Process for ball milling and water washing of waste iron and steel slag, slag slurry treatment process, and apparatus therefor

A liquid treatment and dehydration device technology, which is applied in the field of slag slurry treatment equipment, can solve the problems of unresolved slag slurry treatment process environmental protection problems, insufficient recovery of resources, low production and recovery rates, etc., to achieve comprehensive utilization and solve secondary problems. Pollution, creating simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

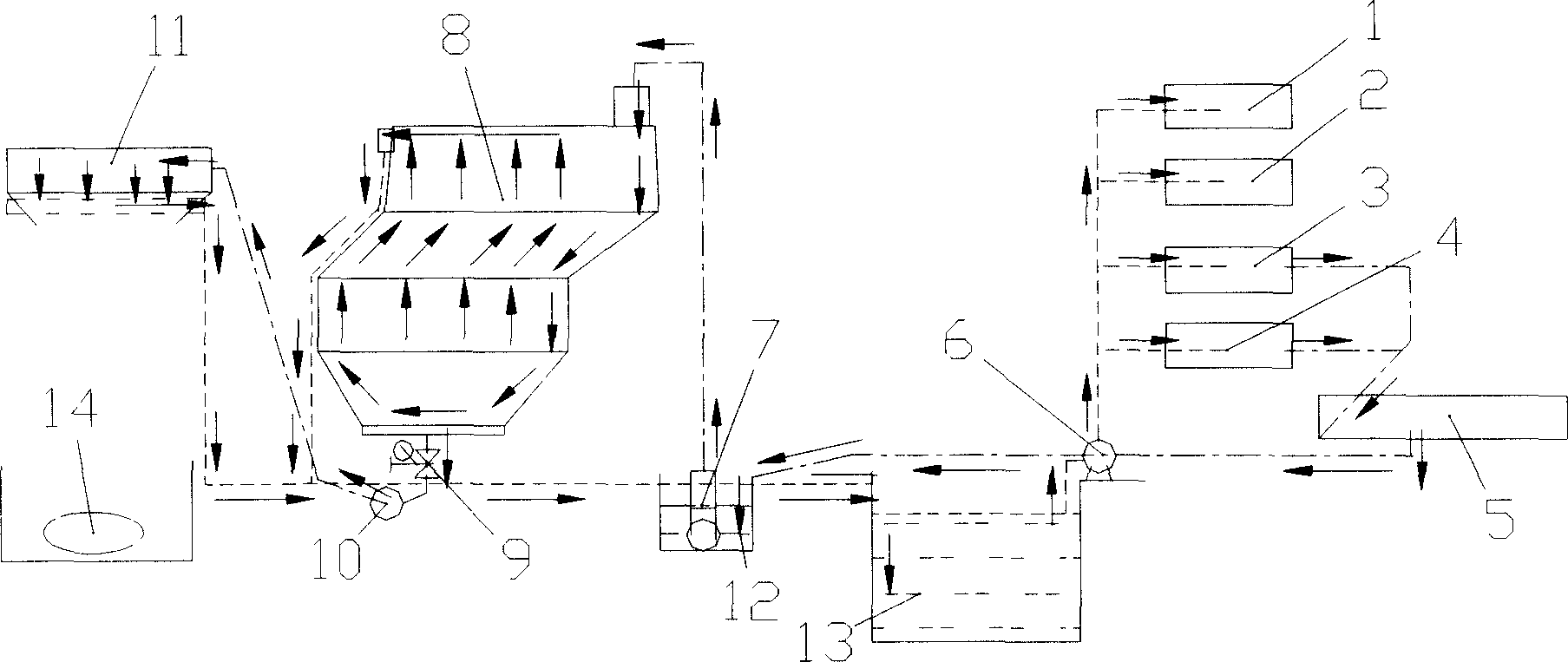

[0014] Embodiment 1, which invented and adopted the existing wet ball mill screening process, dry magnetic separation process and wet magnetic separation process, is characterized in that: after the magnetic iron and steel waste slag is fed into the wet ball mill with a particle size of <30mm through the conveying screen device Add water to carry out wet ball milling. After screening, the steel bean dregs are selected by dry magnetic separation process to select soybean steel with water content, and then dehydrated by a drying device to obtain soybean steel products. The magnetic separation process selects iron ore powder, which is dehydrated by a dehydration device to produce iron ore powder products. The tailings liquid is passed through a particle classification dehydration device to obtain tailings slag products. The tailings slag products are obtained from the slurry through the slurry dehydration device, and the detached clean water and the overflowed clean water from the...

Embodiment 2

[0020] Example 2, the magnetic iron and steel waste slag is sieved through the conveying sieve device, and the waste slag with a grain size of <30mm is fed into the wet ball mill 1, and then water is added for wet ball milling. After being screened by the drum sieve device 2, the steel bean slag is passed through a dry magnetic separation process Soybean steel with water content is selected and dehydrated by a drying device to obtain a soybean steel product.

