Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130 results about "Bauxite tailings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamed ceramic material and preparation method thereof

The invention discloses a foamed ceramic material and a preparation method thereof. The method for preparing the foamed ceramic material comprises the step of: crushing, forming, firing and swelling an ingredient composed of tailings, feldspar, a foaming agent, a foaming regulator and a fluxing agent, wherein the tailings are at least one of iron ore tailings with 60 weight percent of silicon oxide, quartz tailings, kyanite tailings and bauxite tailings. According to the method for preparing the foamed ceramic material, the foamed ceramic material can be prepared by the tailings, so that the high added values of the tailings are utilized. In addition, the prepared foamed ceramic material has the advantages of excellent performances like small density, high strength, low water absorption rate, low heat conduction rate, no combustion, long service life and the like.

Owner:NEW METALLURGY HI TECH GRP

Low-density ceramsite supporting agent and preparation method thereof

InactiveCN102876315AQuality improvementLight in massFluid removalSodium BentoniteExpanded clay aggregate

The invention discloses a low-density ceramsite supporting agent prepared by using bauxite tailings and a preparation method for the low-density ceramsite supporting agent. The low-density ceramsite supporting agent is prepared from the following raw materials in part by weight: 100 parts of calcined bauxite tailings, 1 to 2 parts of bentonite, 1 to 2 parts of chromite and 10 to 15 parts of non-calcined bauxite tailings. The production method comprises the following steps of: calcining and smashing the calcined bauxite tailings, smashing the bentonite, the bentonite and the non-calcined bauxite tailings, adding the materials into the calcined bauxite tailings, preparing ball materials, drying, and sintering to obtain the product. According to the method, the waste bauxite tailing is used as a main raw material, and the high-quality low-density ceramsite supporting agent can be produced by performing secondary sintering and rationally adding auxiliary materials; the preparation method is simple and low in production cost; and resources can be used to the greatest extent.

Owner:SHANXI FANGXING REFRACTORIES CO LTD

Baking-free cylindrical attapulgite fire-retarding ceramsite

The invention discloses baking-free cylindrical attapulgite fire-retarding ceramsite. The key point of the technical scheme is that the baking-free cylindrical attapulgite fire-retarding ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, granulated blast-furnace slag powder, iron tailing powder, coal gangue powder, bauxite tailing powder, kieselguhr tailing powder and aluminate cement. The baking-free cylindrical attapulgite fire-retarding ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging. The baking-free cylindrical attapulgite fire-retarding ceramsite has a rough and hard surface, and is high in compression strength, low in heat conductivity, high in refractoriness and corrosion resistance and good in heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the ceramsite,. The baking-free cylindrical attapulgite fire-retarding ceramsiteis produced by utilizing multiple tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free cylindrical attapulgite fire-retarding ceramsite is suitable for producing fire-retarding ceramsite concrete and heat-preserving and sound-insulating materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

Method for producing polymerization cementitious material with red mud and bauxite tailings

ActiveCN102491657ASolve pollutionSolve resource problemsCement productionRed mudBiological activation

The invention relates to a method for producing a polymerization cementitious material through comprehensive utilization of red mud and bauxite tailing resources. The method is characterized in that the production process adopts red mud and bauxite tailings as main raw materials, which are subjected to drying, batching, high temperature activation, admixture adding, ball milling and other processes in order so as to obtain a cementitious material. After encountering water, the material undergoes a polymerization reaction and form strength. Tests show that the obtained product has the characteristics of high strength, no alkali-aggregate effect, low cost and good cohesiveness, etc. The method provided in the invention can effectively solve the environmental pollution and resource problems of red mud and bauxite.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

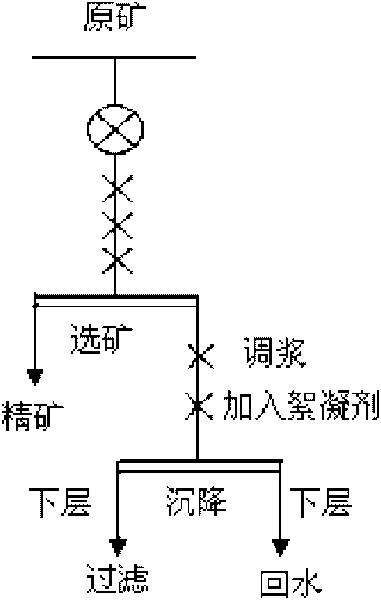

Method for processing bauxite tailings by flocculating agent

InactiveCN101733200AShort processReduce dosageDifferential sedimentationFlocculationMineral particles

The invention relates to a method for processing bauxite tailings by flocculating agent, in particular relating to a method for processing the bauxite tailings by flocculation selectively. Considering the characteristics of the bauxite tailings completely, the invention is characterized by comprising the following steps: using a novel cation polymeric flocculant as the flocculating agent for the flocculation bauxite tailings, preparing the concentration of the novel flocculant to be 0.001-10%, adopting an inorganic flocculant containing Fe ions or Al ions directly or in a combined manner or polyacrylamide in various types, adding into the tailings slurry, and stirring slowly and fully to enable the superfine mineral particles to be in flocculate sedimentation. The invention has the advantages of small medicine dosage, saved production cost, good sedimentation effect, shortened tailings processing procedures and less environmental pollution.

Owner:CENT SOUTH UNIV

Attapulgite river bottom silt ceramsite sand

ActiveCN102515697AHigh strengthReduce energy consumptionFluid removalCeramic materials productionSoil scienceExpanded clay aggregate

The invention discloses attapulgite river bottom silt ceramsite sand. The technical scheme is mainly characterized in that the attapulgite river bottom silt ceramsite sand is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, river bottom silt, red bentonite powder, fly ash, and bauxite tailings. The attapulgite river bottom silt ceramsite sand is prepared by carrying out steps of mixing, granulating, baking, cooling, sieving and packaging on the ingredients of the attapulgite river bottom silt ceramsite. The attapulgite river bottom silt ceramsite is spherical and has the advantages of high strength, low crushing rate, stable quality, porous inner part, corrosion resistance, and good frost resistance and earthquake resistance. The attapulgite river bottom silt ceramsite sand can be produced by comprehensively utilizing the river bottom silt and the tailings, so that the attapulgite river bottom silt ceramsite is good for improving the resource utilization rate, changing wastes to valuable things, reducing the occupied land area, and protecting and purifying the environment; and the attapulgite river bottom silt ceramsite sand is applicable to producing oil field fracturing propping agents and heat-preservation and sound-proof materials.

Owner:南通久通建筑机械有限公司

Preparation method of sulfoaluminate Belite cement

ActiveCN105060744ALow firing temperatureImprove performanceCement productionCalcinationToxic industrial waste

The invention discloses a preparation method of sulfoaluminate Belite cement. The preparation method comprises the following steps: taking industrial waste residues and industrial gypsum as raw materials, taking bauxite or bauxite tailings as a corrective material, adding water for grinding after mixing, molding, carrying out hydrothermal reaction, and then, smashing, calcining and grinding, so as to obtain sulfoaluminate Belite cement, wherein the main components of the sulfoaluminate Belite cement are C4A3S<-> and beta-C2S. According to the invention, the sintering temperature of the sulfoaluminate Belite cement is reduced through the hydrothermal reaction performed in advance, the energy consumption is reduced, the performance of the sulfoaluminate Belite cement is improved through a proper ratio and a proper technology, and the fact that the low-carbon sulfoaluminate Belite cement is prepared under low temperature; besides, limestone is not used, the generation of carbon dioxide is avoided, the environmental pressure is increased, and the energy consumption is low due to low calcination temperature; therefore, the preparation method of the sulfoaluminate Belite cement is low-carbon and environment-friendly.

Owner:YANCHENG INST OF TECH

Non-fired and non-steamed tailing brick and preparation method thereof

ActiveCN104230243AIncreased unconfined compressive strengthRealize mass utilizationSolid waste managementSocial benefitsBrick

The invention provides a non-fired and non-steamed tailing brick and a preparation method thereof. The non-fired and non-steamed tailing brick comprises the following components in percentage by weight: 30-40% of bauxite tailings, 40-50% of iron tailings, 10-30% of cement and 0.5-3.0% of novel admixture. The preparation method comprises the following steps: uniformly mixing the raw materials, adding 11-14% of water, uniformly stirring, then enabling a mixture to enter a brick press, forming by pressing at the pressure of 20-50MPa, and naturally curing for 10-28 days to prepare the non-fired and non-steamed tailing brick. The tailing brick prepared by the preparation method provided by the invention has high unconfined compressive strength which can be up to 21MPa, and has volume density of 1681kg / m3-2099kg / m3 so as to completely meet the standard requirements of national standard 'Non-fired and non-steamed tailing brick', and the tailing bricks of MU10, MU15 and MU20 can be prepared according to different requirements. The invention provides an idea for reasonably and effectively utilizing the iron tailings and the bauxite tailings, provides reference for reasonable secondary utilization of the tailings, can obtain huge social benefits, environmental benefits and economic benefits, and provides an idea for economic transformation proposed by Chinese government at the present stage and adjustment of an industrial structure strategy.

Owner:CENT SOUTH UNIV

Baking-free gravel attapulgite fire-retarding ceramsite

The invention discloses baking-free gravel attapulgite fire-retarding ceramsite. The key point of the technical scheme is that the baking-free gravel attapulgite fire-retarding ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, granulated blast-furnace slag powder, iron tailing powder, coal gangue powder, bauxite tailing powder, kieselguhr tailing powder and aluminate cement. The baking-free gravel attapulgite fire-retarding ceramsite is produced by the following steps of mixing the ingredients, granulating, maintaining, sieving and packaging. The baking-free gravel attapulgite fire-retarding ceramsite is an irregularly-shaped granule, and has high compression strength, low thermal conductivity, high refractoriness and corrosion resistance, and a good heat-preserving and sound-insulating effect; and a large amount of fine pores are formed in the granule. The baking-free gravel attapulgite fire-retarding ceramsite is produced by utilizing multiple tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the baking-free gravel attapulgite fire-retarding ceramsite is suitable for producing fire-retarding ceramsite concrete and heat-preserving and sound-insulating materials.

