Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

221 results about "Pyrrhotite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

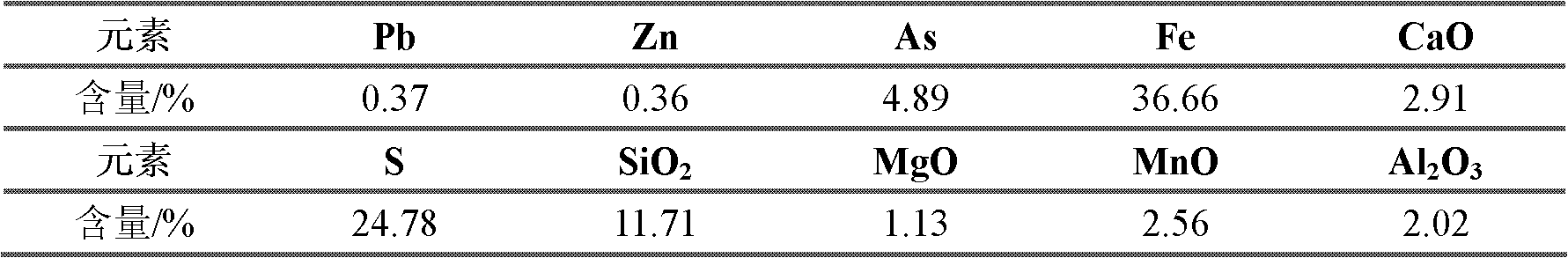

Pyrrhotite is an iron sulfide mineral with the formula Fe₍₁₋ₓ₎S (x = 0 to 0.2). It is a nonstoichiometric variant of FeS, the mineral known as troilite. Pyrrhotite is also called magnetic pyrite, because the color is similar to pyrite and it is weakly magnetic. The magnetism decreases as the iron content increases, and troilite is non-magnetic.

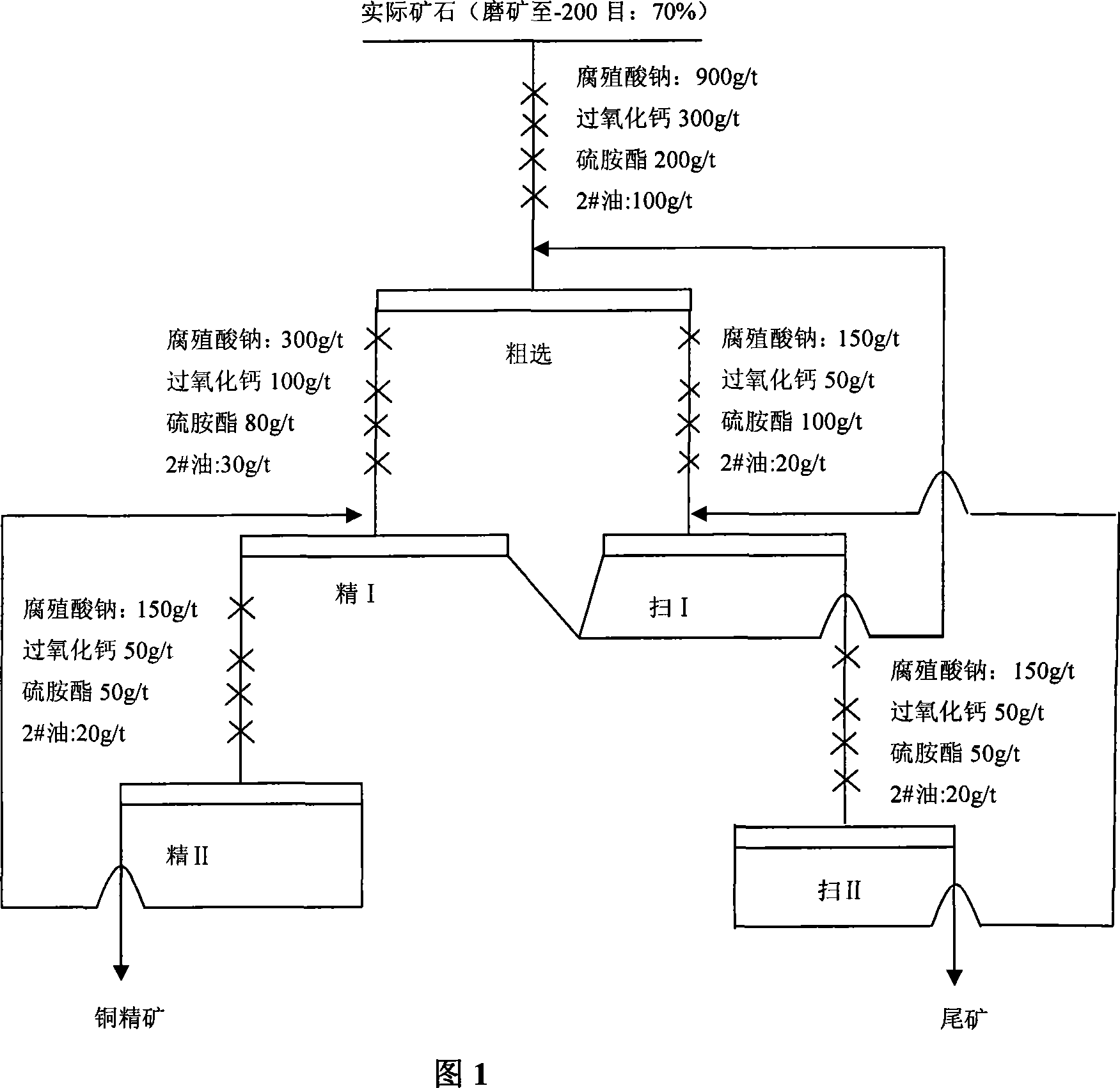

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

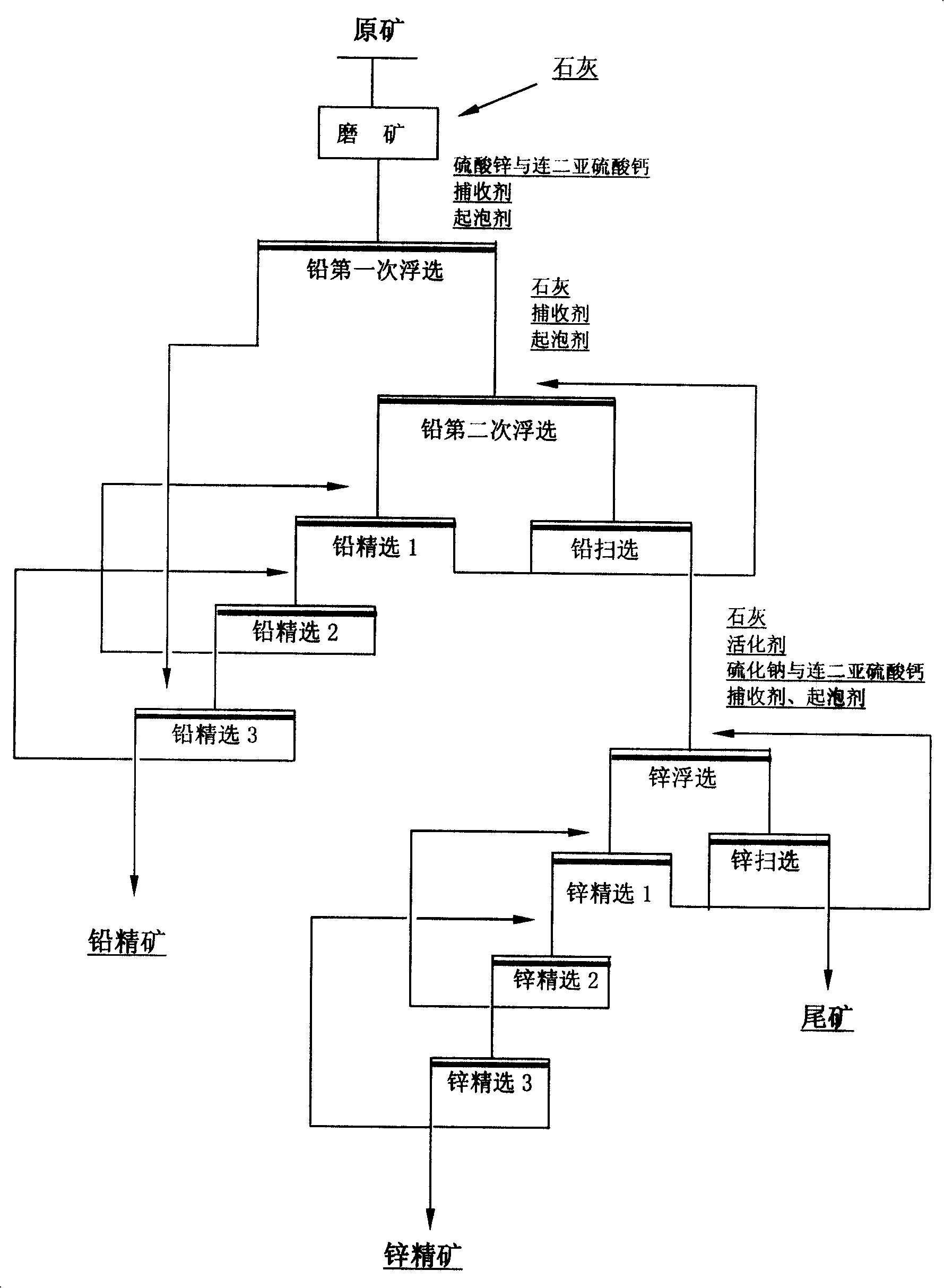

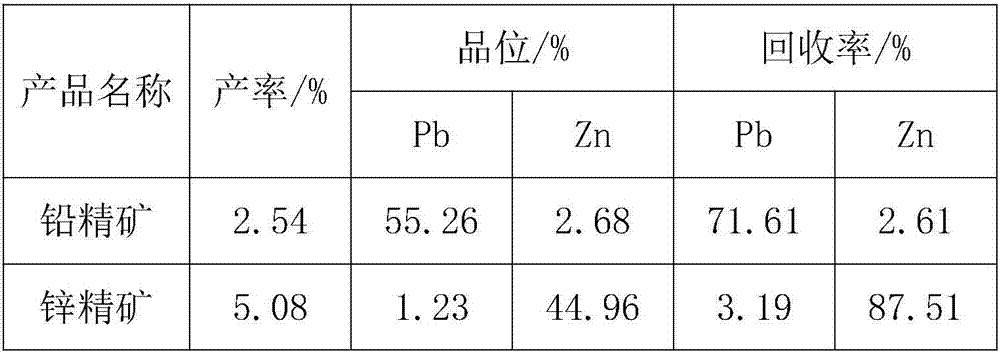

Complex plumbum, zinc, silver vulcanizing ore containing newboldite and pyrrhotite floatation method

