Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

942results about How to "Reasonable configuration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

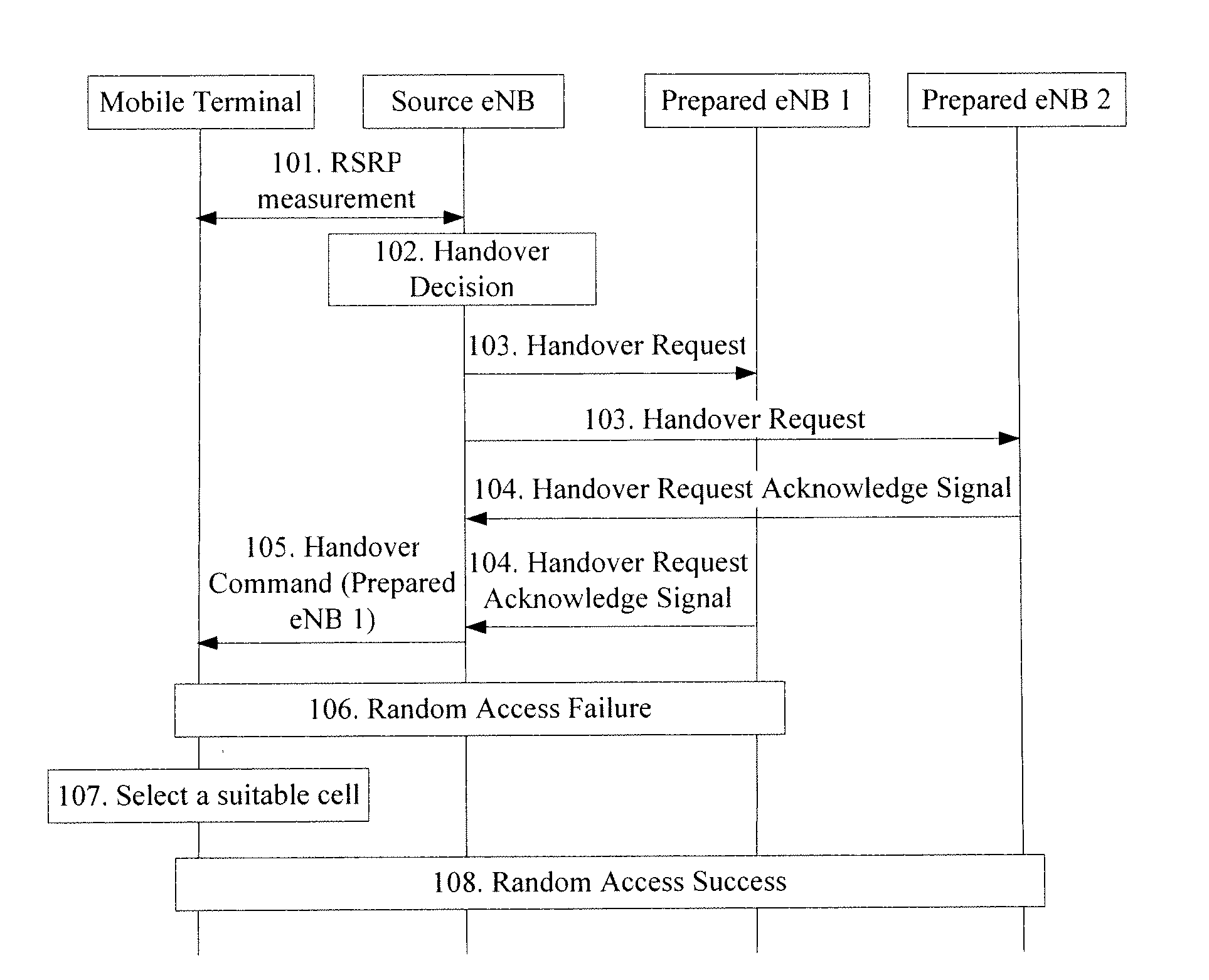

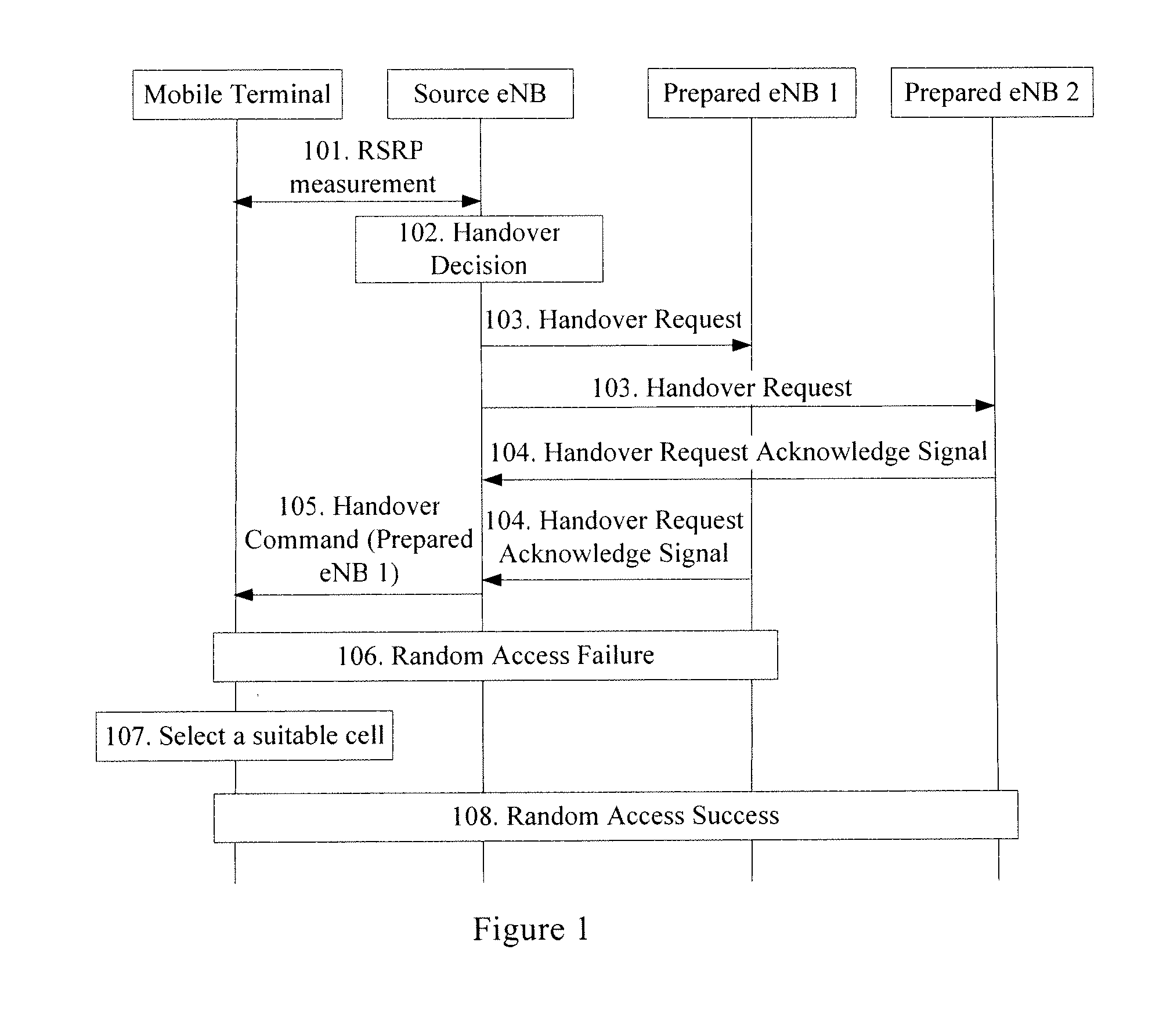

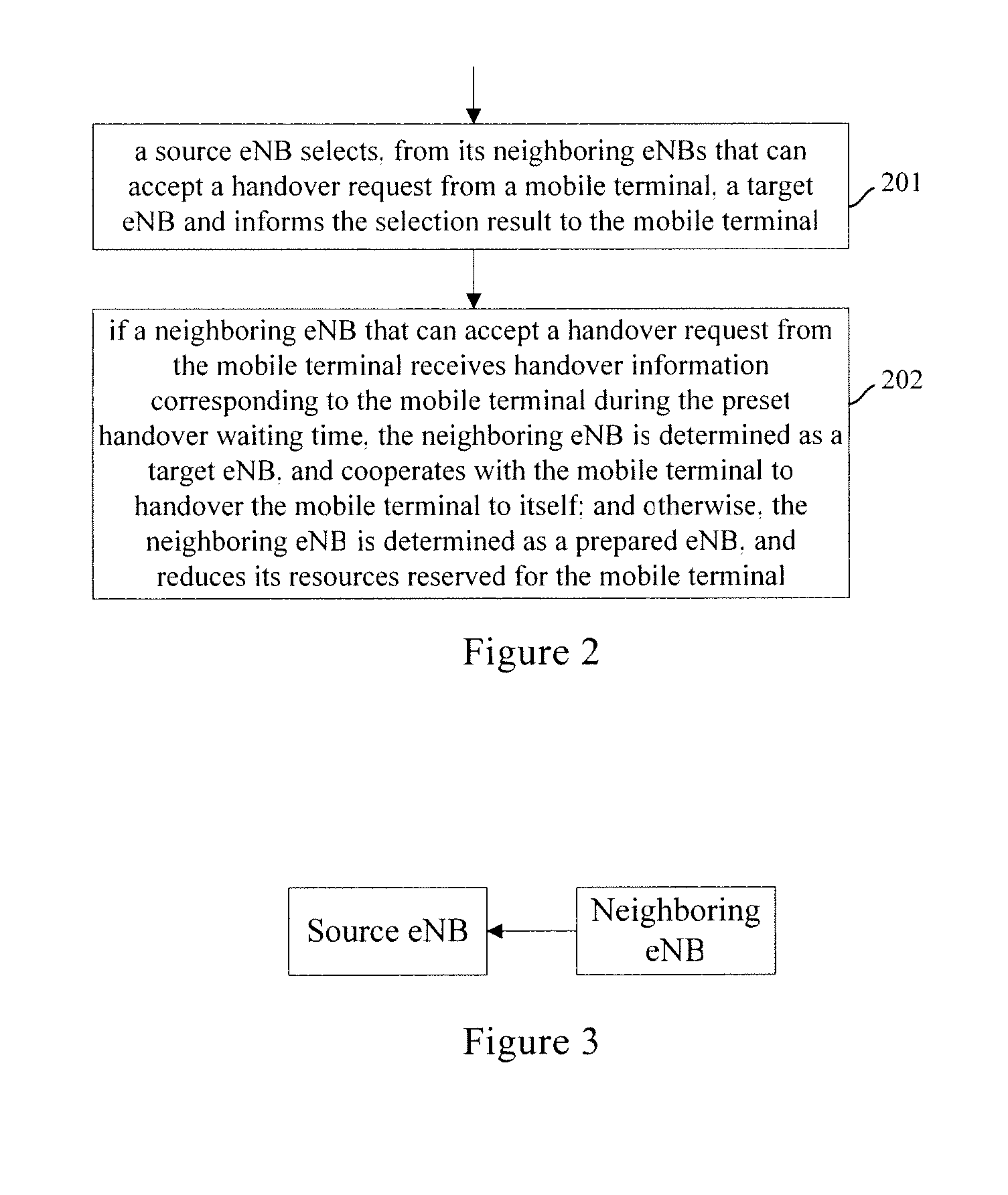

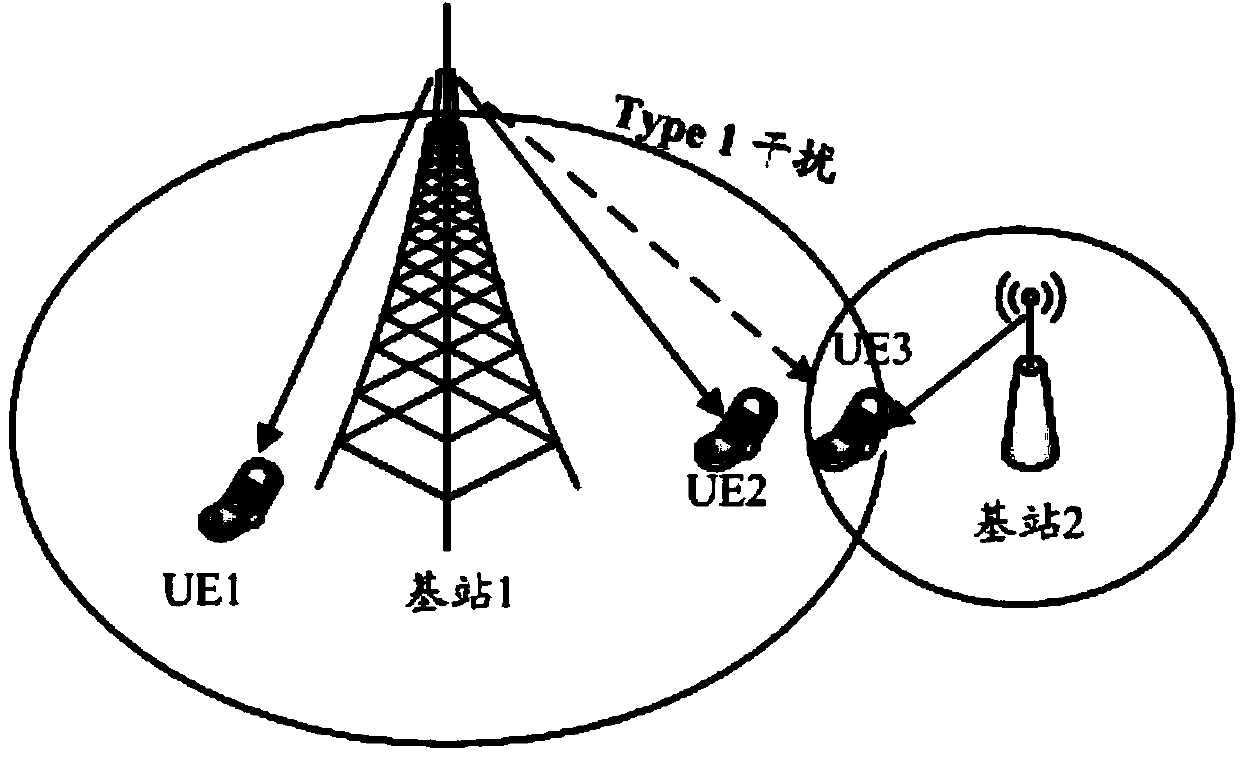

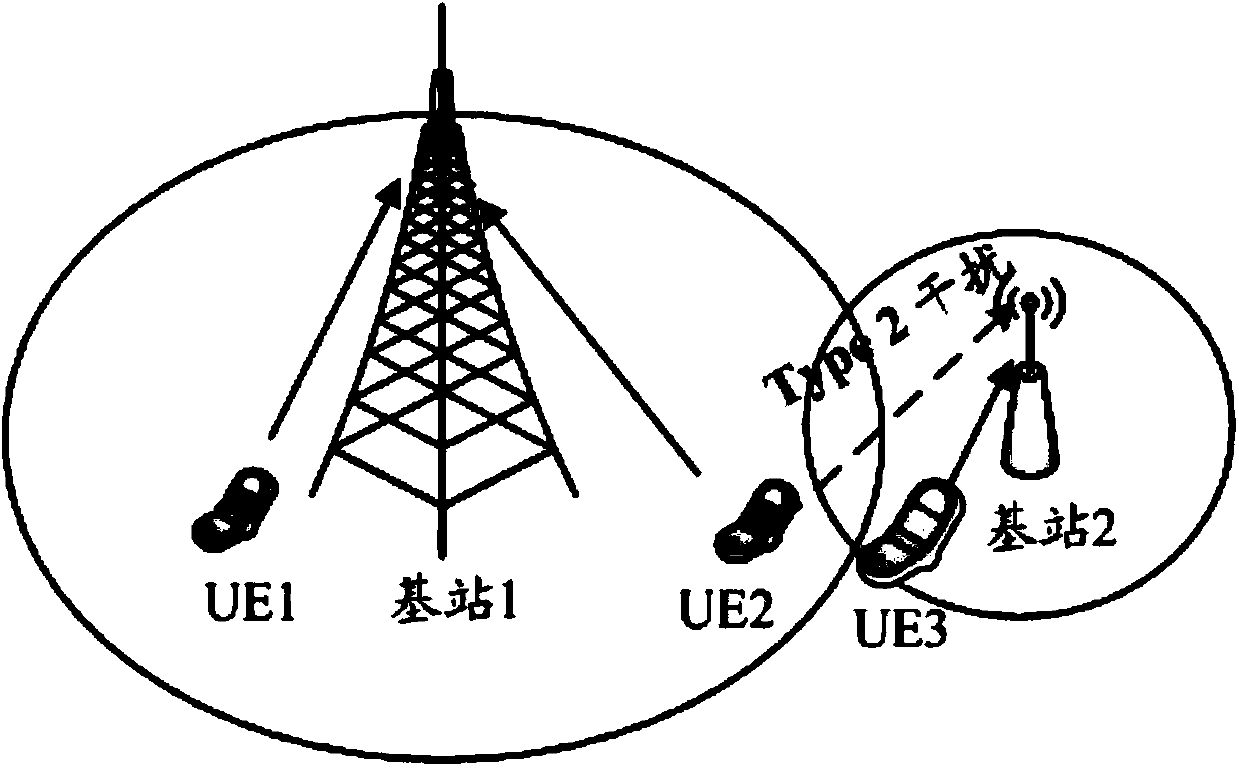

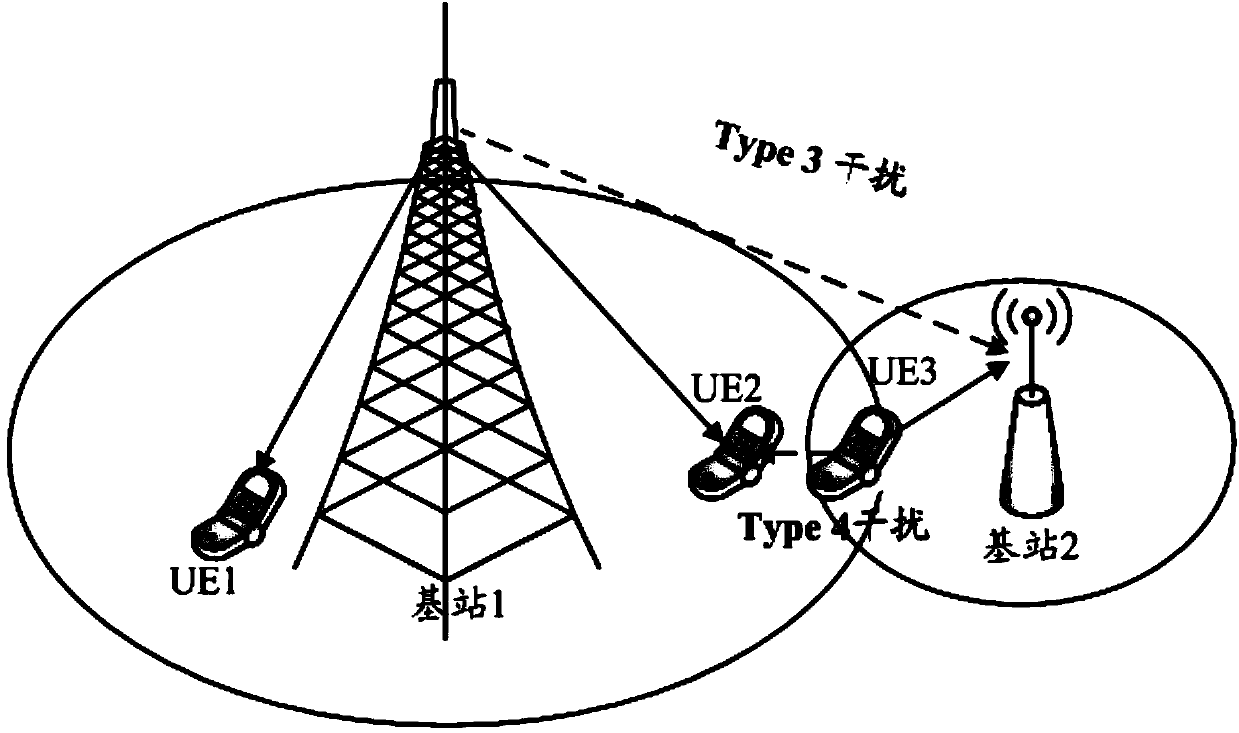

Handover processing method, enb and network communication system thereof

InactiveUS20100027507A1Reduced resourceReduce the amount requiredWireless commuication servicesCommunications systemNetwork communication

Embodiments of the present invention includes a handover processing method, a source eNB, a neighboring eNB and a network communication system. In one embodiment of the handover processing method, a source eNB selects a target eNB from neighboring eNBs that can accept a handover request from a mobile terminal, and notifies a selection result to the mobile terminal; if handover information corresponding to the mobile terminal is received by an neighboring eNB that can accept the handover request of the mobile terminal within a preset handover waiting time, the neighboring eNB determines that it is a target eNB and cooperates with the mobile terminal to perform a handover; otherwise, the neighboring eNB determines that it is a prepared eNB and reduces its resources reserved for the mobile terminal. The present invention can effectively improve the successful handover probability.

Owner:GOOGLE LLC

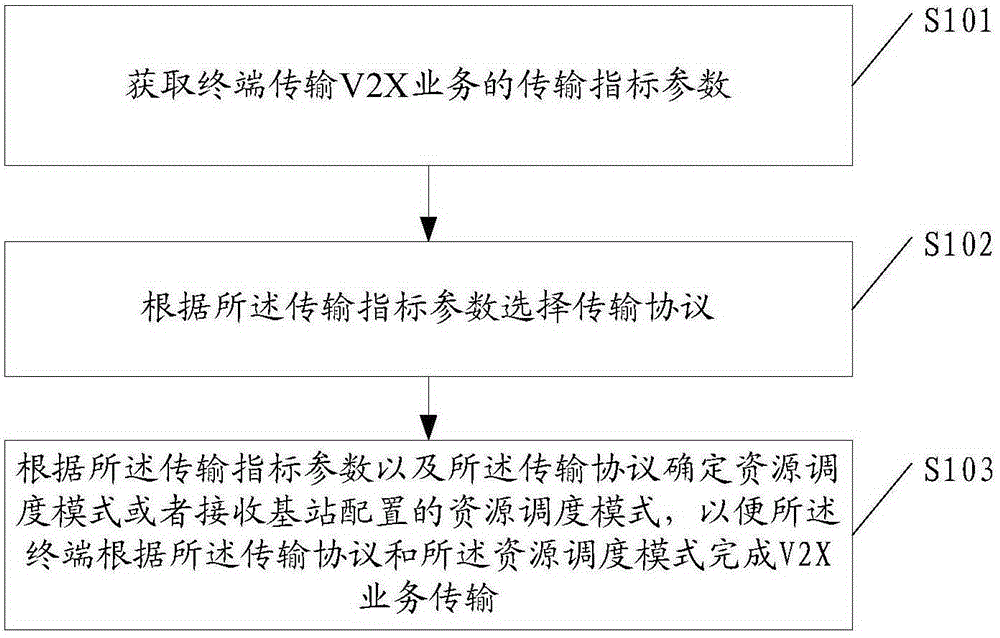

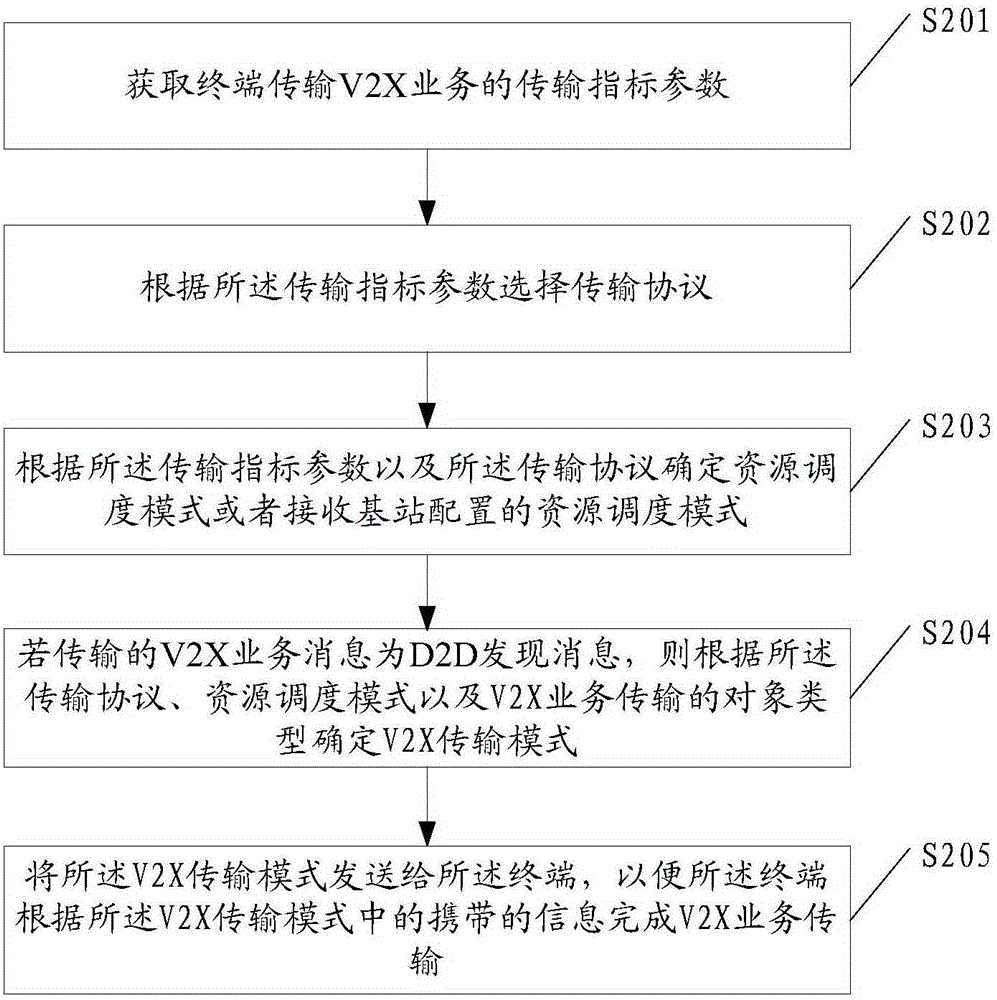

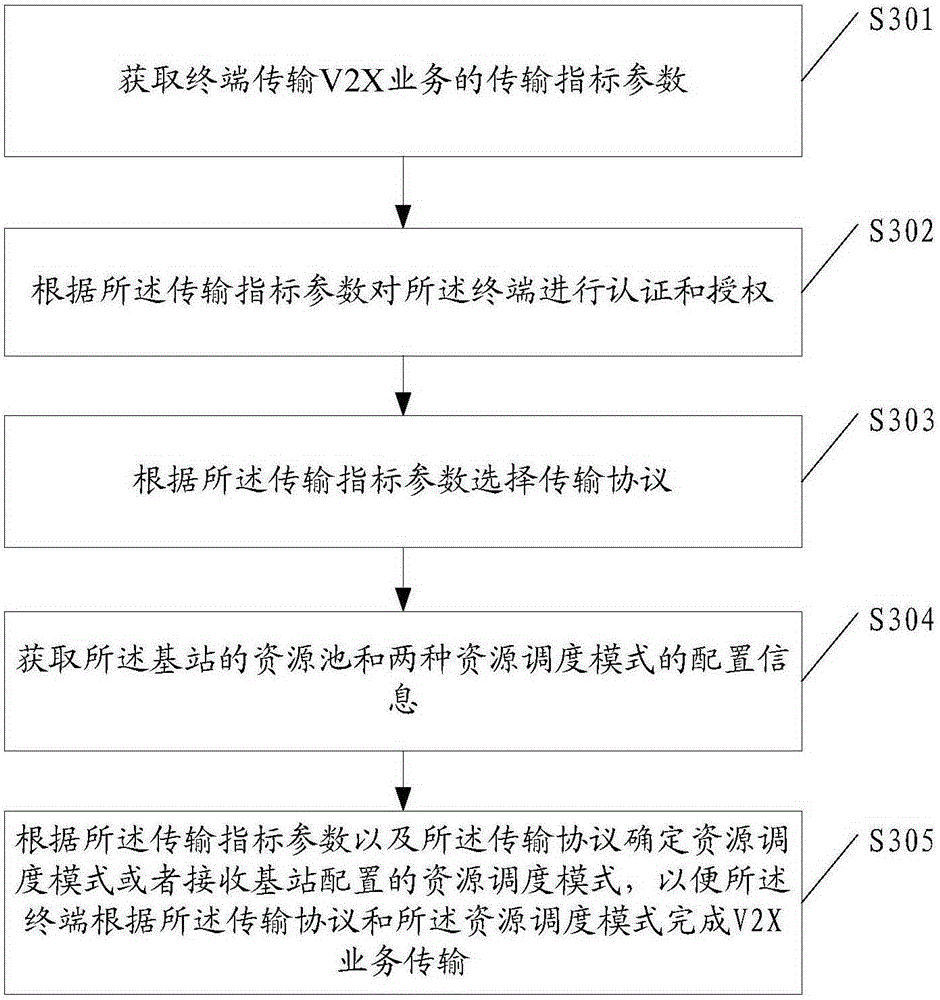

Method of controlling V2X service transmission and device

ActiveCN105246025AHigh-speed transmission is more stable and more scientificEasy to useNetwork traffic/resource managementParticular environment based servicesResource poolTransmission protocol