Owner:南通市通州区十总晨友农产品有限公司

Re-molten spherical alumina casting sand and its prepn

InactiveCN1468673AImprove temperature resistanceStrong collapsibilityFoundry mouldsFoundry coresMolten stateElectric arc furnace

The present invention relates to the formation technology of thermosetting material, and the re-molten spherical alumina casting sand is produced with alumyte or incinerated alumyte tail ore as material. The casting sand has the components including alumina 70-80 wt%, silica 10-20 wt%, ferric oxide less than 5 wt%, and titanium oxide less than 5 wt%. Its production process includes incineration of alumyte under 1000-1400 deg.c for 1-2 hr; blowing incinerated alumyte in molten state inside an electric arc furnace to make spheres; and sieving to take 0.1-2.9 mm grains as the casting sand product. The casting sand product has good heat resistance, high collapsibility, good demolding performance, low powdered and volatile component content, high mechanical strength, and other advantages and may be used in high precision casting mold.

Owner:阳泉中创陶粒股份有限公司

Deposition dehydrating method for processing concentrate or tailing by bauxite

ActiveCN101181701AFacilitates dehydrationFacilitate reuseDifferential sedimentationZeta potentialFlocculation

The invention relates to a settlement and dehydration method of bauxite concentrate or tailings, and relates to a rapid settlement and high-efficiency dehydration method of concentrate or tailings in the bauxite beneficiation process. It is characterized in that it adopts a two-stage process to settle the concentrate or tailings. First, the first stage of the process is to add flocculant to the concentrate or tailings slurry, and realize the fine ore or tailings particles under the dynamic potential of -100-0mv. rapid flocculation and sedimentation; then in the second stage of the process, an acid or alkaline electrolyte is used to adjust the surface charge and dynamic potential of the fine-grained minerals in the overflow of the first stage of the process, so that the fine particles in the overflow can be electrostatically interacted with the residual flocculant in the solution Under the action, flocs are formed and settle quickly. The method of the present invention is simple, easy to implement, low in cost, and environmentally friendly. The water content of the bauxite beneficiation concentrate or tailings after a stage of flocculant sedimentation is greatly reduced, and the concentration can be increased by 3-10 times at the highest, which is beneficial to the realization of concentrate ore or tailings. Tailings dewatering and reuse.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Low-density high-strength ceramsite proppant and preparation method thereof

InactiveCN103484098AIncrease productionExtended service lifeFluid removalDrilling compositionSolubilityExpanded clay aggregate

The invention relates to a low-density high-strength ceramsite proppant and a preparation method thereof. The low-density high-strength ceramsite proppant comprises the following raw materials in parts by mass: 33 to 55 parts of bauxite tailing, 27 to 43 parts of flint clay, 7 to 18 parts of quartz sand, 1 to 7 parts of iron oxide red powder and 1 to 12 parts of aluminum oxide powder. The preparation method comprises the following steps: (1), crushing the raw materials, mixing the materials according to the ratio, crushing, grinding and spray-drying to obtain powdered and granular materials; (2), forcibly balling the powdered and granular materials, drying, sieving, sintering and sieving again to obtain a finished product. The low-density high-strength ceramsite proppant is low in density, high in strength, low in turbidity, low in acid solubility and excellent in roundness and sphericity; the unit-time oil and gas production per unit time is increased and the service life of an oil-gas well is prolonged; the bauxite tailing resources in China are utilized completely, the market pattern and the current situation of fracturing proppants at home and abroad are changed, and the pressure about excessive demand of the high bauxite and insufficient supply of the high bauxite is reduced.