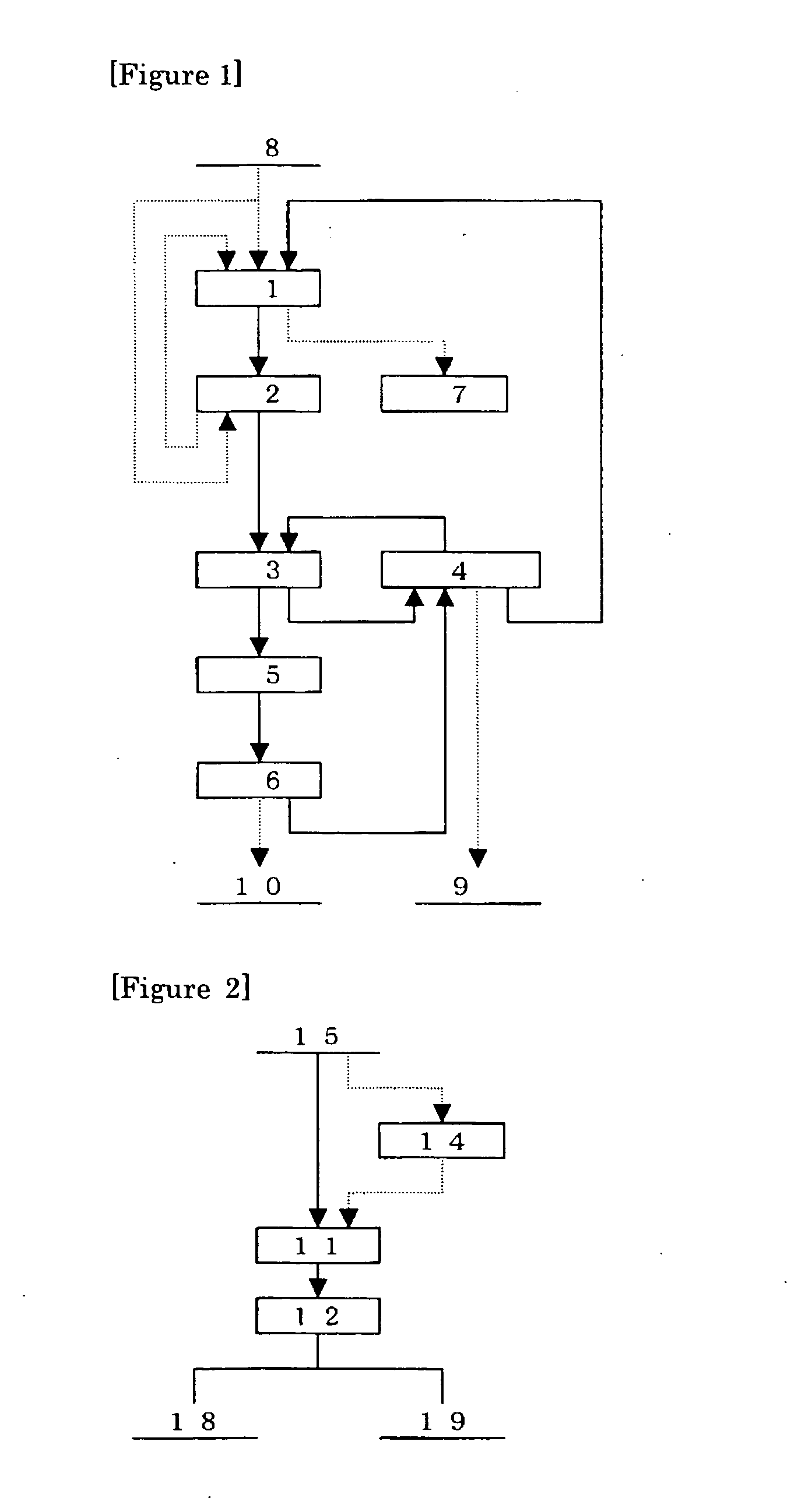

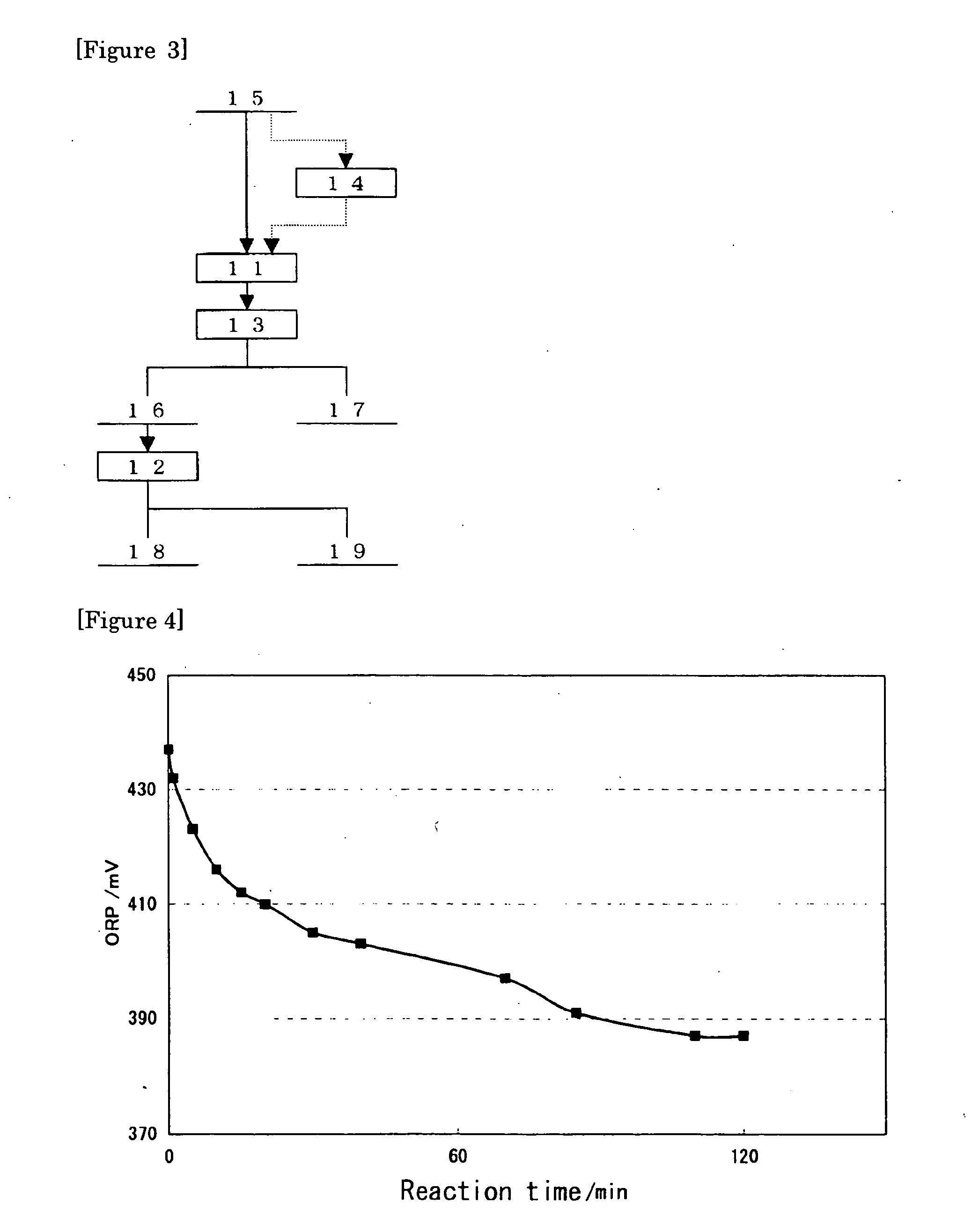

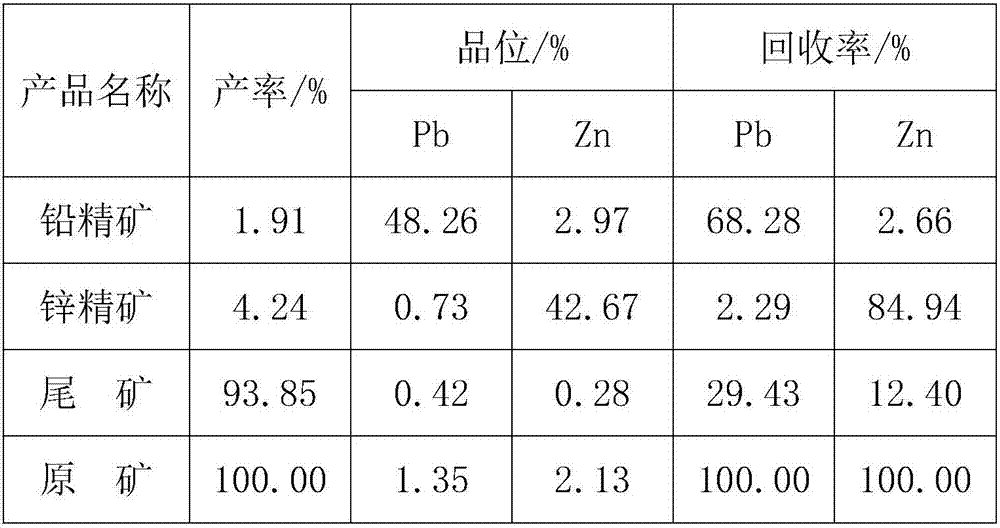

The invention discloses a lead and zinc flotation method to ferreous blende and pyrrhotite typed complex lead zinc silver sulphide ore, mainly comprising lead ore branch flotation which controls the electrochemical conditions of the flotation and the zinc and sulfur flotation separation which controls the electrochemical conditions of the flotation. The invention has the advantages of implementing the lead-zinc sulfur separation by adopting twice branch flotation, carrying out fast flotation to the lead ore by using a novel composite catching agent to the galena and silver ore with easy floating coarse grains under the conditions of higher ore pulp potential and low pH; the normal flotation of the lead ore with difficultly floated fine grains is carried out under the conditions of lower ore pulp potential and high pH. The pH of the ore pulp is adjusted to more than 12 by lime for the gangue after the lead is floated; the iron blende is activated by bluestone; the iron blende is recovered by the catching agent with the same type of the lead sulfide floatation, thus leading the property of the lead flotation waste water to be basically consistent with that of the zinc flotation waste water and being beneficial for the circular application of floatation waste water.

