Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

290 results about "Tailings dam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tailings dam is typically an earth-fill embankment dam used to store byproducts of mining operations after separating the ore from the gangue. Tailings can be liquid, solid, or a slurry of fine particles, and are usually highly toxic and potentially radioactive. Solid tailings are often used as part of the structure itself.

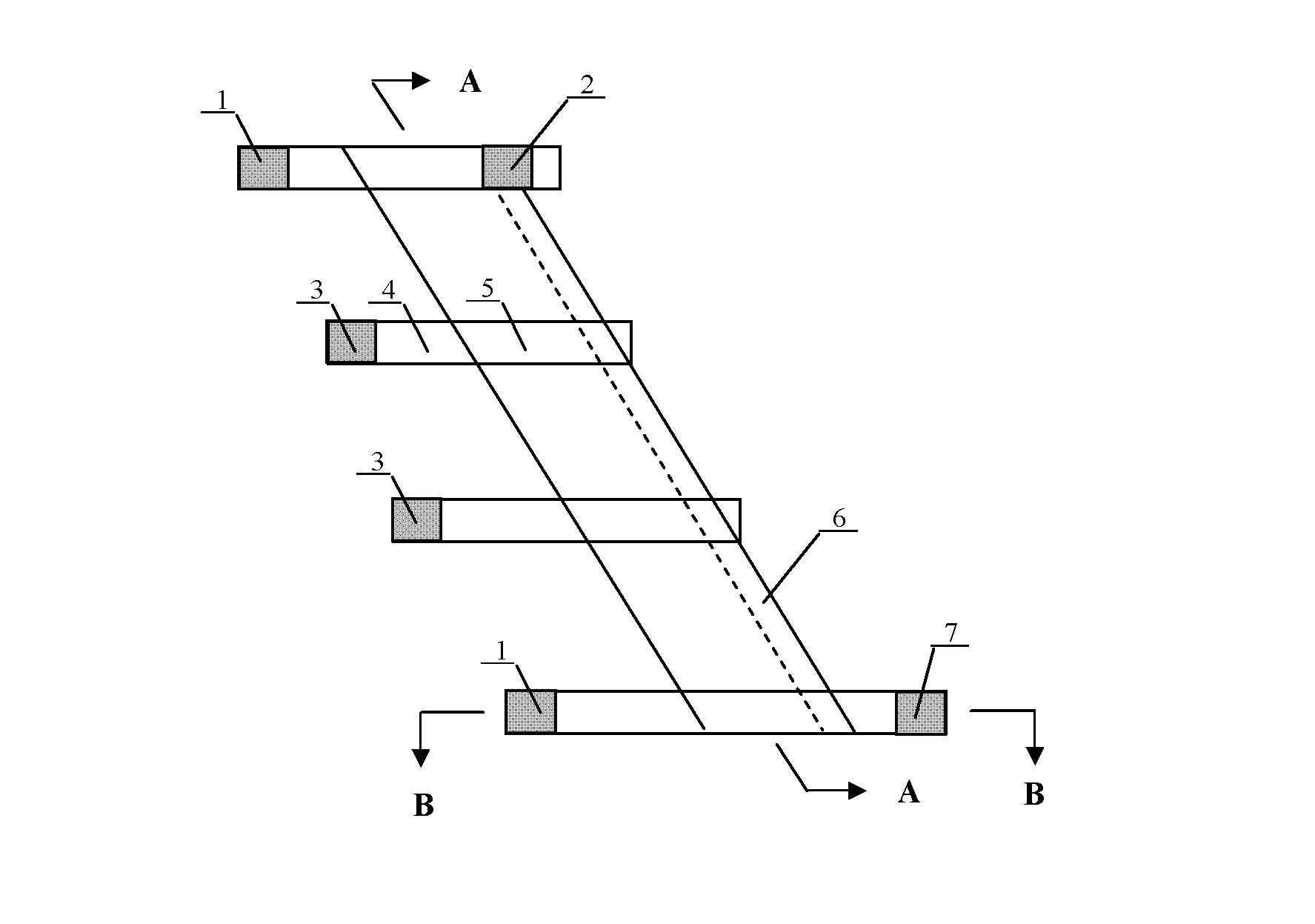

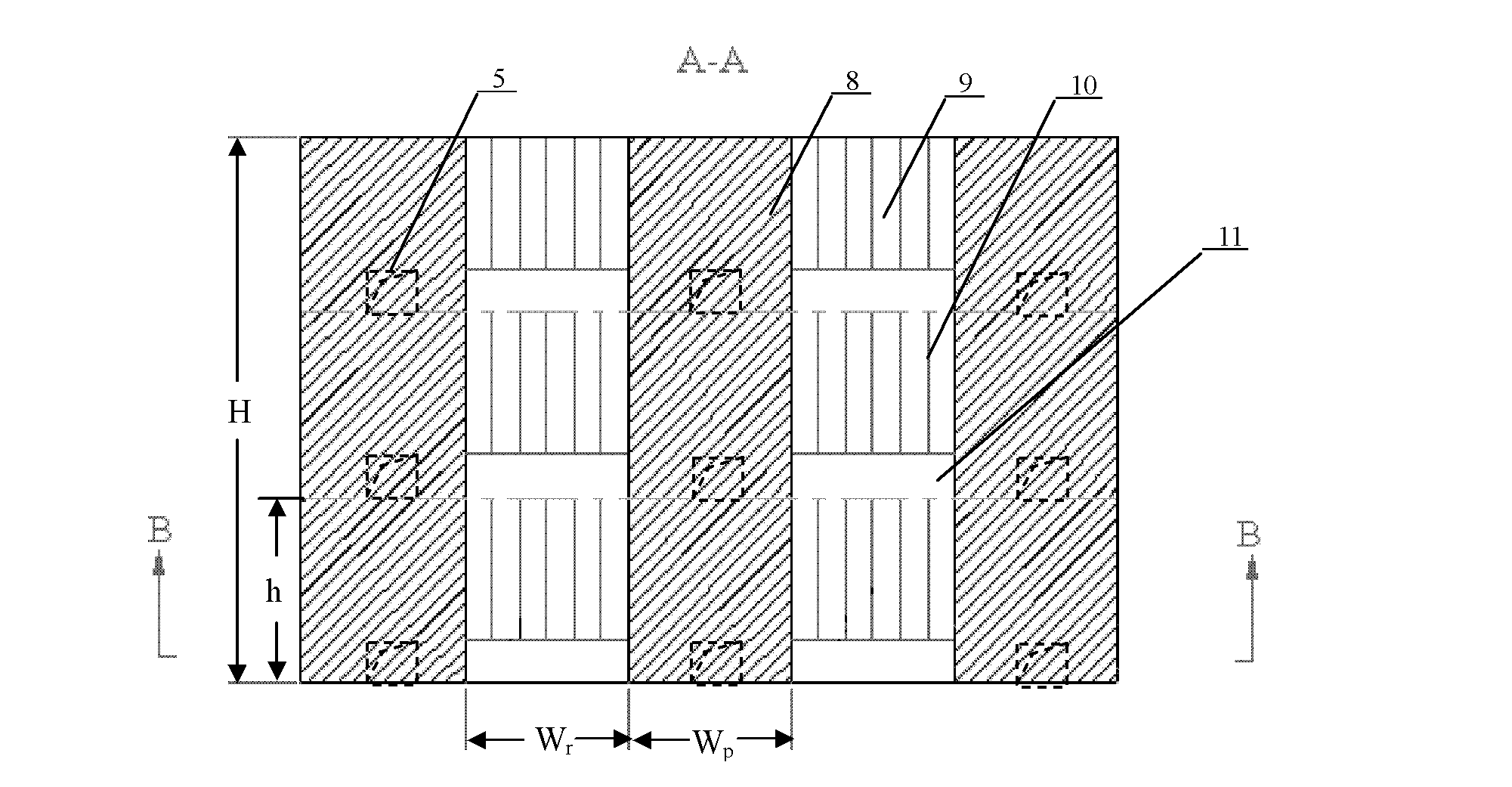

Sublevel open-stop and delayed filling mining method

InactiveCN102562065AImprove drilling positioning accuracyNo lossUnderground miningSurface miningTailings damFilling materials

The invention relates to a sublevel open-stop and delayed filling mining method. According to the method, cutting crosscuts are wholly undercut along the width of chambers and pillars so that the space of scope rock drilling is shared with ore drawing, drilling operations of vertical parallel blast holes are achieved in undercutting space, positioning accuracy of drilling the vertical parallel blast holes is high, the intervals among the blast holes are even, and the defect of high blasting boulder yield caused by drilling sector blast holes in traditional rock drilling cross cuts is avoided; during chamber (or pillar) scoping, driving of ore drawing gateways and ore drawing admission passages in fill materials of adjacent pillars (or chambers) isn't needed, and accordingly the safety is improved; simultaneously, ores are directly drawn from the undercutting space of the chambers and the pillars, the space of ore drawing is large, mutual interference is small, ore drawing efficiency is high, and ores are drawn completely without any dead space and secondary ore loss; artificial sill pillars are constructed, ore sill plates aren't needed to be reserved, the ores are free of primary loss, and the rate of resource recycling is high. Barren rocks and ore beneficiation tailings are used for filling gobs, the barren rocks are not taken out of pits, constructions of tailing dams and barren rock yards are reduced, and land occupation is small.

Owner:UNIV OF SCI & TECH BEIJING

Revegetation method for tailings dams in northern region

InactiveCN102668835ASuppress dustImprove adaptabilityHorticultureSoil-working methodsRevegetationTailings dam

A revegetation method for tailings dams in the northern region includes the following steps: (A) slopes are cleaned up and leveled in order to eliminate potential geological hazards; (B) the surface layer of a tailings dam is covered by 10 to 15 centimeters of planting soil; (C) slurry-like plant-growing soil culture medium is sprinkled on the surface of the covering soil, so that a plant-growing substratum with a stable, excellent crumble structure is formed; (D) plant seeds with high stress resistance combined with artificial soil are chosen to be sowed on the surface of the plant-growing substratum, so that a seed layer which is about 2 centimeters in thickness is formed; (E) a management measure with a spray irrigation system and protective nets is adopted to maintain epigaeous seedlings at the late stage. The revegetation method has the advantages that the revegetation method can enhance the adaptability of plants to the complex adverse environment of a tailings pond, including stronger drought-resisting, saline-alkali tolerant, barren-tolerant and nutrient-obtaining capabilities, the method can be utilized to restore the ecology of the slopes of the tailings dam and build a steady vegetation layer, and also has the effects of stabilizing the slopes, conserving water and soil and inhibiting runoff and flying tailings sand.