Owner:ZIBO JIAFENG MINING

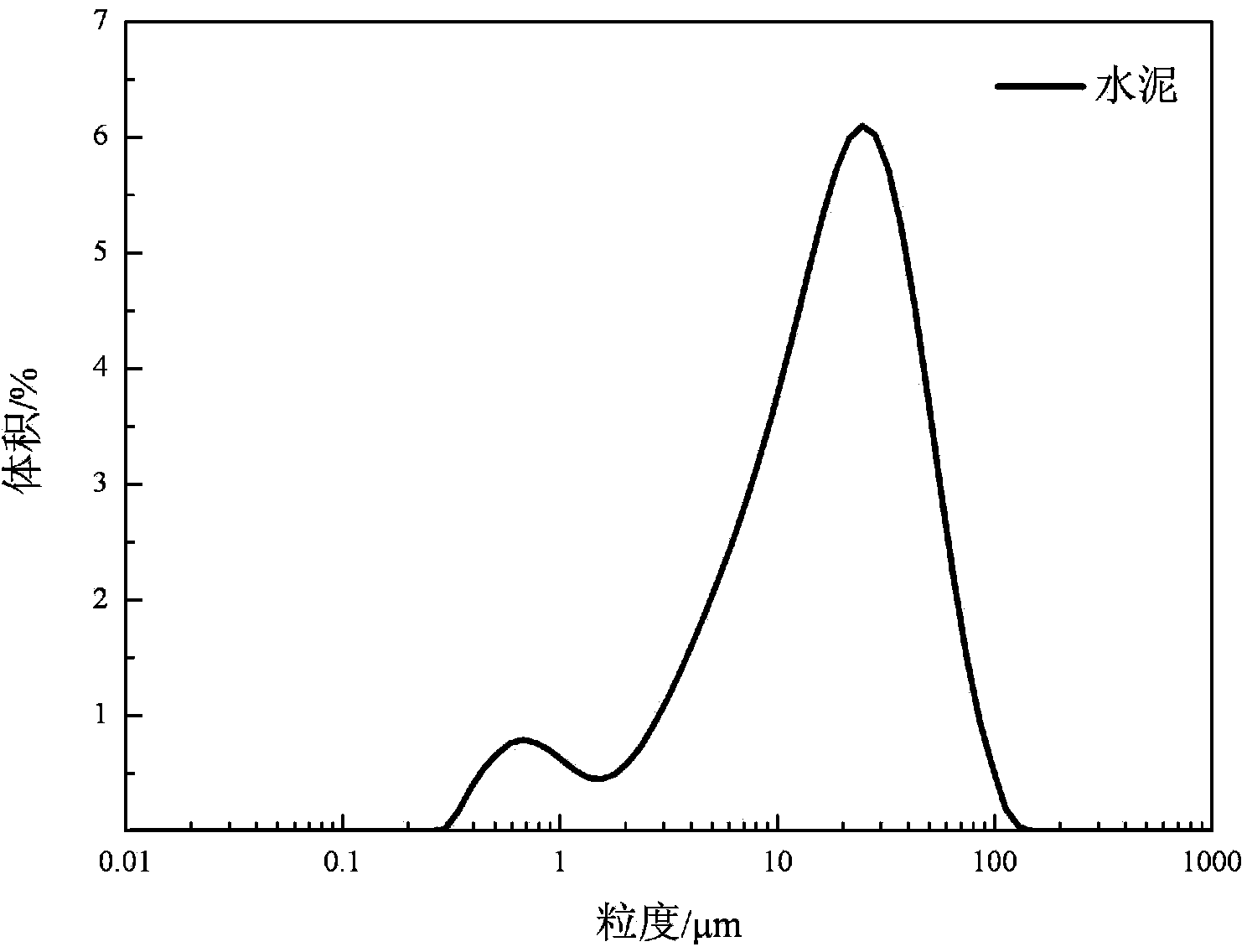

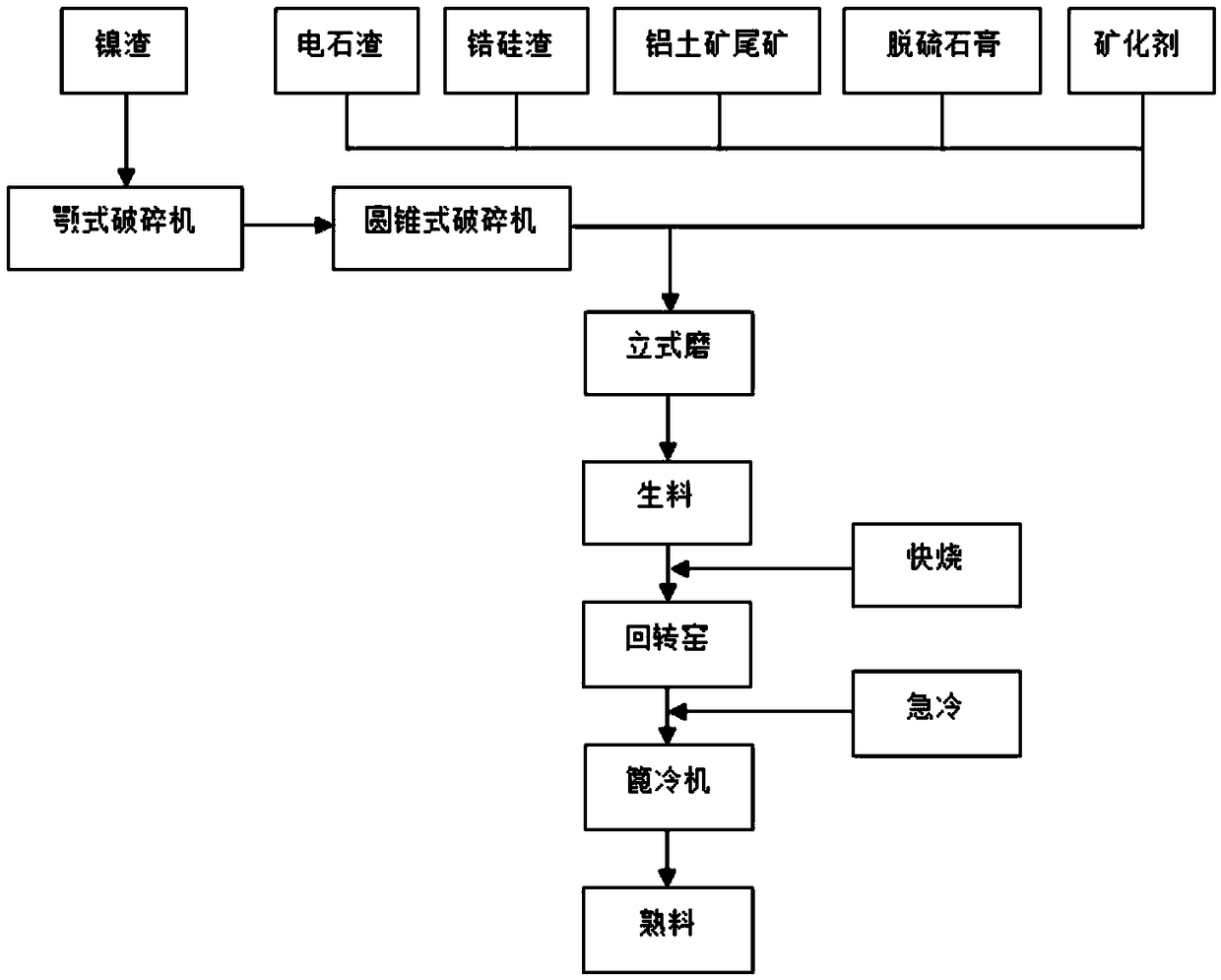

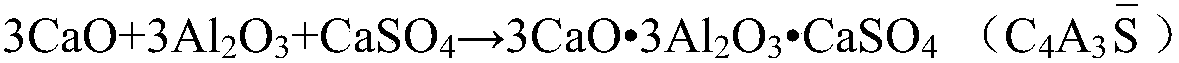

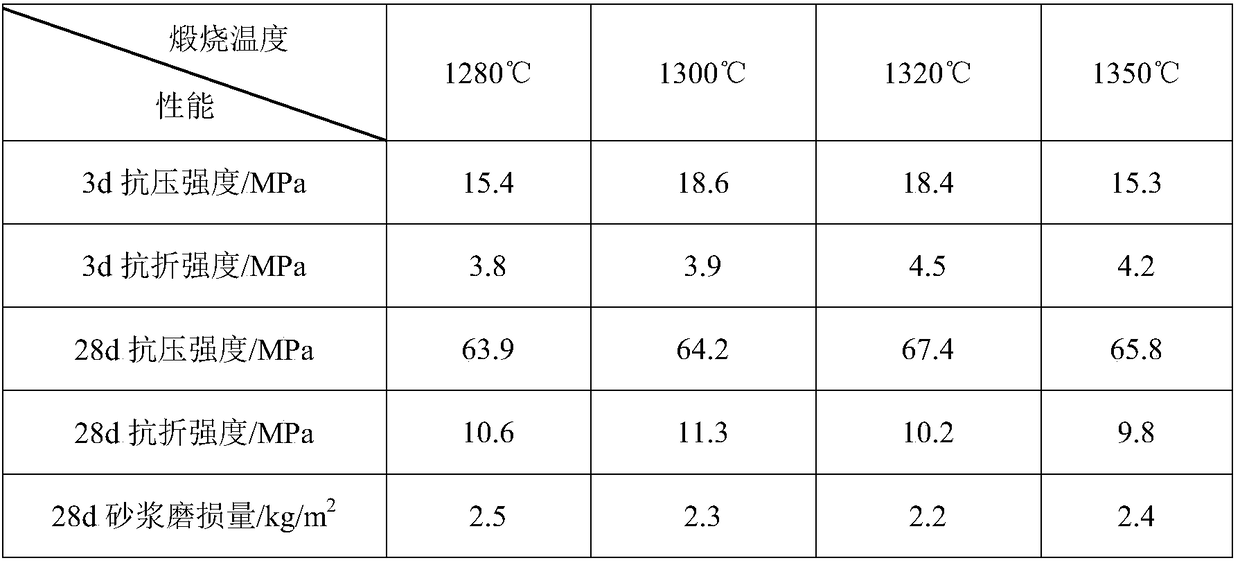

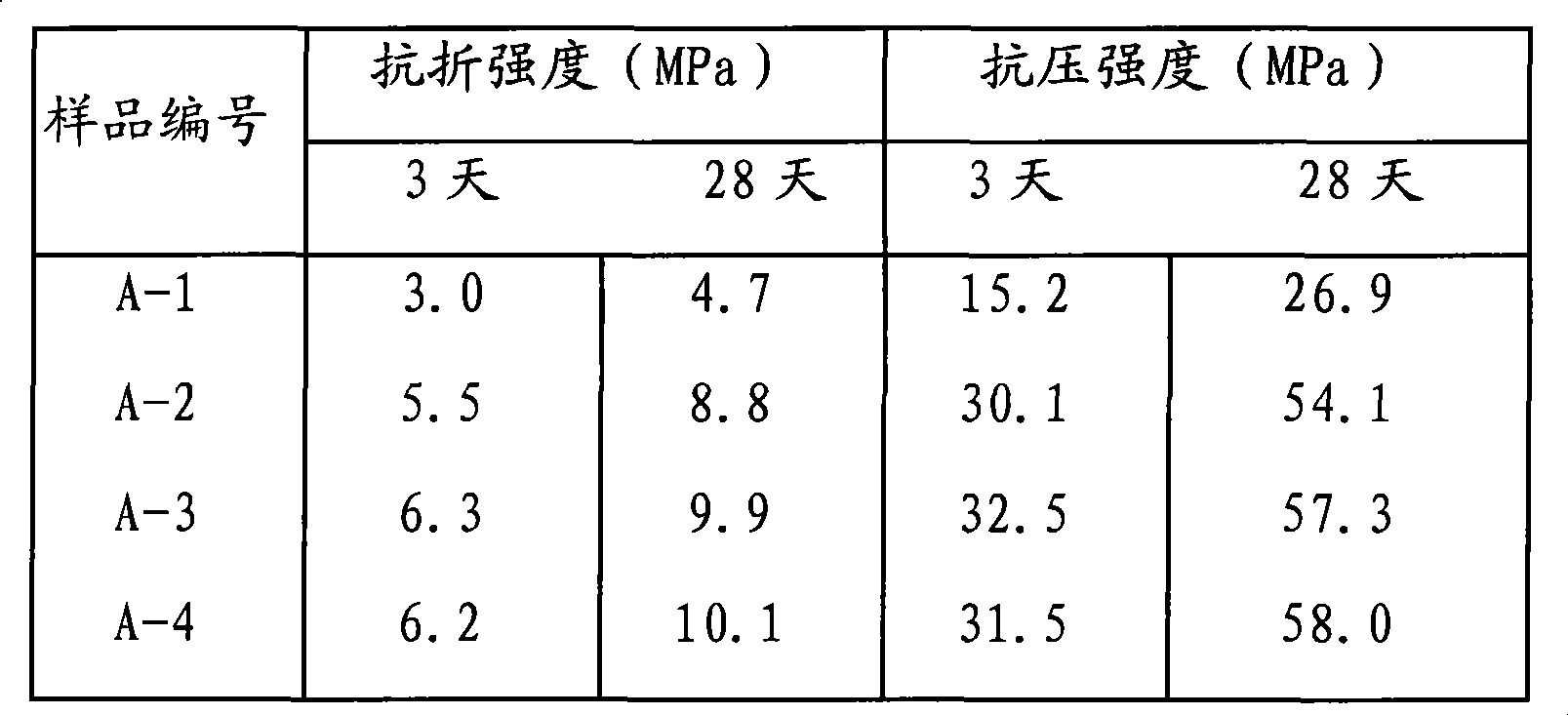

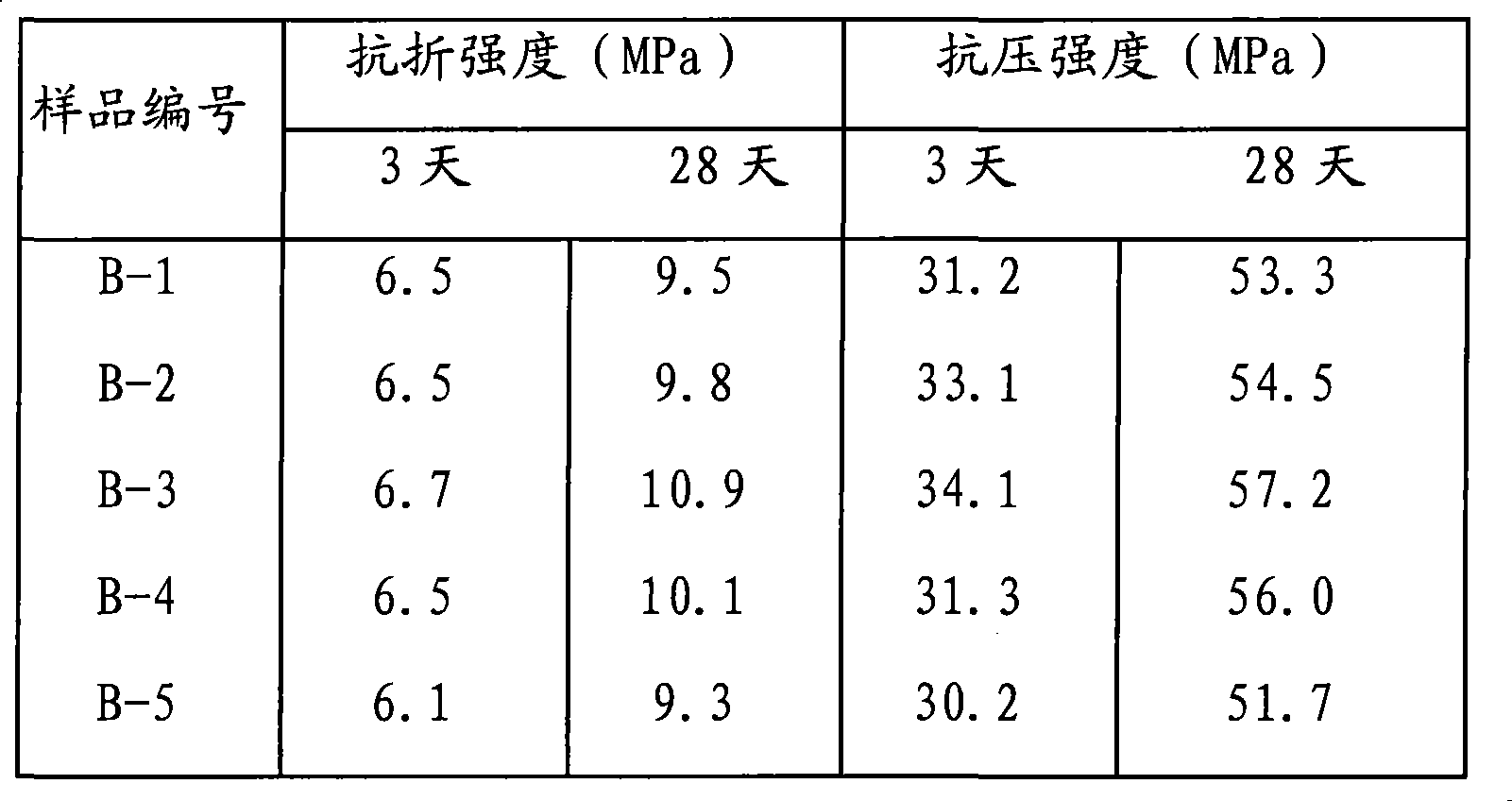

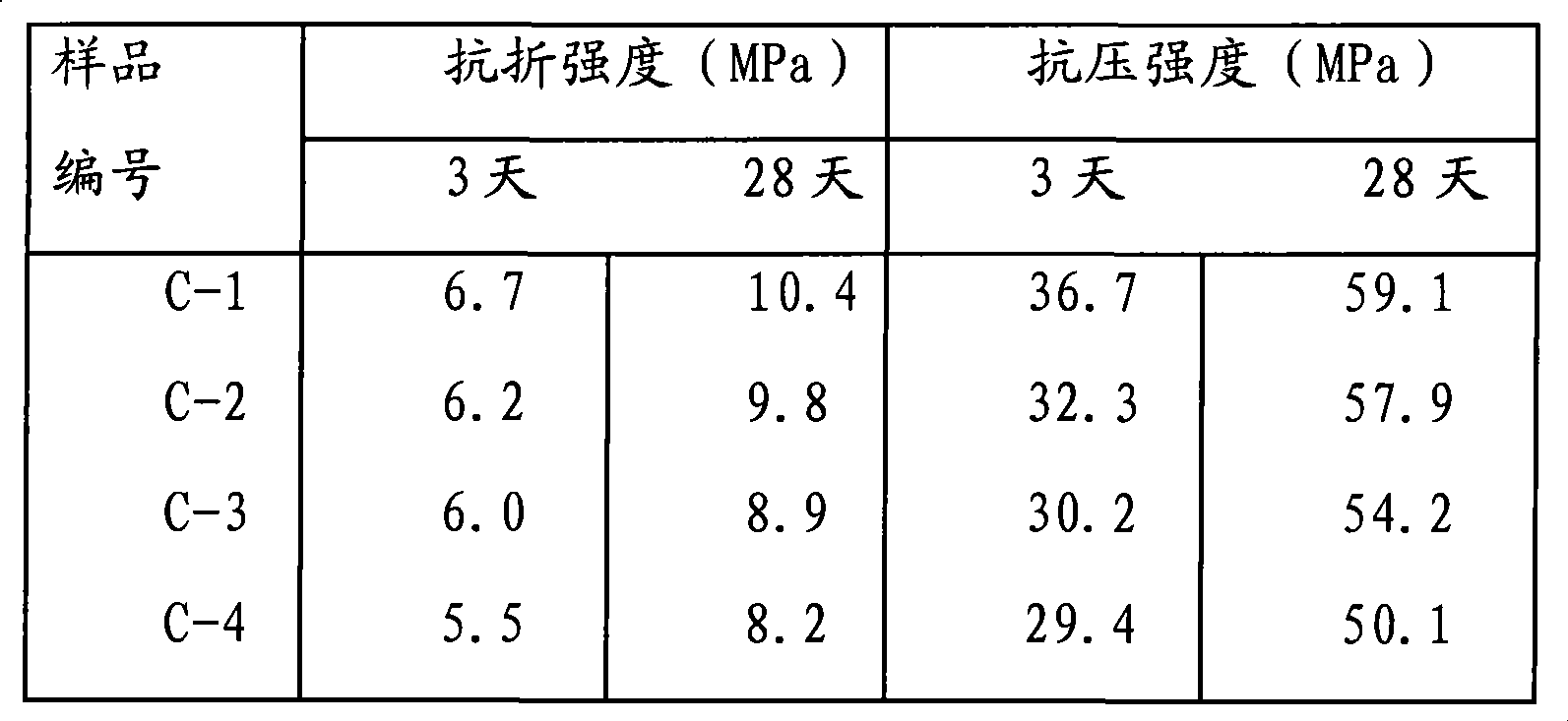

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

Building and other materials containing treated bauxite tailings and process for making same

A process and product are described whereby a waste stream containing bauxite tailings is treated to neutralize alkaline material present, and the resulting material incorporated, for example, into building or other materials to provide enhanced properties.

Owner:JAQUAYS CHARLES D

Unburned spheroidal attapulgite fire-resistant ceramic grain

The invention discloses an unburned spheroidal attapulgite fire-resistant ceramic grain. According to the technical scheme, the unburned spheroidal attapulgite fire-resistant ceramic grain is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, grained blast furnace slag powder, iron tailing powder, gangue powder, bauxite tailing powder, kieselguhr tailing powder and aluminate cement. The raw materials of the unburned spheroidal attapulgite fire-resistant ceramic grain are mixed, pelletized, maintained and screened, and then are packed as the unburned spheroidal attapulgite fire-resistant ceramic grain. The unburned spheroidal attapulgite fire-resistant ceramic grain is spheroidal in shape, has a rough and hard surface, is provided with fine pores inside and is the fire-resistant ceramic grain with high compression strength, low coefficient of heat conductivity, high fire resistance, corrosion resistance and excellent heat-insulating and sound-insulating effect. Various tailings are comprehensively