The embodiment of the invention discloses a method of controlling V2X service transmission. The method comprises steps: transmission index parameters for transmitting a V2X service by a terminal are acquired; transmission protocols are selected according to the transmission index parameters, wherein the transmission protocols comprise a transmission protocol based on D2D discovery technology and a transmission protocol based on D2D communication technology; according to the transmission index parameters and the transmission protocols, a resource scheduling model is determined or a resource scheduling model allocated by a base station is received so as to enable the terminal to complete V2X service transmission according to the transmission protocols and the resource scheduling model, wherein the resource scheduling model comprises a base station scheduling model and a resource pool model. The embodiment of the invention also discloses a device for controlling V2X service transmission. By adopting the method and the device of the invention, a transmission mode for different V2X services can be reasonably allocated, and transmission needs of different V2X services can be met.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

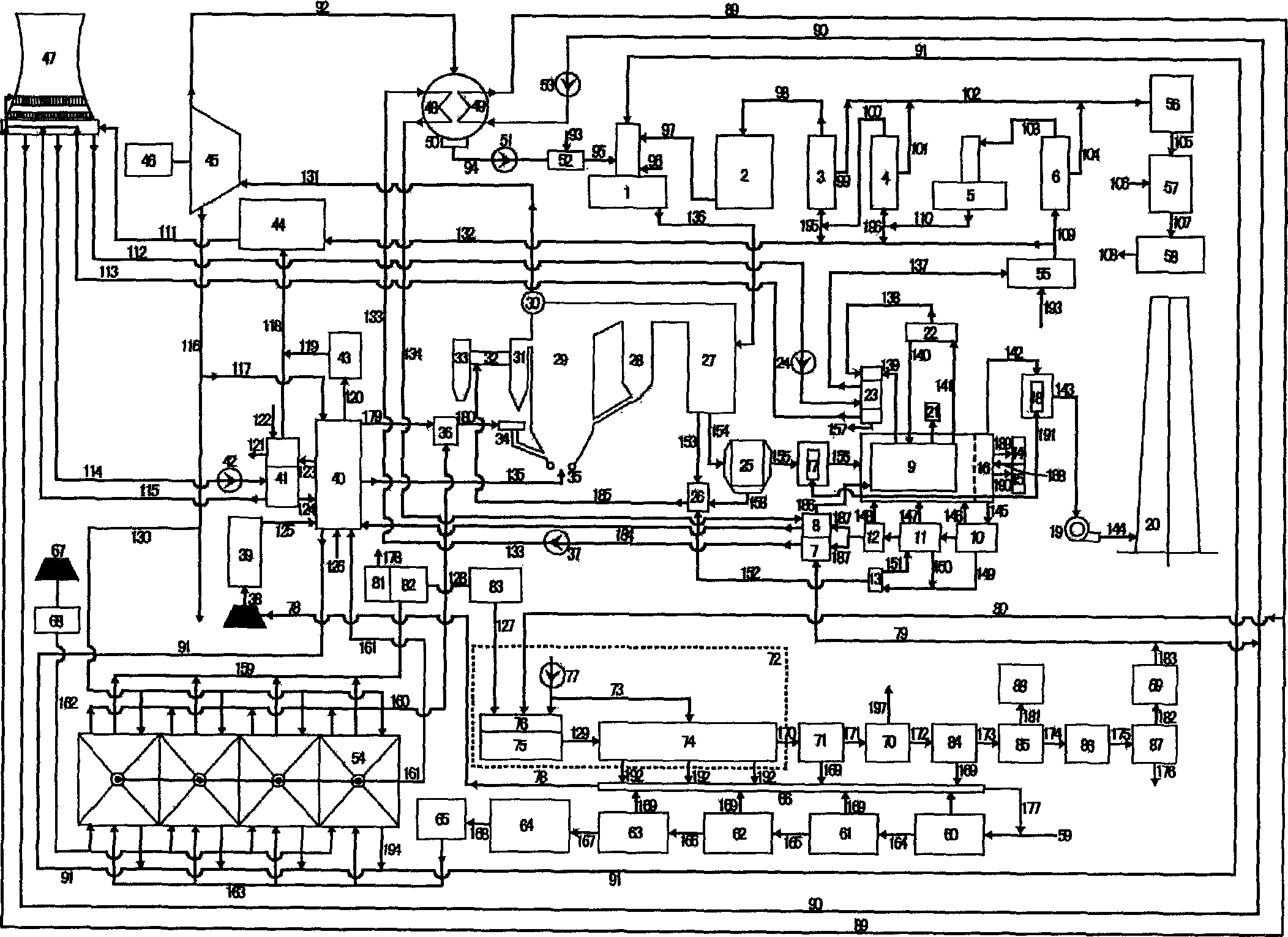

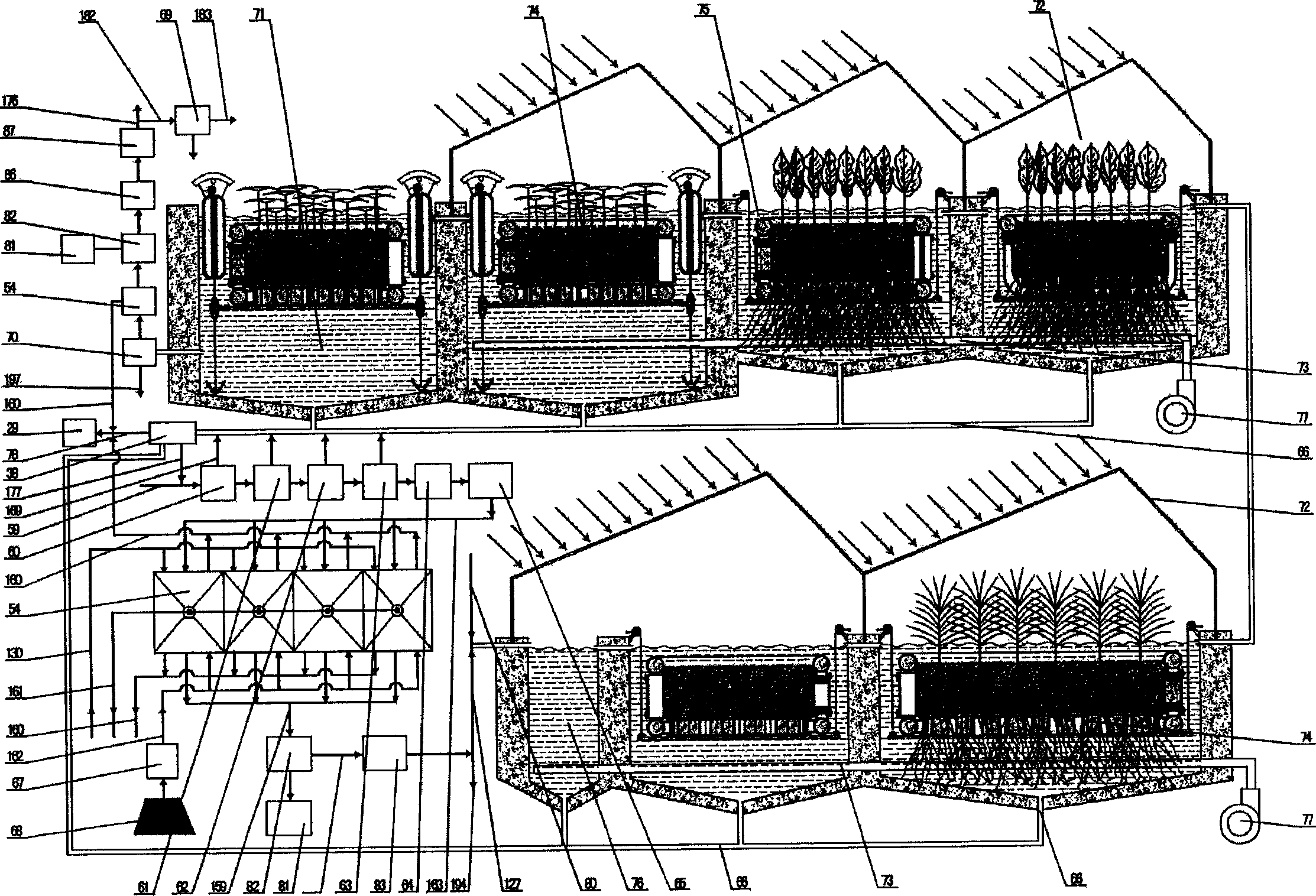

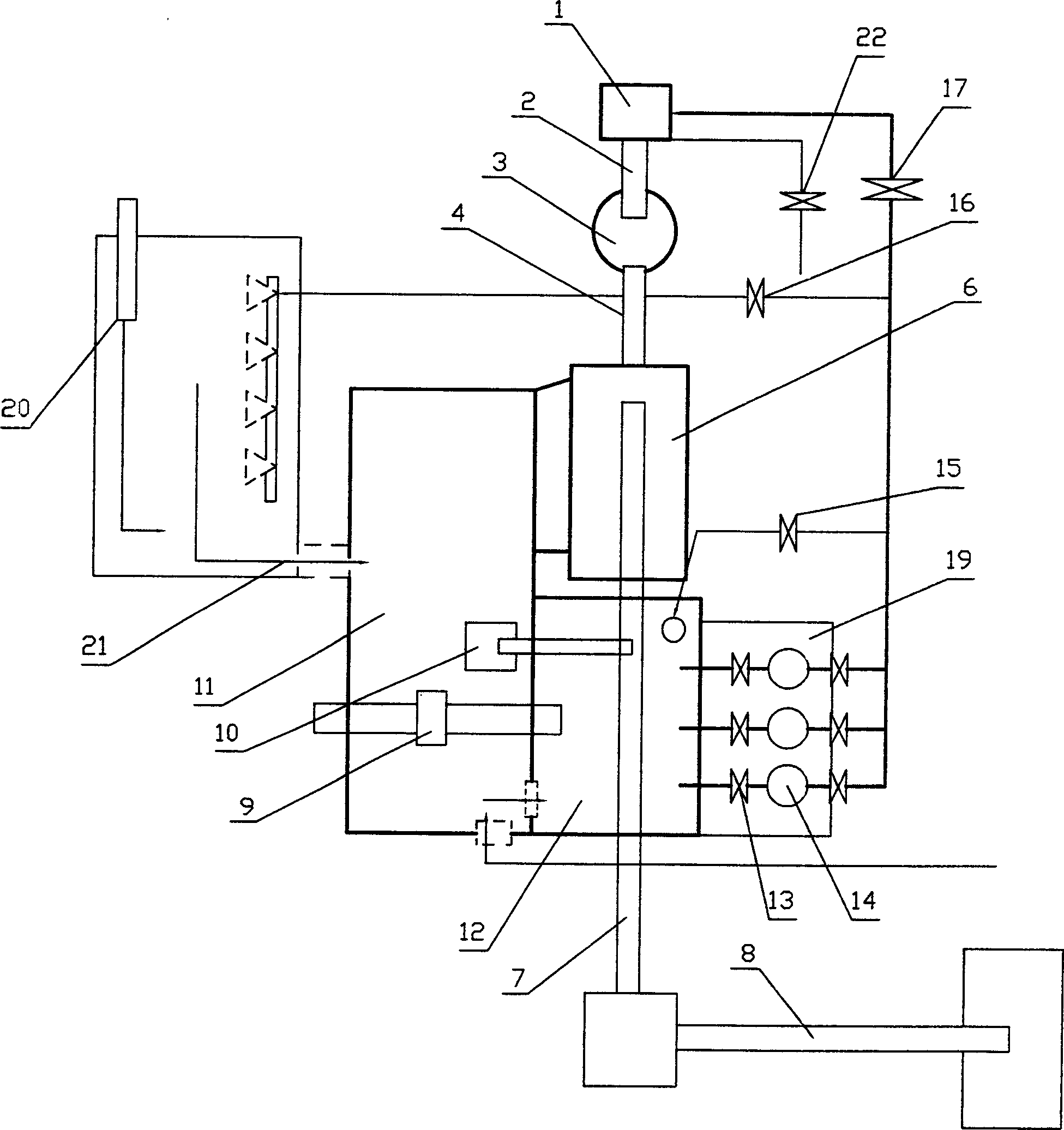

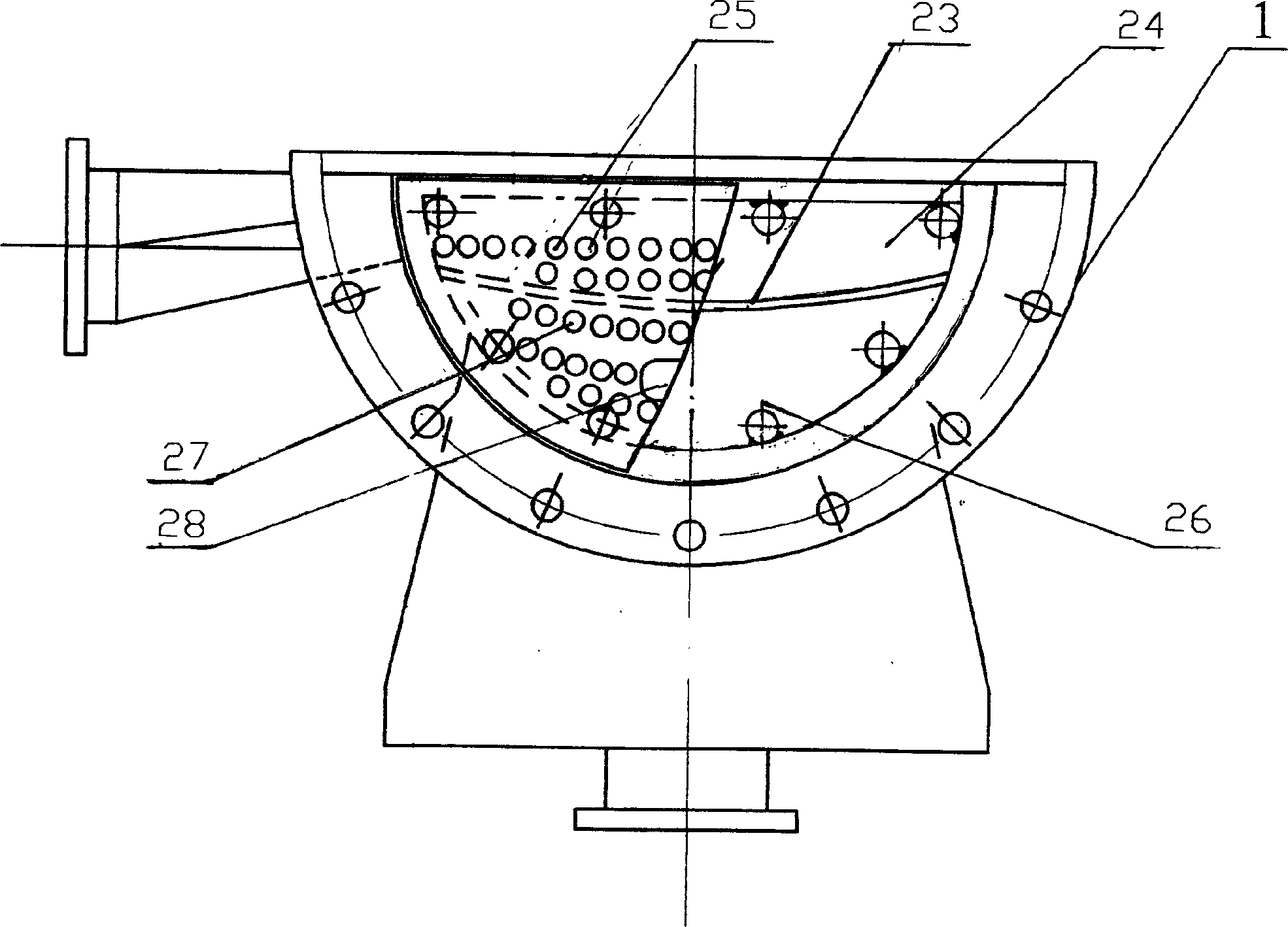

Sewage-refuse treatment clean-production system at the center of generating plant

InactiveCN1743284AImprove efficiencyComplete desulfurizationWater/sewage treatment by irradiationSolid waste disposalSteam condensationCoal

This sewage and garbage treatment system centrally designed for power plant includes sewage treatment unit, fuel processing unit, garbage combustion boiler, fly ash processing unit, smoke processing unit, the de-oxygenating draining steam of turbine steam-extraction heat-supply boiler and circulated water cooling unit. The effluent of sewage treatment unit with coal as filter is led into magnetic water strainer, and condensed water from the domestic garbage dehydration-drying condensed water-recovering combustion-supporting device is cleared by the coal filtration and normal water treatment system to feedback the circulated water-cooling system, the steam condensed water is heated and delivered into the de-oxygenating device. Treated sewage is introduced into multi-medium condenser and the distillation-desalination device; discharged smoke from fly ash incineration device is led into garbage combustion boiler; acid water discharged from distillation unit and alkaline water from coal filter are neutralized and discharged. Water distillation system and the circulation cooling water of the steam turbine condensator are led to the air- water cooling tower.

Owner:徐宝安

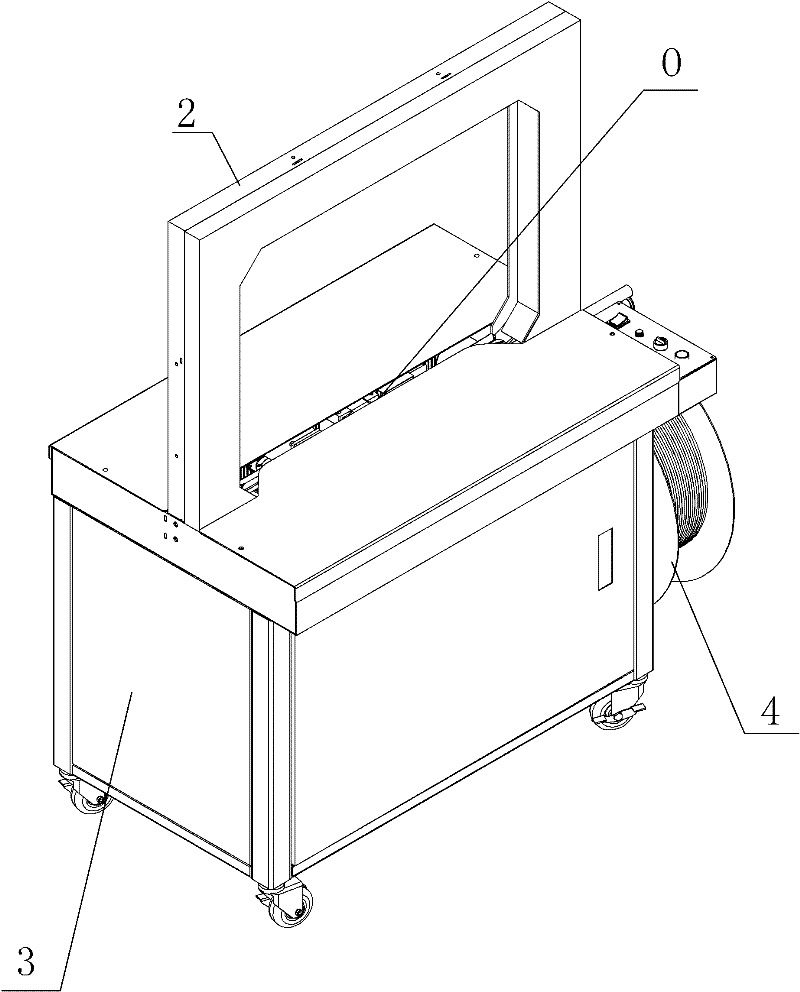

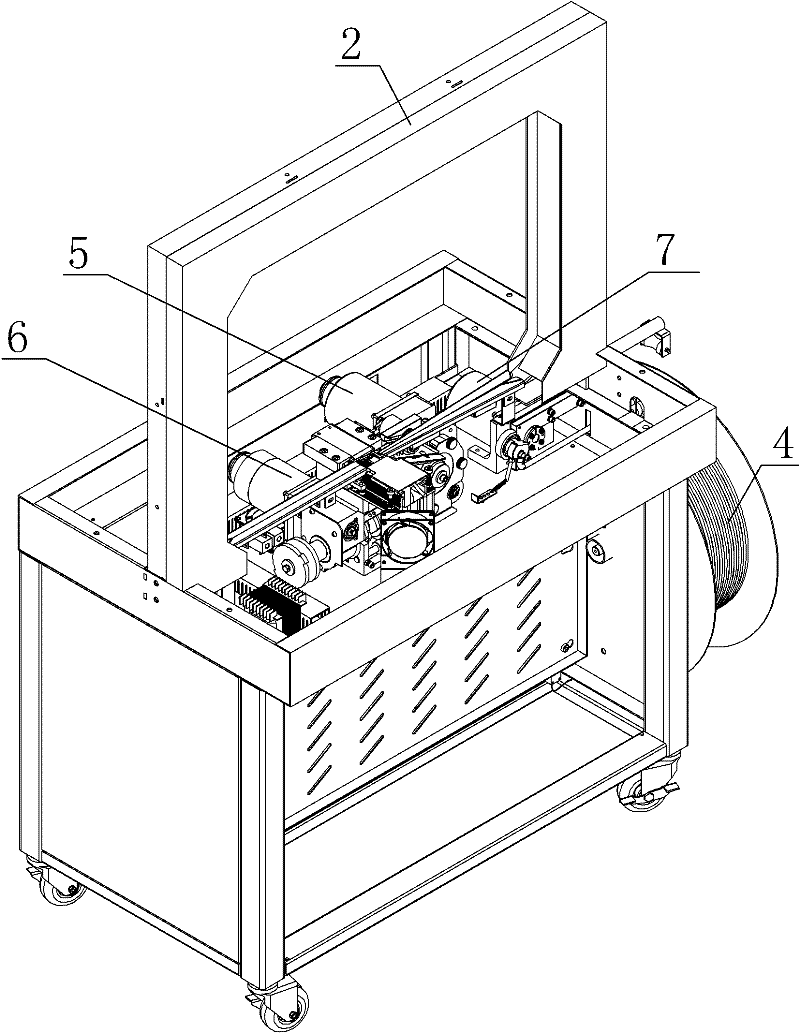

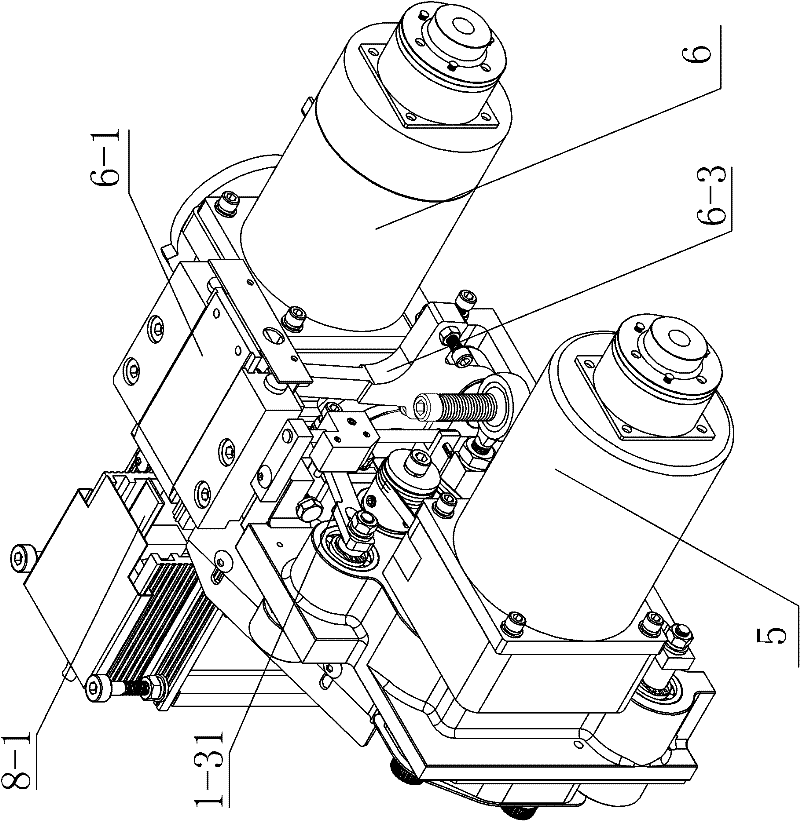

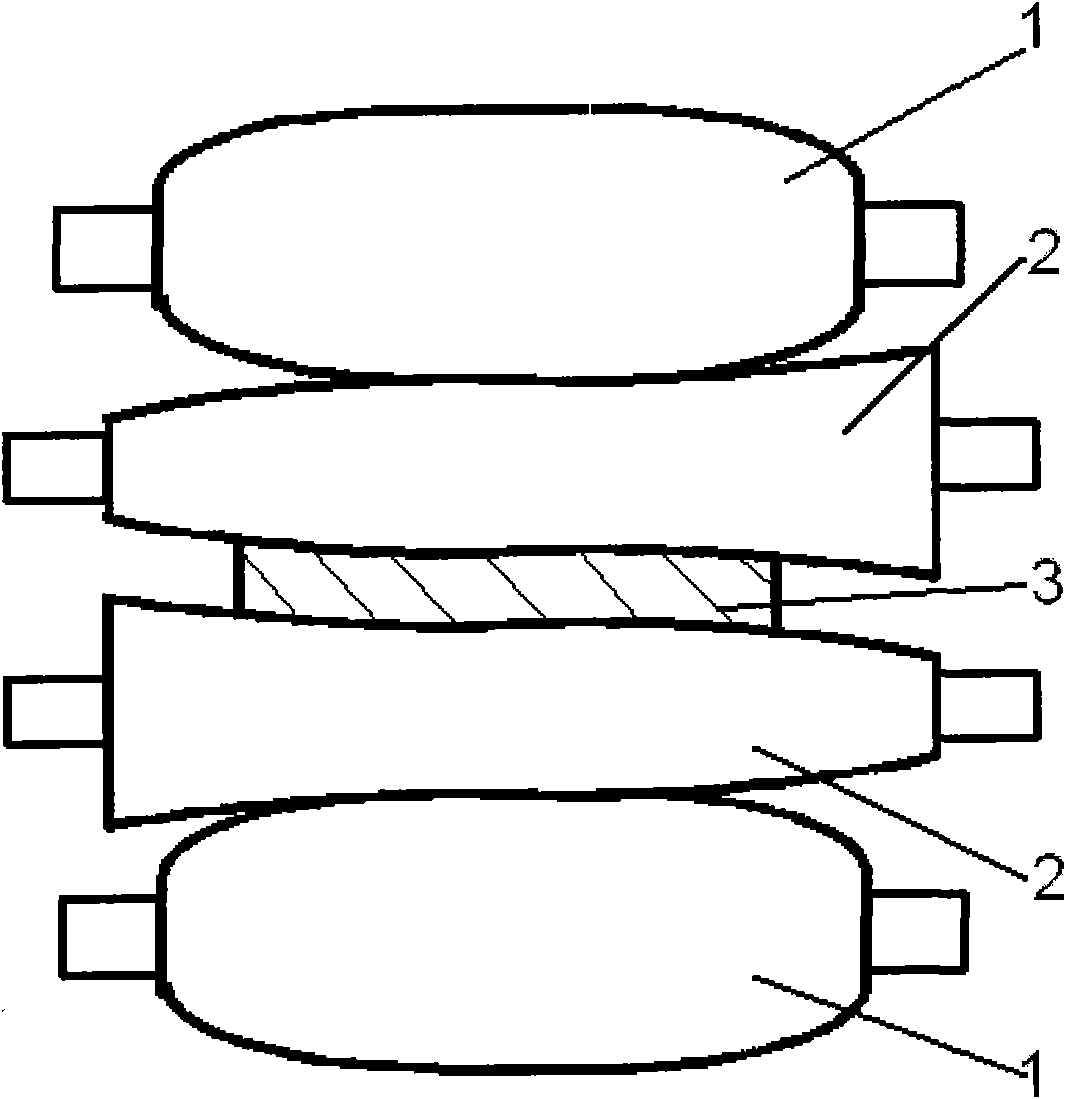

Novel packing machine

ActiveCN102530291AReasonable configurationEasy to controlBinding material applicationBundling machine detailsFixed frameEngineering