Owner:CENT SOUTH UNIV

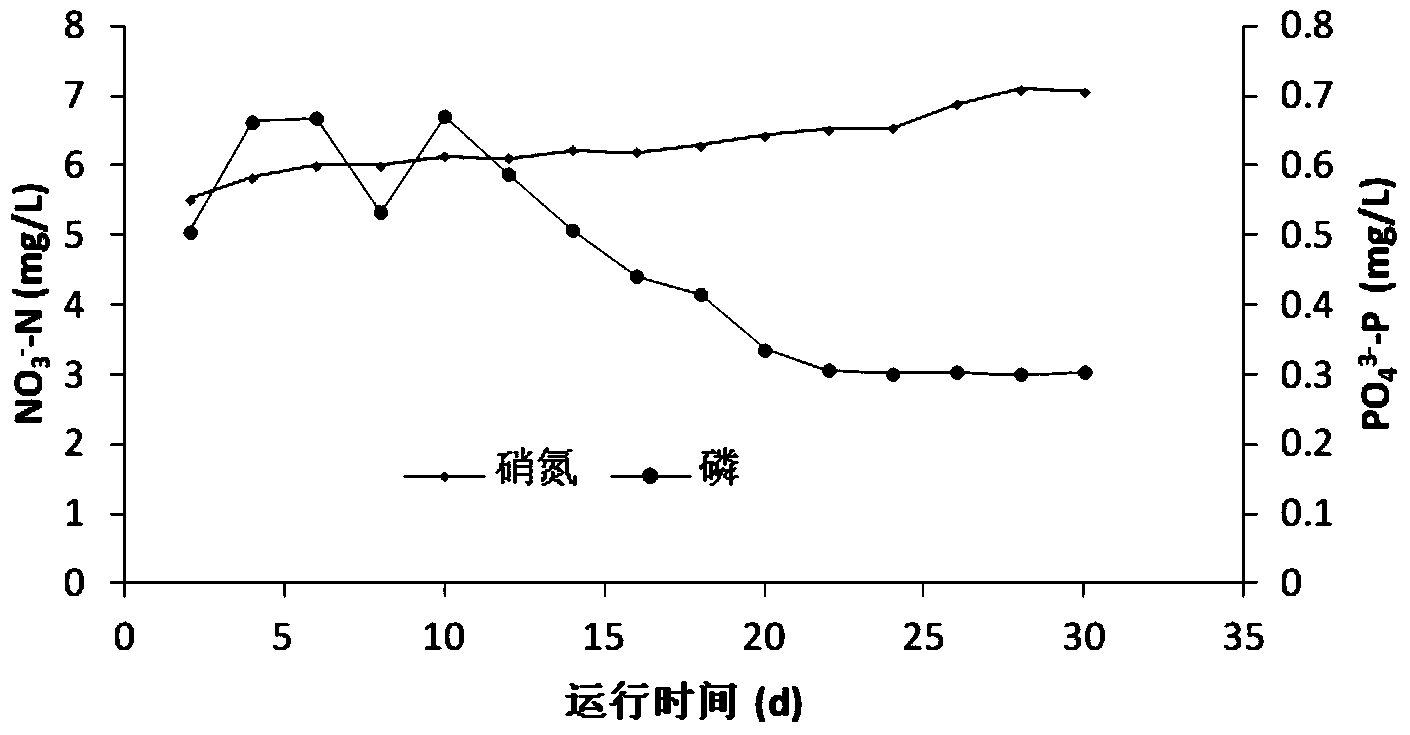

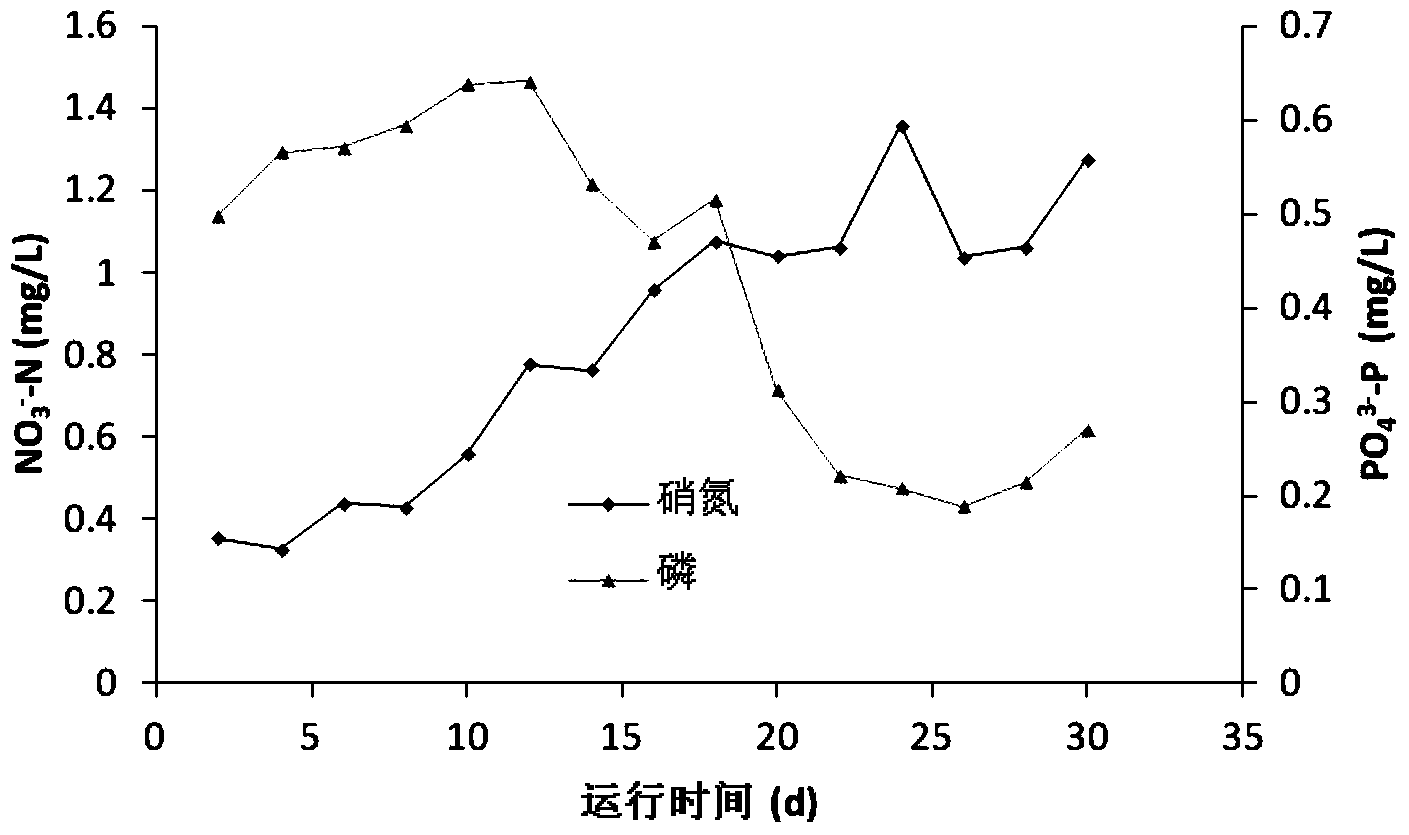

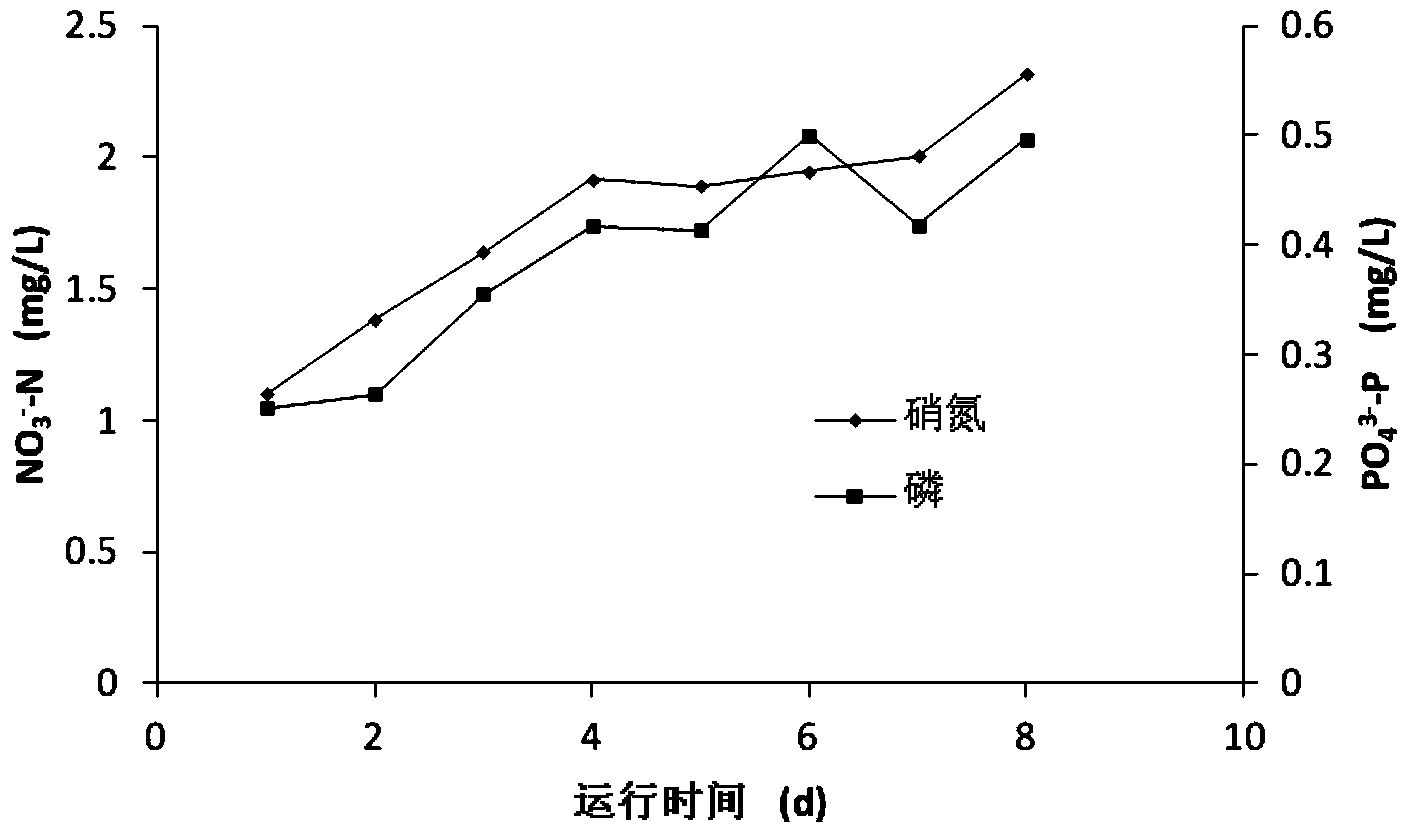

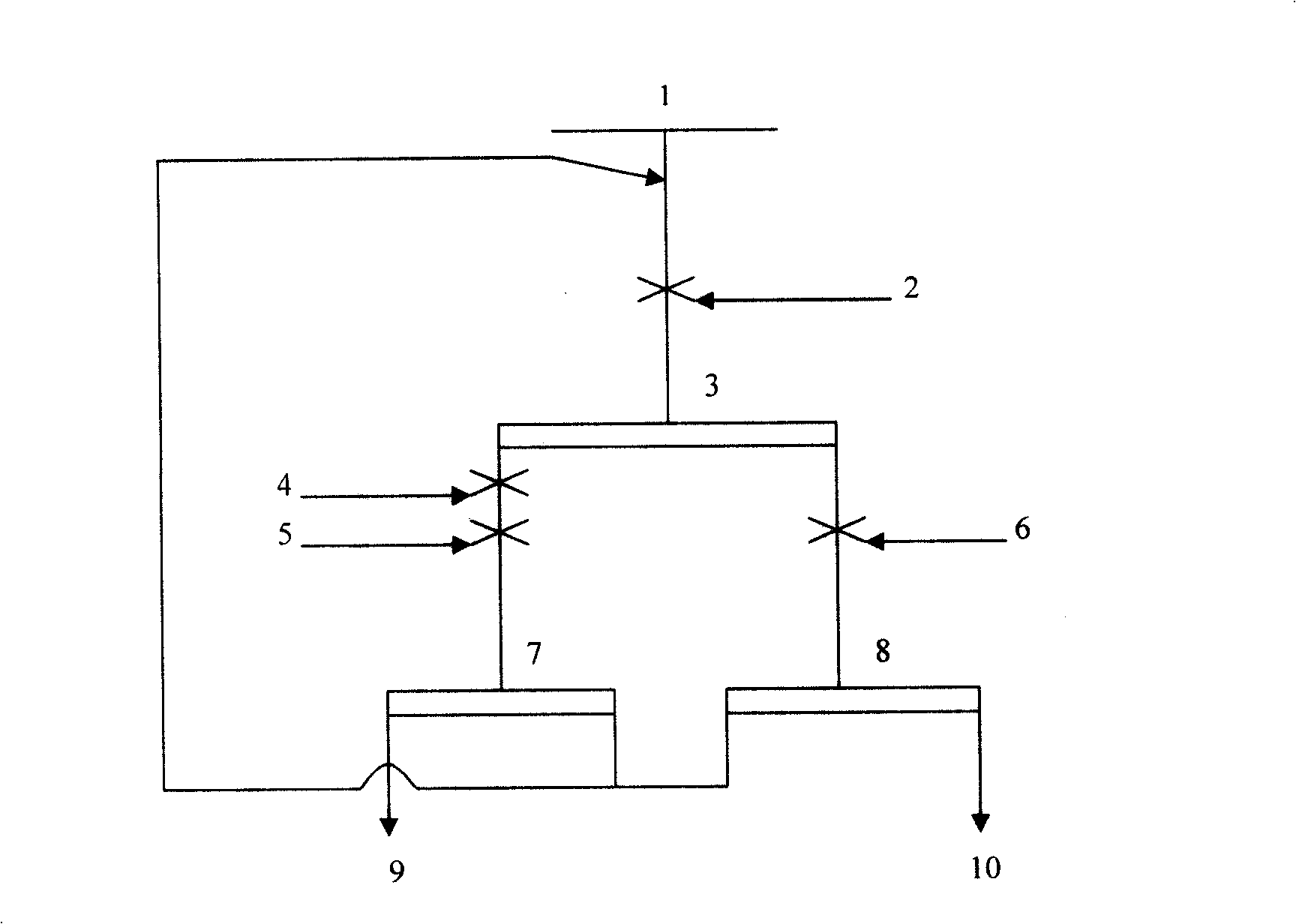

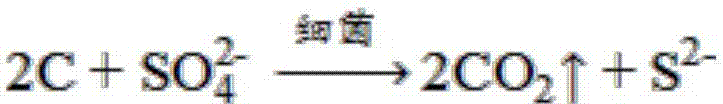

Natural pyrrhotite biological filter and method for synchronously removing nitrate nitrogen and phosphorus out of water by using natural pyrrhotite biological filter

ActiveCN103626293ASync removalEasy to handleWater treatment parameter controlWater treatment compoundsElectron donorBiological filter

The invention discloses a natural pyrrhotite biological filter and a method for synchronously removing nitrate nitrogen and phosphorus out of water by using the natural pyrrhotite biological filter, which belongs to the field of advanced wastewater treatment. The method comprises the following steps: (1) preparing and constructing biological filter fillers; (2) starting the biological filter; and (3) operating the biological filter. Pyrrhotite is used as an electron donor of sulfur autotrophic denitrification bacteria to reduce nitrate in the water to nitrogen so as to remove nitrate nitrogen out of the water; and the pyrrhotite and an oxidative product of the pyrrhotite remove phosphorus in such manners as adsorption and chemical precipitation so as to synchronously remove nitrate nitrogen and phosphorus out of the water. The biological filter disclosed by the invention is simple to construct, convenient to start, stable to operate, high in nitrogen and phosphorus removal efficiency and free of auxiliary materials, and the biological filter is applied to advanced wastewater treatment.

Owner:NANJING UNIV

High-efficiency cleaning mineral separation process of complicated sulfuration mine

The invention discloses an efficient and clean beneficiation method of complex sulfide ore. The method includes the following steps: utilizing an activator selected from one of or some of oxalic acid, ammonium carbonate, ammonium bicarbonate, ammonium sulfate, ammonium bisulfate and ferrous sulfate as a combination; utilizing collectors including xanthate collectors, black collectors, white collectors and thionocarbamate collectors; mixing the activator, the collectors and BC; stirring; and performing flotation separation of the sulfide ore to obtain the sulfur concentrate. The inventive beneficiation method has the advantages of high discrimination property, cleanness and non-toxicity; and is suitable for the flotation separation of the complex sulfide ore, particularly the flotation separation of complex sulfide ore containing pyrrhotites and pyrites with fine dissemination size.

Owner:CENT SOUTH UNIV

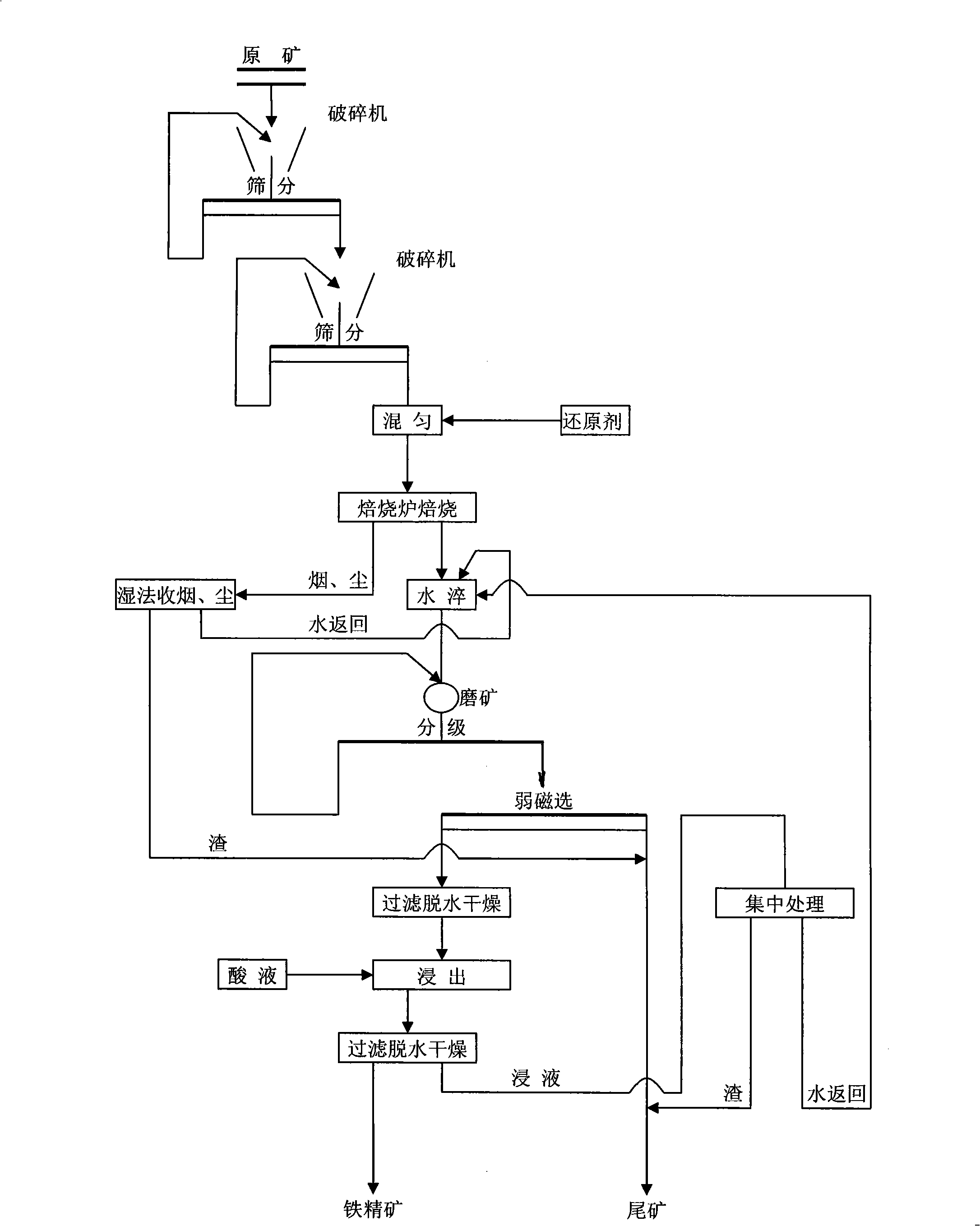

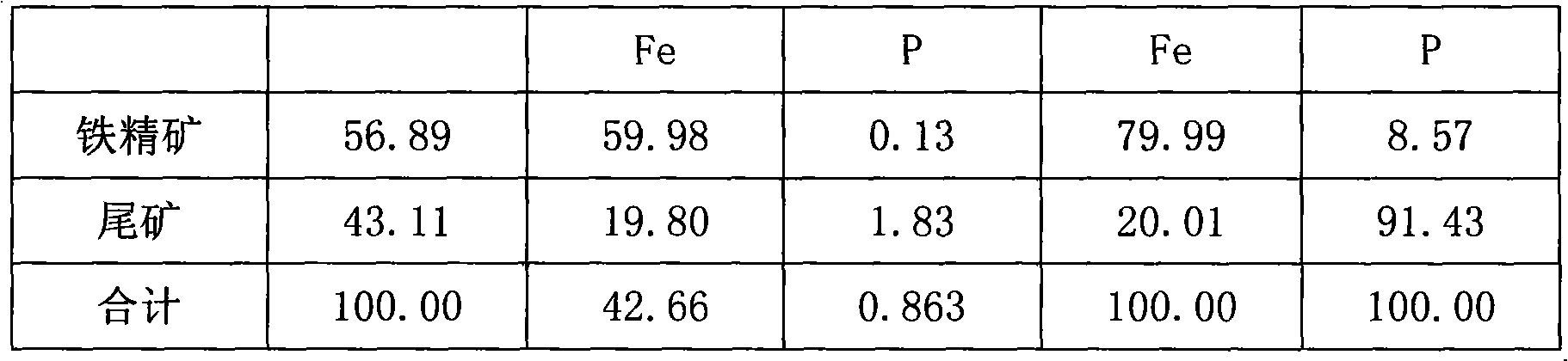

Method for reducing phosphorus in high phosphorus haematite or hematite and limonite ore by magnetization roasting-leaching method

InactiveCN101338361AReduce phosphorus contentProcess efficiency improvementMagnetic separationIronstoneMagnetization

The invention relates to a high phosphorus hematite-hematite-limonite magnetic roasting-extraction phosphorous reduction method, in particular applicable for an extraction phosphorous reduction method for the iron ores which mainly include the hematite-hematite and the limonite and accompany with magnetite, pyrrhotite, iron pyrites, etc. The method of the invention adopts magnetic roasting-wet extraction to reduce phosphorous; after carrying out modifying on high phosphorus iron ore, muriatic acid or vitriol is selected to carry out extraction phosphorous reduction on the iron concentrate obtained by a weak electromagnetic separator which not only can obtain the iron concentrate with an iron grade to be larger than 56 percent; simultaneously the content of the phosphorous in the iron concentrate is lower than 0.30 percent.

Owner:昆明晶石矿冶有限公司

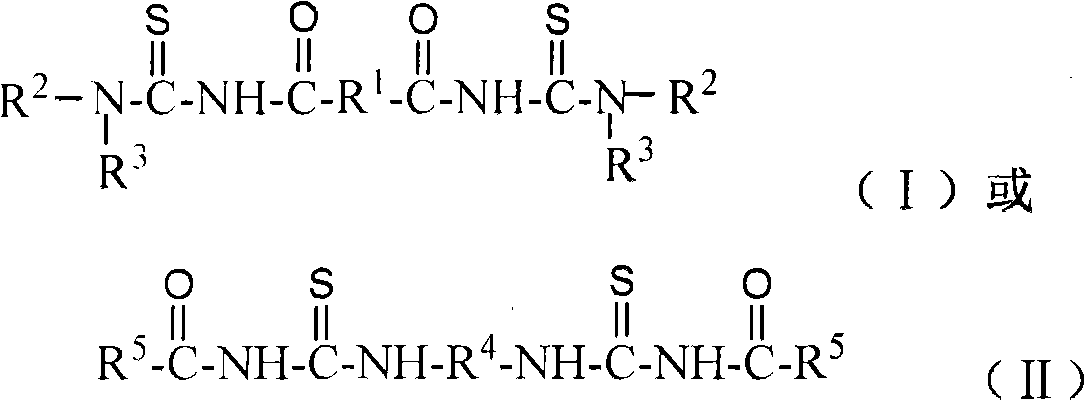

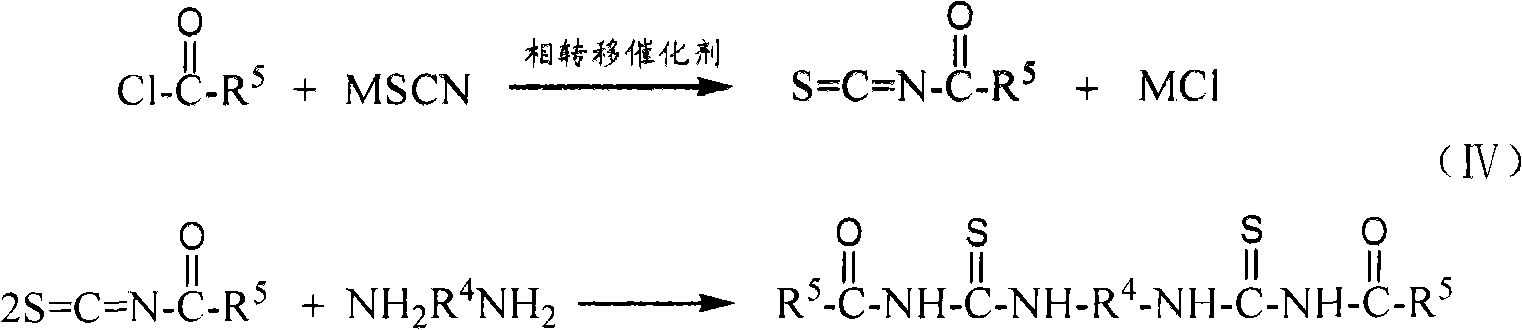

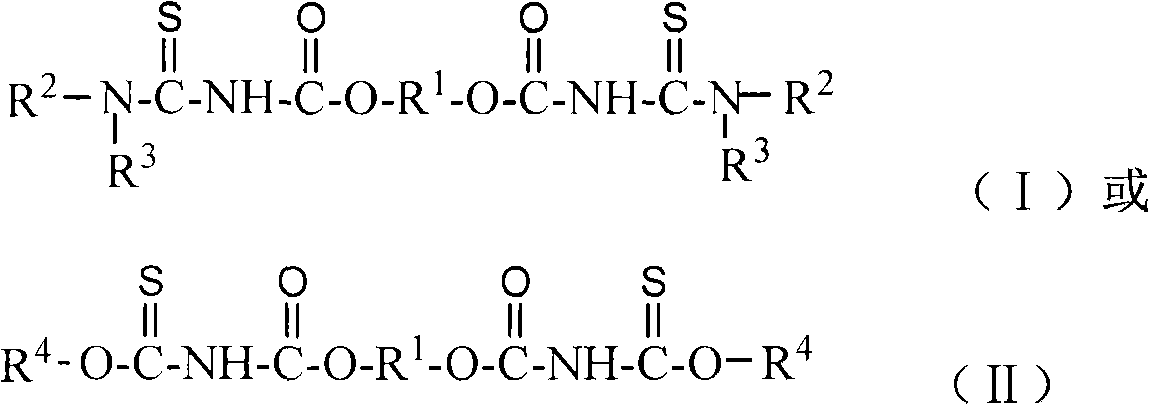

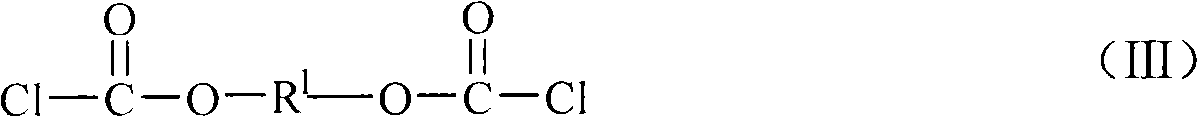

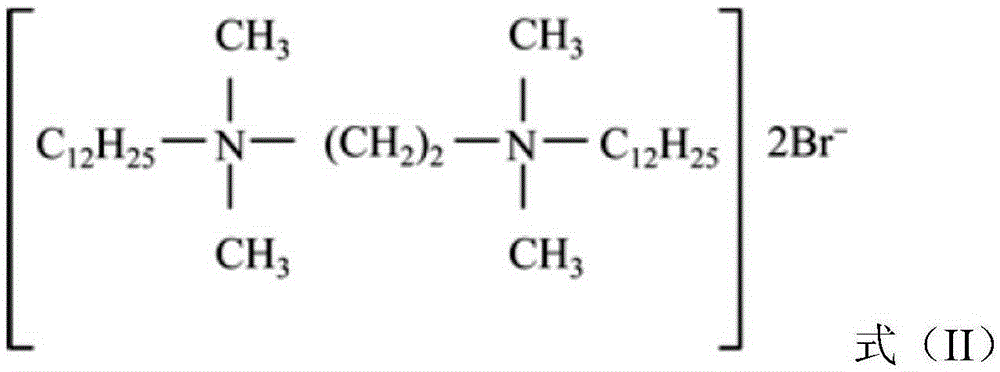

Sulphide ore floation collector and use method of diacyl bis-thiourea and preparation method thereof