utilized to produce the unburned spheroidal attapulgite fire-resistant ceramic grain, so that the use ratio of resources is increased, the waste is turned into the wealth, and the environmental protection is achieved. The unburned spheroidal attapulgite fire-resistant ceramic grain is suitable for the production of fire-resistant ceramic grain concretes and heat-insulating and sound-insulating materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

Foaming thermal-insulation fireproof brick produced by using coal gangue, and preparation method thereof

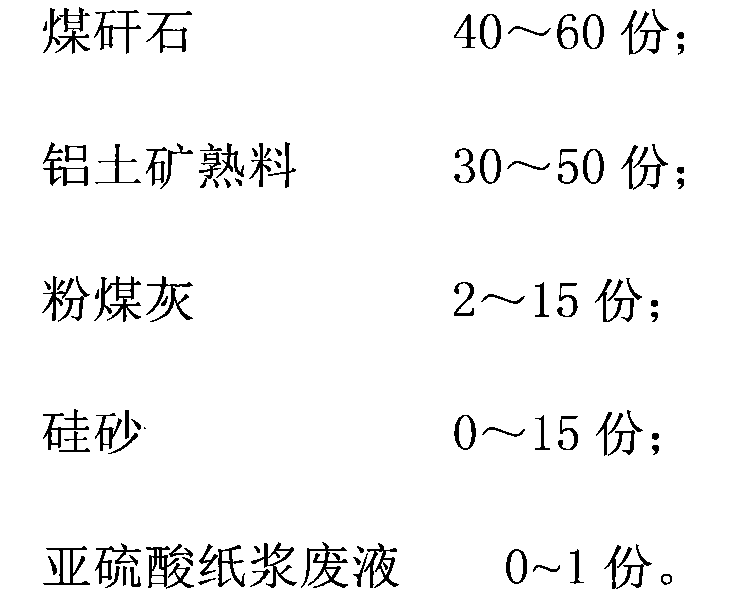

The invention relates to a high-strength foaming thermal-insulation brick produced by using coal gangue, and a preparation method thereof, wherein the raw materials comprise, by weight, 40-60 parts of coal gangue, 30-50 parts of bauxite tailings, 2-15 parts of fly ash, 0-15 parts of silica sand, and 0-1 part of a sulfurous acid paper pulp waste liquid. According to the present invention, with the foaming thermal-insulation fireproof brick produced by using the coal gangue as the main raw material, and the preparation method of the present invention, the problems of low fire resistance, poor molding, low strength and high cost of the light fireproof thermal-insulation brick in the current domestic market are solved, and the product has characteristics of light weight, thermal insulation and fire resistance, and can be widely used for important equipment in the glass-ceramic industry.

Owner:牛艳宁

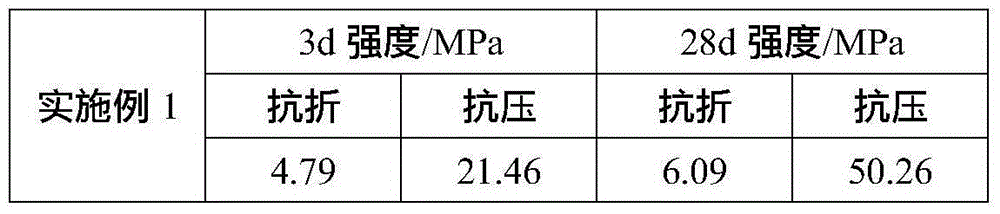

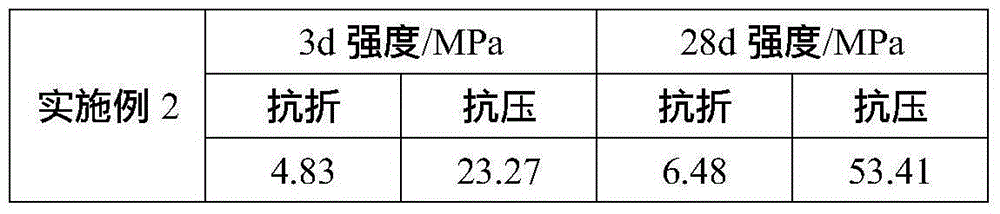

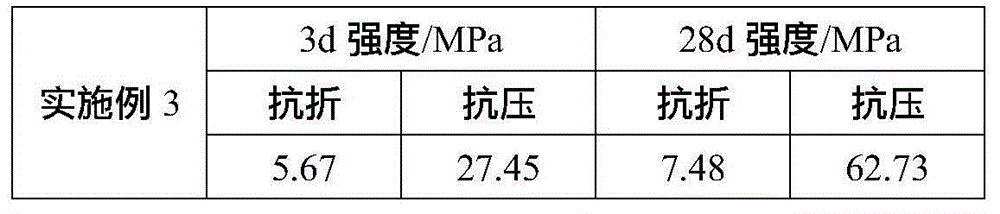

Alkali-activated cementing material and preparation method thereof

ActiveCN106746781AGuaranteed StrengthGuaranteed work performanceCement productionAlkali activatedDissolution