Owner:青岛冠中生态股份有限公司

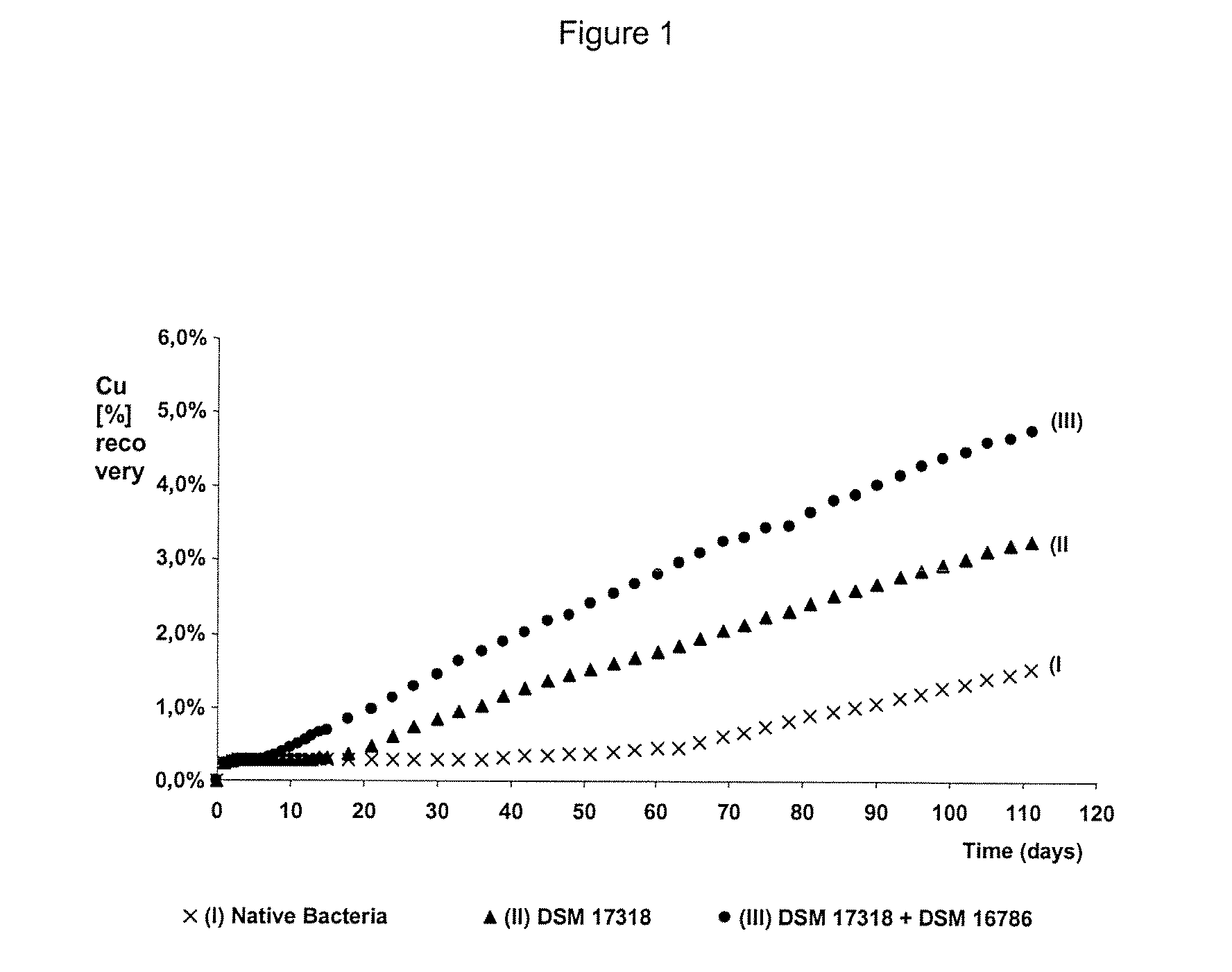

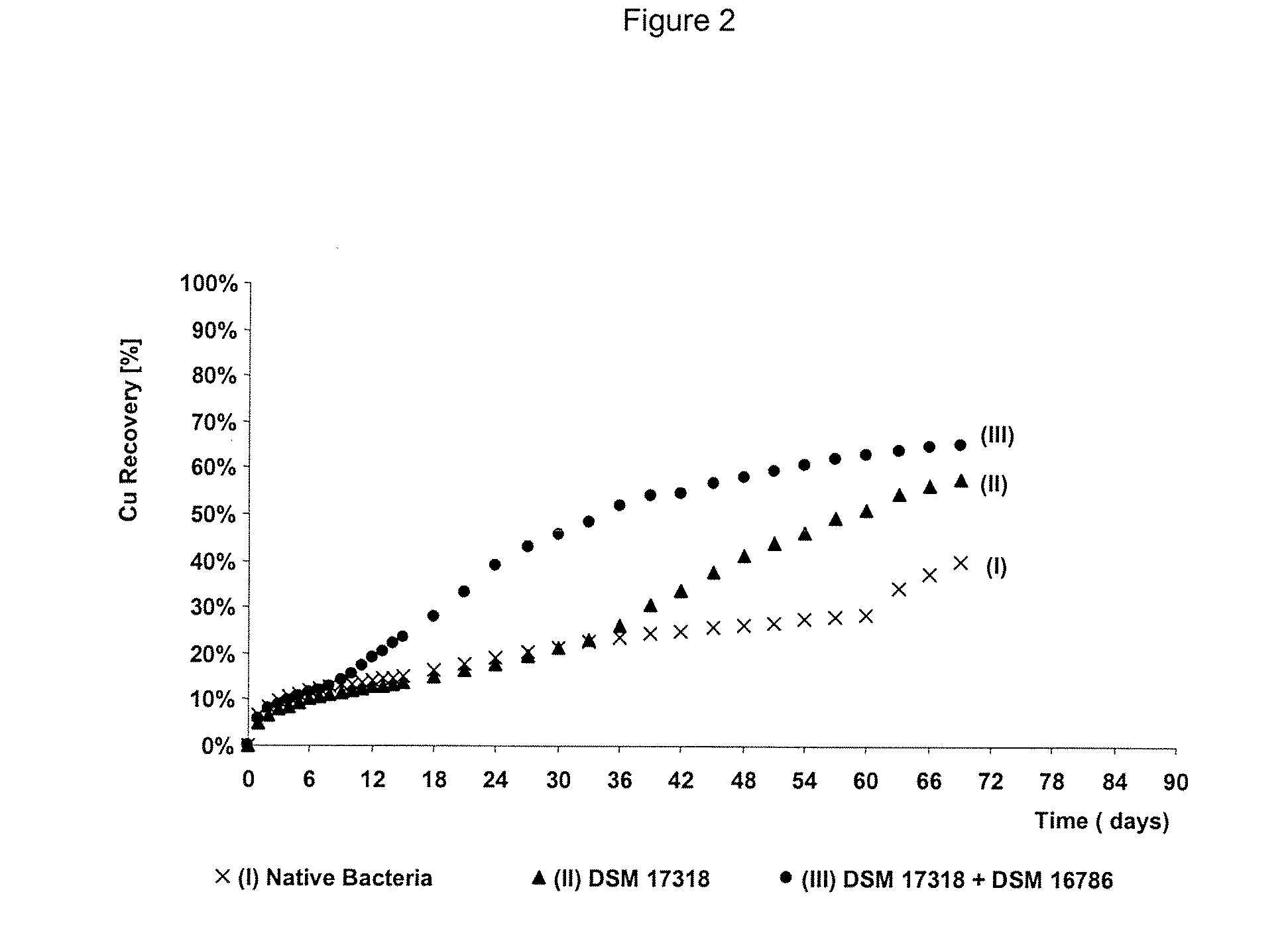

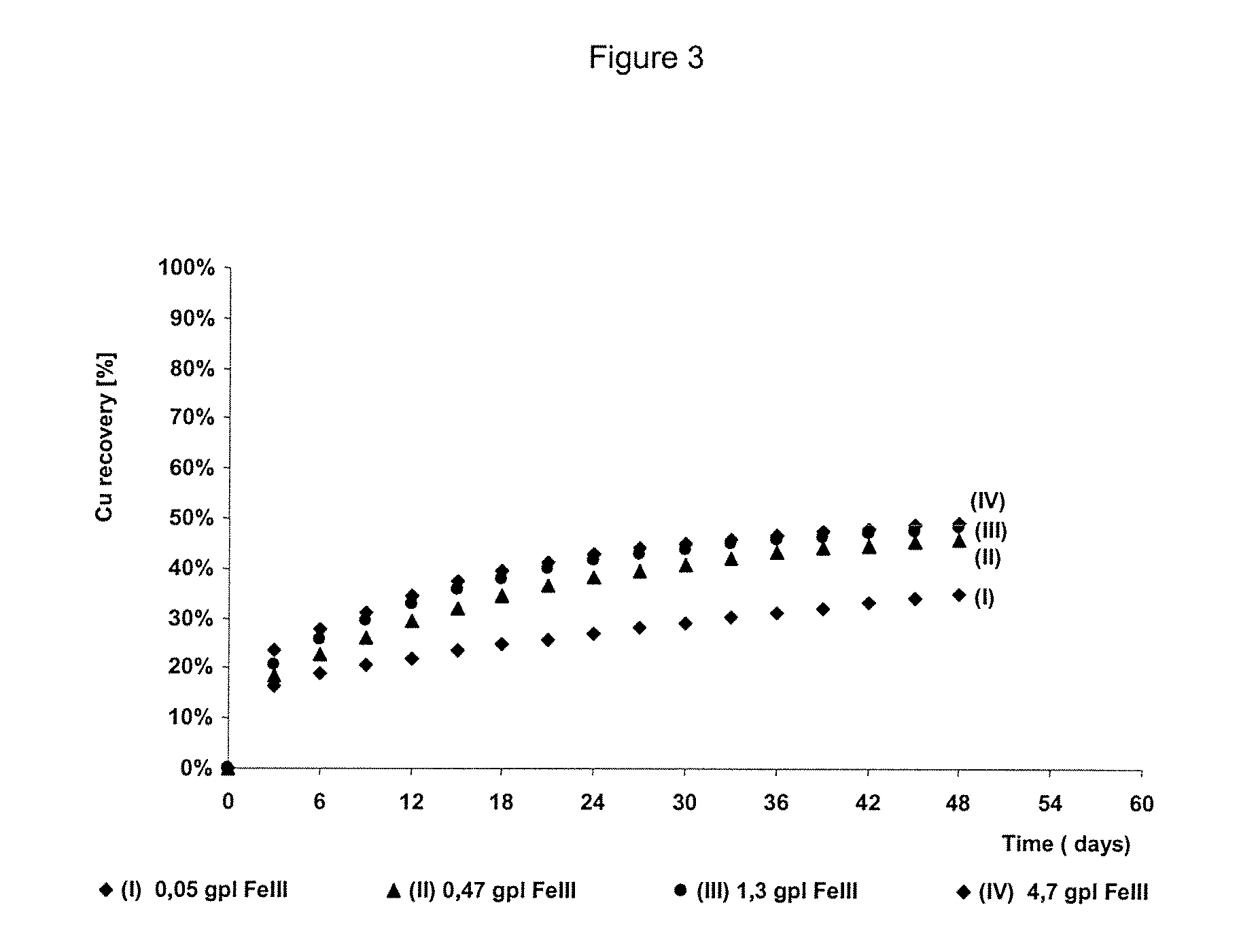

Process to increase the bioleaching speed of ores or concentrates of sulfide metal species, by means of continuous inoculation with leaching solution that contains isolated microorganisms, with or without presence of native microorganisms

ActiveUS20080127779A1Decrease ore bioleaching timeImprove bioleaching conditionSolvent extractionGold compoundsTailings damPotassium

The invention publishes a process to increase the bioleaching speed of ores or concentrates of sulfide metal species in heaps, tailing dams, dumps, or other on-site operations. The process is characterized by the continuous inoculation of the ores or concentrates with isolated microorganisms of the Acidithiobacillus thiooxidans type, together with isolated microorganisms of the Acidithiobacillus ferrooxidans type, with or without native microorganisms, in such a way that the total concentration of microorganisms in the continuous inoculation flow is of around 1×107 cells / ml to 5,6×107 cells / ml. In particular, the invention publishes the continuous inoculation of Acidithiobacillus thiooxidans Licanantay DSM 17318 together with Acidithiobacillus ferrooxidans Wenelen DSM 16786 microorganisms, or with other native microorganisms at a concentration higher than 5×107 cells / ml. In addition to the inoculation of isolated bacteria, the invention includes the addition of oxidizing agents such as the ferric ion produced externally, together with nutrients in the shape of salts of ammonium, magnesium, iron, potassium, as well as air enriched continuously with carbon dioxide to promote bacterial action in the bioleaching process of ores or concentrates.

Owner:BIOSIGMA

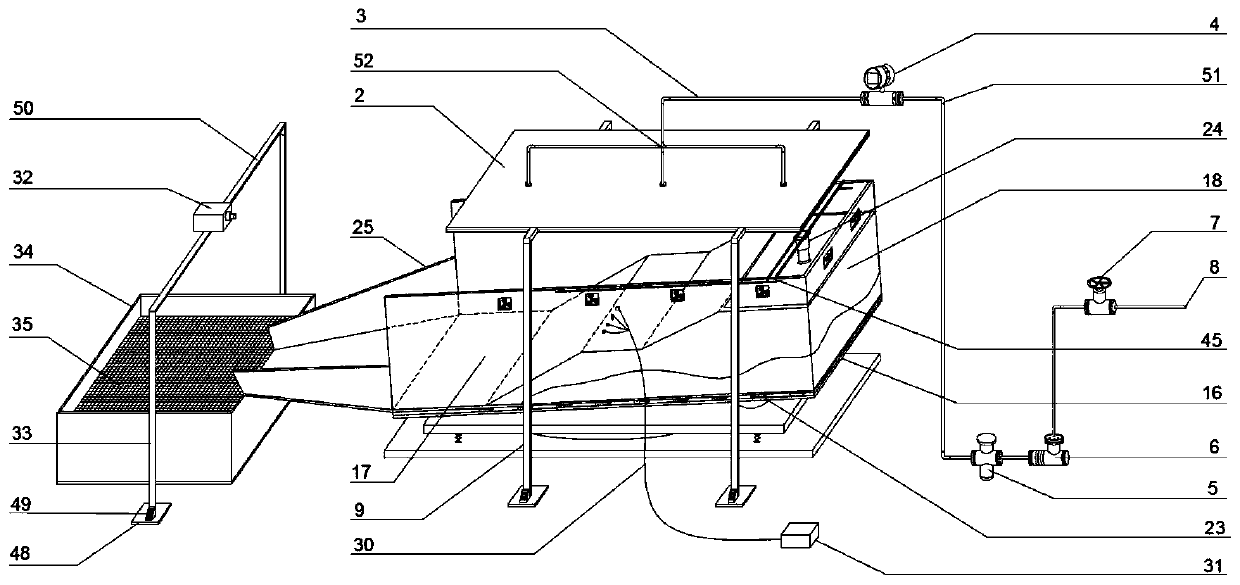

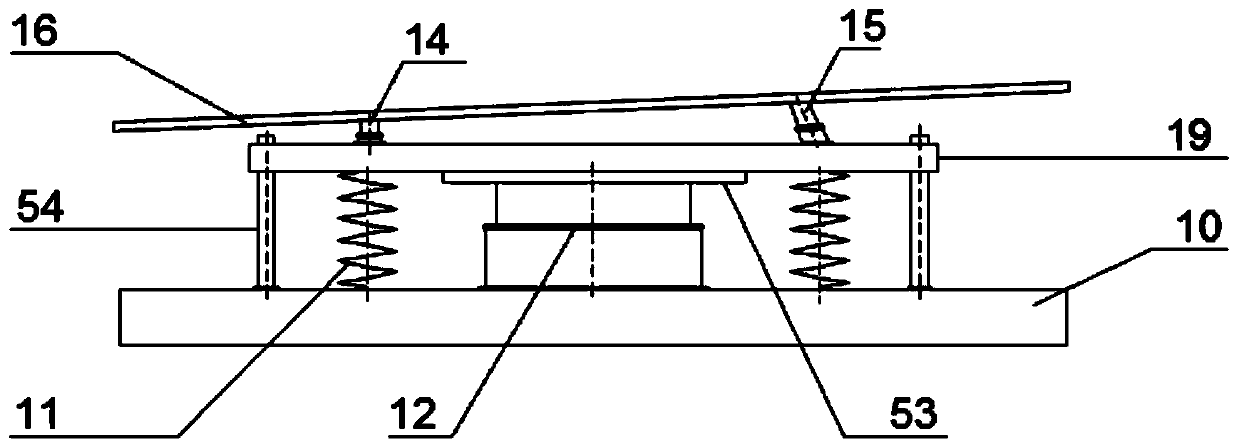

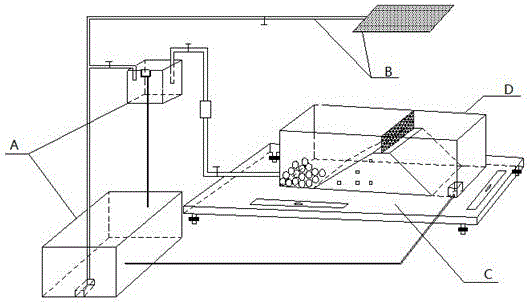

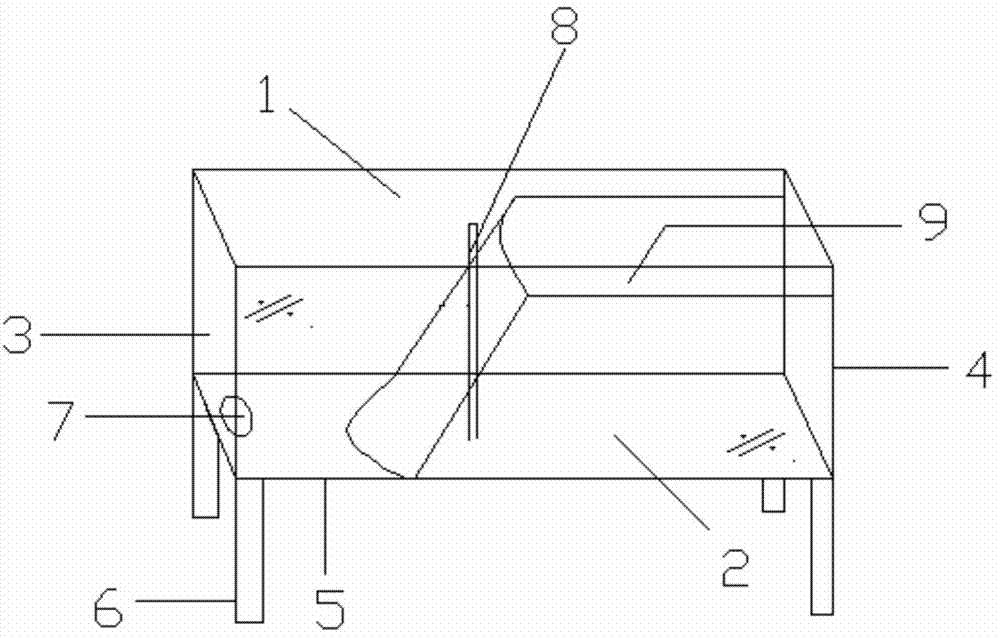

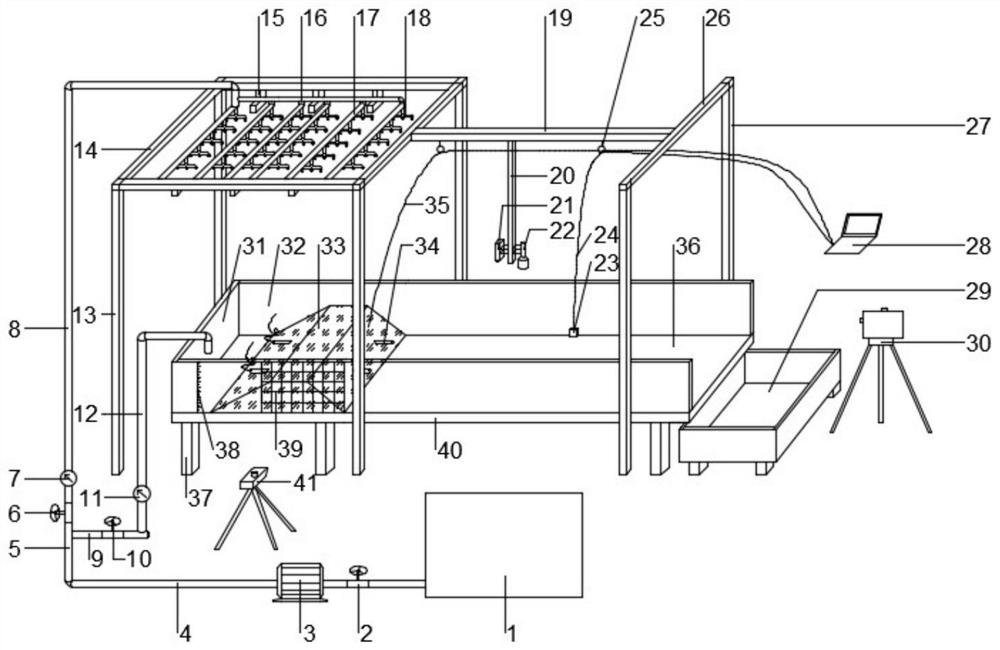

Model test device for simulating the instability failure of rock and soil slopes under complex conditions

PendingCN110658324ASimple structureEasy to operatePhotogrammetry/videogrammetryForce measurementSoil scienceTailings dam

The invention discloses a model test device for simulating the instability failure of rock and soil slopes under complex conditions, and belongs to the technical fields of geotechnical engineering andmining engineering. The model test device comprises a wind and rain simulation system, an earthquake simulation system, a similar model test system and a monitoring system. Through the adoption of the device, similar model test of rock and soil slope bodies such as waste dumps and tailings dams can be carried out efficiently, and the stability and failure modes of the slope bodies under rainfall,earthquake and the coupling action thereof can be researched and analyzed.

