Testing method for color fastness to saliva of textile

A test method and technology of color fastness, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as unreasonable formula of artificial saliva, affecting the test of color fastness of saliva, unable to express the degree and level of color fastness, and achieve artificial Reasonable saliva configuration, simple operation, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Sample to be tested: dark blue children's knitted pullover

[0027] 2. Main test instruments or materials:

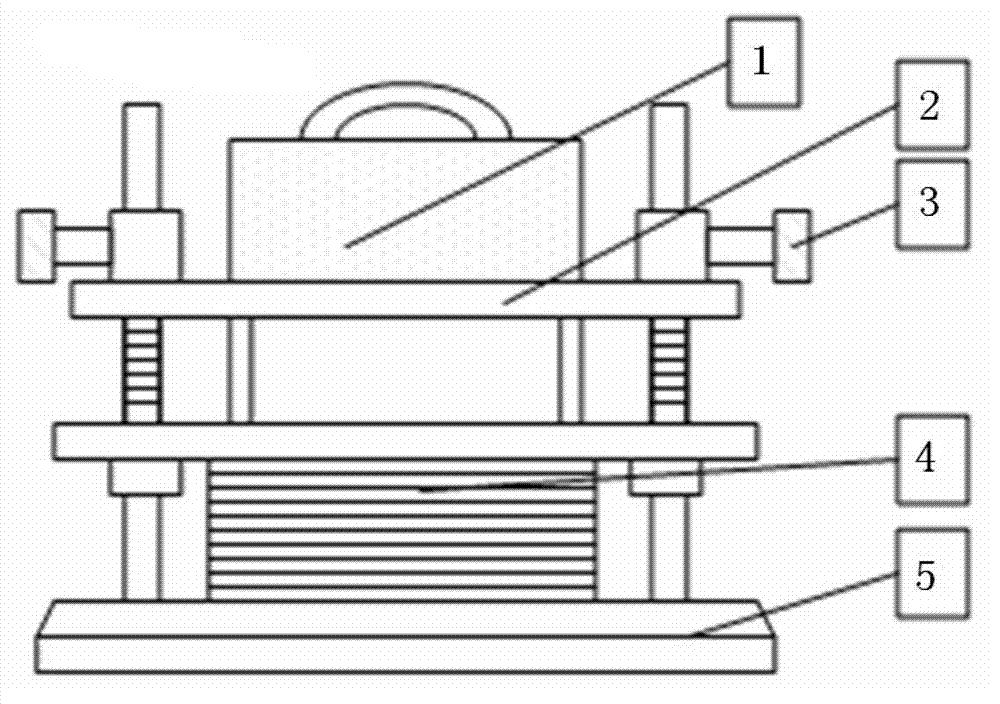

[0028] (1) Perspiration color fastness tester (if attached figure 1 ): It is composed of stainless steel seat frame 5, spring pressure frame 2, fastening screw 3, 50N (±1%) weight 1 and resin plate or glass plate 4 with a size of 60mm×115mm×1.5mm. Apply a uniform specified pressure (12.5kPa) to the sample;

[0029] (2) Oven: the temperature can be set at 37°C±1°C;

[0030] (3) Petri dish: 125mm in diameter;

[0031] (4) glass rod;

[0032] (5) pH meter: accuracy 0.05 or above;

[0033] (6) Multi-fiber lining fabric: comply with GB / T11404;

[0034] (7) Sewing thread: white and does not contain fluorescent whitening agent;

[0035] (8) Sewing needles.

[0036] 3. Test steps:

[0037] 1) Prepare artificial saliva, add 0.75g potassium chloride, 0.33g sodium chloride and 0.53g potassium carbonate into a 1L beaker, then add about 900ml of third-grade water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com