Drying pretreatment method and device for urban domestic garbage

A technology of municipal solid waste and solid waste, which is applied in the field of dry pretreatment of solid waste, can solve the problems of domestic solid waste that plague economic development and environmental governance, insufficient harmless treatment rate, unsuitable fluidized bed, etc., and achieve reduction of equipment Effects of investment, scale reduction, and total waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

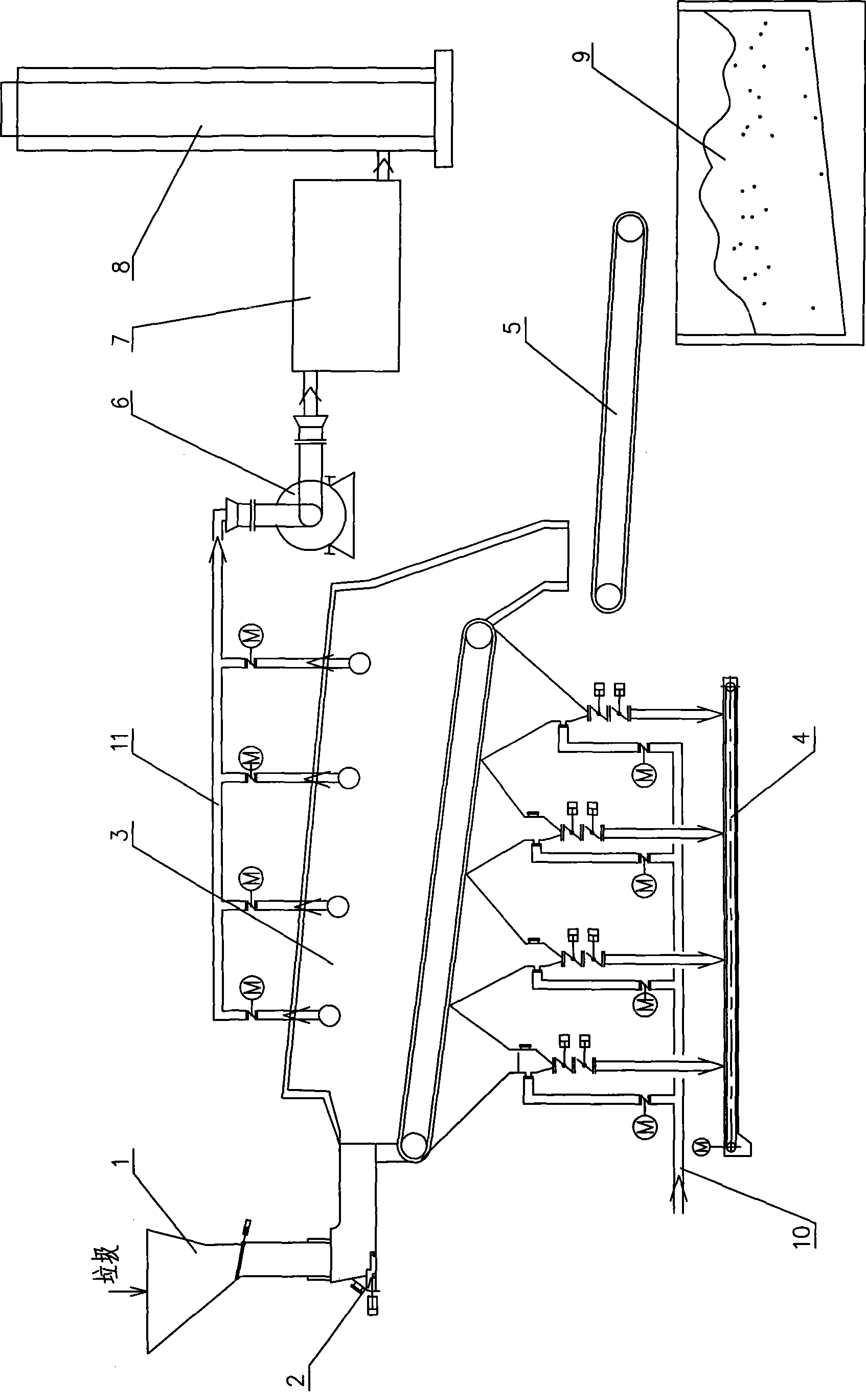

[0022] Such as figure 1 As shown in the drying pretreatment method of municipal solid waste, before the garbage is sent to the hopper of the dryer, the large-sized garbage is first selected and sent to the garbage crusher for crushing, and then mixed and homogenized, and then the mixed and homogenized garbage Put it into the receiving hopper 1 of the garbage dryer, and push the garbage into the garbage dryer 3 through the garbage feeder 2 for drying; the high-temperature flue gas of 140-150 ℃ drawn from the smoke exhauster of the incinerator passes through the lower part of the dryer. The hot air conveying pipe 10 enters the dryer 3 as a garbage drying medium; the domestic garbage is dried on the conveyor belt of the dryer 3, and 10-15% of the moisture in the garbage becomes water vapor together with the dry waste gas from the top of the dryer. The exhaust gas discharge pipe 11 enters the exhaust air induced draft fan 6 after drying; the garbage is discharged due to 10% to 15%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com