Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1075results about How to "Fully recycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

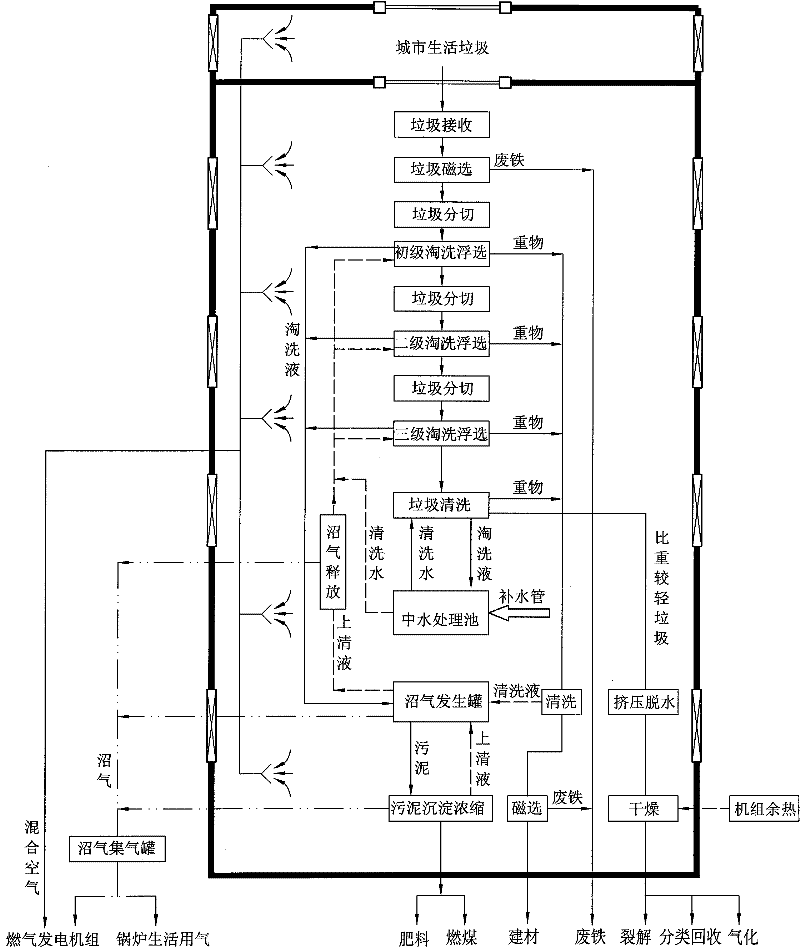

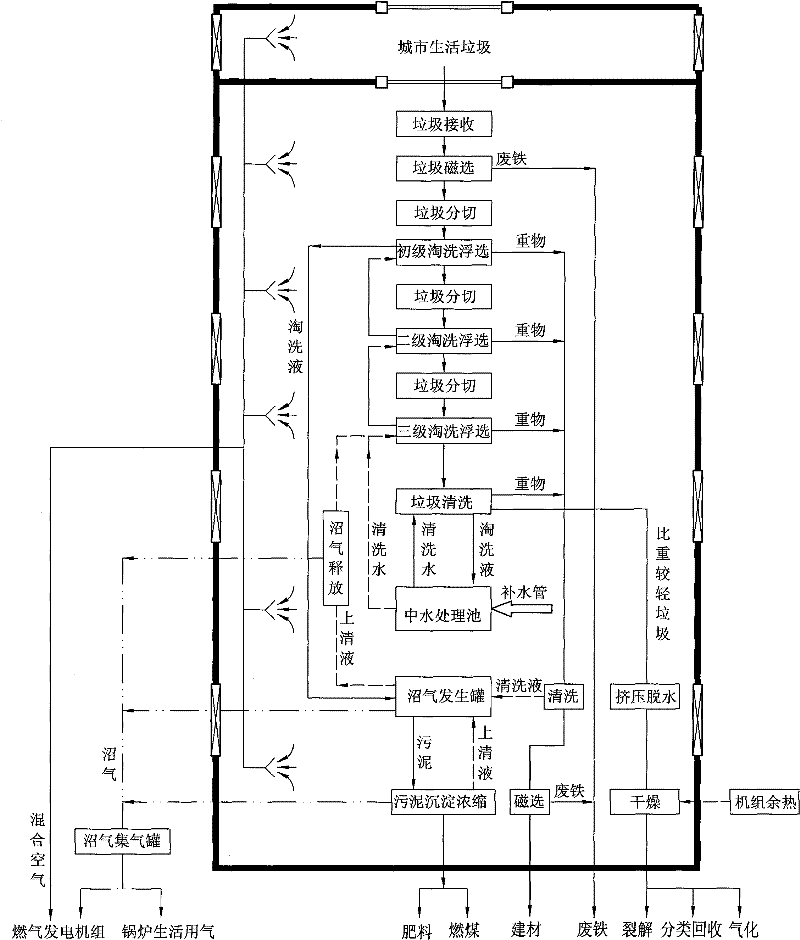

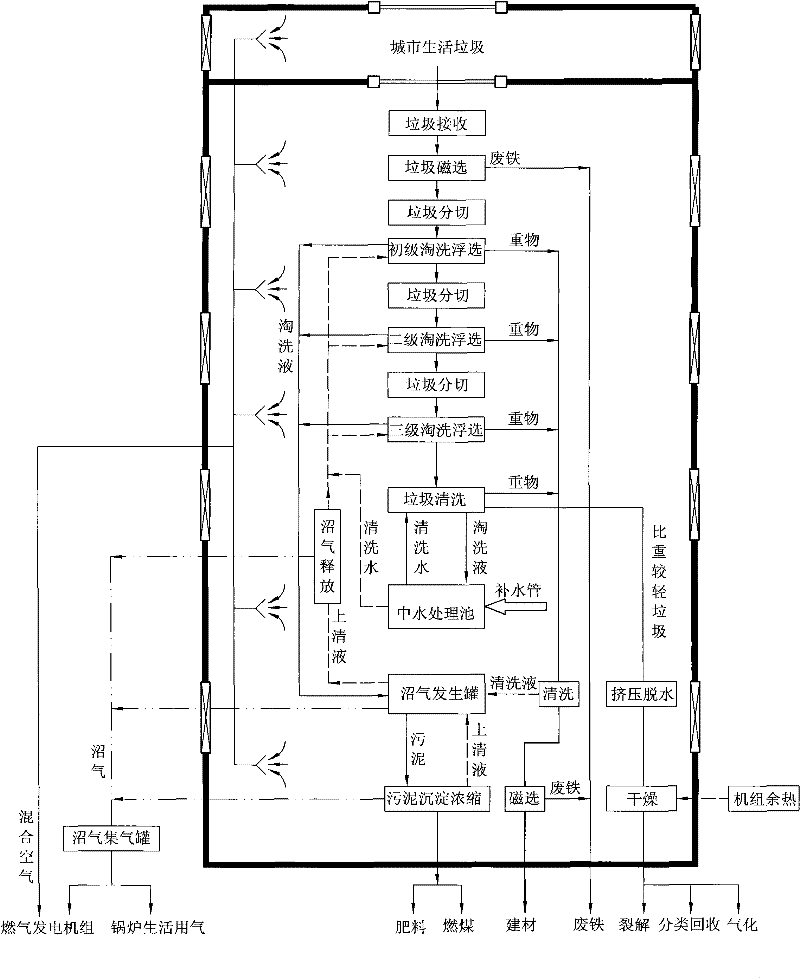

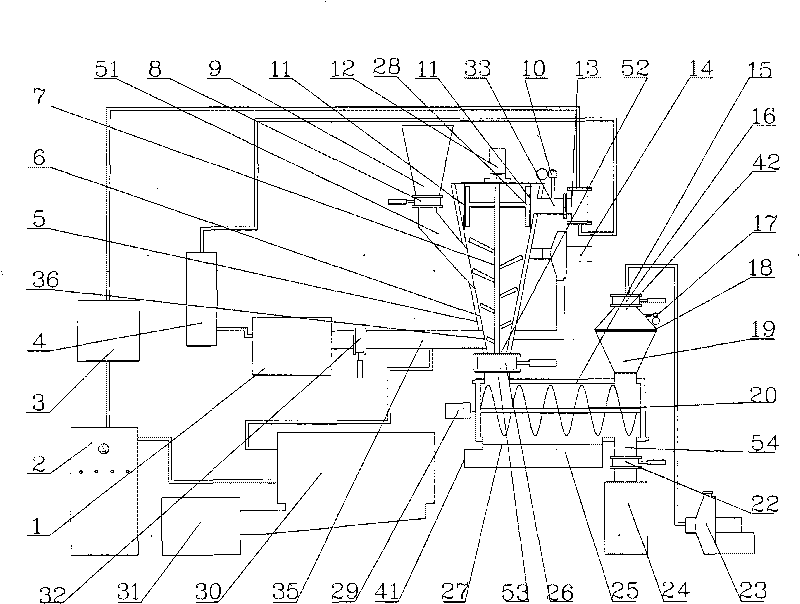

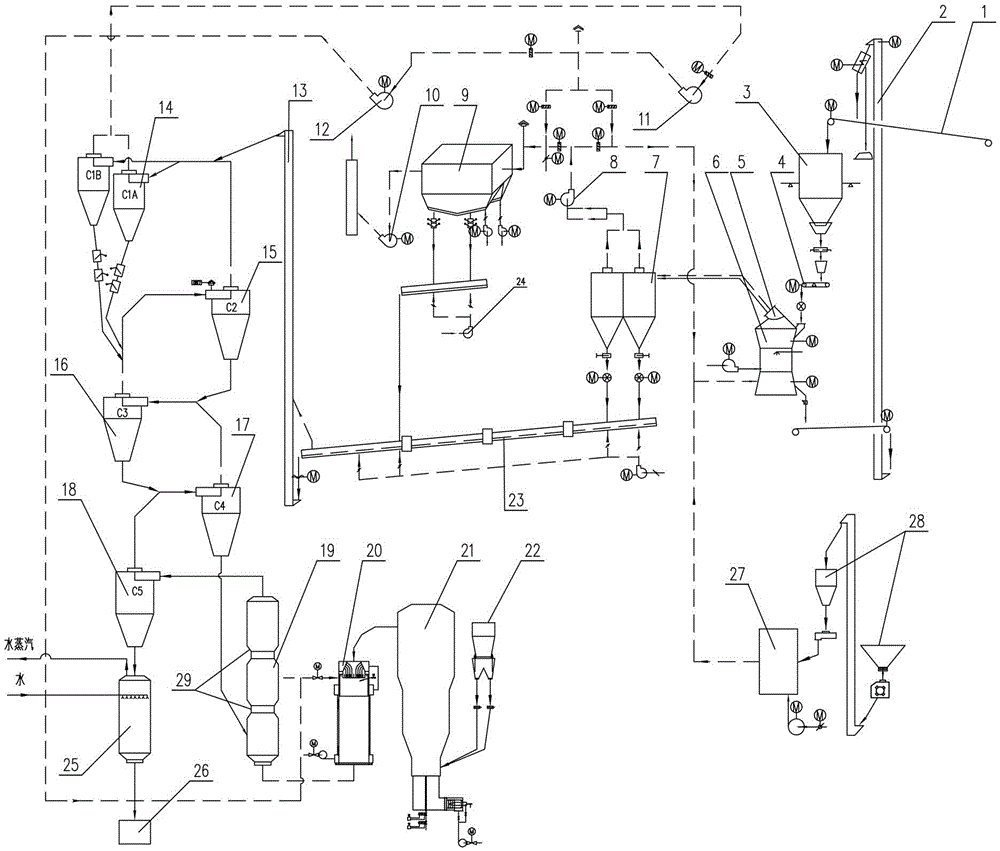

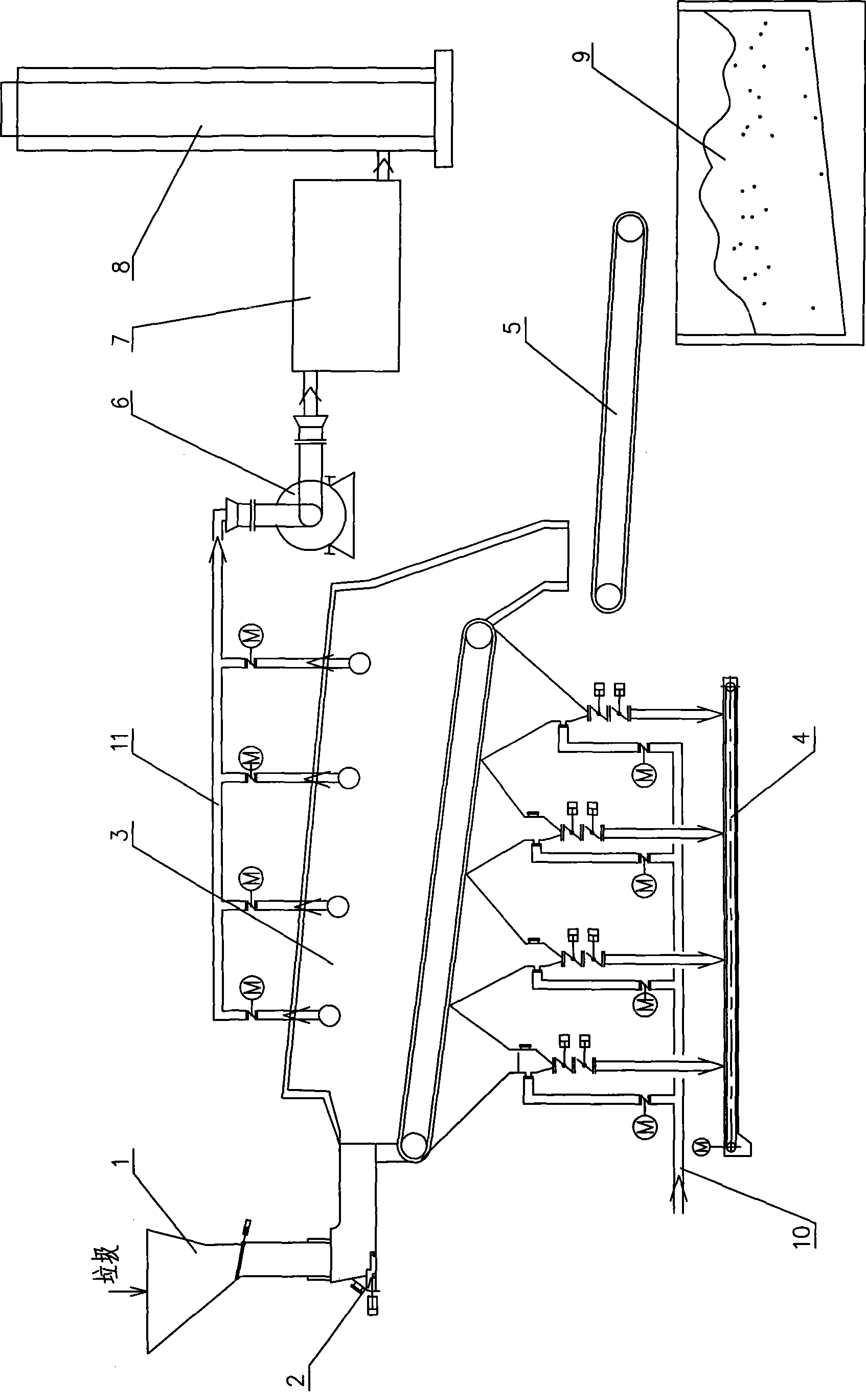

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

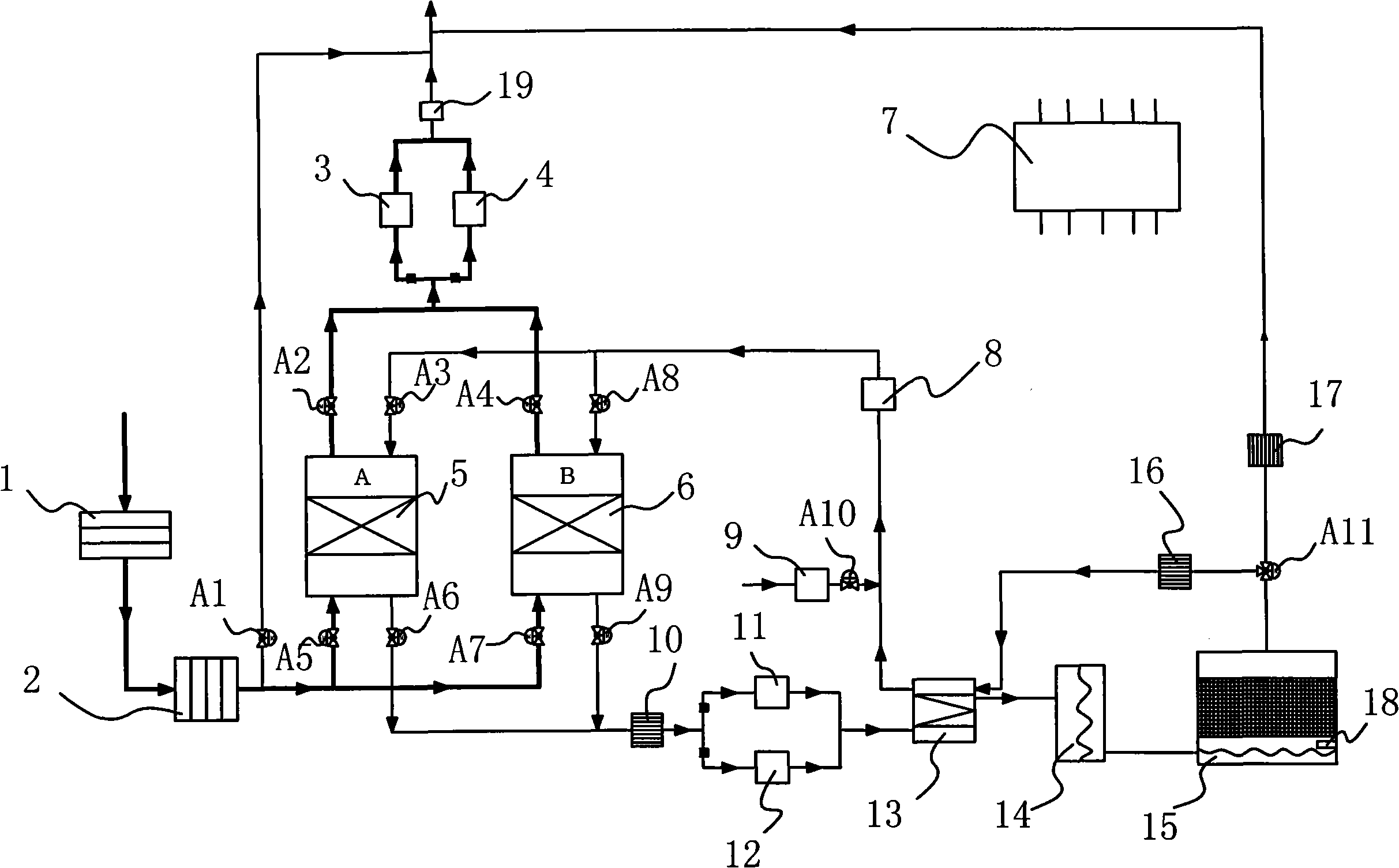

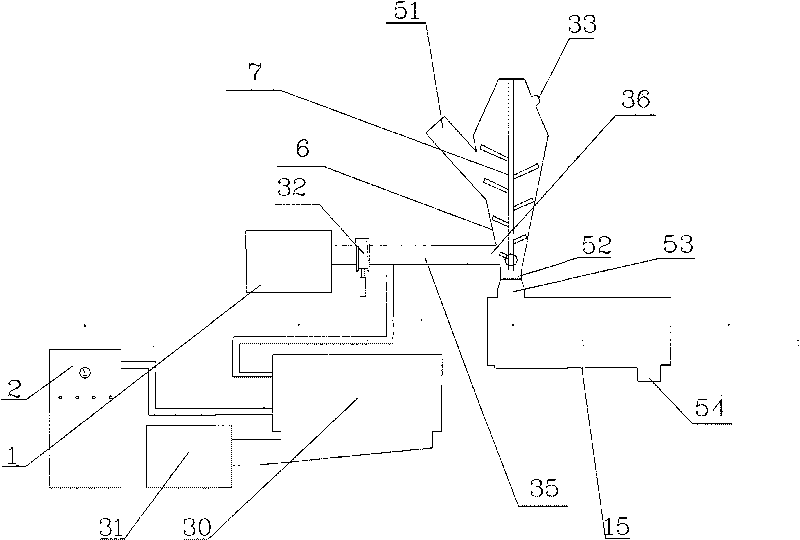

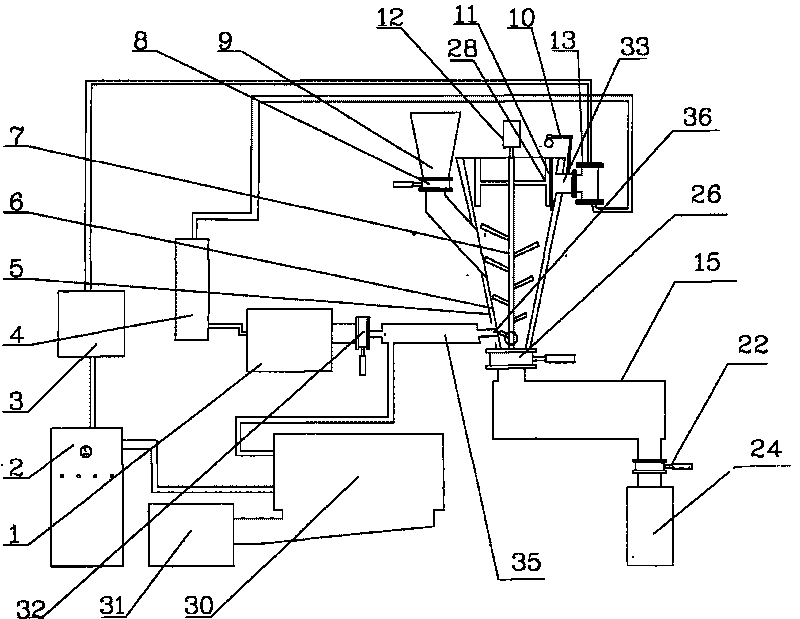

System for treating organic exhaust gas by adsorptive-catalytic combustion

ActiveCN101972602AReduce energy consumptionGuaranteed operational safetyDispersed particle separationExhaust gasAutomatic control

The invention discloses a system for treating organic exhaust gas by adsorptive-catalytic combustion. The system comprises a pretreatment filter which communicates with and sucks the organic exhaust gas, a main adsorption fan which exhausts the adsorbed exhaust gas and a main fixed adsorbent bed which is connected between the pretreatment filter and the main adsorption fan through a pipe and usedfor adsorbing the exhaust gas; the exhaust pipe of the main adsorption fan is connected with a gas monitoring apparatus which is electrically connected with a control device; the entrance of the mainfixed adsorbent bed is connected with a catalytic bed through a main desorption fan via a pipe; the exit of the catalytic bed is connected with the exit of the main fixed adsorbent bed through a pipe; a temperature sensor in electric connection with a control device is arranged in the catalytic bed; and the main fixed adsorbent bed is connected in parallel with an auxiliary fixed adsorbent bed which conducts an alternative adsorptive or catalytic process with the main fixed adsorbent bed. The invention has the advantages of effectively guaranteeing the treatment efficiency of the organic exhaust gas, replacing manual operation with automatic control and effectively improving the production safety degree, the equipment operation reliability and the economy.

