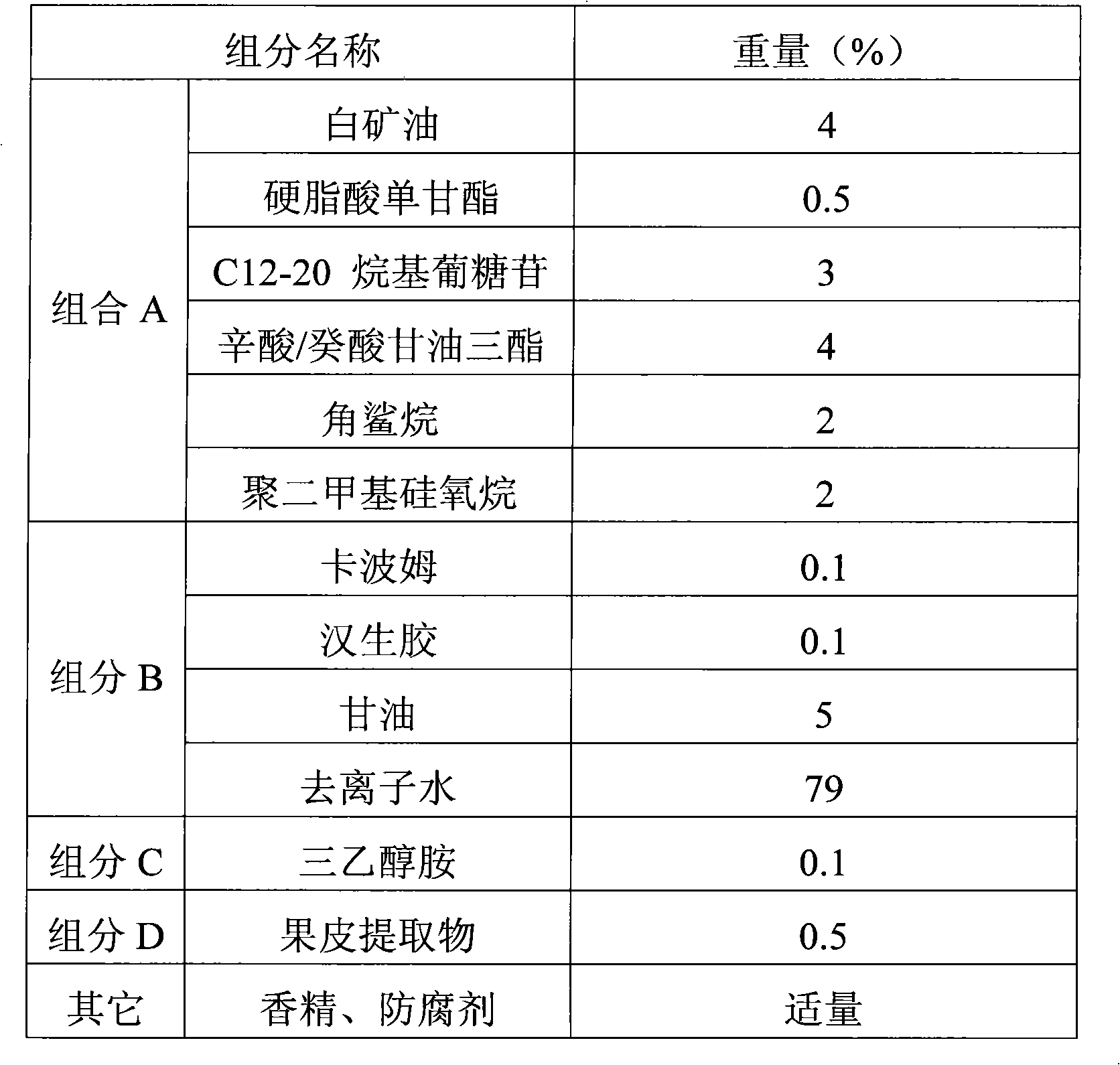

Water-solubility active extract in fruit skin, preparation method and use thereof

InactiveCN101336874AAbundant sourcesLow costCosmetic preparationsToilet preparationsSolubilityFlocculation

The invention relates to a water-soluble active extract derived from fruit peels, the preparation method and the application thereof. The fruit peel is treated by the steps of drying, pulverization, extraction, flocculation, separation and concentration, to prepare a water-soluble active extract. Then, the extract is added in cosmetic matrixes to allow a cosmetic to have skin-whitening and anti-skin ageing functions. The fruit peel extract is obtained after the screening of tyrosinase-inhibiting, antioxidant and free radical-scavenging activities in the water-soluble extracts of fruit peels such as Citrus peels, and has skin-whitening and anti-skin ageing effects. The water-soluble active extract has the advantages of easily-accessible raw materials, renewable resources and simple preparation method. The obtained extract has good stability and durable effect and serves as cosmetic additives in any stage of cosmetic production, without the risks of solvent residue and microbial contamination.

Owner:BEINONG BIOCHEM SUZHOU INDAL PARK

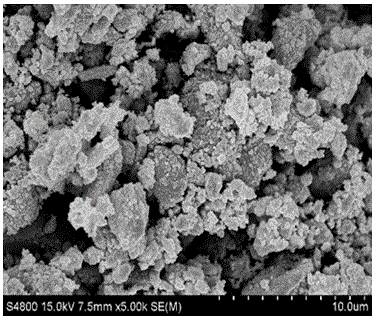

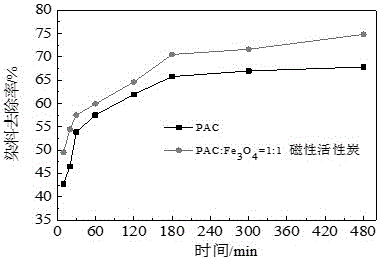

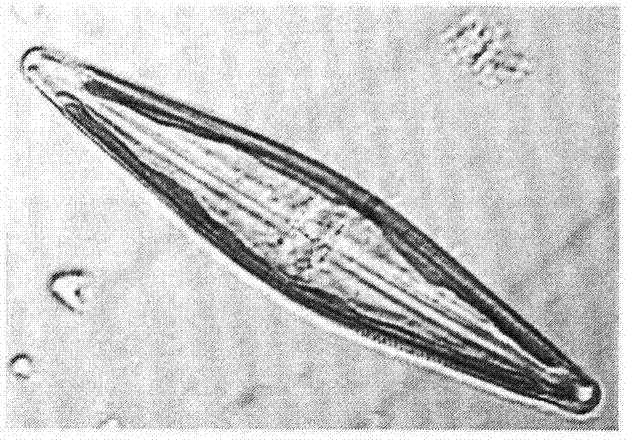

Novel magnetic active carbon and preparation method thereof

InactiveCN105126755AEfficient regenerationIncrease the saturated adsorption capacityOther chemical processesWater contaminantsActivated carbonLiquid medium

The invention discloses a novel magnetic active carbon and a preparation method thereof. The novel magnetic active carbon is a composite material of powdered active carbon (PAC) and nano iron oxide (Fe3O4). Reaction is finished by feeding an alkaline liquid medium into a reaction system Fe<3+> / Fe<2+> (mole ratio)=2 which takes the powered active carbon as a carrier by adopting a chemical co-precipitation method; the ratio of PAC to the iron oxide in the magnetic active carbon is adjusted by controlling the PAC feeding amount so as to optimize the performance of the material. The preparation method has the advantages of simple operation, quickness, batch production, high reproducibility and the like. The novel magnetic active carbon has the performances of large adsorption amount, easiness in separation, recycling and regeneration, good repeated use effect and the like; the problems that the conventional PAC is high in difficulty when separated from treated wastewater and easy to lose, and cannot be regenerated, and the treatment cost is high are well solved; regeneration can be easily and efficiently realized by feeding H2O2, so that the treatment cost of the adsorption technology is reduced, and the feasibility of application of the novel magnetic active carbon into actual engineering and the market competitiveness are improved.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION +1

