Slurry pump exclusively for bauxite ore washing tailing slurry dry method processing and processing system and method thereof

A dry processing, bauxite technology, applied in pumps, piston pumps, liquid variable capacity machines, etc., can solve the problems of low flow efficiency, flocculation failure, easy oil leakage, etc., and achieve stable flow efficiency and conveying pressure. Stable and extended service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

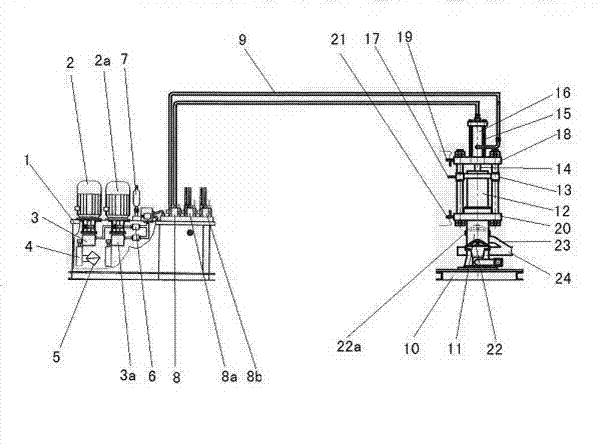

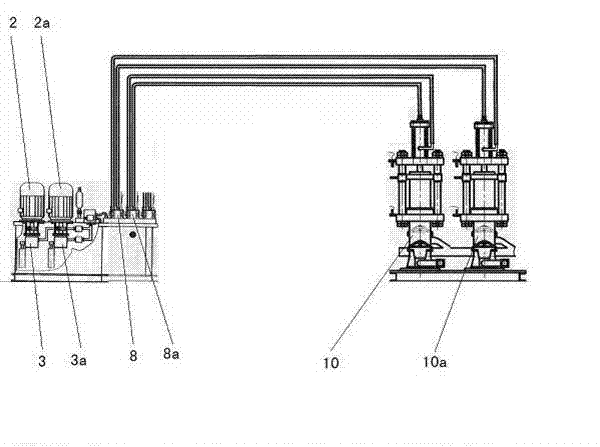

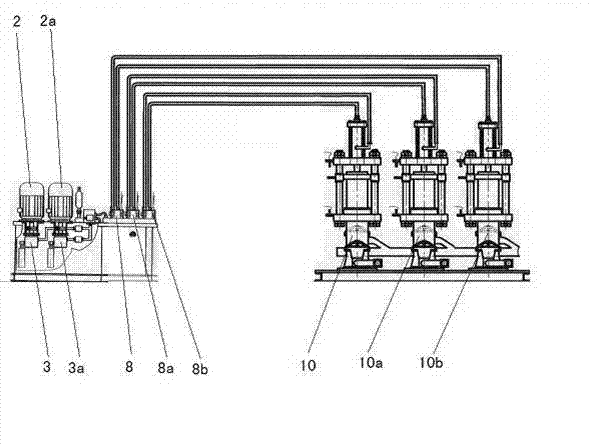

[0049] The specific structure of the special mud pump for dry processing of bauxite washing tailings slurry according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0050] Such as figure 1 As shown, the special mud pump for dry treatment of bauxite washing ore tailings slurry in the present invention includes an oil tank 1, and the oil tank 1 has two sets of drive motors 2, 2a and oil pumps 3, 3a, and one end of the oil pump 3 is connected with an oil filter 4, a cooling 5, the other end is connected with a one-way oil valve 6, and the oil tank 1 is provided with an accumulator 7 and three electromagnetic reversing valves 8, 8a, 8b, one of which is connected to a pump unit through a high-pressure oil pipe 9 The ceramic plunger pump group composed of body 10 is connected. The pump cylinder body 11 of the pump unit 10 has a ceramic plunger 12, and the ceramic plunger 12 with a carriage 13 on the top is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com