The invention provides a novel packing machine. A vertical mounting plate is arranged at the lower half part of the packing machine, a horizontal mounting plate is fixed at the upper part of the vertical mounting plate, a fixing frame is arranged at the upper half part of the vertical mounting plate and wraps the left part, right part and upper part of an article banding station, the mounting plates and the fixing frame are arranged on a rack of the packing machine, and a tape spool is arranged at the lower part of the packing machine; and a movement of the packing machine and a pre-sending belt device are arranged on the horizontal mounting plate, a retreating belt and tensioning belt device is arranged in the movement of the packing machine and comprises a retreating belt mechanism and a tensioning belt mechanism. According to the novel packing machine, all the functional devices are reasonable in configuration and convenient and simple in control, the packing quality can be improved, and the comprehensive improvement of the packing efficiency and the reliable work can be facilitated.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

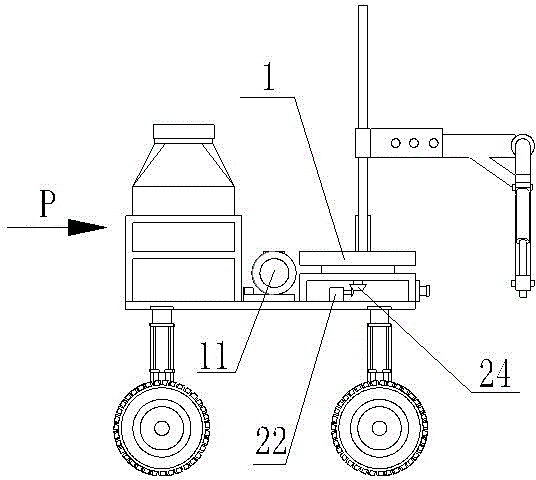

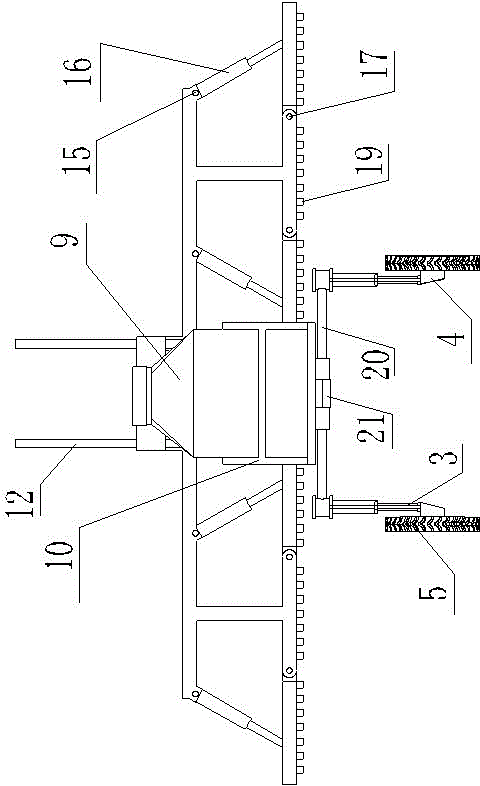

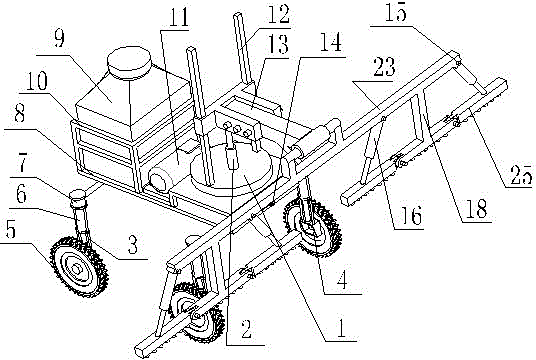

New-concept intelligent multifunctional spaying machine chassis

InactiveCN103329878ADrive stabilityLarge driving torqueInsect catchers and killersTerrainEngineering

The invention discloses a new-concept intelligent multifunctional spaying machine chassis. The new-concept intelligent multifunctional spaying machine chassis comprises a chassis rack, a pesticide tank fixing support, a spray lance lifting support, a spray lance conversion mechanism, a spray head and wheels, wherein the pesticide tank fixing support is arranged at the rear end of the chassis rack, the spray lance lifting support is arranged at the front end of the chassis rack in a rotatable mode, the spray lance conversion mechanism and the spray lance lifting support constitute a vertical moving pair, the spray head is arranged on the spray lance conversion mechanism, and the wheels are installed at the bottom of the chassis rack through a longitudinal adjusting device and a transverse adjusting device. The new-concept intelligent multifunctional spaying machine chassis has the advantages of applying full-hydraulic power, and being stable in driving, large in drive torque, flexible in steering, simple in transmission, concise in overall structure, reasonable in configuration, and stable in center of gravity. In addition, the new-concept intelligent multifunctional spaying machine chassis has the advantages that due to the facts that stepless adjustment of the wheel torque, the ground clearance height and the like can be achieved and the spray lance conversion mechanism can descend, ascend and rotate, the spray lance conversion mechanism can achieve line-shaped conversion, U-shaped conversion and reverse-U-shaped conversion, the effect of omni-directional spraying is achieved, the requirement for all-terrain omni-directional spraying of different plants and different growth cultivation periods of one plant can be overall achieved through the new-concept intelligent multifunctional spaying machine chassis.

Owner:NANJING FORESTRY UNIV +1

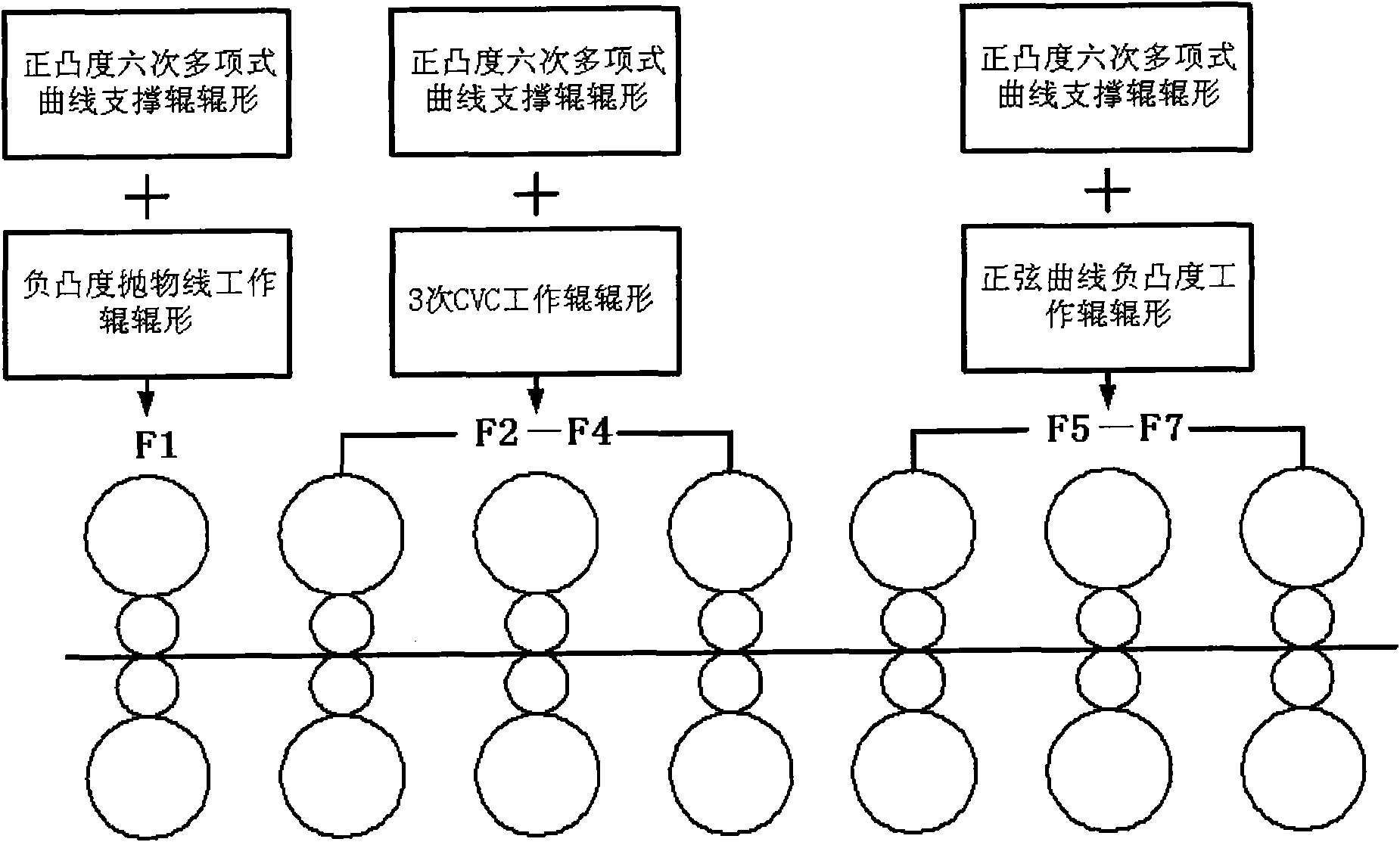

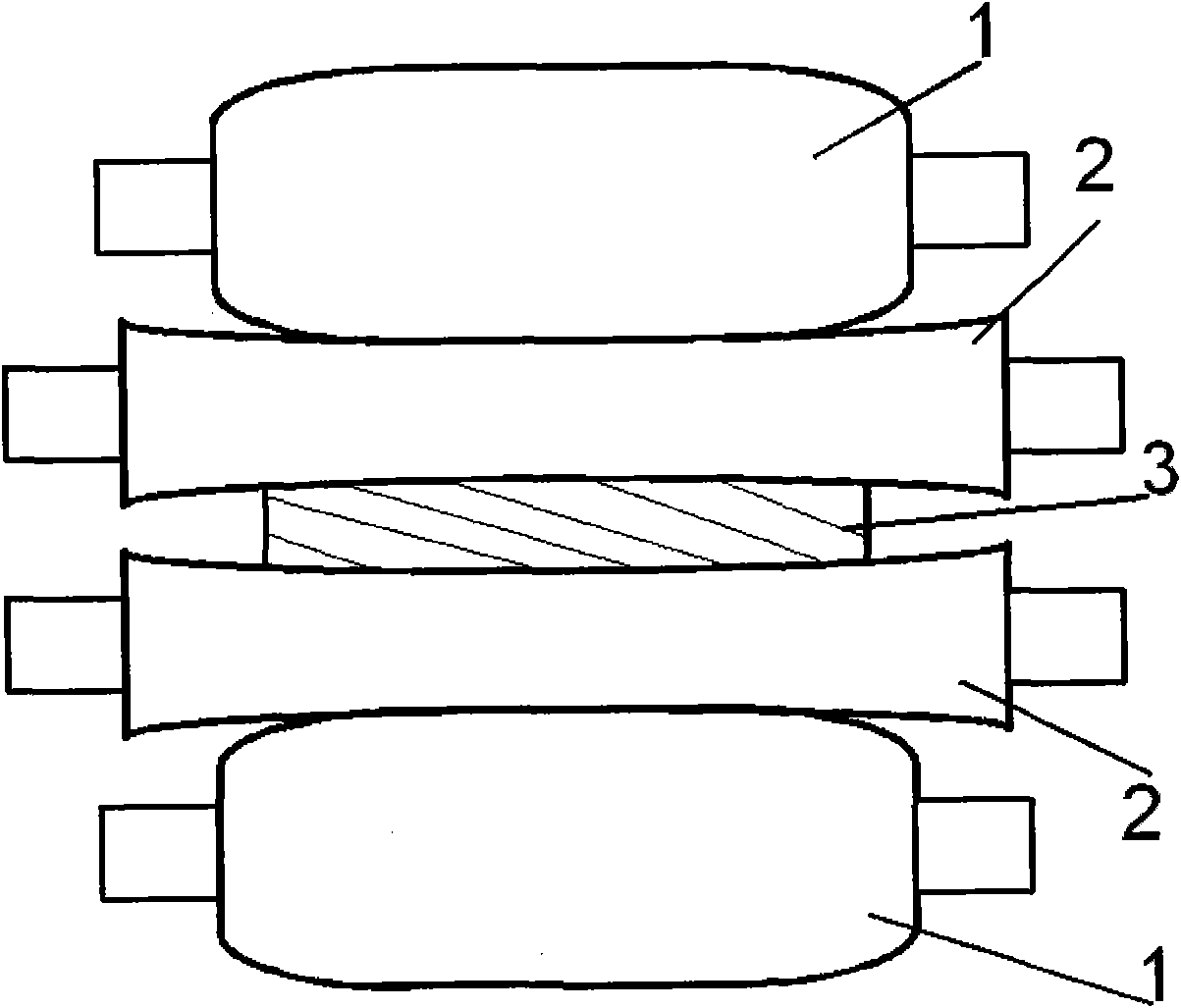

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

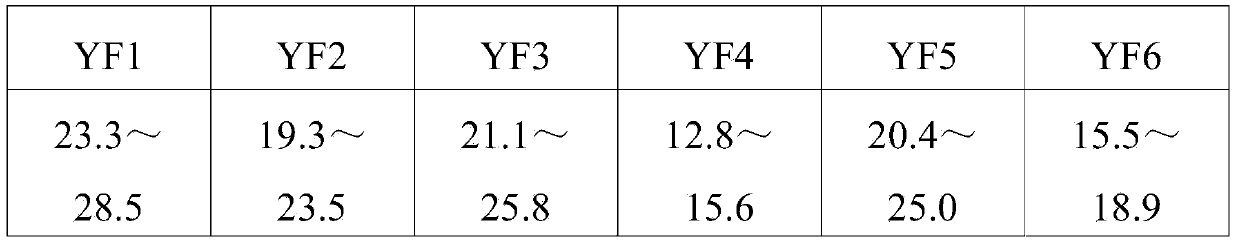

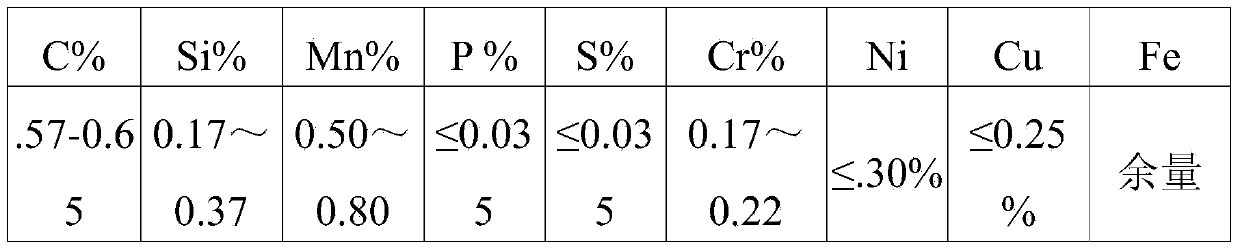

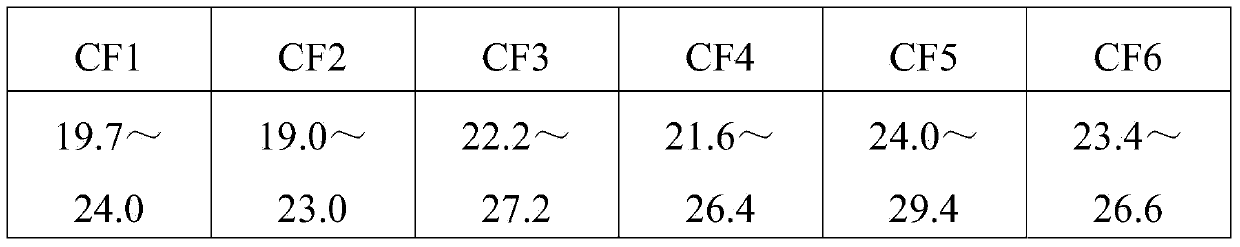

60-steel hot rolling coil rod with high strength and high plasticity and production method thereof

ActiveCN104213033ACompact configurationReasonable configurationTemperature control deviceWork treatment devicesChemical substancePlasticity

A 60-steel hot rolling coil rod with high strength and high plasticity and production method thereof belong to the hot rolling coil rod and production method thereof. The coil rod consists of the following chemical substances by weight percentage (%): 0.57-0.65 % of C, 0.17-0.37 % of Si, 0.50-0.80 % of Mn, 0.16-0.25 % of Cr, <= 0.35 % of P, <= 0.035 % of S, <= 0.30 % of Ni, <= 0.25 % of Cu, and the balance of Fe. The hot rolling coil rod with Phi 6.5 mm has a tensile strength of 990-1060 Mpa, a reduction of area of 50-60 % and a Sorbit rate of 85-90 %. The coil rod and the production method thereof have advantages that the process equipment and parameter setting are reasonable, the long-standing problem is solved, the product quality is improved, the deep processing of the coil rod is easy, a thinner steel wire product is easily drawn, the load that the steel strand processed with the steel wire can bear is substantially increased, the reduction of area of the steel wire is improved, the intermediate thermal treatment process is omitted and the energy is saved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Base station frequency resource allocation method and network device

ActiveCN103813347AReasonable configurationAvoid inter-cell interferenceNetwork planningBase frequencyNetwork Access Device

The invention discloses a base station frequency resource allocation method and aims to achieve reasonable allocation of base station frequency resources and avoid or lower inter-cell interference. The method includes that a cell is determined to conform to each basic frequency resource in each allowed operating frequency band of selectable operating bandwidth; frequency point priority coefficient of each basic frequency resource is determined, and the frequency point priority coefficient represents interference from each adjacent cell which neighbors the location of the cell with the cell in the basic frequency resource, and / or represents load of each adjacent cell in the basic frequency resource; the frequency resources are allocated to cells according to frequency point priority coefficients of the basic frequency resources. The invention further discloses a network device.

Owner:DATANG MOBILE COMM EQUIP CO LTD

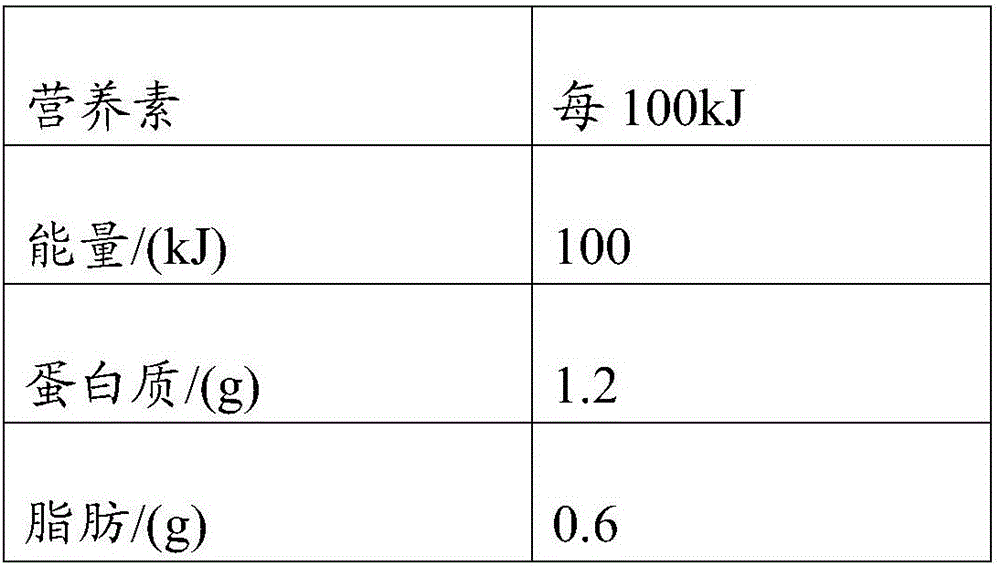

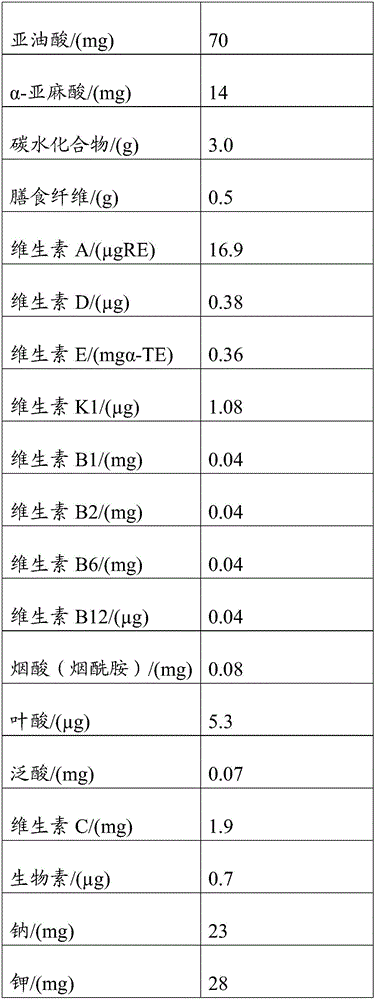

High dietary fiber full nutrition special application formula food and preparing method thereof

InactiveCN106690290AReasonable configurationPromote digestion and absorptionSugar food ingredientsVitamin food ingredientsFiberFeces

The invention relates to a high dietary fiber full nutrition special application formula food and a preparing method thereof, and belongs to the field of formula food. The high dietary fiber full nutrition special application formula food is prepared from, by weight, 0.7-2.1 parts of protein, 0.4-0.9 part of fat, 2.4-4.5 parts of carbohydrate and 0.3-0.7 part of dietary fiber. According to the high dietary fiber full nutrition special application formula food and the preparing method thereof, through screening and matching of raw and auxiliary materials, the food contains an appropriate amount of protein, carbohydrate and fat needed by people in daily life, and further contains mineral substances and vitamin needed by people, is in accordance to daily need by people, is easy to digest and absorb, can serve as a single nutrition source for people group over 10 years old whose eating is limited, can also serve as nutrition supplementation of a patient before and after a surgery, the product has a low GI value at the same time, contains rich dietary fiber, and is a good nutrient food for control sugar content and facilitating feces excretion.

Owner:GUANGZHOU SAIJIAN BIO TECH

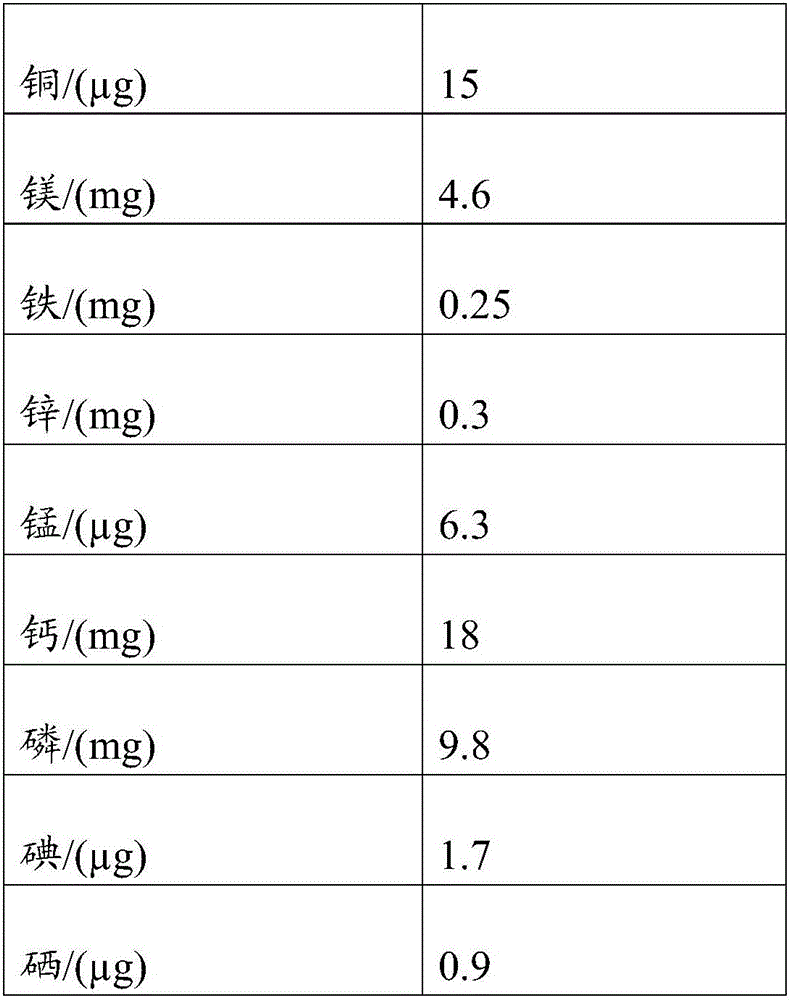

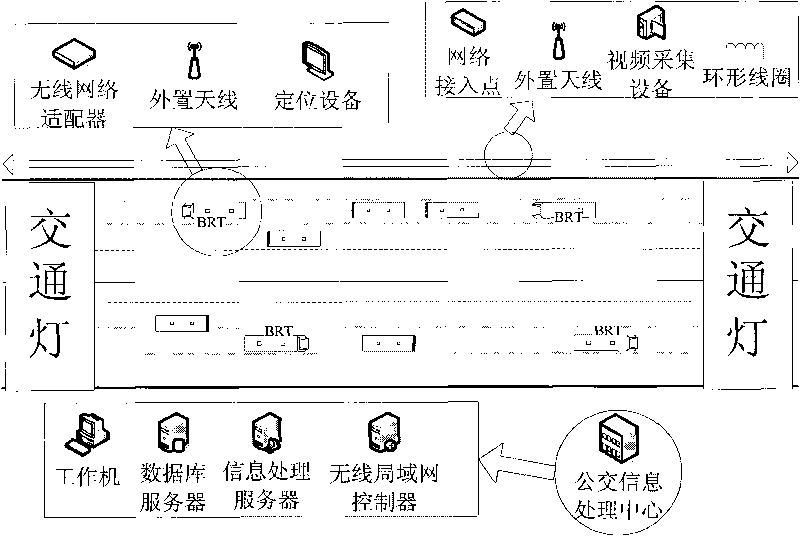

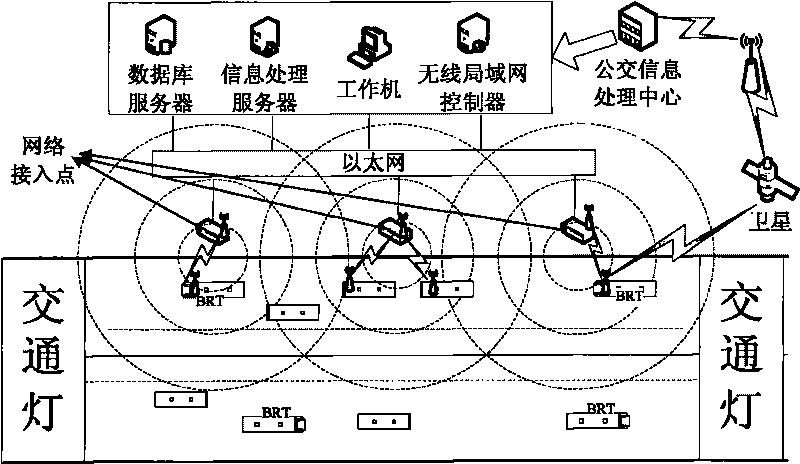

Public transit exclusive lane resource sharing method and system for guaranteeing bus rapid transit priority

InactiveCN101751788AQuick dispatchAccurate schedulingControlling traffic signalsBus laneControl flow

The invention discloses a public transit exclusive lane resource sharing method and a resource sharing system for guaranteeing bus rapid transit (BRT) priority. On the premise of guaranteeing the BRT priority, a common transit bus can enter a BRT bus exclusive lane to run according to the following control rules: (1) a control flow that the common transit bus borrows the BRT bus exclusive lane: calculating a distance between the common transit bus on a non-BRT bus exclusive lane and a BRT bus and marking the distance as d according to geographic location information, setting a minimum value as d borrow, when d is more than or equal to d borrow, determining that the common transit bus is allowed to borrow the BRT bus exclusive lane and enabling the common transit bus to freely select whether to enter the exclusive lane or not, otherwise preventing the common transit bus from entering the exclusive lane; and (2) a control flow that the common transit bus returns the lane after borrowing the BRT bus exclusive lane: sending a lane-returning control instruction to the common transit bus in front of the BRT bus when the distance D between the common transit bus and the BRT bus is less than the minimum safe distance d save, and making the common transit bus to pull out from the BRT bus exclusive lane in set time T. The method and the system effectively improve the utilization ratios of bus lanes.