InactiveCN101337206AEasy to makeEfficient flotation separationOrganic chemistryFlotationMagmaThiourea

The invention discloses the application processes and the preparation methods of a sulphide ore flotation collector as well as a diacyl bis-thiourea. The invention relates to a novel collector used for high efficiently recycling valuable sulfide minerals from metal sulphide ores; the compositions of the sulphide ore flotation collector include diacyl bis-thiourea surface active agents; the diacyl bis-thiourea compound is shown in the constitutional formula (1) or (2). The collector has strong collecting ability to copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and has good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc., thereby realizing the high efficient flotation separation of the copper sulphide minerals and ferric sulfide minerals when the pH value of ore magma is below 11, reducing the used amount of lime, and improving the comprehensive recovery of copper sulphide ores.

Owner:CENT SOUTH UNIV

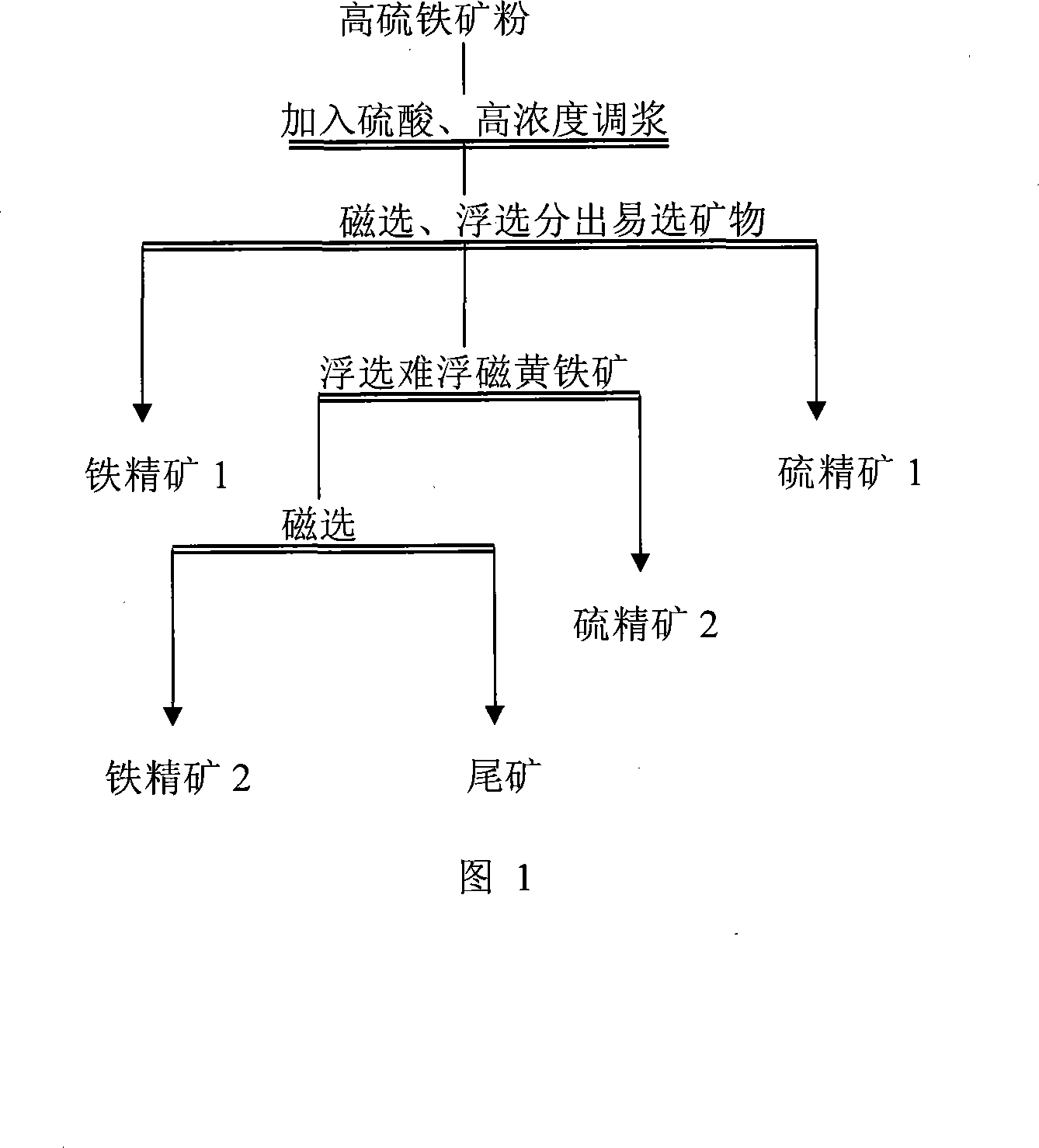

Desulfuration method for high sulfide pyrite powder

ActiveCN101157979ASimple process structureLow costFlotationProcess efficiency improvementIronstoneSulfur

The invention relates to the desulfurizing method of high-sulphur iron ore power, in particular to the iron ore power recycled by using sulfurous iron ore, pyrites and floatation gangue. When the content of sulphur of the iron ore concentrate, which is mostly magnetite, reaches over 15 percent, by adopting the principle of asynchronous size classification, the iron ore concentrate can reach over 65 percent, wherein the content of sulphur is reduced to less than 0.3 percent, and the rate of desulphurization reaches more than 90 percent. The method has the advantages of the simple system of medicament, slight acid-causticity for equipment, and low cost of operation.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Use of diester isosulfocyanate in sulphide ore floation and preparation method thereof

InactiveCN101337205AEasy to makeStrong harvesting abilityOrganic chemistryFlotationMagmaSulfide minerals

The invention discloses a diester-based 2-thiocyanate ester derivate applied in sulphide flotation, and the preparation method thereof. Diester-based 2-thiourea (the formula one) or diester-based 2-ethionine ester (the formula two) is applied as a novel collector for high efficiently recycling valuable sulfide minerals from metal sulphide ores by floatation. The collector has wide pH range in ore magma, thereby having strong ability to collect copper sulphide minerals such as chalcopyrite, etc., lead sulfide minerals or zinc sulfide minerals activated by copper ions, nickel sulfide minerals as well as noble metal minerals such as gold, silver, etc., and having good selectivity to gangue sulphide minerals such as iron pyrites, pyrrhotite, etc.

Owner:CENT SOUTH UNIV

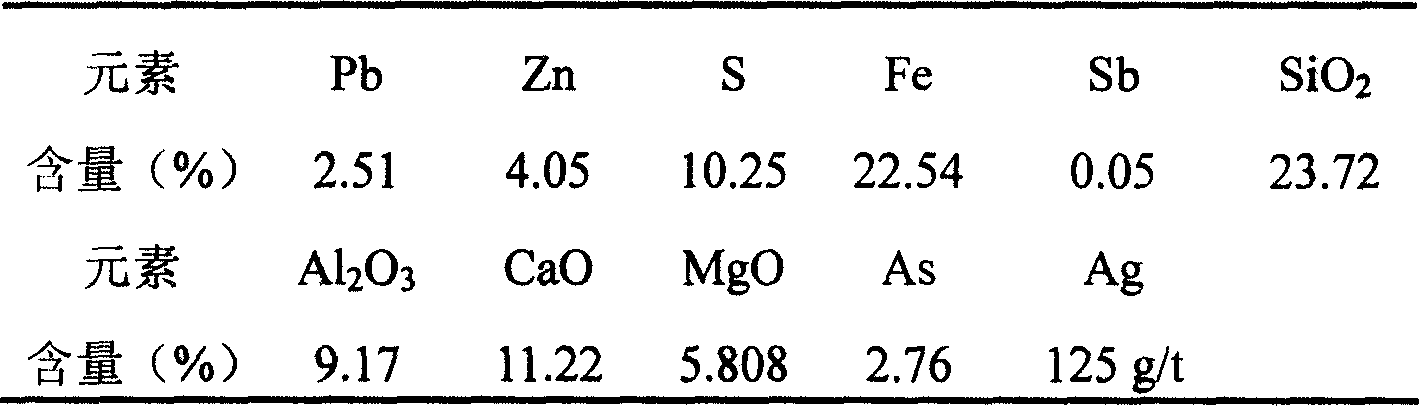

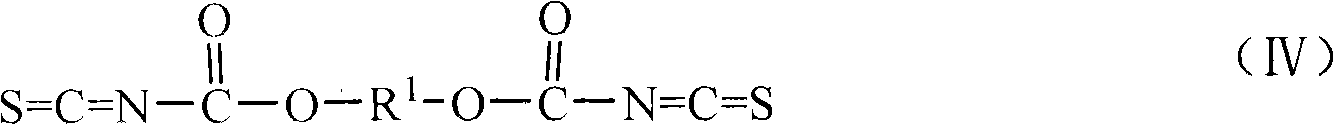

Beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite

ActiveCN107252731ASolve efficiency problemsSolve the accuracy problemFlotationWet separationActivated carbonSeparation technology

The invention discloses a beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite. For the complicated nature of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite, the zinc-sulphide two-stage bulk flotation-zinc-sulphide mixed rough concentrate regrinding and separation technology is adopted, easy-floating zinc-sulphide minerals are preferentially floated during zinc-sulphide mixed first-stage flotation, difficult-floating marmatite flotation is reinforced in the second stage, two-stage mixed rough concentrate is reground so as to promote sufficient monomer separation of zinc-sulphide intergrowth minerals, activated carbon is added in the regrinding process to enhance mineral surface reagent removal, during separation floatation, XKY-12 is added to form deep restraining of pyrrhotite, and efficient separation of marmatite and pyrrhotite is enhanced; according to the method, the good ore dressing recovery rate is ensured, and qualified and high-quality zinc concentrate is obtained; meanwhile, the efficient pyrrhotite inhibitor XKY-12 is adopted, and the problems that the marmatite and pyrrhotite separation efficiency is low and the separation precision is poor are solved.

Owner:WESTERN MINING CO LTD +3

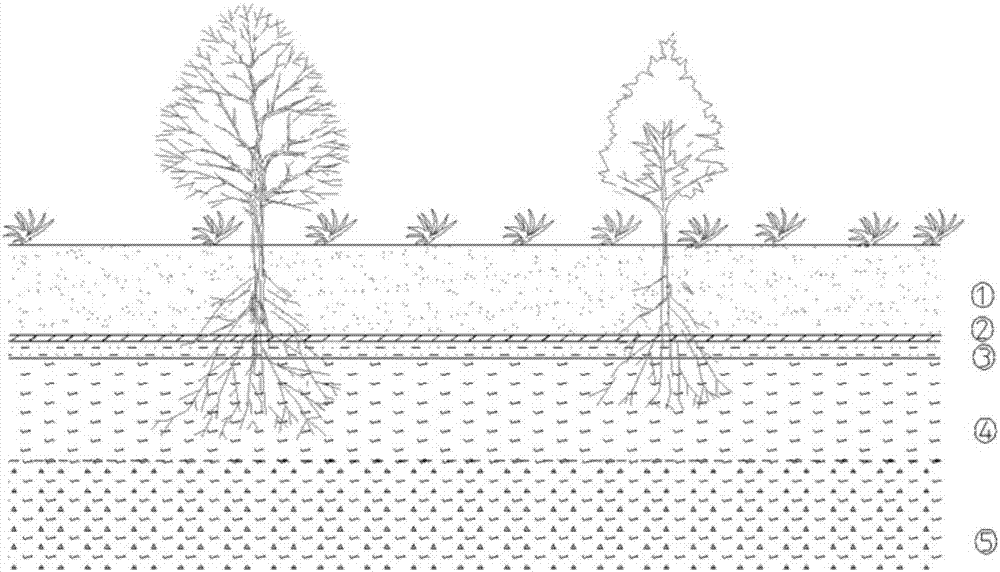

Five-layer coverage forced reduction in-situ mineralization restorative method

ActiveCN107363083AAvoid pollutionReduce penetrationSolid waste disposalContaminated soil reclamationSolubilityReaction layer

The invention provides a five-layer coverage forced reduction in-situ mineralization restorative method, and belongs to the technical field of mine environment ecological restoration. A five-layer structure involved in the method particularly comprises a non-pollution new soil layer, a clay sealing layer, a biomass reduction sealing layer, a main reaction layer and an original tailing layer. The method comprises the steps that organic matter in biomass on the main reaction layer is taken as the reducing agent, arsenic in a high oxidation state is reduced into arsenic in a low oxidation state or in a reduced state under the effect of anaerobic bacteria, and sulphur in a high oxidation state is reduced into sulphur in a reduced state, so that the minerals of realgar, orpiment and the like are formed again; and meanwhile, a large amount of iron is reduced to form iron pyrite, arsenopyrite, pyrrhotite and other minerals with the low solubility, and the heavy metals of Pb<2+>, Zn<2+>, Cu<2+>, Hg<2+>, Cd<2+>, Sb<3+> and the like form galena, blende, copper pyrites, cinnabar, greenockite, stibnite and other sulfide minerals with the extremely low solubility, so that mine heavy metal pollution in-situ mineralization restoration is achieved.

Owner:北科蕴宏环保科技(北京)有限公司

Method for utilizing comprehensive resource of sulfur-containing solid waste

InactiveCN101570341ATo promote metabolismSave resourcesDispersed particle separationSulfur compoundsSulfur containingPollution

The invention discloses a method for utilizing comprehensive resource of sulfur-containing solid waste, which comprises the following steps: (1) pyrolyzing sulfurous iron ore to obtain pyrrhotite and an elemental sulfur product; (2) mixing the pyrrhotite, a carbon-containing substance and a calcium-containing substance to carry out reduction reaction under a high temperature to obtain a solid mixture of elemental iron and calcium sulfide; (3) magnetically separating the solid mixture, and separating and recovering the solid mixture to obtain the elemental iron; (4) mixing and heating the solid containing the calcium sulfide and dehydrated gypsum to obtain tail gas containing SO2 and solid containing calcium oxide; and (5) separating the tail gas containing the SO2 through liquefying to obtain a liquid SO2 product, and using the solid containing the calcium oxide as the calcium-containing substance to participate in the reaction of the step (2) and as flue gas desulfurizing agent for cyclically utilization. The method solves the problems of occupied floor due to the stacking of desulfurization gypsum and coal washing sulfurous iron ore, environment pollution and potential safety hazard, makes full use of calcium, sulfur and iron resources rich in the wastes, and can realize recycling economy and clean production.