[0021] The ore liquid obtained by sifting and washing by the wet ball mill water washing cylinder screen device 2 is subjected to a wet magnetic separation process to select iron ore powder, and the iron ore powder product is obtained after being dehydrated by a dehydration device. In order to achieve better results, the wet magnetic separation process can use a secondary wet magnetic separation device, that is, magnetic separation is performed through the primary magnetic separation device 3 and the secondary magnetic se...

Embodiment 3

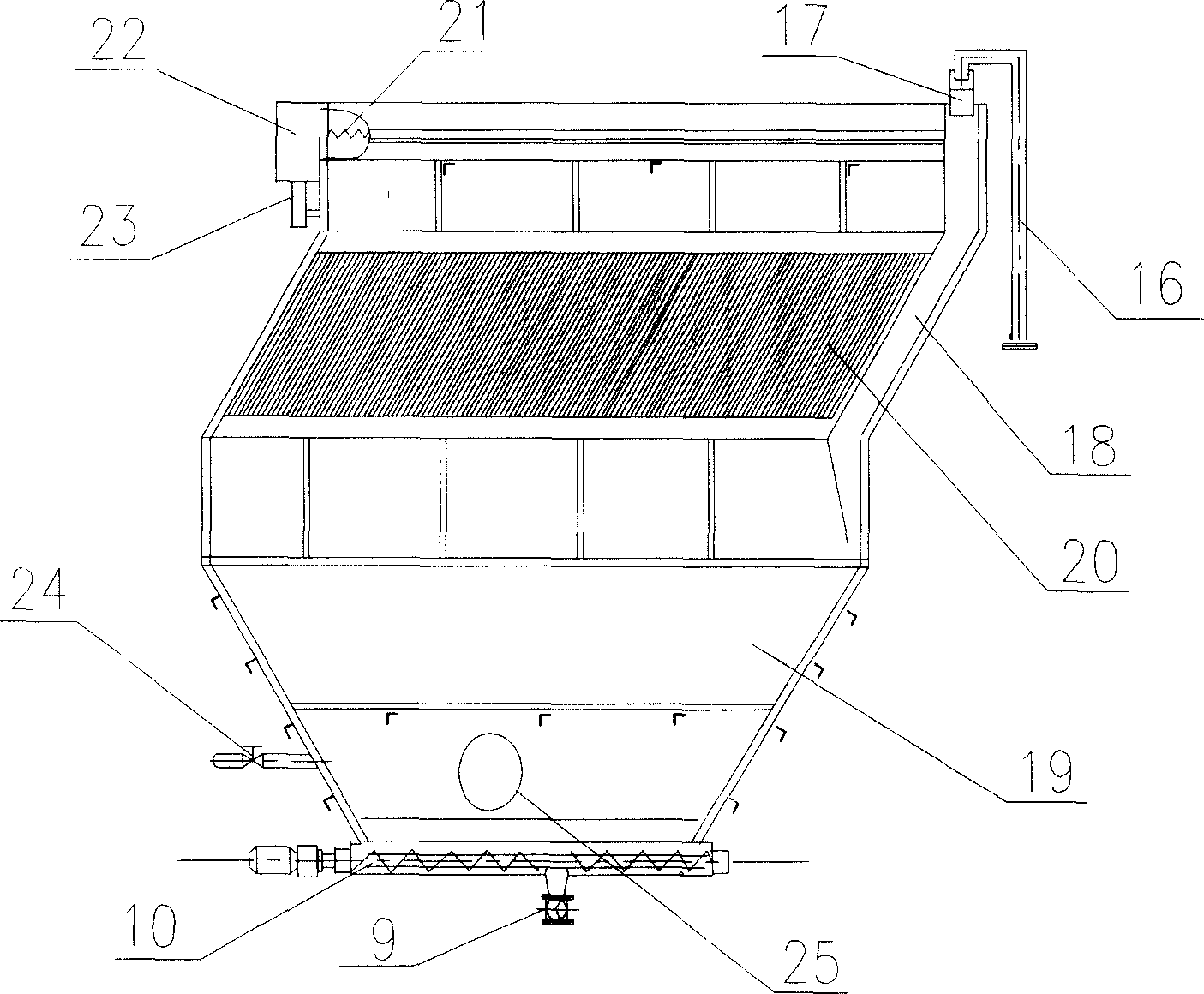

[0023]Embodiment 3, the described device for iron and steel waste slag ball mill water washing beneficiation and slag slurry treatment process, the upper part of the main chamber 19 is fixedly connected with the settler 20, and the upper side of the main chamber 19 is provided with an isolation chamber 18, The top of the settler 20 is provided with an overflow tank 21, the overflow tank 21 is connected with the clear water tank 22, and the downpipe 23 is connected with the clear water tank 22, and the bottom of the main chamber 19 is provided with a drain pipe valve 24 and a manhole 25, and the main chamber 19 A slurry feeder 10 is provided at the bottom, and an electric / manual slurry valve 9 is provided on the slurry feeder 10; a distributor 17 for connecting the slurry into the pipe 16 is provided on the upper part of the isolation chamber 18. The slurry enters the isolation chamber 3 through the slurry pump through the slurry inlet pipe 1 and the slurry distributor 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com