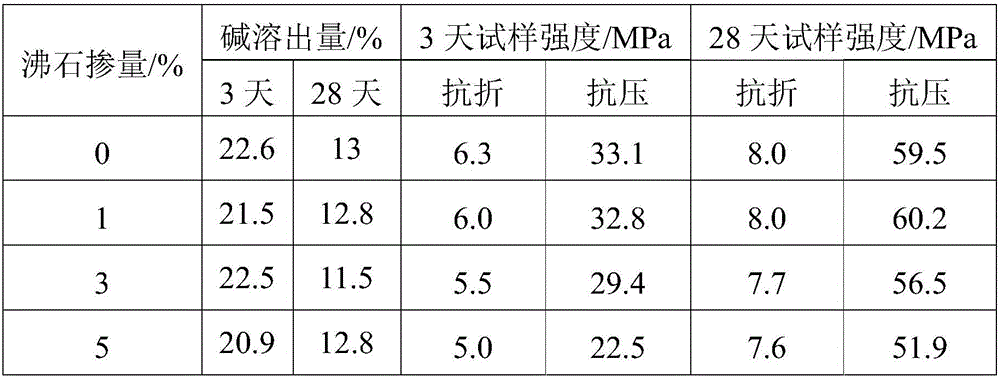

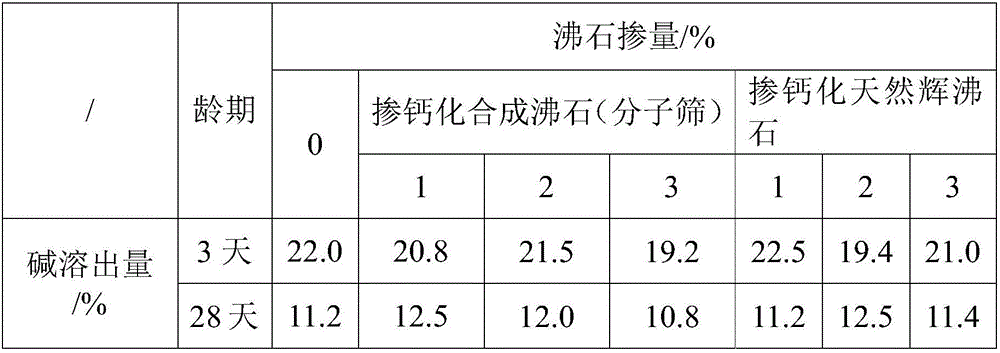

The invention discloses an alkali-activated cementing material and a preparation method thereof, belonging to the building field. The preparation method comprises the following steps: (1) weighing raw materials, wherein the raw materials include powder, an aqueous solution of a liquid activator and calcium-containing zeolite, the powder is prepared by mixing calcined bauxite tailings and slag powder in a mass ratio of (7-8):(3-2), the mass of the aqueous solution of the liquid activator is 4-5% of the mass of the powder based on the mass of Na2O, and the mass of the calcium-containing zeolite is 1-5% of the mass of the powder; and (2) mixing the raw materials to obtain the alkali-activated cementing material, wherein the mass ratio of the water to solid raw materials in the raw materials is 0.4-0.5. In the invention, the cementing material prepared by the method has the advantage of low alkali dissolution.

Owner:CHINA BUILDING MATERIALS ACAD

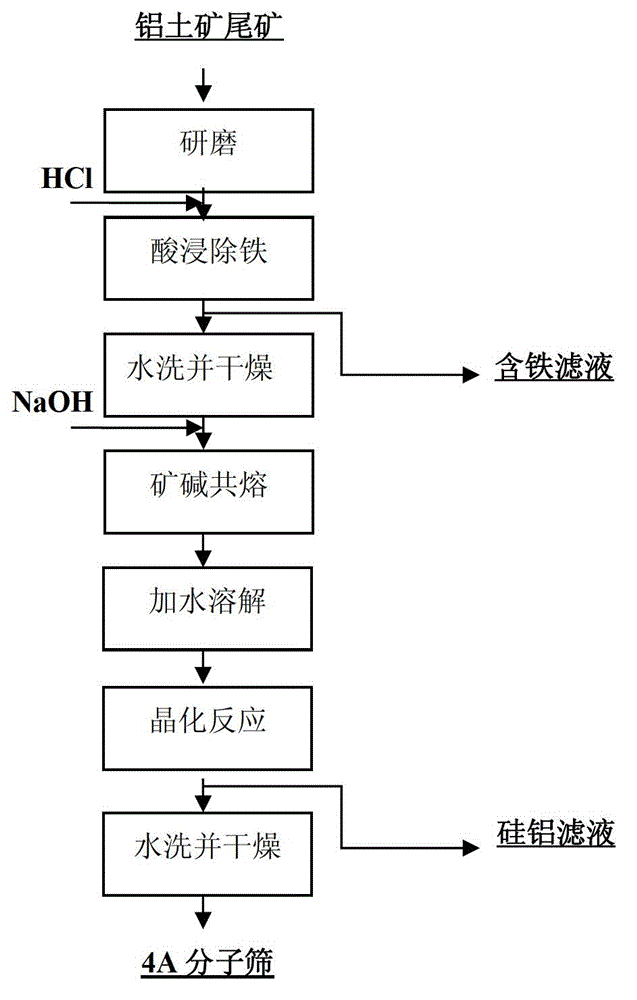

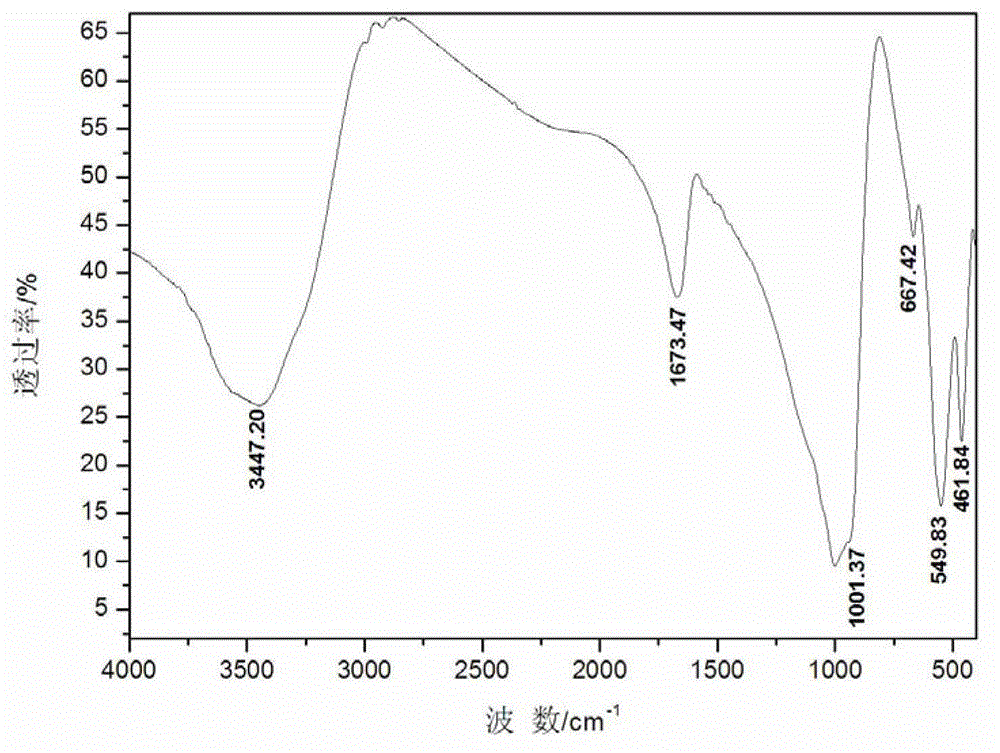

Method for preparing 4A molecular sieve from bauxite tailings

InactiveCN102976353AIncrease added valueImprove performanceAluminosilicate zeolite type-AMolecular sieveIron removal

The invention belongs to the field of aluminosilicate compounds, and in particular relates to a method for preparing a 4A molecular sieve from bauxite tailings. The preparation method comprises the following steps of: (1) iron removal by using an acid process; (2) congruent melting of tailings and alkali; (3) solution preparation; (4) crystallization reaction; and (5) washing. According to the preparation method, the 4A molecular sieve which is suitable for a detergent builder is prepared by taking bauxite milltailings as a raw material, the raw material is abundant in source, and the production cost of the 4A molecular sieve is reduced; and meanwhile, the environment problems caused by low utilization rate and long-term disposal of the bauxite tailings are solved, the utilization rate and the additional value of the bauxite tailings are increased, and a new approach is opened up for comprehensive utilization of the bauxite tailings.

Owner:UNIV OF SCI & TECH BEIJING

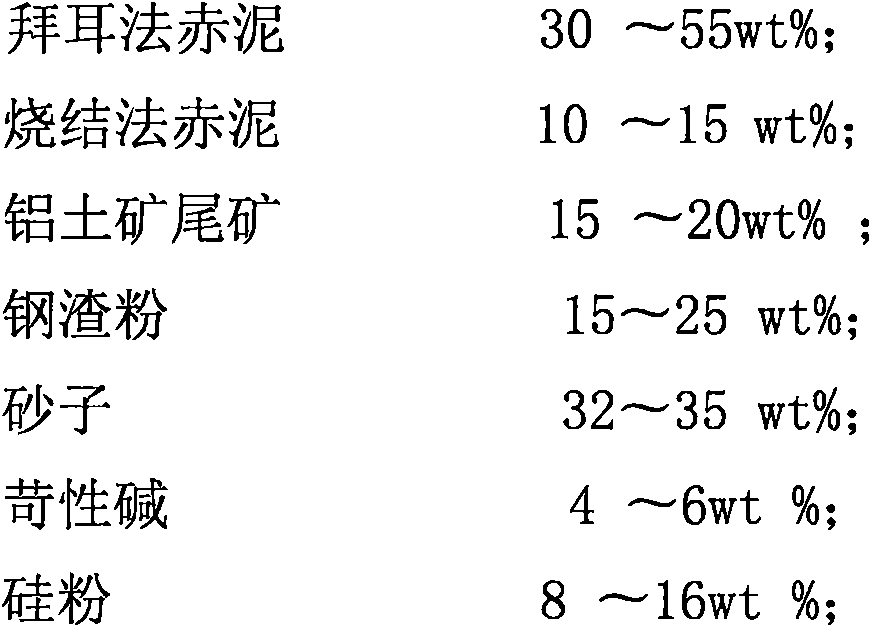

Method for producing geopolymer cement mortar through red mud and bauxite tailing

InactiveCN108726926ADoes not consume resourcesLow costSolid waste managementCement productionRed mudSlag

The invention discloses a method for producing geopolymer cement mortar through red mud and bauxite tailing. The geopolymer cement mortar is prepared from the following components: 30 to 55 wt percentof bayer red mud; 10 to 15 wt percent of sintered red mud; 15 to 20 wt percent of bauxite tailing; 15 to 25 wt percent of ground steel slag; 32 to 35 wt percent of sands; 4 to 6 wt percent of causticalkali; 8 to 16 wt percent of silicon powder. The method comprises the following steps: adding the caustic alkali into the bayer red mud, the sintered red mud and the bauxite tailing, and laying thematerials into a ball mill, so as to form a ball milling material; laying the ball milling material into a moderate temperature furnace to perform modification, so as to form a modified material; adding the ground steel slag and the silicon powder into the modified material, so as to form a mixture; laying the mixture into the ball mill, so as to form red mud and bauxite tailing geopolymer cement;uniformly mixing the geopolymer cement and the sands, adding water, and grouting while stirring. The geopolymer cement mortar has a wide flow range, forms hard paste, does not cause alkali-aggregatereaction, and belongs to a novel green building material with low cost and high performance.