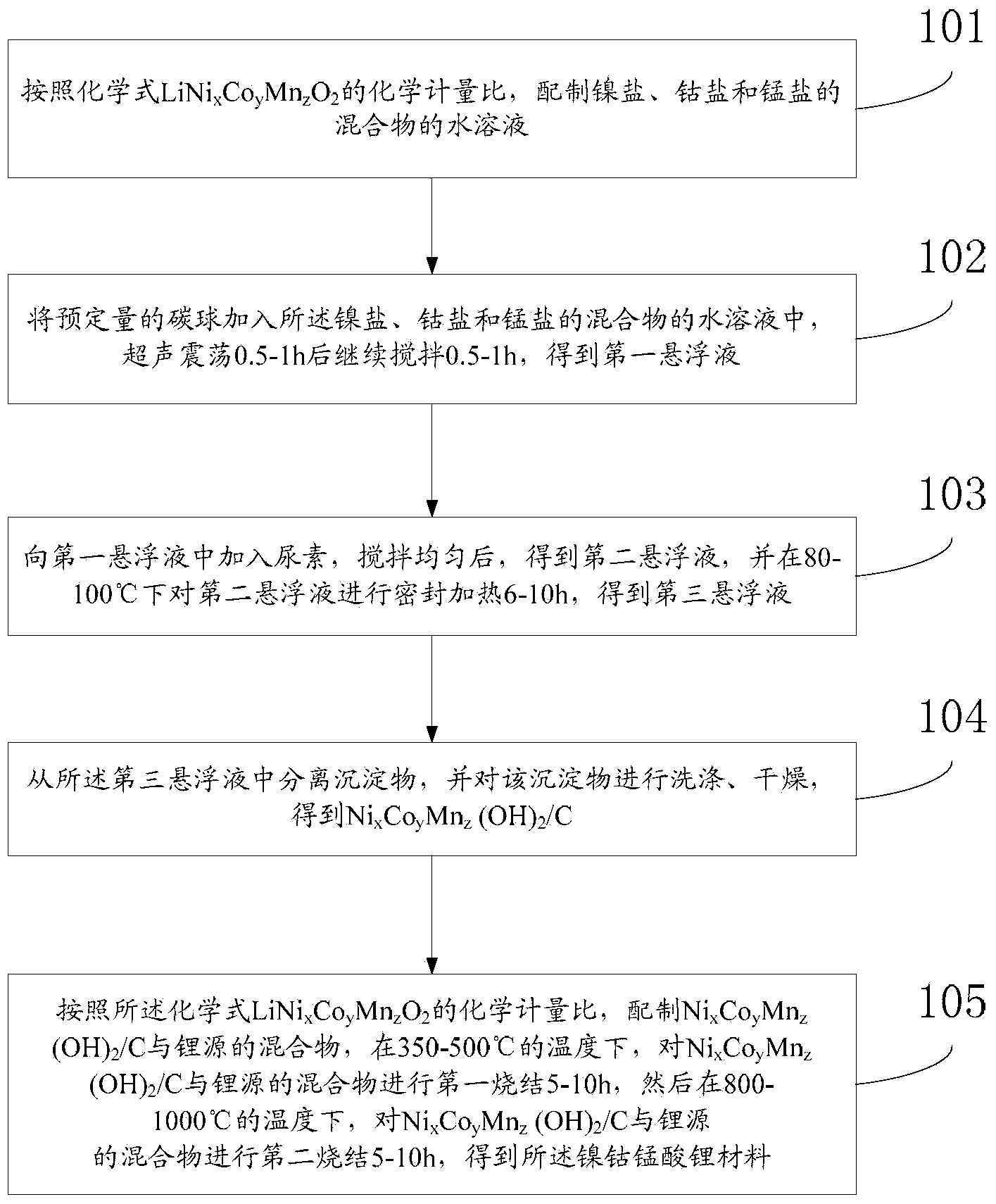

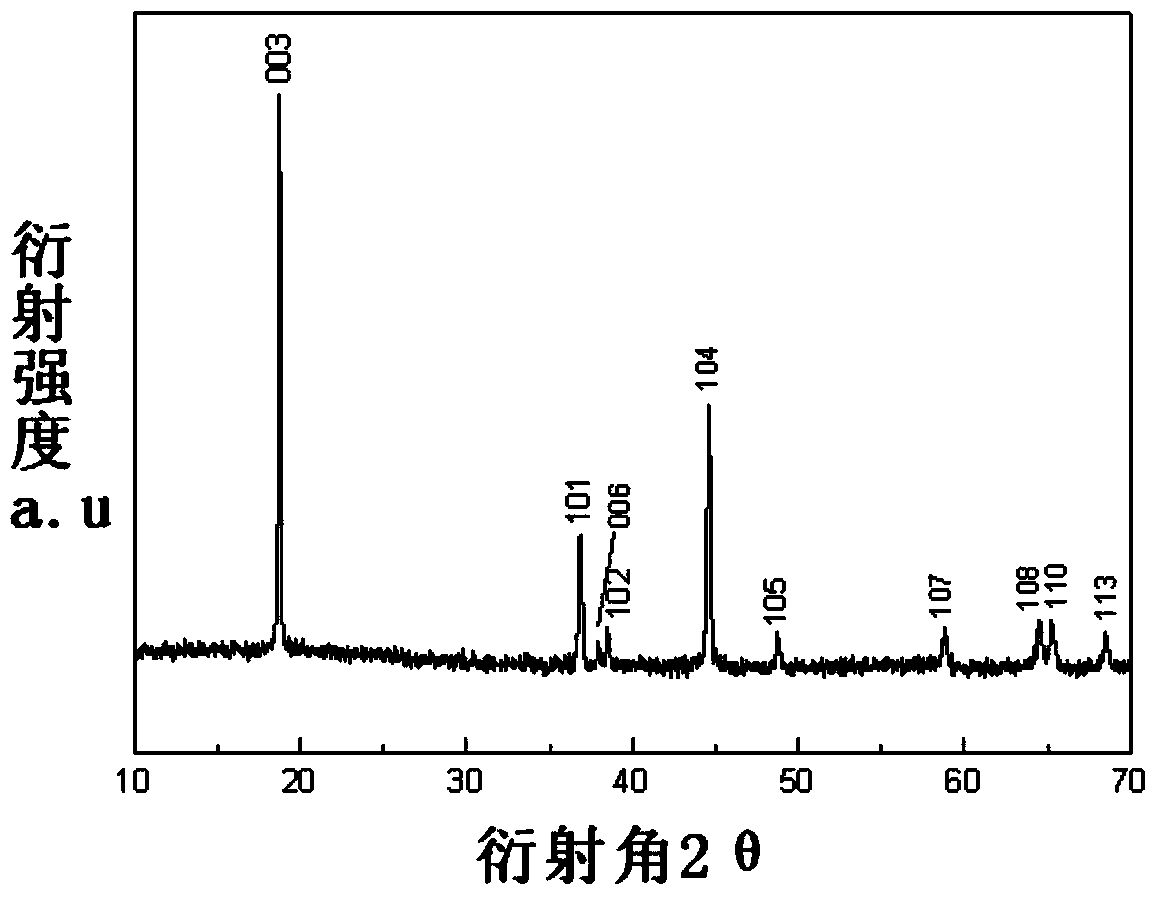

Lithium nickel cobalt manganate hollow sphere as well as preparation method and application thereof

ActiveCN104241630ALarge specific surface areaHigh specific capacityCell electrodesSecondary cellsElectrical batteryManganate

The invention discloses a lithium nickel cobalt manganate hollow sphere as well as a preparation method and an application thereof, belonging to the field of lithium ion battery anode materials. The specific surface area of the lithium nickel cobalt manganate hollow sphere is 150 to 250 m<2> / g. By adopting the lithium nickel cobalt manganate of the hollow spherical structure, on one hand, more lithium storage active sites can be provided, and high specific capacity can be achieved; on the other hand, the lithium nickel cobalt manganate of the hollow spherical structure is larger in specific surface area (150-250 m<2> / g), the diffusion way of the lithium ion can be reduced, and high multiplying power performance can be achieved.

Owner:CHERY AUTOMOBILE CO LTD

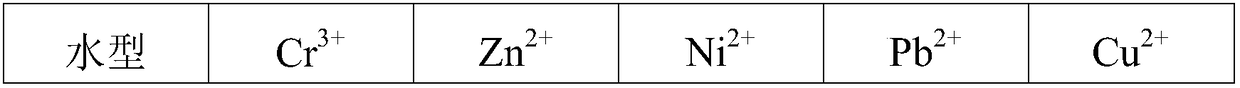

Method for treating electroplating integrated waste water

InactiveCN101549919AShort reaction timeImprove processing efficiencyWaste water treatment from metallurgical processMultistage water/sewage treatmentChemistryWaste pond

The invention relates to a method for treating electroplating integrated waste water. Aiming at overcoming the defects that the precipitation of heavy metal is not complete and treated electroplating waste water is difficult to reach a standard of the prior method of adopting a sodium hydroxide solution to regulate the pH value of the electroplating integrated waste water to precipitate the heavy metal in the electroplating waste water so as to treat electroplating integrated waste water, the invention provides the method for treating the electroplating integrated waste water, which ensures heavy metal precipitates completely and the treated electroplating waste water can reach a standard and is easy to operate and control. The method comprises the following steps: (1) the electroplating waste water is filled into an electroplating integrated waste water pond, and lime slurry is added and stirred to the electroplating waste water (2) ferrous sulfide is added to the supernatant fluid of the electroplating waste water treated by the lime slurry; (3) a PAC flocculating agent is added and stirred to the electroplating waste water; (4) a PAM flocculating agent is added to the electroplating waste water and stirred to the same for a while for naturally precipitation; and (5) the supernatant fluid of the electroplating waste water which reaches the standard is drained off, precipitate press filter is carried out, and filter liquid returns to the electroplating integrated waste water pond.

Owner:邵琳

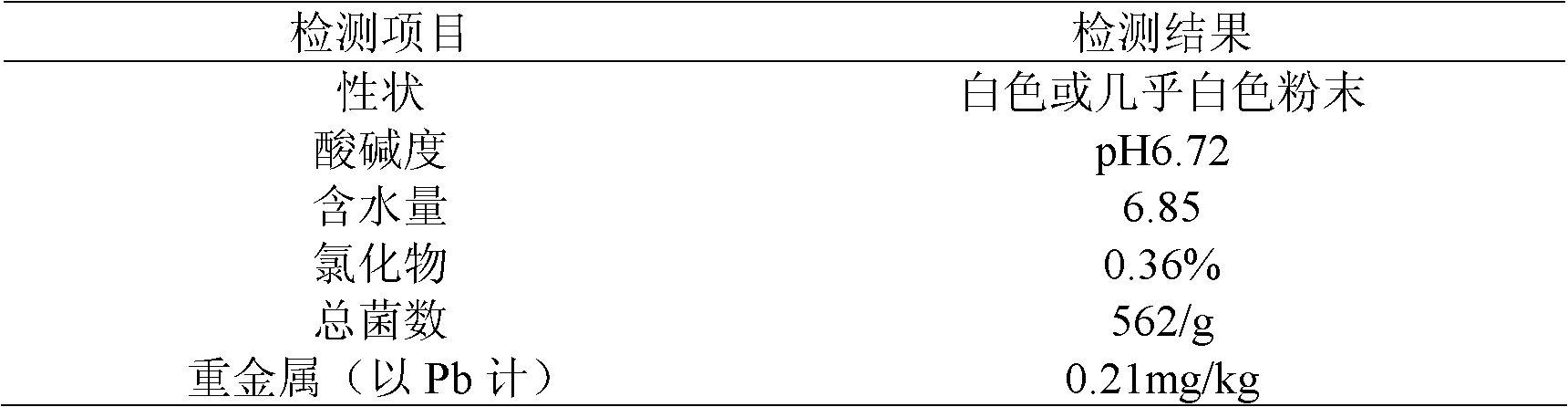

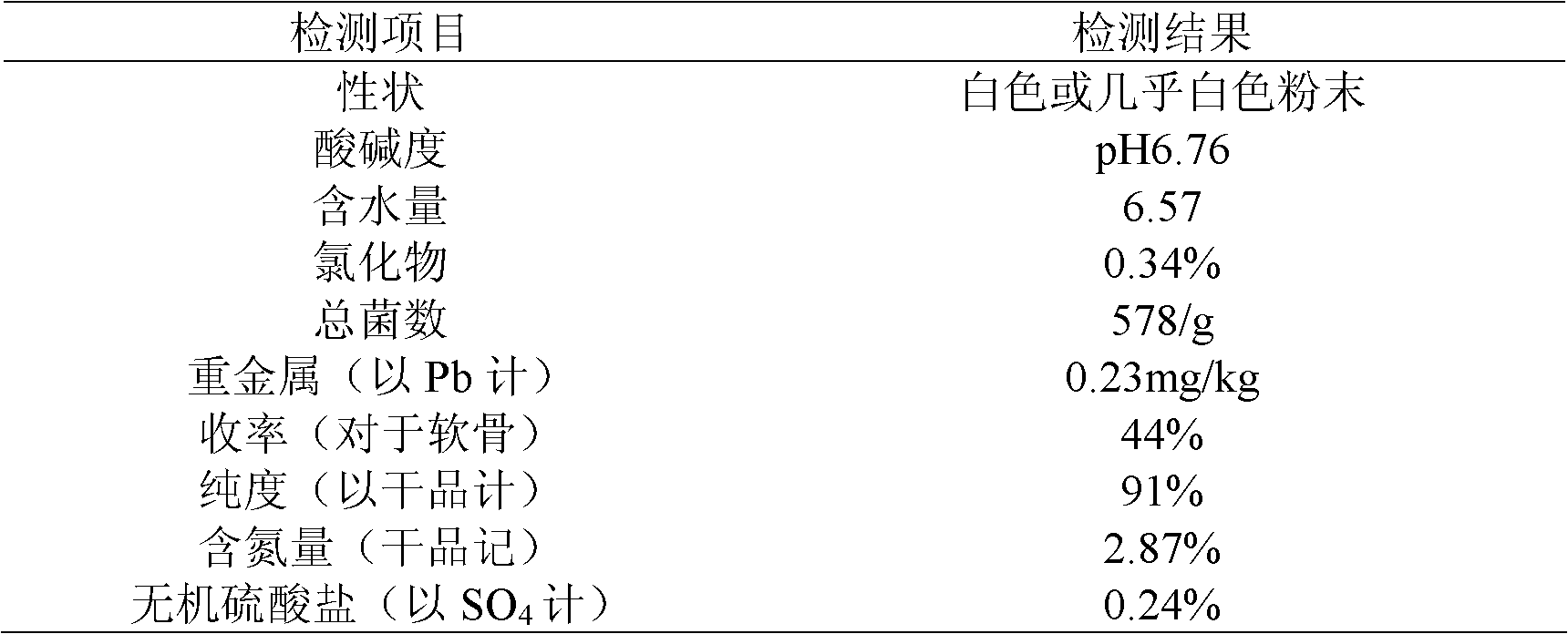

Process for extracting chondroitin sulfate from pigs

The invention provides a process for extracting chondroitin sulfate from pigs, which comprises: raw material treatment, enzymolysis, absorption decolorizing, salting of protein, alcohol precipitation and crystallization, vacuum drying and the like. In method disclosed by the invention, the extraction rate of chondroitin sulfate is taken as an index, a static optimizing method combining single factor experiment, factorial experiment and response overall analysis experiment is adopted to optimize the extraction process, the process conditions are reasonable, and the effect is very stable. The method has the advantages of extracting the chondroitin sulfate from pig gristles by one step of enzymolysis reaction, ensuring white product color and high product purity, avoiding pollution caused by alkaline extraction, contributing to environment protection, making industrial production easy, along with mild extraction conditions, short production period, and high extraction rate.

Owner:HUNAN WUXING BIOLOGICAL TECH CO LTD

Series cultivation and rapid collection method for marine microalgae

InactiveCN104593262AAvoid light damageReduce wasteUnicellular algaeMicroorganism based processesSurface oceanPhotobioreactor

The invention discloses a series cultivation and rapid collection method for marine microalgae, belonging to the field of aquaculture cultivation and solving the deficiencies that marine microalgae is originally cultivated by adopting a photobioreactor or an open cement pond, which is large in capital construction investment, complicated in technology, high in technical requirement, easy to pollution, troublesome to operate and low in efficiency. The sequential cultivation and rapid collection method for marine microalgae has the technical characteristics that the two microalgaes are mixedly bred so as to achieve mutual advantages and mutual promotion and reduce the resource waste; introduced gas can be utilized for three times by adopting the sequential cultivation of conical flasks, so that the energy can be saved and cannot be easily contaminated; after a compound precipitator is added, the microalgae liquid is stored in a dark environment at the low temperature of 5 DEG C, the collection efficiency is high, the nutrition is not lost, the operation is simple and the practicability is strong.