Owner:深圳盈和环境物联科技有限公司

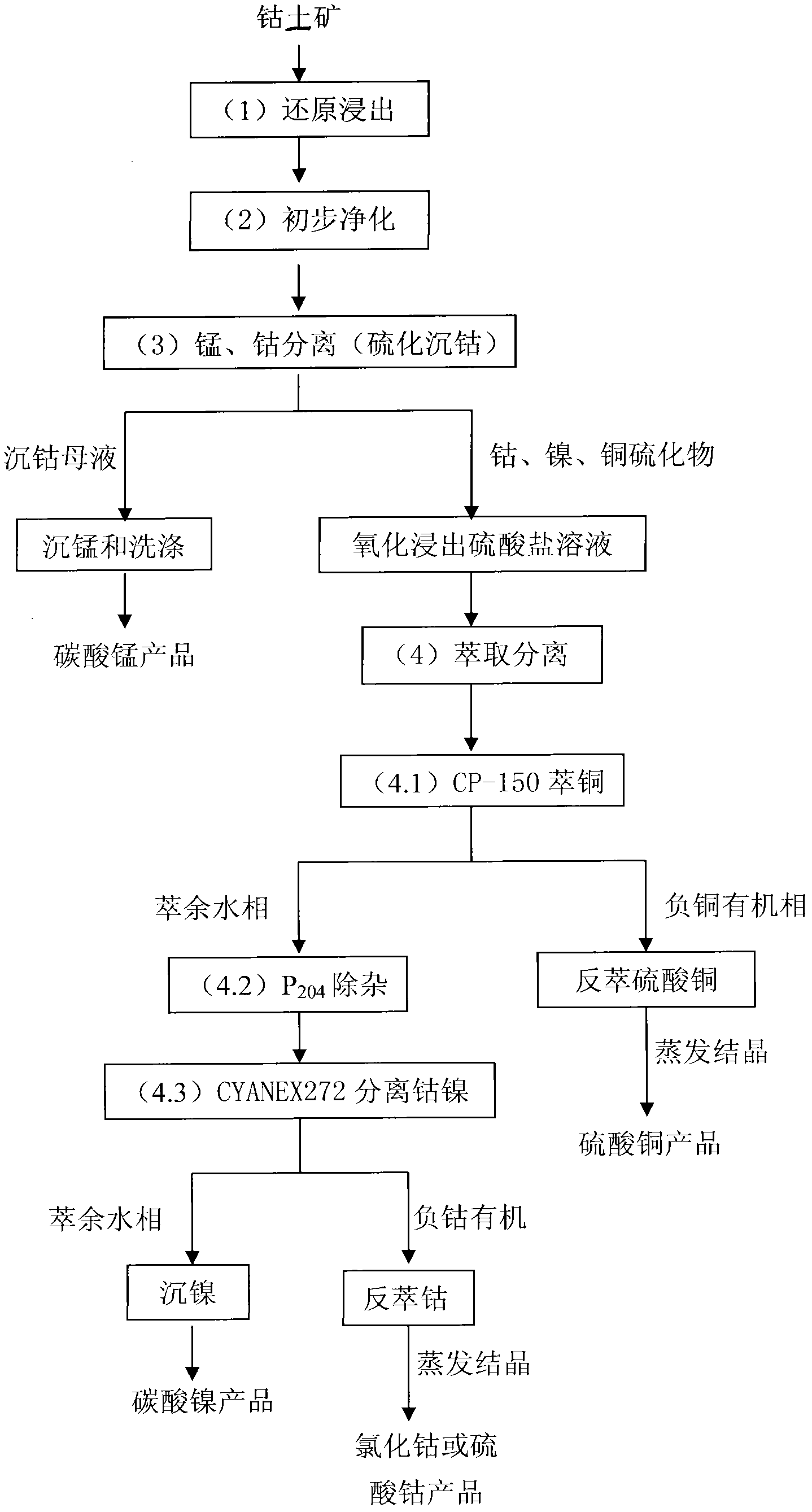

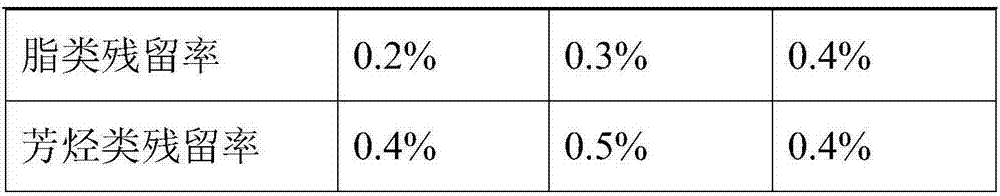

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

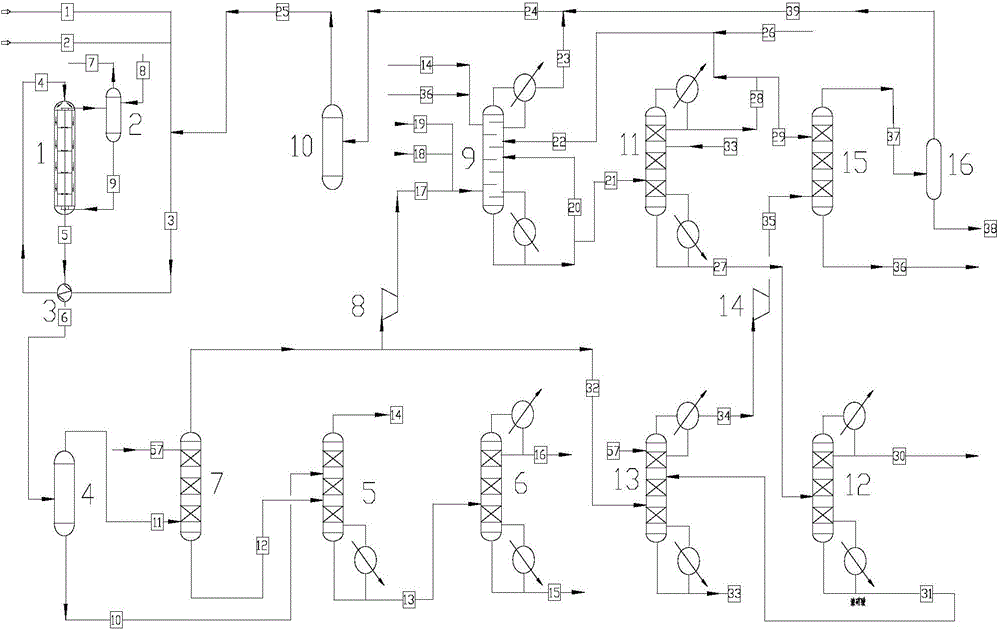

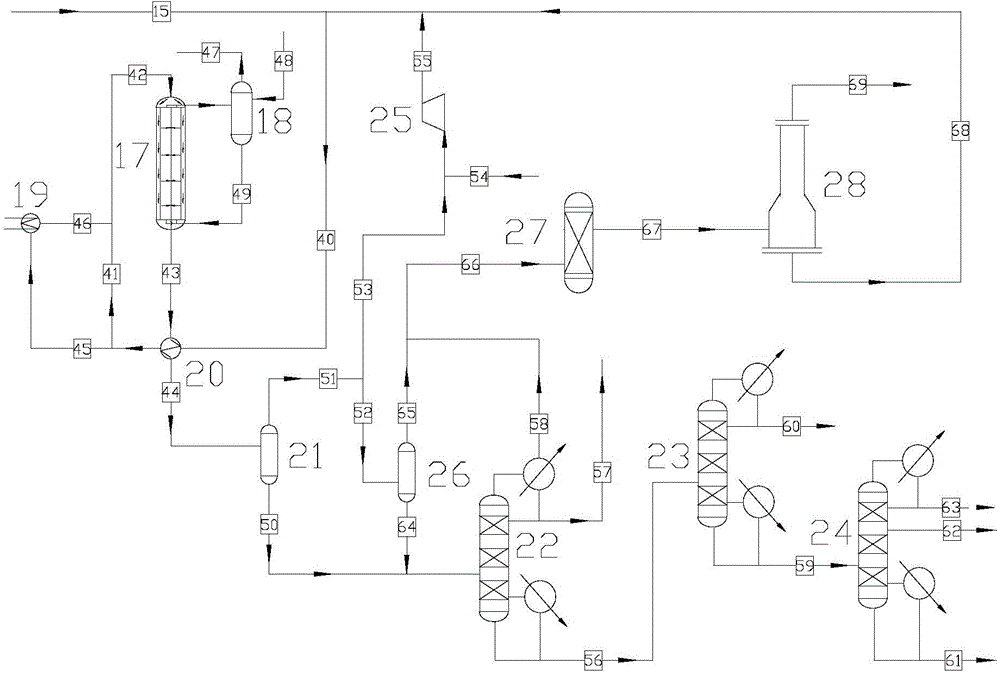

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

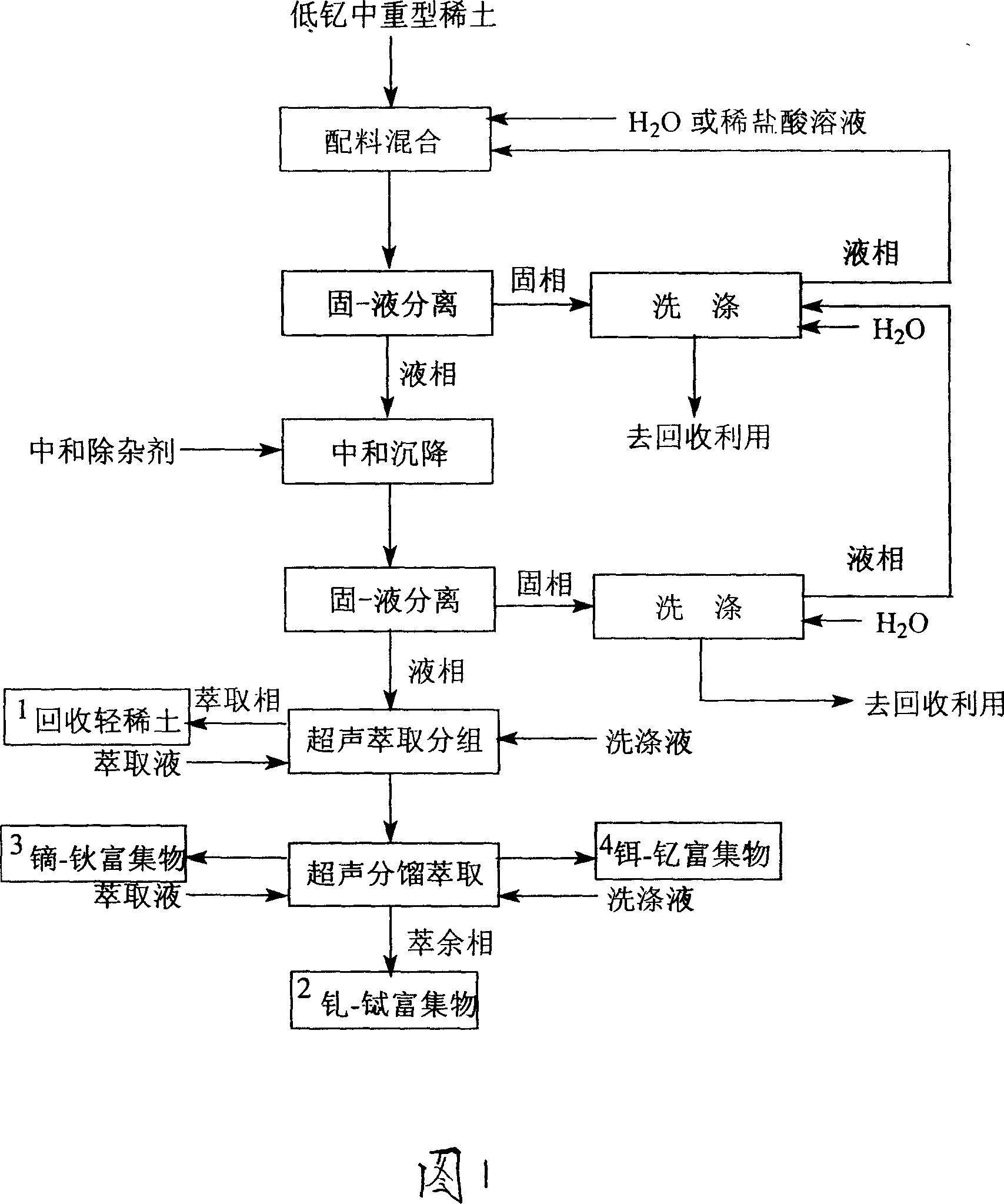

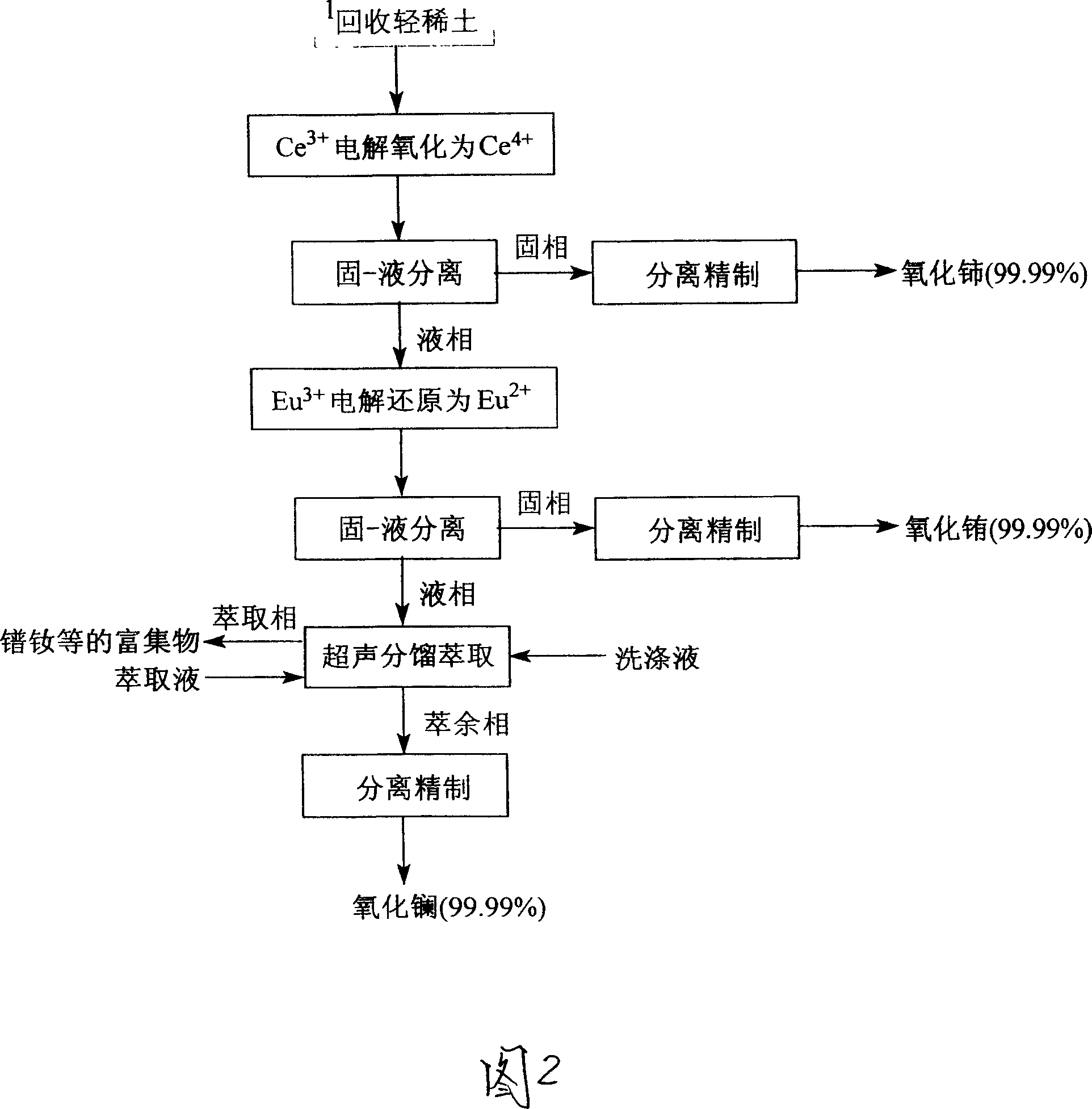

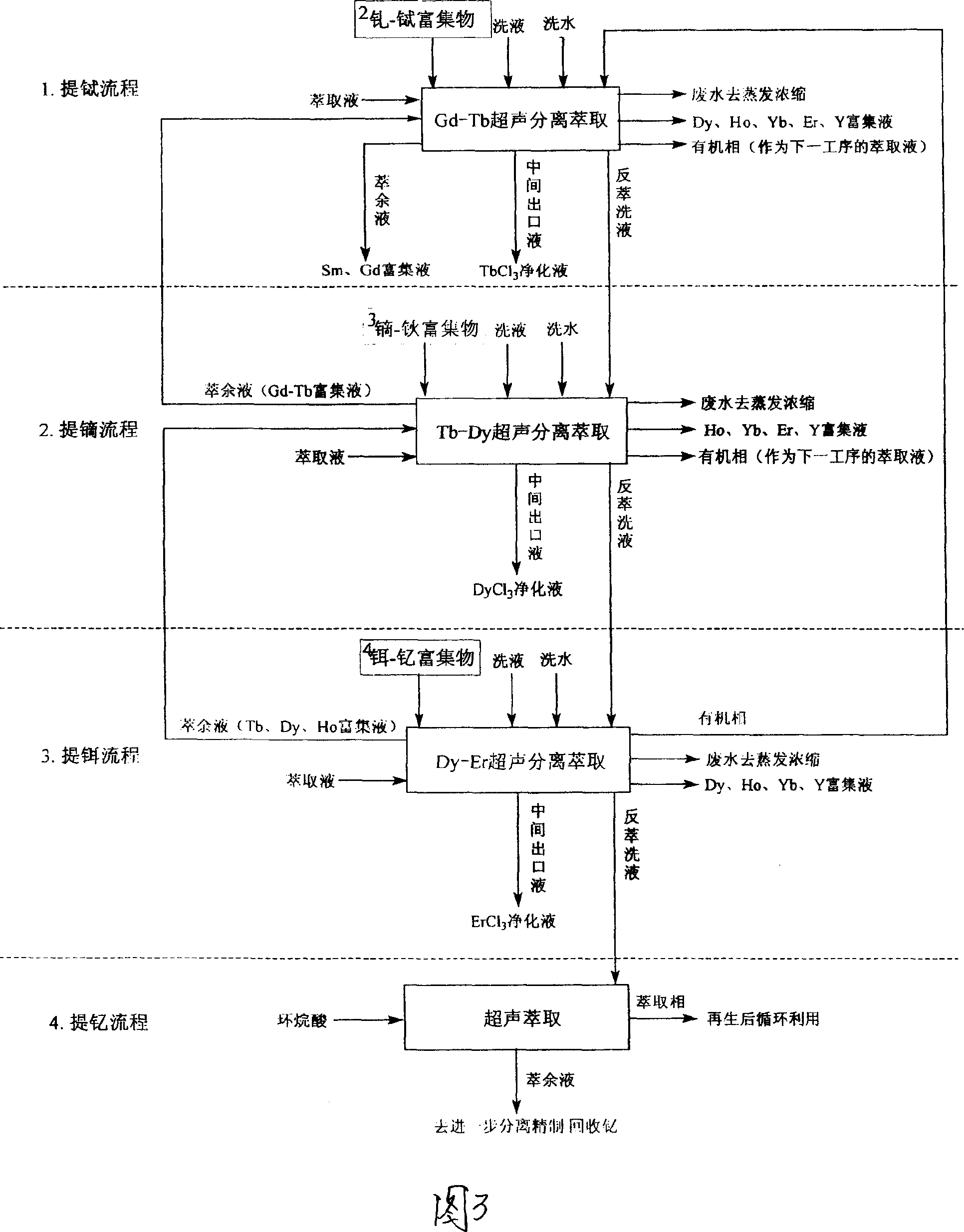

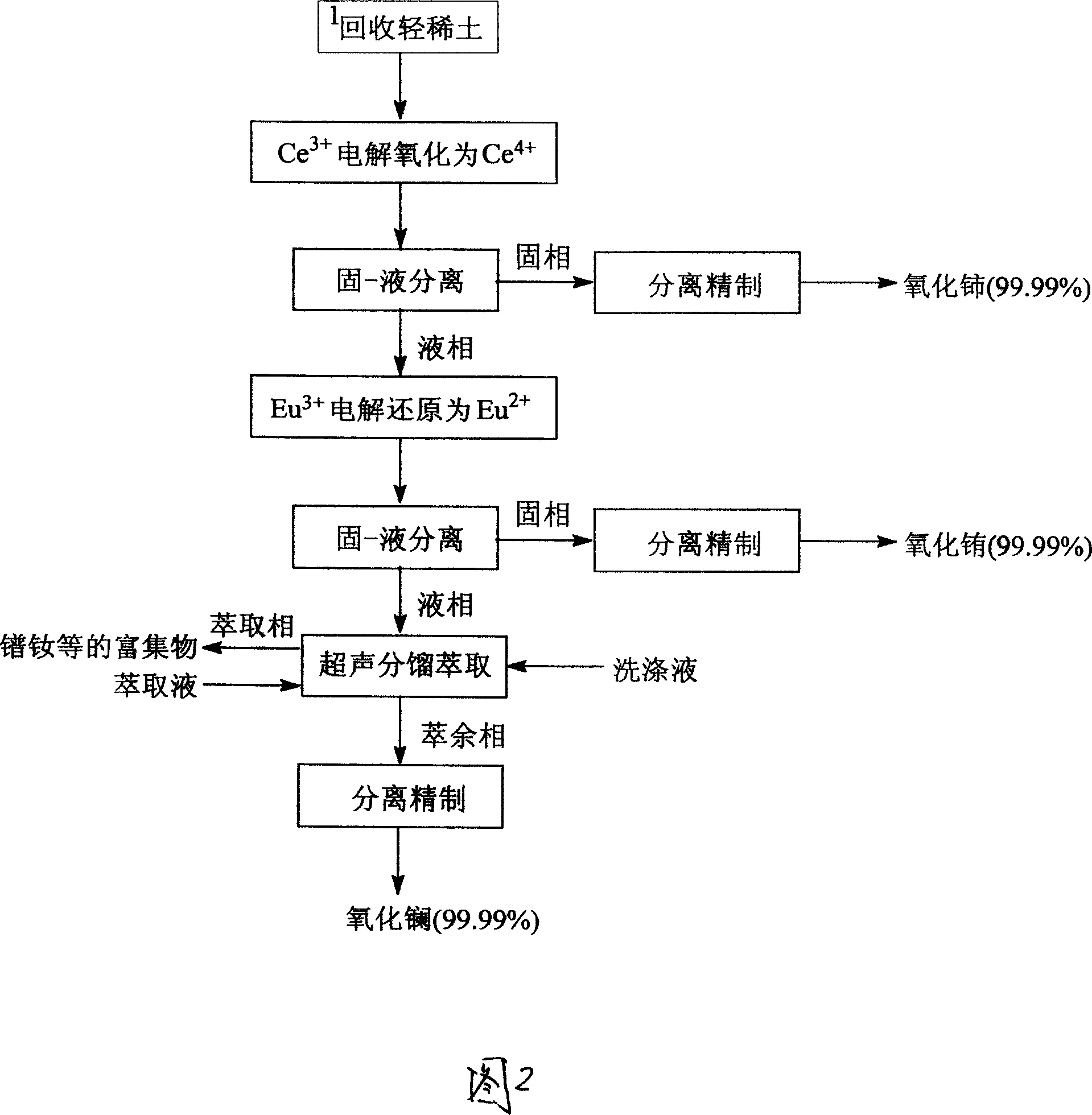

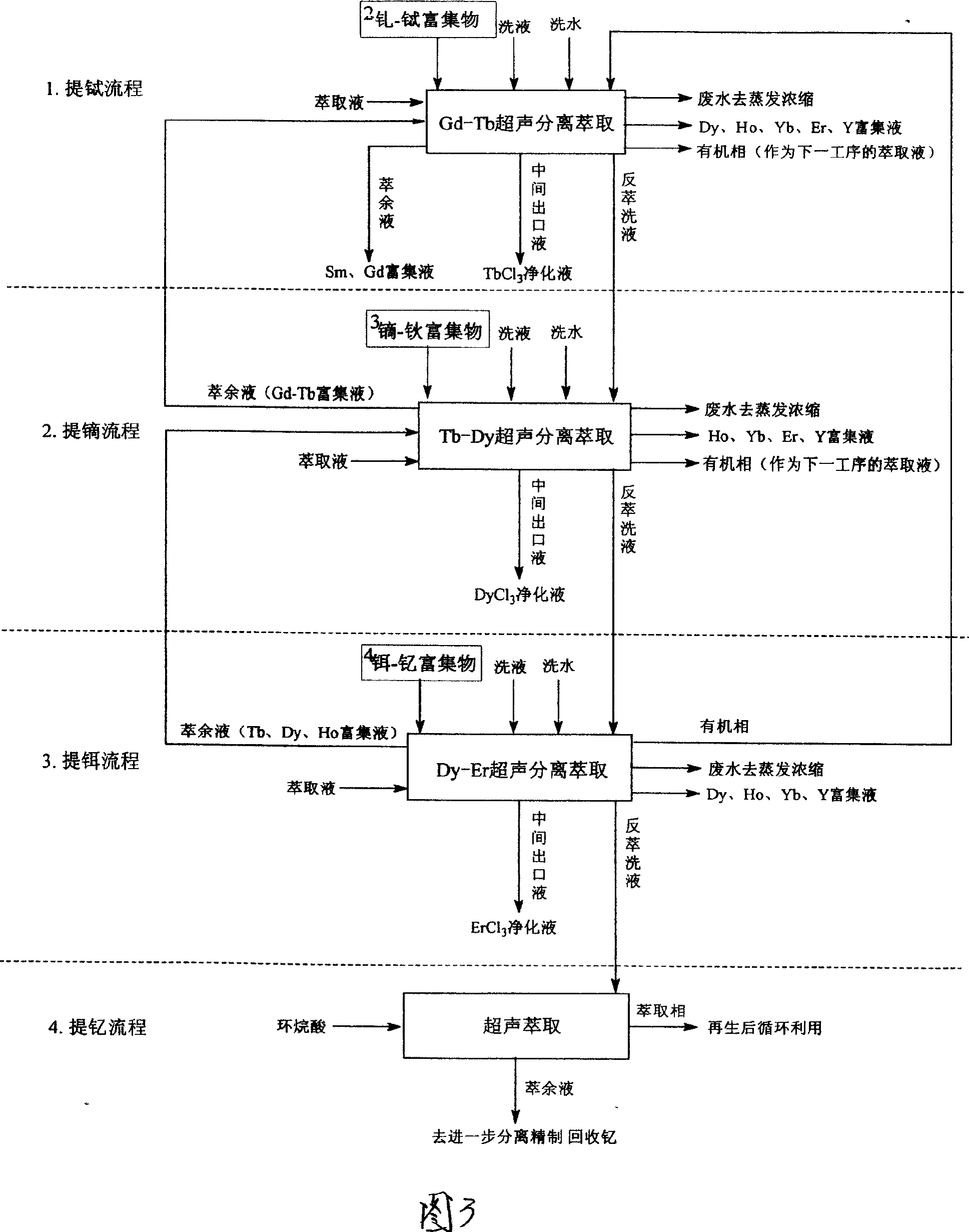

Method for separating highly-pure rare-earth oxide from yttrium-rich rare earth mine

InactiveCN101012501AIncrease concentrationReduce processingProcess efficiency improvementRare earthYttrium

The invention discloses a full-separating method of high-purity rare earth oxide from low-yttrium middle-heavy rare earth rare