Owner:KUNMING UNIV OF SCI & TECH

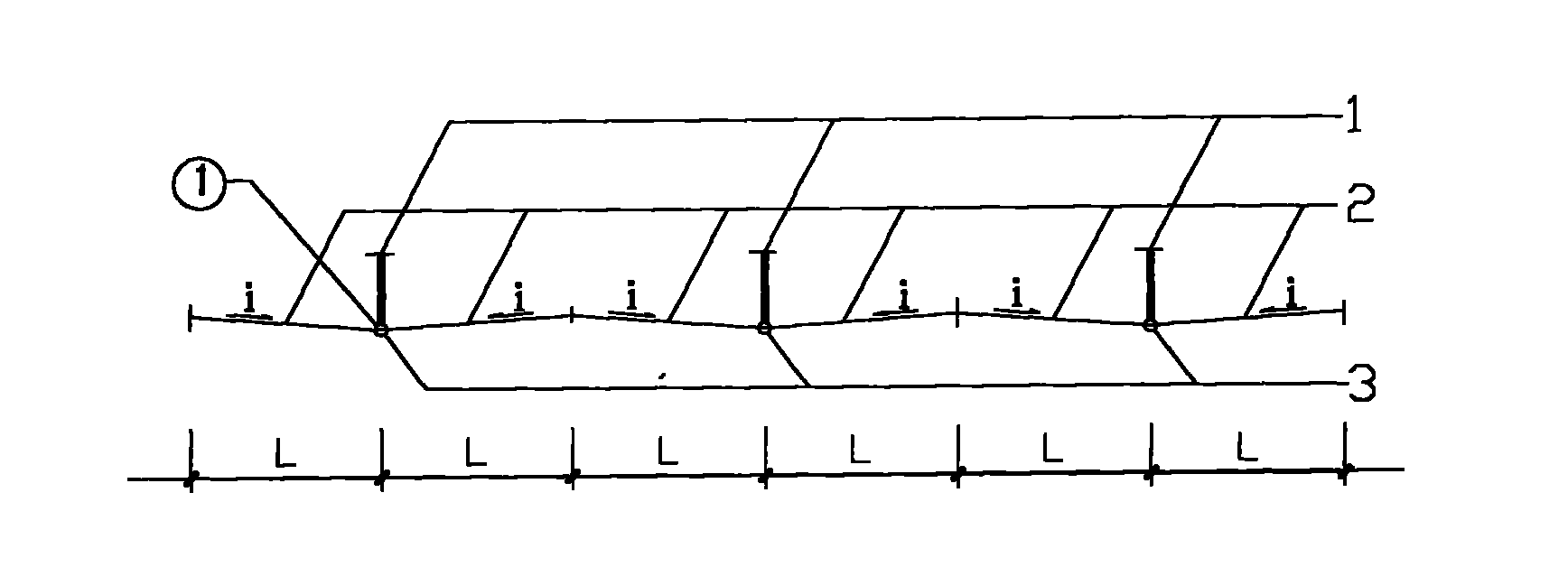

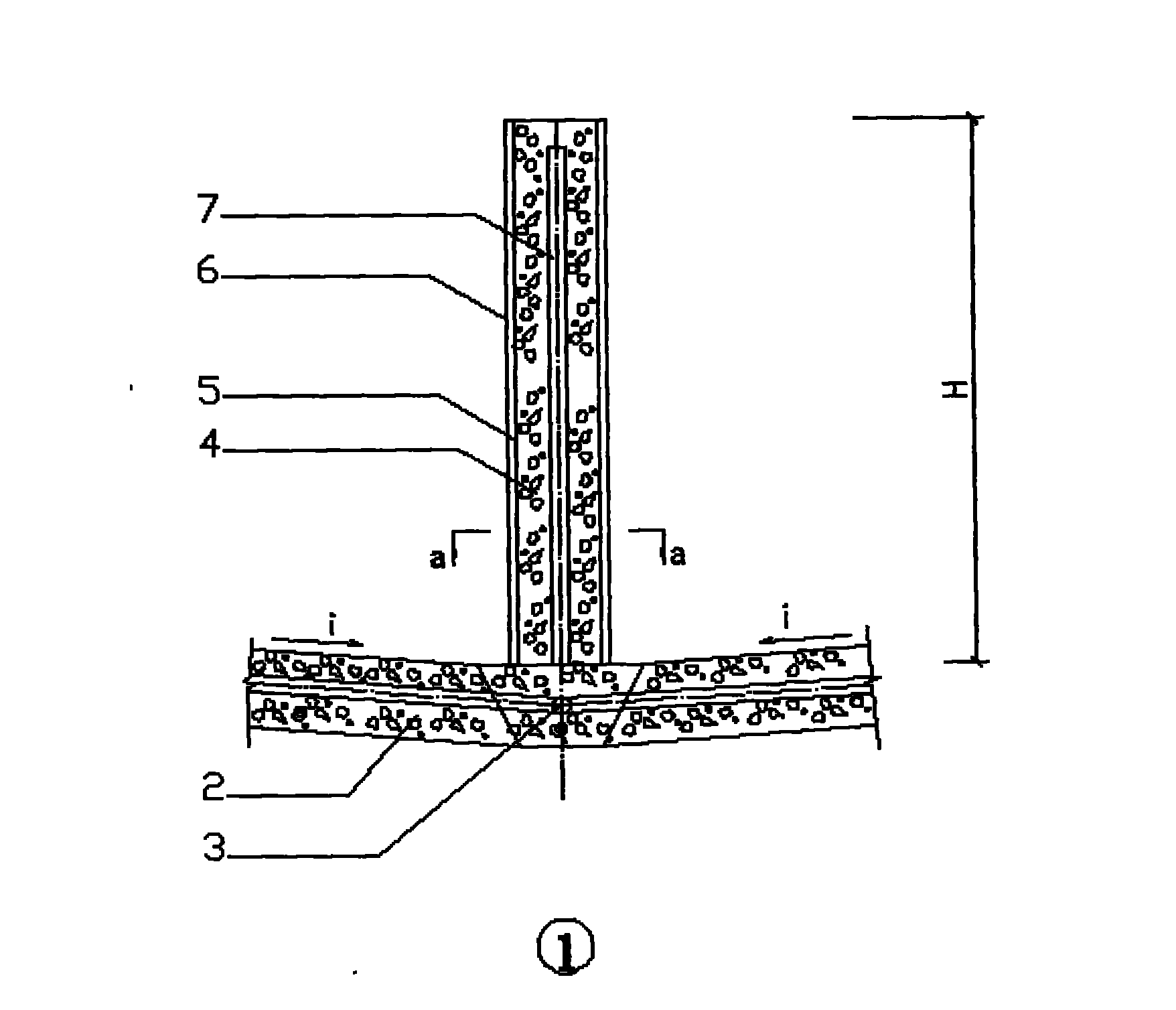

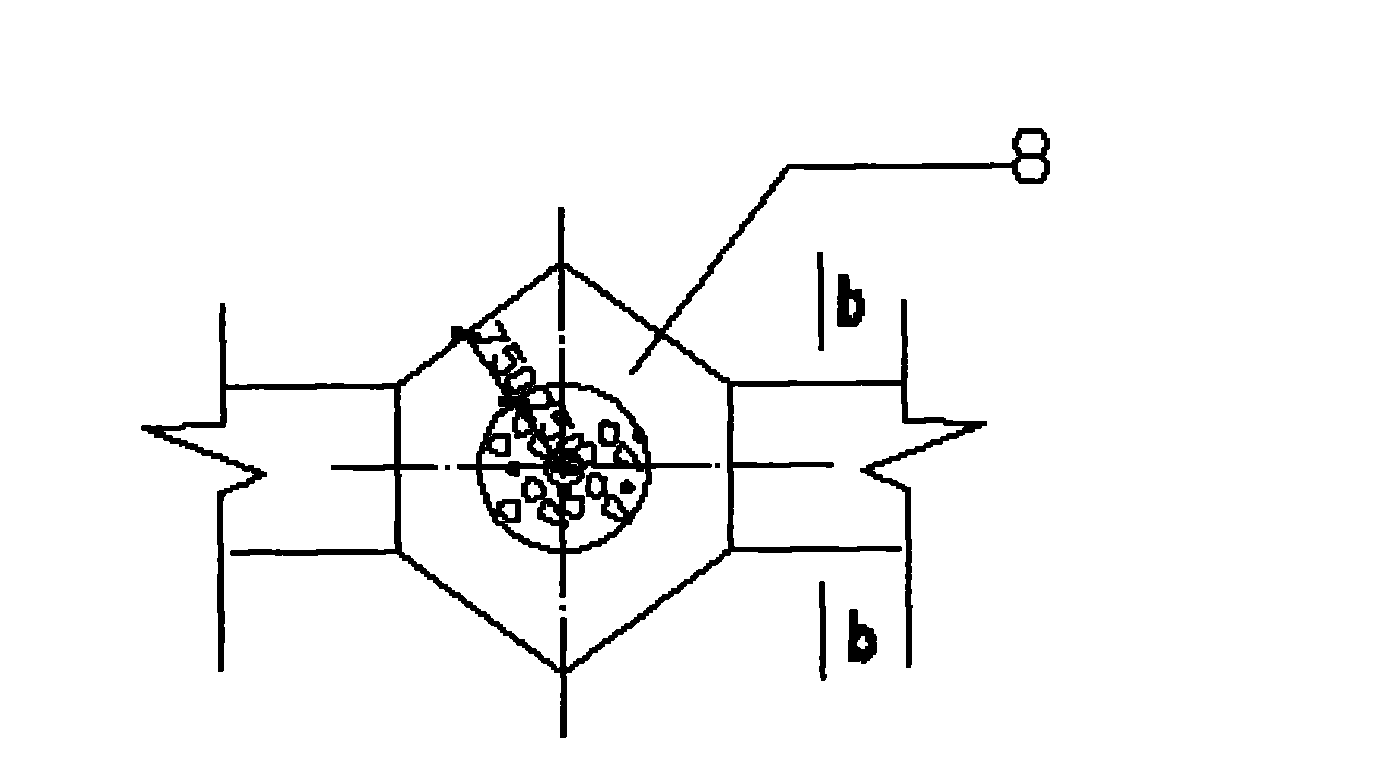

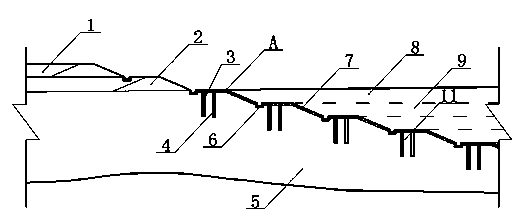

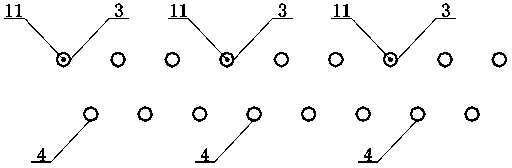

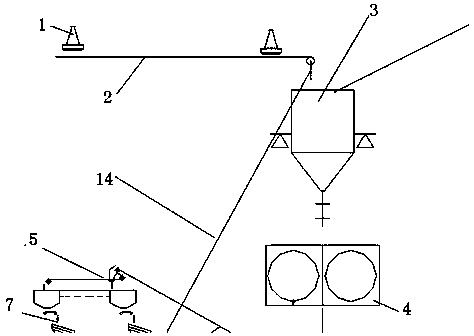

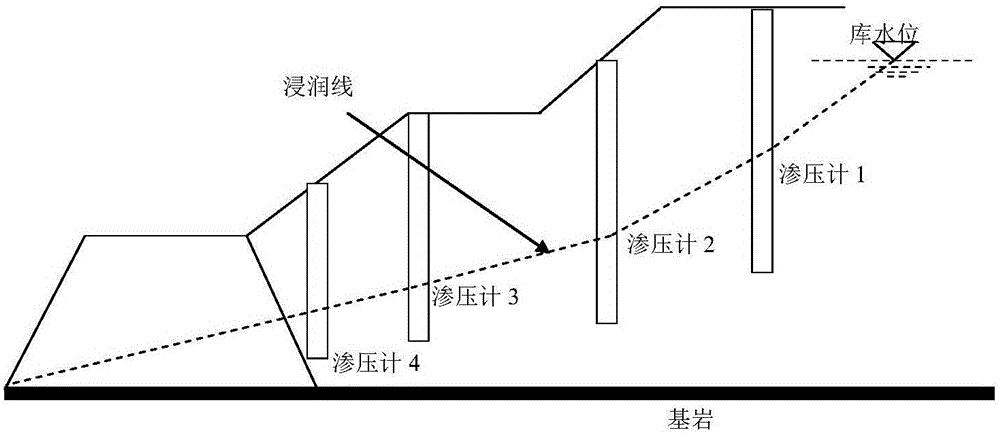

United draining system for effectively lowering seepage lines in fill dam of tailing reservoir

InactiveCN102041845AReach the design heightEliminate self-drainingSewerage structuresSewage drainingTailings damEngineering

The invention discloses a united draining system for effectively lowering seepage lines in a fill dam of a tailing reservoir, which comprises vertical draining wells, transverse draining blind ditches (2) parallel to a dam axis, as well as longitudinal draining pipes (3) perpendicular to the dam axis, wherein the transverse draining blind ditches (2) are provided with inversely trapezoidal sections, which are excavated on a tailings-deposited beach face away from a dam top by the designed distance are parallel to the dam axis, and sand gravels (4) are filled in the transverse draining blind ditches (2) after geotextile (4) is laid; the vertical draining wells are arranged at interval along the transverse draining blind ditches (2) , skeletons woven from bamboos or reinforcing mattresses or other materials with similar functions are externally wrapped with the geotextile (6) and internally filled with the sand gravels (4); and the joints of the vertical draining wells and the transverse draining blind ditches are connected to draining open ditches on a dam slope by the longitudinal draining pipes (3). A combined whole capable of draining through automatic flow is formed by adopting three-direction united drainage so that the united draining system can effectively lowers the seepage lines in the fill dam and ensure the safe running of the tailing dam.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

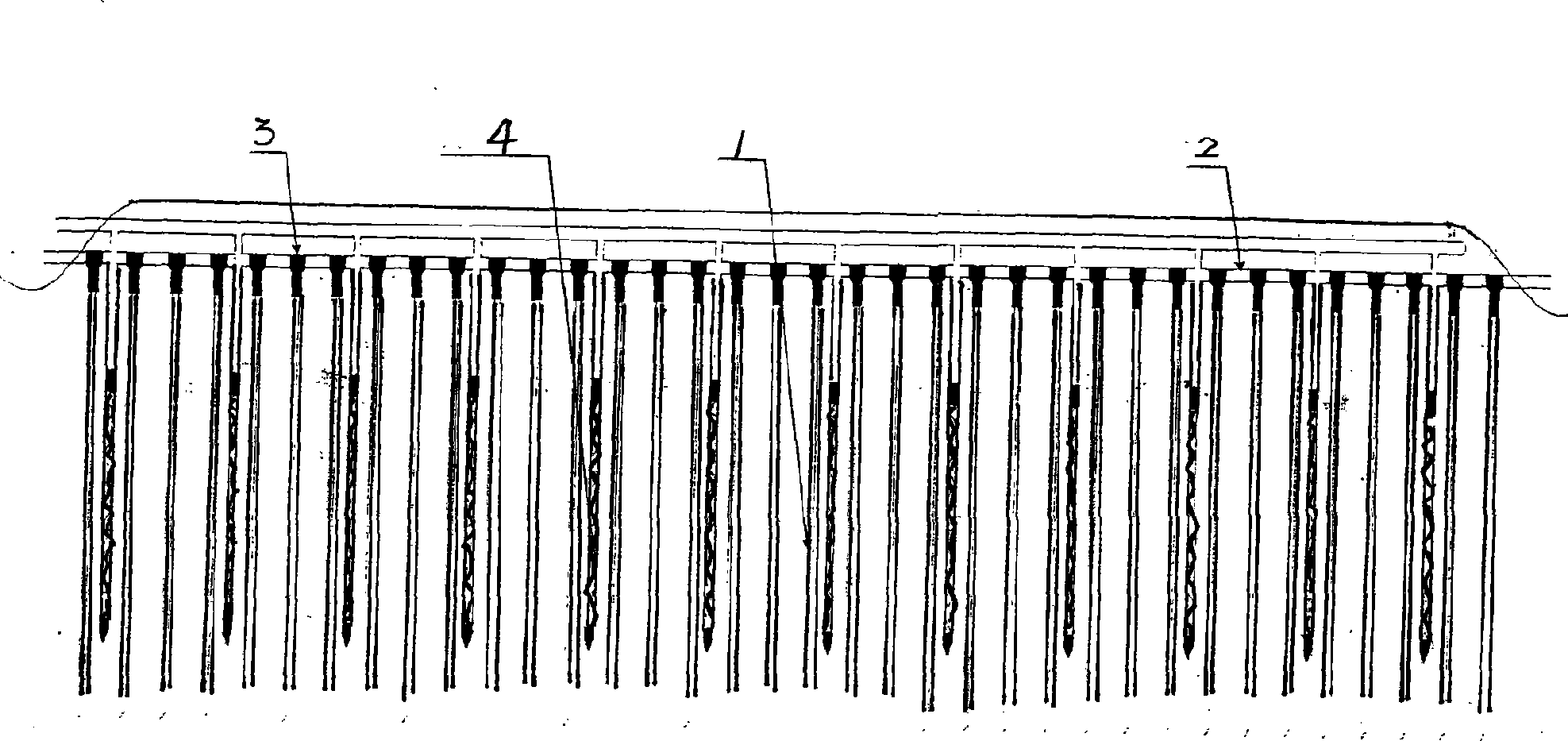

Method for processing soft land base/tail slag/lake silt by supercharging preconsolidation at vacuum

ActiveCN101418566AIncreased Consolidation DepthReinforcement time shortenedSoil preservationVacuum pumpingSoil mass

The invention relates to a method for treating a soft soil foundation / mine tailings / lake sludge by means of booster vacuum preconsolidation, which belongs to a construction method for the soft soil foundation / the mine tailings / the lake sludge, wherein insides of a plurality of rows of plastic drainage plates which are horizontally distributed inside soil mass / the slag / the sludge are subjected to vacuum pumping, and partial soil mass / partial slag / partial sludge between the plastic drainage plates is subjected to uniform supercharging simultaneously. The method can really reflect the reinforcing mechanism and the reinforcing effect of vacuum precompression on cohesive soil, tailing dam slag and the lake sludge, improves the consolidation depth by one time, shortens half of the reinforcing time, has low manufacturing cost, and is safe and effective.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