Owner:ZHEJIANG UNIV OF TECH

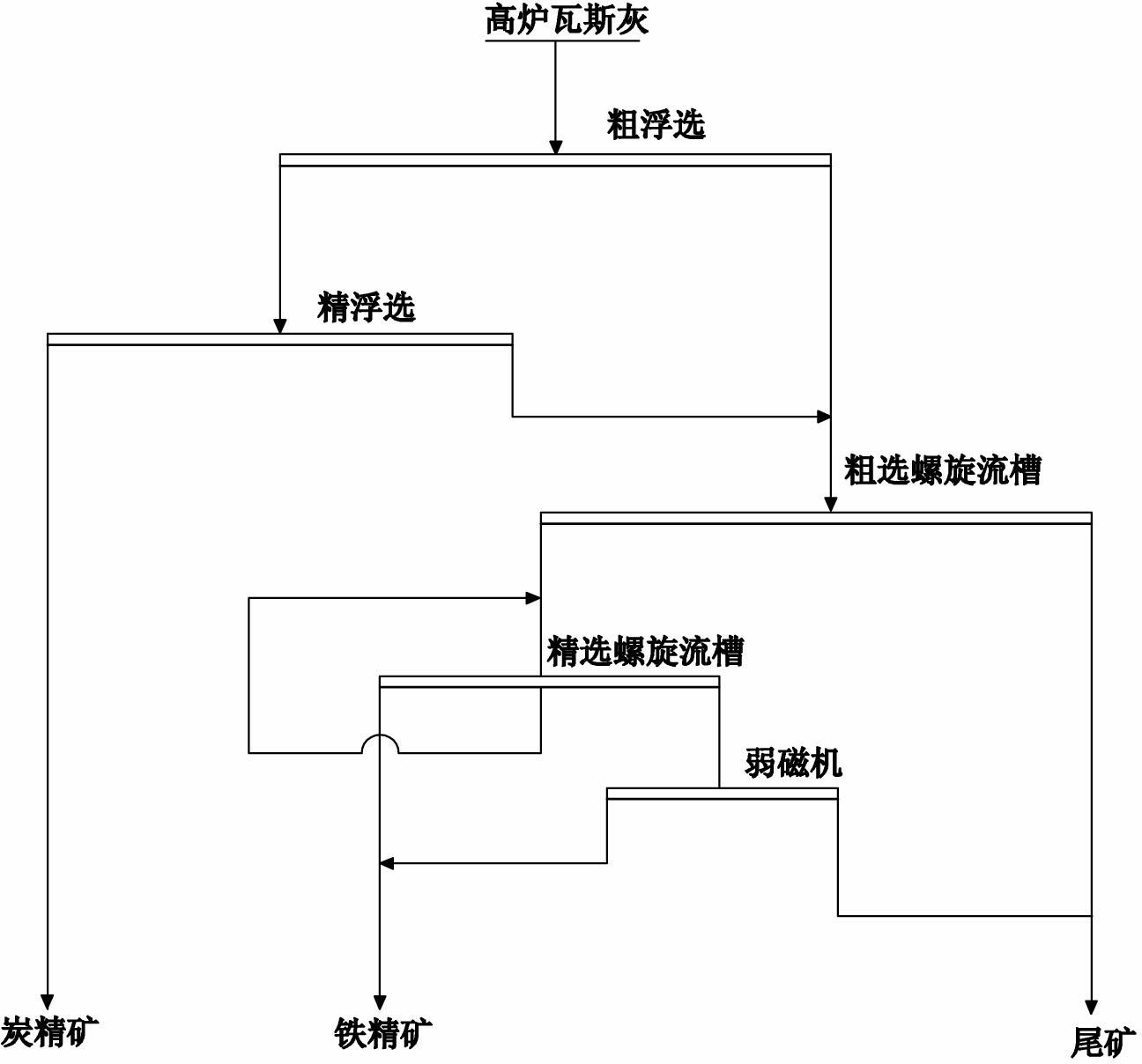

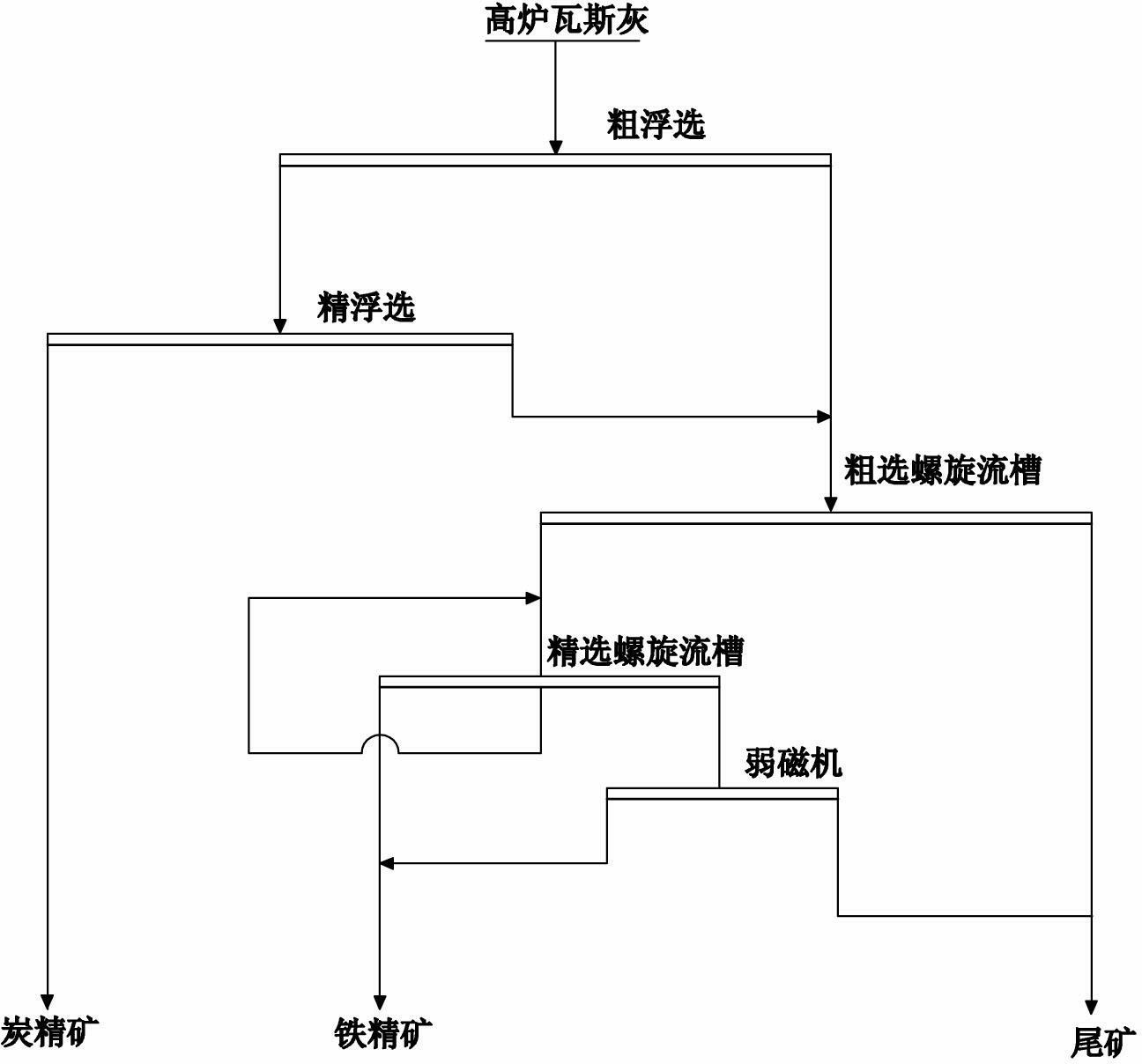

Process for recovering iron and carbon elements from blast furnace gas ash

ActiveCN102319617AGood enrichment and recovery effectHigh removal rateRecycling and recovery technologiesFlotationSlurryProcess configuration

The invention relates to the technical field of blast furnace ash resource reutilization, in particular to a process for recovering iron and carbon elements from blast furnace gas ash. A flotation method is adopted for recovering carbon, a re-separation and magnetic separation method is adopted for recovering iron, the total separation process is the combined technical process flow of flotation, re-separation and magnetic separation, the gas ash enters the coarse flotation after the slurry preparation and medicine adding, coarse flotation concentrates enter fine flotation, the fine flotation concentrates are final carbon concentrates, coarse flotation tailings and fine flotation tailings enter a re-separation coarse separation spiral chute to separate out re-separation tailings, the coarse spiral concentrates enter a fine separation spiral chute to obtain re-separation concentrates, ores in a fine separation spiral chute carries out self circulation, the tailings in the fine separation spiral chute enter a weak magnetic separation machine for carrying out magnetic separation, the weak magnetic concentrates and the re-separation concentrates are combined into final iron concentrates, and the weak magnetic tailings and the re-separation tailings are combined into final tailings. The process has the beneficial effects that the process is simple, the varieties of reagents are few,the process configuration is reasonable, the purification and impurity removal effects are obvious, the product quality is better, the recovery rate is high, and a new path is provided for the comprehensive utilization of the blast furnace gas ash.

Owner:ANSTEEL GRP MINING CO LTD

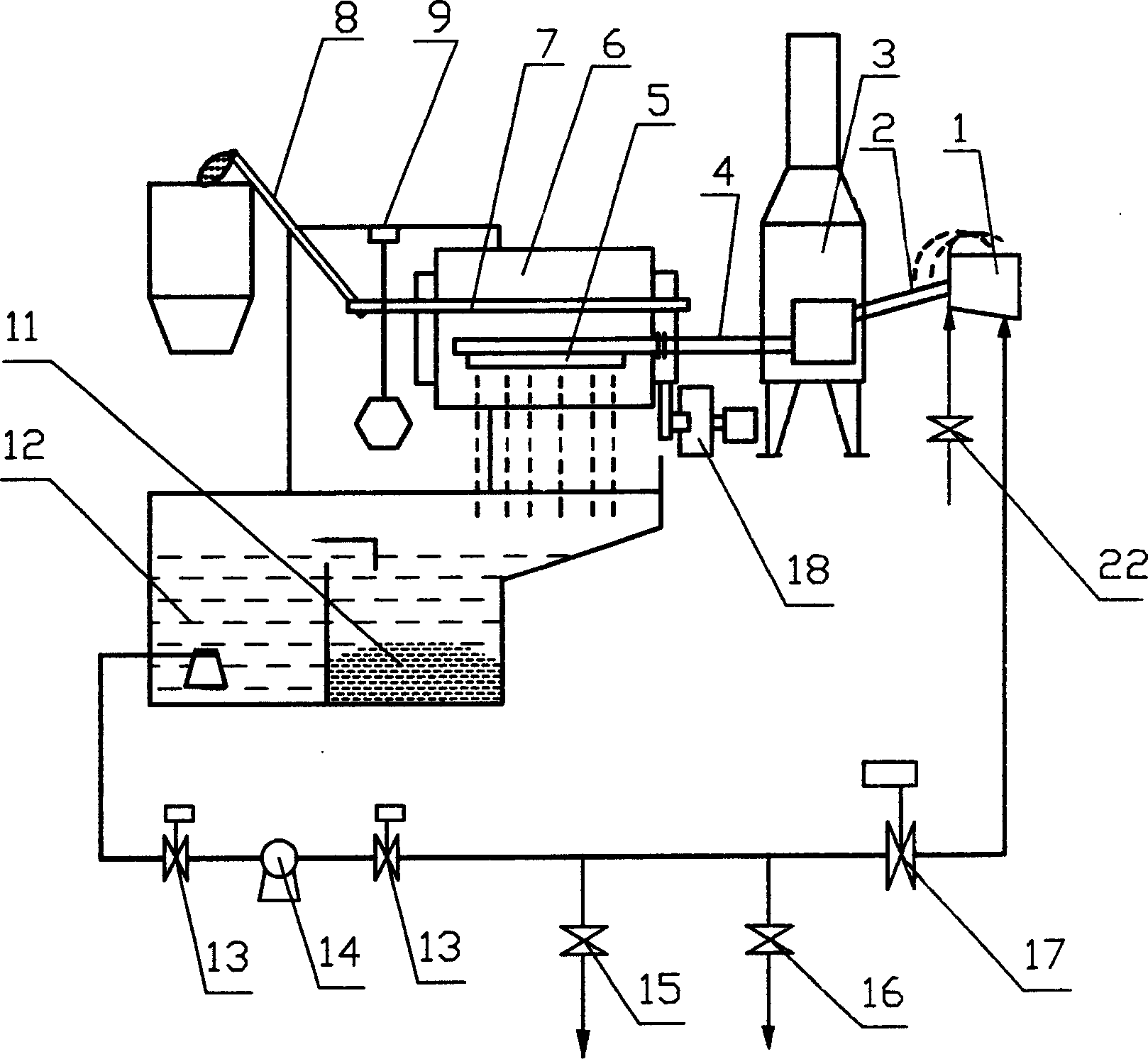

Blast furnace cinder water quenching processing unit

ActiveCN1769498ASimple configurationReasonable configurationRecycling and recovery technologiesCooling towerQuenching

This invention belongs to the molten slag treatment, especially relates to the blast furnace molten slag treating apparatus. The slag ditch connects with the granulating device and slag flume, the down part of the slag flume connects with the communicating pipe, the distributing trough that connects with the communicating pipe extends into the rotating drum filter, the belt device in the canister connects with the rotating belt device to form a finished articles warehouse; the down part of the rotating filter is arranged with the storage cabinet, laying-up basin, which are connected by the overflow on the pool wall, the dregs cleaning device is arranged on the storage cabinet the laying-up basin connects with the granulating device by the tube connector, valve and dregs cleaning pump. The device fault rate is low, the dregs punching out rate reaches up to more than 99úÑ, which is propitious to the operation and steady production of the blast furnace. And the dreg cleaning water and the sewage is used in closed cycle, so it can save a lot of pure water.

Owner:MAANSHAN IRON & STEEL CO LTD

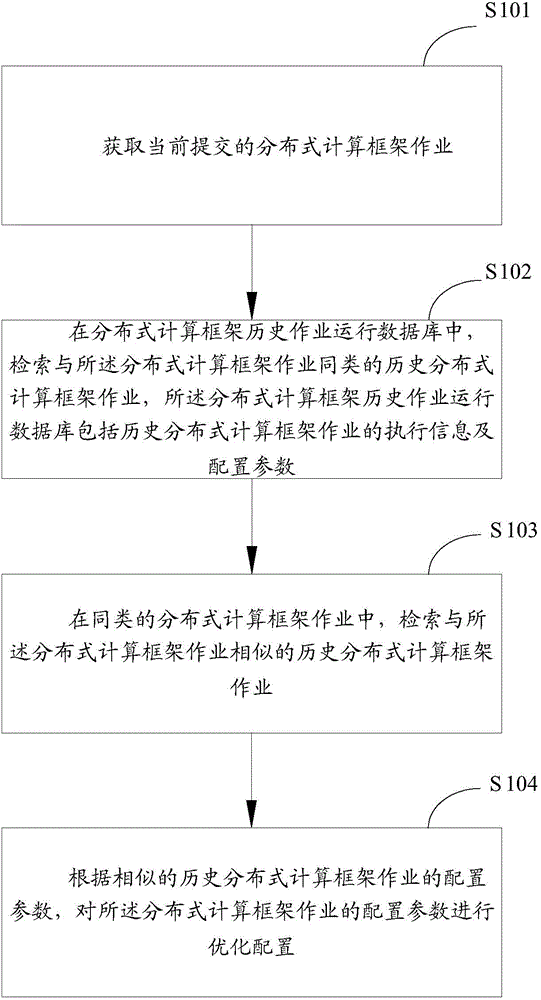

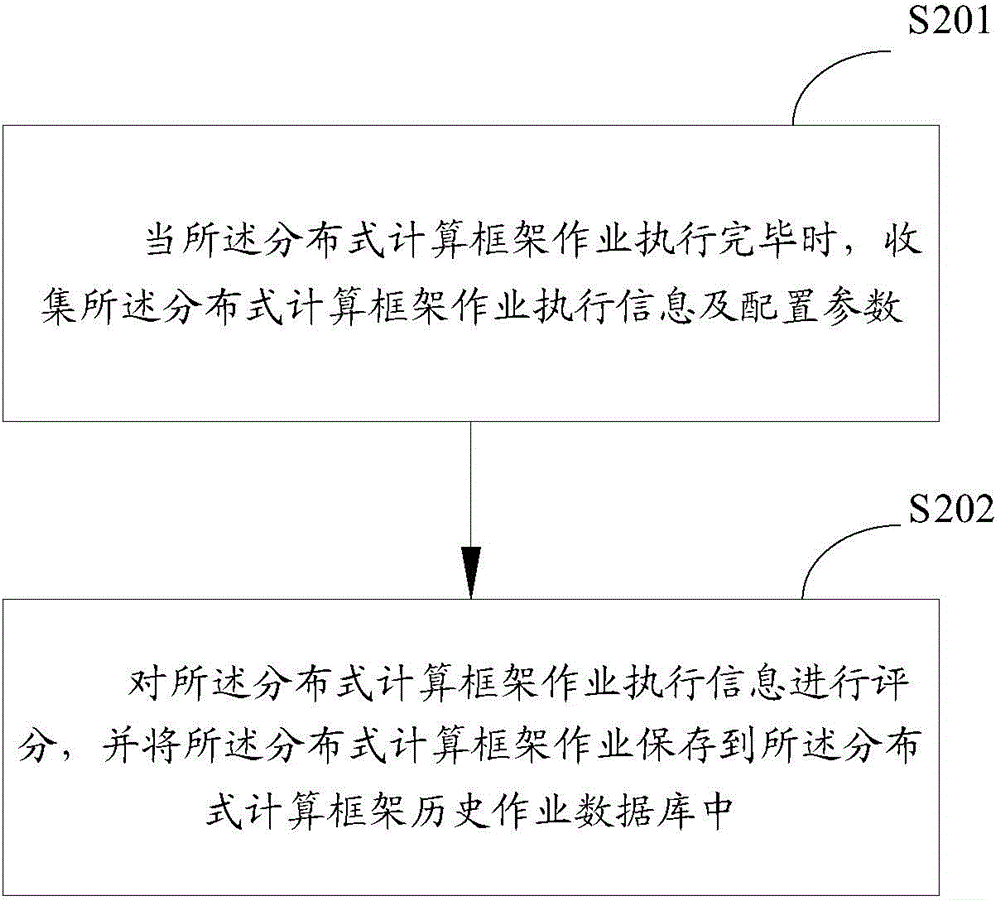

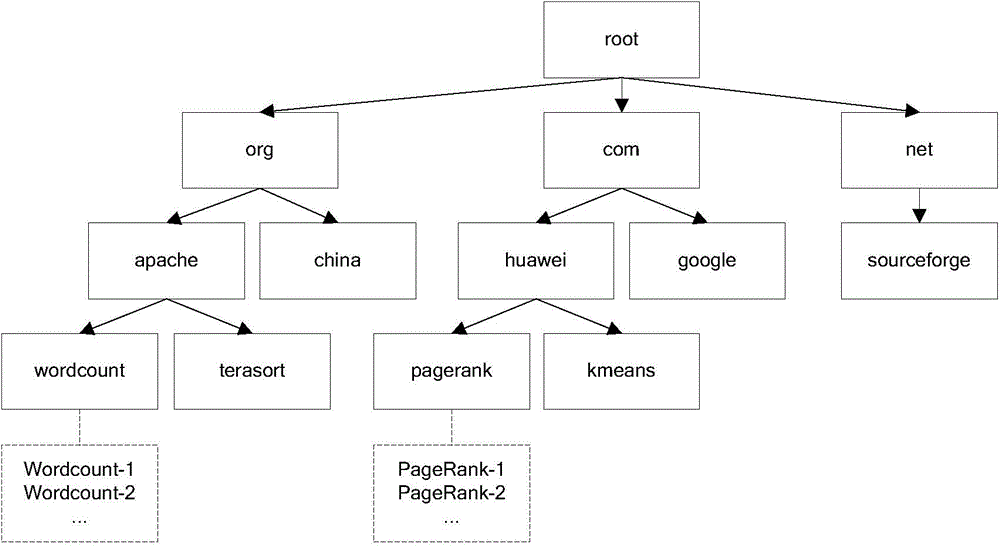

Distributed computation frame parameter optimizing method, device and system

ActiveCN103605662ALow efficiencyReasonable configurationProgram controlSpecial data processing applicationsReal-time computing

The invention is suitable for the IT technical field and provides a distributed computation frame parameter optimizing method, device and system. The method comprises the steps of obtaining currently-submitted parallel computation frame operation; retrieving historical distributed computation frame operation similar to the distributed computation frame operation in a distributed computation frame operation historical operation database, wherein the distributed computation frame operation historical operation database comprises execution information and configuration parameters of the distributed computation frame operation; retrieving historical distributed computation frame operation similar to the distributed computation frame operation during the similar distributed computation frame operation; performing optimizing configuration on the configuration parameters of the distributed computation frame operation according to configuration parameters of the similar historical distributed computation frame operation. By adopting the distributed computation frame parameter optimizing method, device and system, parameter configuration rationalization, automatization and self learning of Mapreduce operation can be achieved.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

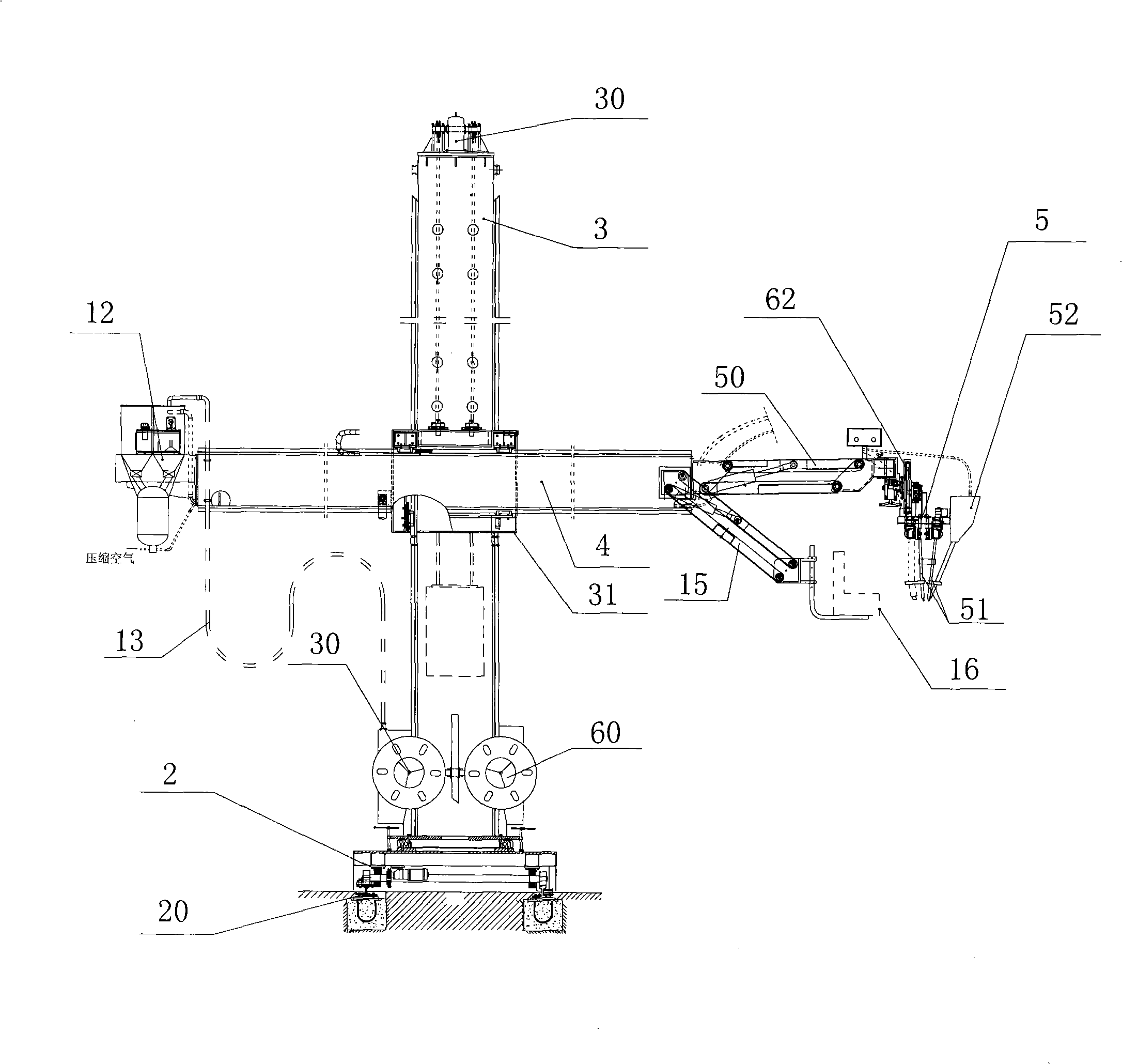

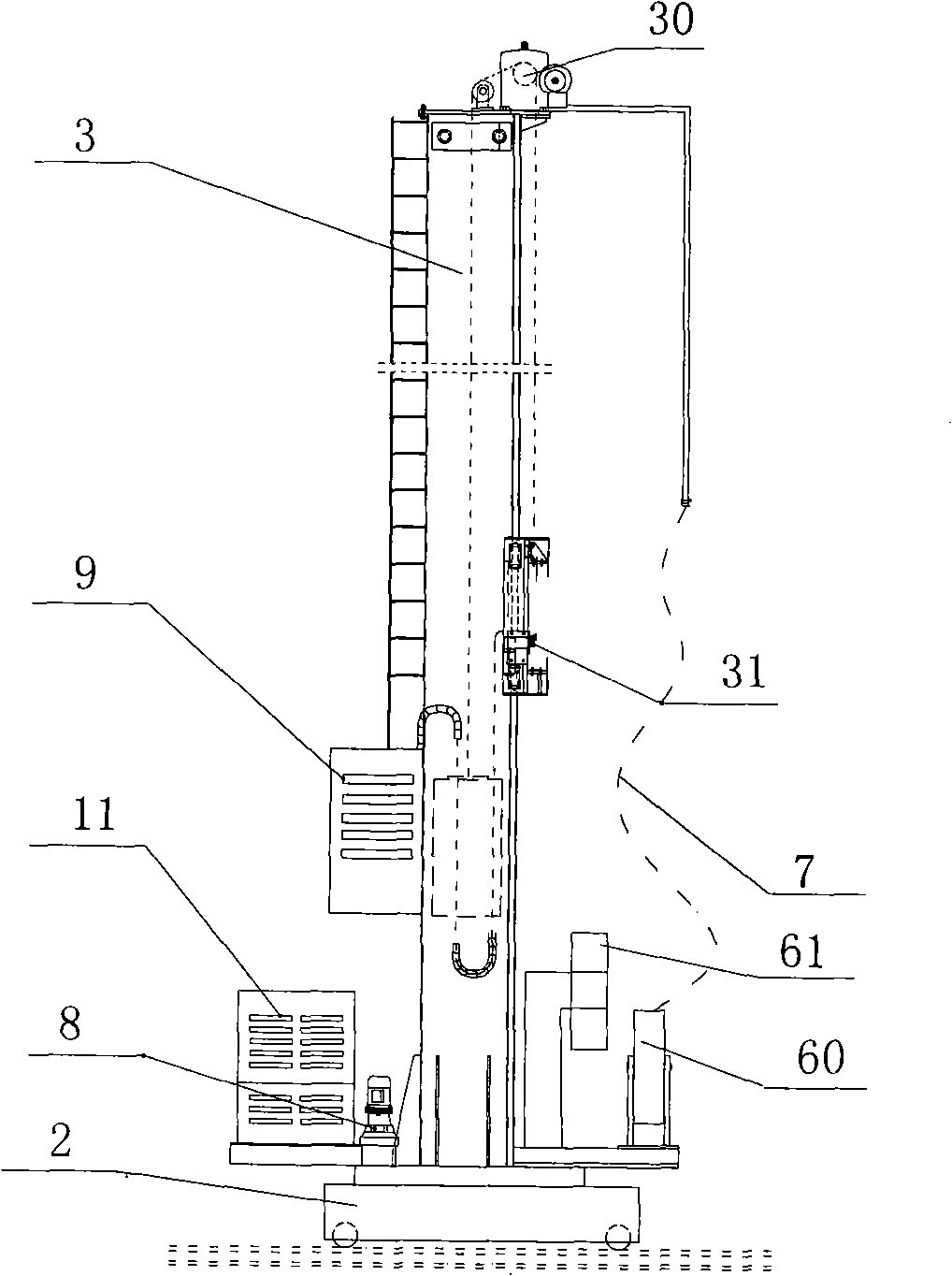

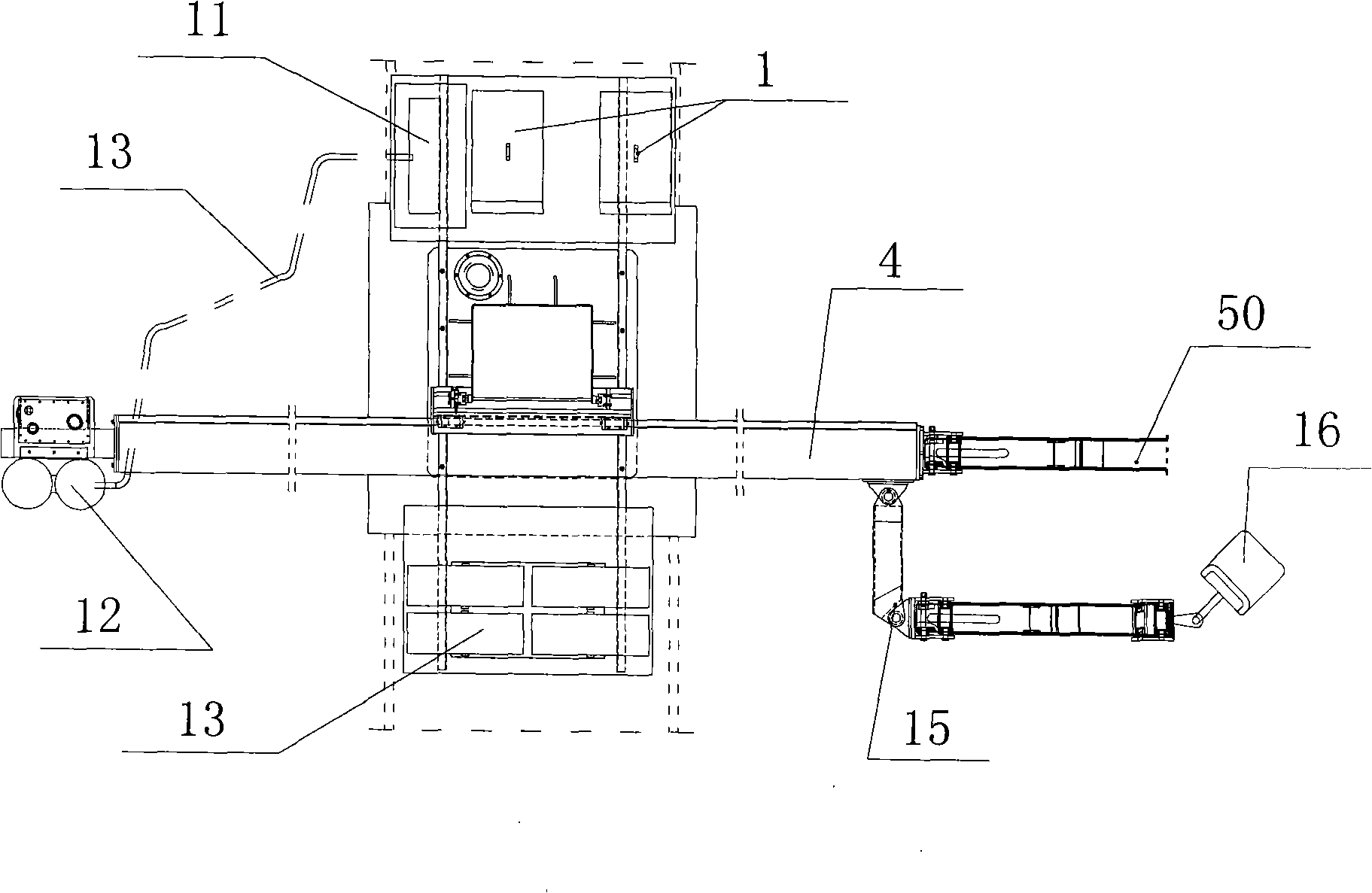

Double arc four wire automatic arc-submerging welder and manufacture method thereof