earth ore, which is characterized by the following: adopting enriched yttrium rare earth ore as raw material; producing high-purity Y2O3, La2O3, Ce2O3, Pr5O11, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3, Er2O3 and Y2O3 through ultrasonic extracting-electrochemical, quantivalence-changing and chemical coupling technique; obtaining the product.

Owner:常州市西南化工研究所 +2

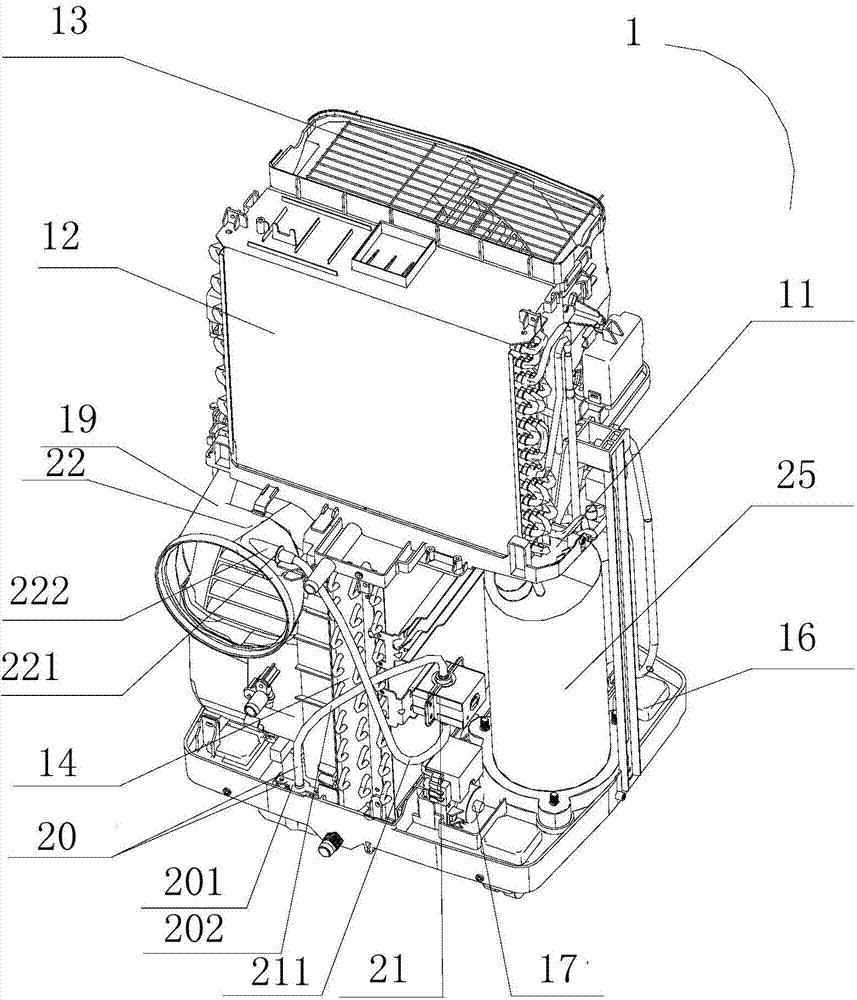

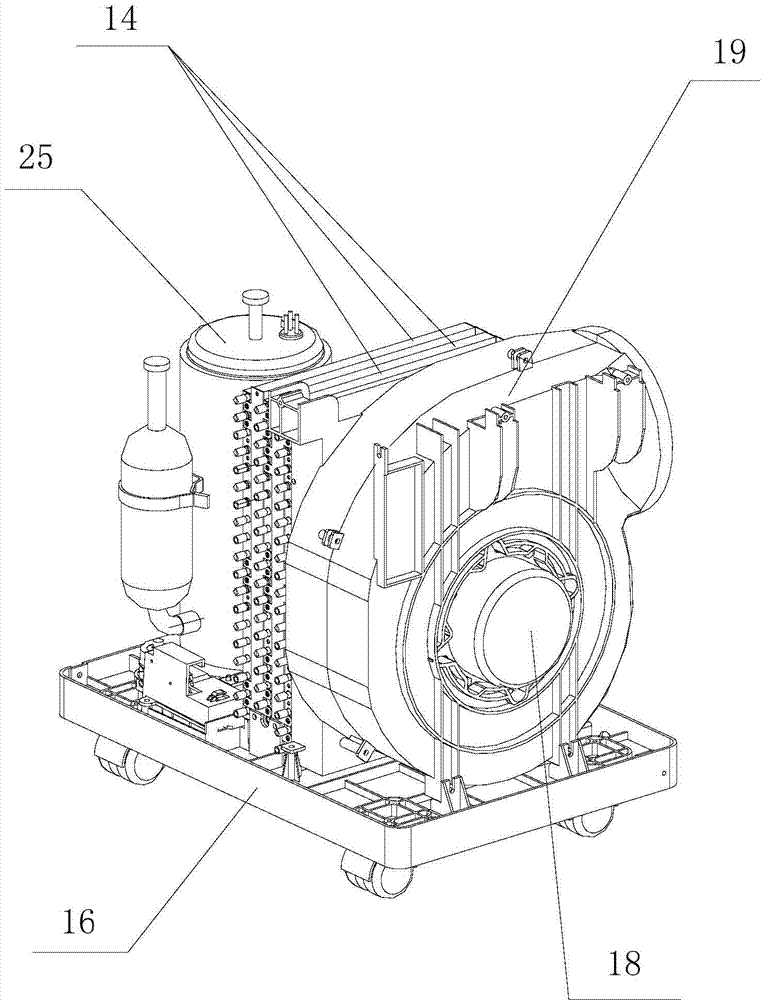

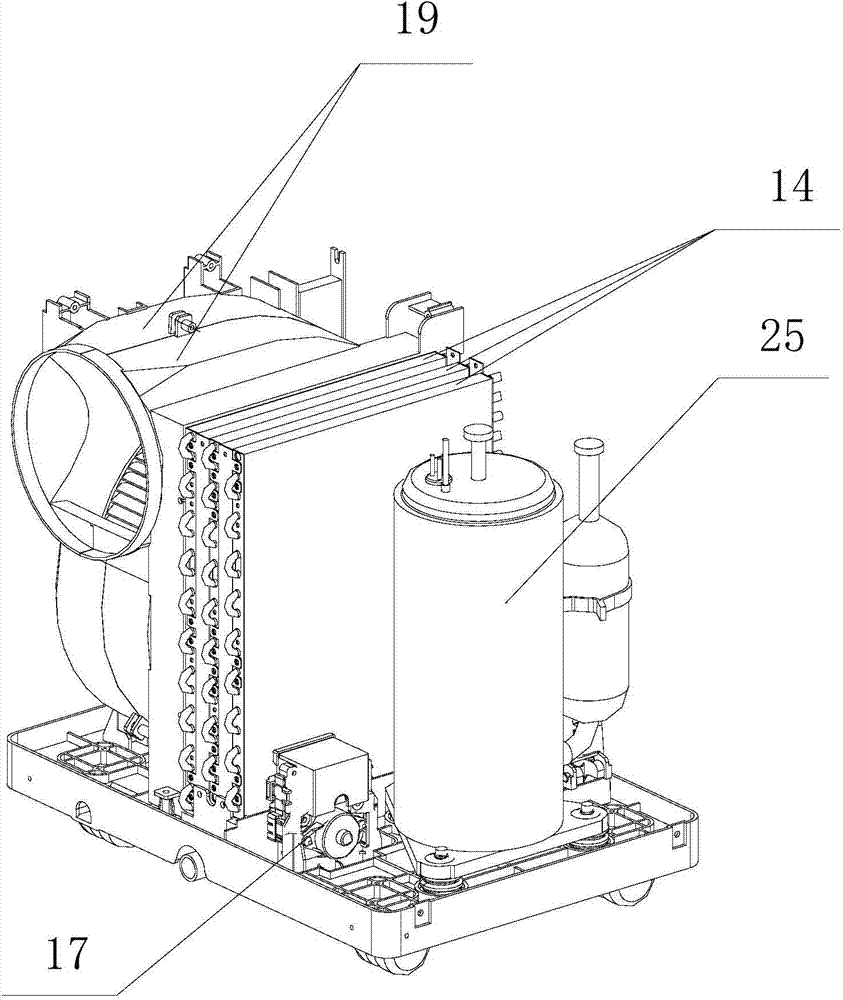

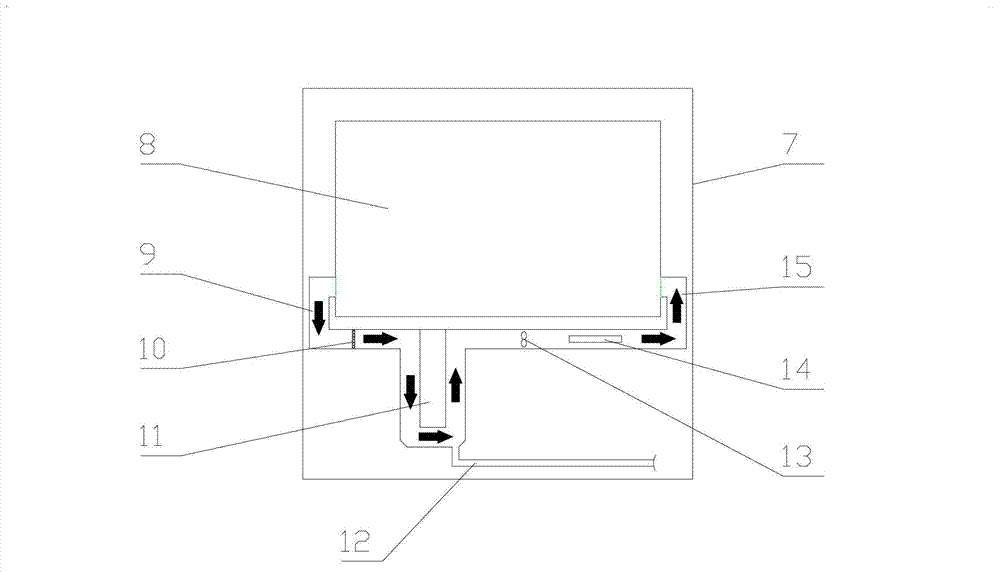

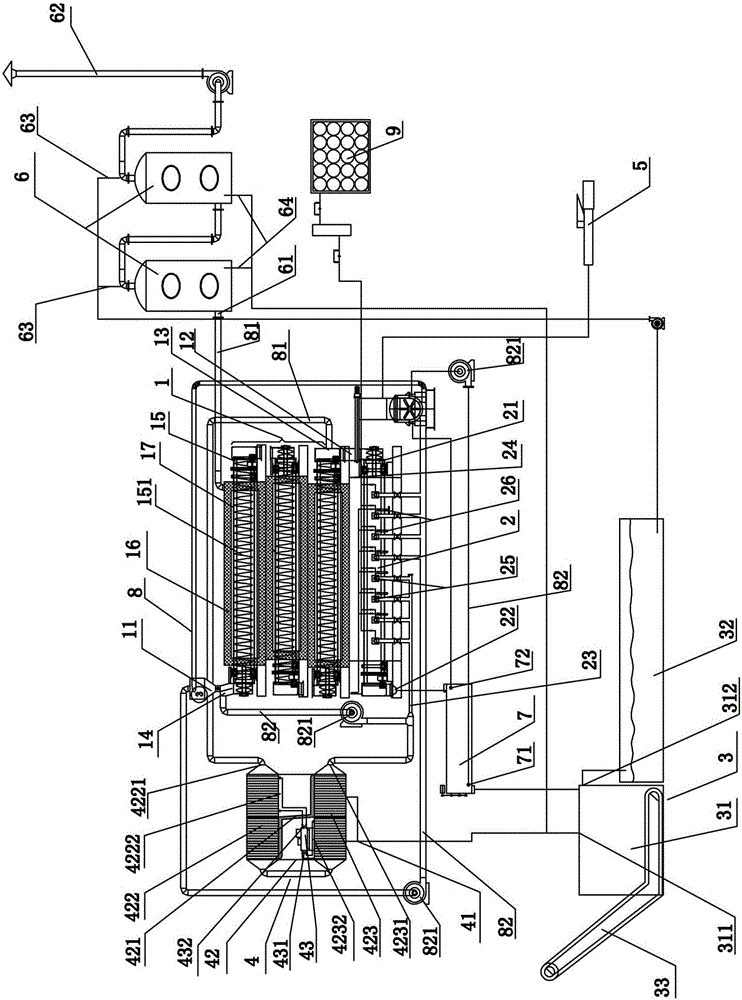

Integrated air conditioner and condensed water processing method for integrated air conditioner

ActiveCN104764095AImprove human needsFully recycleCondensate preventionLighting and heating apparatusEnvironmental engineeringWater processing