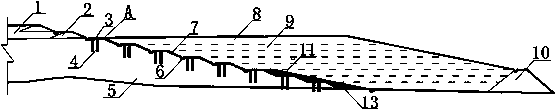

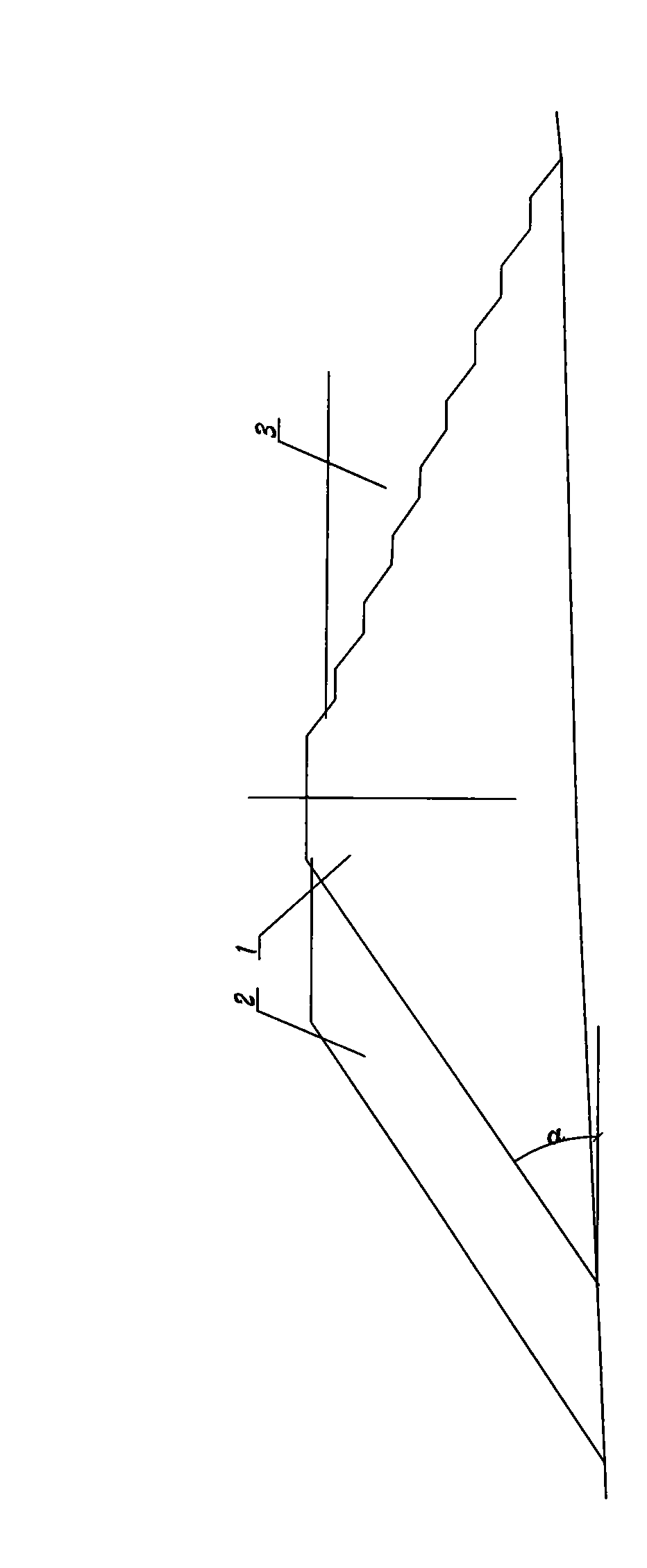

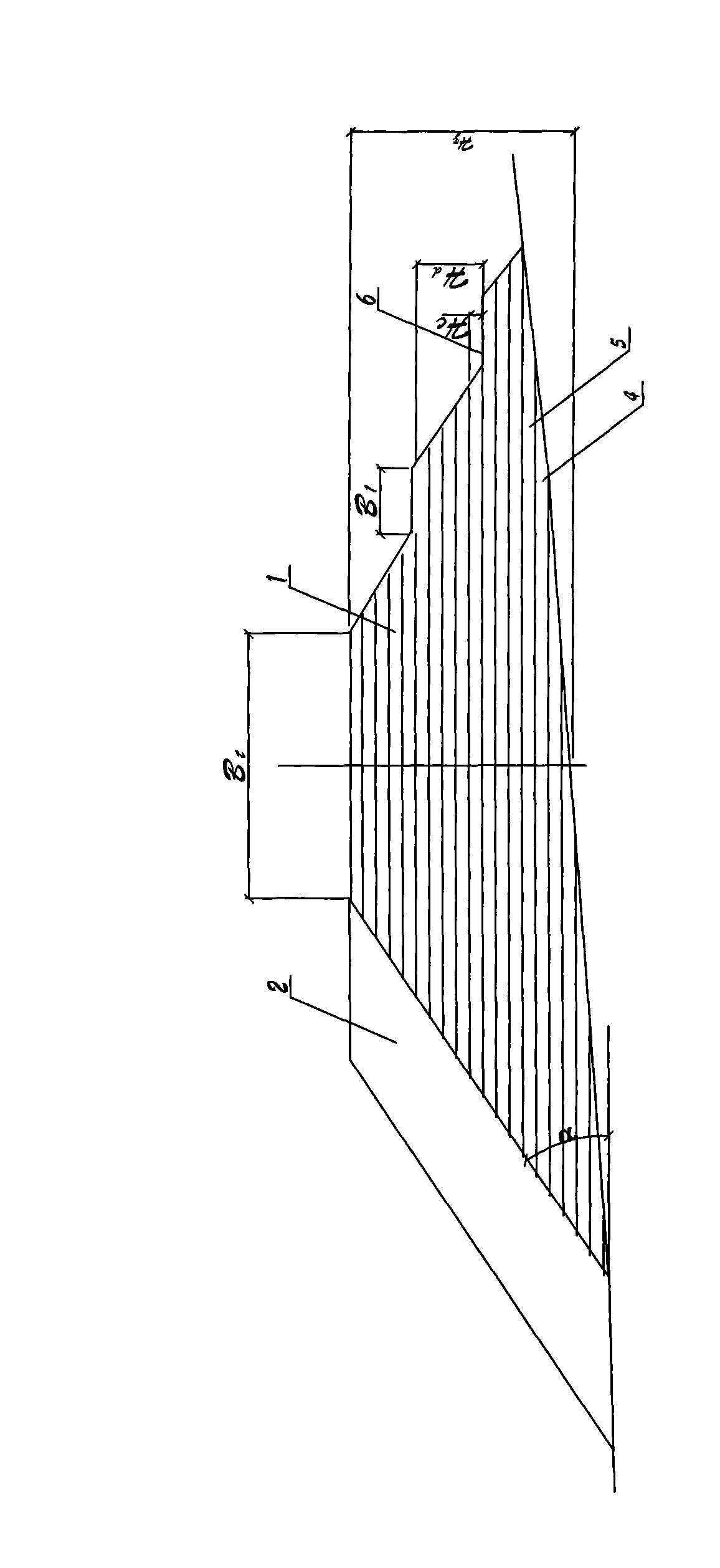

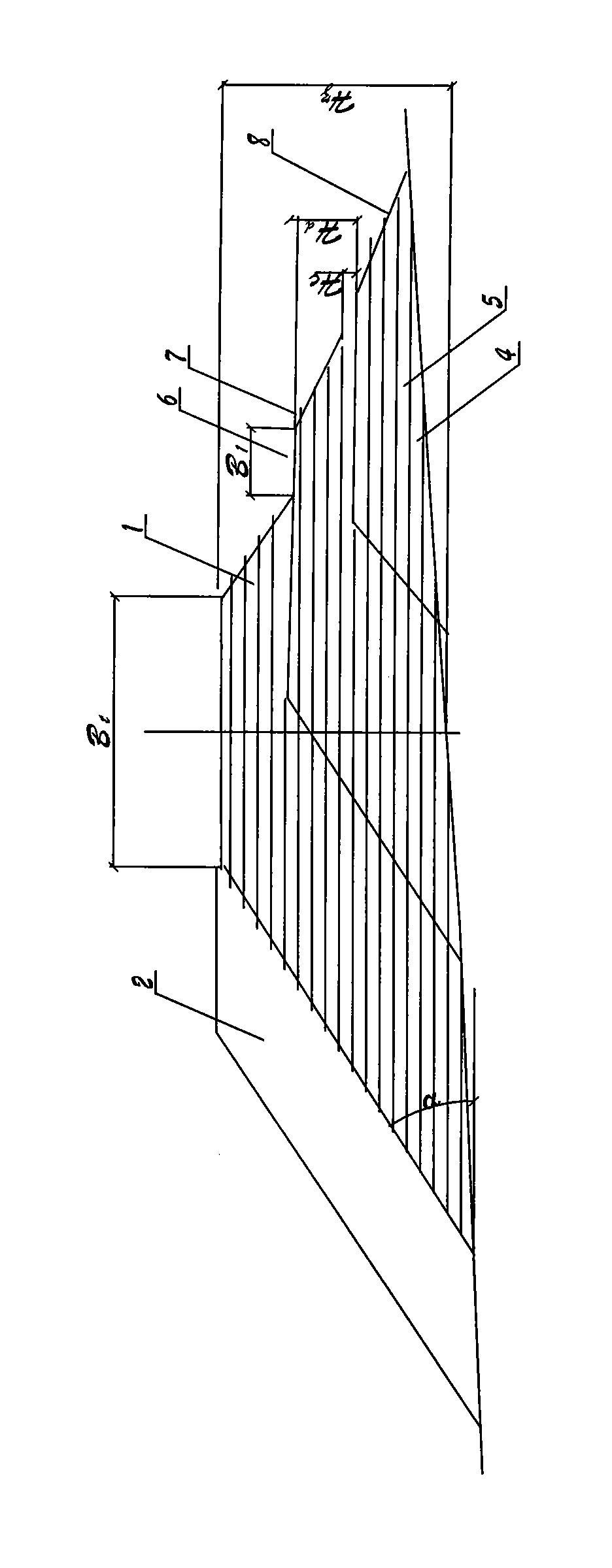

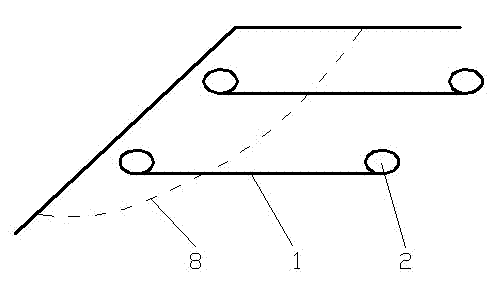

Stoping technology for dam slope tailing of tailing dam

ActiveCN103967495AAddressing Stability ImpactsGuarantee normal productionUnderground miningSurface miningTailings damMineral Sources

The invention discloses a stoping technology for a dam slope tailing of a tailing dam. The stoping technology comprises the following steps: assigning 1-2 rows of gravel piles (4) in the front of each stoping step; assigning a row of unwatering, pumping and reinforcing facilities comprising unwatering pump drainage water wells (3) and the gravel piles (4) at intervals; adopting submersible pumps to conduct groundwater pump drainage in the unwatering pump drainage water wells (3); excavating a tailing in the area on a first construction separated layer (8) of the tailing stoping in a dry type; conducting construction on slope surface protection measures (7) after the tailing stoping of the tailing pound tailing stacking dam slope; constructing tailing stacking dam side slope stepped drainage ditches (6); repeating the constructing steps, and excavating a tailing in the area on a second construction separated layer (9) of the tailing stoping of tailings stacking dam slope. The stoping technology solves the problem of safety and stability of the stacking dam side slope during tailing stoping of a valley type tailing stacking dam slope, reduces vast capital cost and land-use cost of new-building a tailing pond, realizes recovery of the most valuable tailings in the tailing pond, and improves mineral resource utilization ratio and economic benefits.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Bioremediation method for arsenic-containing tailings or waste residue

InactiveCN101992209AEliminate pollutionSmall amount of workContaminated soil reclamationRevegetationTailings dam

The invention discloses a bioremediation method for arsenic-containing tailings or waste residue. An arsenic-containing tailings dam and a waste residue pile are subjected to quick on-site remediation by artificially transplanted pteris vittata and Chinese silvergrass. The tailings dam and the waste residue pile are flattened, and bulkhead dams and gutters are established; the pteris vittata and Chinese silvergrass are transplanted to the tailings dam and the waste residue pile; in the next year, the tailings dam and the waste residue pile grow normally; and after 2 to 3 years, a stable pteris vittata-Chinese silvergrass dominant plant community can be formed, and 10 kinds of arsenic-resistant plants are naturally settled simultaneously. After the vegetation of the tailings dam and the waste residue pile is recovered, the wind erosion and water erosion are eliminated, and the arsenic content in storm dripping and filtration water of the tailings dam and the waste residue pile is reduced from 5mg / L before remediation to 100 mu g / L.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

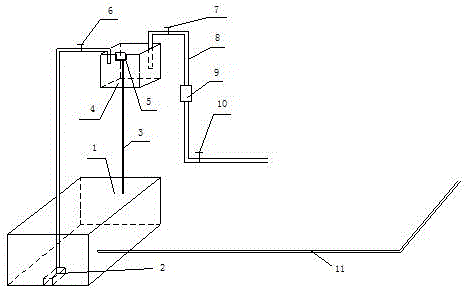

Simulation tester for similar damage of tailings dam bursting

InactiveCN101761049AImprove compatibilitySimple structureBarrages/weirsHydraulic modelsBurstingHydraulic cylinder

The invention discloses a simulation tester for similar damage of tailings dam bursting, which is provided with a simulation reservoir, and the dam of the simulation reservoir is connected with a simulation cleugh. The simulation tester for similar damage of tailings dam bursting is characterized in that the bottom of the simulation reservoir at the tail of the reservoir is provided with a jacking pushrod; the jacking pushrod is arranged on a hydraulic cylinder; the simulation cleugh consists of at least two grooves connected end to end in sequence; the neighboring grooves are connected by an adjustable joint; the dam of the simulation reservoir consists of a fixed bracket and at least one movable baffle. The simulation tester for similar damage of tailings dam bursting has the obvious effects of strong compatibility, simple structure, low cost, easy maintenance, and convenient operation, can simulate tailings reservoirs with different heights and volumes, and can all obtain the data like fluid state evolution characteristics of slurry out of the burst dam, the stress field and flow field distribution rules during the moving process of slurry, and the relationship of the alluvial fan scope of slurry and sedimentary thickness with the moving distance of slurry when facing to the grooves of the tailings dam with different bursting widths, directions and slopes.

Owner:CHONGQING UNIV

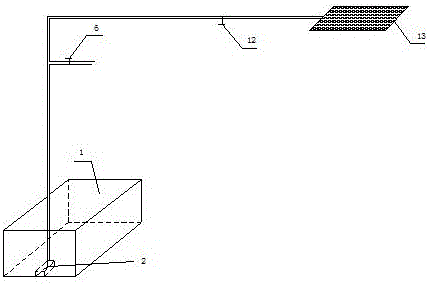

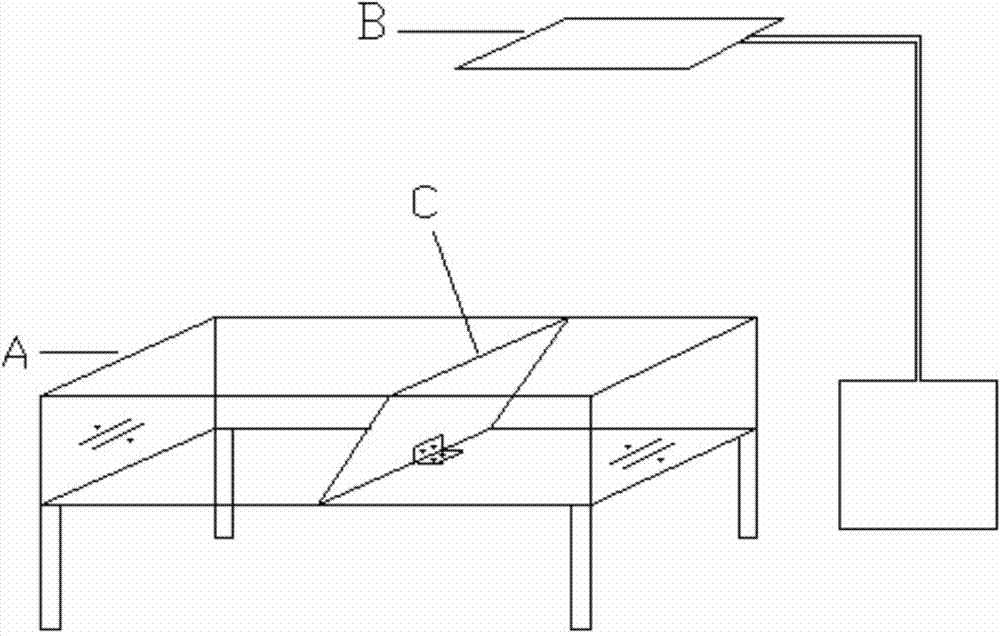

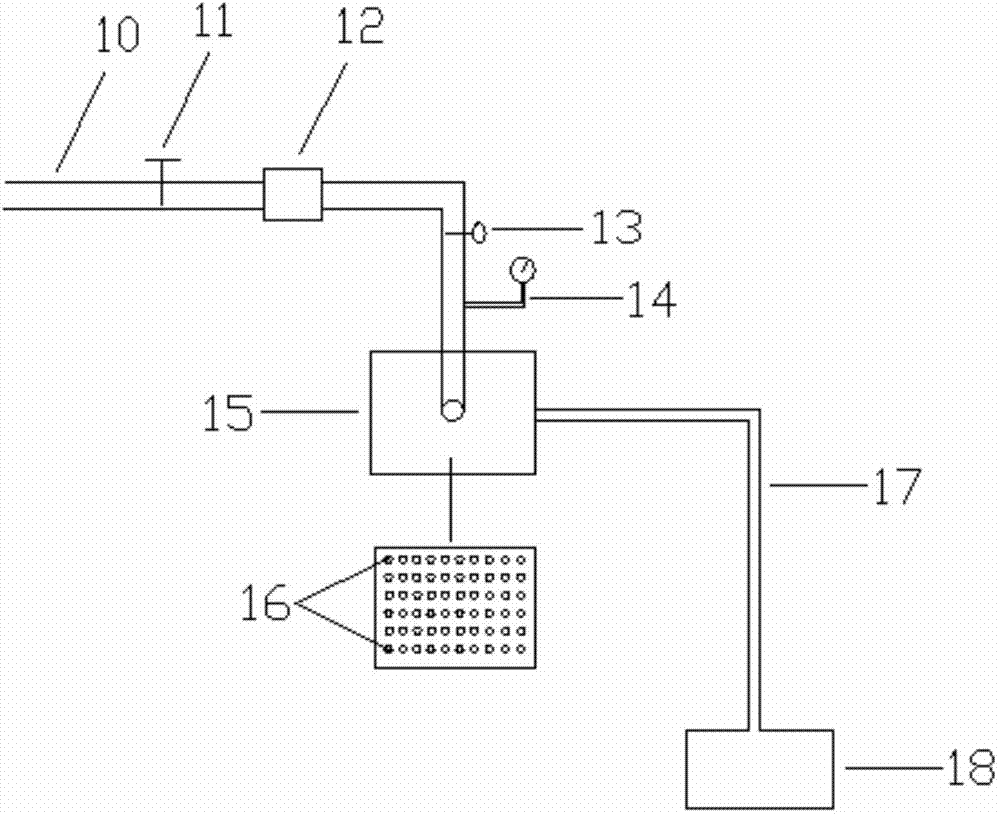

Experiment device for simulating dam overtopping of tailing dam under rainfall action and experiment method