ActiveCN101306488AMeet the welding process requirementsImprovement of process technical parametersWelding accessoriesWelding power supplyEngineering

The invention discloses a double-arc four-wire automatic submerged arc welding machine and the manufacturing method thereof. The automatic submerged arc welding machine include a welding power supply, an upright post which is arranged on a trolley and a running gear and is provided with a top part with a lifting mechanism, a cross arm which is movably connected with the lifting mechanism and can move up and down along the upright post, a welding head which is equipped with a welding gun and a solder hopper, a wire guide arranged between the welding gun and a welding wire spool, a wire feeding device, a swing mechanism which is arranged on the trolley and is used for control the upright post to rotate relatively to the trolley, and an electric control cabinet which is fixed on the upright post. Compared with the prior art, the double-arc four-wire automatic submerged arc welding machine of the invention has the advantages as follows: the structure is novel, the arrangement is reasonable; the process engineering parameters such as power efficiency and so on are improved for satisfying technological requirements of welding a gas steam turbine; the welding efficiency can be increases by at least three times; a machine head, an operator seat lifting arm, a corner, a falling protector and other devices are arranged; the solder can be automatically reclaimed and fed, and applied continuously, thereby reducing labor intensity, improving operational environment and conducing to operation.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

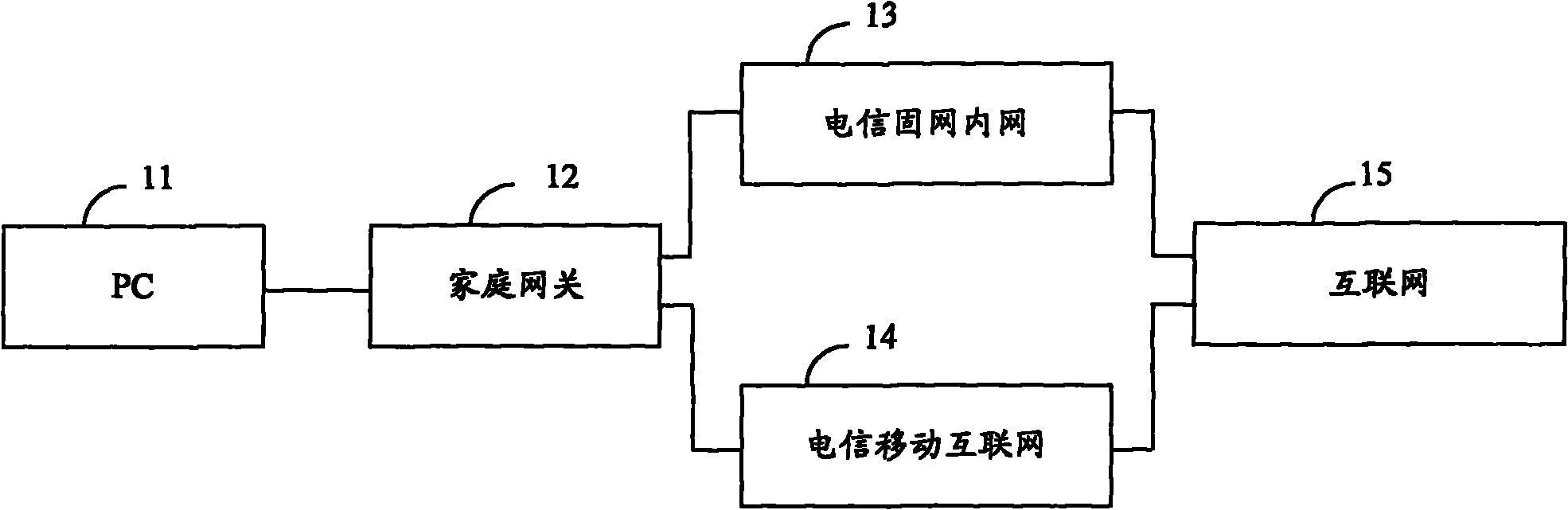

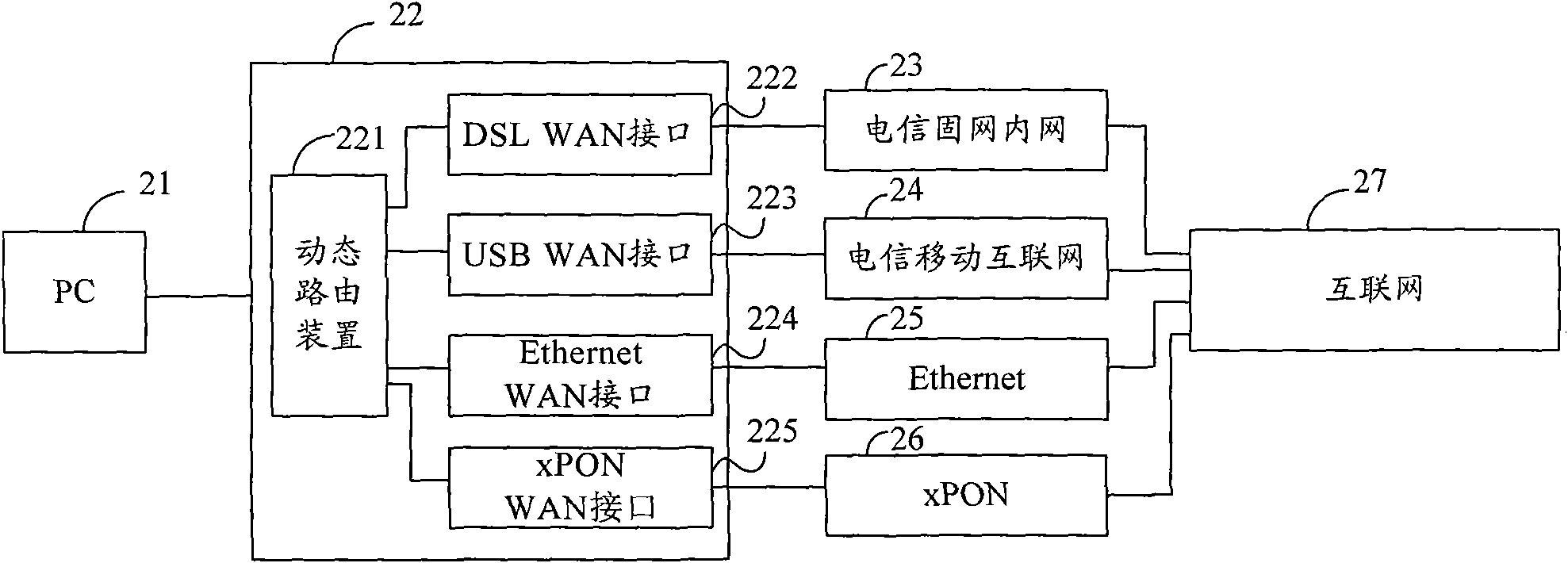

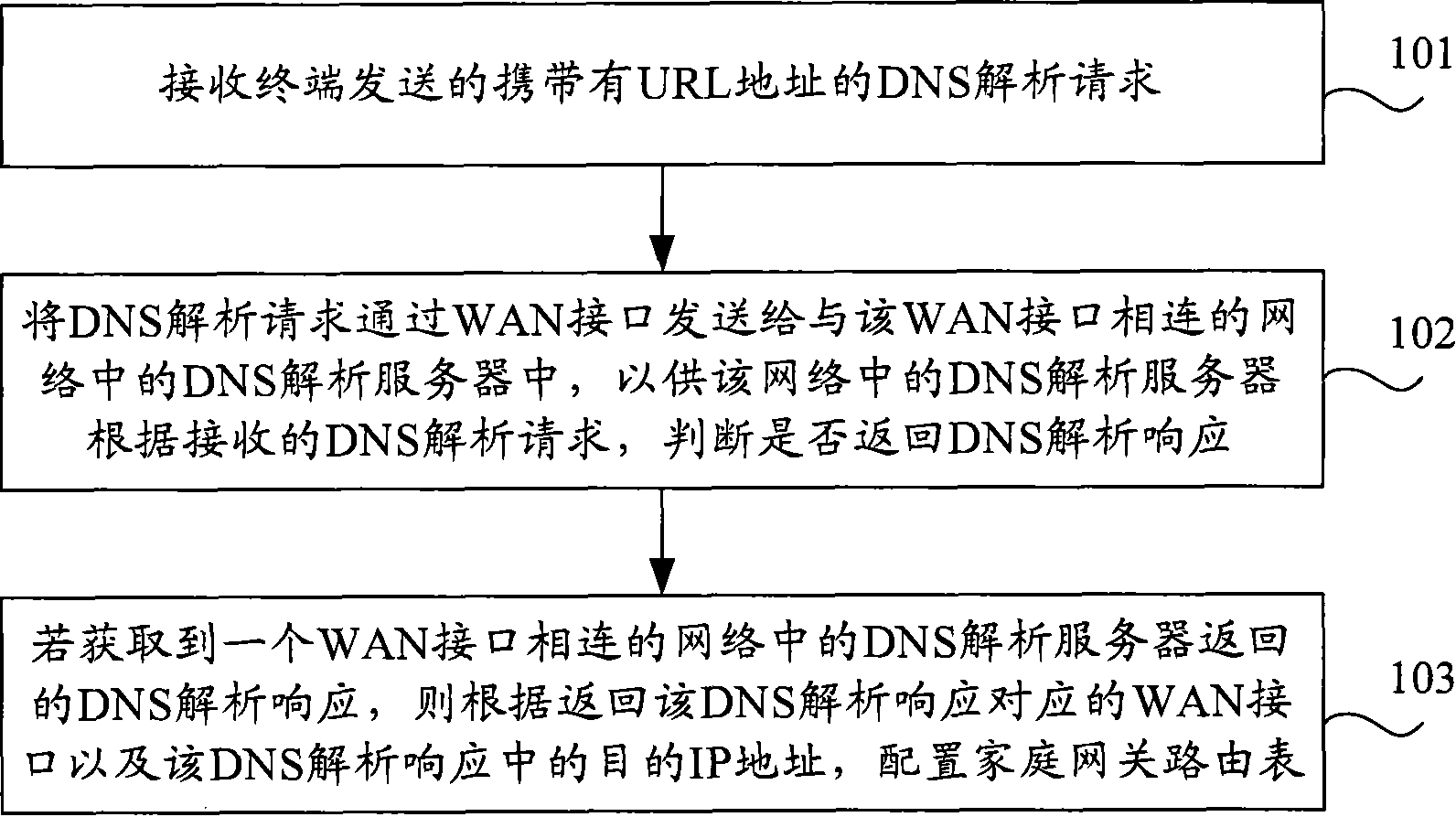

Dynamic routing processing method and dynamic routing processing device and home gateway thereof

ActiveCN102143243AEfficient configurationReasonable configurationNetwork connectionsDomain nameRouting table

The invention provides a dynamic routing processing method and a device and a home gateway thereof. The dynamic routing processing method comprises the following steps: a domain name system analysis request carrying a uniform resource locator address and sent by a terminal is received; the domain name system analysis request is sent into a domain name system analysis server in a network connected with a wide area network interface through the wide area network interface, so that the domain name system analysis server can judge whether the domain name system analysis response is returned according to the received domain name system analysis request; if the domain name system analysis response returned by the domain name system analysis server in the network connected with the wide area network interface is acquired, a home gateway routing table is configured according to the wide area network interface corresponding to the domain name system analysis response and a destination internet protocol address in the domain name system analysis response.

Owner:HUAWEI DEVICE CO LTD

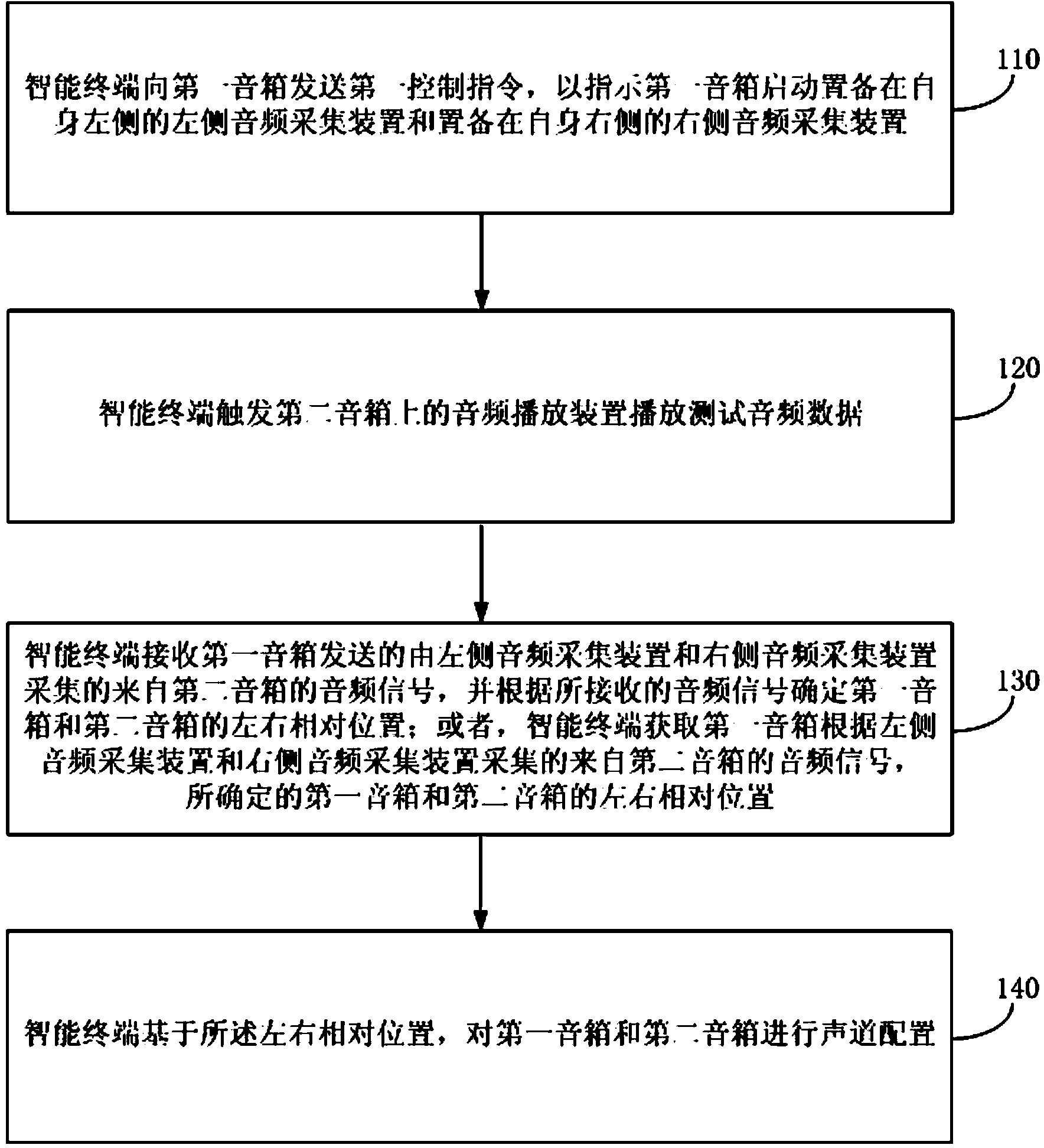

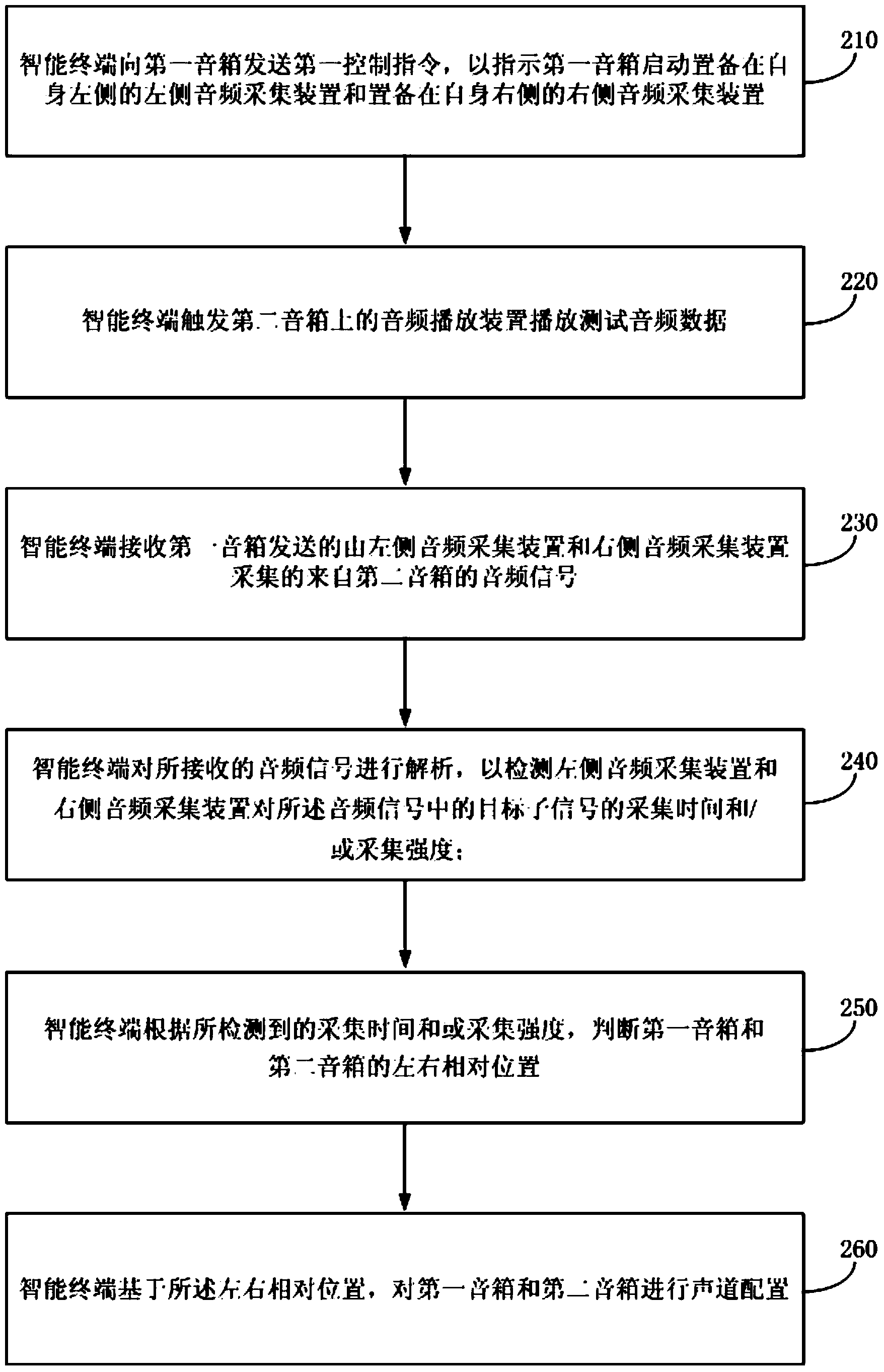

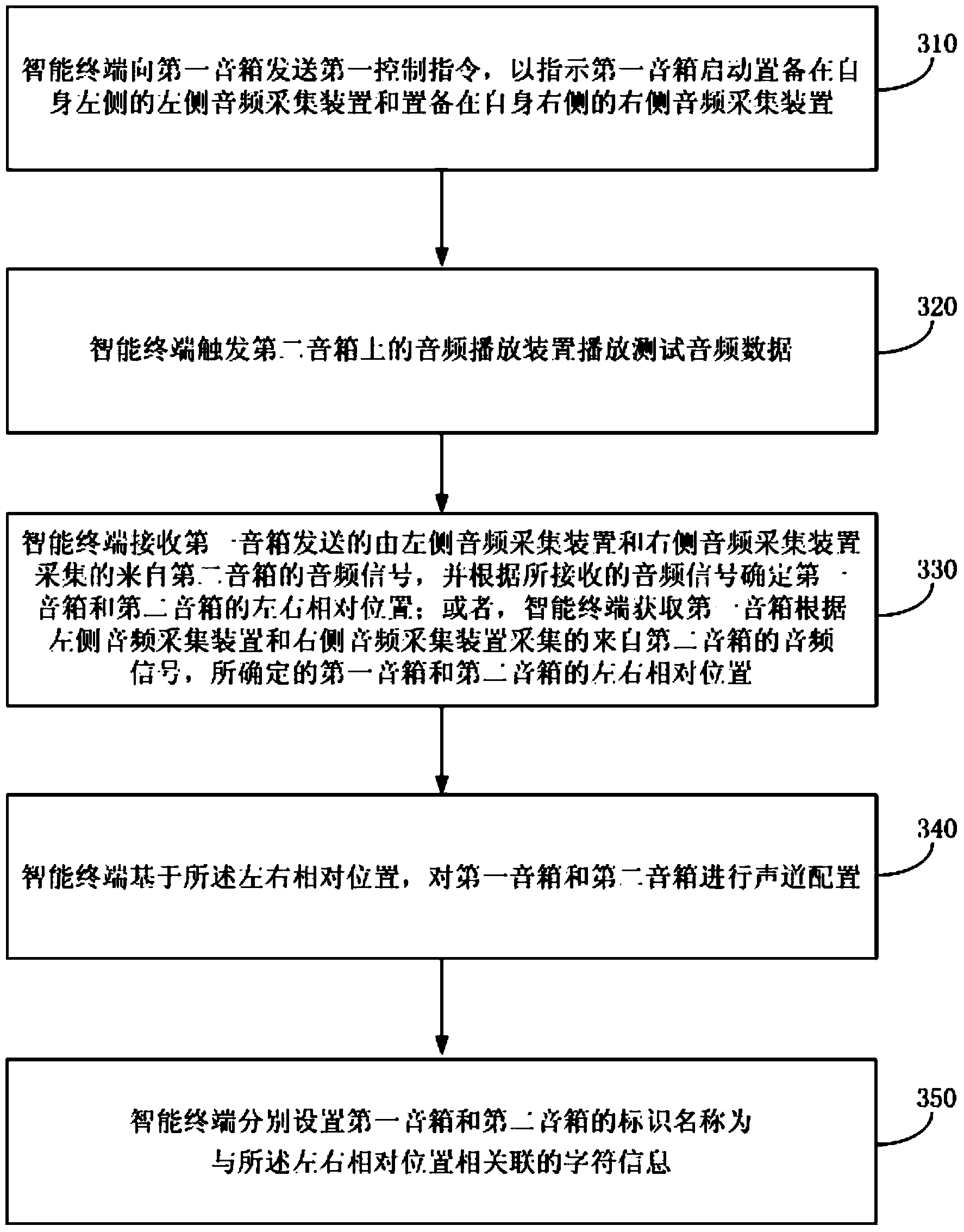

Audio track configuration method, intelligent terminal and corresponding system

ActiveCN104185132AReasonable configurationNo manual operation requiredPublic address systemsSpecific program execution arrangementsLoudspeakerAudio signal

The embodiment of the invention discloses an audio track configuration method, an intelligent terminal and a corresponding system. The method comprises the steps that the intelligent terminal sends a first control instruction to a first loudspeaker box for instructing the first loudspeaker box to start a left audio collecting device and a right audio collecting device which are arranged on the two sides of the first loudspeaker box; an audio playing device on a second loudspeaker box is triggered for playing testing audio data; audio signals which are sent by the first loudspeaker box and collected by the left and right audio collecting devices and come from the second loudspeaker box are received, and left and right opposite positions of the first loudspeaker box and the second loudspeaker box are determined according to the received audio signals; or the left and right opposite positions, determined by the first loudspeaker box according to the audio signals, of the first loudspeaker box and the second loudspeaker box are obtained, wherein the audio signals are collected by the left and right audio collecting devices and come from the second loudspeaker box; based on the left and right opposite positions, audio tract configuration is carried out on the first loudspeaker box and the second loudspeaker box. According to the technical scheme, the attribution of loudspeaker box audio tracks in a loudspeaker box system can be automatically configured.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