The invention discloses an integrated air conditioner and a condensed water processing method for the integrated air conditioner. The integrated air conditioner comprises an indoor water receiving plate, a drainage device connected with the indoor water receiving plate and used for leading the condensed water in the indoor water receiving plate to the outer side walls of multiple rows of condensers of the integrated air conditioner, the multiple rows of condensers used for heating condensed water on the outer side walls to at least vaporize part of the condensed water, a water tank arranged on a chassis of the integrated air conditioner and used for receiving non-vaporized condensed water on the outer side wall, and a water beating motor which comprises a plurality of water beating wheels and is used for beating the non-vaporized condensed water to the outer side walls of the condensers through the water beating wheels so as to enable the multiple rows of condensers to vaporize the non-vaporized condensed water again. By means of the technical scheme, the condensed water in the integrated air conditioner can be discharged automatically, and a user is protected from manually discharging the condensed water.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

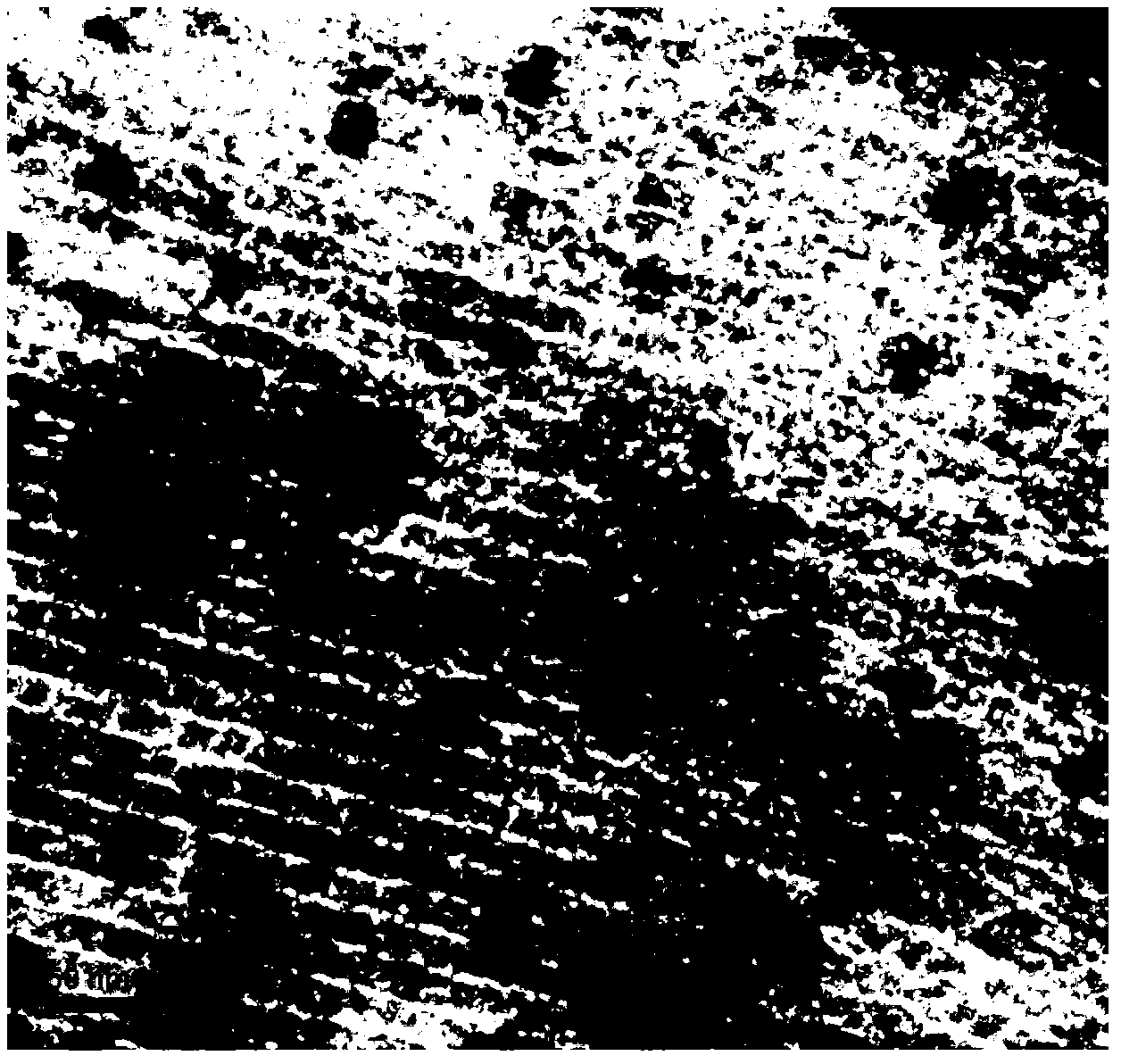

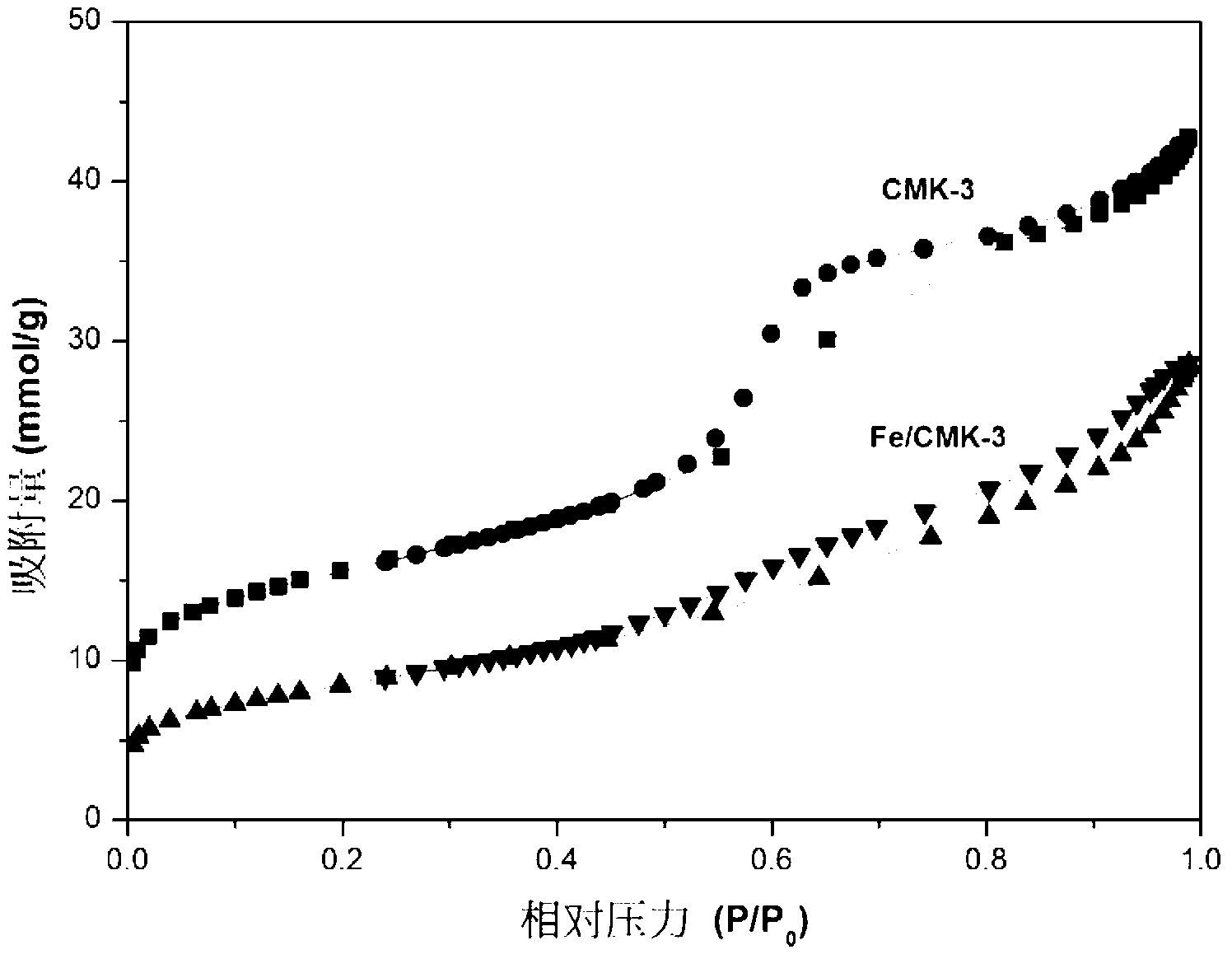

Magnetic carrier iron ordered mesoporous carbon, preparation method and application thereof

InactiveCN103301809AEfficient removalLow toxicityOther chemical processesWater contaminantsSource materialMagnetite Nanoparticles

The invention discloses a magnetic carrier iron ordered mesoporous carbon. The ordered mesoporous carbon is taken as a carrier, the carrier is prepared by a hard template method, and magnetic nanoparticles are loaded onto the carrier by a nano-joint casting method; the magnetic nanoparticles mainly consist of zero-valent iron and oxide of iron, wherein the proportion of the iron element is taken as 1-1.5m mol of each gram of a mesoporous silicon template, and the pore diameter distribution of the mesoporous carbon is mainly concentrated nearby 5nm and 3.8nm. A perpetration method of the magnetic carrier iron ordered mesoporous carbon provided by the invention comprises the following steps of: dissolving iron source materials and cane sugar in sulfuric acid, dipping the mesoporous silicon template, and adopting two-section type heat treatment; secondly, dipping by cane sugar-containing sulfuric acid solution, and adopting two-section type heat treatment; and finally carrying out constant-temperature high-temperature carbonization so as to obtain the silicon template in a demoulding way by hot NaOH solution, and drying to obtain the magnetic carrier iron ordered mesoporous carbon. The magnetic carrier iron ordered mesoporous carbon disclosed by the invention has the characteristics of being large in specific surface area and pore volume, wide in application range, stable in physicochemical property and the like, and the heavy metal hexavalent chromium ions in water body can be removed.

Owner:HUNAN UNIV

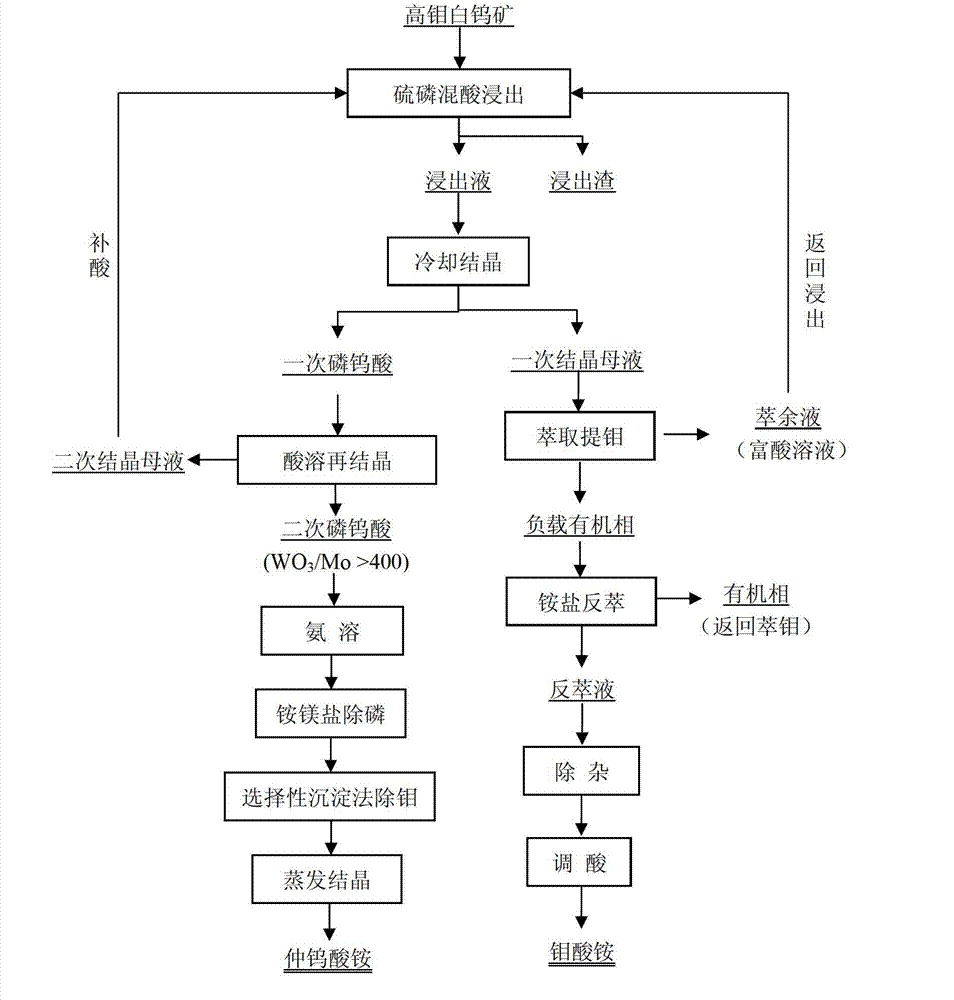

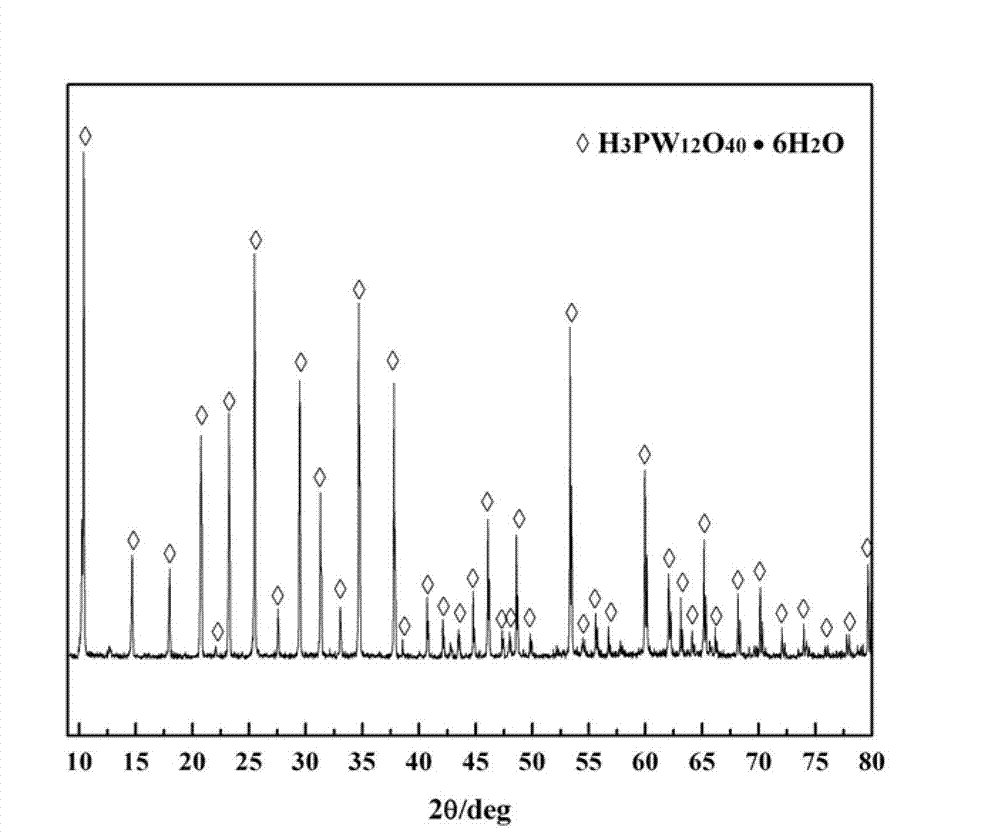

Method for extracting tungsten and molybdenum in high molybdenum scheelite

ActiveCN103073061AAdaptableEfficient decompositionMolybdeum compoundsTungsten compoundsTungsten orePhosphate

The invention relates to a method for extracting tungsten and molybdenum in high molybdenum scheelite. The method comprises the following steps: employing mixed acid of sulfuric acid and phosphoric acid for leaching the high molybdenum scheelite; separating a leachate by employing a cooling crystallization method to obtain the primary phospho-tungstic acid crystal and dissolving in an acid solution for secondary cooling crystallization, the processes of performing ammonia dissolution, removing phosphate by an ammonium magnesium salt method, removing molybdenum by a selective precipitation method as well as evaporating and crystallizing to obtain the APT which accords with a national zero-grade standard; a mother liquor after the primary cooling crystallization is performed with the processes of extracting molybdenum, performing back extraction by ammonium salt, removing the impurities and adjusting acidity to obtain ammonium molybdate; and a raffinade containing spent acid and the mother liquor after secondary cooling crystallization are directly returned for leaching to realize the circulation of acid. The invention realize the extraction with high efficiency under normal pressure of tungsten, the leaching rate of tungsten and molybdenum reach more than 98.5%; the complete separation of tungsten and molybdenum can be effectively realized by using a refrigeration crystallization and extraction technology, subsequent operation processing burden is reduced, the leaching process is simple, and the acid consumption is less, recycleleaching of most acid can be realized, and the production cost and waste water discharge can be greatly reduced.

Owner:CENT SOUTH UNIV

Steam sterilizing method

ActiveCN101732740AProtect from moistureGuaranteed qualityFood preservationHeatEngineeringSuperheated steam

The invention discloses a steam sterilizing method, which comprises a sterilizing treatment procedure and a sterilizing treatment post cooling procedure. Before the sterilizing procedure, the interior of a sterilizing chamber is preheated by adopting the hot air provided by a first hot air draught fan; and meanwhile, a second hot air draught fan connected with a hot air inlet of the sterilizing chamber through a storage steam heat exchanger is opened to preheat the storage steam heat exchanger. After the preheating treatment for the sterilizing chamber and the storage steam heat exchanger reaches a set temperature, the material is continuously preheated by the first hot air draught fan; and after the preheating treatment is finished, the material to be sterilized is sterilized by high-temperature steam or over-heated steam. The sterilizing method is simple and efficient, and avoids the problem that the high-temperature steam caused by the sterilizing method without the preheating treatment is condensed in the sterilizing chamber to damp the material so as to influence the quality.

Owner:LANZHOU NONGZHIPIN ECOLOGICAL TECH CO LTD

Zinc leaching slag treatment method

ActiveCN103421955AShort processShorten the smelting processProcess efficiency improvementLead smeltingMolten bath

A zinc leaching slag treatment method comprises the following steps: 1) The dried zinc leaching slag is evenly mixed with coke powder, and then the mixture is added to a volatilization kiln through a feeding scraper-trough conveyer at the tail of the kiln; 2) under the high-temperature condition of the volatilization kiln, the mixture generates kiln slag and smoke, valuable metals in the zinc leaching slag are deoxidize, as a result, lead and zinc steam is generated and gathered in the smoke, and gold, silver and copper enters to the kiln slag; 3) the kiln slag is delivered to a smelting furnace, furnace burden is added from the top of the smelting furnace, oxygen-enriched air is blown through an oxygen lance, the furnace hearth is stirred, the smelting temperature of the smelting furnace and the ratio of oxygen quantity to kiln slag dry measure are controlled, and slagging smelting is completed; 4) after the slagging smelting carried out in step 3), the valuable metals gold, silver and copper in the kiln slag are gathered in matte, the generated lead steam is gathered in smoke, and the kiln slag is cooled gradually. According to the zinc leaching slag treatment method, the technological process is short, the energy consumption is low, the cost is low, and the valuable metal recovery rate is high.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

Process for extracting lithium salt from spodumene by adopting sulfuric acid pressure boiling method

ActiveCN104071811AFully recycleShort process routeLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention discloses a process for extracting lithium salt from spodumene by adopting a sulfuric acid pressure boiling method. The process comprises the following steps: transforming the spodumene at high temperature, and adding sulfuric acid for pressure boiling to obtain soluble lithium sulfate and insoluble high-silicon residues, and separating lithium from lithium concentrate to further prepare lithium carbonate and obtain a byproduct-high-silicon soil; adding lime for purifying leachate liquid containing a small quantity of aluminum, iron and other alkali metal sulfate, removing impurities in a multi-step way to obtain a high-purity lithium sulfate solution, and carbonizing to generate a lithium carbonate product and a sodium sulfate byproduct. According to the process, the yield is high, the wastewater discharge quantity is low, mother liquor can be recycled, and the cost is low.