Owner:HUAZHONG UNIV OF SCI & TECH

Iron pyrite inhibitor for use under low-alkalinity condition

The invention discloses an iron pyrite inhibitor for use under a low-alkalinity condition. The iron pyrite inhibitor consists of the following components in parts by weight: 40-50 parts of sodium thiosulfate, 40-50 parts of citric acid and 5-15 parts of polyacrylamide, wherein the polyacrylamide is hydroxyl-containing low molecular polyacrylamide of which the molecular content is 400-600. The inhibitor is prepared by using a method comprising the following steps of weighing sodium thiosulfate, citric acid and polyacrylamide; uniformly mixing to obtain 1-5 percent by weight of aqueous solution; and stirring. The iron pyrite inhibitor is used for selectively inhibiting iron sulfide minerals under a low-alkalinity condition, has good inhibition effects on minerals such as pyrite, magnetic pyrite and the like, has the advantages of stable performance, small using amount, low cost and environment friendliness, can be widely applied to sulfide ore dressing of copper, copper lead, copper zinc, lead zinc, copper lead zinc, gold and the like, and contributes to effectively increasing the scoring indexes of copper, lead, zinc, metal minerals and pyrite, effectively enhancing the flotation separation effect of multi-metal sulfide minerals and increasing the recovery rate of associated gold and silver.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

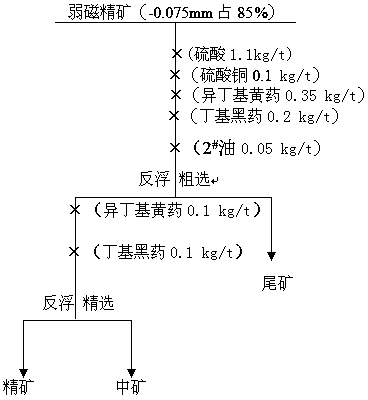

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

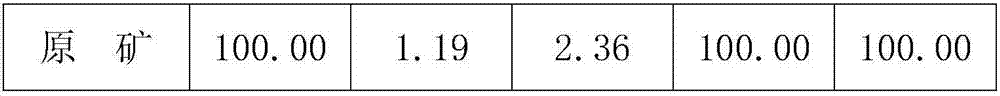

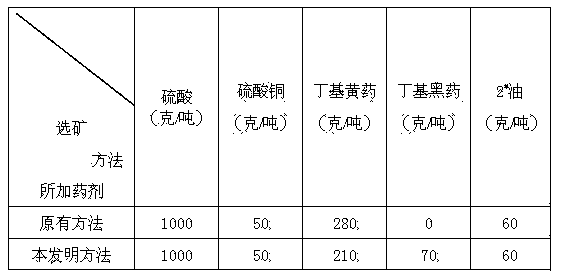

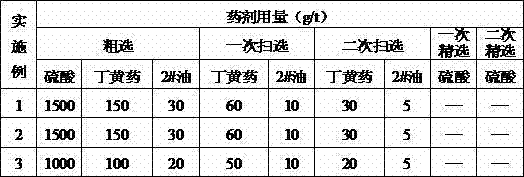

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

Method for separating and recovering sulfur and arsenic from sulfur and arsenic containing materials

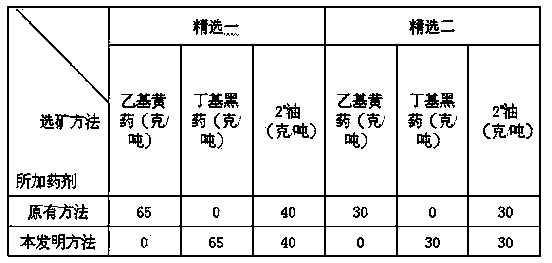

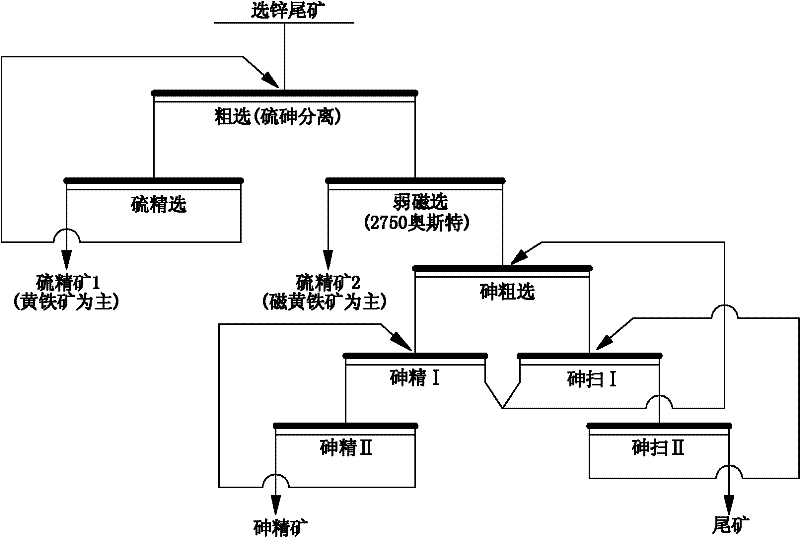

InactiveCN102240600ASimple processEasy to separateFlotationMagnetic separationEconomic benefitsSulfur containing

The invention relates to a method for separating and recovering sulfur and arsenic from sulfur and arsenic containing materials, comprising the following steps of: firstly inhibiting arsenopyrite and pyrrhotite by adopting an inhibitor to obtain sulfur ores a mainly containing pyrites through floatation; and then separating the pyrrhotite and the arsenopyrite from flotation tailings by adopting magnetic separation so as to obtain arsenic ores and sulfur ores b mainly containing the pyrrhotite. Compared with the prior art, the method provided by the invention has the advantages of simple process, effectiveness for separation and recovery of the sulfur and the arsenic, good economic benefit and higher popularization value.

Owner:厦门紫金矿冶技术有限公司

Applications of specific restraining agent in complicated sulfuration mine

The invention discloses a specific inhibitor application in complex sulfide ore. The inventive organic compound contains mineral-philic group -SH, hydrophilic group -COOH, -OH, -SO3, etc. in molecular structure, which fully shows the inhibiting property against pyrrhotite, pyrite and chalcopyrite in complex sulfide ore flotation separation, and is a high selectivity desulphurizing inhibitor. Compared with the prior inorganic inhibitors such as cyanide, lime, zinc sulfate, trisodium phosphate, dichromate, potassium permanganate, sodium sulfide, sulfite, etc., the inventive inhibitor has the advantages of low usage amount, good index and no pollution.

Owner:CENT SOUTH UNIV

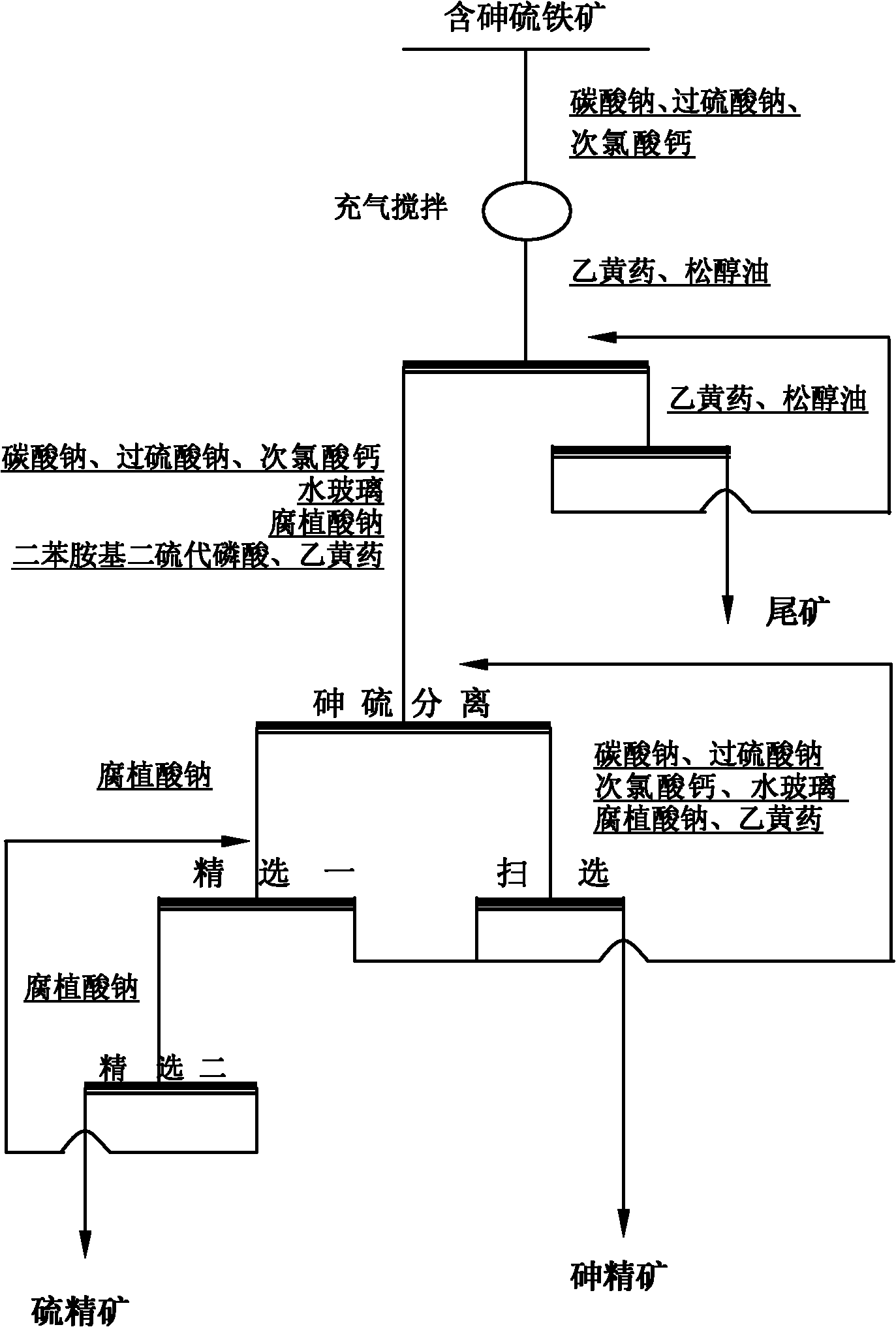

Floatation separation method for pyrites from arsenopyrites

InactiveCN101844108AIncrease oxygen contentElectrochemical conditions for stable flotationFlotationMineral flotationElectrochemistry

The invention aims at floatation separation of arsenic from sulfur in arsenic-containing pyrites. The floatation separation comprises the following steps of: adjusting an ore pulp to keep the pH value of the pulp between 9 and 10; adjusting the potential of the ore pulp to between 350 and 380 millivolts by adding oxidant medicaments of sodium persulfate and calcium hypochlorite; introducing air to increase oxygen content in the ore pulp; and stabilize electrochemical conditions of mineral floatation. During the floatation separation of the pyrites from the arsenopyrites, the potential of the ore pulp is stabilized by adding the oxidant medicaments of sodium persulfate and calcium hypochlorite; the arsenopyrite is suppressed by using a new collector of dianilino dithiophosphoric acid, and regulators of sodium silicate and sodium humate according to a principle of an electrochemical floatation process to make the pyrites such as arsenopyrites, iron pyrites, pyrrhotites and the like acted with a medicament selectively in the subsequent floatation process; and the floatation separation of the pyrites from the arsenopyrites is performed so as to form a sulfur concentrate with low arsenic content.