Owner:鄢金松

Composite heat storage material and preparation method thereof

InactiveCN101649186AImprove stress resistanceImprove fire resistanceHeat-exchange elementsMixed materialsHeat storage material

The invention discloses a composite heat storage material and a preparation method thereof. The composite heat storage material is prepared by adopting hematite ore as main material, bauxite tailing as forming material and clay as auxiliary material and adding water to mix. The proportioning of the materials is that the contents of hematite ore, bauxite tailing and clay are separately 70-87%, 7-15% and 6-15%. The preparation method comprises the following steps: firstly mixing the materials: mixing tailing and clay evenly, adding water for soaking, then adding hematite ore to mix, placing themixture in a ventilated place while controlling the moisture content; then shaping: placing the mixed materials in moulds to form and prepare test blocks; then drying: placing the test blocks in a oven to dry; finally roasting and cooling to obtain the heat storage material. The specific heat of the heat storage material is 0.150-0.166cal-g<-1>-K<-1> and the thermal conductivity is 1.18-1.30W-m<-1>-K<-1>. The preparation method of the heat storage material is characterized by easy process, low cost, higher value of mineral tailing and the like and the prepared composite heat storage material has high specific heat and good heat conductivity.

Owner:CENT SOUTH UNIV

Method for preparing polysilicate aluminium molten iron processing agent using bauxite gangue

InactiveCN1994881AAluminium silicatesWater/sewage treatment by flocculation/precipitationWastewaterMaterials science

The invention discloses a making method of bauxite tailing disposing and aluminium polysilicate molten iron disposing agent, which comprises the following steps: adopting bauxite tailings as raw material; sintering; immersing in the acid; dissolving in the alkali; polymerizing polysilicate acid; adding aluminium salt solution in the polysilicate acid to obtain the product.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

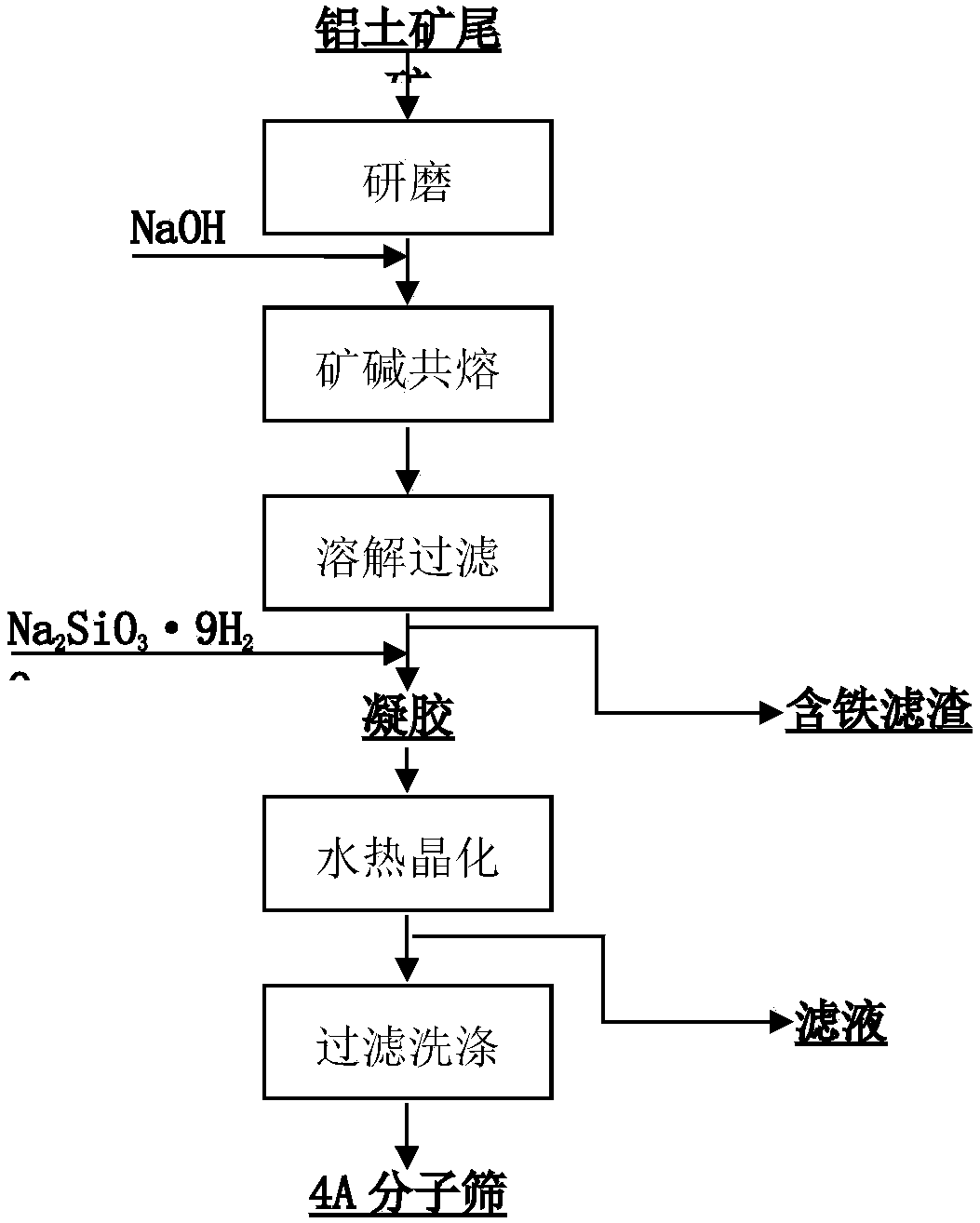

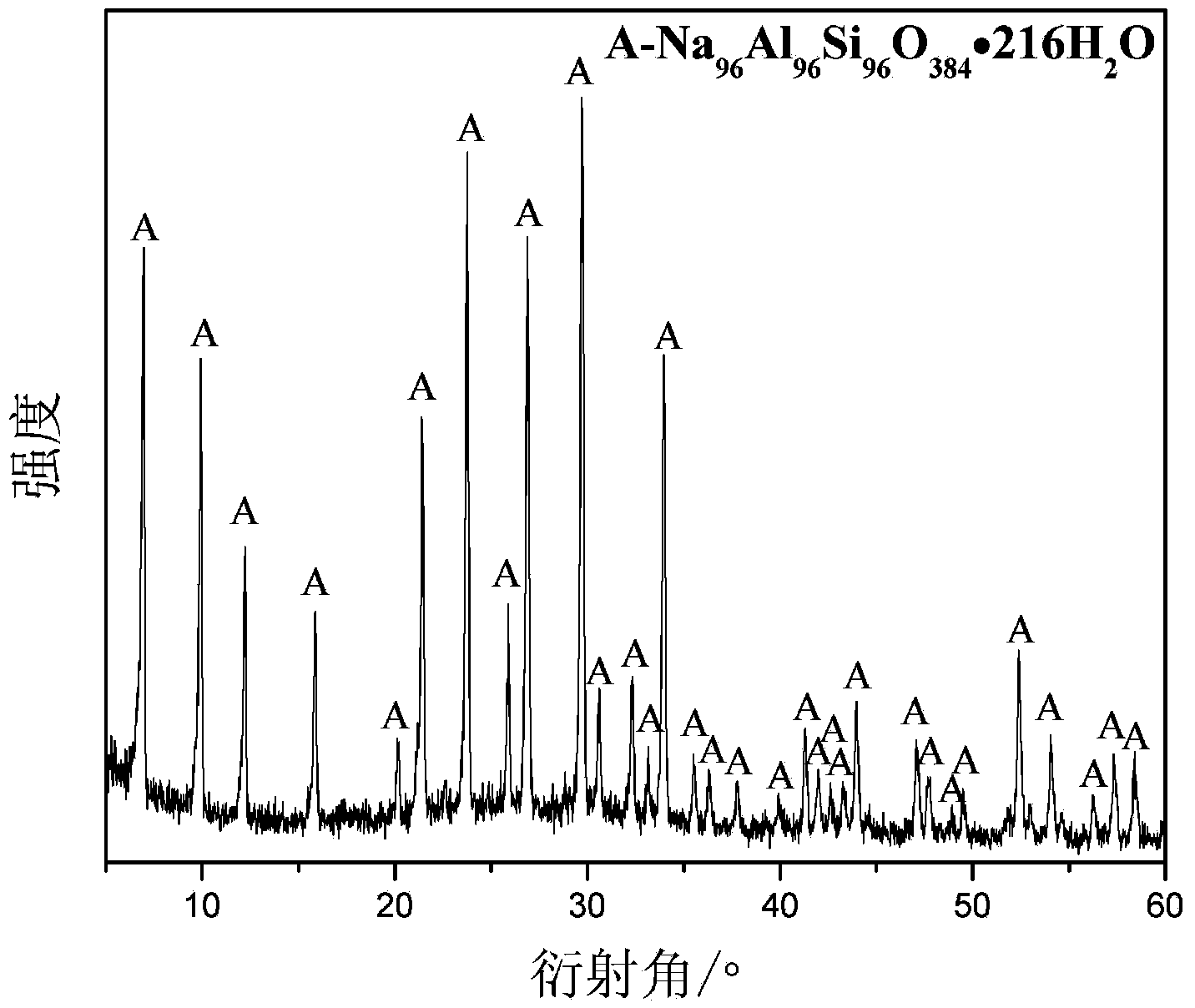

Hydrothermal synthesis method of 4A molecular sieve from high-iron bauxite tailings

InactiveCN104108723AShorten the timeShorten the production cycleAluminosilicate zeolite type-AMolecular sieveFiltration

The invention belongs to the field of aluminosilicate compounds, and relates to a hydrothermal synthesis method of a 4A molecular sieve from high-iron bauxite tailings. The method comprises the following steps: (1) mineral / alkali co-melting; (2) gel preparation; (3) hydrothermal crystallization; and (4) filtration and washing. By preparing the 4A molecular sieve for detergent assistants from the bauxite tailings by mineral separation, the method has abundant raw material sources and lowers the production cost of the 4A molecular sieve. The method solves the environmental problem due to low utilization ratio and long-term discarding of the bauxite tailings, enhances the utilization ratio and added value of the bauxite tailings, and opens up a new way for comprehensive utilization of bauxite tailings.