Owner:江西雅保锂业有限公司

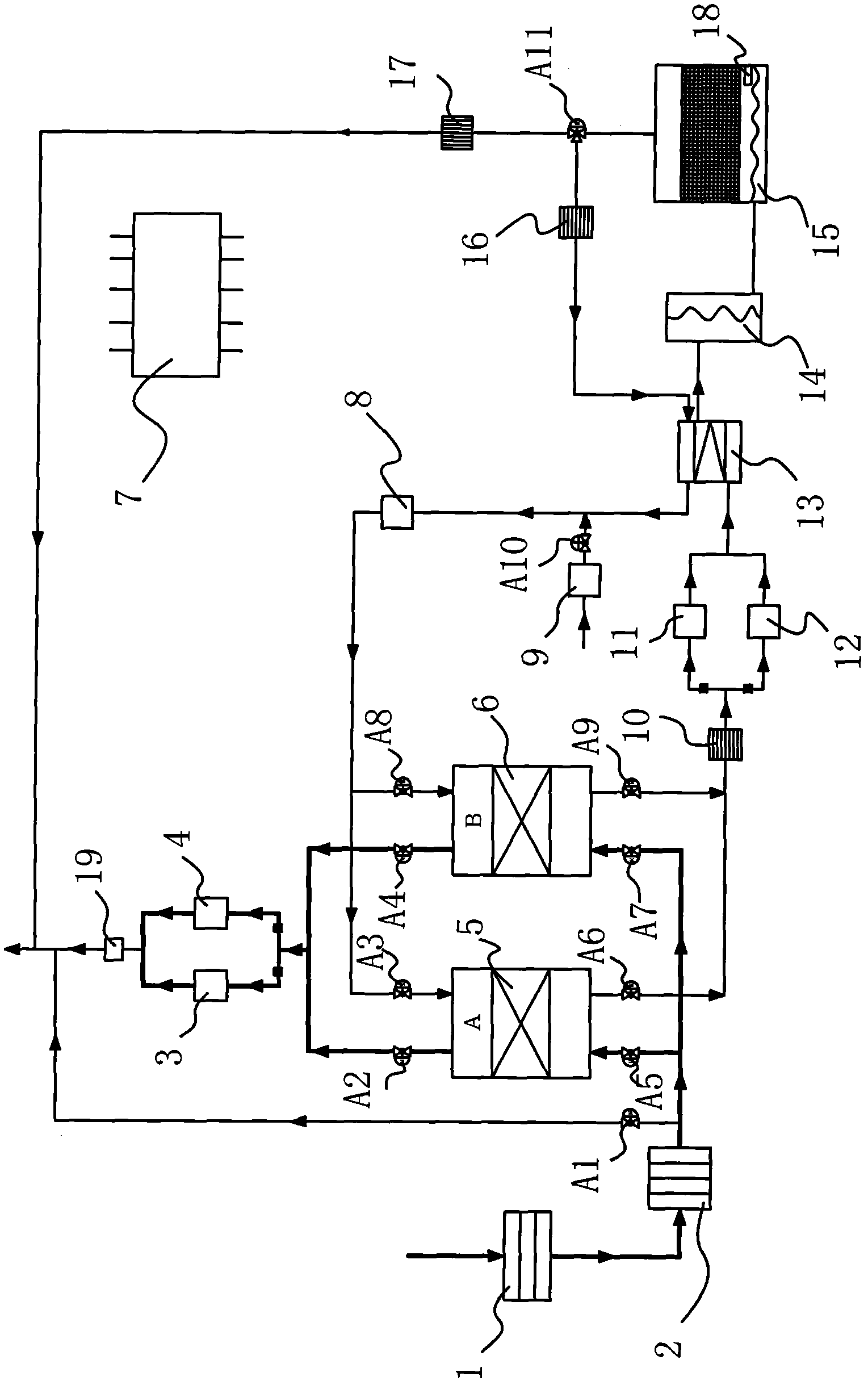

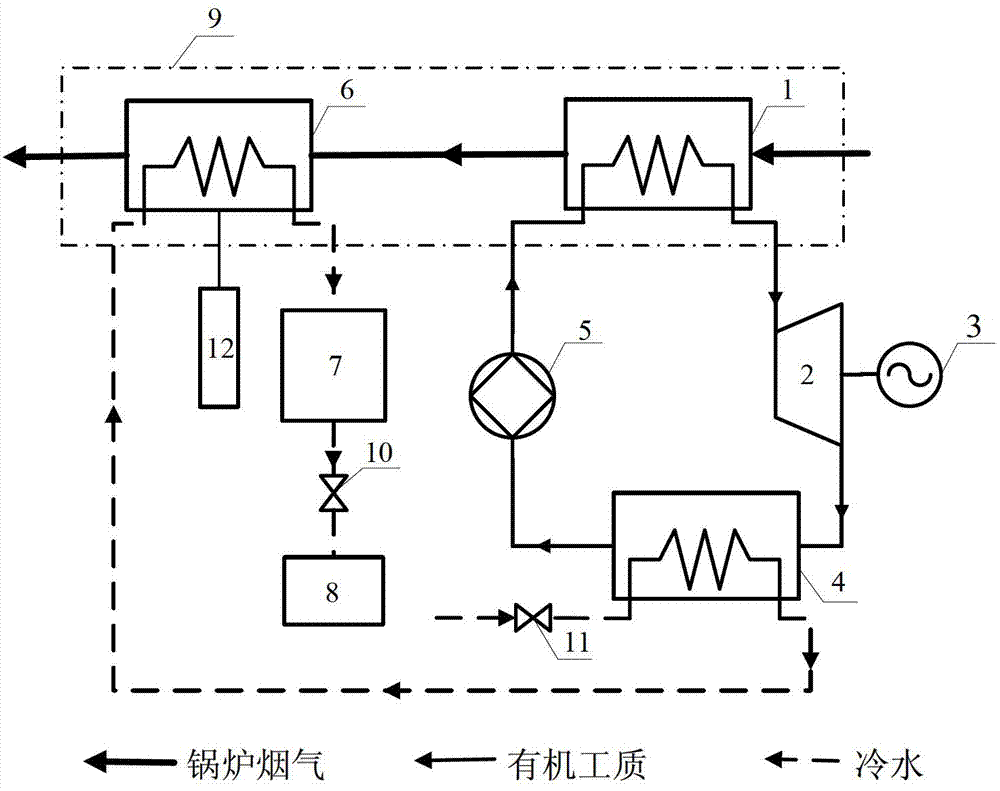

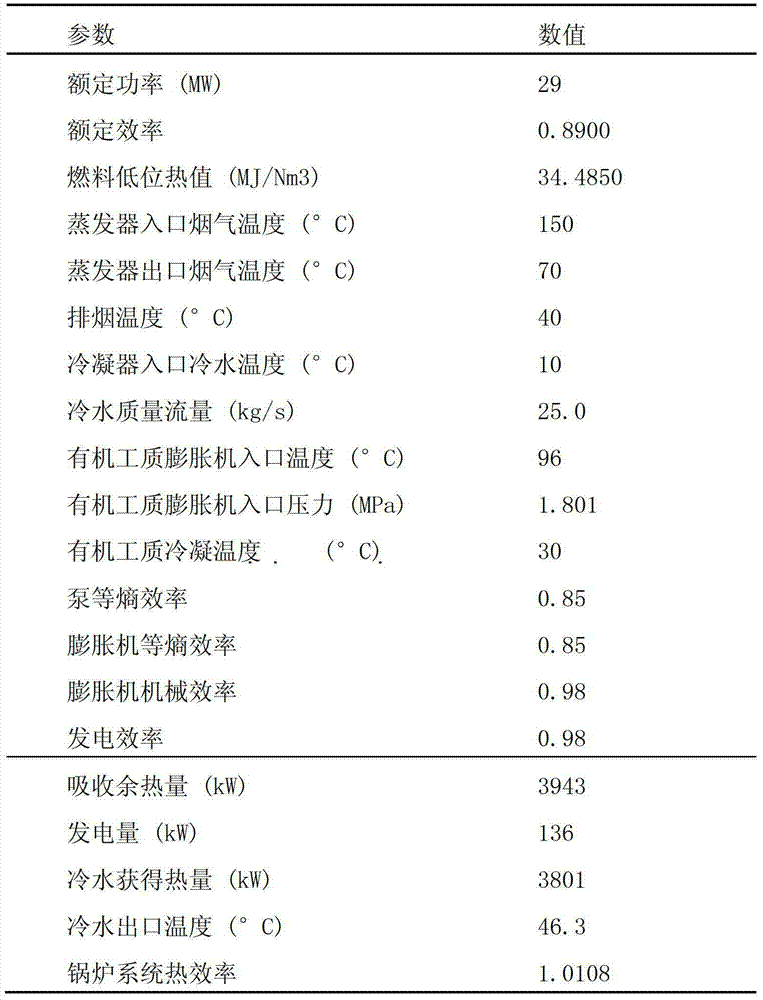

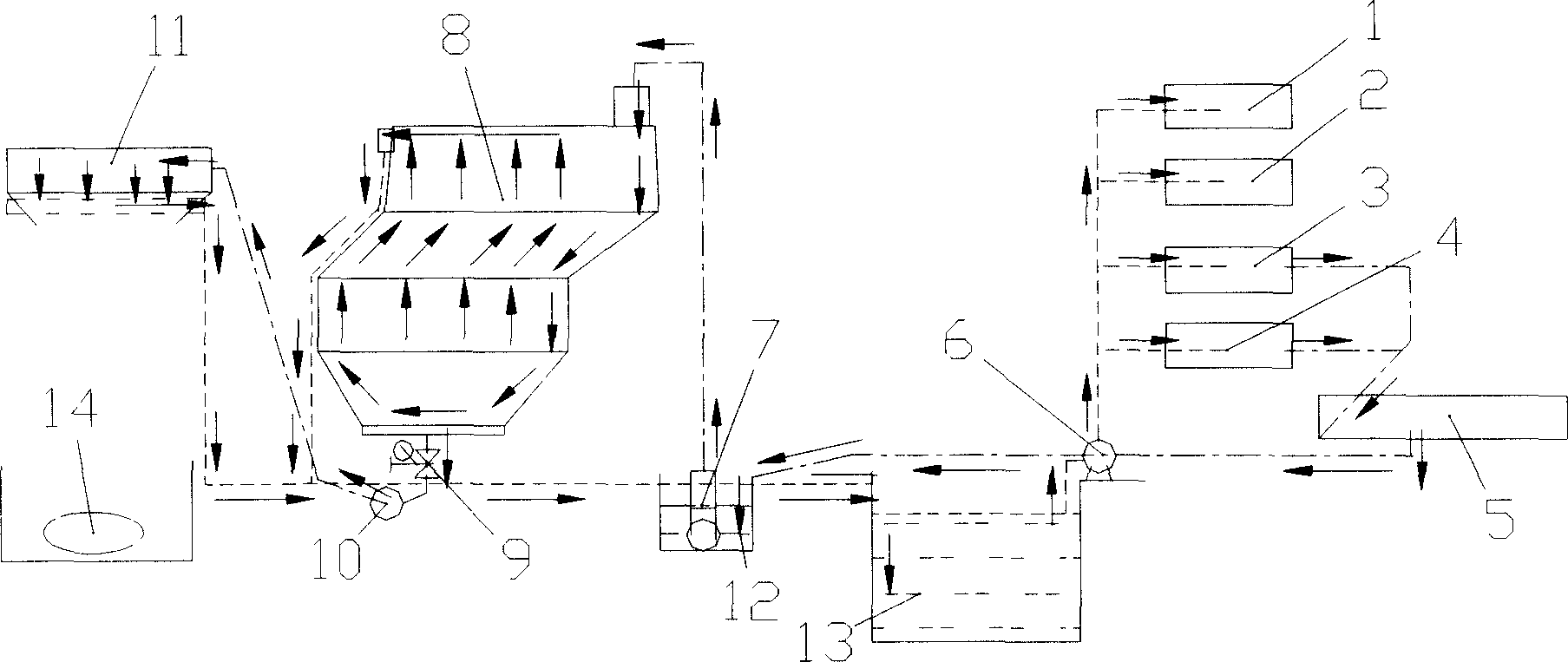

Smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle

ActiveCN103244214AHigh thermal efficiencyImprove utilization efficiencyEnergy efficient heating/coolingSteam useThermal energyOrganic Rankine cycle

The invention relates to a smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle and belongs to the technical field of energy utilization. The system comprises an evaporator (1), a condenser (4) and the like. The evaporator (1) and a smoke condensation heat exchanger (6) are disposed in a boiler tail flue. The system is used for step recovery of boiler smoke sensible heat and latent heat to allow for gradient deep utilization of smoke waste heat; high-quality sensible heat in the smoke is absorbed and utilized to output electric energy by organic Rankine cycle; and low-quality sensible heat and vapor latent heat in the smoke are absorbed by cold water, and the smoke is cooled to the temperature below dew point. In addition, organic Rankine cycle condensation temperature is lower than smoke temperature, so that the cold water sequentially passes the condenser and the smoke condensation heat exchanger to be heated and smoke waste heat is utilized deeply. The smoke condensation heat recovery combined heat and power supply system based on organic Rankine cycle allows for combined heat and power supply by organic Rankine cycle and gradient deep utilization of natural gas boiler smoke and fully recovers the heat; is environment-friendly; and is important to improving comprehensive utilization rate of fossil energy in China and promoting industrial energy conservation.

Owner:淳能热电科技股份有限公司

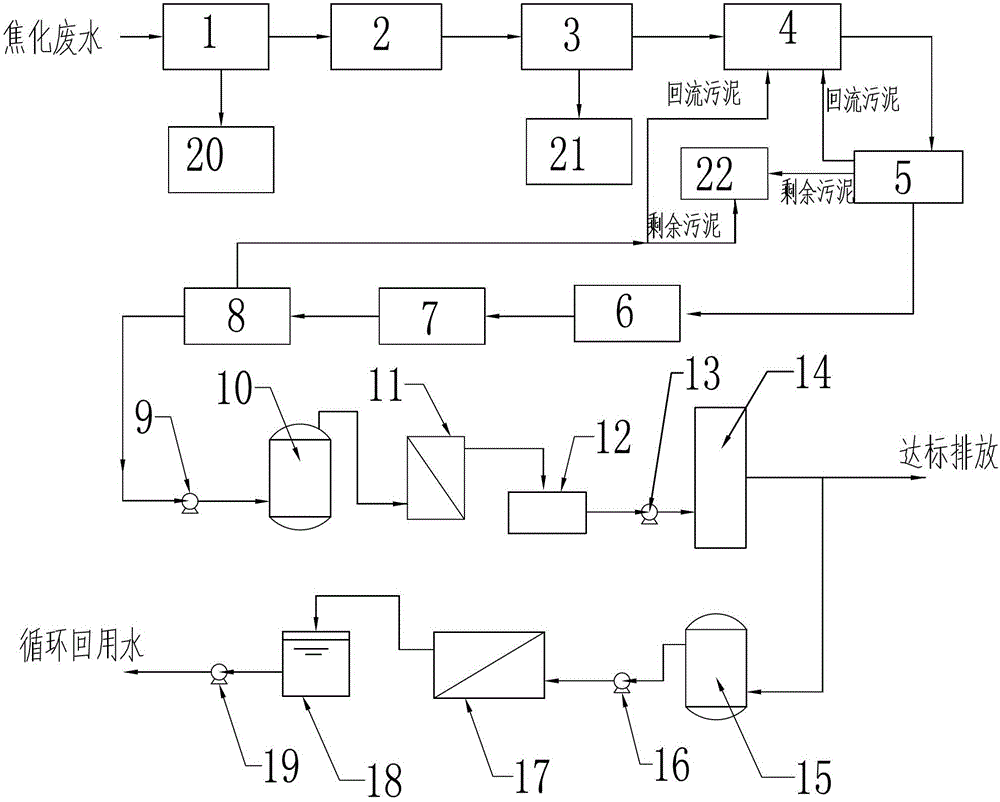

Coking wastewater comprehensive treatment method and system thereof

InactiveCN102718363AGuaranteed uptimeSimple processWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisOxygenPre treatment

The invention discloses a coking wastewater comprehensive treatment method comprising the following steps of: pre-treatment, biochemical treatment and deep treatment. The deep treatment step comprises sequential steps of filtering, ultra-filtering, carrying out resin adsorption, re-filtering, and carrying out reverse osmosis. With the adoption of a coking wastewater comprehensive treatment system of the coking wastewater comprehensive treatment method, the pre-treatment step adopts a de-oiling pond, an adjusting pond and an air floating pond, which are connected in sequence; the biochemical treatment step adopts a primary aeration pond, a primary settling pond, an oxygen-poor pond, an aerobic pond and a secondary settling pond, which are connected in sequence; and the deep treatment step adopts a multi-medium filter, an ultra-filtering device, a resin adsorption column and a reverse osmosis device. The coking wastewater comprehensive treatment method has the beneficial effects that the method is stable to operate and has a simple process and good treating effects.

Owner:浙江晶泉水处理设备有限公司

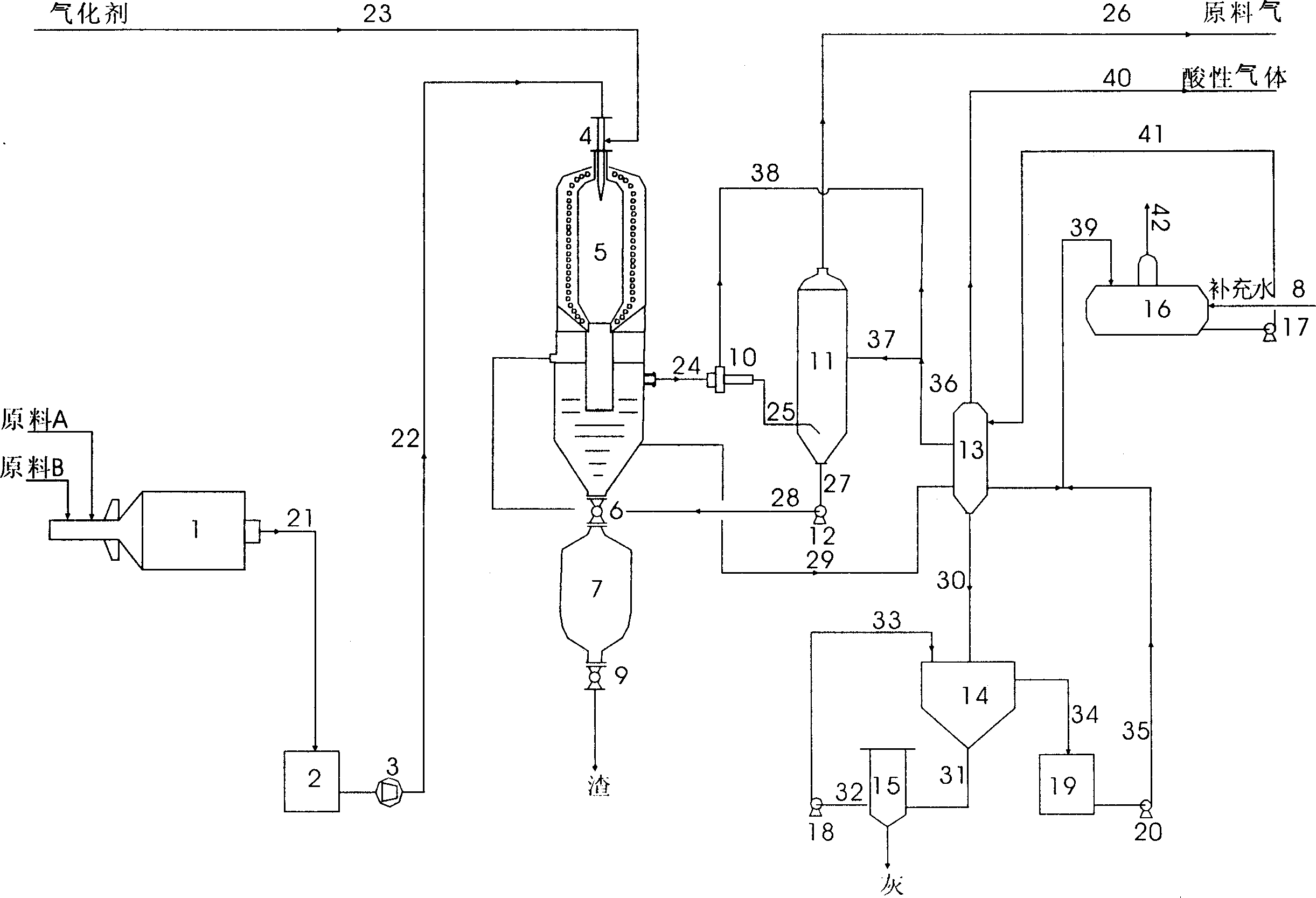

Pressurized gasifying process of polynary slurry

ActiveCN1637118AWide variety of sourcesFulfil requirementsChemical industryCombustible gas purificationThermal energyHydrogen

The pressurized gasifying process of polynary slurry includes five steps of preparing polynary slurry, pressurizing to gasify, purifying coarse gas, exhausting cinder and processing grey water. Specifically, the slurry prepared with one or several kinds of carbon and hydrogen containing material through grinding is made to produce intense oxidation with gasifying agent in gasifying furnace, so as to produce coarse gas with CO and H2 as main components; the coarse gas is thrice washed to produce required material gas; the cinder is chilled before exhaust; and the wash produced grey water is processed through concentration, precipitation and filtering to eliminate its ash component before being returned to the system for reuse while its heat is recovered. The said technological process has wide material adaptability, high gasification index, low investment in apparatus and other advantages.