Owner:CENT SOUTH UNIV +1

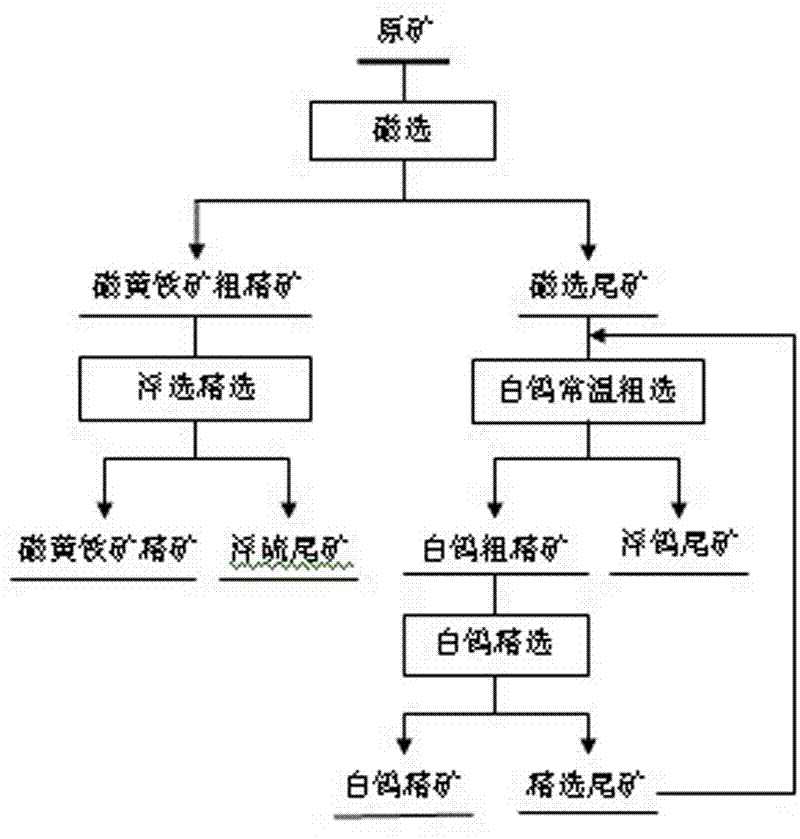

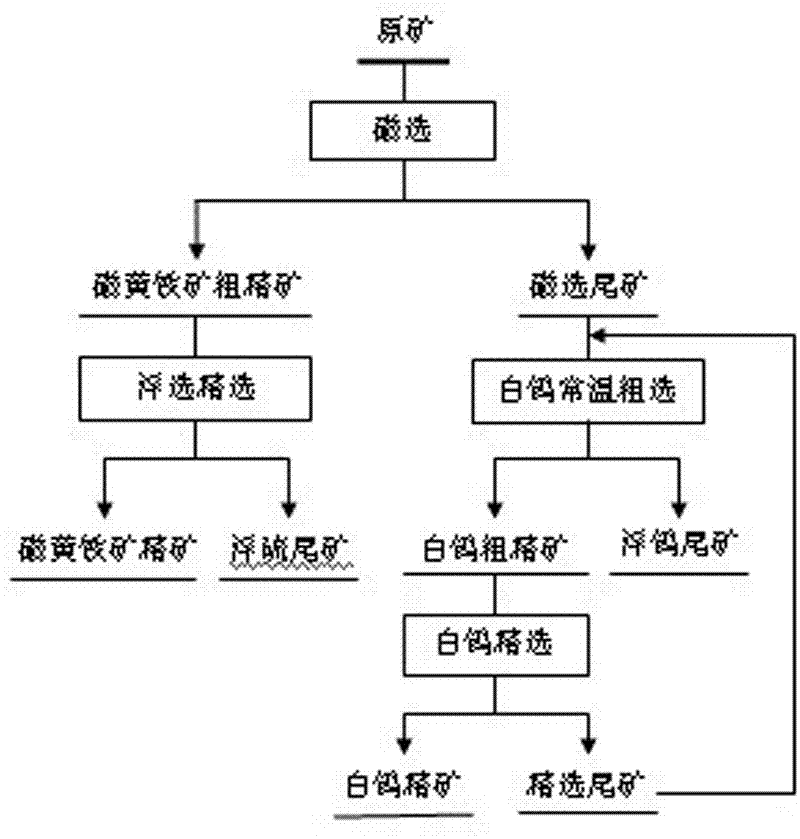

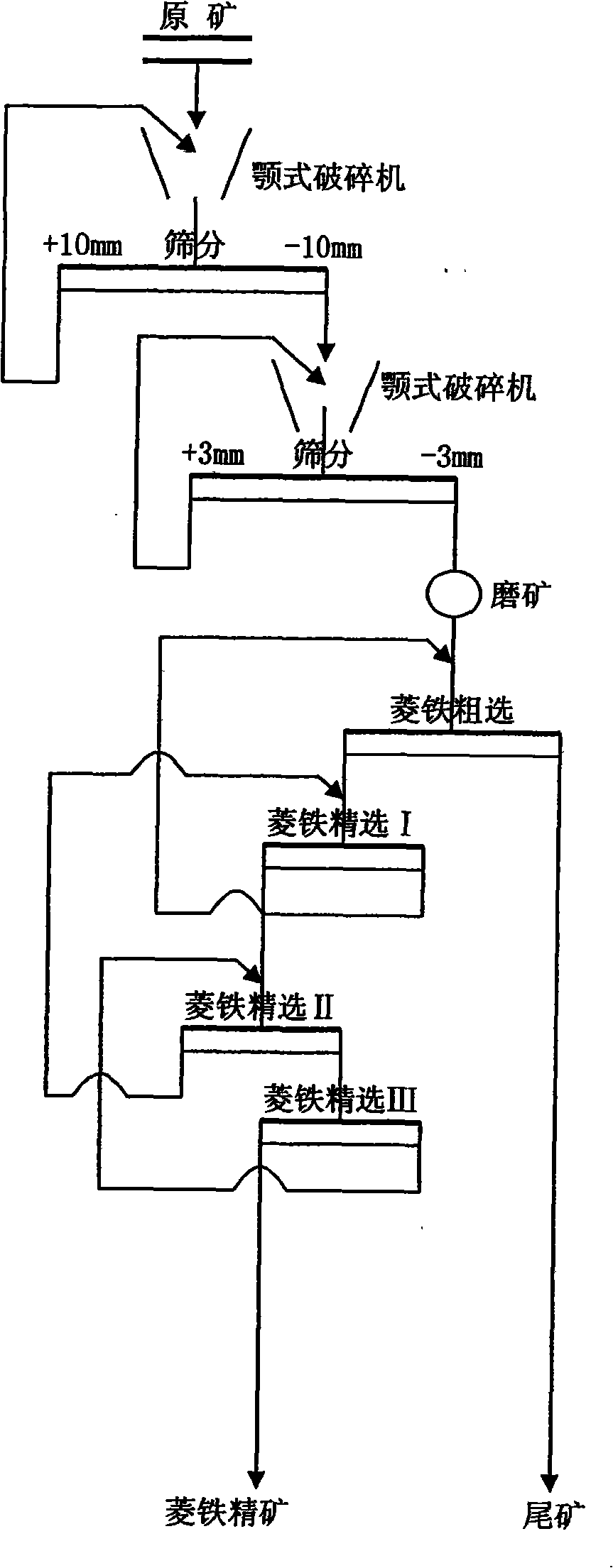

Mineral separation method for scheelite containing rich pyrrhotite

The invention discloses a mineral separation method for scheelite containing rich pyrrhotite, which comprises the following steps of: magnetically separating to obtain pyrrhotite rough concentrates and magnetically separated tailings; roughly separating, secondarily scavenging and secondarily blankly finely separating the pyrrhotite rough concentrates to obtain pyrrhotite concentrates and floating sulfur tailings; roughly separating, secondarily scavenging and secondarily finely separating the magnetically separated tailings to obtain white tungsten rough concentrates and floating tungsten tailings; and concentrating the white tungsten rough concentrates, carrying out floatation at normal temperature or the temperature of 80-100 degrees centigrade to obtain white tungsten concentrates and cleaner tailings. The method disclosed by the invention eliminates the influence caused by the pyrrhotite which is difficultly removed in the traditional flotation method, not only guarantees the quality of the tungsten concentrates but comprehensively recovers the pyrrhotite, and is suitable for mineral separation of the scheelite containing rich pyrrhotite.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

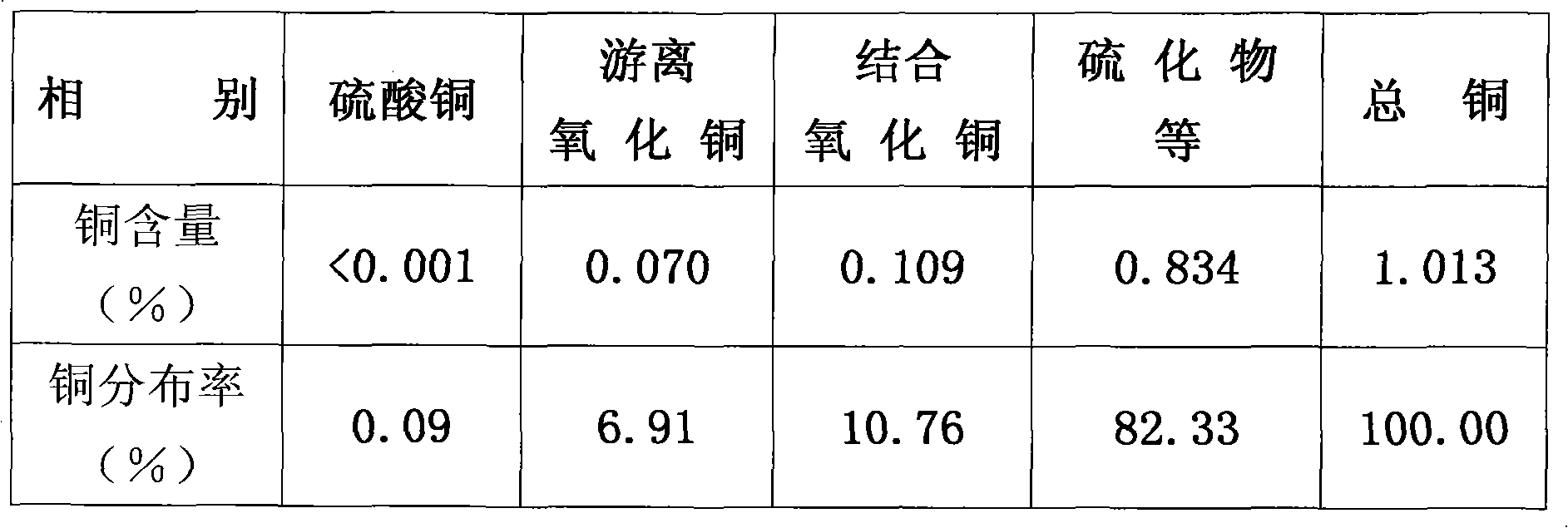

Comprehensive treatment method for high-mud content high-combination rate mixed copper ore

The invention provides a comprehensive treatment method for high-mud content high-combination rate mixed copper ore, which comprises the following steps of: grinding the mixed copper ore and roughing copper sulfur so as to obtain copper sulfur ore and tailings; concentrating the copper sulfur ore to obtain the copper ore and middlings; concentrating the copper ore to obtain the copper concentrate, and performing copper rough concentration on the middlings to obtain the copper ore and middlings simultaneously; concentrating the copper ore to obtain the copper concentrate, and performing copper scavenging on the middlings to prepare sulfur concentrate for recovery; performing magnetic separation on the middlings subjected to the copper scavenging so as to obtain magnetic for recovery, and returning the tailings to copper sulfur roughing. In the method, the pyrite (sulfur concentrate) is separated from the copper concentrate successfully in the flotation process for the first time so as to obtain high-quality copper concentrate; meanwhile, a large amount of magnetic pyrite is separated from the middlings subjected to flotation through the magnetic separation step, the iron sulfur content in the middlings is reduced to the greatest degree, the middlings become high-quality sulfur concentrate which can be directly used as raw materials for producing sulfuric acid, the tailings subjected to magnetic separation return to the system for recycled production, and valuable resources are fully recycled.

Owner:YUNNAN DIQING MINING DEV

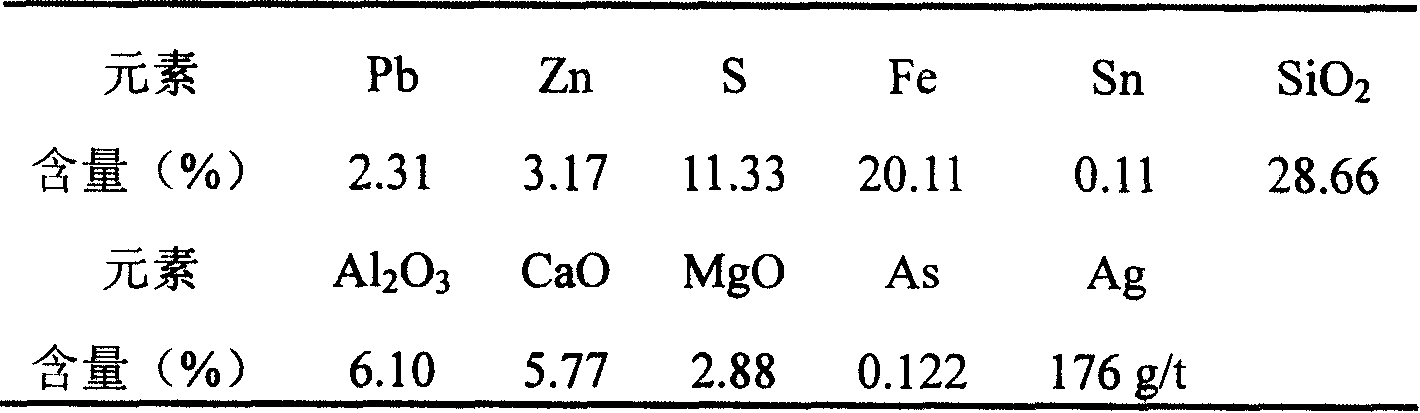

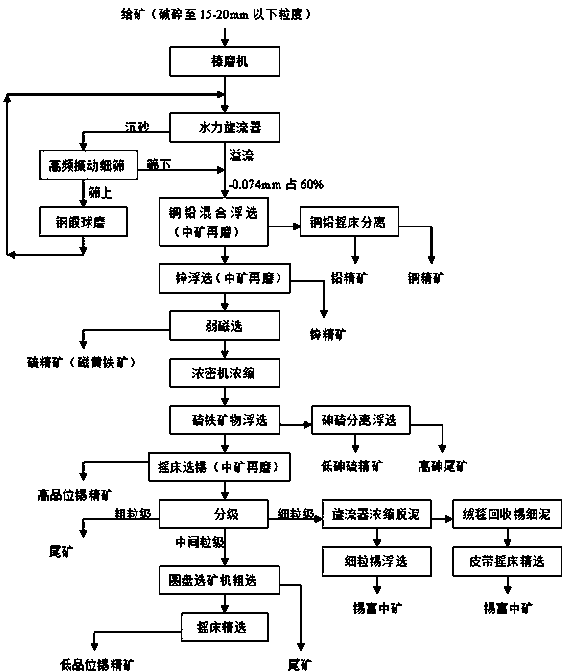

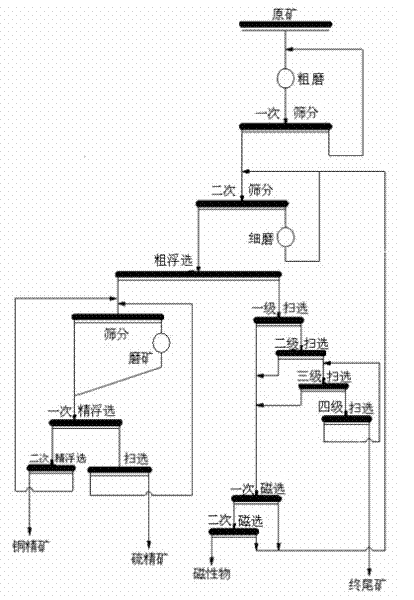

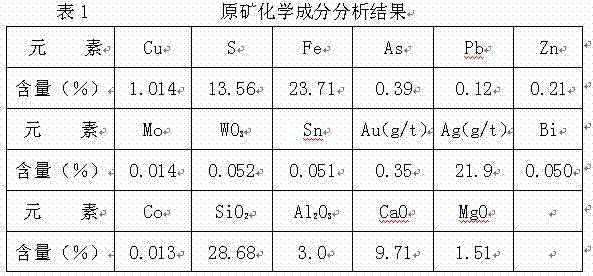

Beneficiation method for high-tin-content multi-metal sulfide ores

ActiveCN104226463AImprove recycling ratesHigh recovery rateWet separationMaterials scienceMagnetic separation

The invention relates to a beneficiation method for high-tin-content multi-metal sulfide ores, and belongs to the technical field of ore processing engineering. The high-tin-content multi-metal sulfide ores are subjected to rod milling ore discharging and hydraulic cyclone grading to obtain overflow and setting sand, the overflow enters copper lead for mixed flotation, the setting sand is subjected to high-frequency vibration fine sieving and is graded again, and undersize products after the hydraulic cyclone overflowing and the high-frequency vibration fine sieving grading are merged into ore milling products containing 60 percent of particles with the granularity being smaller than 0.074mm, and the ore milling products enter flotation operation; the ore grinding products are subjected to flotation, magnetic separation and reselection in steps, and then, lead concentrates, copper concentrates, zinc concentrates, pyrrhotites, low-arsenic-content sulfur concentrate, high-grade tin concentrates, tin concentrates and rich-tin middlings are respectively produced. The beneficiation method provided by the invention has the advantages that the tin ores can be recovered to the maximum degree, meanwhile, the recovery of all valuable metal sulfide ores can be considered, the valuable minerals in the ores are recovered to the maximum degree, and the integral recovery and utilization rate of ore resources is improved.