Owner:UNIV OF SCI & TECH BEIJING

Method of preparing light thermal insulation material by employing bauxite tailings

InactiveCN106830796ARealize resourcesHigh strengthCeramicwareThermal insulationUltimate tensile strength

The invention discloses a method of preparing a light thermal insulation material by employing bauxite tailings and relates to a comprehensive utilization method of bauxite tailings. The method is characterized by comprising the following steps of: adding the bauxite tailings into kaolin to calcined and reconstructed; and preparing the light thermal insulation material by taking the mixture as a raw material of the light thermal insulation material. The method disclosed by the invention makes full use of industrial solid wastes such as bauxite tailings, coal ash and flue gas desulfurization gypsum, and the material is low in cost, high in strength and good in thermal insulation property, and meanwhile, the requirement on SiO2 content is relatively low. The solid waste bauxite tailings can be scientifically utilized to realize reclamation of wastes, so that the method has far-reaching environmental-friendly meaning.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

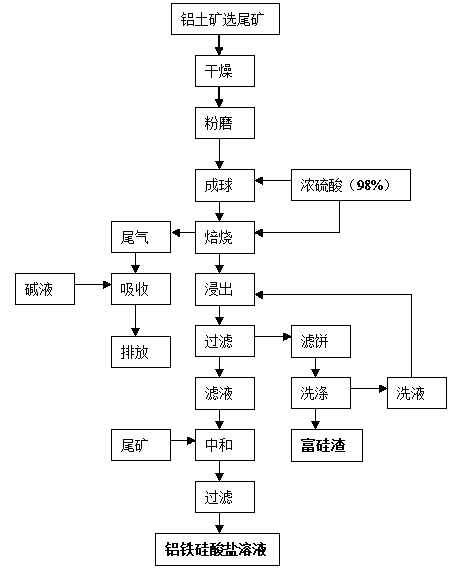

Method for efficiently recycling ferro-aluminium from bauxite tailings and synchronously preparing high siliceous residues

InactiveCN103421960ADischarge fullyGuaranteed emission standardsProcess efficiency improvementPregnant leach solutionMineral Sources

The invention relates to a method for efficiently recycling ferro-aluminium from bauxite tailings and synchronously preparing high siliceous residues, and belongs to the technical field of waste comprehensive utilization and mineral resource processing. The method comprises the following steps: drying and grinding bauxite tailings, adding concentrated sulfuric acid, uniformly mixing, making into spheres, then heating and calcining, continually adding concentrated sulfuric acid during the calcining process, adding cleaning solution and leaching calcined bauxite tailings spheres, filtering, and gaining filter liquor, namely acid leaching initial liquid, gaining filter residue from filter cake to gain filter residue, namely high siliceous residue, and taking the gained cleaning solution as leaching agent of bauxite tailings spheres for next calcining to use; neutralizing the acid leaching initial liquid by grinding tailings, filtering, and gaining filter liquor, namely solution containing aluminum sulfate and ferric sulfate. The method realizes enrichment and edulcoration of silicon, and the recycle of silicon from the acid leaching residue or the preparation of silicate products is facilitated.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing ganged brick by utilizing red mud and bauxite tailings

The invention discloses a method for producing a ganged brick by utilizing red mud and bauxite tailings, relates to comprehensive resource utilization in the process of alumina production, and in particular relates to a method for producing the ganged brick by utilizing the red mud and bauxite tailings. The method is characterized in that in the production process, the red mud and bauxite tailings in the oxidation production process are used as raw materials, coal ash or waste glass is mixed, and then a building ganged brick is prepared by ageing, dehydration, molding, drying and firing processes. According to the invention, components in the red mud, such as base and iron, are utilized to regulate the firing temperature of a green body, thereby being contributed to generating of a liquid phase and causing a porous structure in the green body; a once firing process is adopted, which can recycle wastes and save a large amount of energy consumption, so that good effect and economic benefits are generated; after the raw materials are mixed, plasticity is good, initial strength is high, and a phenomenon that a dry green body is damaged does not occur; and in the method, used materials, such as red mud and bauxite tailings, are thin in particle size, thereby avoiding a large amount of ball milling operations and reducing production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Low-density and high-strength ceramsite proppant prepared by utilizing bauxite tailings and fly ash

InactiveCN108706960AHigh hardnessHigh strengthFluid removalDrilling compositionEcological environmentExpanded clay aggregate

The invention discloses a low-density and high-strength ceramsite proppant prepared by utilizing bauxite tailings and fly ash. The low-density and high-strength ceramsite proppant is prepared from thefollowing raw materials in parts by weight: 50-80 parts of the bauxite tailings, 50-70 parts of the fly ash, 15-20 parts of sintering aid, 20-30 parts of manganese mineral powder, 5-10 parts of quartz sands, 2-8 parts of aluminum oxide powder and 20-30 parts of water. A preparation method comprises the following steps of S1, crushing and dry grinding: crushing the bauxite tailings, then performing continuous dry grinding on the crushed bauxite tailings, and weighing the bauxite tailings after dry grinding, ready for use; and S2, mixing: weighing the fly ash, the quartz sands and the sinteringaid according to a proportion, putting the weighed fly ash, quartz sands and sintering aid in a ball mill for wet milling, and adding the quartz sands and the manganese mineral powder for mixing to obtain a mixture. By taking the bauxite tailings as a raw material, the low-density and high-strength ceramsite proppant provided by the invention can improve the ecological environment, turns harm into good, changes waste into valuable and is improved in the strength and simple in preparation method.

Owner:SHANXI FUSEN ENERGY TECH

Silicon-aluminum polymeric material and preparation thereof

InactiveCN101412596AIncrease added valueConvenient sourceSolid waste managementCement productionSlagChemical corrosion

The invention discloses a silicon-aluminum polymeric material, which comprises 60 to 90 weight percent of calcined bauxite tailing powder, 40 to 10 weight percent of slag powder, and 20 to 80 percent of water glass of the total weight of calcined bauxite tailing and slag. The invention also discloses a preparation method for the material, which comprises the following steps: a. calcining the bauxite tailing, and grinding the calcined bauxite tailing to obtain the calcined bauxite tailing powder; b. mixing 40 to 10 weight percent of the slag powder and 60 to 90 weight percent of the calcined bauxite tailing powder evenly, and preparing powder material; and c. adding 20 to 80 percent of the water glass of the weight of the powder material in step b, and preparing the silicon-aluminum polymeric material, wherein the calcining temperature is between 800 and 1,000 DEG C, and the calcining time is between 0.5 and 10 hours. The material has the advantages of excellent mechanical performance, chemical corrosion resistance and volume stability; and the preparation method is simple, uses industrial wastes as raw materials, has low cost, not only can solve stockpiling problem of wastes, but also achieves comprehensive utilization of resources.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