The invention discloses an experiment device for simulating dam overtopping of a tailing dam under a rainfall action and an experiment method and belongs to the technical field of theories and experiments of the dam overtopping of the tailing dam under the rainfall action. By combining two aspects including a theoretical technology and a testing technology, a dam overtopping mechanism of the tailing dam is jointly disclosed. The experiment device comprises a water circulating and hydrostatic load applying system, a simulated rainfall system, a levelness control system and a simulated reservoir area system; when the simulated reservoir area system is used for simulating rainfall under a real field condition, a dam body attribute replacement body need to be replaced with a real material. By combining a differential hydrostatic pressure theory based on a water-crossing section shape and a similar experiment for simulating real rainfall conditions, the experiment device has the advantages of water saving and environment protection, low cost, convenience and flexibility in dynamic and static load application, flexibility of replacing the dam body attributes, high controllability and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for building tailings dam through adoption of mine dumping

ActiveCN101632993AExtended service lifeImprove utilization factorSolid waste disposalTailings damMining engineering

The invention relates to a method for building a tailings dam, in particular to a method for building a tailings dam through adoption of mine dumping. The method comprises the following steps that: a mine dumping yard and a tailings dam of a concentrating mill are combined; the mine dumping is adopted for directly building the tailings dam; a layered damming method or a strip damming method is implemented; after the tailings dam is formed, the inner side of the tailings dam is a tailings warehouse; and the outer side is a dumping yard. As mine dumping technology and damming technology of the tailings dam of the concentrating mill are combined, the method can greatly reduce the area occupation of the dumping yard, enlarge the utilization coefficient of the tailings warehouse and overcome the disadvantages of the prior damming construction method of the tailings warehouse and the difficult problems of sand lifting of tailings sand and the like; and meanwhile, after a mine stops production, under the condition that the mine dumping cannot be used for building the tailings dam, the concentrating mill can also utilize waste stone of the dumping yard to continue building the tailings dam. The process is suitable for the tailings warehouses of a valley type, mountain-surrounding type, flat type, cut-off river type and other types, is also suitable for building the tailings dam of the concentrating mill of other industries, is also suitable for newly building the tailings dam of the concentrating mill and is also suitable for building the tailings dam of the concentrating mill in course of production.

Owner:ANSTEEL GRP MINING CO LTD

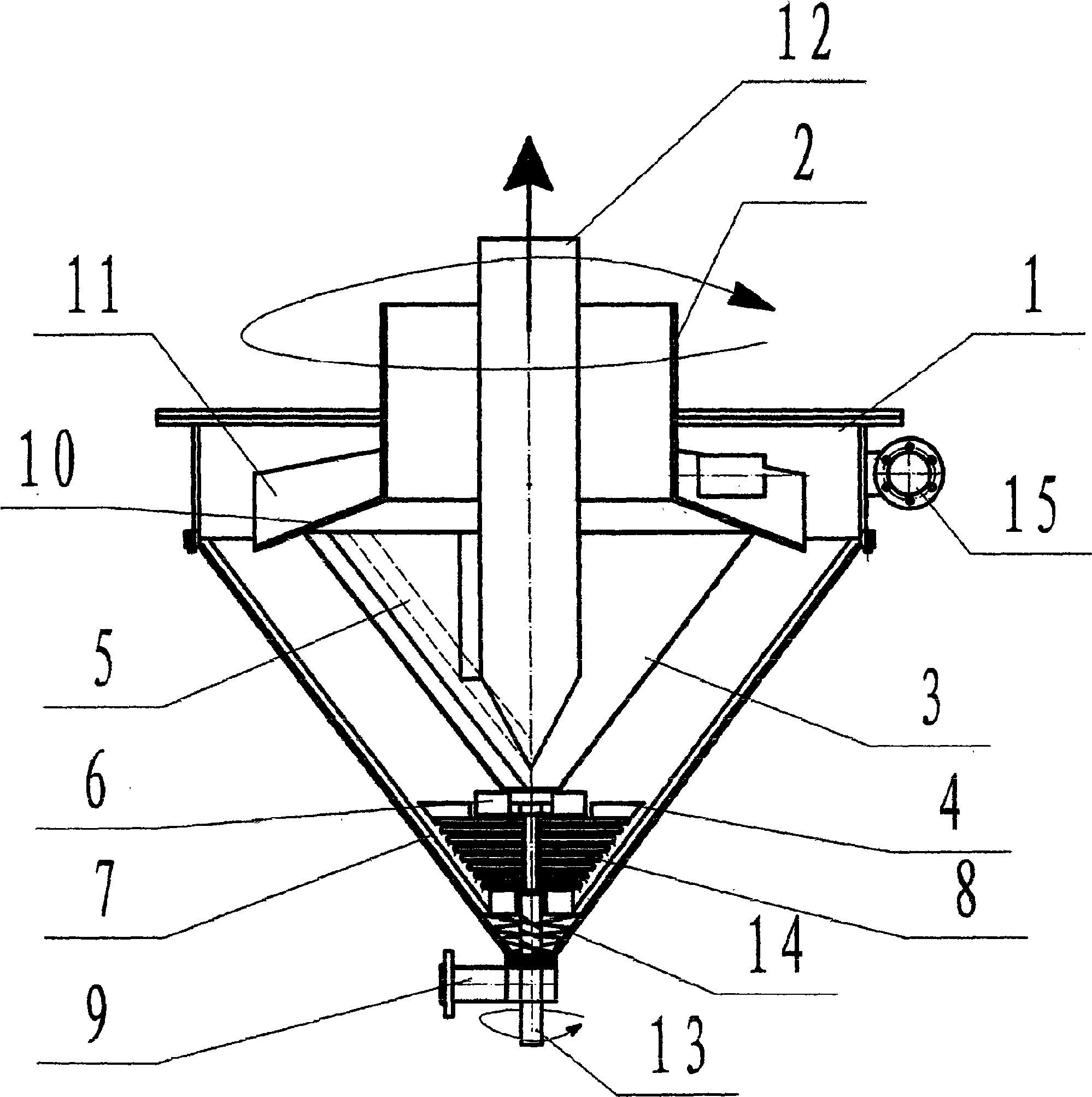

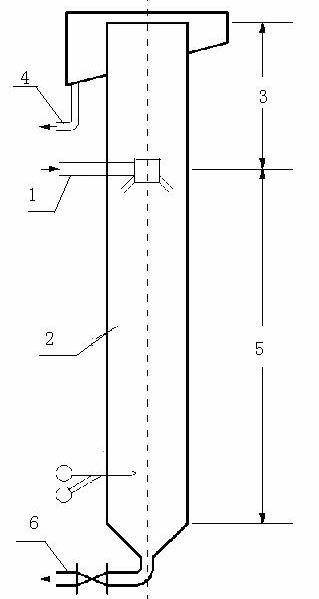

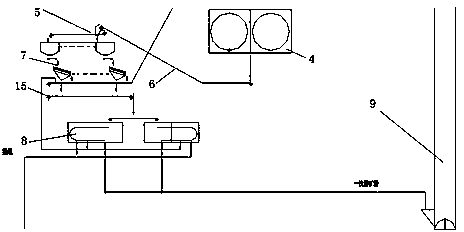

Solid-liquid separating device and solid-liquid separating process with filtering and air separating machine

InactiveCN101543694AHarm reductionReduce the total project investmentFiltration circuitsTailings damSlag

The invention relates to a solid-liquid separating device and a solid-liquid separating process with a filtering and air separating machine. The solid-liquid separating device consists of a sedimentation tank 1, a central hollow shaft 2, a filtering device 3, a swirl flow pressboard 4, a self-cleaning device 5, a stop plate 6, a slag guide device 7, an air separating device 8, a slag outlet 9, a limiting flat cone plate 10, a flow guide centrifugal device 11, a vacuum tube 12, a hollow shaft 13, a helical extrusion device 14 and a tailing inlet 15. The solid-liquid separating process with a filtering and air separating machine can greatly improve solid-liquid separation quality, discharge water molecules under the action of a high-pressure air flow, allow ultrafine particles to enter space between large particles, achieve close combined by extrusion, make the dewatering more complete and more cleanly, and greatly reduce the infection density of a tailing dam and project invention.

Owner:LUOYANG HUAYE GENERAL MACHINERY COMPLETE MFG

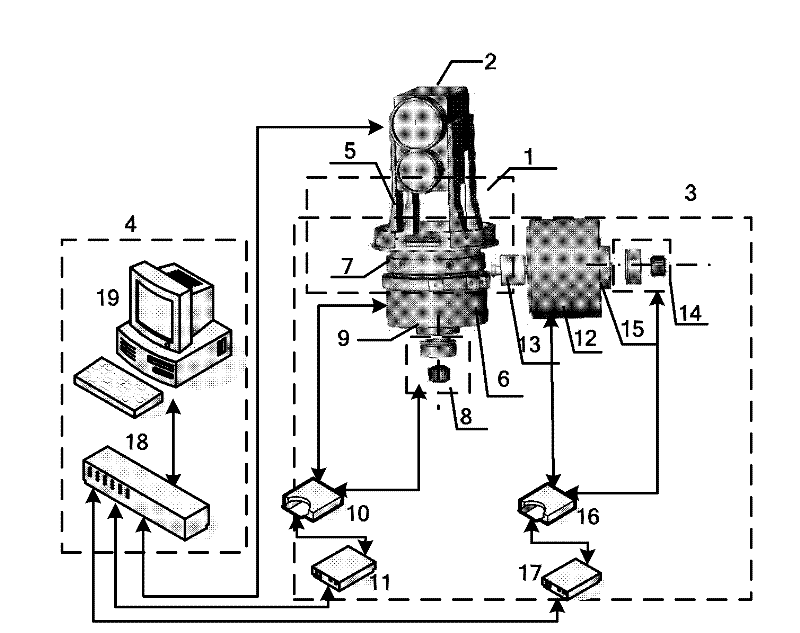

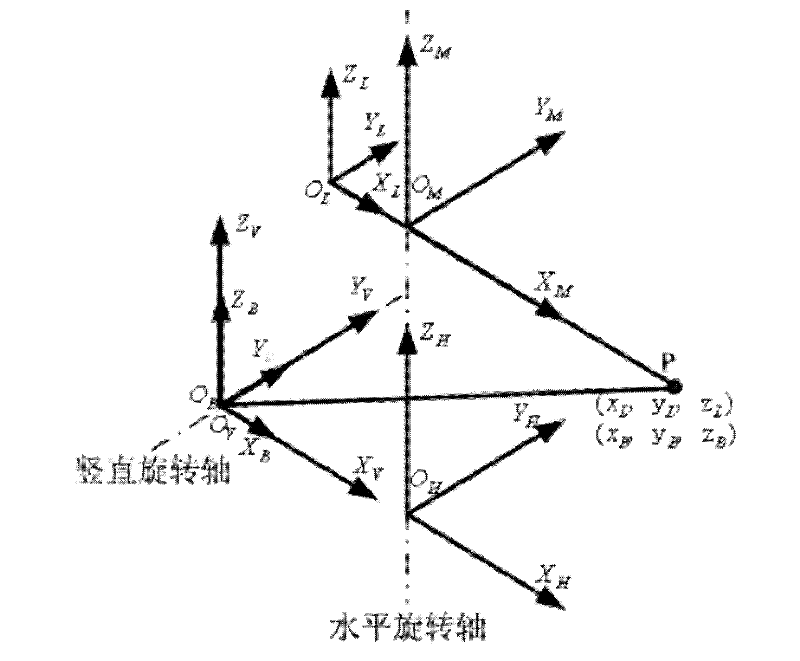

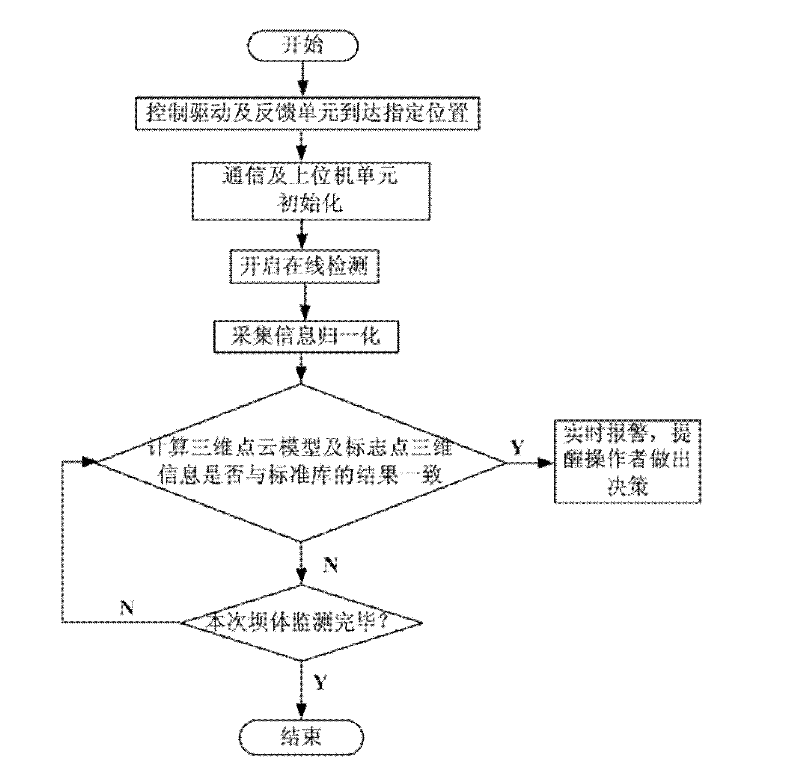

Dynamic monitoring system device for tailing dam body by three-dimensional laser scanning

InactiveCN102410834AImprove reliabilityEasy to detectSurveying instrumentsTailings damData acquisition

The invention discloses a dynamic monitoring system device for a tailing dam body by three-dimensional laser scanning. The dynamic monitoring system device mainly comprises a mechanical unit, a laser data acquisition unit, a control driving and feedback unit, and a communication and upper computer unit. In the device, the laser data acquisition unit is used for acquiring scene polar radius information of the surface of the tailing dam body; the control driving and feedback unit is used for driving the laser data acquisition unit to rotate in the horizontal dimension and vertical dimension, toscan the large scene on the surface of the tailing dam body at a constant speed and to acquire angle information in the horizontal dimension and the vertical dimension in real time; the communicationand upper computer unit is used for transmitting the acquired distance information and the acquired angle information to an upper computer through a high-speed data acquisition card; and software of the upper computer is used for processing the scene polar radius and the rotation angle information in the horizontal dimension and the vertical dimension to recover a real three-dimensional image of the scene, building a tailing dam body standard point cloud model in an ideal state, and storing the model into a database as an intelligent monitoring comparison template. During dynamic scanning of the device, qualitative and quantitative estimation for unexpected disasters is realized by using a dynamic monitoring algorithm through comparison with the template; operators and managers can immediately start corresponding emergency plans to avoid further expansion of the disasters.