Owner:蒙自矿冶有限责任公司

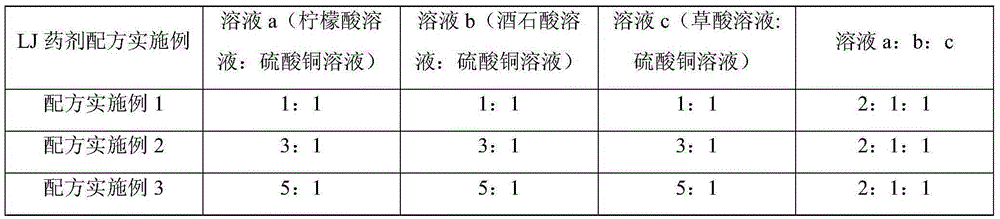

Desulfurization reagent for removing pyrrhotite in iron concentrate containing high sulphur by flotation method

ActiveCN105363564ATaking desulfurization into considerationTaking into account the recovery rateFlotationMagnetitePyrrhotite

The invention relates to a desulfurization reagent for removing pyrrhotite in an iron concentrate containing high sulphur by a flotation method. The desulfurization reagent is characterized in that a flotation agent is prepared by mixing citric acid, tartaric acid, oxalic acid and copper sulfate which are prepared into a, b and c mixed solutions. For magnetic iron concentrate with different pyrrhotite contents, 0 to 50% of mixed solution b and 0 to 50% of mixed solution c are added to the mixed solution a to prepare a floatation desulfurization reagent which can effectively activate the pyrrhotite so as to separate the pyrrhotite and magnetite, and as a result, the optimal desulfurization effect can be achieved. The flotation desulfurization reagent is simple and easy to prepare and use, common tap water and industrial backwater can be used for preparation of desulfurization reagent, and the current problems of low desulfurization and low recovery rate of the iron concentrate containing high sulphur can be solved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

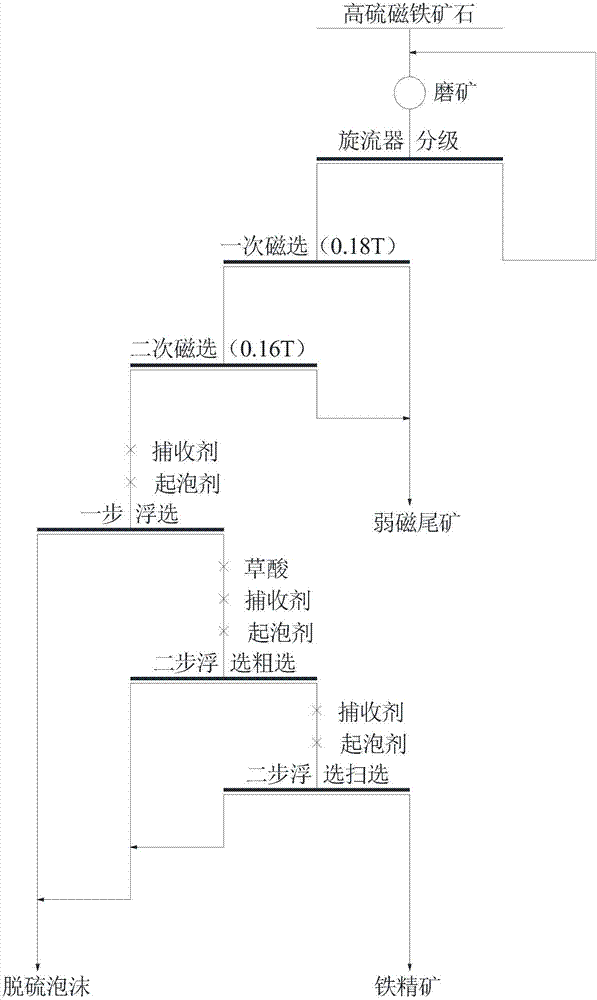

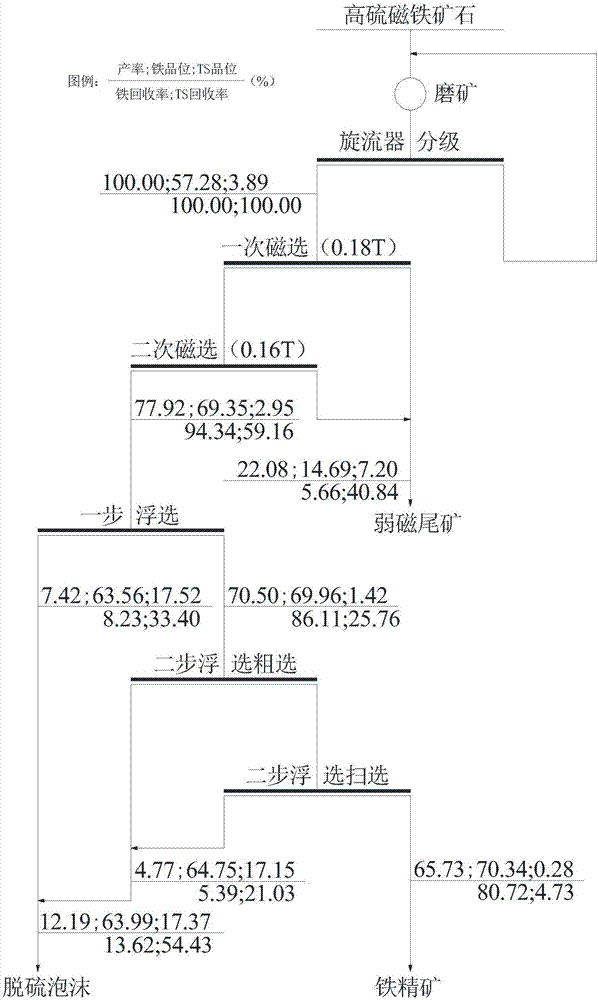

Beneficiation method for high sulphur magnetite containing pyrrhotite and pyrite

The invention discloses a beneficiation method for high sulphur magnetite containing pyrrhotite and pyrite. The method is used for beneficiation of the high sulphur magnetite with the grade of raw ore TFe being 56%-60% and the content of TS being 3.5%-4.2%. The method comprises the following technological steps that (1) the high sulphur magnetite is subjected to grinding and grading-low-intensity magnetic separation operation; (2) the pyrite is removed through primary flotation, specifically, butyl xanthate is used as a collecting agent for the pyrite, and 2#oil serves as a foaming agent; and (3) the pyrrhotite is removed through secondary flotation, specifically, primary roughing and primary scavenging are adopted, oxalic acid is used as a pH value regulator and an activating agent of the pyrrhotite, the butyl xanthate serves as a collecting agent of the pyrrhotite, and the 2#oil serves as the foaming agent. The beneficiation method has the advantages that the grade of iron ore concentrate TFe is high, the content of a harmful impurity S is low, production is stable, and safety and high efficiency are achieved, so that safety risks are reduced; and the oxalic acid (solid) is adopted to replace concentrated sulfuric acid to serve as the pH value regulator and the activating agent of the pyrrhotite, operation is simple and easy in the production process, and the safer and more reliable effect is achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Desulfur method of iron ore

InactiveCN1757769AImprove efficiencyLow costProcess efficiency improvementThiobacillus ferrooxidansThiobacillus

A process for desulfurizing iron ore concentrate includes such steps as culturing the mixture of thiobacillus ferro oxidans and thiobacillus sulfur oxidans in the non-Fe culture medium containing sulfur powder as energy source, adding the high-S iron ore concentrate containing pyrrhotite, naturalizing culture to obtain desulfurizing bacteria, putting them in water, immersing said high-S iron ore concentrate in it, vibrating in shaker for desulfurizing, washing and drying.

Owner:SHANGHAI INST OF TECH +1

Method for concentrating precious metals contained in leaching residue discharged from copper hydrometallurgical process

A method for concentrating precious metals contained in the leaching residue discharged from a copper hydrometallurgical process by removing pyrite from the residue. A method for concentrating precious metals in the leaching residue containing pyrite, elementary sulfur, precious metals and gangue, discharged from a copper hydrometallurgical process which comprises steps of leaching in an acidic, aqueous solution, reducing the copper-containing leaching liquor and electrolysis for copper recovery to treat copper sulfide ores, comprising (1) pyrolysis step in which the leaching residue is thermally treated at 550° C. or higher in a non-oxidative atmosphere, to produce the calcined ore containing pyrrhotite, precious metals and gangue, and (2) a re-leaching step in which the calcined ore is re-leached in an acidic, aqueous solution, to be separated into the re-leaching residue and iron-leached liquor, the former containing elementary sulfur, precious metals and gangue.

Owner:SUMITOMO METAL MINING CO LTD

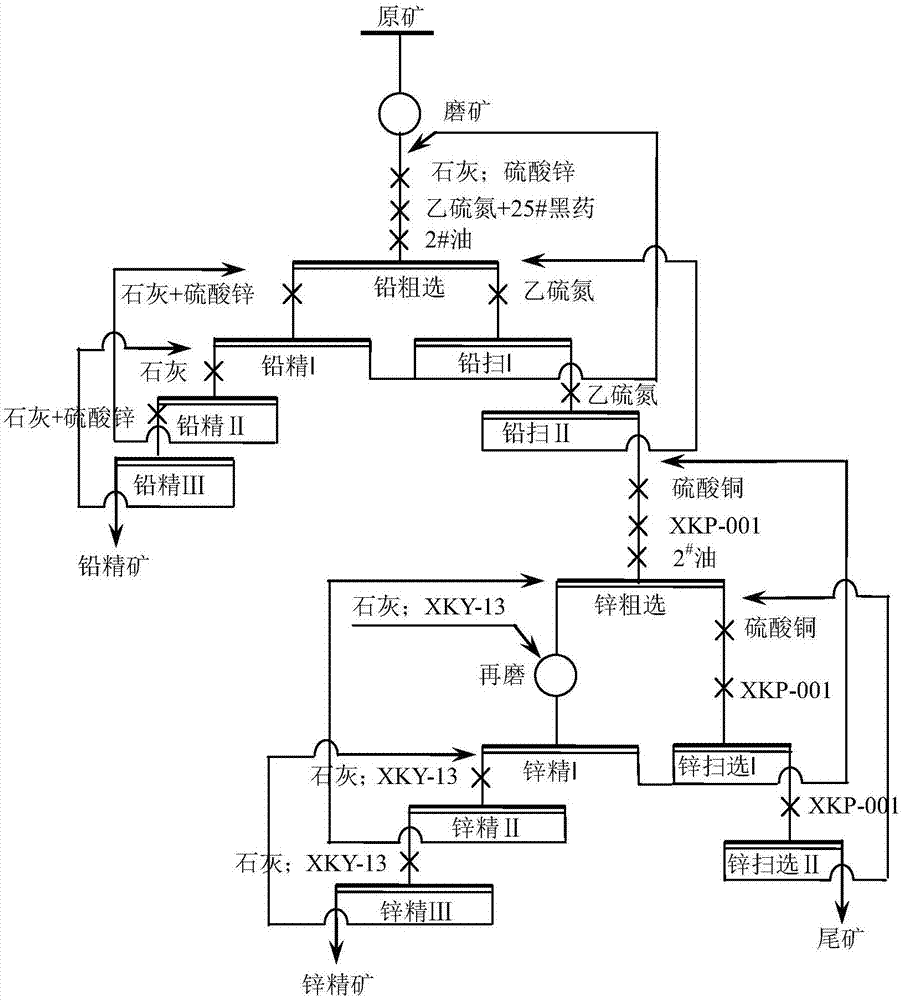

Method for floating micro-fine particle hard-to-separate marmatite

The invention discloses a method for floating micro-fine particle hard-to-separate marmatite. The method can be used for obtaining a good zinc flotation index from micro-fine disseminated grain size of hard-to-separate lead-zinc sulfide ore such as marmatite, pyrrhotite, pyrite, etc. The method comprises the steps: ore preparation and ore grinding, lead roughing, lead scavenging, lead concentration, zinc roughing, zinc regrinding, zinc concentration, etc. The method develops a novel efficient pyrrhotite and pyrite inhibitor XKY13 and an efficient selective marmatite collector XKP001. The inhibitor forms deep selective inhibition for pyrrhotite and pyrite and enables mineral to be hydrophilic. The collector has strong collecting capacity and selectivity for marmatite and strengthening hydrophilic floating-upward of marmatite. The two medicaments realize efficient separation of marmatite and pyrrhotite and pyrite and improve the comprehensive recovery capacity of mineral containing marmatite.

Owner:WESTERN MINING CO LTD +2

Singleness siderite full flotation mineral separation method

InactiveCN101264465AEfficient separationStrong physicochemical adsorptionFlotationIronstoneChemical adsorption

The invention relates to a single siderite all-flotation mineral separation method, belonging to the technical field of iron ore separation of mineral processing engineering, which adopts all-flotation technological process to process the single siderite ore with small amount of hematite-limonite, magnetic pyrite, pyrite and other ores. The processing method comprises the following steps: (1) the material is crushed below 3mm, mixed evenly and ground with liquid-solid weight ratio 1:2 and 75% to 95% of particle size of 0.074 mm, and (2) one roughing and triple cleaning are processed and the siderite concentrate ore with grade TFe larger than or equal to 38% and 75 to 86% of the iron recovery is acquired. The single siderite all-flotation mineral separation method has the advantages of adopting the siderite collecting agent for collecting, enabling the strong physico-chemical adsorption between the siderite surface and the collecting agent surface, and realizing the effective separation of the siderite and other ores.