Owner:LINYI UNIVERSITY

Method for producing rare earth ferro-silicon raw material with fluorine containing alkali waste water

The invention relates to a wastewater treatment method during the rare-earth hydrometallurgy process, which obtains products that can be used as the material for smelting rare-earth silicoferrite. The method comprises the steps as follows: the rare-earth is acid-dipped, the slurry is stirred and mixed after being added with water; salt solution containing metal ions is added; fluorine-containing waste alkaline water is added in the mixture to form fluoride and hydroxide precipitate, and the addition amount is controlled according to the precipitated metal ion amount that is 10wt percent to 95wt percent; other precipitators are added in sequentially to precipitate the metal ions fully; water is added for washing until the pH value ranges from 7 to 8; solid is dried and dewatered at the temperature that ranges form 110 to 600 DEG C after solid-liquid separation; products can be used as the material for smelting the rare-earth silicoferrite after dehydration. In the waste water discharged in wastewater treatment method, the content of fluorine ion is less than 10mg / L, the pH value ranges from 8 to 9, and the waste water is neutral.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

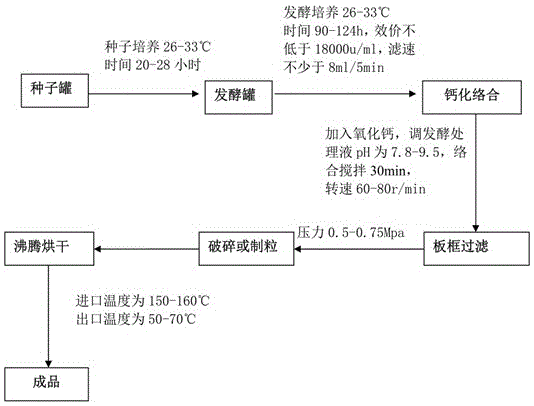

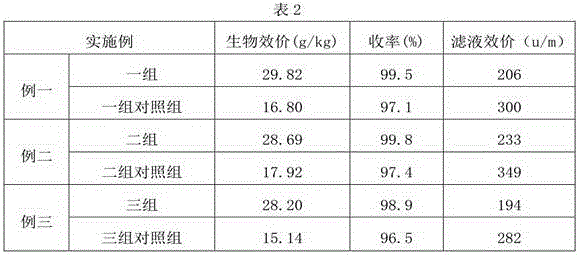

Extraction process of chlortetracycline premixed agent

InactiveCN106011212ASimple production processEasy to operateMicroorganism based processesCarboxylic acid amide separation/purificationFiltrationCalcification

The present invention discloses an extraction process of a chlortetracycline premixed agent. The process includes seed cultivation, fermentation cultivation and product refining. The product refining includes: taking a chlortetracycline fermentation liquid, adding calcium oxide; controlling the pH value of the fermentation liquid at 7.8 to 9.5, conducting complexation stirring under normal temperature for 30min at the speed of 60-80 r / min to obtain a calcification complexing liquid; and conducting plate filtration and boiling drying to obtain a finished chlortetracycline premixed agent. The extraction process can improve the quality, content and yield of the chlortetracycline premixed agent and reduce the production cost.

Owner:PUCHENG CHIA TAI BIOCHEM

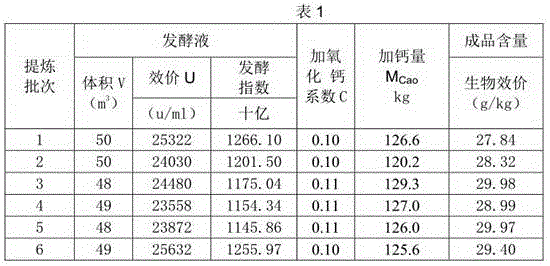

Preparing and feeding method for chlamys farreri larva baits

ActiveCN104719669APromote growthGrow fastClimate change adaptationAnimal feeding stuffWater storage tankPollution

The invention discloses a preparing and feeding method for chlamys farreri larva baits, and belongs to the field of aquaculture. In a chlamys farreri seedling growing process, the problems of tender physique of seedlings and low survival rate which are caused by inadequate baits exist. The technical key points of the preparing and feeding method are that four ocean microalgaes are aquacultured by magnetized water and blue light so as to prepare algae paste which is fed to chlamys farreri larva seedlings; the nutrition is comprehensive, the chlamys farreri larva grows fast and is strong in physique and high in survival rate; the microalgaes are cultured by the magnetized water, so that microalgae bodies grow fast and are pure in color; the microalgaes are cultured by a water storage tank, so that the cleaning is convenient, the cost is low, damage caused by collision seldom occurs, repeated use is realized, and pollution is basically avoided; with the adoption of blue light cultivation, the EPA and DHA contents in the microalgaes are high; the algae liquid is prepared into the algae paste for feeding, so that the feeding amount is easy to control, and a water body cannot be polluted; the baits can be produced all the year round, the occupied space is small, and the transportation and the storage are facilitated.

Owner:LINYI UNIVERSITY

Method for carrying out phosphorus removal on acidic vanadium-containing solution

ActiveCN104894374AGood phosphorus removal effectPrecipitation completeProcess efficiency improvementHydrogen peroxideSulfate

The invention relates to the field of phosphor removal of an acidic vanadium-containing solution, and discloses a method for carrying out phosphorus removal on the acidic vanadium-containing solution, wherein the method comprises the following step: under the condition with a pH value of 2.5-3.5, carrying out a contact process on the acidic vanadium-containing solution, hydrogen peroxide and zirconium sulfate. According to the method for carrying out phosphorus removal on the acidic vanadium-containing solution disclosed by the invention, the allowed concentration range of the acidic vanadium-containing solution is large, and the phosphor removal can be effectively carried out on the acidic vanadium-containing solution; moreover, the vanadium loss is relatively small when the phosphor removal is carried out.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

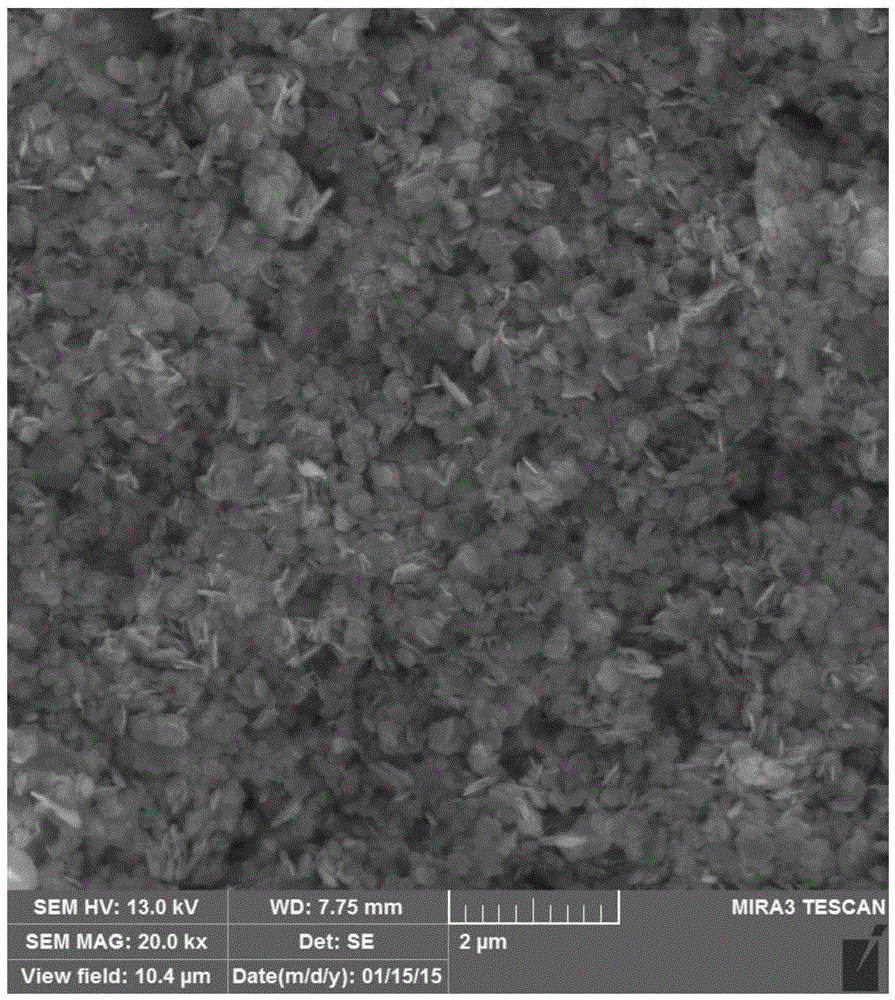

Method for preparing flaky nano CoO or Co3O4 through assistant microwave heating

ActiveCN105271443APrecipitation completeSimple processMaterial nanotechnologyCobalt oxides/hydroxidesAir atmosphereCobalt salt

The invention belongs to the technical field of new material preparation, and relates to a method for preparing flaky nano CoO or Co3O4 through assistant microwave heating. The method is characterized by comprising the following steps that 1, soluble cobalt salt is dissolved in deionized water to prepare a cobalt salt solution with the concentration of 0.2-1 mol / L, and 0.01%-0.1% ascorbic acid is added in the cobalt salt solution; 2, sodium hydroxide and stronger ammonia water are prepared into a mixed alkali solution in proportion, wherein the concentration of the sodium hydroxide in the mixed alkali solution is 2-4 mol / L, and the volume of the stronger ammonia water accounts for 0.5%-10% of the total volume of the mixed alkali solution; 3, the mixed alkali solution is added in the cobalt salt solution, stirring reacting is performed for a period of time under microwave heating, filtering, washing and drying are performed, and then solid dried substances are obtained; 4, the solid dried substances are placed in a chamber electric furnace or microwave sintering furnace for a solid-phase reaction in an inert atmosphere or air atmosphere, and then the flaky nano CoO or Co3O4 is obtained. According to the method, precursors are synthesized through microwave assistant heating, the precursors do not need to be processed through ball milling after being dried, and after calcining is performed, the uniform flaky nano CoO or Co3O4 can be obtained.

Owner:江西省钨与稀土产品质量监督检验中心(江西省钨与稀土研究院)