Owner:BEIHANG UNIV

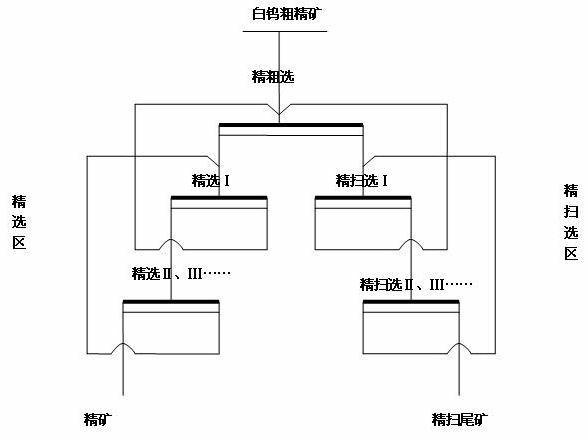

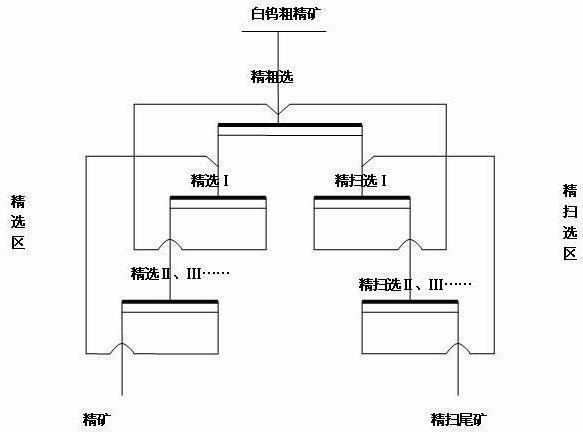

Flotation process adopting flotation column to regrading scheelite instead of flotation machine

InactiveCN102658241AHigh degree of automationSimple structureFlotationTailings damMining engineering

The invention belongs to the technical field of scheelite flotation, and discloses a flotation process adopting a flotation column to regrading scheelite instead of a flotation machine, wherein, the flotation column technology is adopted in scheelite regrading after the scheelite is processed through rough concentration; rough concentrate is regraded repeatedly; well-chosen tailings are also processed through fine scavenging for a plurality of times by adopting the flotation column so as to obtain scheelite concentrate with high grade, that is, the rough concentrate is obtained after rough concentration; ore slurry that is concentrated is then processed through heating, reagent removal and size mixing, so that the ore slurry can enter the flotation column for fine roughing when the contraction of the ore slurry ranges from 20 to 30 percent; foam products obtained in the fine roughing enter a regrading area comprising at least one flotation column and are regraded once or repeatedly, so as to obtain high-grade scheelite concentrate; and the tailings obtained in the fine roughing enter a fine scavenging area, and the tailings that are processed through fine scavenging are conveyed to a tailing dam or return for scheelite roughing. The flotation process can obtain scheelite concentrate with higher grade, the operation energy consumption of the flotation column is low, the mineral dressing index is increased, the labor environment can be improved, the labor intensity is reduced, and smoother production can be ensured.

Owner:CHINA MOLYBDENUM

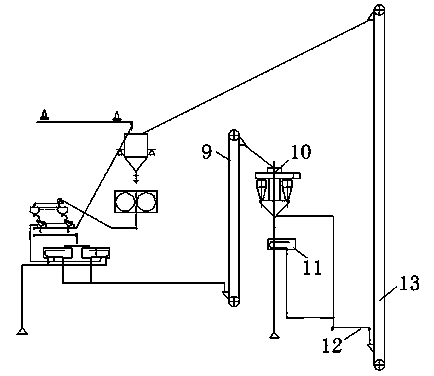

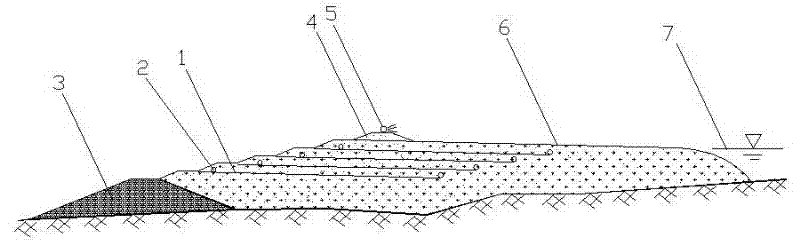

Dry heaping and wet discharging combined tailing heaping and discharging method

ActiveCN103397645AGuaranteed continuitySolve the heap problemBarrages/weirsEmbankmentsTailings damWater discharge

The invention discloses a dry heaping and wet discharging combined tailing heaping and discharging method. Tailing slurries are discharged from a dressing plant (10), part of the tailing slurries enter a pressing and filtering dehydration workshop (9) to be dehydrated and filtered, dry tailings are used for piling up a dry tailing dam (5), the left tailing slurries are transferred to the inner side of the top of the dry tailing dam (5) to be discharged into a tailing bank, and wet tailings (2) are deposited on the upstream slope of the dry tailing dam (5); at the beginning of the formation of the dry tailing dam (5), a cofferdam (4) used for blocking the wet tailings (2) and floods is arranged on the inner side of the bottom of the dry tailing dam (5); a horizontal water discharging member (6') between the bottom of the dry tailing dam (5) and a dam base (7), and a prismatic water discharging member (6) is arranged at the downstream slope toe of the dry tailing dam (5). By the method of heaping and discharging granule tailings, the problem of difficulty in piling up the dam with the granule tailings can be solved, mine construction speed can be increased, tailing tank investment and operation cost are reduced, and economic benefits of the mine are improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Seepage drainage method for tailing dam and seepage drainage pipe for use therein

ActiveCN1963040AEliminate accidentsEliminate safety hazards such as dam failuresExcavationsSoil preservationTailings damOutcrop

The invention discloses a eliminating outcrop water method of tailing dam and it includes the following steps: drilling hole: drilling hole as required depth, angle and direction in the tailing dam to forming the pore path leading to the top of the dam from the lower; pulling the tubes: pulling the specially-produced drainage pipes into the pore path drilled in the tailing dam; decortication: taking off the outer layer of protective layer of drainage pipes. The specially-produced drainage pipes of the method comprise of the body pipe, the gauze and the protective layer which are prepared out the body pipe one by one, said body pipe is equipped with percolating water groove along the axial center direction of pipe body uniformly and the bottom of percolating water groove is equipped with percolating water holes which reach the inner of pipe body discontinuously. The invention is facilitating to construction, the effect of drainage is fine and it is good for eliminating the hidden danger of the tailings dam is in danger, cave-in collapse and breaking.

Owner:付文堂

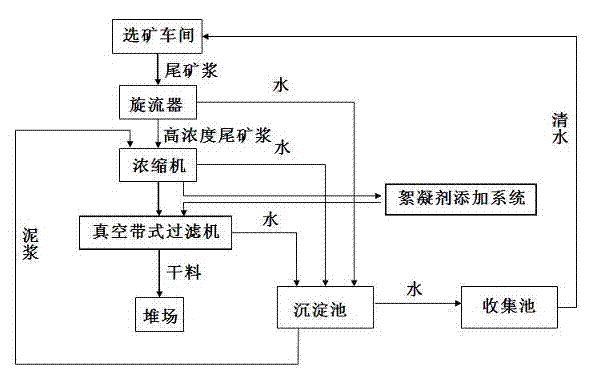

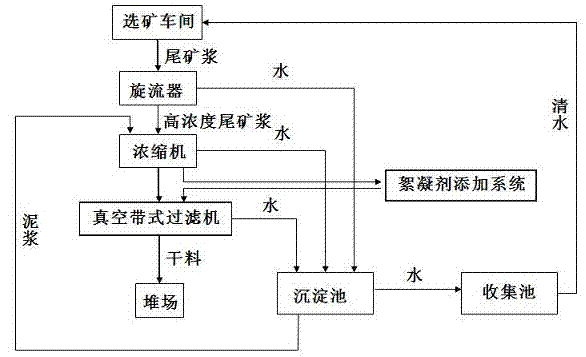

Dehydration method and device of tailings

ActiveCN102228762AEliminate the risk of dehydrationAvoid accidentsFiltration circuitsCycloneTailings dam

The invention relates to a dehydration method and a dehydration device of tailings. The dehydration device mainly comprises a cyclone, a thickener, a vacuum belt filter and a sedimentation basin. A tailing slurry discharged from an ore dressing workshop go through the cyclone, the thickener and the vacuum belt filter in order to form dry materials which are placed in a stock dump. And a flocculating agent adding system is installed between the thickener and the vacuum belt filter. The sedimentation basin is connected to a collection basin used for collecting the clear water overflowing from the sedimentation basin, and then the clear water come into the ore dressing workshop for recycling. With the dehydration method and dehydration device of tailings, risks from dehydration with a tailing dam can be eliminated, so that accidents are effectively avoided. Meanwhile, the device of the invention has low investment, low running cost and high dehydration rate.

Owner:YUNNAN DAHONGSHAN PIPELINE

Magnetite beneficiation method

InactiveCN103736663APerfect development conditionsReduce constructionSolid separationTailings damMining engineering

The invention relates to the field of beneficiation, in particular to a magnetite beneficiation method. Through technological closed cycle production, technological path is shortened, and production and transport costs are remarkably saved; energy is saved by 0.5-1 degree / ton; plant construction area is reduced; building of tailings ponds is reduced due to dry discarding. By the beneficiation method, large-scale tailings discarding before milling is realized, milling grade is remarkably improved, and technical parameters of ball-milling magnetic separation sections are changed thoroughly. The magnetic-gravitational beneficiation process can be applied to preconcentration of low-grade ore, ore resources are pre-concentrated, the milling grade is improved, and beneficiation cost is reduced; the magnetic-gravitational beneficiation process can also be applied to recleaning of tailings to recover the tailings relatively concentrated on dry slope sections of tailings dams; the magnetic-gravitational beneficiation process can be further applied to powdered iron purification of dressing plants to discard lean intergrowth and gangue in powdered iron, product grade is improved, and technical additional value of products of the dressing plants is increased. The magnetic-gravitational beneficiation process substitutes for the wet-type magnetic separation process and is a qualitative leap for dry-type preconcentration and tailings discarding of beneficiation of mines.

Owner:陕西三沅重工发展股份有限公司

Experiment device and experiment method for overtopping failure simulation for tailing dam

The invention relates to an experiment device and an experiment method for overtopping failure simulation for a tailing dam, which belong to the field of mine geotechnical engineering. The experiment device disclosed by the invention comprises a simulated experiment container, a simulated rainfall device and a gradient change device, wherein the simulated rainfall device is installed above the simulated experiment container. The experiment device disclosed by the invention is capable of simulating the overtopping failure conditions for the tailing dam under different rainfall intensities and different tailing dam slope angles.

Owner:CHONGQING UNIV +1

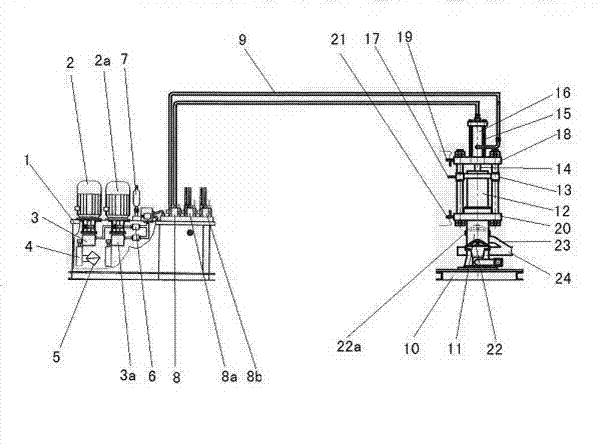

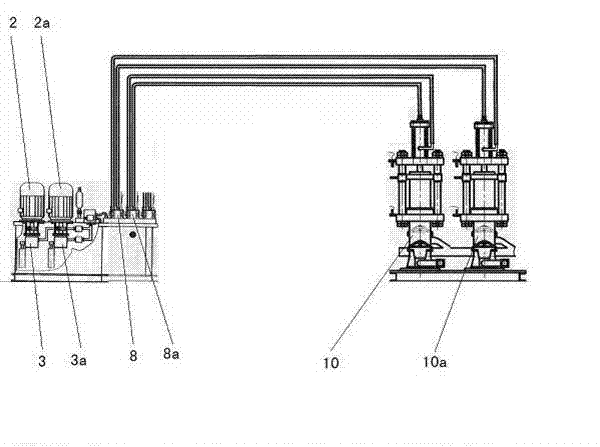

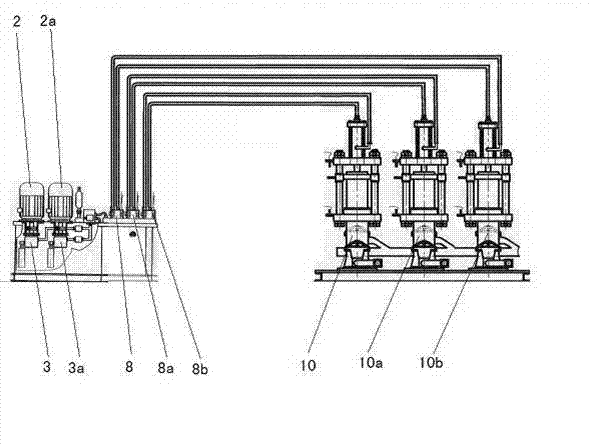

Slurry pump exclusively for bauxite ore washing tailing slurry dry method processing and processing system and method thereof

InactiveCN103047101AExtended service lifeGuaranteed passabilityPiston pumpsPositive-displacement liquid enginesHydraulic cylinderTailings dam

The invention belongs to the technical field of slurry pump and discloses a slurry pump exclusively for bauxite ore washing tailing slurry dry method processing and processing system and method thereof. The slurry pump is substantially characterized in that the slurry pump includes a fuel tank which is provided with driving motors and fuel pumps, electromagnetic directional valves are arranged on the fuel tank, an electromagnetic directional valve is connected with a ceramic plunger pump unit, a pump cylinder body of a pump individual is provided with a ceramic plunger, the ceramic plunger with a carriage on the top is connected with a cylinder piston of a hydraulic cylinder through a transmission rod, a vortex board is arranged on the carriage on the top of the ceramic plunger, and proximity switches which match with the vortex board and are connected with the electromagnetic directional valve are arranged on a upper beam of a the hydraulic cylinder base and on a lower beam which is on the upper portion of the pump cylinder body. According to the slurry pump, sealing effects are good, slurry can pass through a miter valve smoothly and no sand are retained, an electromagnetic directional mechanism enables a plunger pump and a fuel supply station to be installed in a spit mode, remote control of the fuel supply station and pumps are achieved, large flow delivery of pumps are achieved, bauxite ore washing tailing slurries can be processed with no tailing dam construction required, and dry method processing and exhausting is achieved.

Owner:杨德平

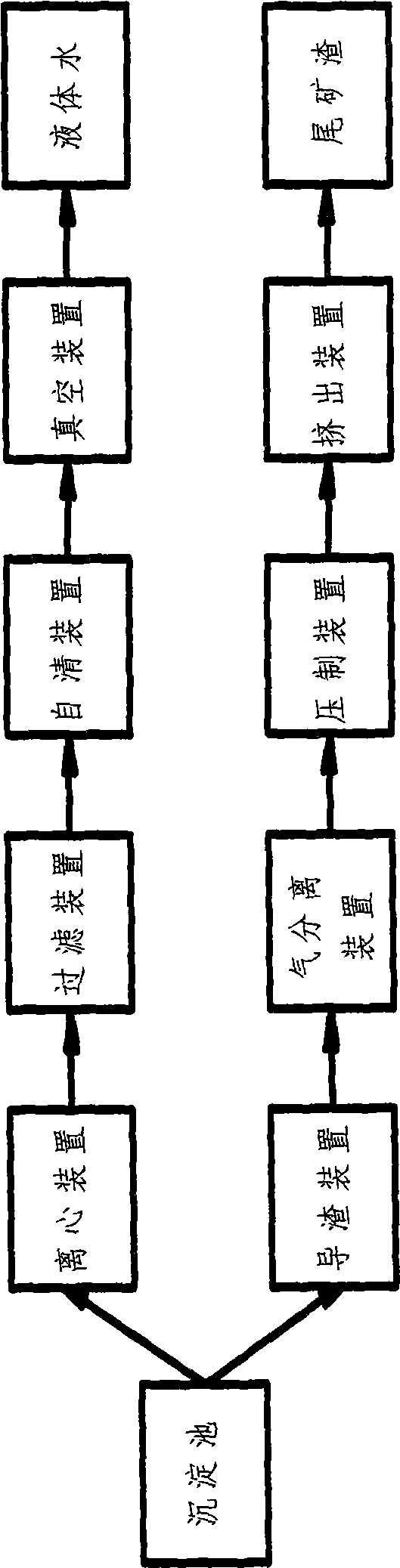

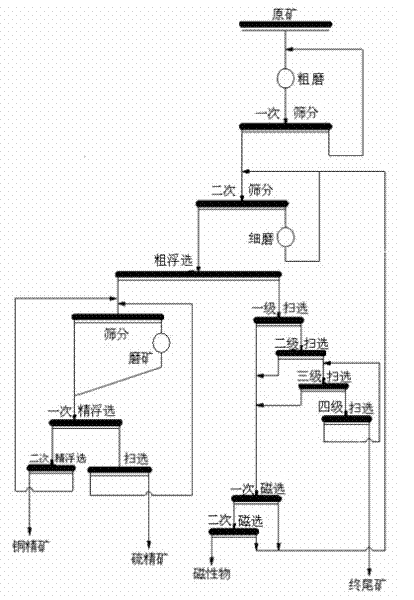

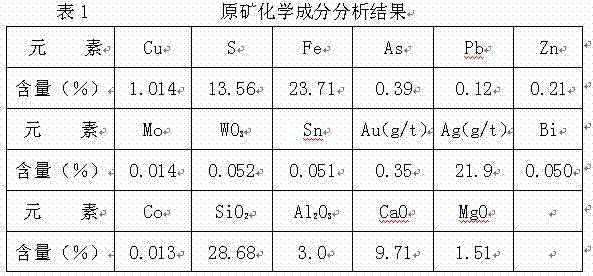

A comprehensive treatment method for mixed copper ore

The invention provides a comprehensive treatment method for mixed copper ore, which successfully separates sulfur concentrate and copper concentrate through the process steps of rough grinding, screening, fine grinding, rough flotation, fine flotation, magnetic separation, and sweeping. , so as to obtain high-quality copper concentrate, and then select a large amount of pyrrhotite from the middling ore through the magnetic separation step, which minimizes the iron and sulfur content of the middling ore, and can make the middling ore a high-quality Good sulfur concentrate can be directly used as raw material for sulfuric acid production, and the tailings after magnetic separation can be returned to the system for circular production, so that valuable resources can be fully recycled, and the tailings are discharged to the tailings dam after multi-stage screening Storage, to overcome the problems of heavy production load caused by the return of tailings, low concentrate grade and low recovery rate, the comprehensive recovery rate of copper is over 80%, the concentrate grade is over 19%, and the gold content of copper concentrate is 6g / t Above, the gold recovery rate is over 45%, the copper concentrate contains more than 418g / t of silver, and the silver recovery rate is over 50%.

