Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

A technology of iron oxide ore and weak magnetism, which is applied in the field of preparation of strong magnetic magnetite from refractory weakly magnetic iron oxide ore, which can solve problems such as low concentrate grade and recovery rate, large-scale equipment, and large investment , to achieve the effect of increasing the reaction speed and roasting efficiency, improving the recovery rate and improving the heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

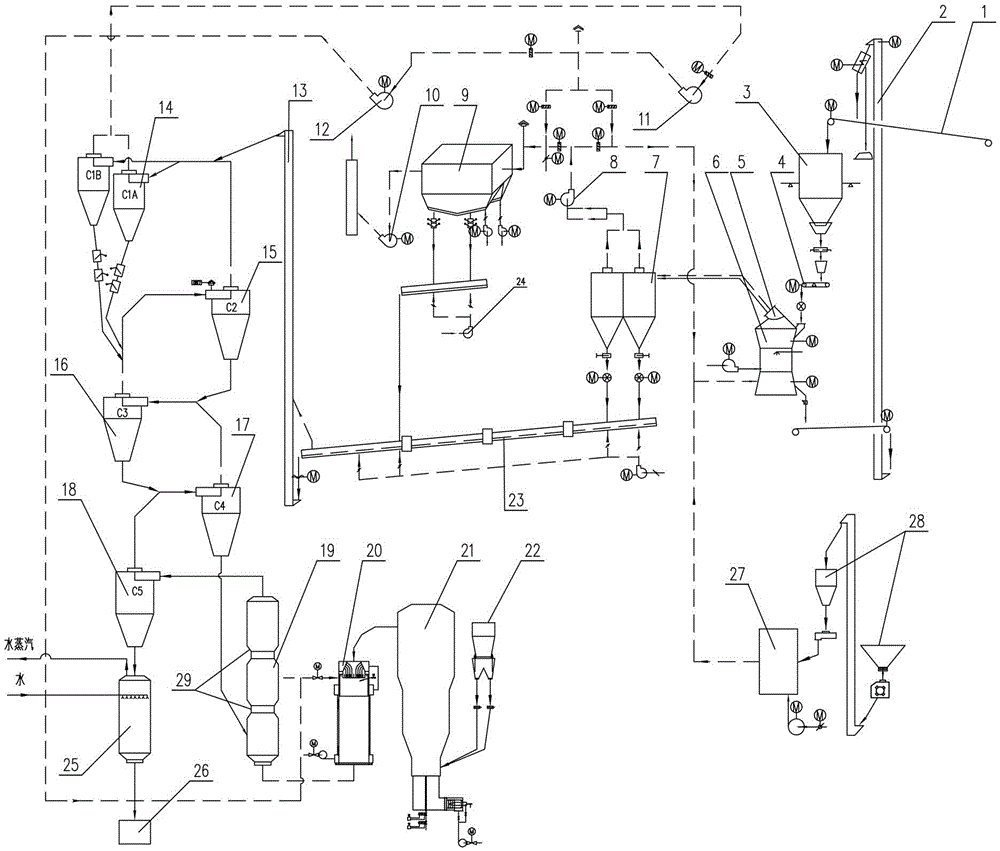

[0024] Example 1: see figure 1 The process of applying the present invention to prepare high-grade magnetite concentrate from rhombohedral and limonite comprises the following steps: (1) Milling and processing: sending rhombohedral and limonite with a particle size of 25-80mm through a belt conveyor 1 To the ore bin 3, the ore is fed from the ore bin 3 and enters the high-efficiency vertical roller mill 5 for grinding through the quantitative feeding device 4. It is equipped with a low-temperature flue gas fluidized furnace 27 (and a coal feeding system 28) Generate 300-500°C low-temperature hot air and mix with the return air of the subsequent roasting system to 300°C and enter the high-efficiency vertical roller mill 5 while drying and grinding, and the fine-grained ore powder after being dried and ground is under the action of hot gas Enter the high-efficiency powder separator 6 for powder separation, select powder ore with a particle size of ≤0.2mm and a water content of l...

example 2

[0035] Example 2: The steps of the basic process production method are the same as Example 1, but the following adjustments are made, (1) The low-temperature roasting time is 10s; (2) The temperature of the low-temperature reducing gas prepared by the tempering furnace is 650°C, and the volume fraction of CO is controlled at 3%; (3) A four-stage cyclone preheater is used; (4) The solid-to-gas ratio of the ore powder and the low-temperature reducing gas introduced during low-temperature roasting in step (2) is 1.5kg / Nm 3 ; (5) The roasting chamber of the jetting roaster is equipped with 3 special-shaped necks.

[0036] The grade of magnetite concentrate produced from refractory water chestnut and limonite by adopting the process method of Example 2 reaches 62%, and the recovery rate reaches 87%.

example 3

[0037] Example 3: The steps of the basic process production method are the same as in Example 1, but the following adjustments are made, (1) The low-temperature roasting time is 60s; (2) The temperature of the high-temperature reducing gas prepared in the tempering furnace is 700°C, and the volume fraction of CO is controlled at 5%; (3) A six-stage cyclone preheater is used; (4) The solid-to-gas ratio of the ore powder and the low-temperature reducing gas introduced during low-temperature roasting in step (2) is 1.8kg / Nm 3 ; (5) The roasting chamber of the jetting roaster is equipped with 4 special-shaped shrinks.

[0038] The grade of magnetite concentrate produced from refractory water chestnut and limonite by adopting the process method of Example 3 reaches 62.5%, and the recovery rate reaches 88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com