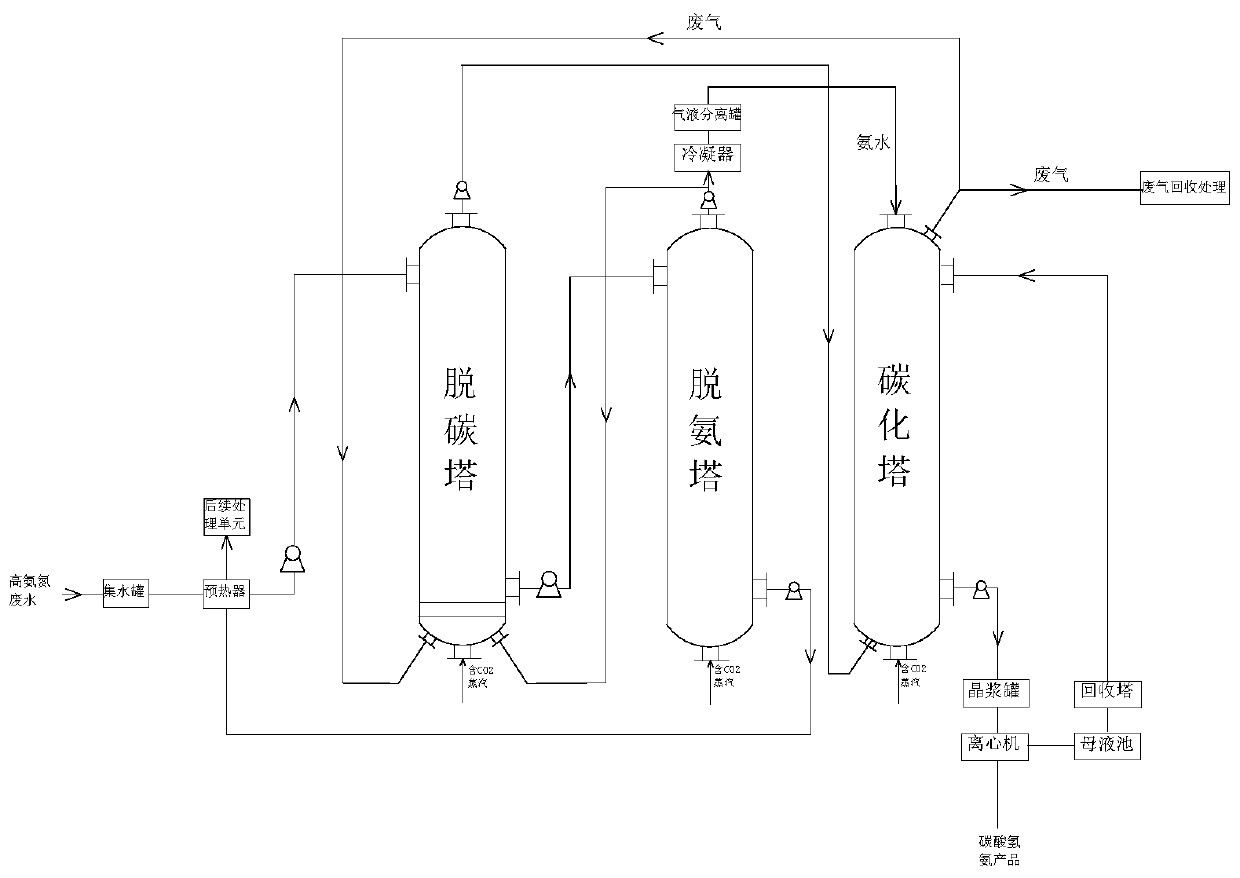

Ammonia recovery method of high-ammonia-and-nitrogen waste water

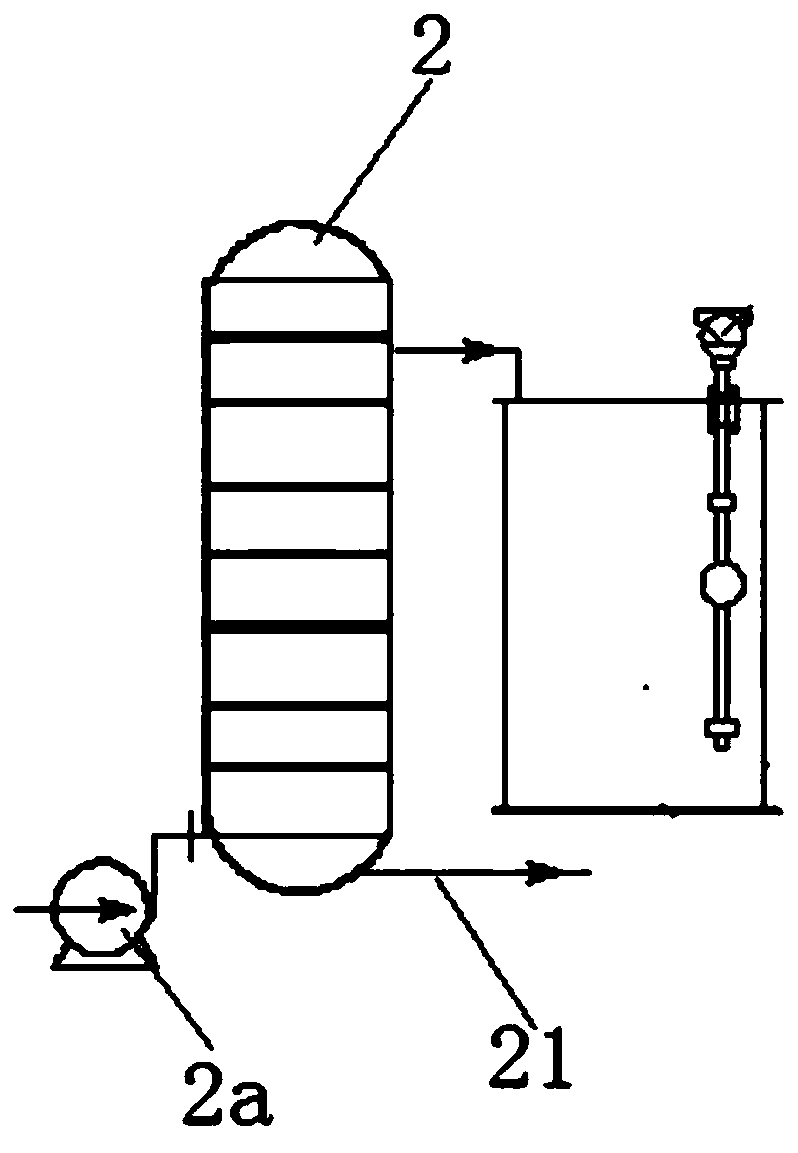

ActiveCN109879510APrecipitation completePrevent sedimentation and scalingWater contaminantsAmmonium carbonates/bicarbonatesRecovery methodHigh concentration

The invention discloses an ammonia recovery method of high-ammonia-and-nitrogen waste water, and belongs to the technical field of sewage treatment. The ammonia recovery method comprises the steps: firstly, the high-ammonia-and-nitrogen waste water passes through a decarburization tower where carbon-dioxide-containing steam and ammonia-containing steam are introduced, and calcium and magnesium ions in the waste water are removed; then the high-ammonia-and-nitrogen waste water passes through a deamination tower, steam-stripping deamination is carried out at 80-90 DEG C, ammonia and nitrogen inthe waste water enter a steam phase, high-concentration ammonia-containing mixed steam is formed and collected at the top of the deamination tower, one part of the ammonia-containing mixed steam flowsback to the decarburization tower, and the remaining part of ammonia-containing mixed steam is introduced into a condenser to be condensed and then subjected to gas-liquid separation; and finally, effluent of the deamination tower enters a subsequent treatment facility to be subjected to biochemical treatment, separated ammonia water enters a carburization tower where the carbon-dioxide-containing steam is introduced, and ammonium bicarbonate is formed and serves as a recycled product. By adopting the method for high-ammonia-and-nitrogen waste water treatment and ammonia recovery, the deamination effect and ammonia recovery efficiency of the high-ammonia-and-nitrogen waste water can be improved greatly, and additionally treatment equipment can further be prevented from being scaled.

Owner:TONGJI UNIV

Preparation method of environment-friendly bait for pinna

ActiveCN104782933AFormulation ScienceReasonable formulaFood processingUnicellular algaeGARLIC POWDERPorcine blood

The invention discloses a preparation method of environment-friendly bait for pinna and belongs to the field of aquaculture. The method is characterized in that high quality benthic diatom is cultured by an optimized culture medium, magnetized water, green light, palm bark, a glass goldfish bowl and the like, and then the mixed bait for the pinna is prepared by taking the benthic diatom as a major component and adding a small amount of sheep manure, rabbit manure, porcine blood powder, yeast powder, corn distiller, potamogeton malaianus powder, water caltrop powder, hydrilla varticillata powder, bone tankage, earthworm powder, fly maggot powder, artemia powder, kelp powder, garlic powder, methionine, lysine, potato powder, locust powder, lucerne meal, clam worm powder, trash fish and spiral shell meat meal. The bait is scientific and reasonable in formulation, nutrient-rich and lower in cost, is used for feeding the pinna and does not pollute water, the pinna grows quickly, has a strong constitution and is high in survival rate, and the yield is increased by 160%.

Owner:江西鑫臻科技有限公司

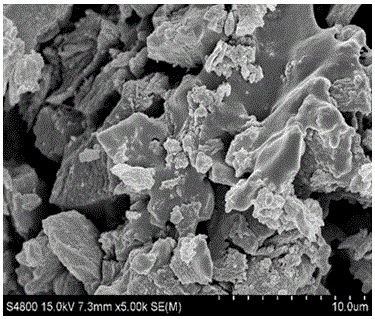

Preparation method of antimony doped nanometer stannic oxide powder

ActiveCN107758741AFacilitate blendingLower surface energyMaterial nanotechnologyAntimony oxides/hydroxides/oxyacidsDispersityAlcohol

The invention discloses a preparation method of an antimony doped nanometer stannic oxide powder. The preparation method comprises the following steps: (1) mixing an antimonic salt and a tin salt, dissolving in an ethyl alcohol solution, and conducting ultrasonic concussion for 10-20 minutes at the room temperature to obtain a solution A; sequentially dissolving butanetetracarboxylic acid and ammonium dihydrogen phosphate into deionized water to obtain a solution B; (2) mixing the solution A and the solution B, conducting ultrasonic concussion for 5-10 minutes at the room temperature, adding alkali and diethanol amine at the stirring state, enabling the pH of the solution to reach 8-9, heating to 65-75 DEG C, reacting for 2-4 hours to obtain a precipitate precursor; and (3) washing, dryingand calcining the precipitate precursor to obtain the antimony doped nanometer stannic oxide powder. The prepared antimony doped nanometer stannic oxide powder is even in particle size distribution and good in dispersity, the average particle size of the prepared antimony doped nanometer stannic oxide powder is less than 120 nm, the electrical resistivity is less than 25 ohm.cm, the specific surface area is 4-6 m<2> / g, and the electrical conductivity is excellent.

Owner:广西生富锑业科技股份有限公司

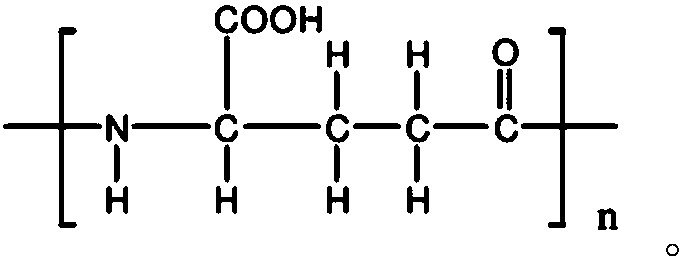

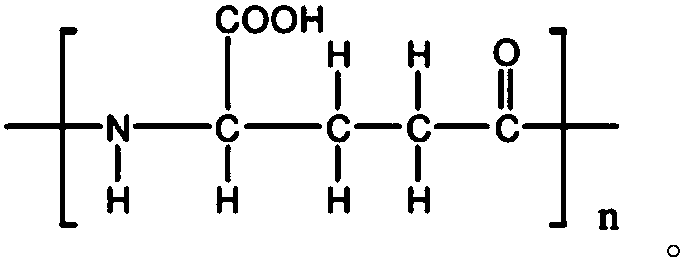

Biological composite flocculating agent for adsorbing heavy metal ions in heavy metal wastewater and applications thereof

InactiveCN108217893AImprove adsorption capacityIncrease the scope of applicationOther chemical processesWater contaminantsAluminium chlorohydrateWastewater

The invention relates to a biological composite flocculating agent for adsorbing heavy metal ions in heavy metal wastewater and applications thereof. The composite flocculating agent is prepared by compounding polyglutamic acid, polymeric aluminum chloride, and poly(aspartic acid) according to a weight ratio of 1: 4-6: 15-17. When the flocculating agent is used, at first, the pH value of heavy metal wastewater is adjusted to 6-9; then the biological composite flocculating agent is added into the heavy metal wastewater, the system is vibrated and stirred for 15 to 20 minutes, after vibration and stirring, centrifugal separation or static settlement is performed, and the flocculent precipitates that adsorb heavy metal ions are recovered and processed. The adsorbing performance and application range of the biological composite flocculating agent are both enhanced. The processing mode is simple and environmentally friendly. Furthermore, polyglutamic acid and poly(aspartic acid) can be easily degraded by organisms and will not generate secondary pollution; the preparation and application are convenient, and the cost is low.