Owner:YUNNAN DIQING MINING DEV

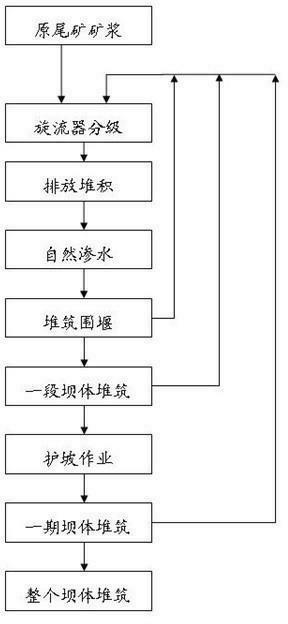

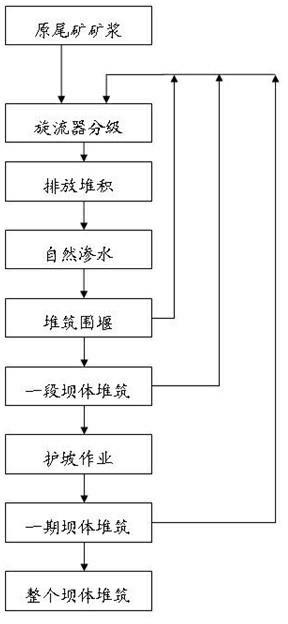

Tailing dam damming method

InactiveCN102535480APile up fasterEnhanced safety technical conditionsEmbankmentsCycloneTailings dam

The invention provides a tailing dam damming method, which includes: a, producing coarse sand for damming by utilizing a cyclone to screen original tailing pulp; b, discharging and stacking screened coarse sand at the damming position naturally, screening for 2 to 4 days, stopping screening for 1 to 2 days when the coarse sand cannot be discharged and stacked naturally, discharging original tailing pulp into a tailing pond, dewatering deposited coarse sand naturally until the water content of the coarse sand for damming is smaller than 20%; c, constructing a coffer at the damming position and enclosing a space for stacking coarse sand continuously, repeating classification-dewatering-coffer constructing for 6 to 10 times and damming a dam section; d, repeating the above steps, performing slope protection for an inner slope and an outer slope so that the gradient of the outer slope of the tailing dam is controlled by 1:3 integrally and further completing the first-stage damming of the dam body; and e, damming the next-stage dam body by raising the center axis of the dam body of the first stage. The tailing dam damming method has the advantages that the height of the dam body can be increased greatly at one time, safety technical conditions of the tailing pond can be enhanced, and damming quantity and cost can be reduced.

Owner:JIANGXI COPPER

Method for calculating length of dry sand of tailings reservoir based on image recognition

InactiveCN101718527AMeet detection errorImprove recognition accuracyCharacter and pattern recognitionUsing optical meansTailings damDry sand

The invention discloses a method for calculating the length of the dry sand of a tailings reservoir based on image recognition, which comprises the following steps: binarizing a dry sand image of the tailings reservoir through image recognition technology so that the dry sand image is more simple, a data size is reduced and the outlines of a dam body of a tailings dam and the dry sand are shown; processing and analyzing the binarized dry sand image and utilizing pixel detection technology to calculate and analyze the height of the dry sand to further analyze accurate required data results; and finally utilizing the recognized height of the dry sand and a slope to calculate the length of the dry sand of the tailings reservoir. In the method, the image recognition technology is utilized to accurately divide the dry sand image of the tailings reservoir; data obtained by analysis and calculation is accurate; the accuracy of the calculated length of the dry sand is relatively higher and real-time property is relatively stronger; and the requirements of the online and real-time monitoring of the length of the dry sand of the tailings reservoir are met.

Owner:DANDONG DONGFANG MEASUREMENT&CONTROL TECHCO

Soil culture medium suitable for growth of plant on metallurgy tailings dam and preparation method of soil culture medium

InactiveCN102659482AStrong corrosion resistanceAvoid churnSeed coating/dressingFertilizer mixturesPorosityTailings dam

The invention discloses a soil culture medium suitable for growth of a plant on a metallurgy tailings dam and the preparation method of the soil culture medium. The soil culture medium consists of a component A and a component B, wherein the component A is clean water, and the component B is prepared by compounding the following components by weight percent: 30%-38% of clay, 18%-25% of montmorillonite, 36%-40% of organic substances, 3% of slow release fertilizer, 1%-3% of stabilizer, 0.35%-0.85% of granulation agent and 0.5%-3% of plant seeds. The soil culture medium provided by the invention is great in porosity and good in water and fertilizer conservation, can complex heavy-metal ions, reduces the salinity and alkalinity of the soil, increases the content of the organic substances in the soil, provides various nutrients required by the growth of the plant, can solve the problems of poor vegetational type stability, insufficient soil replacement raw materials, over-high cost and the like in the biological reparation of the existing tailings pond, and has good environment benefit and social benefit.

Owner:青岛冠中生态股份有限公司

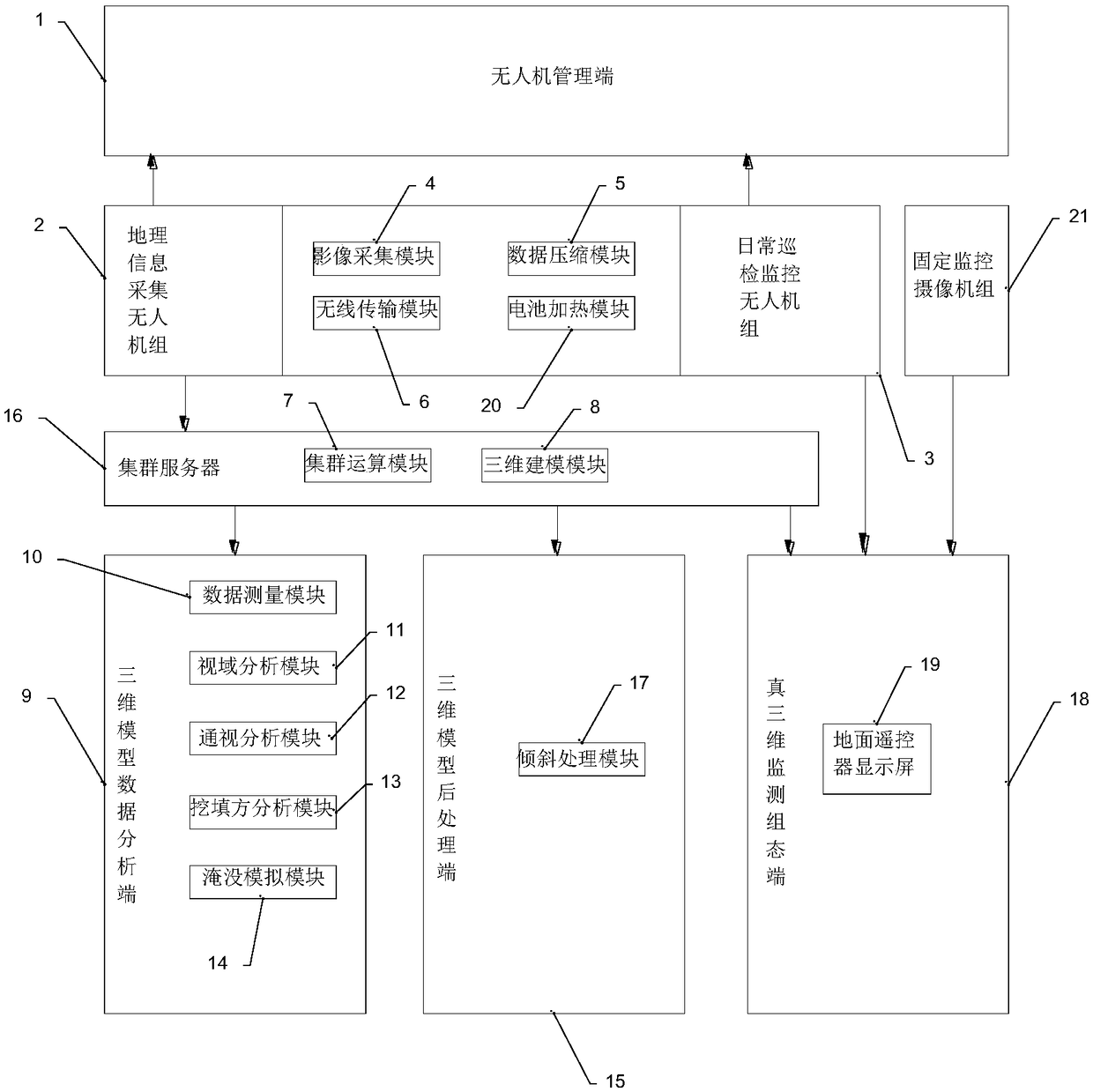

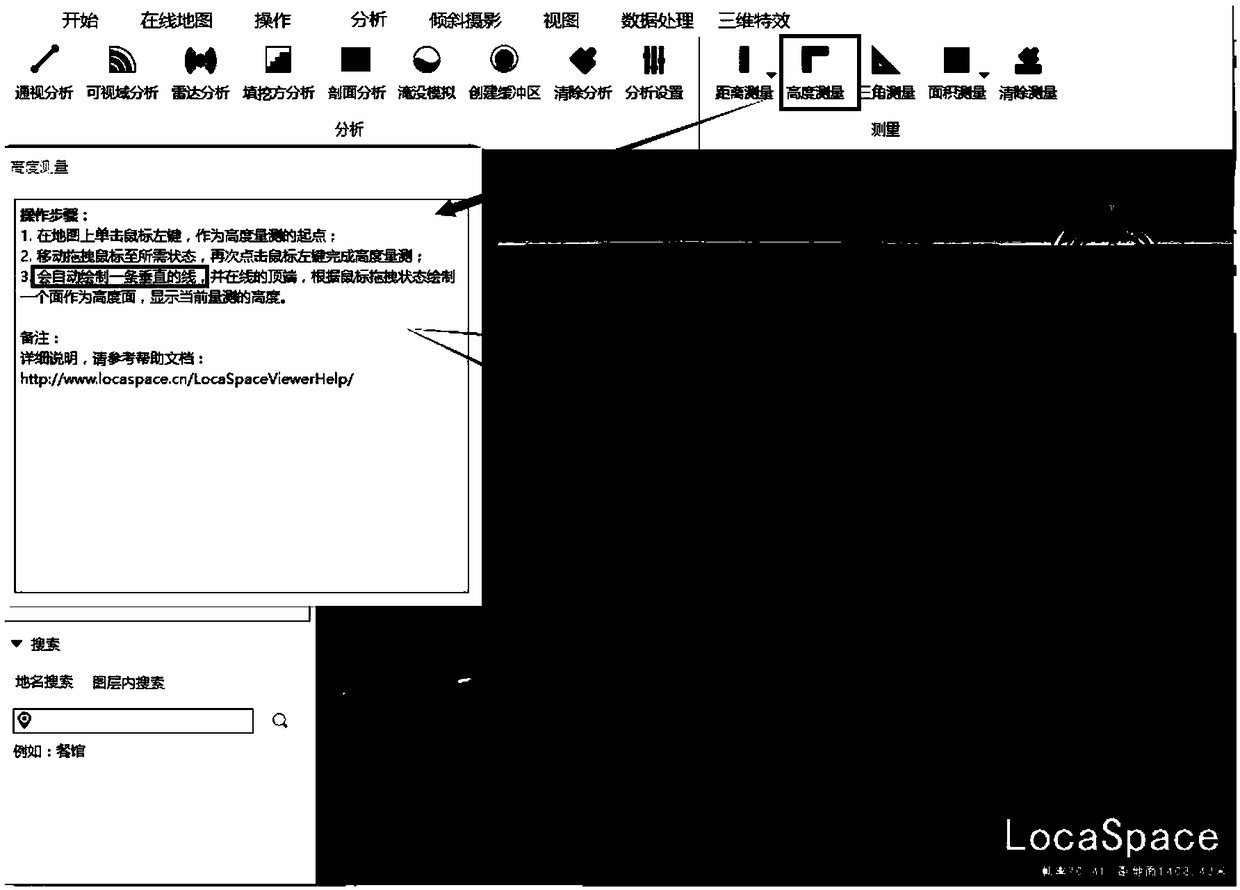

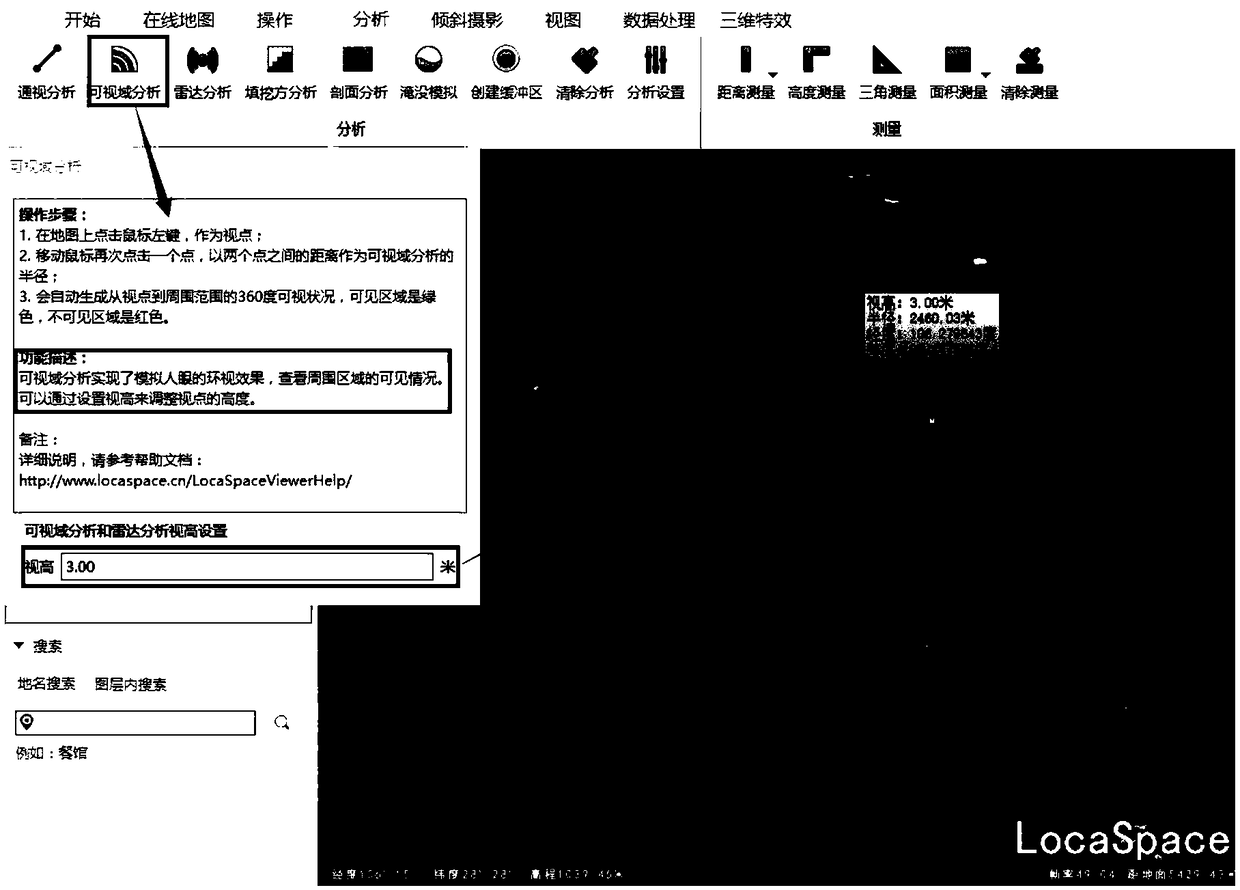

Security monitoring system and method of tailings pond based on unmanned aerial vehicle and three-dimensional modeling technology

InactiveCN109269555AEasy to add and deleteEasy maintenanceTelevision system detailsDetails involving processing stepsData compressionTailings dam

The invention provides a security monitoring system and method of a tailings pond based on an unmanned aerial vehicle and a three-dimensional modeling technology. An image acquisition module is used for acquiring geographical information of a to-be-detected tailings pond; a data compression module is equipped with an encoder supporting an onvif protocol and used for compression coding of an acquired video signal, an audio signal and a data signal of the to-be-detected tailings pond; a wireless transmission module is equipped with antennas of 2.4 GHz and 5.8 GHz frequency bands and used for wireless data transmission between a geographical information acquisition unmanned aerial vehicle group and a daily tour inspection monitoring unmanned aerial vehicle group; a cluster operation module isused for performing cluster operation image processing on obtained image geographical information data of the to-be-detected tailings pond; and a three-dimensional modeling module is used for performing aerotriangulation resolution and remodeling on the obtained geographical information data of the to-be-detected tailings pond. According to the system and method, all-weather monitoring of surrounding environments including onsite transmission tail pipelines, tailings dams, water lines, phreatic lines, and tailings ponds without dead angles can be realized.