Owner:XIAN ORIGIN CHEM TECH

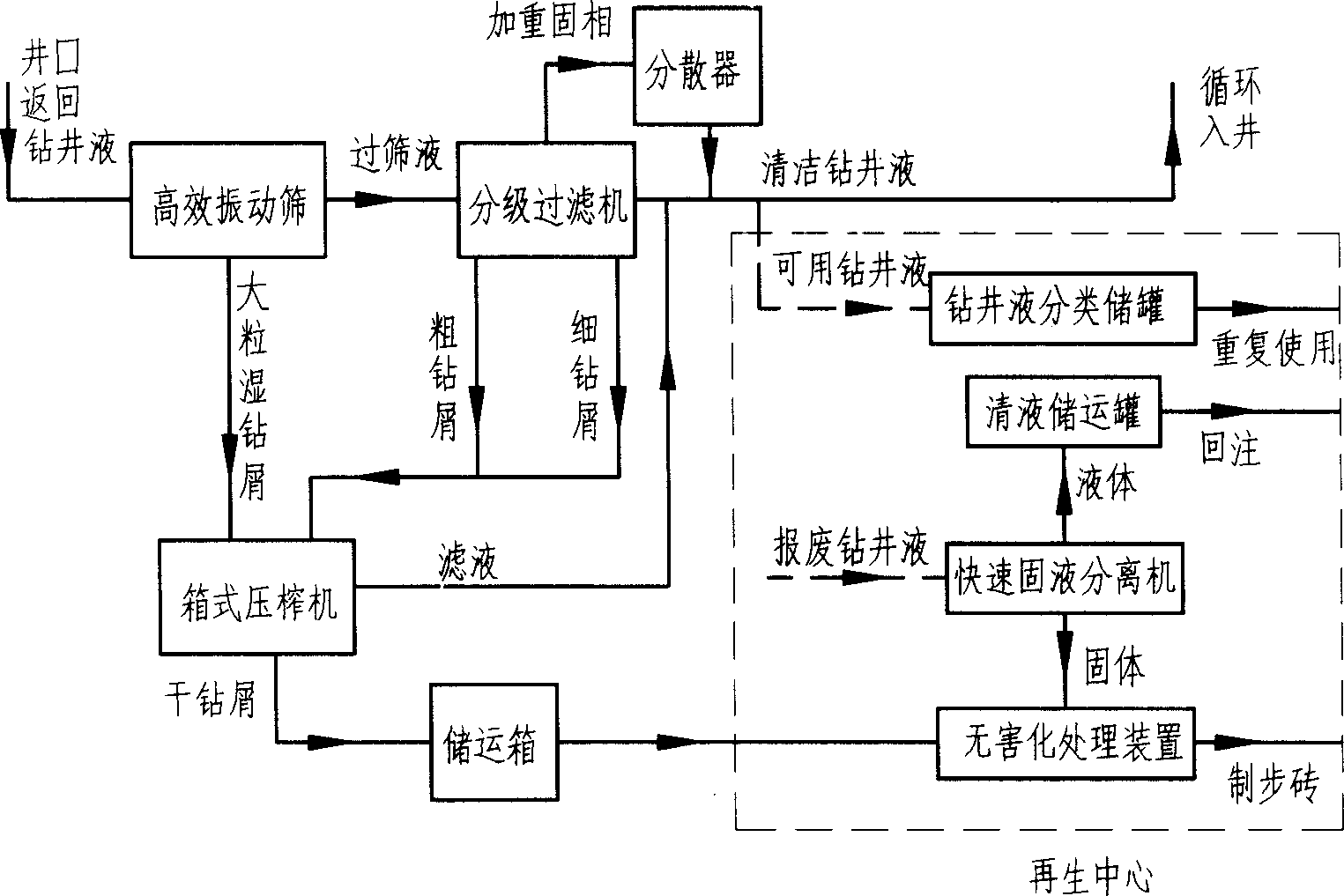

Technique for parallel processing drilling fluid and zero discharge of drill cuttings

The present invention belongs to the field of oil and gas field drilling engineering technology, and relates to a kind of drilling fluid and drill cuttings zero-discharge parallel treatment process. Said treatment process includes the portions of drilling fluid selective solid-phase control, drill cuttings on-line treatment and recovery utilization and drilling fluid regeneration and utilization. Said process utilizes high-effective vibration sieve and sorting filter to make selective solid-phase control of drilling fluid, at the same time utilizes one-box type press filter to make discharged wet drill cuttings undergo the process of drying treatment and further recover the drilling fluid. The dried drill cuttings can be used for making bricks.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

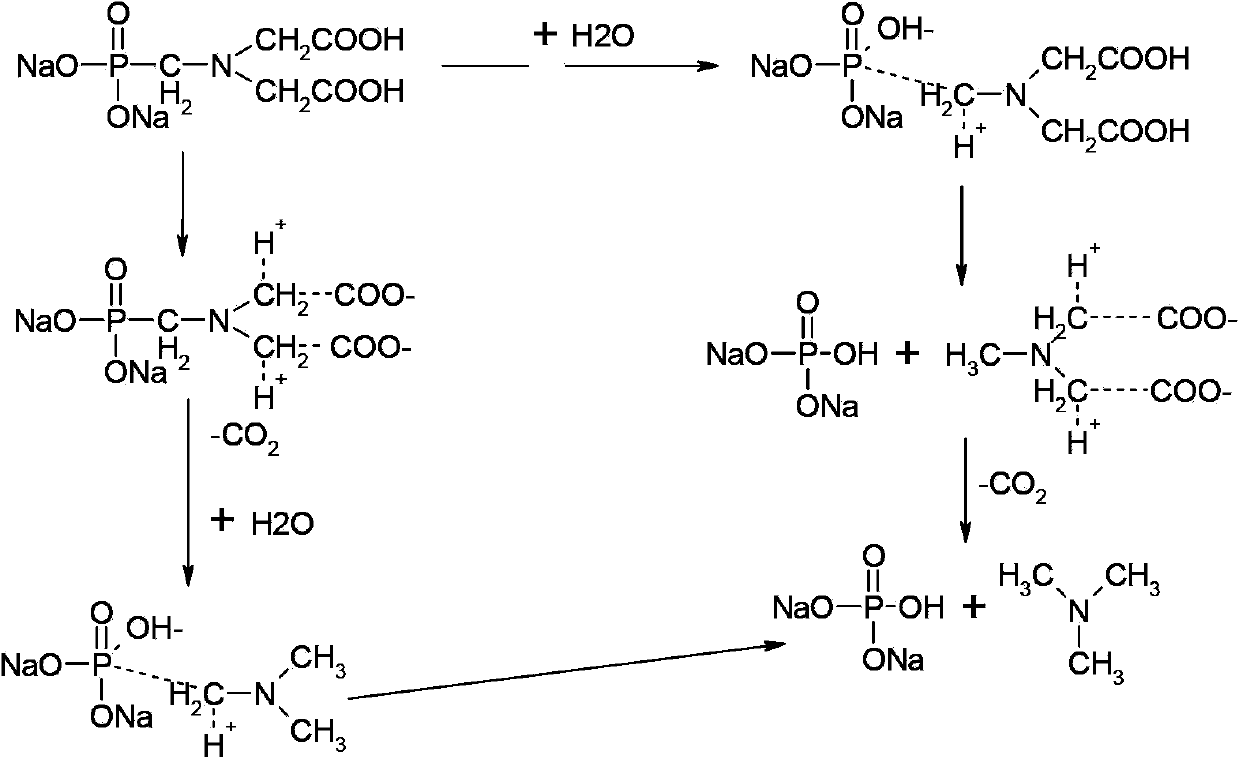

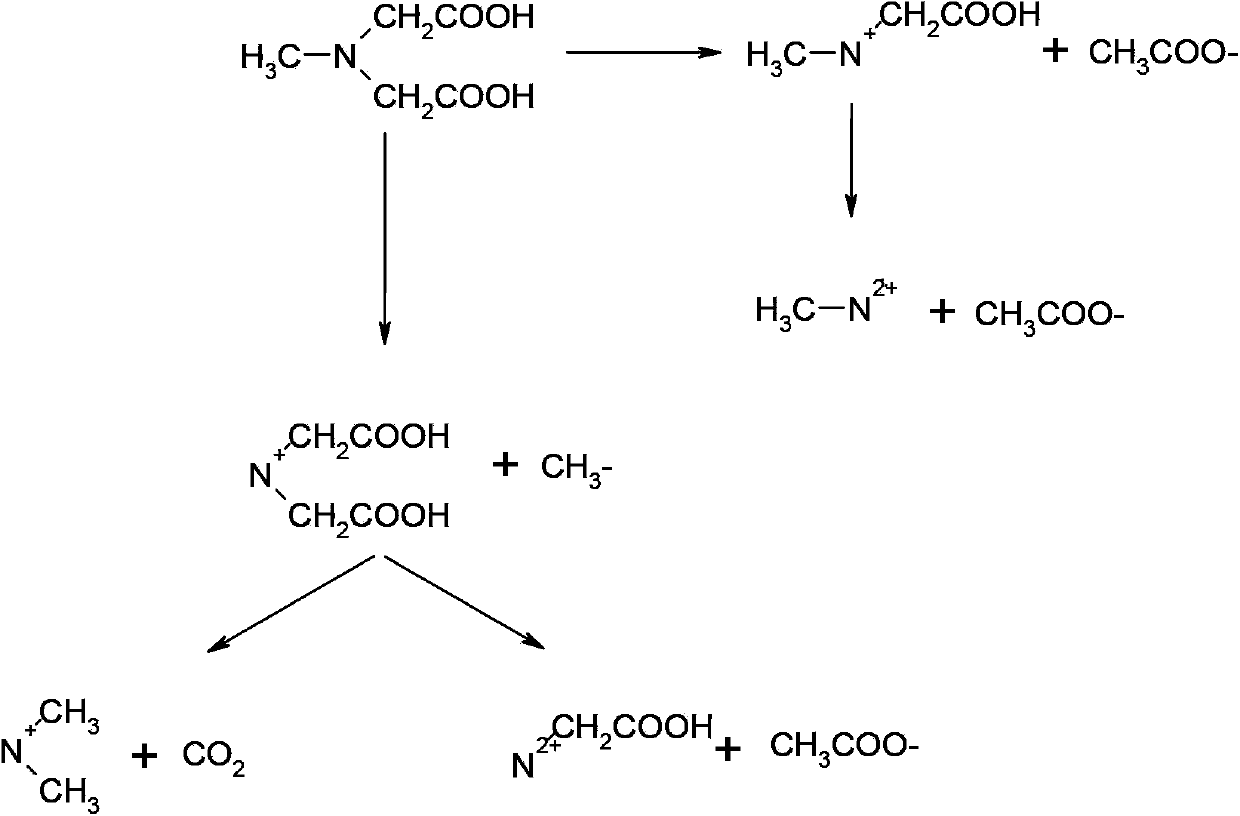

Comprehensive treatment and resource utilization method for industrial organic phosphorus waste liquid

ActiveCN103964622AFully recycleReduce generationMultistage water/sewage treatmentWater/sewage treatment by neutralisationResource utilizationEvaporation

The invention discloses a comprehensive treatment and resource utilization method for an industrial organic phosphorus waste liquid. The technology includes firstly the industrial organic phosphorus waste liquid allows organic phosphorus to be oxidized into inorganic phosphorus by a catalytic wet oxidation method, then the inorganic phosphorus material is subjected to evaporation, concentration and desalination, small-molecule organic matters generated from oxidation are removed, the material after concentration is subjected to high temperature treatment, and a solid product is recycled. Through the method of the invention, the waste liquid can be avoided from being directly subjected to a high temperature contact oxidation process to possibly generate nitrogen oxides, dioxin, smoke dust and other air pollution factors difficult to deal with, and secondary pollution cannot be generated. The waste liquid after treatment is appropriately blended to be transformed into pyrophosphate, polyphosphate, metaphosphate, orthophosphate and other substances according to needs, so that recycling and reutilization of phosphorus is achieved.

Owner:JIANGSU YOUTH CHEM +1

Full-body graining polyethylene plastic wood composite and preparation method thereof

ActiveCN104744955AImprove experienceEffective control of melt flow indexLow-density polyethyleneMasterbatch

The invention provides a full-body graining polyethylene plastic wood composite, which includes a mixture formed by a color masterbatch and a base material. The color masterbatch and base material contain a high density polyethylene recycled material, so as to not only reduce the cost of raw materials but also treat the waste plastics in a resource way, and reduce the waste of resources. The low density polyethylene added in the color masterbatch is the key component for the regulation of color masterbatch melt flow index, helps to achieve comprehensive, convenient and effective recovery and reuse of the waste high density polyethylene plastic. The coextruded plastic wood composite prepared by the invention has the advantages of low price, similarity to the natural wood and good user experience. The invention also provides a preparation method of the full-body graining polyethylene plastic wood composite, and the method is simple in equipment, high in automation degree and easy to large scale production.

Owner:GEM CO LTD

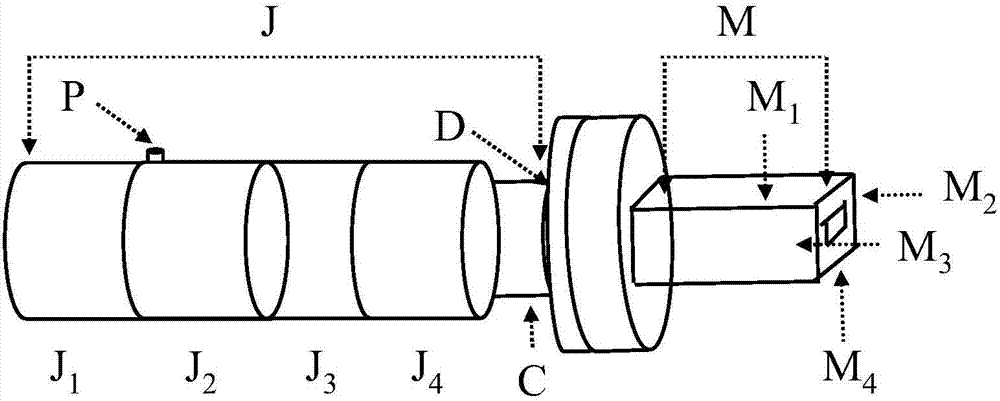

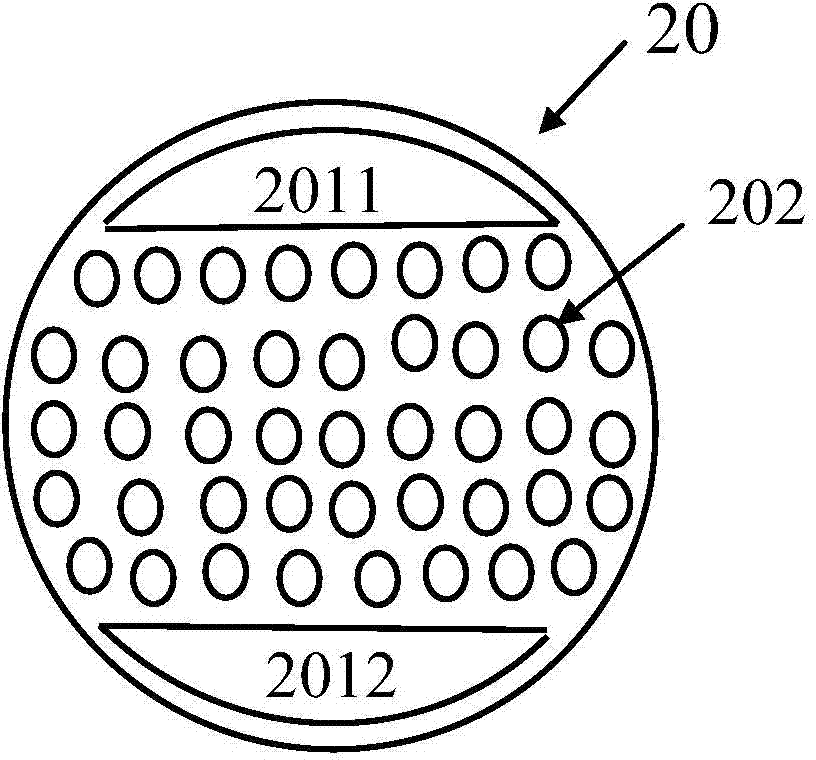

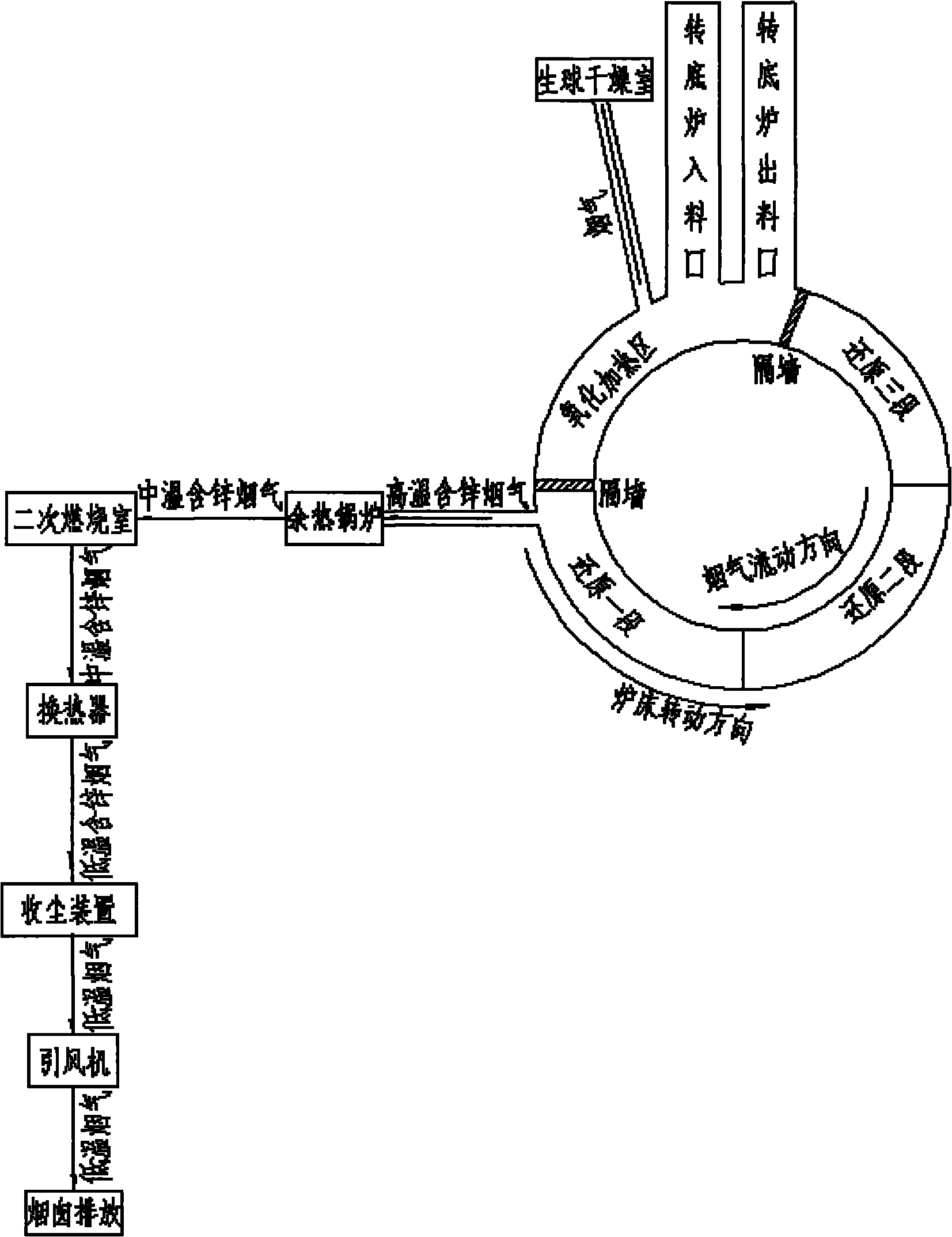

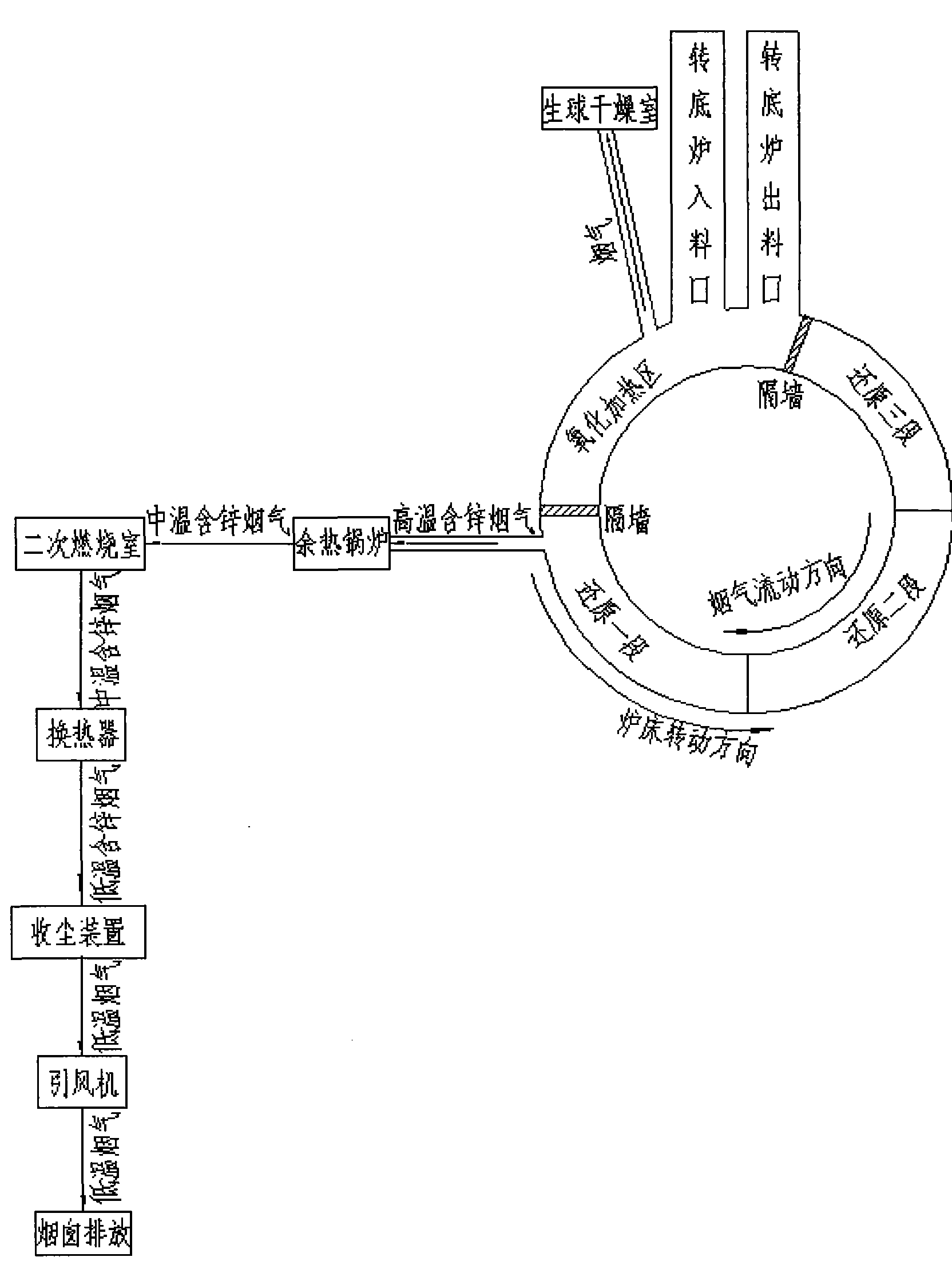

Process for processing smoke

InactiveCN101893387AHigh recovery rateReduce processingEnergy industryIncreasing energy efficiencyCombustionProcess engineering

The invention relates to a process for processing smoke, which is characterized in that: in the process, the smoke generated by a rotary hearth furnace is subjected to segmental processing. In the process for processing the smoke, the segmental processing is performed on the smoke generated by the rotary hearth furnace, and the low zinc content smoke in an oxidation heating region is used for drying a preheated green ball, so the waste heat of the smoke can be completely recycled, unburned gas can also be combusted completely to recycle usable waste heat further; the smoke in a high-temperature reducing region where the zinc is gasified and volatilized intensively is subjected to dust removal and zinc recycling after waste heat recycling and secondary combustion, and the amount of the smoke which needs to perform zinc recycling is reduced, so the equipment investment and operation cost of a smoke processing system are reduced; and due to the secondary waste heat recycling and the secondary combustion of the smoke in the high-temperature reducing region, the waste heat of the smoke in the region can be completely recycled, the recovery rate of the zinc is improved, and the environmental pollution is reduced.