Owner:水友环保技术(苏州)有限公司

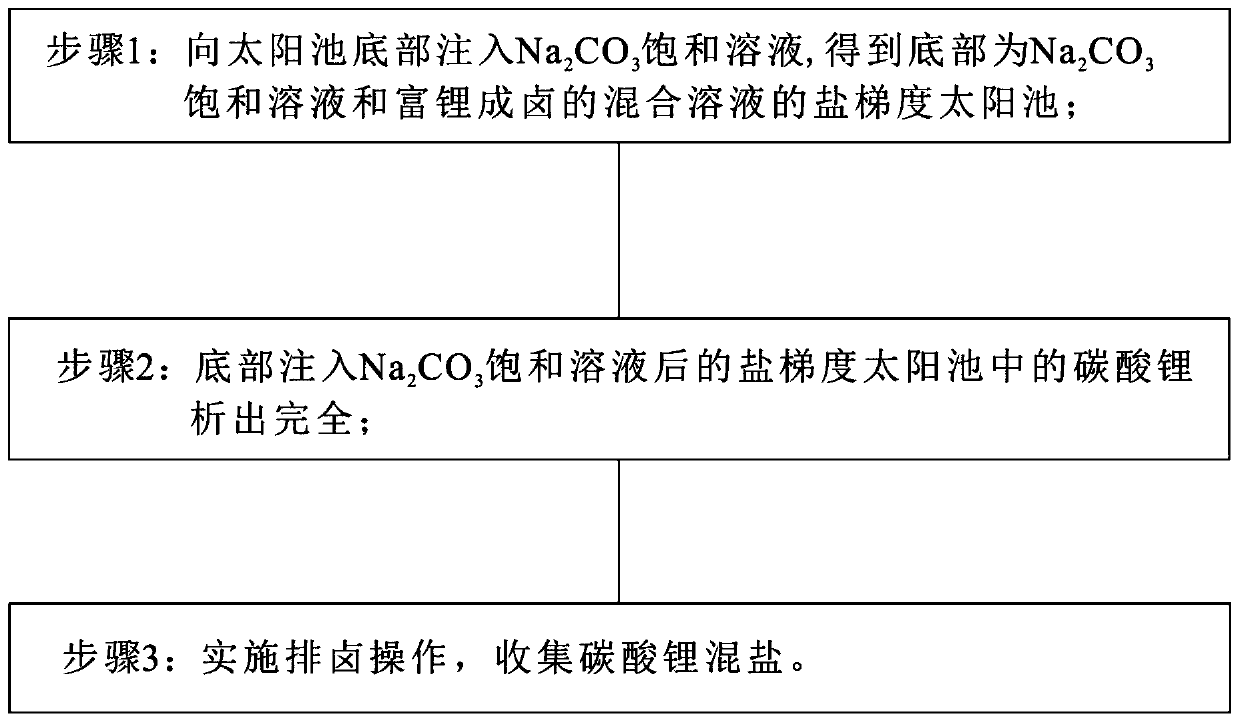

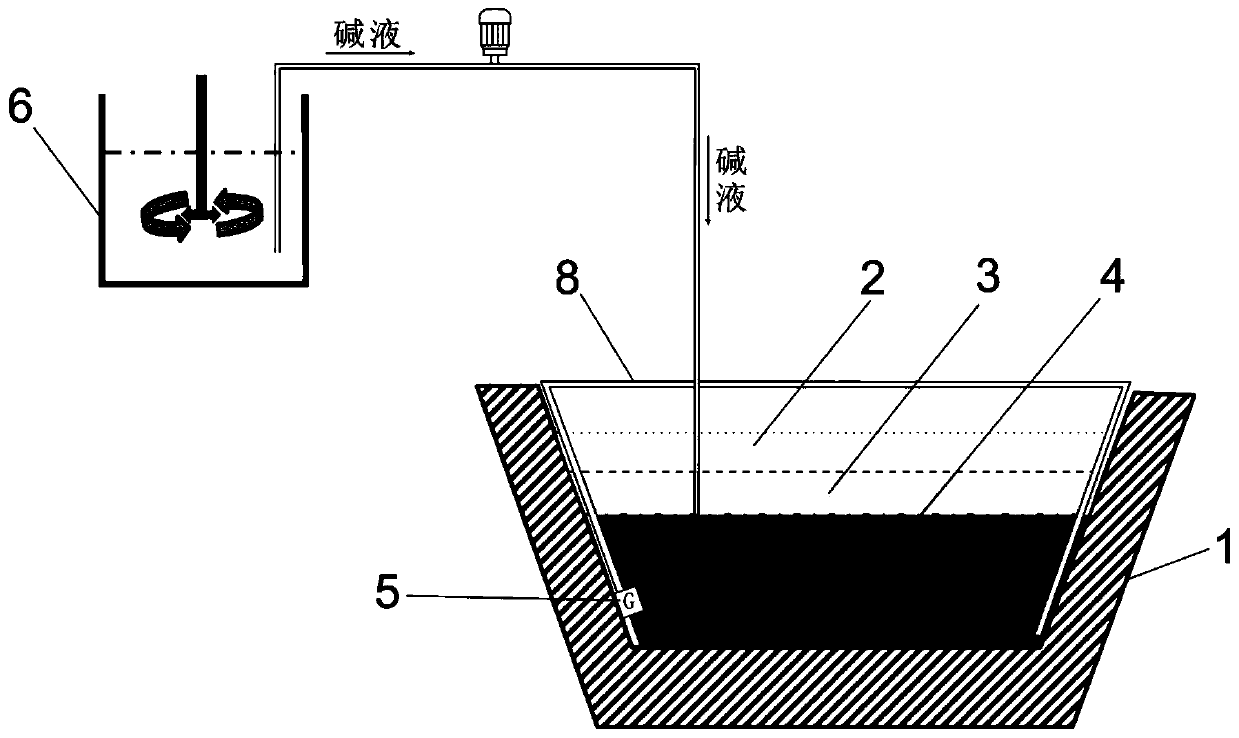

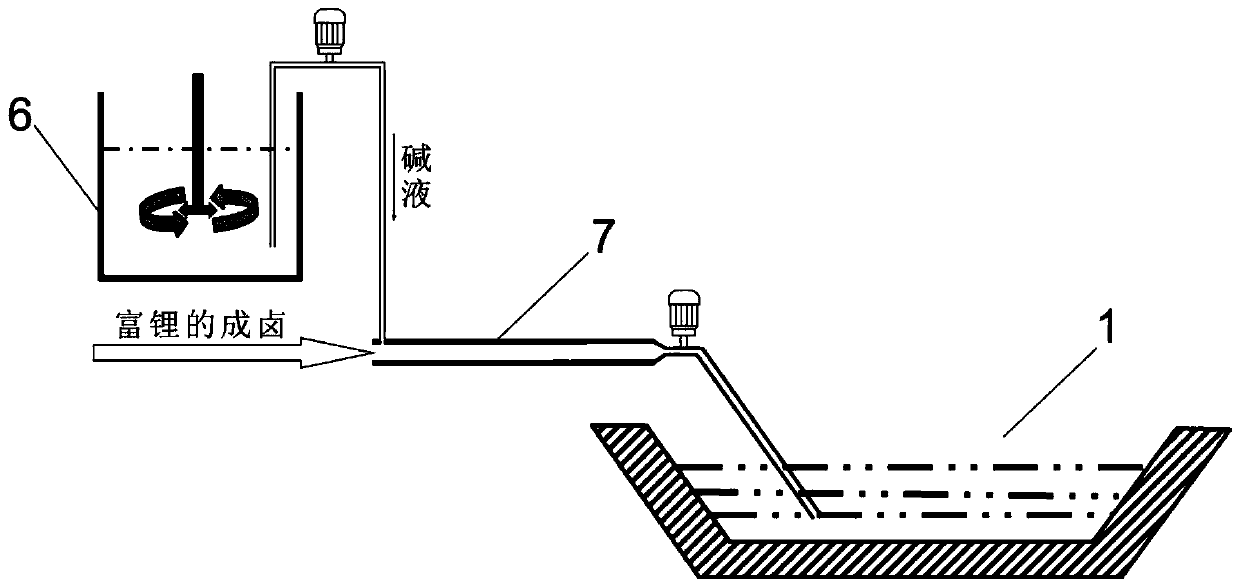

Solar pond lithium extraction method

ActiveCN111470521AHigh yieldRaise the gradeEnergy inputLithium carbonates/bicarbonatesLithium carbonateSolar pond

The invention relates to a solar pond lithium extraction method, belongs to the technical field of carbonate type salt lake lithium extraction, and solves the problem that the lithium yield of methodsusing carbonate type salt lake high-Li<+> and low-CO3<2-> brine as raw materials and using a traditional solar pond heating lithium precipitation method is low. The disclosed method comprises the following steps: step 1, injecting a Na2CO3 saturated solution into the bottom of a solar pond to obtain a salt gradient solar pond of which the bottom is a mixed solution of the Na2CO3 saturated solution and a lithium-rich brine; step 2, completely separating out lithium carbonate in the salt gradient solar pond after injecting the Na2CO3 saturated solution into the bottom of the salt gradient solarpond; and step 3, implementing bittern discharging operation, and collecting the lithium carbonate mixed salt. The method is suitable for all solar ponds, is easy to operate, is economical and environment-friendly, and can greatly improve the yield and grade of lithium carbonate mixed salt in a single pond.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Method for repairing heavy metal contaminated soil

InactiveCN110293120AGood repair effectHigh in nutrientsContaminated soil reclamationOrganic fertilisersSodium polyacrylateContaminated soils

The invention relates to the field of soil repairing, and provides a method for repairing heavy metal contaminated soil aiming at the problem that an existing repairing method of heavy metal contaminated soil easily causes secondary influence on the environment. According to the technical scheme, the method comprises the following steps of S1, crushing the soil; S2, adding a heavy metal eluent andammonium hydroxide for elution; S3, adjusting the pH and fishing suspended matter; S4, filtering out the metal eluent, sun-drying the soil, and then completing soil repairing, wherein the heavy metaleluent is prepared from, by mass, 50-55 parts of chitosan, 60-65 parts of water, 15-22 parts of sodium polyacrylate and 10-15 parts of aloe fiber powder. All the components of the heavy metal eluentare poisonless and harmless, the source is natural, and thus the environment is unlikely to get influenced; meanwhile, heavy metal precipitant is fished for centralized treatment, so that the situation does not easily occur that heavy metal eluted out of the soil is re-discharged to the environment and influences the environment accordingly.

Owner:粤风环保(广东)股份有限公司

Nickel-manganese-based positive electrode material precursor and synthesis method of positive electrode material thereof

ActiveCN111498914AImprove filtering effectOvercome timeSecondary cellsPositive electrodesNickel saltLithium hydroxide

The invention belongs to the field of lithium ion battery material preparation, and particularly relates to a nickel-manganese-based positive electrode material precursor and a synthesis method of a positive electrode material of the nickel-manganese-based positive electrode material precursor. The synthesis method comprises the following steps: 1) adding a soluble T salt, a soluble nickel salt and a soluble manganese salt into deionized water, and preparing a metal salt solution in proportion; 2) preparing a precipitant solution from sodium hydroxide, potassium hydroxide or lithium hydroxide;3) adding pure water, metal powder or metal oxide into a precipitation reactor, then respectively heating the metal salt solution and the precipitant solution, and then adding into the precipitationreactor for coprecipitation reaction, and filtering the reaction product while hot; and finally, stirring and washing the filtered precipitate with deionized water, and carrying out vacuum drying treatment to obtain the nickel-manganese-based positive electrode material precursor. The precursor and a lithium source are mixed, pre-roasted and calcined at high temperature, the prepared positive electrode material is perfect in layered structure, good in crystallization degree and stable in electrochemical performance, and the charge-discharge capacity of the positive electrode material reaches 200 mAh / g or above.