Owner:空中梦想(北京)科技有限公司

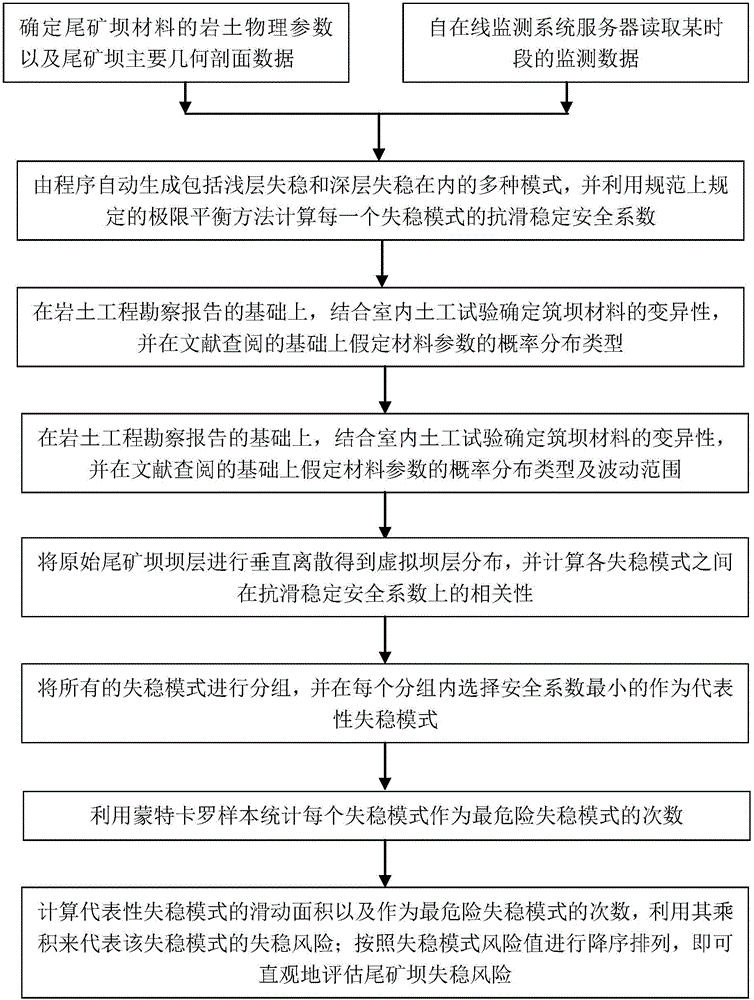

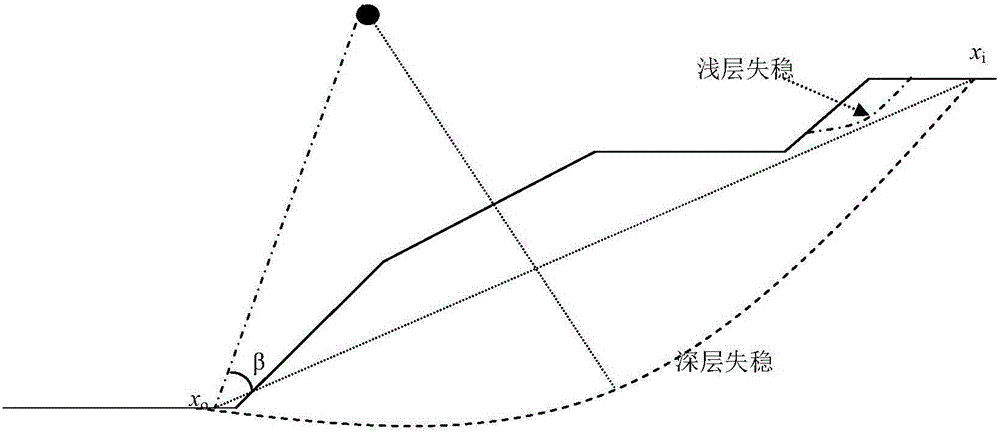

Real time monitoring data-based mine tailing dam instability risk evaluating method

ActiveCN105913184AInstability risk assessment method scienceThe instability risk assessment method is intuitiveResourcesTailings damInstability

The invention relates to a real time monitoring data-based mine tailing dam instability risk evaluating method and belongs to the technical field of special-purpose digital computation or data processing methods. The method helps overcome defects of technologies of prior art that cannot be applied to determining magnitude of dam slope instability risk, risk sources and the like. According to the real time monitoring data-based mine tailing dam instability risk evaluating method, based on a condition that monitoring data is obtained and a representative instability mode is determined; failure probability and slide area of all instability modes are used for determining instability risk thereof, mine tailing dam instability risk can therefore be quantified, mine tailing dam instability risk can be evaluated mostly based on the monitoring data, mode grouping is realized and the representative instability mode is selected according to correlation of anti-sliding stability safety factors of shallow-layer and deep-layer instability modes, and frequency and a glide plane of the representative instability mode which is regarded as an instability mode with maximum danger are used for evaluating risk in a quantified manner. The real time monitoring data-based mine tailing dam instability risk evaluating method is characterized by scientific property, visual property, reasonability and feasibility; scientific basis is provided for mine tailing dam operation safety management and risk control.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

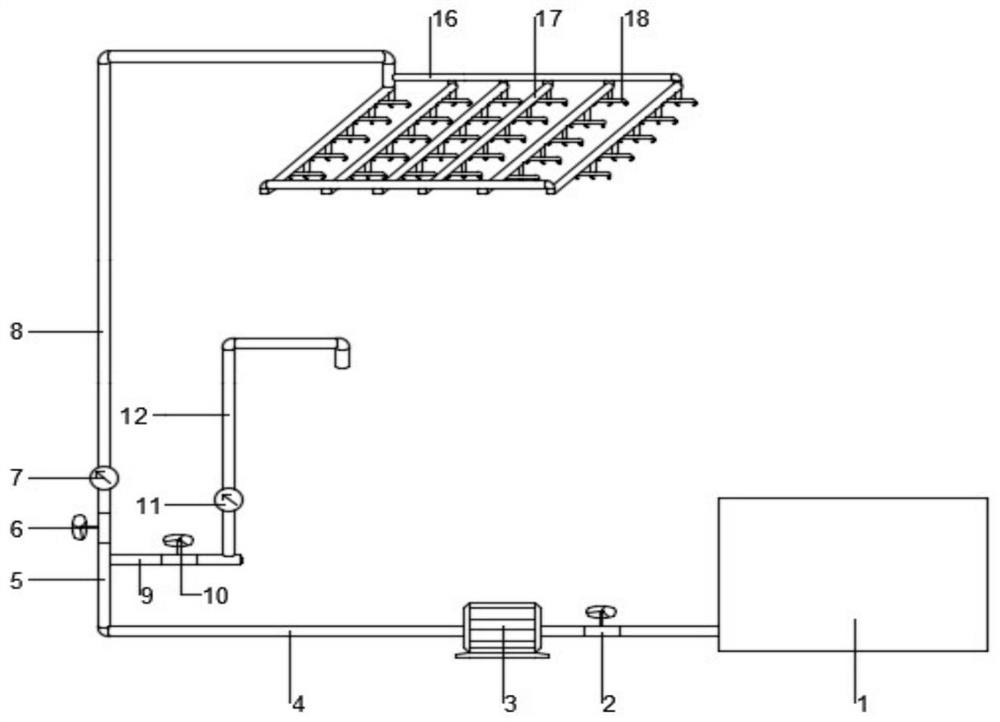

Experimental device for monitoring whole process of instability disaster of discrete fill dam

PendingCN111855443ARealize Simulation StudiesImprove the efficiency of simulation experimentsWeather/light/corrosion resistanceHydrodynamic testingWater useRainfall simulation

The invention relates to an experimental device for monitoring the whole process of an instability disaster of a discrete fill dam, and belongs to the technical field of geotechnical engineering. Thedevice comprises a water supply device, a rainfall simulation device, a support device and a dam body damage and dam break debris flow motion experiment device. The water supply device provides required water for experiments, the rainfall simulation device is used for simulating rainfall working conditions, the support device is used for supporting the rainfall simulation device and mounting ultrasonic equipment, and the dam body damage and dam break debris flow movement experiment device is mainly used for completing dam body damage and dam break debris flow (flood) movement process research.According to the invention, the evolution process from dam body damage to dam break debris flow (flood) of a tailing dam or a homogeneous earth dam in a downstream river channel can be simulated andresearched under the conditions of rainfall, flood overtopping and piping, parameters such as dam body damage degree, dam body pore water pressure, dam body deformation, dam break debris flow (flood)impact force, flow speed and submerging height are recorded through automatic monitoring equipment, and research on dam body damage and disaster-causing processes is achieved.

Owner:KUNMING UNIV OF SCI & TECH

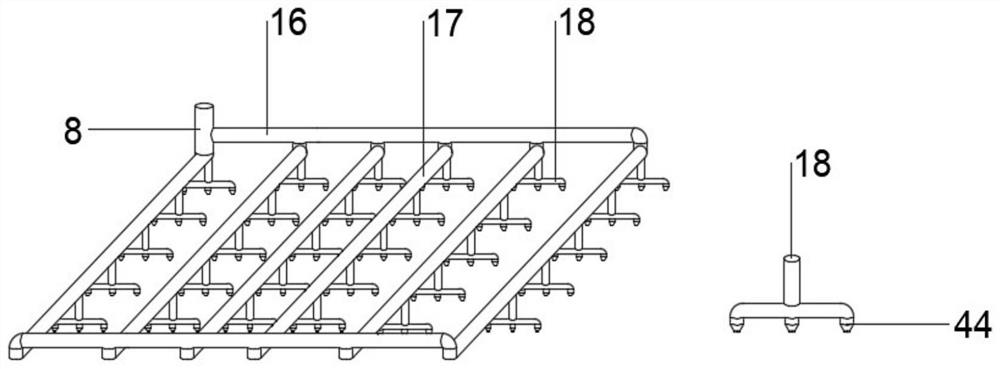

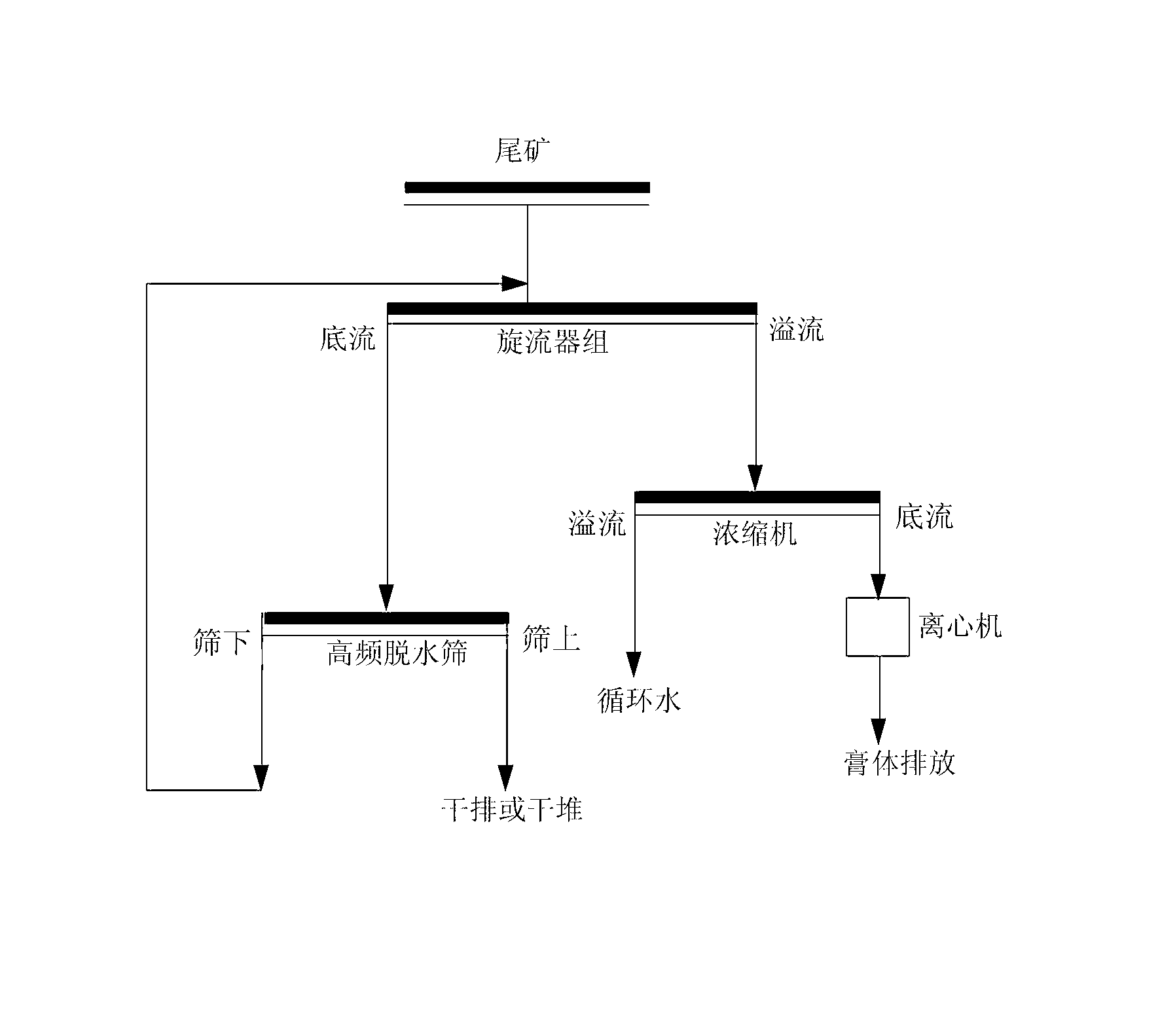

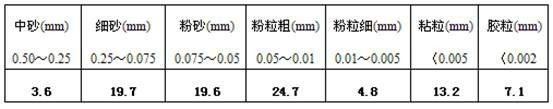

Conveying technology for iron tailing paste

InactiveCN103272686AImprove delivery efficiencyEliminate potential safety hazardsSpecific fluid pumpsSolid separationTailings damMining engineering

The invention relates to a conveying technology for iron tailing paste. The conveying technology comprises the steps of classifying tailings with the concentration of 15%-20% through a cyclone to form coarse-grain products with the concentration of 55%-65% and fine-grain products with the concentration of 10%-15%, base flow coarse-grain products classified by the cyclone are fed to a high-frequency dewatering screen, products over the high-frequency dewatering screen are tailing dry sand with the concentration of 80%-85%, while products below the high-frequency dewatering screen return to the cyclone to form a closed cycle. The conveying technology is characterized in the overflow fine-grain products classified by the cyclone are conveyed to a feeding box of a paste thickener through a slurry pump and flow into the paste thickener automatically, overflow water of the paste thickener returns to a concentrating mill and is reused as circulating water after being clarified through a clarifying tank, and paste thickener base flow slurry with the concentration of 65%-75% and the size fraction of -200 meshes and larger than 95% is conveyed to a tailing dam through a centrifugal pump. The conveying technology has the advantages that after implementation of the technology, the conveying efficiency of the iron tailing paste is improved effectively, operation costs of devices are low, the operation is easy, and elimination of potential risks of tailing ponds is facilitated.

Owner:ANSTEEL GRP MINING CO LTD

Damming method for tailing dam

InactiveCN102182193ASafe and stable operationSolve the problem of insufficient lengthSolid waste disposalEmbankmentsTailings damEngineering

The invention discloses a damming method for a tailing dam and relates to a method for directly embanking the tailing dam by adopting fine-grain tailings. The method is characterized in that a die bag filled with tailing sand is adopted for embanking a dam body during the damming process. In the damming method for the tailing dam, the die bag method is adopted for stacking the dam by adopting the tailings, the median grain diameter of the tailings can be fully utilized, and the properties of being water permeable and non-slurry permeable of the die bag are utilized, thereby having the advantages of being fast in drainage and consolidation speed and being conductive to fast damming, and effectively solving the difficult points in stacking of the dam by adopting finer grains; furthermore, the process is mature, the operation is simple, the damming can be performed while performing production, and the production is not affected, thereby being a big progress in comparison with the traditional upstream method for damming.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method of Reinforcement of Tailings Accumulation Dam with End Scroll Geogrid

InactiveCN102261076AIncrease the reinforcement forceImprove reinforcementEmbankmentsSoil preservationEffective solutionTailings dam

Owner:CHONGQING UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com