Owner:CISDI ENG CO LTD

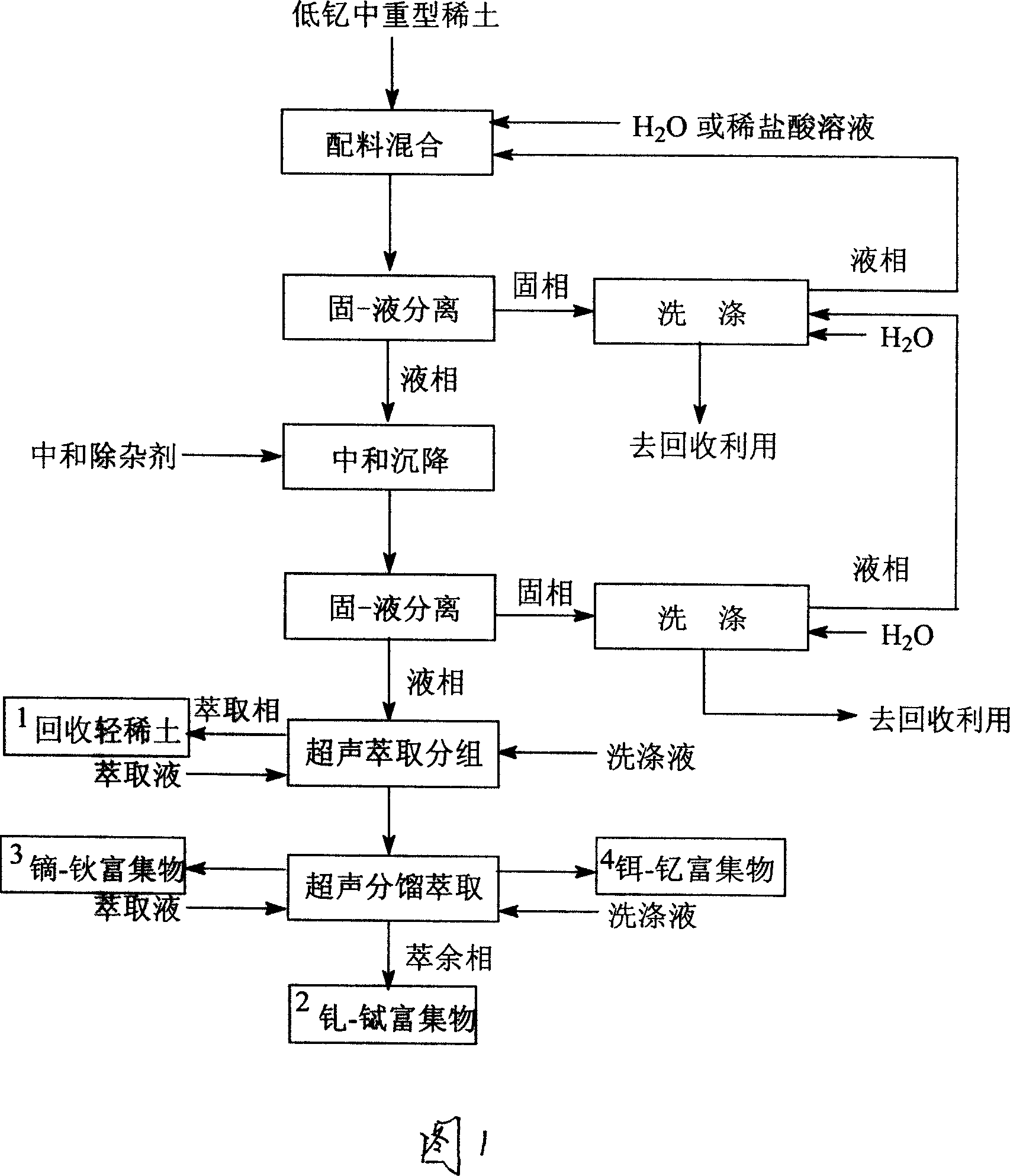

Method for separating highly-pure rare-earth oxide from low-yttrium middle-heavy rare earth mine

InactiveCN101012500ATake advantage ofImprove the utilization efficiency of the whole processProcess efficiency improvementChemical treatmentRare earth

The invention discloses a full-separating method of high-purity rare earth oxide from low-yttrium middle-heavy rare earth rare earth ore, which is characterized by the following: producing La2O3, Ce2O3, Pr5O11, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3, Er2O3 and Y2O3 through ultrasonic extracting-electrochemical quantivalence-changing synthetic separating technique; fractionating; extracting.

Owner:CHANGZHOU HUANAN CHEM +2

Secondary water supply system peak shifting water replenishing dispatching management platform

InactiveCN108755842AImprove water supply efficiencyFully recycleService pipe systemsWater mainsMicrocontrollerRole management

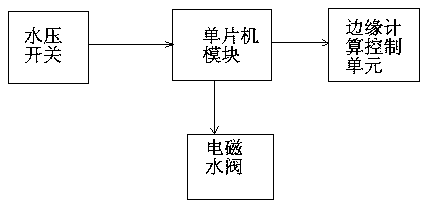

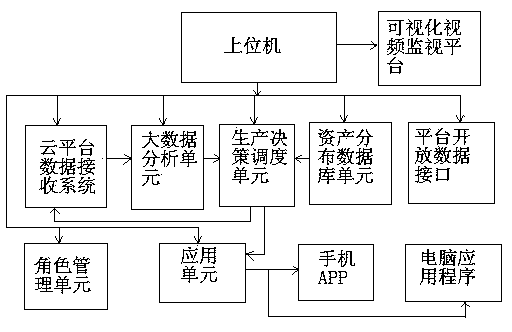

Disclosed is a secondary water supply system peak shifting water replenishing dispatching management platform. A plurality of secondary water supply systems are each provided with a set of data collecting and emitting control equipment, each data collecting and emitting control equipment comprises a water pressure switch, a single-chip microcomputer module, an edge calculating control unit, and anelectromagnetic water valve installed on a water tank and connected with a municipal tap water pipe network pipeline; a manager is provided with an upper computer, a cloud platform data receiving system, a big data analyzing unit, a production and decision dispatching unit, an asset distribution database unit, an open platform data interface, a role management unit and an application unit are installed inside the upper computer, the manager is further provided with a visualized video and data monitoring platform, the application unit comprises a manager mobile phone side APP and a computer side program. It is ensured that water inside the water tank is sufficiently recycled, water is sufficiently supplemented to the water tank at a non-peak period, the water quality is improved, water generated by drainage is reduced, and energy consumption generated by drainage is lowered, and the whole water consumption safety of residents is improved through maintenance, cleaning and management ofthe water tank.

Owner:成都优链加科技有限公司

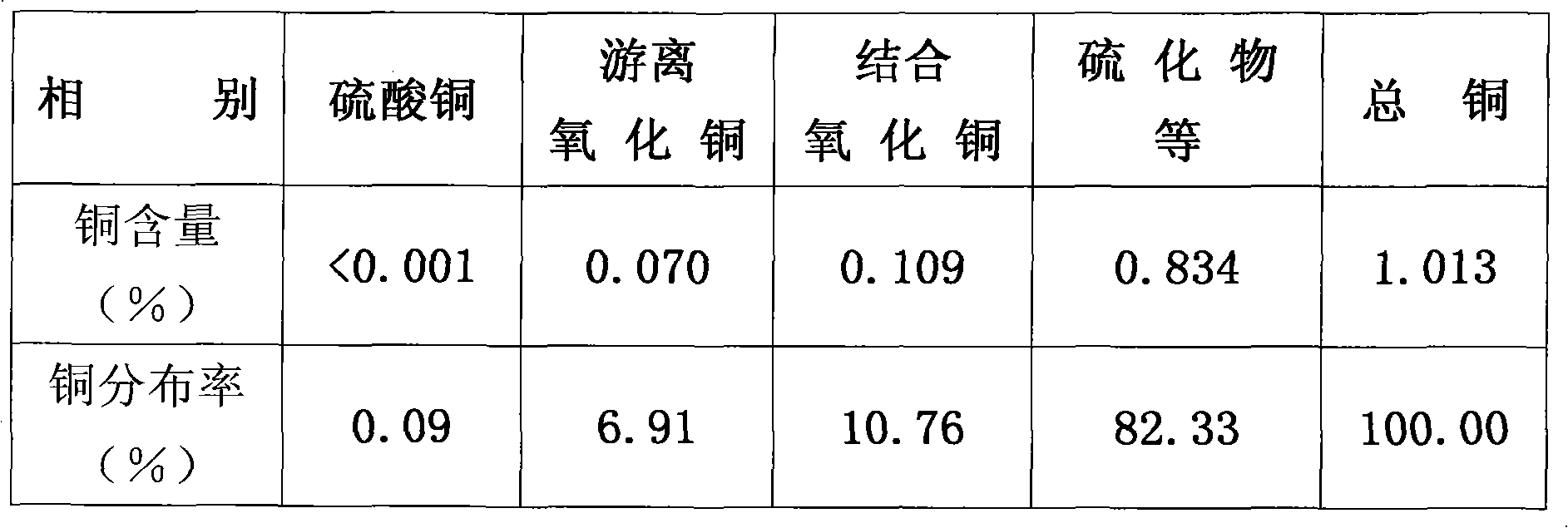

Comprehensive treatment method for high-mud content high-combination rate mixed copper ore

The invention provides a comprehensive treatment method for high-mud content high-combination rate mixed copper ore, which comprises the following steps of: grinding the mixed copper ore and roughing copper sulfur so as to obtain copper sulfur ore and tailings; concentrating the copper sulfur ore to obtain the copper ore and middlings; concentrating the copper ore to obtain the copper concentrate, and performing copper rough concentration on the middlings to obtain the copper ore and middlings simultaneously; concentrating the copper ore to obtain the copper concentrate, and performing copper scavenging on the middlings to prepare sulfur concentrate for recovery; performing magnetic separation on the middlings subjected to the copper scavenging so as to obtain magnetic for recovery, and returning the tailings to copper sulfur roughing. In the method, the pyrite (sulfur concentrate) is separated from the copper concentrate successfully in the flotation process for the first time so as to obtain high-quality copper concentrate; meanwhile, a large amount of magnetic pyrite is separated from the middlings subjected to flotation through the magnetic separation step, the iron sulfur content in the middlings is reduced to the greatest degree, the middlings become high-quality sulfur concentrate which can be directly used as raw materials for producing sulfuric acid, the tailings subjected to magnetic separation return to the system for recycled production, and valuable resources are fully recycled.

Owner:YUNNAN DIQING MINING DEV

Treatment method for direct coal liquefaction residues

ActiveCN104845652AAvoid high costRealize large-scale industrial production applicationWorking-up pitch/asphalt/bitumen by selective extractionSolventChemistry

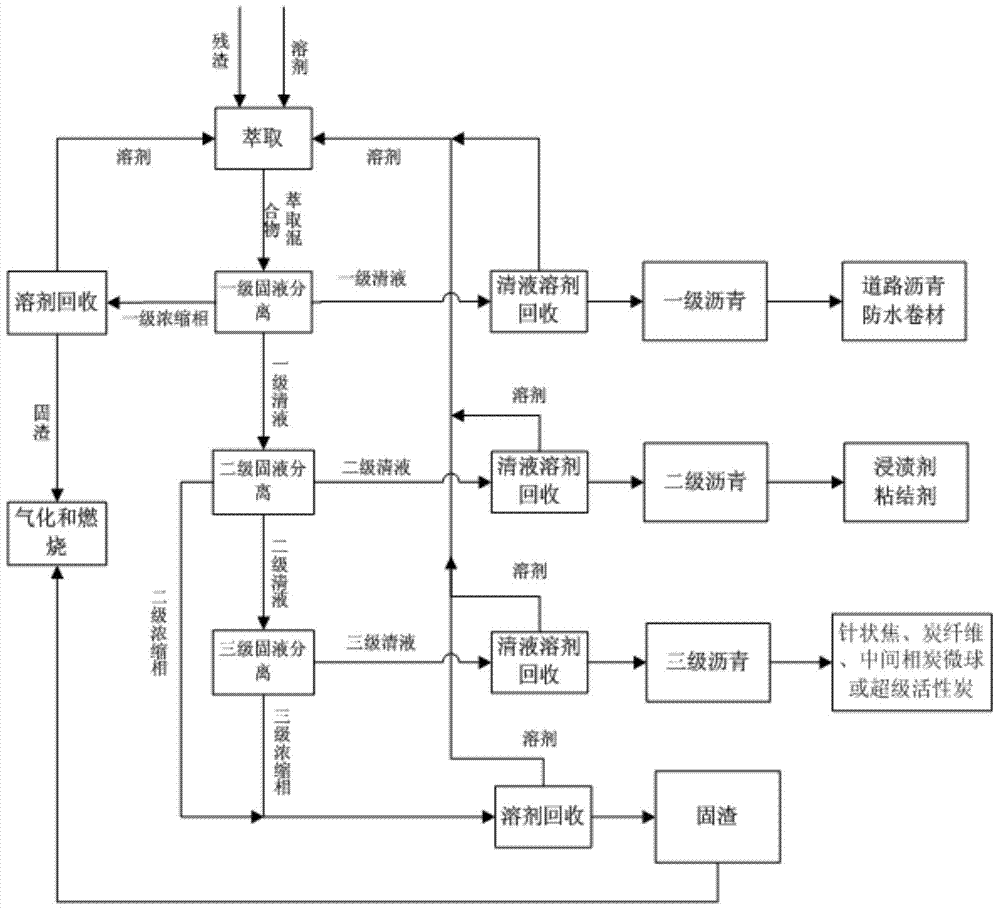

The invention provides a treatment method for direct coal liquefaction residues. The treatment method comprises the following steps: extracting direct coal liquefaction residues with an extraction solvent to obtain an extraction mixture; performing first-stage solid-liquid separation on the extraction mixture to obtain a first-stage clear liquid and a first-stage concentrated phase; performing second-stage solid-liquid separation on a part of or all the first-stage clear liquid to obtain a second-stage clear liquid and a second-stage concentrated phase; performing third-stage solid-liquid separation on a part of or all the second-stage clear liquid to obtain a third-stage clear liquid and a third-stage concentrated phase; performing second-stage solid-liquid separation on a part of the first-stage clear liquid and performing clear liquid solvent recovery treatment on rest of the first-stage clear liquid to obtain first-stage pitch; performing third-stage solid-liquid separation on a part of the second-stage clear liquid and performing clear liquid solvent recovery treatment on rest of the second-stage clear liquid to obtain second-stage pitch; and performing clear liquid solvent recovery treatment on all the third-stage clear liquid to obtain third-stage pitch. By the treatment method disclosed by the invention, three pitch products can be obtained and the added profit value of pitch in the direct coal liquefaction residues can be improved favorably.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

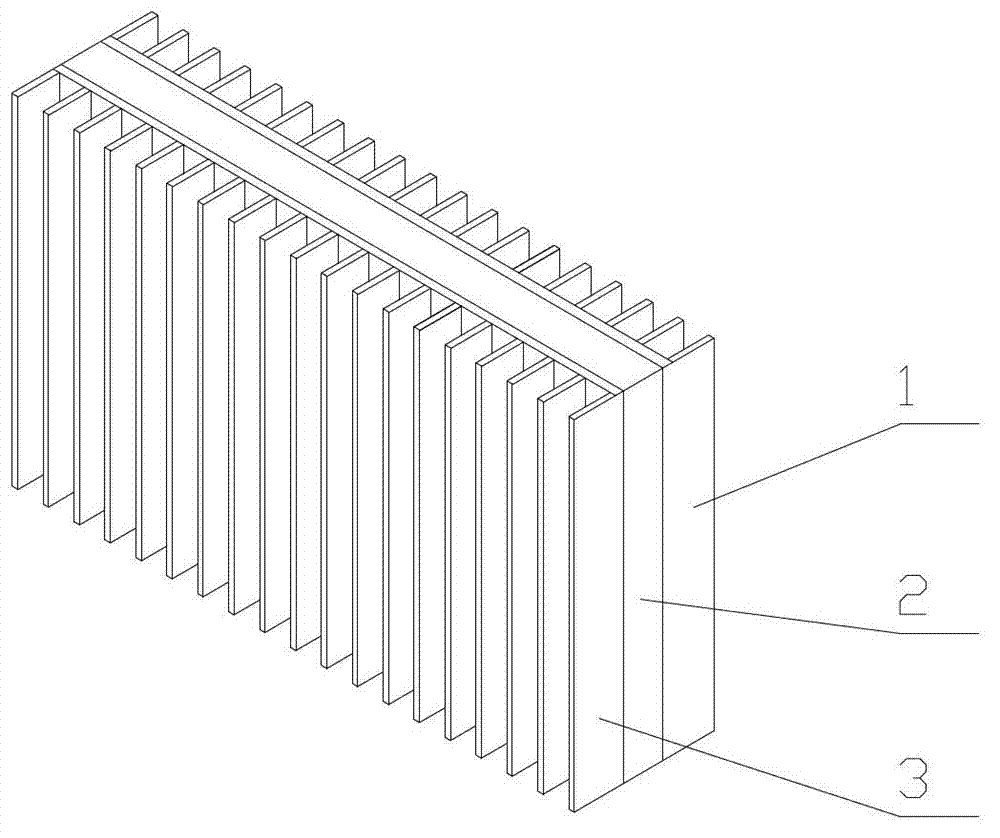

Condensing unit and clothes dryer with condensing unit

ActiveCN102899874APromote sheddingReduce lossesMachines using electric/magnetic effectsTextiles and paperWater vaporEngineering

The invention discloses a condensing unit, which comprises a semiconductor refrigeration fin, wherein two sides of the semiconductor refrigeration fin are respectively connected with hot end cooling fins and cold end heat absorbing fins through two heat conduction blocks, and a heat insulation material is filled between the hot end cooling fins and the cold end heat absorbing fins so as to insulate the heat conduction between the hot end cooling fins and the cold end heat absorbing fins. The clothes dryer comprises a clothes drying cavity and a circulating air duct, wherein two ends of the circulating air duct are communicated with the clothes drying cavity, and the condensing unit is arranged into the circulating air duct. The air in the circulating air duct is condensed and dehumidified through the cold end heat absorbing fins of the condensing unit when the air is circulated, and then, is returned into the clothes drying cavity after being heated by the hot end cooling fins. The condensing device and the clothes drying machine with the condensing device can condense water vapor and heat the air, and makes the best of the air circulation, so that the clothes drying machine has higher clothes drying efficiency and is free from vibration and noise.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