Owner:SICHUAN UNION SHINE NEW ENERGY SCI TECH CO LTD

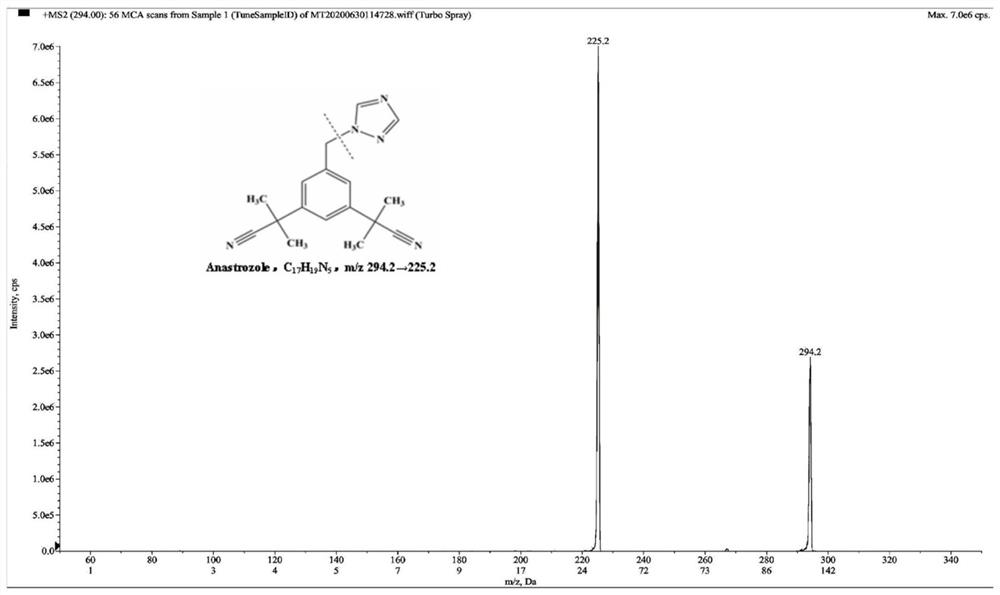

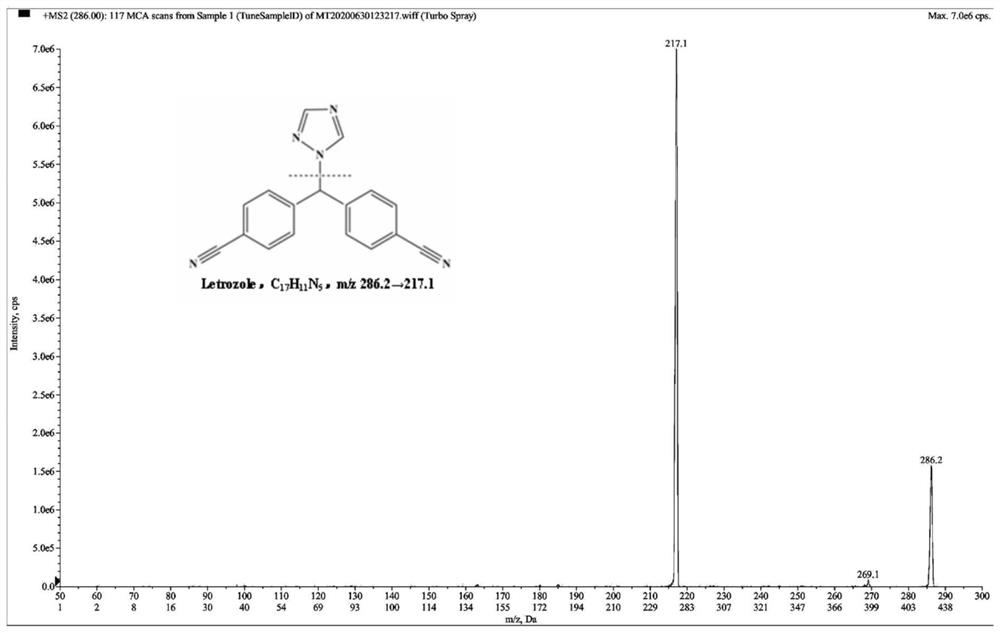

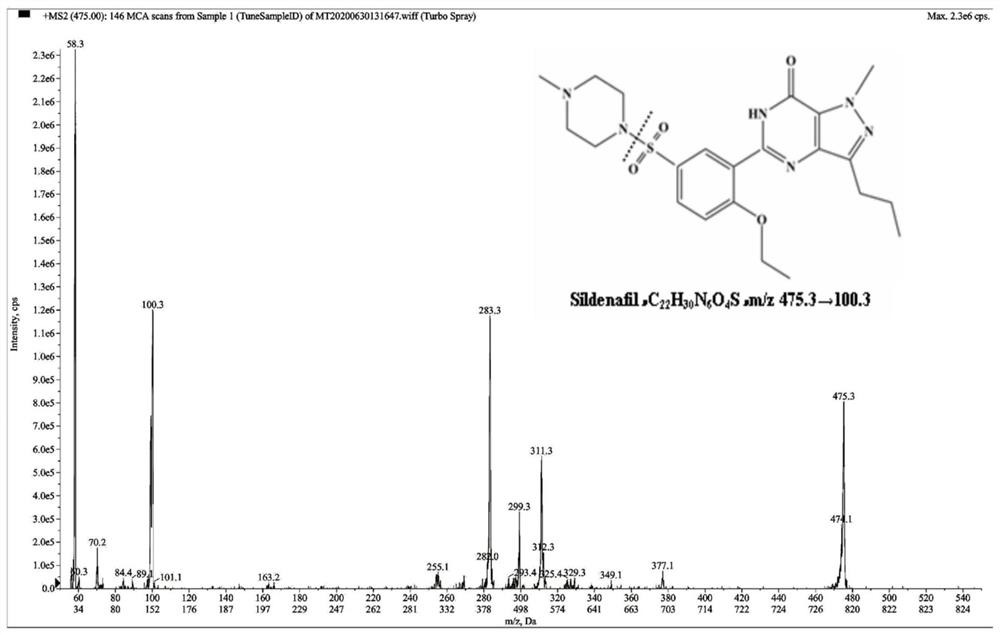

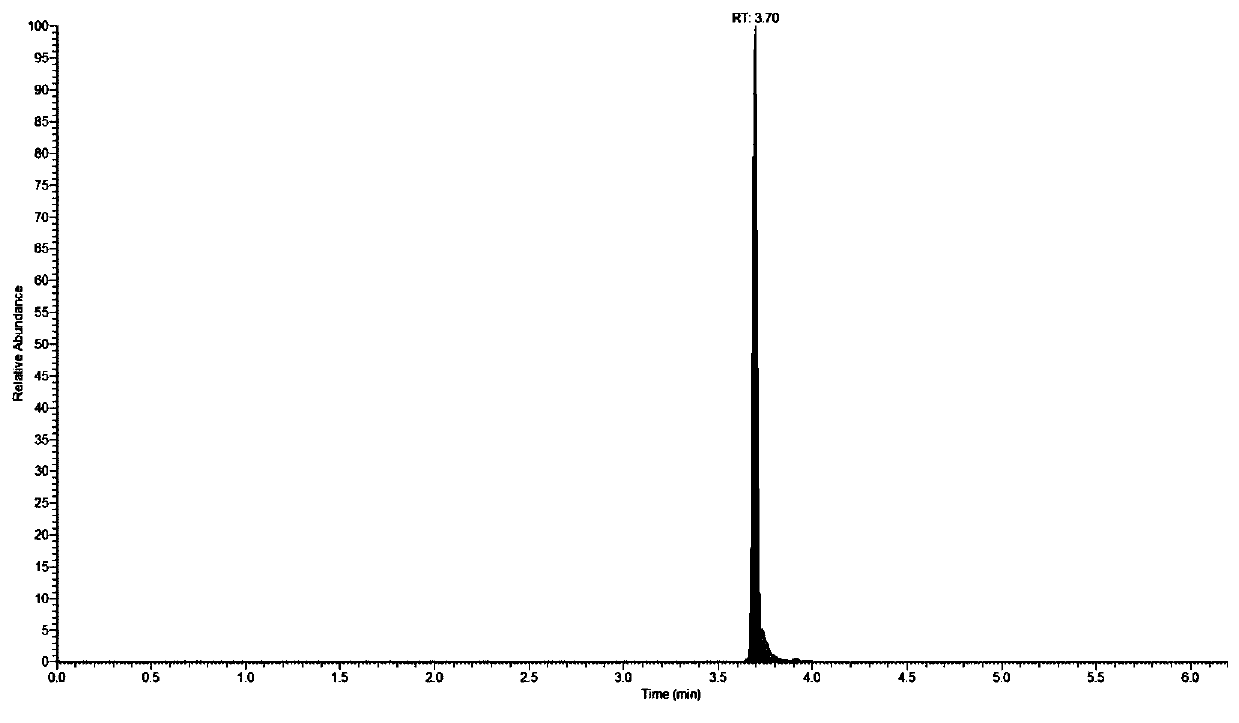

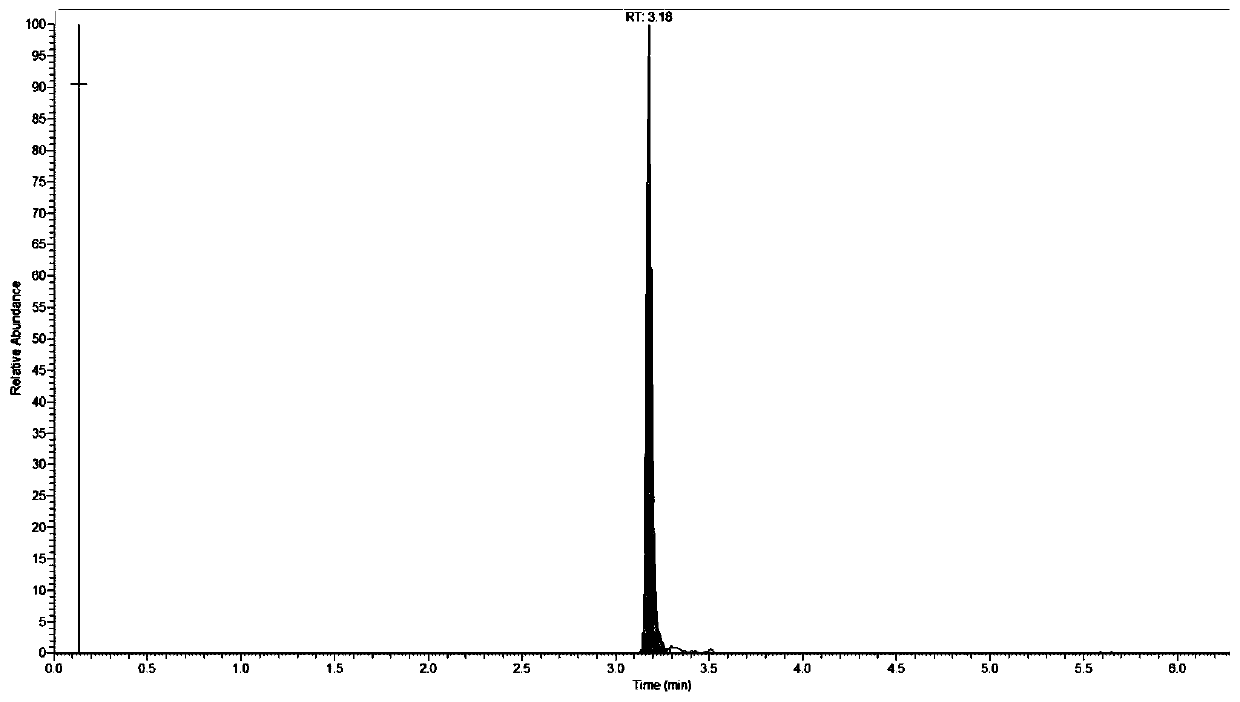

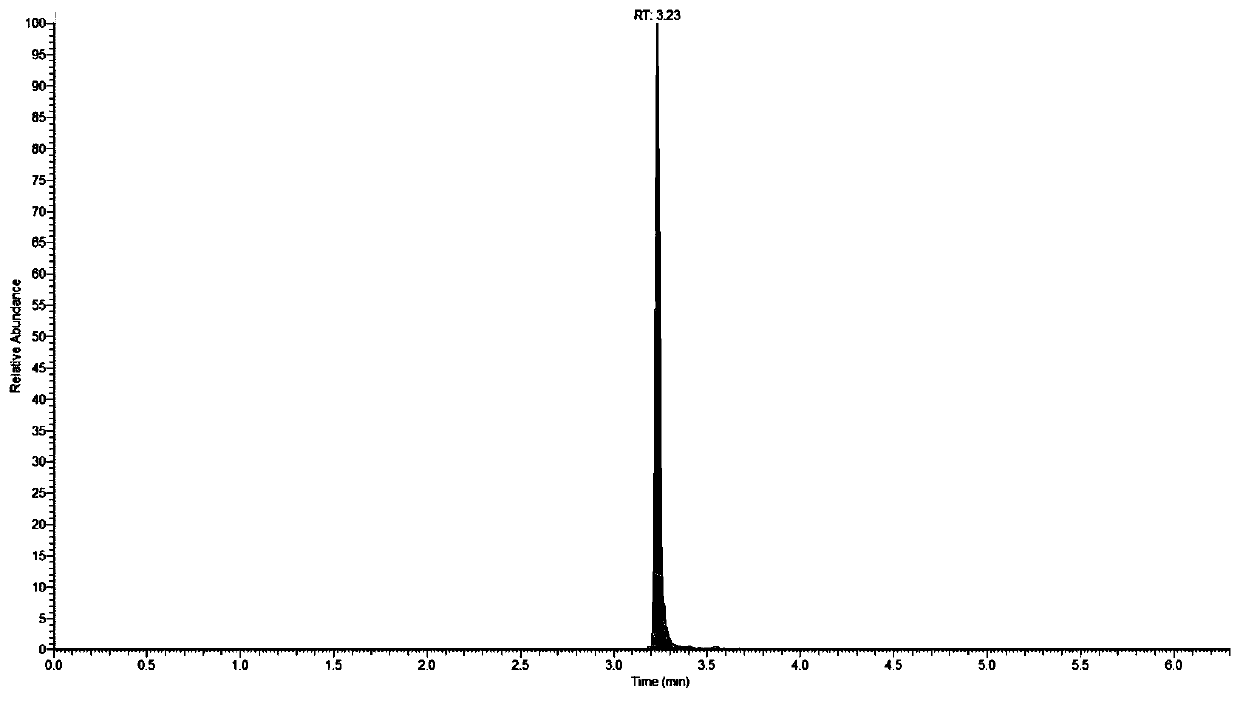

Method for simultaneously detecting concentration of aromatase inhibitor, type 5 phosphodiesterase inhibitor and metabolites of aromatase inhibitor and type 5 phosphodiesterase inhibitor in human plasma

ActiveCN113155992ADetect without interferenceHigh selectivityComponent separationMetabolitePhosphodiesterase inhibitor

The invention provides a method for simultaneously a detecting concentration of aromatase inhibitor, a type 5 phosphodiesterase inhibitor and the metabolites of the aromatase inhibitor and the type 5 phosphodiesterase inhibitor in human plasma. The method comprises the following steps of: adding a protein precipitant into a human plasma sample to precipitate protein in the human plasma sample; measuring the obtained sample solution by high performance liquid chromatography-mass spectrometry; determining the aromatase inhibitor, the 5 type phosphodiesterase inhibitor and the metabolites thereof in the sample solution according to retention time; and performing quantifying by adopting an internal standard curve method so as to determine the concentrations of the aromatase inhibitor, the 5 type phosphodiesterase inhibitor and the metabolites thereof in the sample solution. The method not only is simple and rapid and accurate in quantification, but also has the advantages of high sensitivity, high selectivity, good repeatability, high recovery rate and the like, and meets the clinical large-batch biological sample analysis requirements of simple operation, reliable data and controllable conditions.