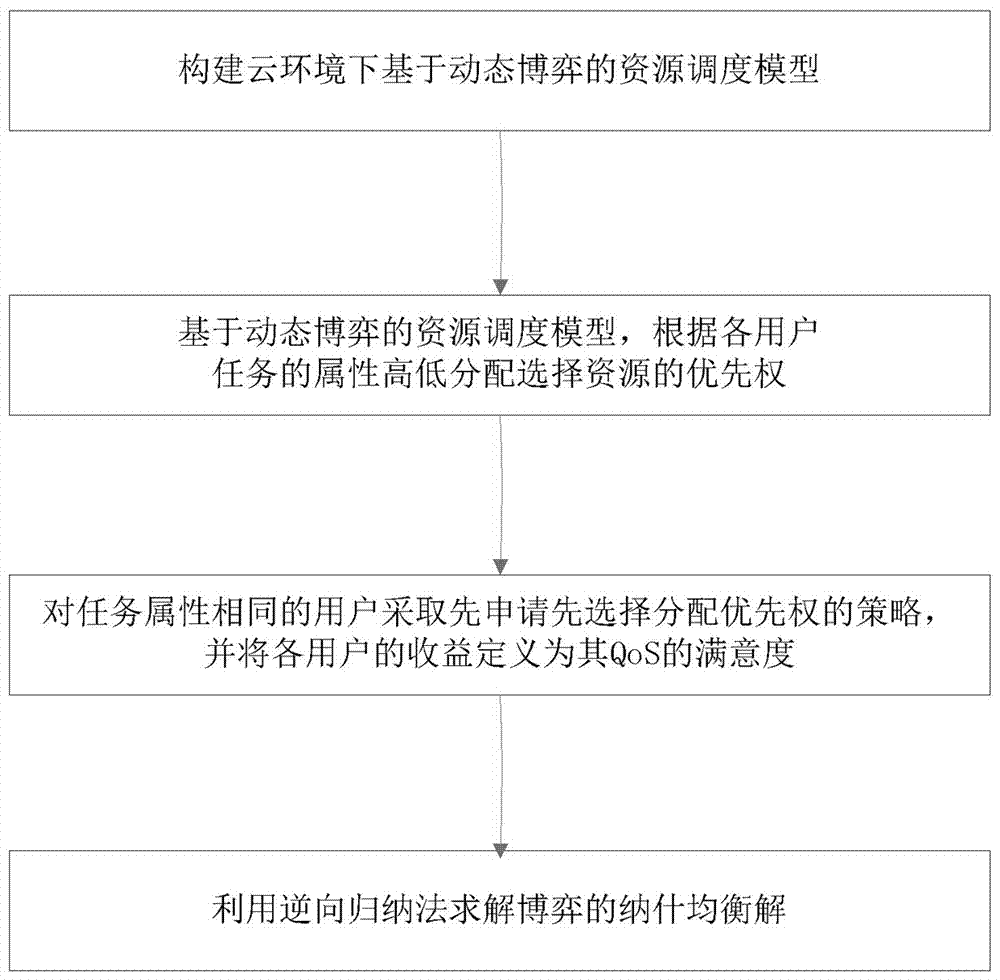

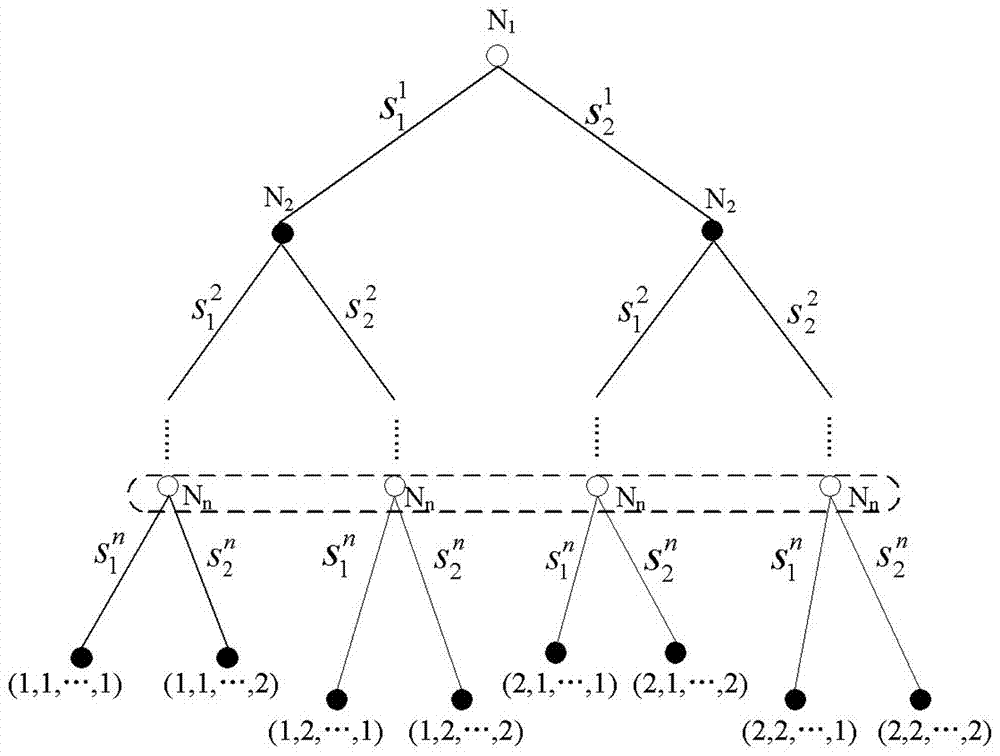

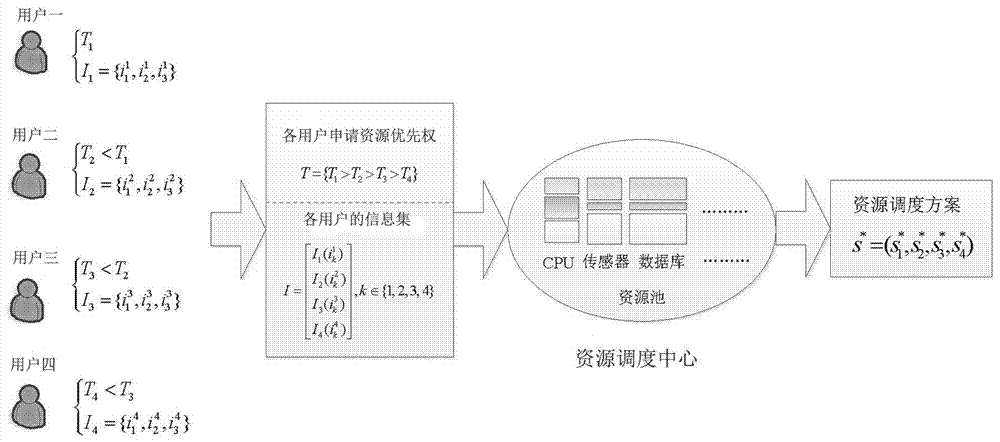

A resource scheduling method based on dynamic gaming in a cloud environment

InactiveCN107168797AImplement resourcesThe most reasonable and effective configurationResource allocationForecastingCloud computingResource scheduling

The invention belongs to the technical field of cloud computing-based resource scheduling and in particular provides a resource scheduling method based on dynamic gaming in a cloud environment. The method comprises the steps of building a model of resource scheduling based on dynamic gaming in a cloud environment; based on the model of resource scheduling based on dynamic gaming, distributing priority of resource selection user task attributes; employing a strategy that those who apply first select distribution priority first for users with the same task attributes and defining the earnings of each user as the satisfaction degree of QoS; obtaining a Nash equilibrium solution of the gaming by using a backward induction method. For the problem of resource competition caused by simultaneous submitting of tasks by users in a cloud environment, the method builds the cloud environment dynamic gaming resource scheduling model, performs modeling and analysis on resource competition between the users by using the dynamic gaming theory, and satisfies the QoS requirements of all the users as much as possible; the method meets the requirement of each user to the greatest extent; the method obtains a Nash equilibrium solution of the dynamic gaming model by using a backward induction method, thereby achieving the most reasonable and effective allocation of resources.

Owner:THE PLA INFORMATION ENG UNIV

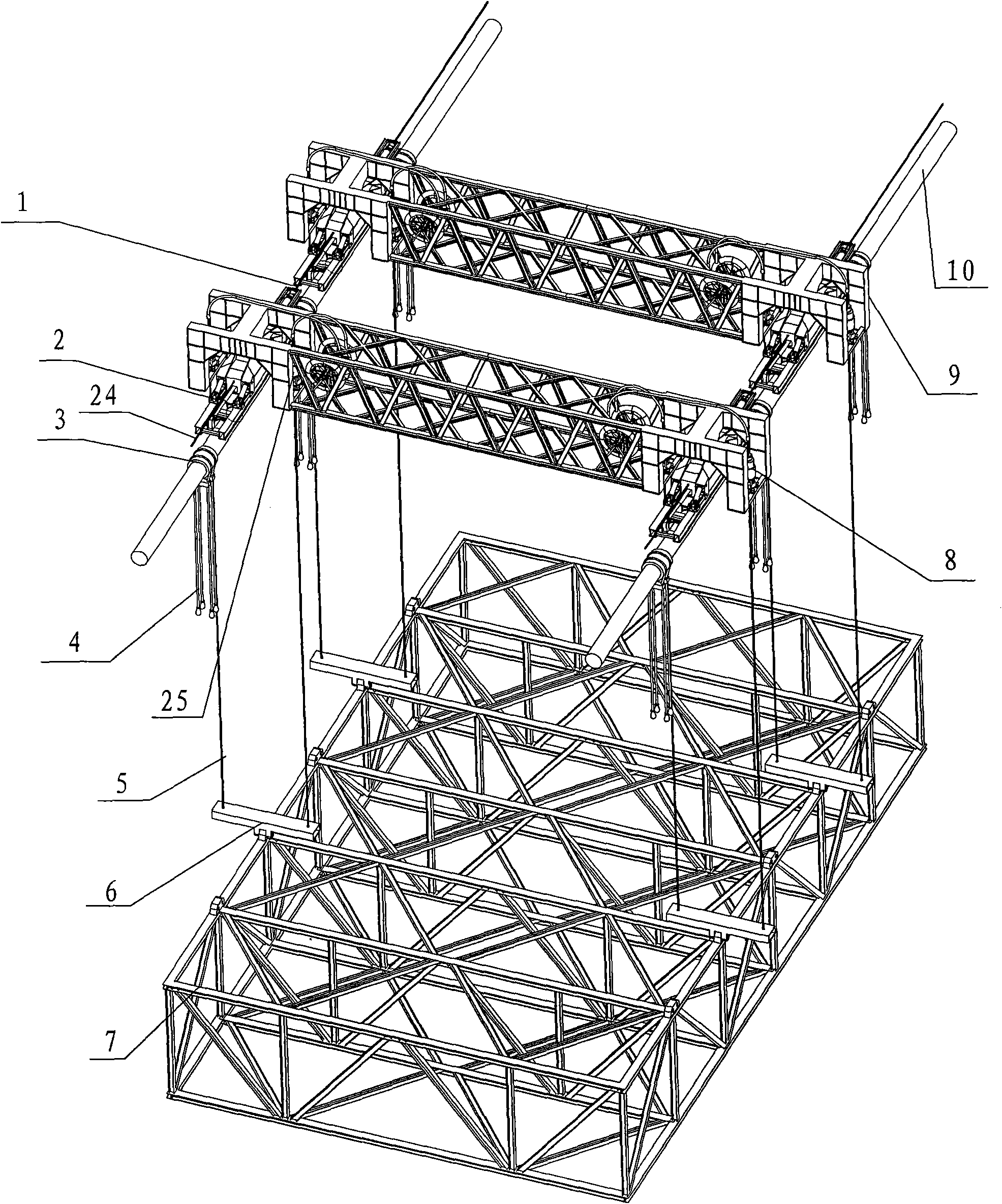

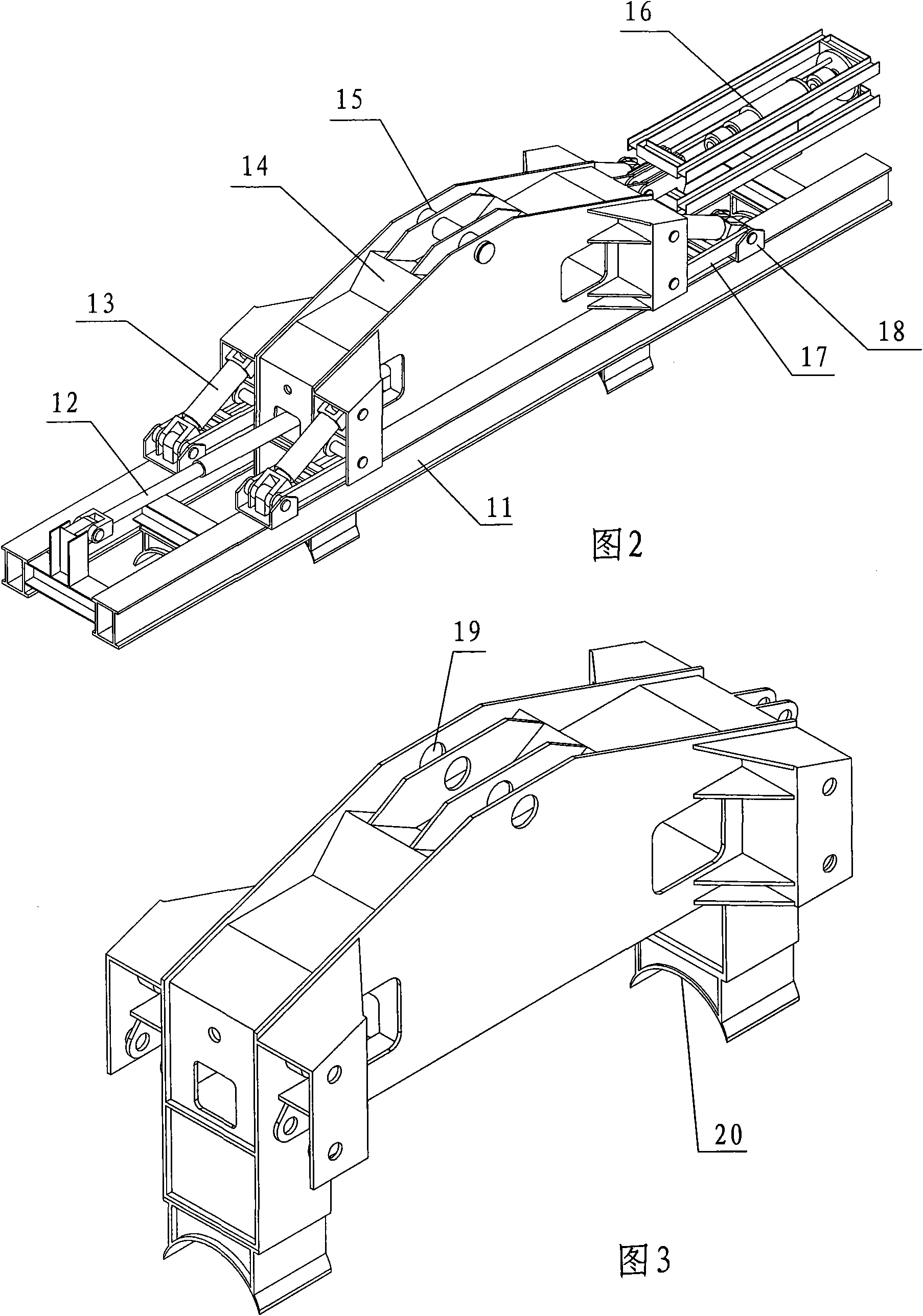

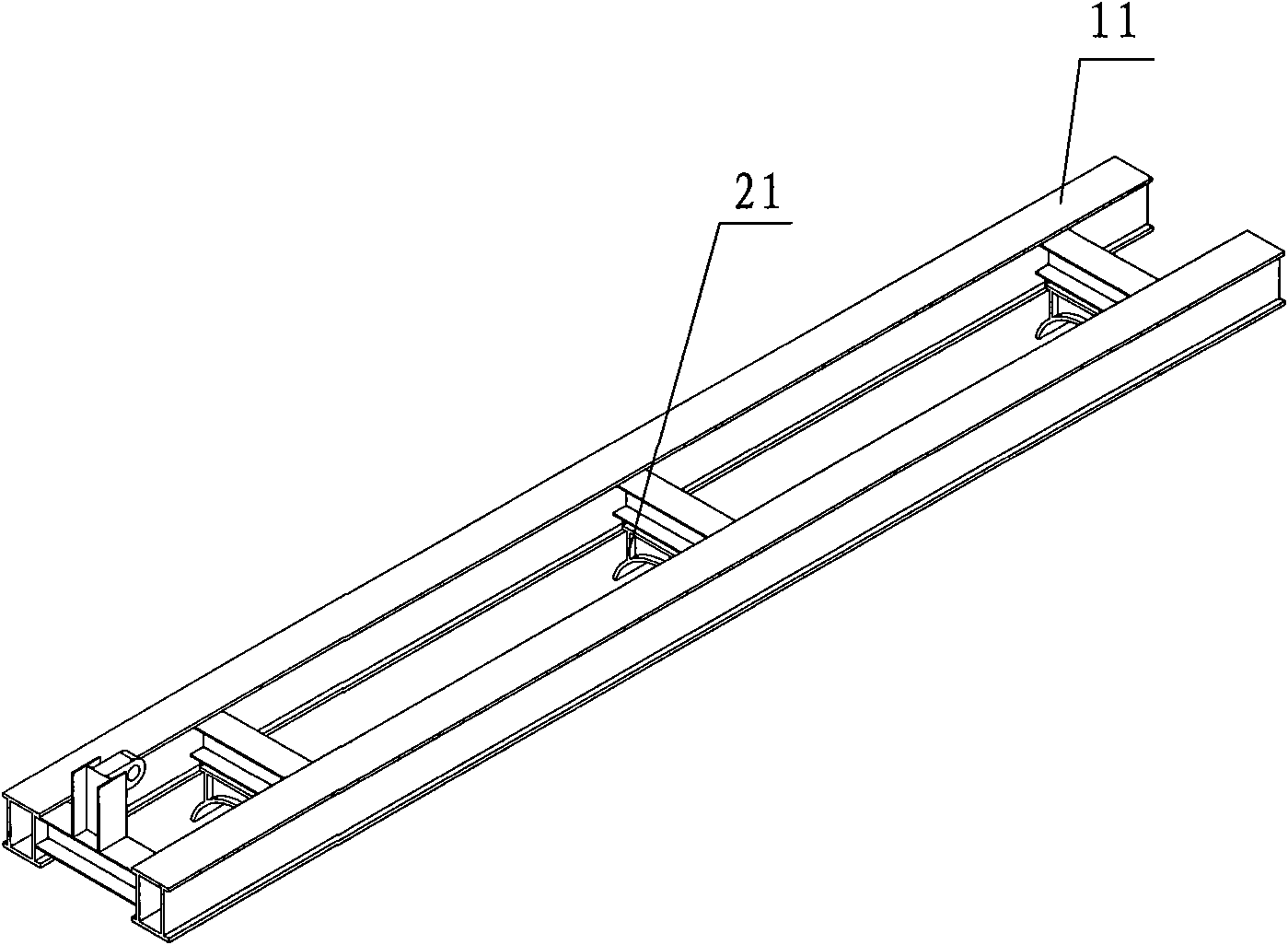

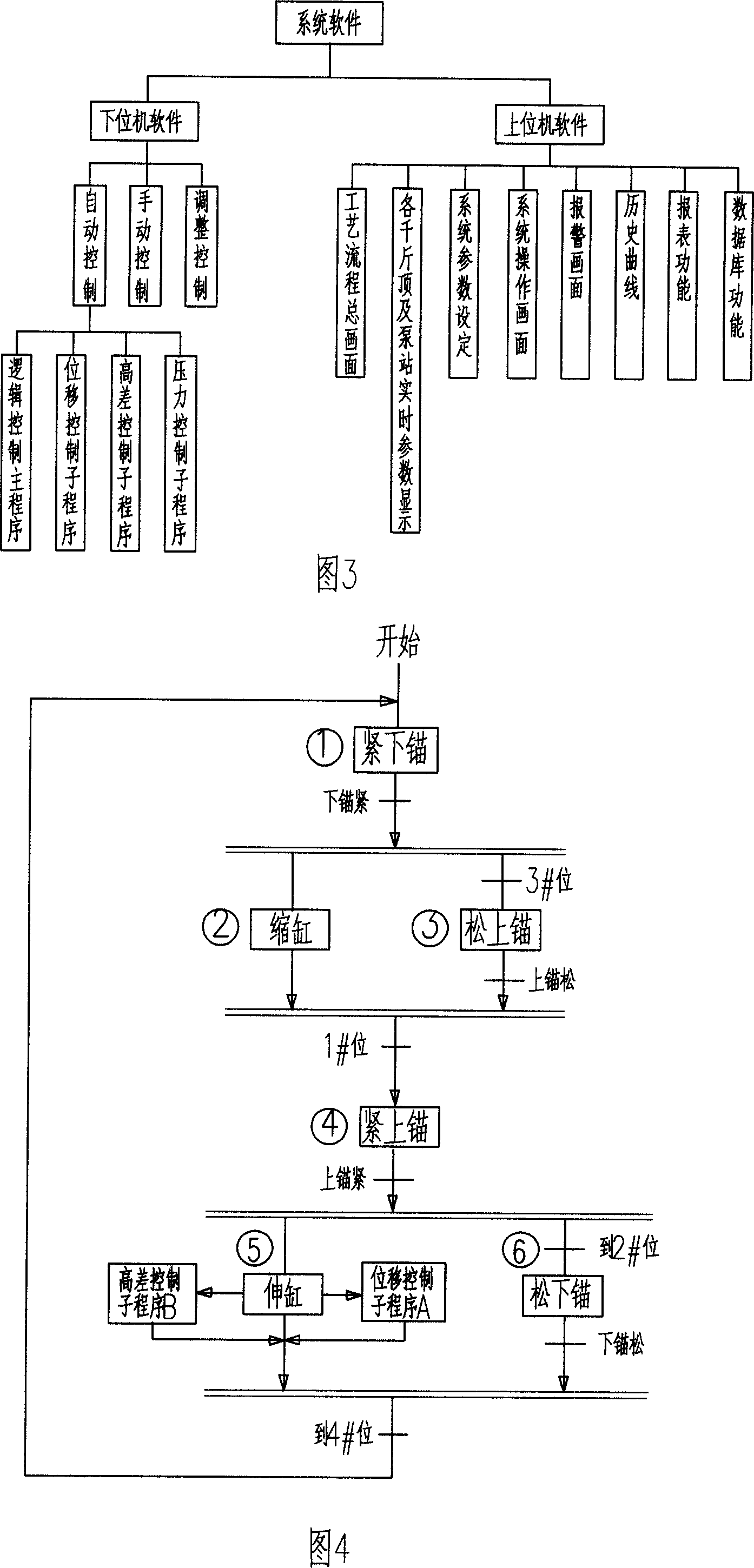

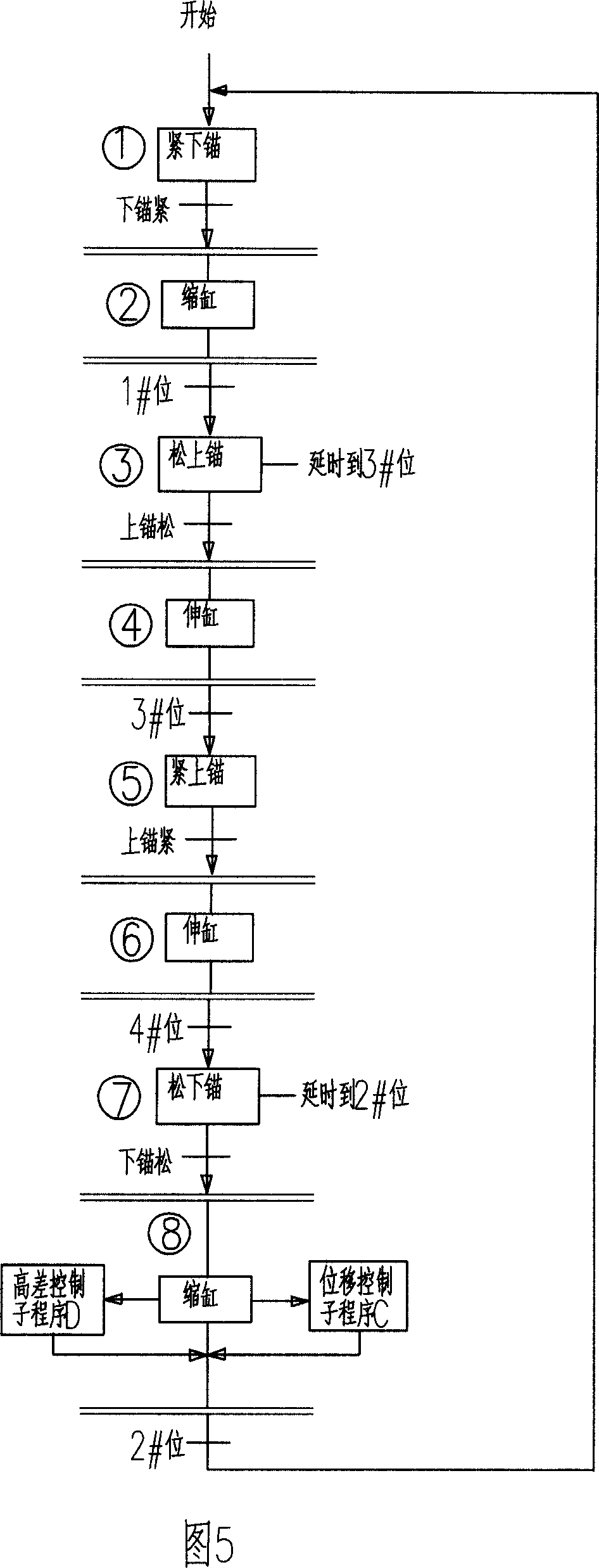

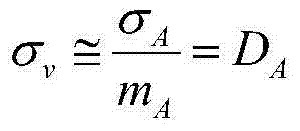

Dual-machine loading-and-walking type hydraulic numerical control deck erection gantry and control system and control method

ActiveCN101786577AImprove lifting performanceImprove work efficiencyCable carsSafety gearNumerical controlControl system

The invention provides a dual-machine loading-and-walking type hydraulic numerical control deck erection gantry, which comprises two sets of loading-and-walking type hydraulic numerical control deck erection gantries and a control system, wherein each set of the loading-and-walking type hydraulic numerical control deck erection gantries comprises the following four parts: a transverse truss girder, two sets of walking type loading-and-walking devices arranged at two ends of the transverse truss girder, a hydraulic lifting device and a carrying pole of a hanger; each set of the walking type loading-and-walking devices consists of a guideway, a walking mechanism steel framework, m traction jacks, 4n load conversion jacks, a supporting pull rod, a walking roller bracket and P guideway walking jacks; all the components are connected with one another by pin shafts; and the control system of the deck erection gantry is a distributed computer network control system which consists of a main control station, Y field controllers, Y pump stations, Y pump station starting boxes, a data acquisition system, and a plurality of data wires and communication wires. The deck erection gantry has the advantages of great lifting force and high work efficiency and stability; and when the deck erection gantry walks with load, the control system of the deck erection gantry can effectively and synchronously control every jack.

Owner:LIUZHOU OVM MASCH CO LTD

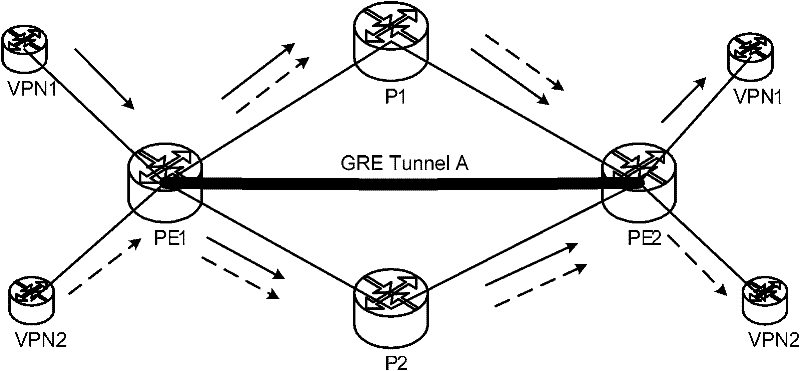

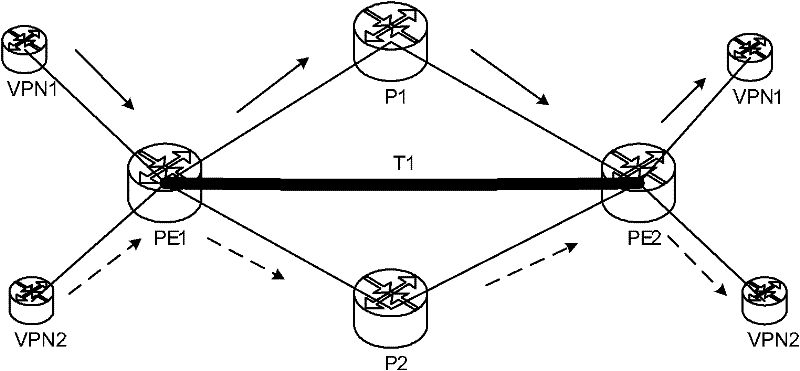

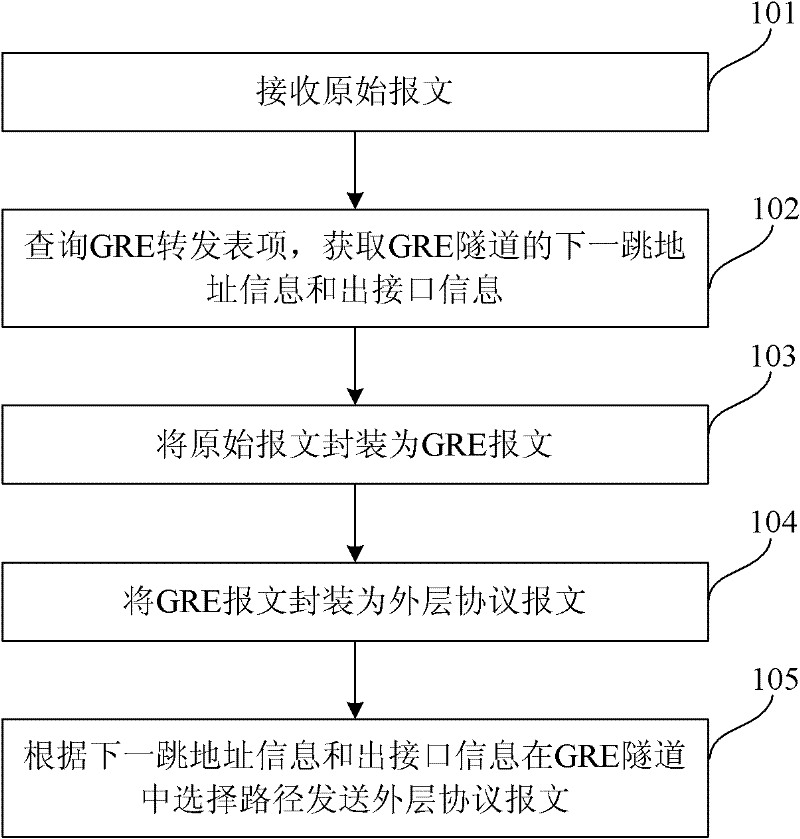

Message transmitting method and device

InactiveCN102130826AImprove sending efficiencyReasonable configurationHybrid transportComputer networkGeneric Routing Encapsulation

The embodiment of the invention relates to a message transmitting method and a message transmitting device. The message transmitting method comprises the following steps of: receiving an original message; querying a preconfigured generic routing encapsulation (GRE) forwarding list item comprising the next hop address information and out-interface information, and acquiring the next hop address information and out-interface information of a GRE tunnel for transmitting the original message; encapsulating the original message into a GRE message; encapsulating the GRE message into an external protocol message; and selecting a transmission path in the GRE tunnel according to the next hop address information and out-interface information, and transmitting the external protocol message through the transmission path. Therefore, in the message transmitting method and the message transmitting device, the transmission path is selected in the GRE tunnel according to the next hop address information and out-interface information, so that the transmission path of the message can be autonomously selected. Therefore, various paths in the GRE tunnel can be reasonably configured and effectively utilized, and message transmitting efficiency is improved.