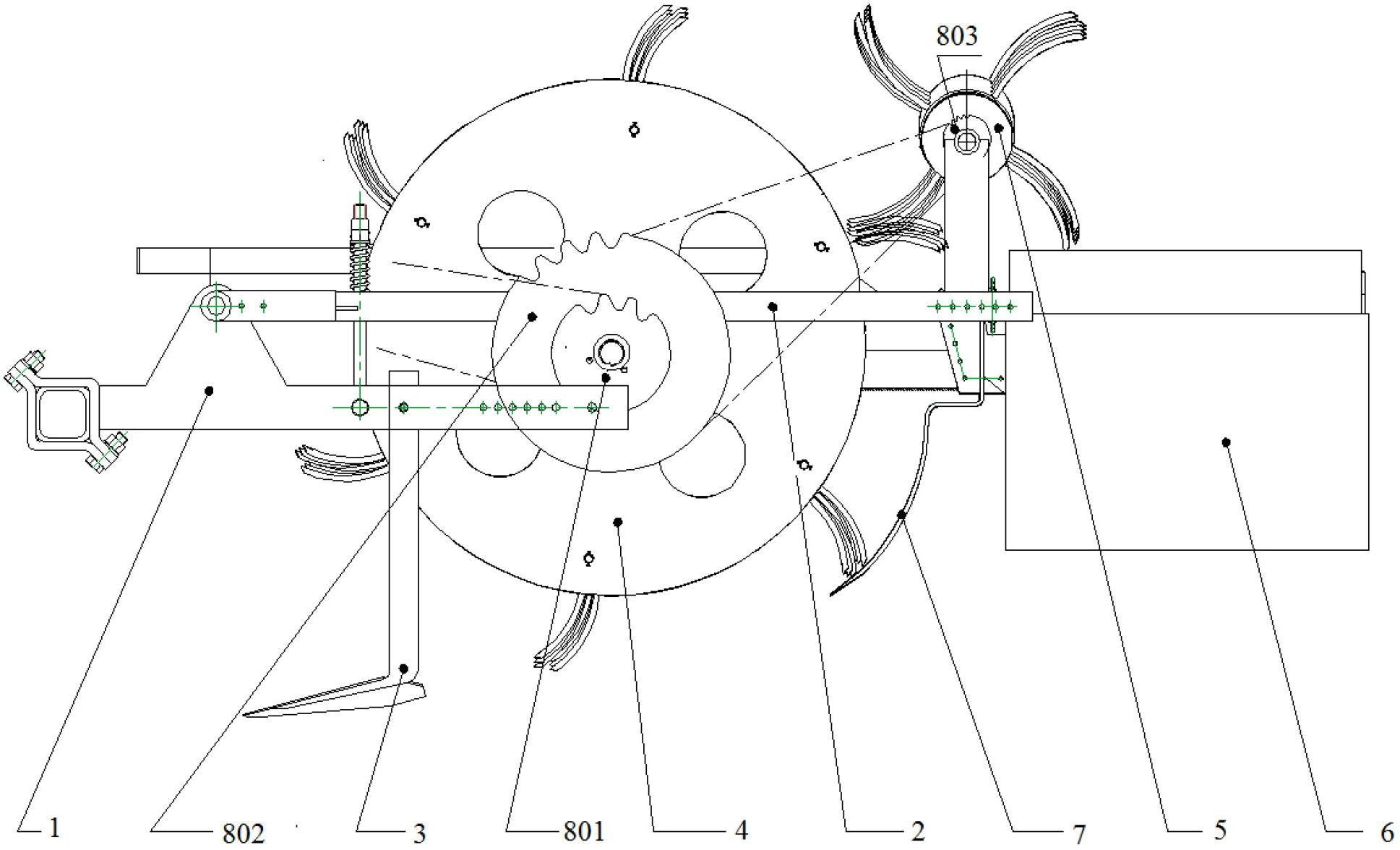

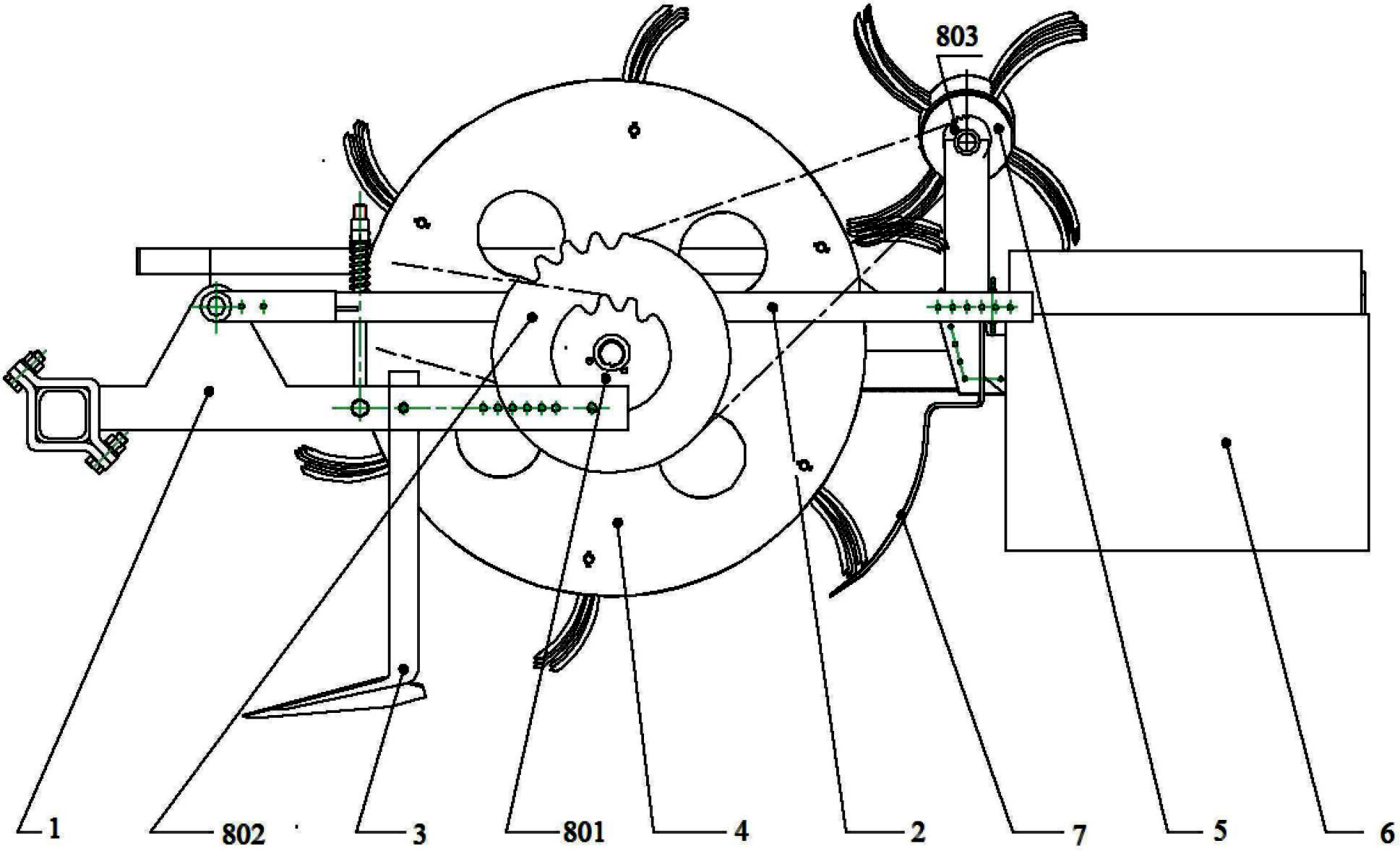

Film-picking and film-unloading mechanism for residual film recovery of straight-rod crops

InactiveCN102668939AReasonable configurationSimple structureGatherer machinesPlant protective coveringsDrive shaftEngineering

The invention belongs to the field of minitype agricultural machinery, and in particular relates to a film-picking and film-unloading mechanism for residual film recovery of straight-rod crops. A frame is connected with a profiling frame; a break shovel is arranged under the middle of the frame; a film-picking component and a film-unloading component are arranged in parallel on the profiling frame according to front and back positions; a first transmission wheel and a second transmission wheel which synchronously move are arranged on a drive shaft of the film-picking component; a third transmission wheel is arranged on a drive shaft of the film-unloading component; the first transmission wheel is connected with a traction mechanism through a chain; the second transmission wheel and the third transmission wheel are driven by the chain; film-rising shovels are arranged behind the film-picking component and on the profiling frame under the film-unloading component; and a film collection box is arranged at the rear end of the profiling frame. The mechanism is reasonable in arrangement, simple in structure and reliable in film-picking and film-unloading, low in cost and is convenient and feasible, and is convenient to mount and repair; and moreover, the mechanism can continuously operate, and the film can be picked cleanly.

Owner:CHINA AGRI UNIV

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

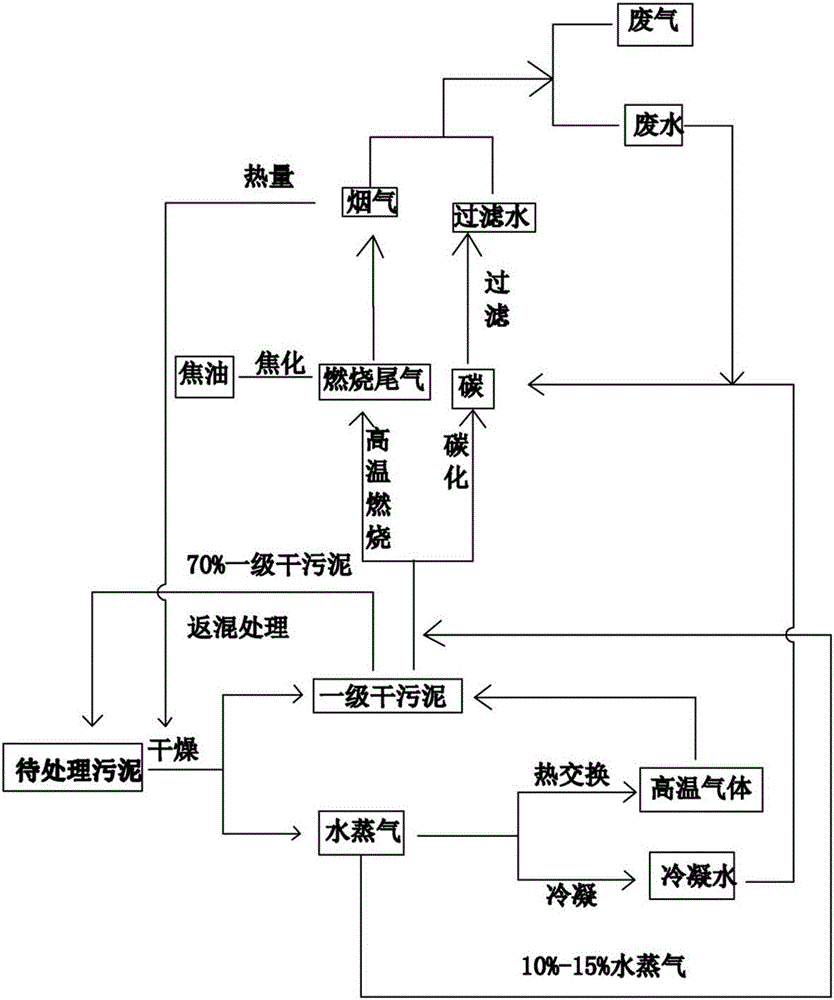

Continuous thermal decomposition method and apparatus for sludge

InactiveCN104986934AReduce the temperatureReduce lossSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeWater vapor

The invention relates to a continuous thermal decomposition method and apparatus for sludge. The method comprises the following steps: drying and carbonization: a step of drying and carbonizing to-be-treated sludge at negative pressure; heat exchange and recovery: a step of subjecting high-temperature water vapor produced in the drying process of the sludge to heat exchange and condensation, recovering heat, applying the recovered heat to drying, adsorbing and filtering condensed water with carbon produced by carbonization and then recovering the treated condensed water for cyclic utilization; and treatment of combustion tail gas: a step of cooling flue gas produced by carbonization with the outer wall of a drying system, washing the flue gas with the condensed water, discharging the washed flue gas and subjecting waste water produced in washing to adsorption and impurity removal by carbon produced by carbonization of the sludge so as to form filtered water for cyclic utilization. The continuous thermal decomposition method for the sludge makes full use of heat and products produced in drying and carbonization of the sludge, recovers the heat and cyclically applies the recovered heat to drying and carbonization of the sludge, so a self-sufficient heat energy supply system is established, and no extra energy is consumed; thus, the method is energy-saving and environment-friendly.

Owner:李学文

Process for ball milling and water washing of waste iron and steel slag, slag slurry treatment process, and apparatus therefor

InactiveCN1628910AFully recycleEasy to separateSolid waste disposalMagnetic separationIron powderSlag

This invention relates to a steel waste residue ball grinding and washing that is the residue plasm process and its device. Its technique scheme keys comprise the following: current wet ball grinding filtering process, dry magnetic selection process and wet magnetic selection process. It is characterized by the following: the magnetic steel waste residue is put into the wet ball grinding device through transmission and filter device for wet ball grinding; after filtering, its steel residue are selected through dry magnetic selection process and is processed into bean products through dry device; the mineral liquid got from the wet ball grinding and filtering selects the mineral powder through wet magnetic selection process to get the iron powder product through dehydrate device.

Owner:湘潭钢铁集团有限公司

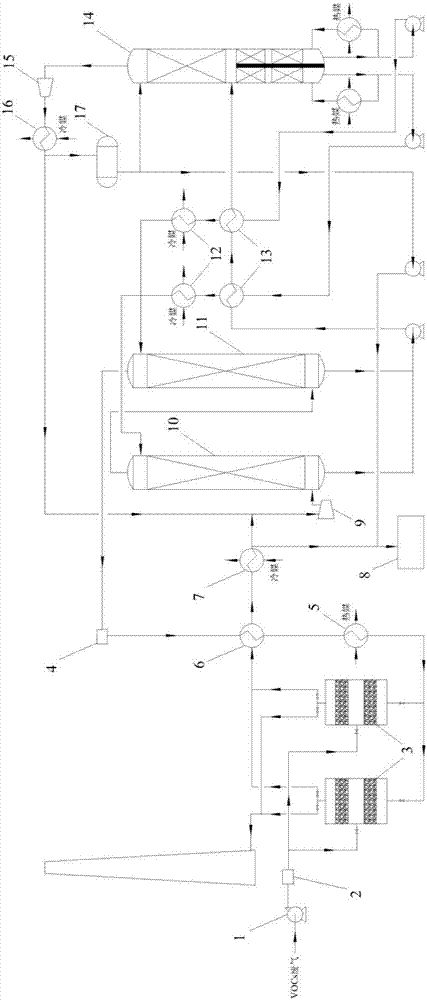

Method and device for recycling and treating waste gas with VOCs (volatile organic compounds)

PendingCN107261754AImprove adsorption capacityContains low VOCsGas treatmentDispersed particle separationEnvironmental engineeringEnergy consumption

The invention relates to a method and a device for recycling and treating waste gas with VOCs (volatile organic compounds). The device comprises an adsorption unit, an absorption unit and a rectification unit. The adsorption unit is used for adsorbing the VOCs, the absorption unit is used for absorbing the VOCs, and the rectification unit is used for recycling the VOCs and regenerating absorbents. The method and the device for recycling and treating the waste gas with the VOCs have the advantages that the VOCs absorption efficiency can be improved, loss of the absorbents can be reduced, and the VOCs further can be recycled; energy consumption in production procedures can be effectively reduced, and accordingly the production cost can be saved to a great extent.

Owner:HEBEI XIANHE ZHENGYUAN ENVIRONMENTAL TREATMENT TECH CO LTD

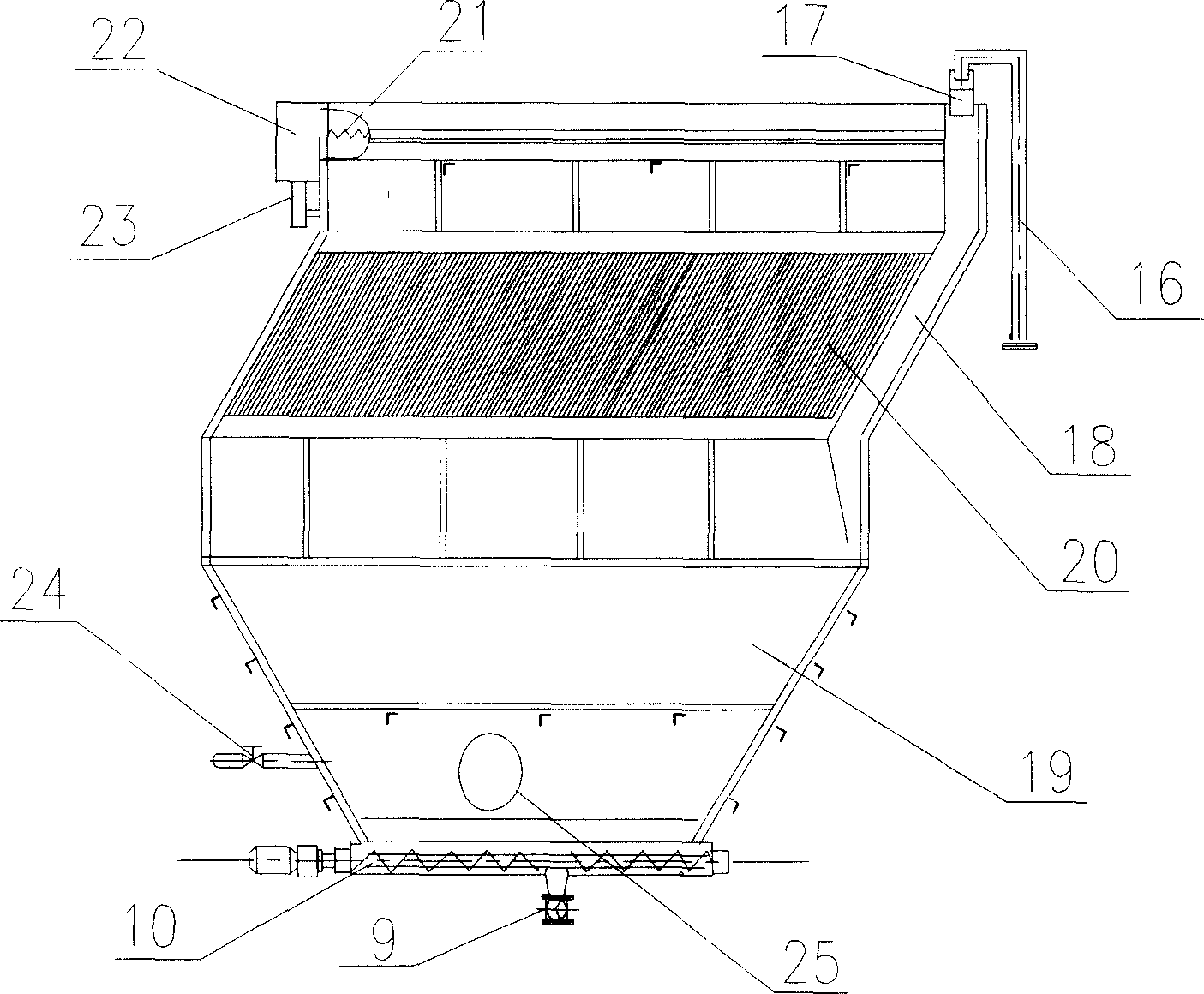

Drying pretreatment method and device for urban domestic garbage

InactiveCN101476729AIncrease the low calorific valueFully recycleIncinerator apparatusCombined combustion mitigationPretreatment methodEnvironmental engineering

The invention relates to a method and a device for drying pretreatment on municipal domestic refuse by municipal domestic refuse incineration technology. The invention adopts the technical proposal that the method comprises: incinerating the municipal domestic refuse, removing dust of the municipal domestic refuse, taking fume guided out of a fume extractor as a heat source for drying the domestic refuse, and utilizing the fume residual heat to dry the domestic refuse to be treated. The device and the method have the advantages that: 1) high-temperature fume generated from incineration is utilized to dry the domestic refuse, thereby fully recycling the heat energy, and having no influence on the steam generation amount and electricity generation amount synchronously; 2) the high-temperature fume generated from incineration is utilized to dry the domestic refuse, thereby reducing moisture in the refuse, improving 300 to 400 kacal / kg of lower heating value of the refuse, reducing auxiliary fuel addition amount, and reducing operation cost; and 3) after the refuse is dried, because partial moisture in the refuse is discharged, the total amount of the incinerated refuse is reduced, the scale of a incinerator can be reduced, and equipment investment is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Method for extracting and separating nickel and molybdenum from nickel-molybdenum-containing coal gangue

InactiveCN102199710AHigh recovery rateNo pollution hazardProcess efficiency improvementSodium bicarbonateSulfur

The invention discloses a method for extracting and separating nickel and molybdenum from nickel-molybdenum-containing coal gangue. The method comprises the steps of: pulverizing raw ores and blending sodium carbonate to prepare pellets, and smelting the coal gangue at high temperature by using carbon contained in the coal gauge per se to extract nickel and obtaining ferro-nickel alloy and molten slag; lixiviating the ferro-nickel alloy with water to obtain molybdenum-containing lixivium; and carbonating the molybdenum-containing lixivium by using CO2-containing furnace gas generated in high-temperature smelting to precipitate sulfur and sodium hydroxide in sequence, and filtering to obtain the sulfur and the sodium hydroxide, wherein the sodium carbonate is recycled for the step of high-temperature smelting, and filtrate is further subjected to a molybdenum wet-process smelting process for molybdenum extraction. Compared with the traditional method, the method disclosed by the invention is an efficient, economic and harmless production method and has the advantages that a carbon reducing agent is unnecessary to add, the nickel and the molybdenum are effectively separated and have high purity and raw materials are utilized comprehensively and favorably.

Owner:CENT SOUTH UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com