Owner:金橄榄科技(上海)有限公司

Method for preparing lysionotin from lysionotus pauciflorus medicinal material

The invention provides a method for preparing lysionotin from lysionotus pauciflorus medicinal material. The method is characterized in that dry leaves of lysionotus pauciflorus are taken, crushed and placed in continuous reflux ultrasonic extraction equipment to be subjected to ultrasonic extraction, extract is extracted once to twice by the aid of ethyl ether, a water layer is taken to be acidified, filtered sediment is sequentially washed for twice to three times by the aid of water and diluted alcohol, then is dissolved by the aid of acetone and is crystallized for twice to three times, and crystal products are obtained. The method is simple in operation and low in energy consumption, production cost is lowered, environmental pollution is reduced, and accordingly the method has an industrial significance.

Owner:苏州宝泽堂医药科技有限公司

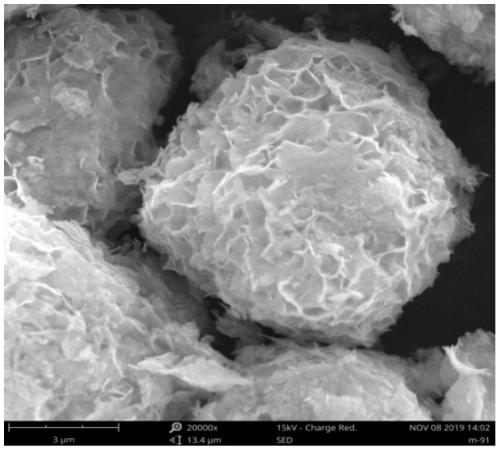

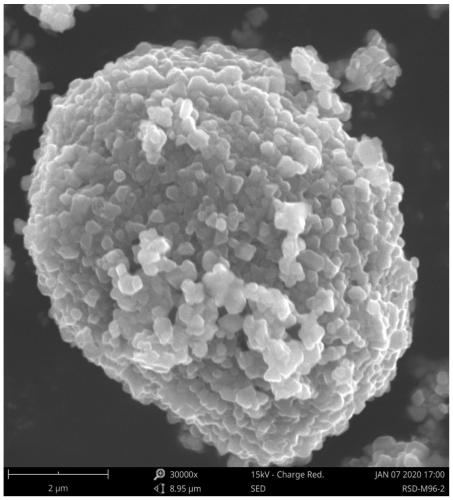

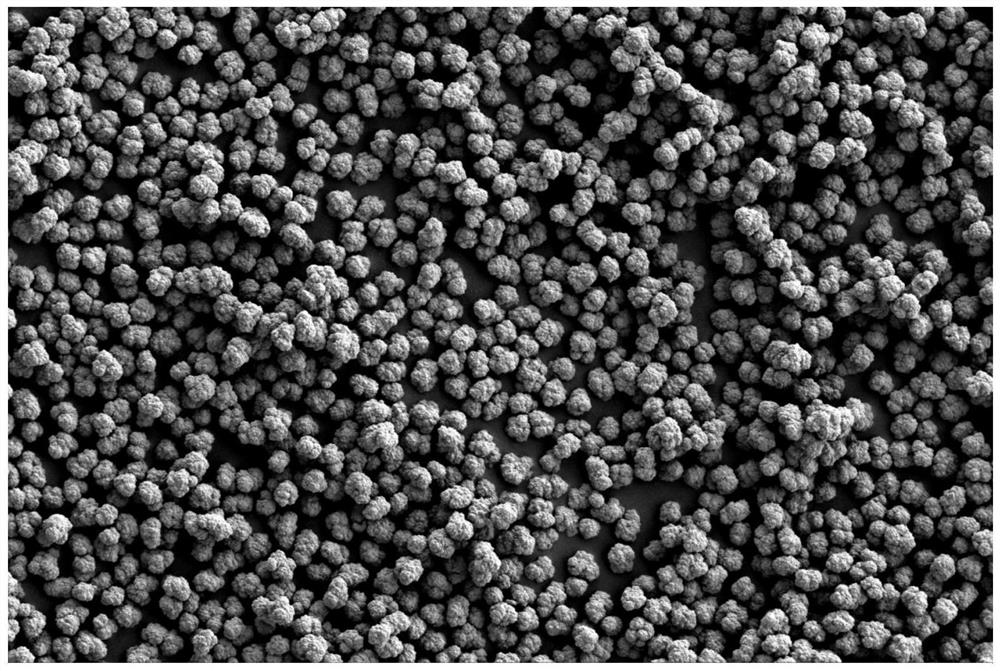

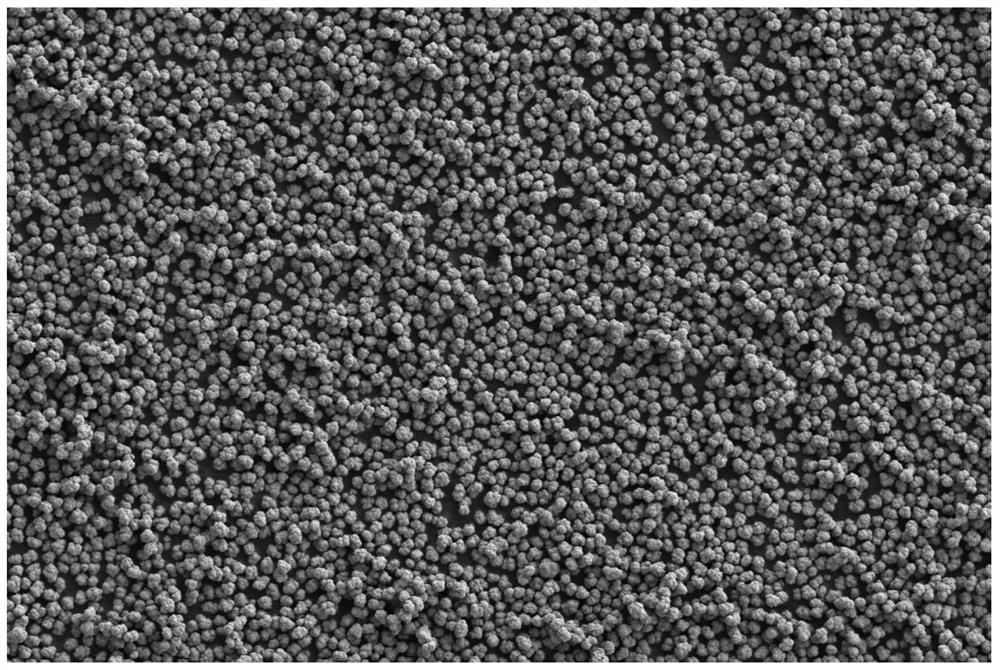

Preparation method of homogeneous-phase aluminum-doped small-particle-size cobaltosic oxide

ActiveCN112357970AReduced activityEffectively control the degree of bindingCell electrodesSecondary cellsCobalt(II,III) oxidePhysical chemistry

The invention relates to the technical field of preparation of lithium ion battery precursor cobaltosic oxide, in particular to a preparation method of homogeneous-phase aluminum-doped small-particle-size cobaltosic oxide. According to the method, a composite complexing agent is adopted to balance the reaction rate of Co <2+> and Al <3+> in the system, so that Co <2+> and Al <3+> can be subjectedto homogeneous coprecipitation, and the purpose of uniformly doping aluminum is achieved, by adopting the composite complexing agent, the combination degree of the complexing agent and metal ions canbe effectively controlled, so that the concentration of the metal ions in the tail liquid is reduced. The particle size of the aluminum-doped cobaltosic oxide prepared by the method is 2.0-6.0 [mu]m,the morphology of the aluminum-doped cobaltosic oxide is spherical, the tap density of the aluminum-doped cobaltosic oxide is 2.6-3.0 g / cm <3>, and the mass percent of Al is 0.1-1.2%.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

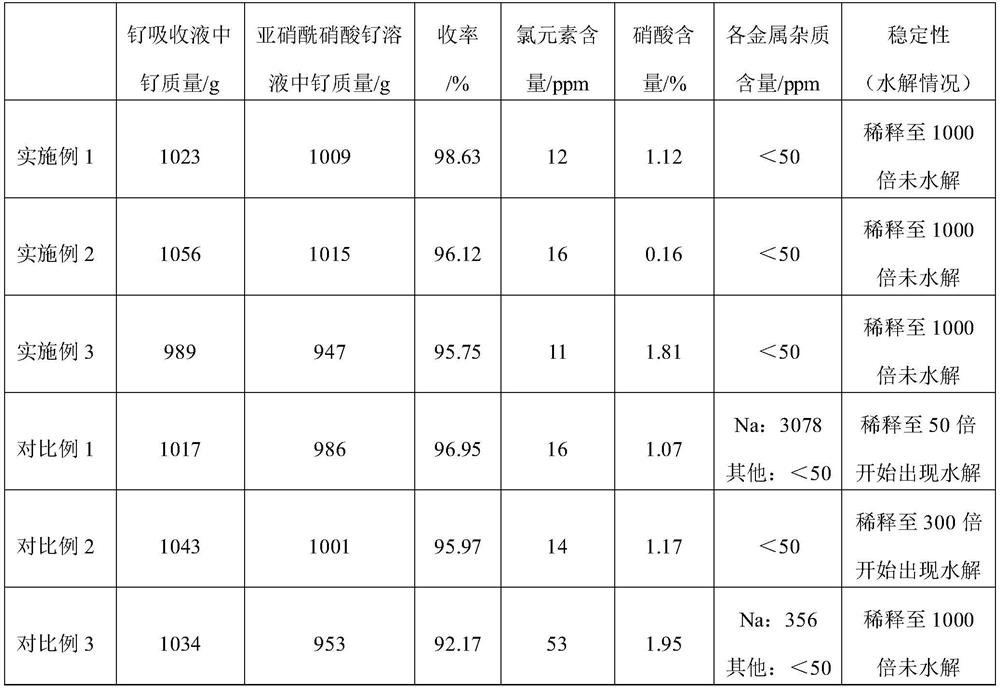

Method for preparing ruthenium nitrosyl nitrate solution

ActiveCN112142127AReduce chlorine contentMeet the use requirementsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsMetal impuritiesAqueous solution

The invention relates to a method for preparing a ruthenium nitrosyl nitrate solution, and belongs to the technical field of precious metal compound preparation. The method comprises: introducing ruthenium tetroxide gas into a nitric acid aqueous solution, and carrying out an absorption reaction to prepare a ruthenium absorption liquid; adding a reducing agent into the ruthenium absorption liquid,and reacting at 5-15 DEG C to obtain a ruthenium absorption liquid containing nitrosyl; adding a pH regulator A, regulating the pH value to 5-7, adding a pH regulator B, regulating the pH value to 8-10 to obtain a ruthenium precipitate, and repeatedly filtering and washing to remove impurities; and adding a nitric acid aqueous solution, and carrying out a reflux reaction for more than 2 hours toobtain a ruthenium nitrosyl nitrate solution; According to the invention, the ruthenium nitrosyl nitrate solution prepared by the method has the characteristics of low chlorine content, low nitric acid content, low metal impurity content, low corrosion and high stability.