Owner:KUNMING UNIV OF SCI & TECH +1

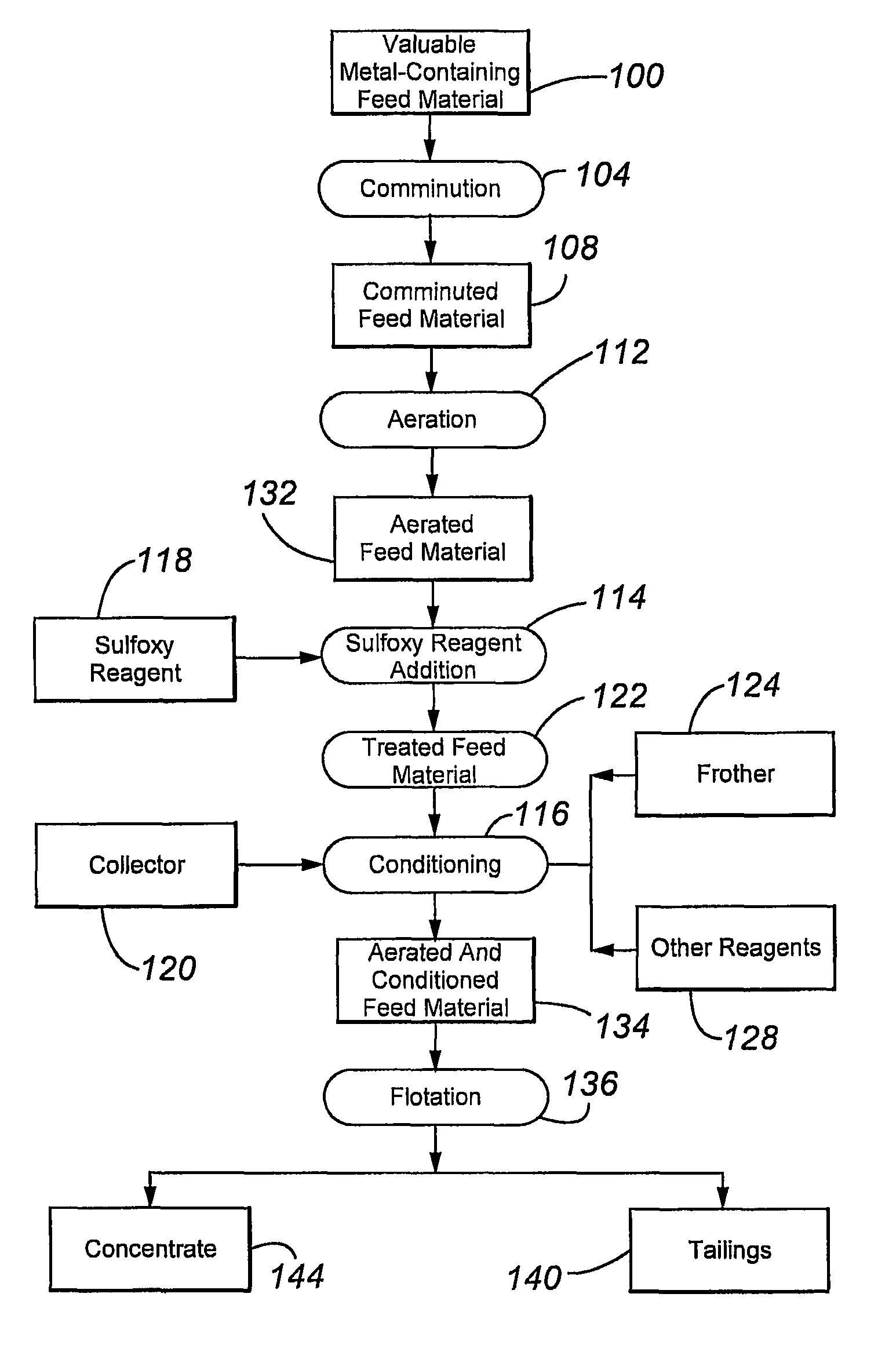

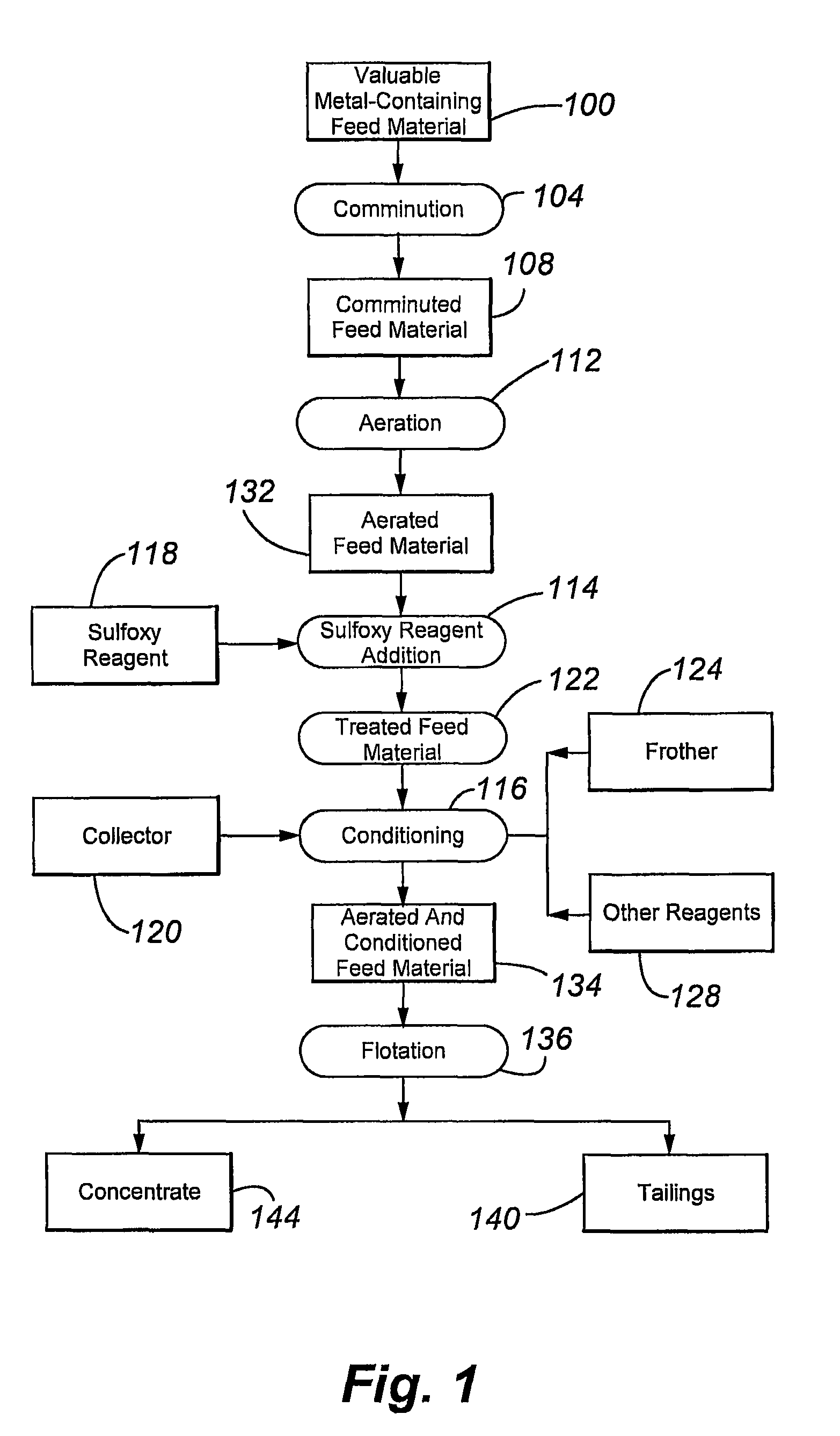

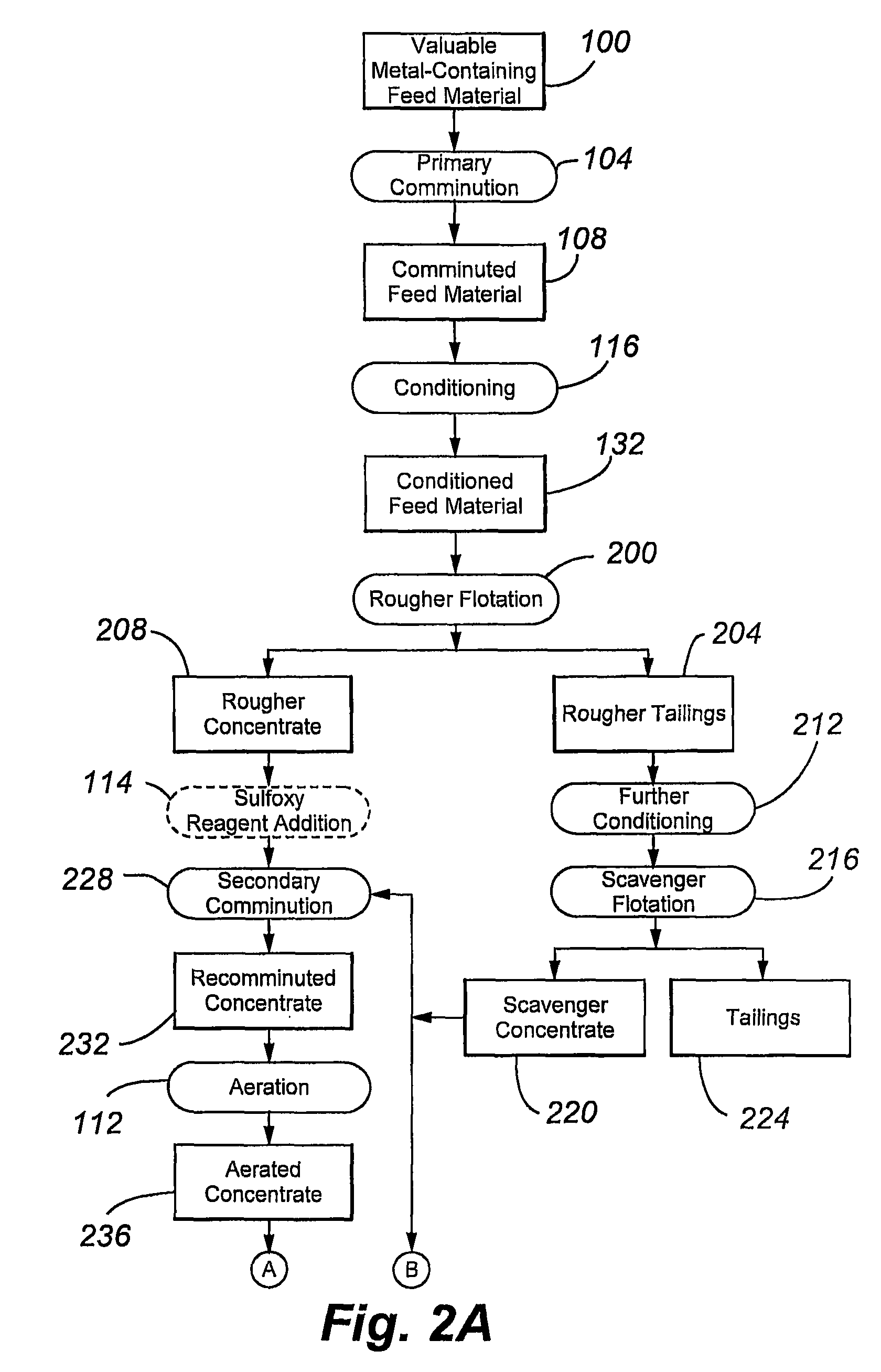

Separation of copper minerals from pyrite using air-metabisulfite treatment

ActiveUS9346062B2Improve efficiencyIncrease sulfoxy reagent consumptionEvaporationFlotationCopperMaceral

The present invention relates to flotation of sulfidic copper- molybdenum- and gold-containing minerals. More specifically, the invention relates to sulfoxy reagent-assisted flotation for separating of sulfides of copper, molybdenum and gold from pyrite, marcasite, pyrrhotite, arsenopyrite, and other gangue minerals following aerating by an oxidizing gas and contacting by a sulfoxy reagent. To promote collection and flotation the feed mineral materials are preferably not contacted with an externally generated non-oxidizing gas to lower the dissolved molecular oxygen content prior to flotation.

Owner:BARRICK GOLD

A comprehensive treatment method for mixed copper ore

The invention provides a comprehensive treatment method for mixed copper ore, which successfully separates sulfur concentrate and copper concentrate through the process steps of rough grinding, screening, fine grinding, rough flotation, fine flotation, magnetic separation, and sweeping. , so as to obtain high-quality copper concentrate, and then select a large amount of pyrrhotite from the middling ore through the magnetic separation step, which minimizes the iron and sulfur content of the middling ore, and can make the middling ore a high-quality Good sulfur concentrate can be directly used as raw material for sulfuric acid production, and the tailings after magnetic separation can be returned to the system for circular production, so that valuable resources can be fully recycled, and the tailings are discharged to the tailings dam after multi-stage screening Storage, to overcome the problems of heavy production load caused by the return of tailings, low concentrate grade and low recovery rate, the comprehensive recovery rate of copper is over 80%, the concentrate grade is over 19%, and the gold content of copper concentrate is 6g / t Above, the gold recovery rate is over 45%, the copper concentrate contains more than 418g / t of silver, and the silver recovery rate is over 50%.

Owner:YUNNAN DIQING MINING DEV

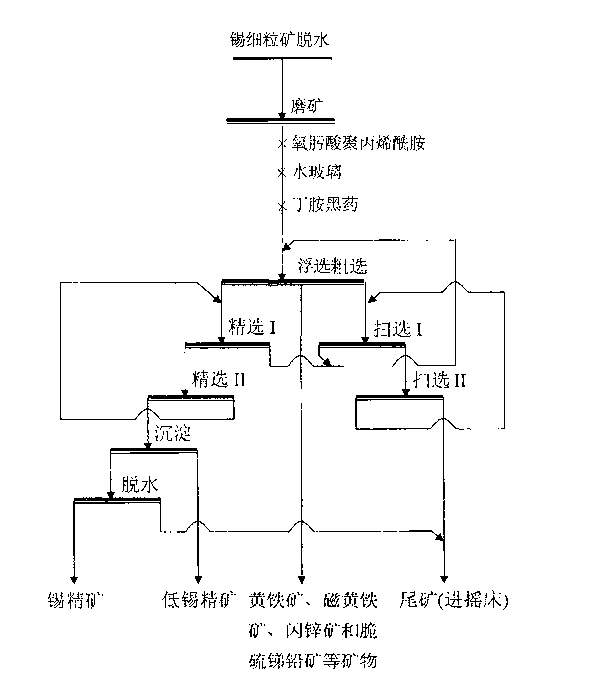

Method for selectively milling cassiterite multi-metal sulfides ores

The invention discloses a method for selectively milling cassiterite multi-metal sulfides ores. In the method, by utilizing the hydrophily / hydrophobicity difference between the surface of cassiterite and the surfaces of sulfides ores such as pyrite, pyrrhotite, blende and jamesonite, and by adding a floating agent in a milling process, floatation separation of cassiterite and the sulfides ores in ores can be realized under a condition of larger milling granularity by using a floatation method. The method disclosed by the invention can be adopted for treating the cassiterite multi-metal sulfides ore which contains 0.5 to 1 percent of Sn and 12 to 17 percent of S; and by adopting the method, the ore milling granularity required in floatation can be decreased, the content of fine-grained cassiterite (with the granularity of minus 0.039 millimeter) is reduced by 20 percent, and over-crushing phenomena of cassiterite are greatly reduced.

Owner:CENT SOUTH UNIV +1

Selective milling-flotation method for cassiterite multi-metal sulfide ore

The invention discloses a selective milling-floatation method for cassiterite multi-metal sulfide ore. In the method, cassiterite multi-metal sulfide ore is selectively milled, so that the surface hydrophilic / hydrophobic properties of cassiterite and sulfide minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like in ore are changed, the surface of cassiterite does not react with a flotation collector but reacts with hydroxamic acid polyacrylamide, and selective flocculation is performed on the surfaces of cassiterite minerals; and surfaces of minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like do not adsorb hydrophilic substances, and a fresh surface which is obtained by milling ore and dissociating reacts with a flotation collector which is added into an ore mill, so that floatability is realized for the surface hydrophilic property, the problems of low cassiterite floatation efficiency, high tin loss rate and severe environmental pollution caused by excessive smashing of cassiterite with the conventional floatation method in the ore dressing process of cassiterite multi-metal sulfide ore are solved, and the recovery of cassiterite with a subsequent gravity separation technology is facilitated.

Owner:GUANGXI GAOFENG MINE IND

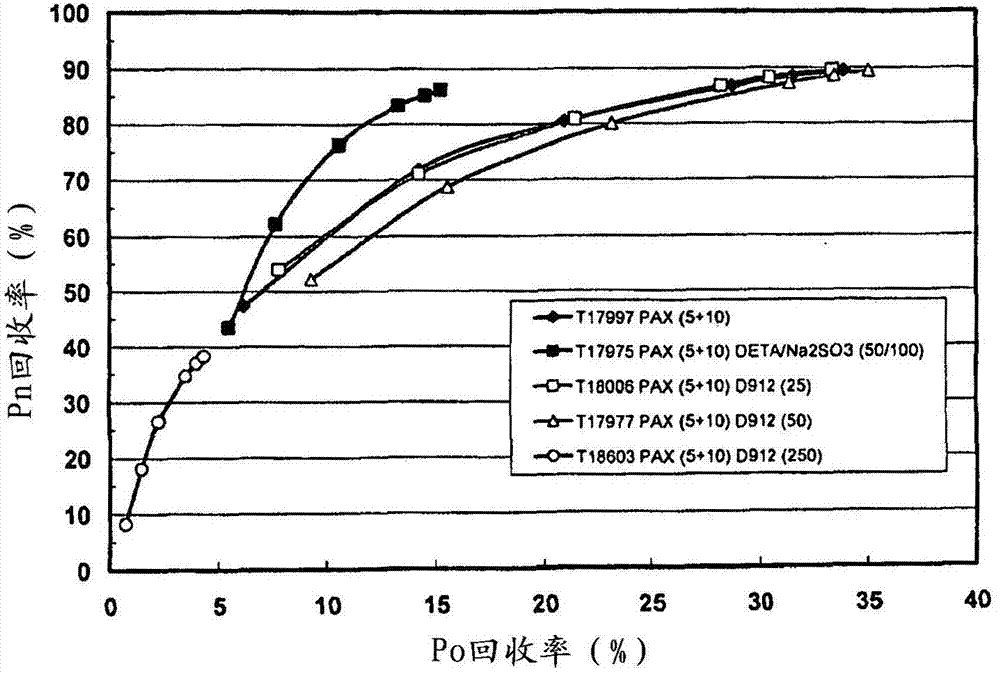

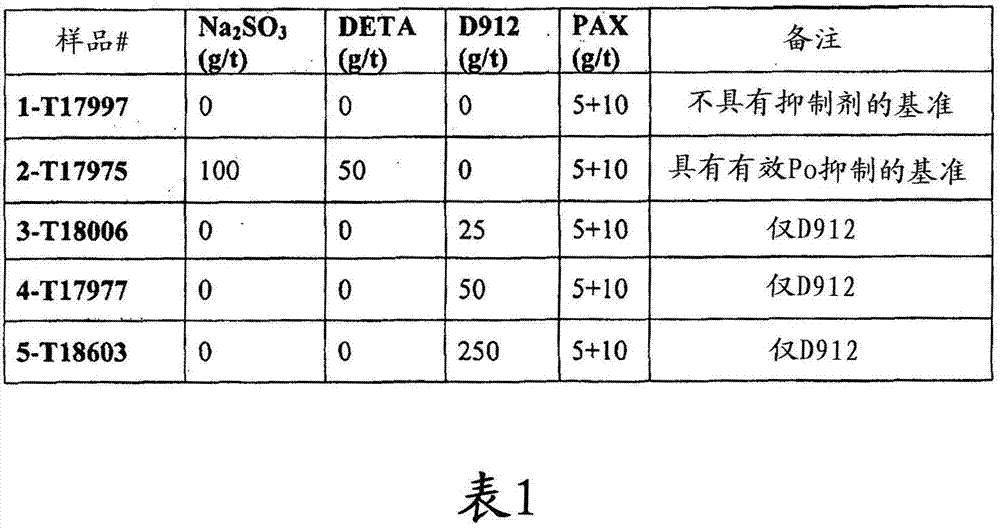

A method for improving selectivity and recovery in the flotation of nickel sulphide ores that contain pyrhotite by exploiting the synergy of multiple depressants

ActiveCN104718027AGood synergyPolyamine dose reductionFlotationProcess efficiency improvementDepressantSulfide minerals

A method of using the synergy of multiple depressants to improve the depression of iron sulphide without compromising the recovery of the valuable sulphide minerals in the flotation of non-ferrous metal sulphides, while reducing or eliminating the use of environmentally problematic chemicals such as polyamines. The method has significant economic and environmental benefits. The multiple depressants comprise at least one organic polymer, at least one sulphur-containing compound and / or at least one nitrogen-containing organic compound.

Owner:VALE LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com