Owner:HUAWEI TECH CO LTD

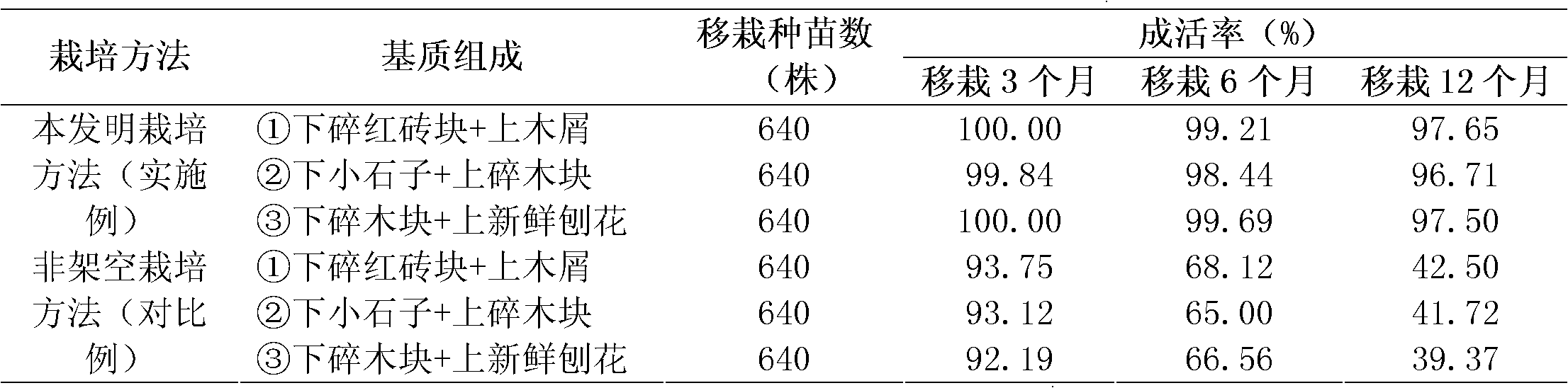

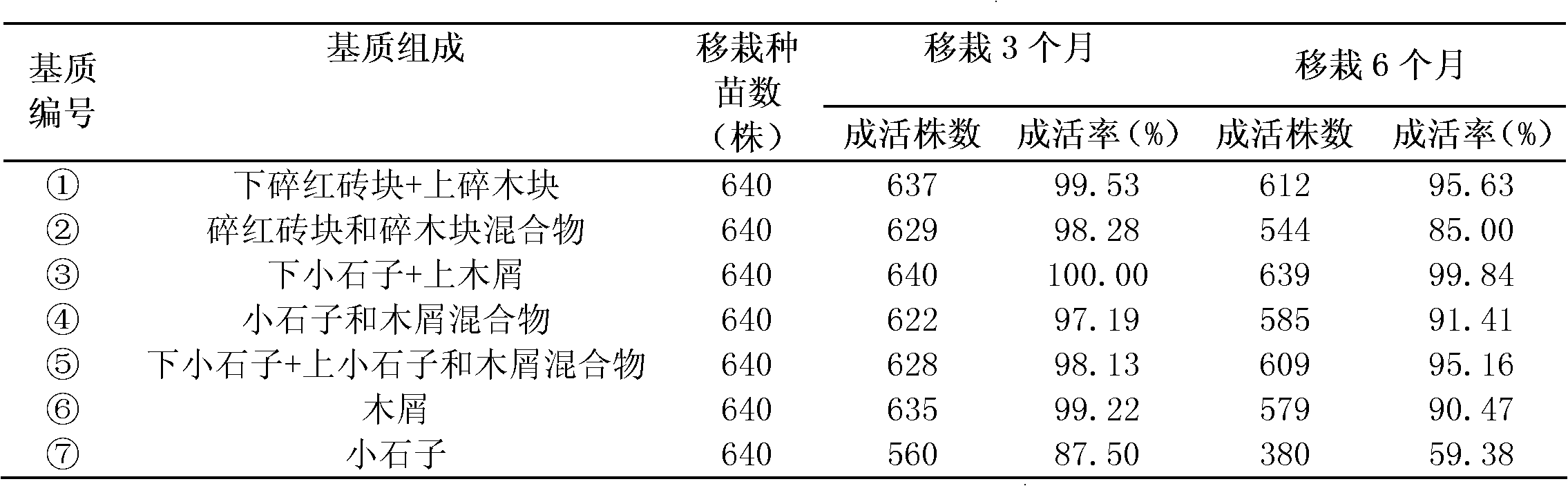

Overhead cultivation method of Dendrobium huoshanense test-tube seedlings

ActiveCN102318547AAvoid harmAvoid spreadingCultivating equipmentsSoilless cultivationGreenhouseInsect pest

The invention relates to an overhead cultivation method of Dendrobium huoshanense test-tube seedlings. The method comprises the following steps: leveling land, building a greenhouse, arranging stereoscopic racks (seedling beds), disinfecting the greenhouse, arranging planting media, planting seedlings in field, carrying out fertilizer and water management and harvesting. The method comprises the following specific steps of: firstly constructing infrastructure of a base, after the greenhouse is built up, arranging the stereoscopic racks, disinfecting the greenhouse before transplanting seedlings, and then arranging cultivation containers containing the planting media on the stereoscopic racks or directly arranging the planting media on nets of the cultivation racks, planting seedlings in field after the temperature inside the greenhouse is more than 10 DEG C, then carrying out fertilizer and water management according to the requirement and harvesting 2 years later. By using the cultivation method, the transplanting survival rate of Dendrobium huoshanense can be obviously improved, diseases and insect pests can be effectively prevented, the production period is shortened, and the product quality is uniform and consistent; and the method is simple to operate and is favorable to the mass production of Dendrobium huoshanense seedlings.

Owner:安徽康顺名贵中草药产业开发有限公司

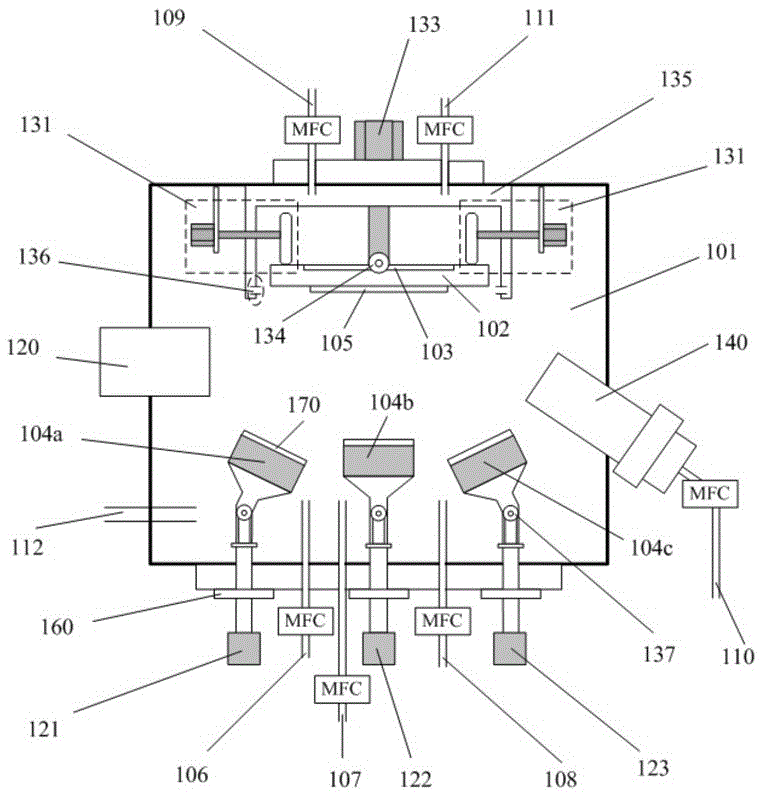

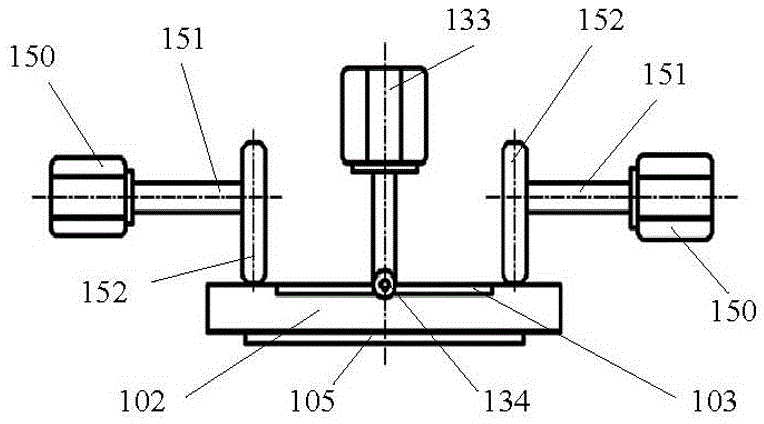

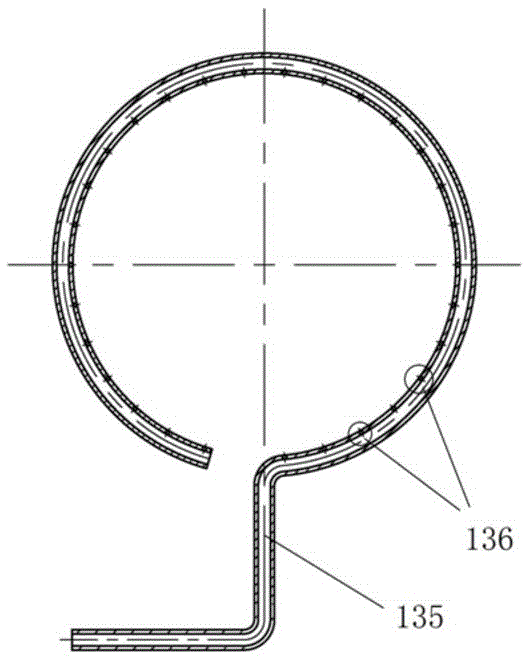

Magnetron sputtering device and magnetron sputtering method

ActiveCN105543792AReasonable device configurationVersatileVacuum evaporation coatingSputtering coatingPhysicsThin membrane

The invention discloses a magnetron sputtering device and a magnetron sputtering method. The magnetron sputtering device comprises a substrate table for placing a substrate, a target opposite to the substrate table and used for sputtering the substrate, and a reaction cavity for accommodating the substrate table and the target. The magnetron sputtering device further comprises an angle adjusting device corresponding to the target and used for adjusting an angle of the corresponding target to the substrate table. The magnetron sputtering method comprises the following steps: (1) the reaction cavity and the substrate are cleaned; and the target is mounted; (2) the angle of the target corresponding to the substrate and the distance between the target and the substrate are adjusted; (3) the reaction cavity is vacuumized; (4) the presputtering is performed; and meanwhile, the rotating and swinging functions of the substrate table are started; and (5) the magnetron sputtering is performed. The device can be applied to deposition of large-area films with high uniformity and excellent repeatability, and can realize continuous magnetron sputtering of multiple layers of films; and the method can save the film plating time and improve the film plating efficiency.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

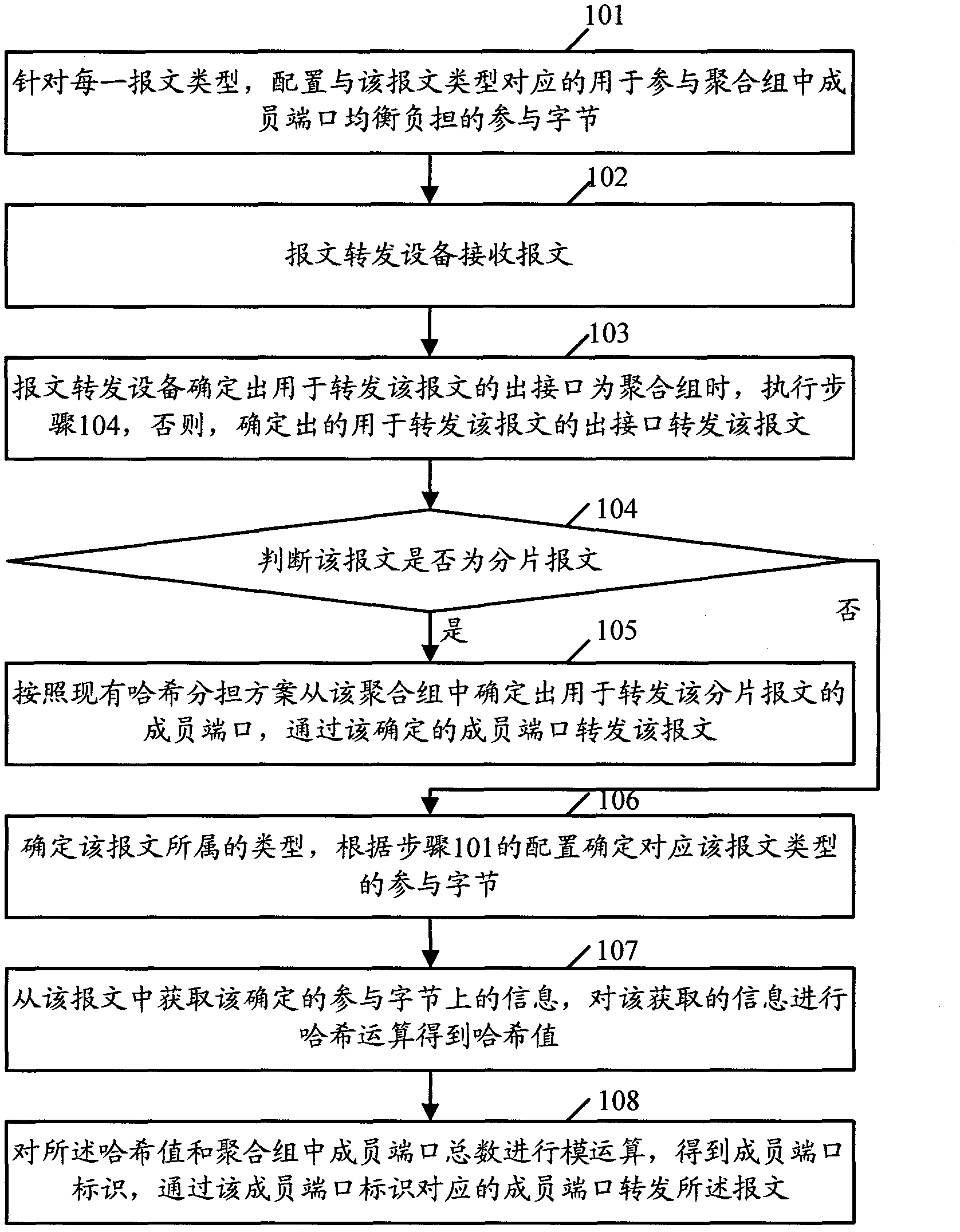

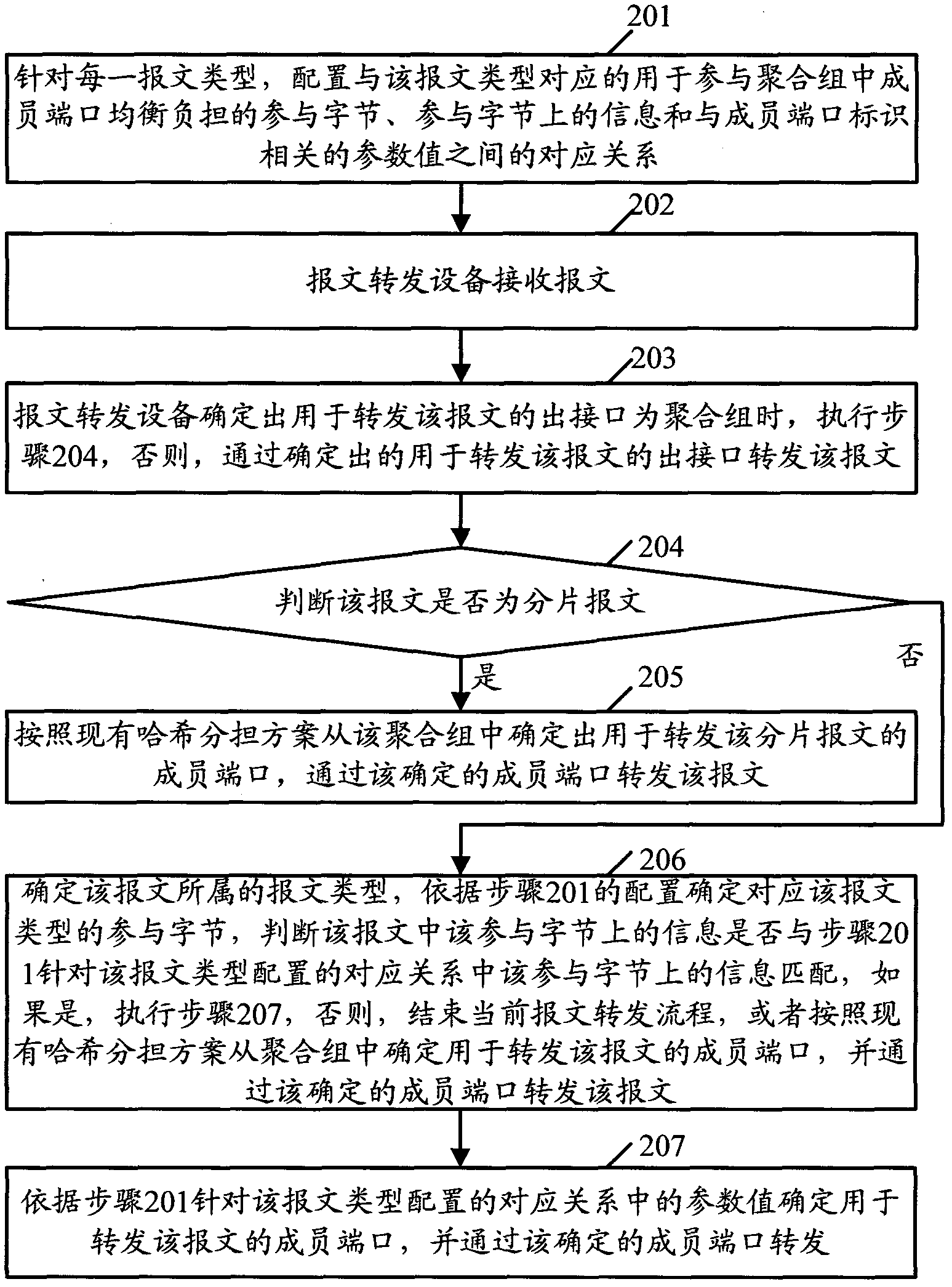

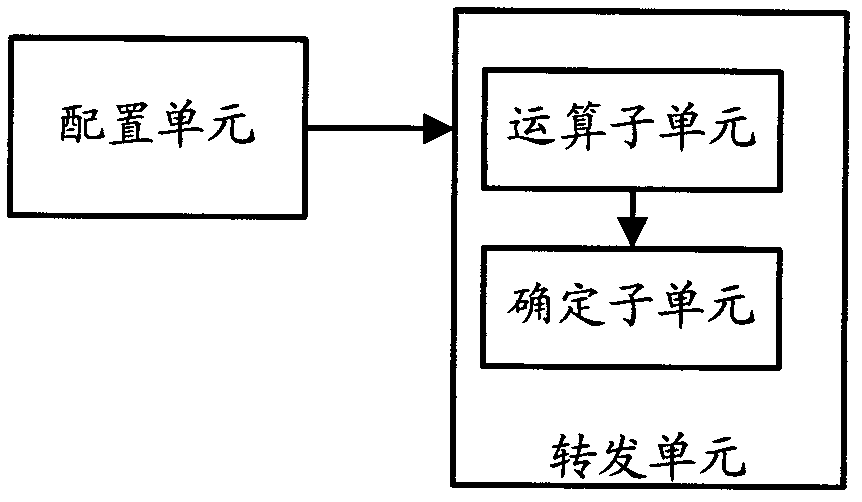

Message forwarding method and device

ActiveCN102148768AIncrease flexibilityReasonable configurationData switching networksPort forwardingDistributed computing

The invention provides a message forwarding method and device, wherein the method comprises the following steps of: A, configuring a participation byte for each message type, wherein the participation byte corresponds to the message type and is used for balancing loads of member ports in a participation polymerization group; and B, when an outbound interface of each received message not belonging to a fragment message is determined as the polymerization group, determining a participation byte corresponding to the message type of the message according to the configuration in the step A by the message forwarding device and obtaining information on the determined participation byte from the message; and determining a member port for forwarding the message from the polymerization group according to the obtained information and forwarding the message through the determined member port. By using the invention, the loads of the member ports in the polymerization group are equally shared to save resources.

Owner:NEW H3C TECH CO LTD

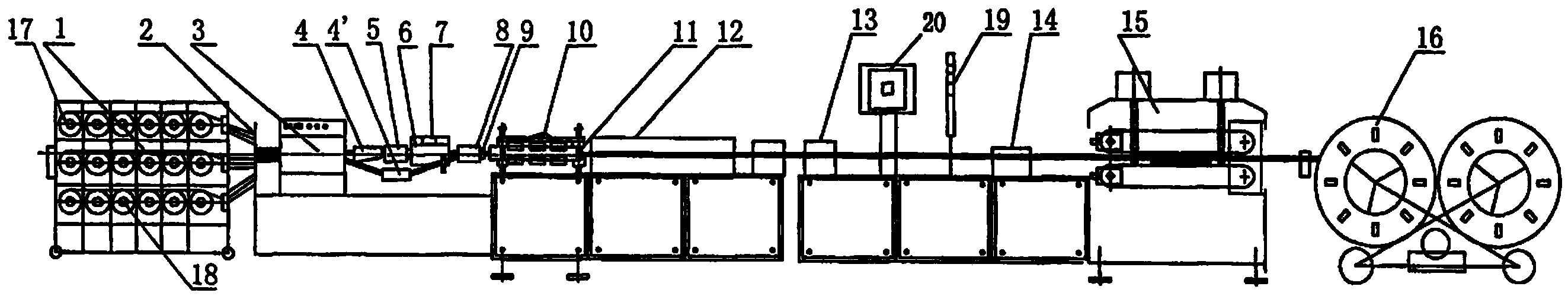

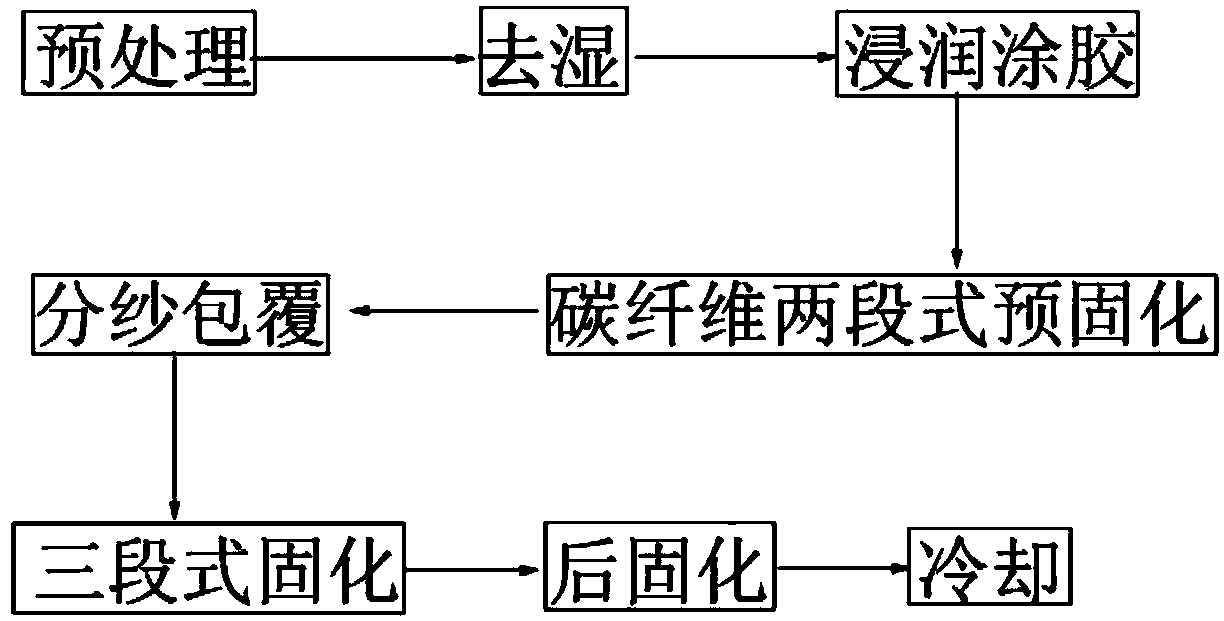

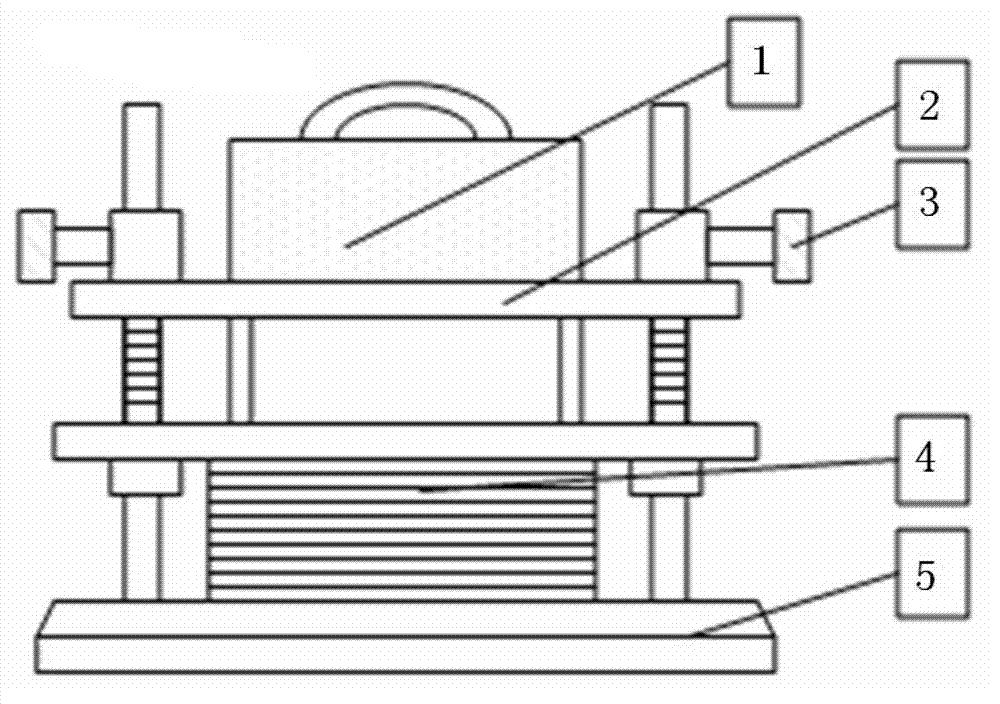

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

Testing method for color fastness to saliva of textile

ActiveCN103033480AReasonable configurationEnsure safetyColor/spectral properties measurementsColour fastnessFiber

The invention relates to the technical field of color fastness testing of textile, in particular to a testing method for color fastness to saliva of the textile. The testing method comprises the following steps of preparing artificial saliva, bonding a to-be-tested sample cut to a given size with multi-fiber accompanying fabric to form a composite sample, soaking in the artificial saliva, extruding the composite sample with a glass rod after soaking, pressing the composite sample with a counter weight, placing the composite sample in a drying oven simulating human body temperature, drying, placing the composite sample under standard atmospheric conditions with the temperature of 18-22 DEG C and the relative humidity of 61-69%, humidifying for at least four hours, and conducting an evaluation test on discoloring of the to-be-tested sample and staining of the accompanying fabric with a standard discoloring gray card and a standard staining gray card respectively. With the adoption of the testing method, the degree and the grade of the color fastness to saliva of the textile can be evaluated, deficiencies of the traditional staining test with filter paper are overcome, preparation of the artificial saliva is more reasonable, and the testing method is simple and easy to operate.