Owner:中国船舶集团有限公司第七一八研究所

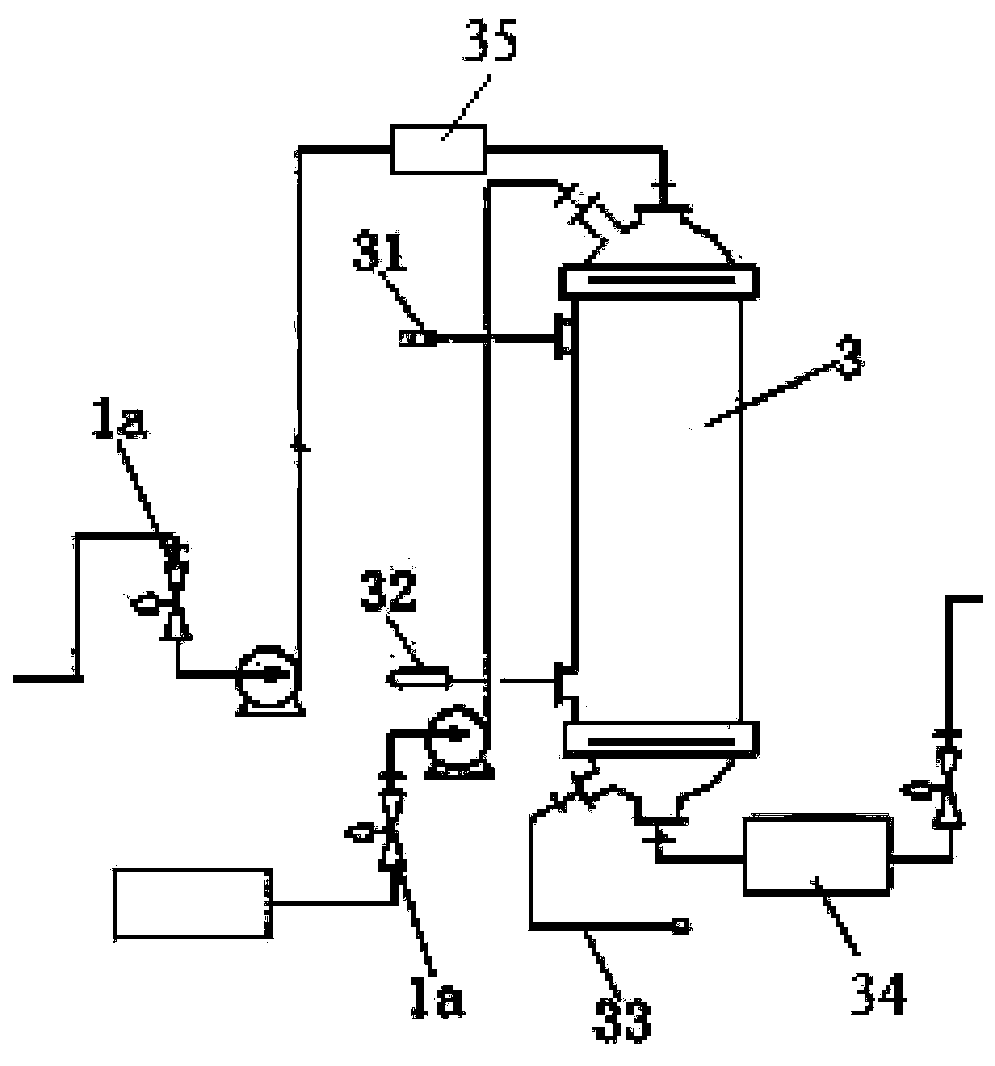

Automatic treatment system for waste acid liquid generated after metal pickling and process thereof

ActiveCN110316866ARealize harmless treatmentEliminate pollutionWater treatment parameter controlSpecific water treatment objectivesSite monitoringPhysical separation

The invention provides an automatic treatment system for waste acid liquid generated after metal pickling and a process thereof, and relates to the technical field of environmental protection and governance. The automatic treatment system comprises an oxidation reaction system, a physical separation system, an ion trapping system and a purification and regeneration system which are connected in sequence. The automatic treatment system has the advantages that the pickling waste acid liquid generated by metal pickling is treated, and dissolved metal ions in the waste acid liquid are recycled, wherein treatment is all performed through automation control over the whole process, thereby saving manpower for on-site monitoring and reducing the cost of human resources, and no secondary pollutionis caused in the whole operation process, so that the system is conducive to environmental protection and has important social, economic and ecological benefits.

Owner:BEIBU GULF UNIV

Method for simultaneously detecting four protein-bound uremic toxins in blood sample

InactiveCN110907569AEasy to handleImprove throughputComponent separationProtein bound uremic toxinUremia

The invention discloses a method for simultaneously detecting four protein-bound uremic toxins in a blood sample. The method comprises the following steps of pretreating the blood sample, and carryingout ultra-high performance liquid chromatography-tandem mass spectrometry detection on the treated sample to be detected, wherein the pretreatment process of the blood sample comprises the followingsteps of mixing the blood sample with a precipitant, carrying out centrifugal separation, adding the separated supernatant into the formic acid-containing water, and uniformly mixing to obtain the sample to be detected, wherein the precipitant is a mixed solution of acetonitrile and ethanol, the volume ratio of acetonitrile to ethanol is 2: (0.9-1.1), and the four protein binding uremia toxins areCMPF, IS, PCS and HA. According to the invention, the detection time of the four protein-bound uremic toxins can be shortened.

Owner:JINAN YING SHENG BIOTECH

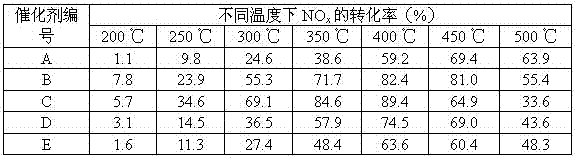

SCR denitration catalyst and preparation method thereof

InactiveCN107376898AHigh NH

<sub>3</sub>

-SCR denitrification activityWide denitrification temperature windowGas treatmentHeterogenous catalyst chemical elementsCeriumTitanium ion

The invention discloses an SCR denitration catalyst. Cerium, tungsten and titanium are taken as active elements of the catalyst, and the molar ratio of cerium, tungsten and titanium is (5-30):(1-20):100. The invention also provides a preparation method of the SCR denitration catalyst. The preparation method comprises the following steps: dissolving soluble cerium salt, soluble tungsten salt and soluble titanium at the molar ratio (cerium, tungsten and titanium) of (5-30):(1-20):100, and then adding a H2O2 solution to obtain a mixed solution; and selecting excessive urea as a precipitator, performing hydrothermal treatment for a certain period of time to promote cerium, tungsten and titanium ions to be completely deposited, and filtering, washing, drying and calcining the obtained deposition product to obtain the SCR denitration catalyst. H2O2 complexing modification can improve the low-and-medium-temperature NH3-SCR denitration activity in a cerium-tungsten-titanium composite oxide catalyst, the preparation method is simple and feasible, and the SCR denitration catalyst is suitable for a selective catalytic reduction and denitration process of NOx.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

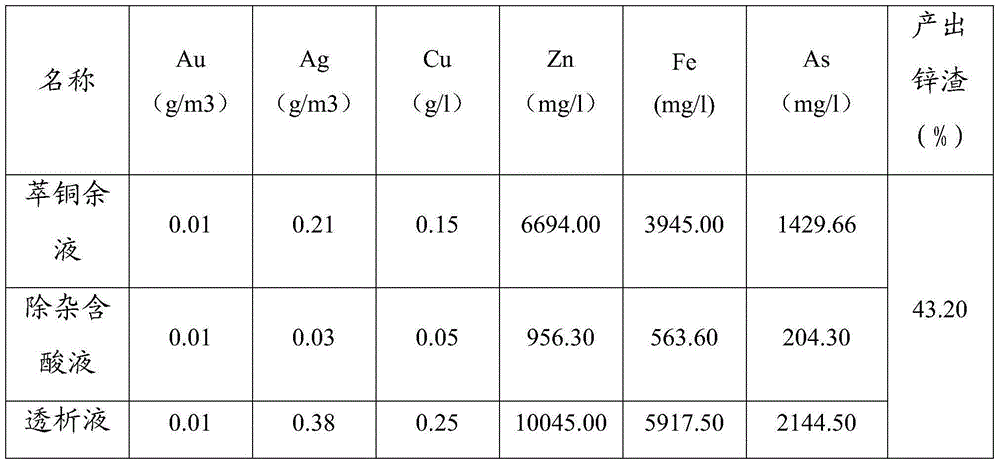

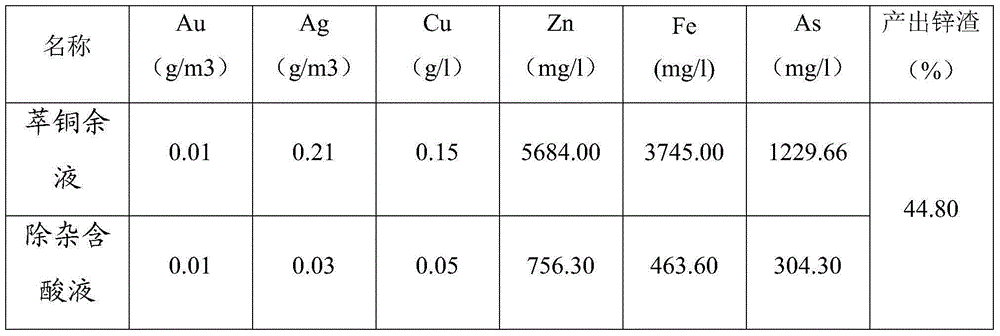

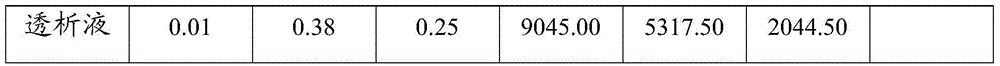

A method for comprehensive recovery and recycling of copper extraction residual liquid

The invention relates to a copper extraction raffinate comprehensive recycling and cyclic utilization method comprising the following steps: roasting a zinc-copper-gold containing concentrate, carrying out acid leaching treatment, and thus obtaining an acid leached ore pulp; carrying out liquid-solid separation on the acid leached ore pulp, to obtain a zinc-copper containing acid leached liquid and a gold-silver containing solid material; extracting a cathode copper from the zinc-copper containing acid leached liquid through an extraction device and an electrodeposition device, filtering the copper extraction raffinate, and separating the filtrate by an ion exchange membrane to obtain a dialysate and an impurity-removing acid-containing liquid; pumping the dialysate into a stirring tank by a pump, adding lime, and producing a slurry; filtering the slurry to obtain a zinc-containing filtrate and a precipitation residue; conveying the zinc-containing filtrate to a zinc precipitation stirring tank, and simultaneously adding a sodium sulfide solution and an ammonium bicarbonate solution into the stirring tank until zinc is precipitated out; and carrying out press filtration. The method is simple and easy to implement, obtains the zinc slag with the zinc content of 43.2%-45.8%, fully recycles gold, silver, copper and sulfur valuable metals, also fully recycles the valuable metal zinc, effectively utilizes the gold-containing multi-element gold concentrate resource, turns waste into treasure, and further, improves the resource utilization rate and increases enterprise economic benefits.

Owner:SHANDONG GUODA GOLD

Method for preparing superfine aluminate fluorescent powder

The invention relates to a method for preparing superfine aluminate fluorescent powder. An improved coprecipitation method is used for preparing the aluminate fluorescent powder, and simple process and large-scale production are realized. The central grain size of the prepared fluorescent powder is smaller than 3 micrometers, grain shapes are hexangular and flaky, and powder grains have uniform size distribution and no coarse grains. The prepared fluorescent powder has excellent luminous performance and can be used as a plasma display panel (PDP) material, tri-phosphor fluorescent powder or alight-cumulating type fluorescent material, and the like without ball-milling. The coprecipitation method is used for preparing the aluminate fluorescent powder. Under the condition of the invention,Al ions are precipitated in the form of ammonium aluminum carbonate hydroxide (NH4AlO(OH)HCO3) or hydrates thereof but are not precipitated in the form of Al(OH)3 gel. When being calcined at high temperature, the NH4AlO(OH)HCO3 can be decomposed without sintering, thus the phenomenon of agglomeration can be effectively avoided. Because the process is precisely controlled, no coarse grain residuesexist after high-temperature calcination.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com