Owner:SGS STANDARD TECHNICAL SERVICES SHANGHAI CO LTD

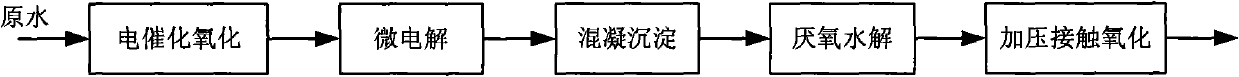

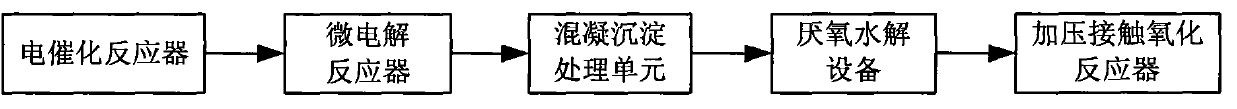

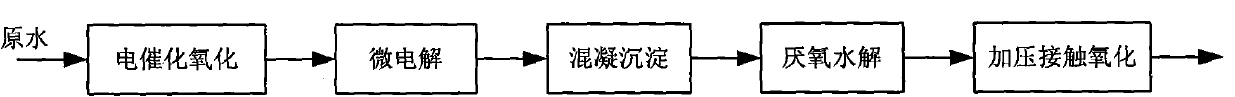

Process and equipment for treating high-concentration pyridine waste water

InactiveCN102139992AStrong resistance to shock loadsEfficient decompositionMultistage water/sewage treatmentWater/sewage treatment by oxidationChemical treatmentHigh concentration

The invention relates to a process for treating high-concentration pyridine waste water, which comprises the following steps of: regulating raw water of waste water to be acidic, and treating the raw water in electro-catalytic oxidation equipment; leading effluent to a micro-electrolysis device for treatment under the condition of maintaining the acidity and oxygen enrichment of the waste water; regulating the effluent to be meta-alkalescent, and adding chemicals to perform coagulating sedimentation; and controlling the salinity of the waste water to be below 2 percent, and performing biochemical treatment in an anaerobic hydrolyzing device and a pressurizing biological contact oxidation device, so that the effluent reaches the conventional first-level standards for sewage discharge. Due to the adoption of a physico-chemical treatment process serving electro-catalytic oxidation as a core, pyridine pollutants can be decomposed effectively, the toxicity of the waste water can be reduced, and the biodegradability of the waste water can be improved; for biochemical treatment is realized by a combination process of anaerobic hydrolysis and pressurizing biological contact oxidation, the organic loads, treatment efficiency and salt-tolerant capacity of the biochemical treatment are improved; and the process has the characteristics of high impact load resistant capacity, good treatment effect and low operating cost, and the treated high-concentration pyridine waste water can reach the standard stably before discharge.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

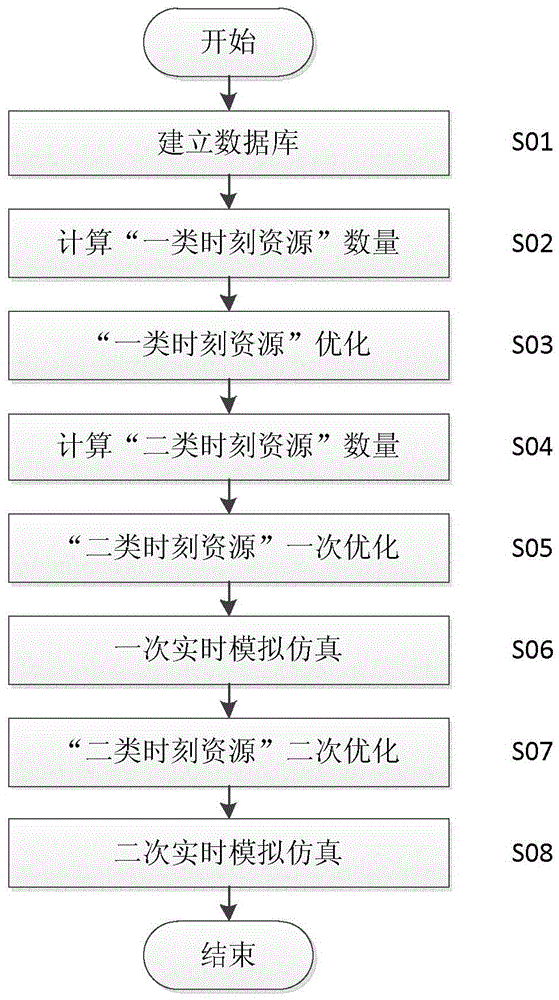

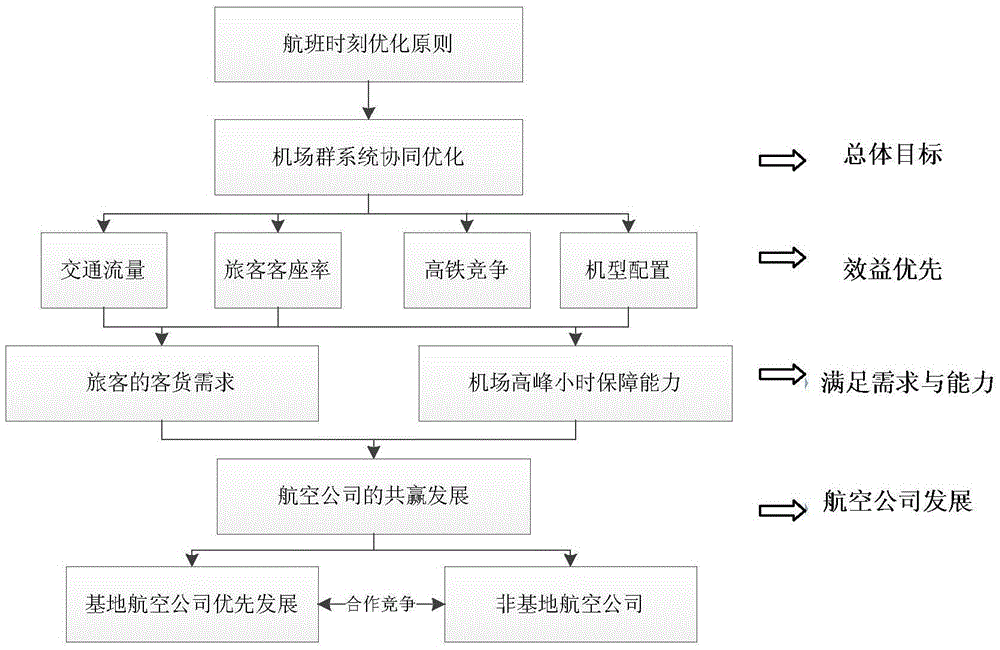

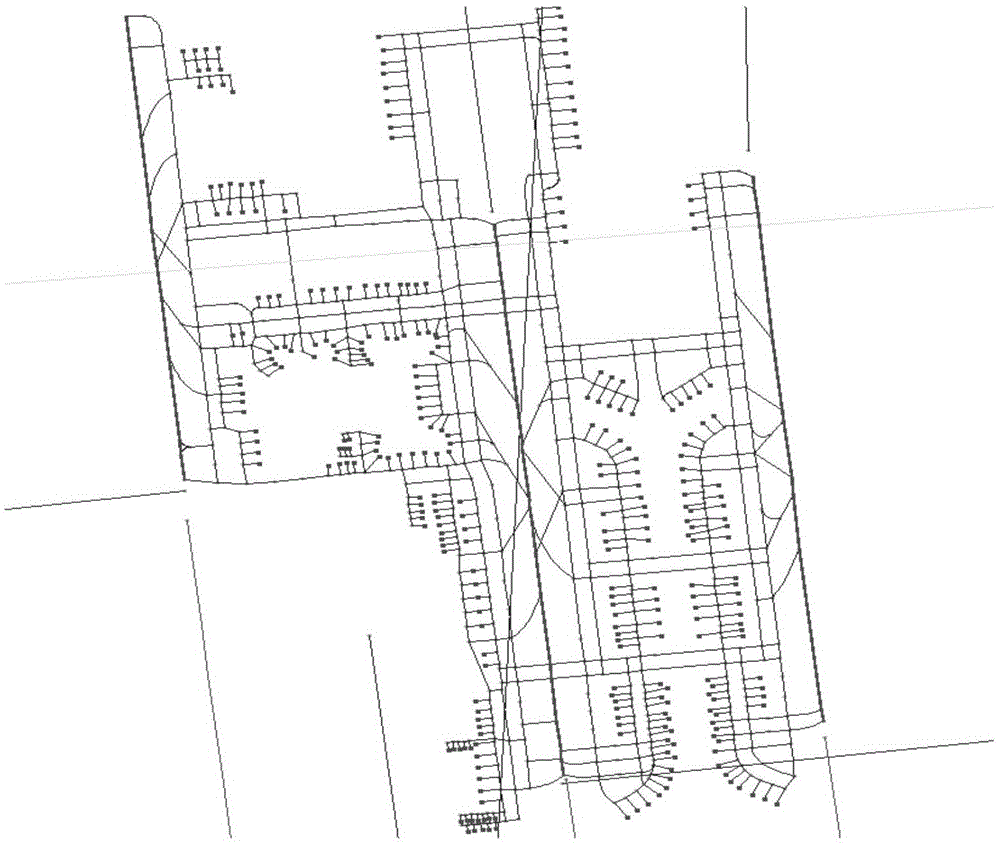

Flight time resource configuration and optimization method suitable for airline hubs

A flight time resource configuration and optimization method suitable for airline hubs is disclosed. The flight time resource configuration and optimization method comprises the steps of calculating the quantity of first-type time resources; optimizing the first-type time resources; calculating the quantity of second-type time resources; optimizing the second-type time resources for the first time; performing primary real-time analog simulation and conflict regulation; optimizing the second-type time resources for the second time; and performing secondary real-time analog simulation and conflict regulation, and the like. The flight time resource configuration and optimization method can bring benefits for multiple sides and can realize the maximum of social benefit; for passengers, reasonable flight time can greatly reduce probability of flight delays, so that the passengers can enjoy the more good-quality air transportation service; for airports, the airline hubs can optimize the airport management systems, expand international market shares and improve the competitiveness of the airports; and for airlines, the airlines can establish and construct main center radiation type airline network, ensure the flight service quality and improve the reputation of the airlines consequently.

Owner:CIVIL AVIATION UNIV OF CHINA

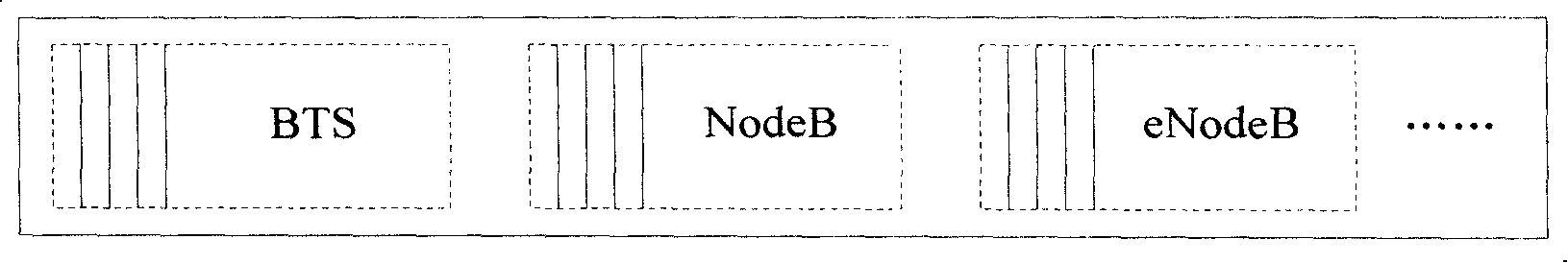

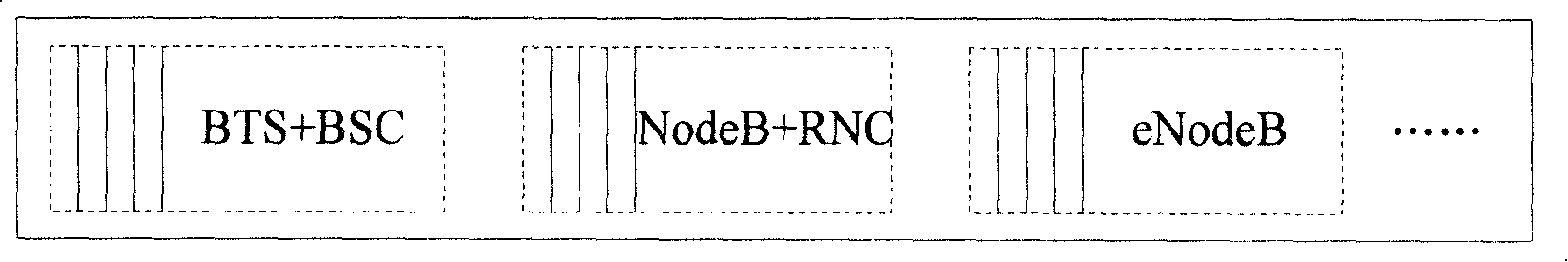

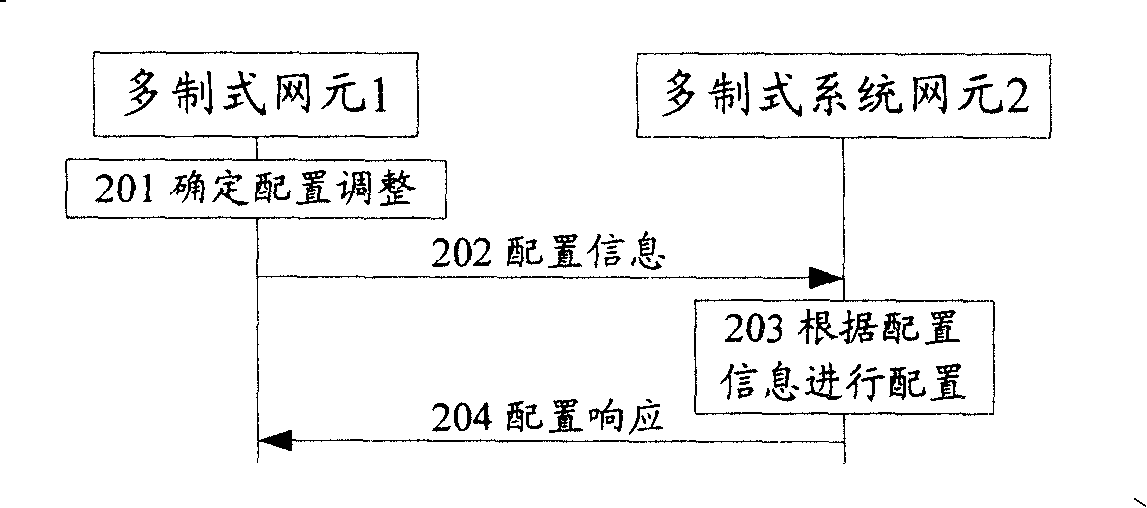

Processing method and system for implementation of net element collocation in multi-standard communication system

InactiveCN101203016AImprove resource utilizationReduce operating costsRadio/inductive link selection arrangementsTransmissionOperational maintenanceOperational costs

The invention provides a processing method and a system of realizing network element configuration in a multi-standard communication system. In the processing steps of the method: after adjusting the configuration information of different standards, the multi-standard network element initiates the configuration of the configuration information to other multi-standard system network elements; and the network element not only can directly provide the configuration information for other multi-standard system network elements, but also can provide the configuration information for other multi-standard system network elements through a set operation and maintenance module. According to the proposal provided by the invention, the multi-standard communication system can allocate the whole multi-standard communication system more reasonably according to such configuration condition as the load information, resource using condition, etc., of each single-modulation network element; if idle resource is dynamically allocated to the multi-standard network element which is relatively lack of the resource so as to comprehensively consider supported configuration information of different standards, the dynamic configuration and the dynamic adjustment of the resource are realized; the resource utilization rate of the multi-standard communication system is increased; and the operation cost of the multi-standard communication system is reduced.

Owner:HUAWEI TECH CO LTD

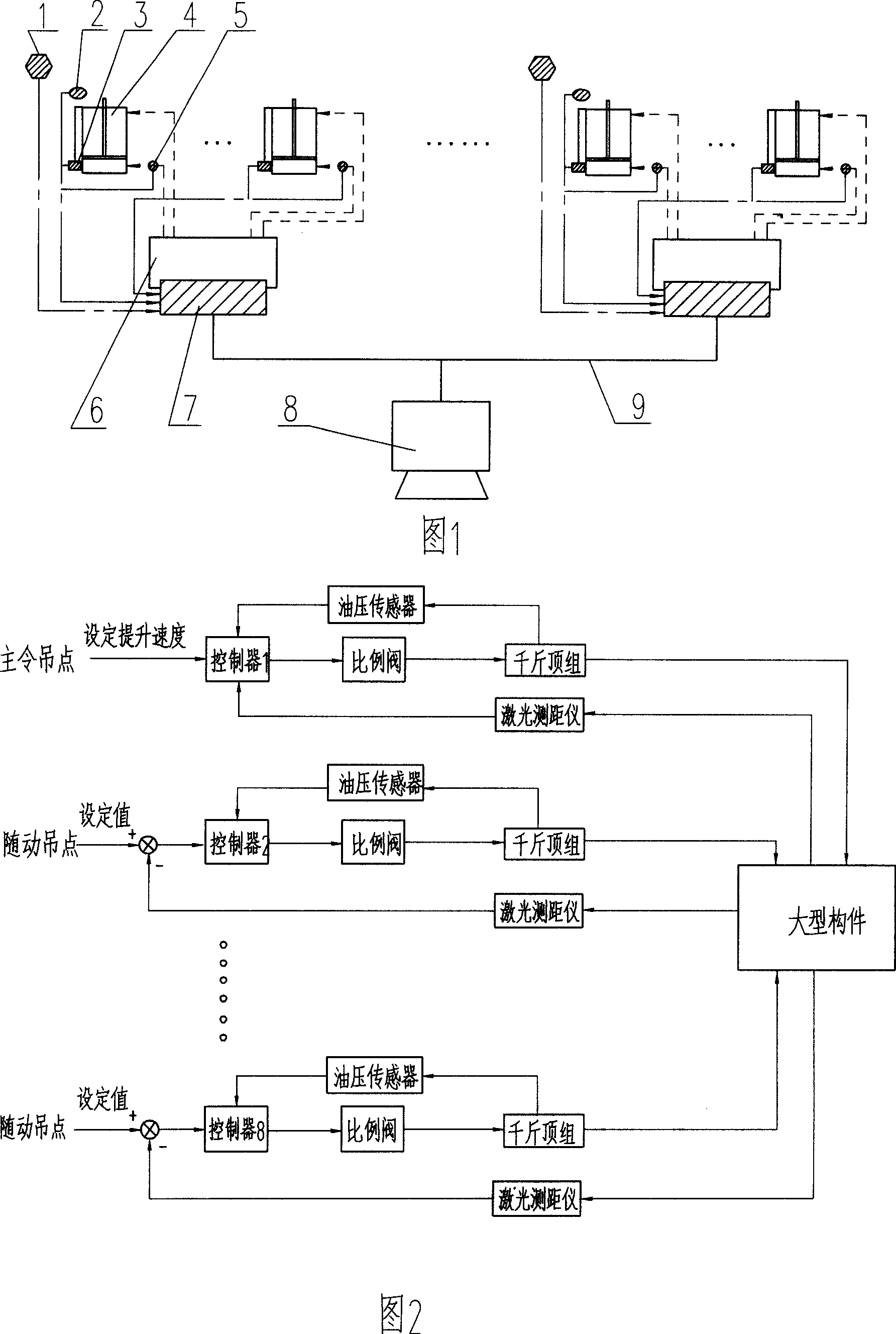

Hydraulic hoisting monitor system and its use in hydraulic hoisting control

ActiveCN1987700AReasonable configurationStrong fault toleranceSafety devices for lifting equipmentsComputer controlData acquisitionEngineering

The monitored control (MC) system is composed of up device, low device and data acquisition system. The up device is a MC computer with monitored control software in use for monitored controlling system and data management. The low device includes n pieces of site controller composed of n pieces of programmable controller with logic control main program and synchronous adjustment sub program being written into. Being installed on y pieces of hydraulic power unit, the n pieces of site controller through real time network is connected to MC computer. The method includes remote control mode, and local control mode. No mater how large the system is, direct selecting mode for jacks is adopted in the system. Features are: simple system circuit, intuitive operations, and accurate measurement. Configuration software is in use for monitoring system and querying historical data. The invention is in use for lifting control of large-scale component.

Owner:LIUZHOU OVM MASCH CO LTD

Method for optimizing land subsidence monitoring net

InactiveCN104123470ABreak through limitationsProtection securitySpecial data processing applicationsSubsidenceCloud modeling

The invention relates to a method for optimizing a land subsidence monitoring net. The method includes the following steps that firstly, a ground monitoring net is built, wherein a GPS point and a benchmark are arranged in a land subsidence area, a GPS and a leveling monitoring net are built, and therefore a land subsidence monitoring point is obtained; secondly, an air-land monitoring net is built, and the air-land monitoring net is formed by merging an optimized PSInSAR monitoring point, the benchmark and the GPS point, wherein obtaining of the optimized PSInSAR monitoring point includes the step of obtaining the PSInSAR monitoring point through the PSInSAR technology and obtaining three cloud numerical characteristics of the PSInSAR monitoring point through the cloud model algorithm. According to the method for optimizing the land subsidence monitoring net, the land subsidence monitoring capability can be improved, high-precision land subsidence monitoring information can be obtained, and the property safety and the life safety of the masses are protected.

Owner:CAPITAL NORMAL UNIVERSITY

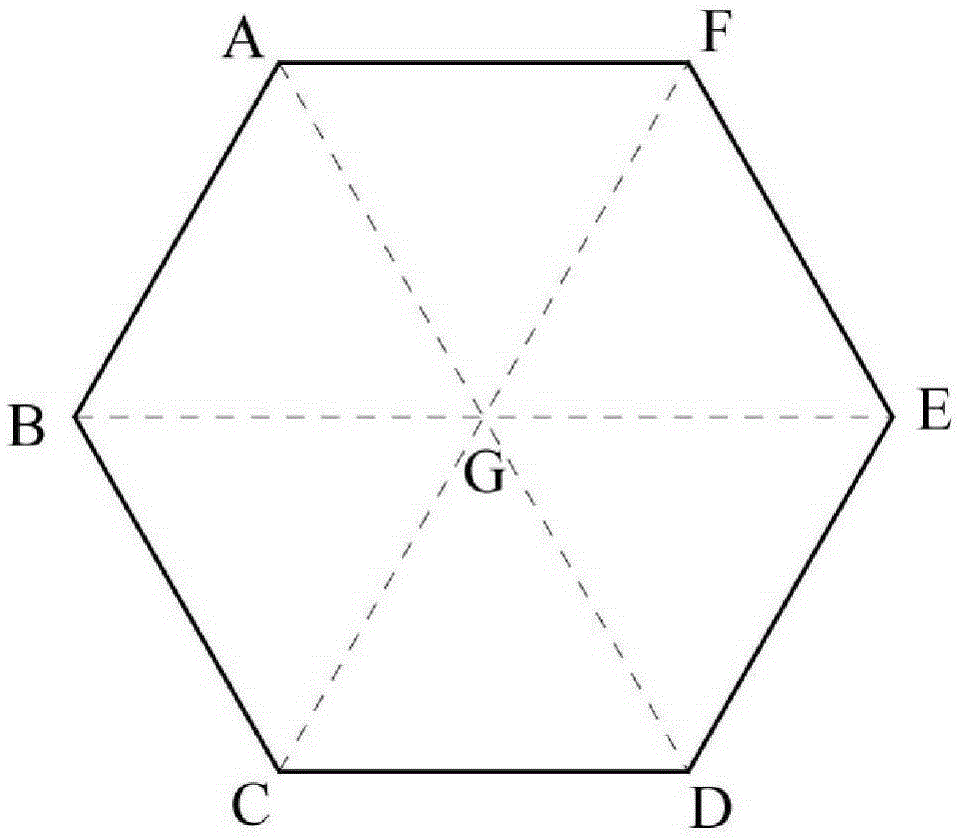

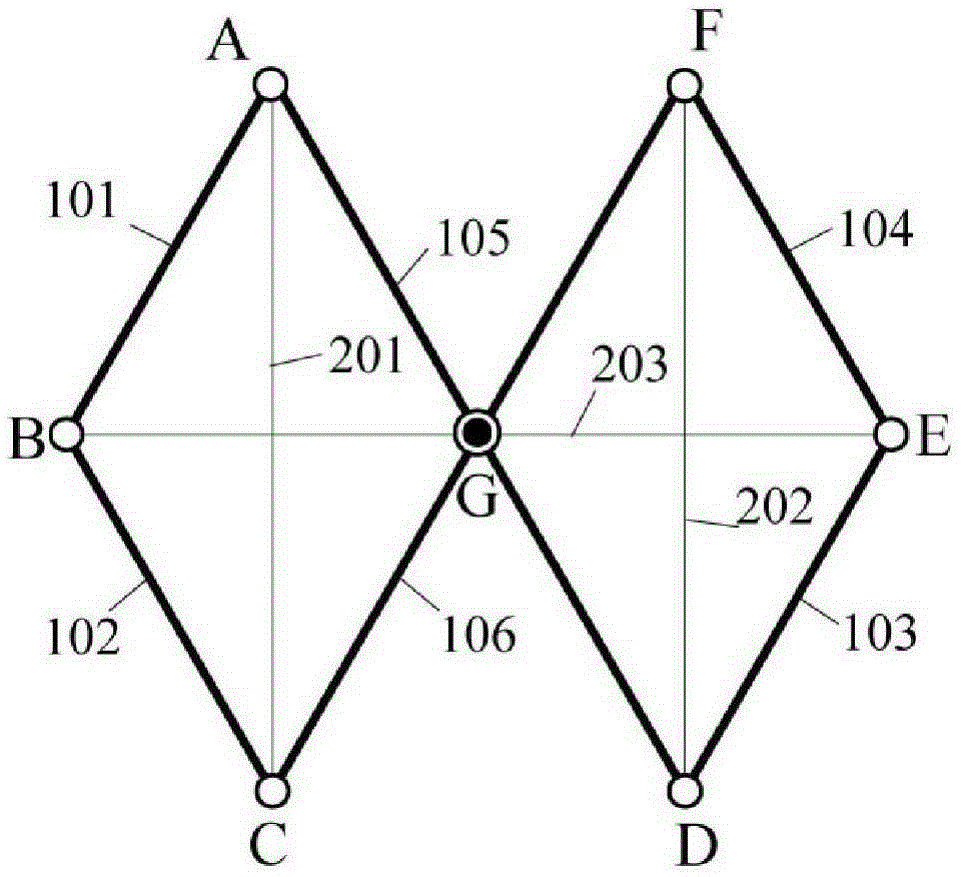

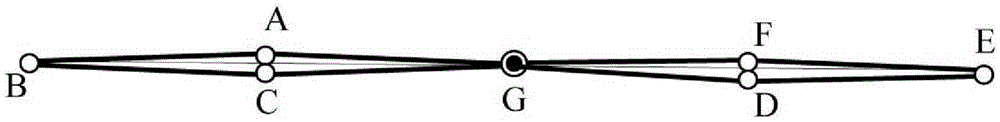

Foldable cable bar structural unit based on hexagonal geometry

ActiveCN105297902ALow utilization efficiencyImprove utilization efficiencyBuilding constructionsHexagonal geometryEngineering

The invention discloses a foldable cable bar structural unit based on hexagonal geometry. The structural unit is composed of six hinging nodes, one pivoting node, three stay cables and six pressure bars. The six hinging nodes are respectively located at the six vertexes of a two-dimensional hexagonal geometry, and the pivoting node is located at the central point of the hexagonal geometry. The four first-type pressure bars are symmetrically arranged on the two sides of the hexagon, and coincide with the four edges of the hexagon. The other two second-type pressure bars are located inside the hexagon, and form a scissor-like hinge through the pivoting node. The three stay cables are located inside the hexagon, and the six hinging nodes are connected in pairs by the three stay cables. When all the stay cables are pre-tensioned, pre-pressure exists in all the pressure bars, and the structural unit is a self-balancing cable bar system. When the first-type stay cable or the third-type stay cable is loosened, the structural unit can be folded to form a compact bundle shape. The foldable cable bar structural unit has a good application prospect in foldable / scalable cable bar structural systems.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com