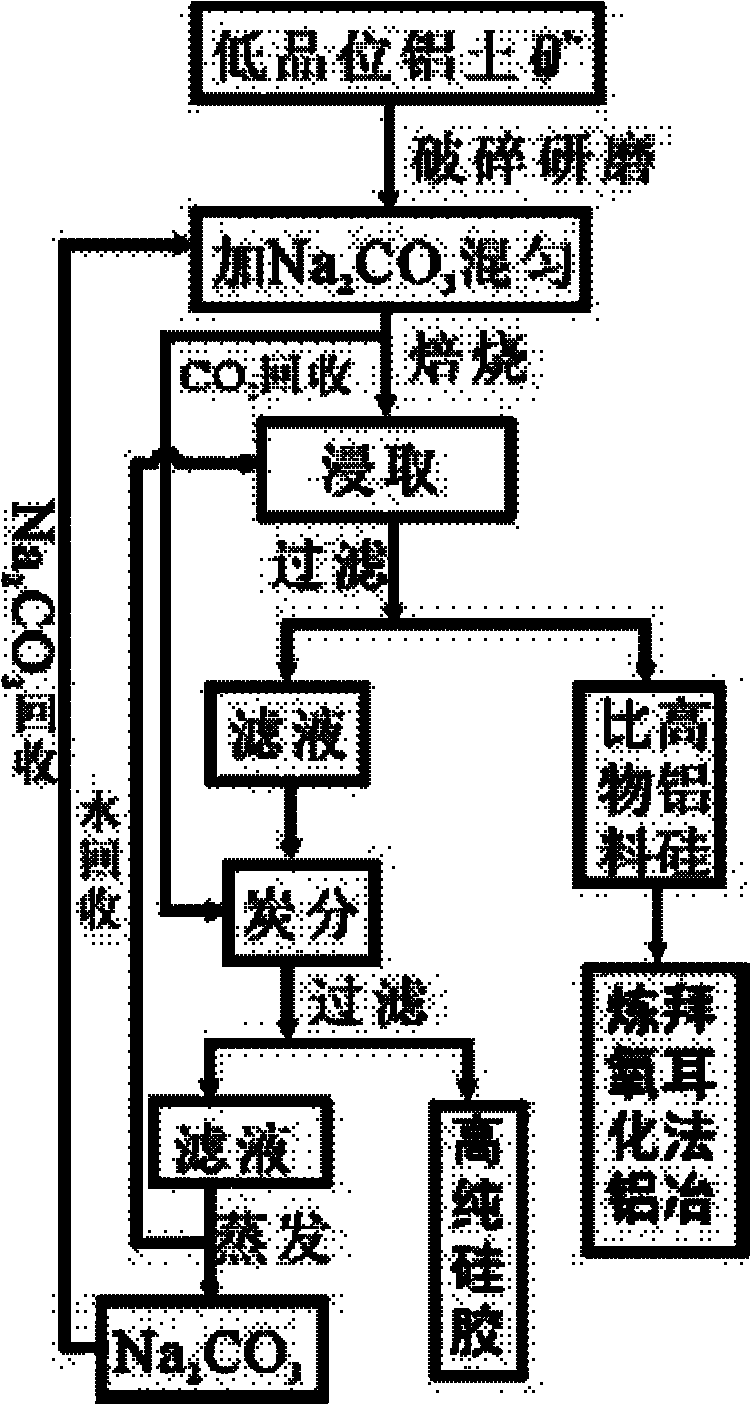

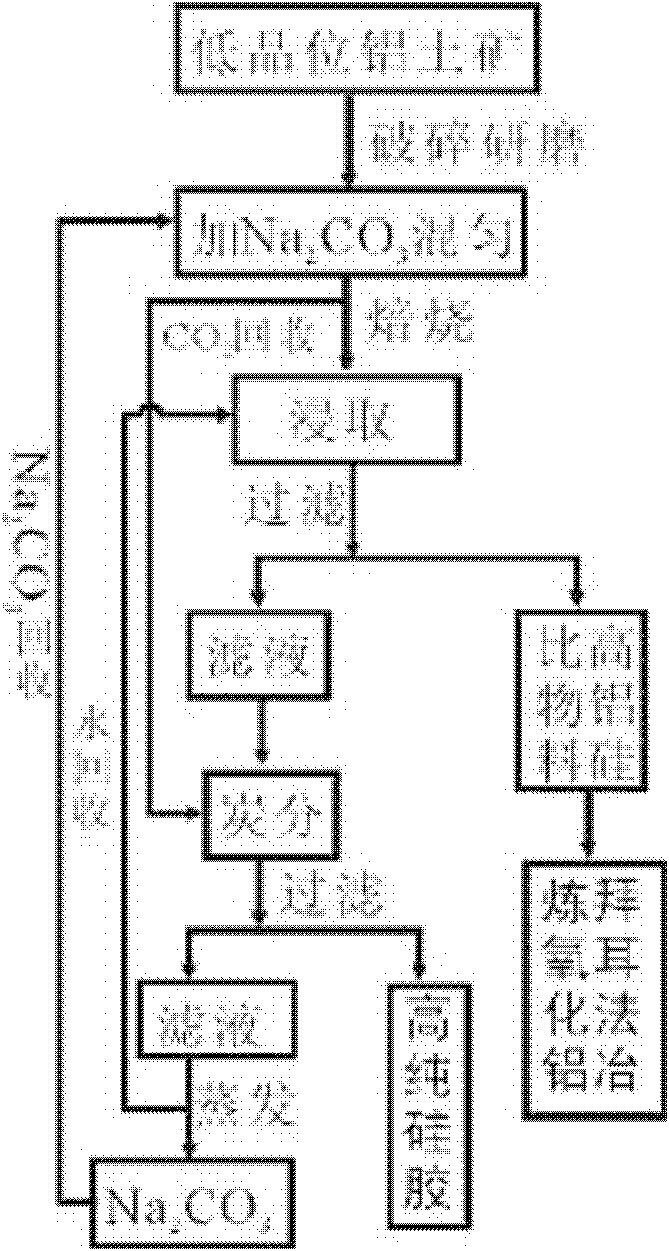

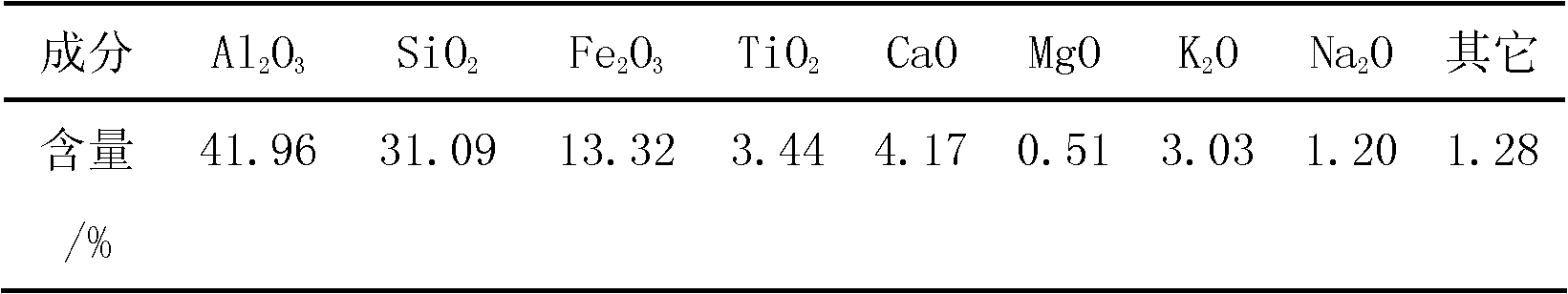

Method for improving alumina silica ratio of low-grade bauxite

ActiveCN101913615ALower taste requirementsSolve problemsSilicaAluminium silicatesLoss rateCarbonization

The invention discloses a method for improving the alumina silica ratio of low-grade bauxite. The method comprises the steps of crushing, grinding, roasting, activating, leaching desilicification, carbonization, recovery of auxiliary agents and water and the like, so that high-quality materials which can meet the requirement of high alumina silica ratio required for producing alumina by a Bayer process can be obtained, and a certain amount of high-purity silica gel can be obtained. The method fulfils the aim of utilizing the low-grade bauxite (including bauxite tailings) and develops a new way for the development and utilization of the low-grade bauxite. During the entire process, the produced CO2 and the used auxiliary agents and water can be recovered and recycled. Compared with other chemical mineral processing methods, the method has the characteristics of high desiliconization rate, low alumina loss rate, low energy consumption, low cost and simple process; and the removed silicon is directly produced in the form of high-purity silica gel with high added value and can also be effectively utilized.

Owner:北京蔚然欣科技有限公司

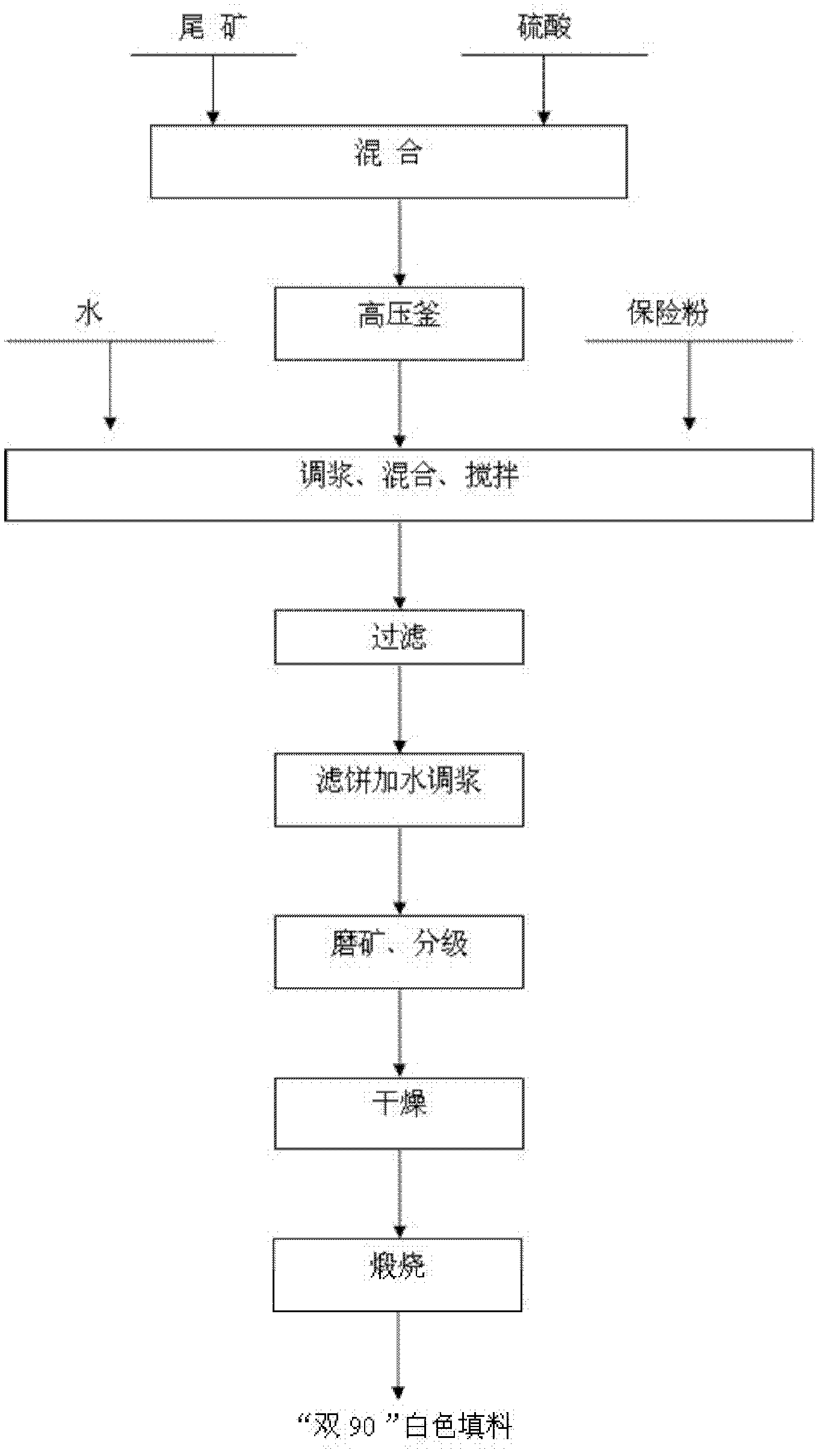

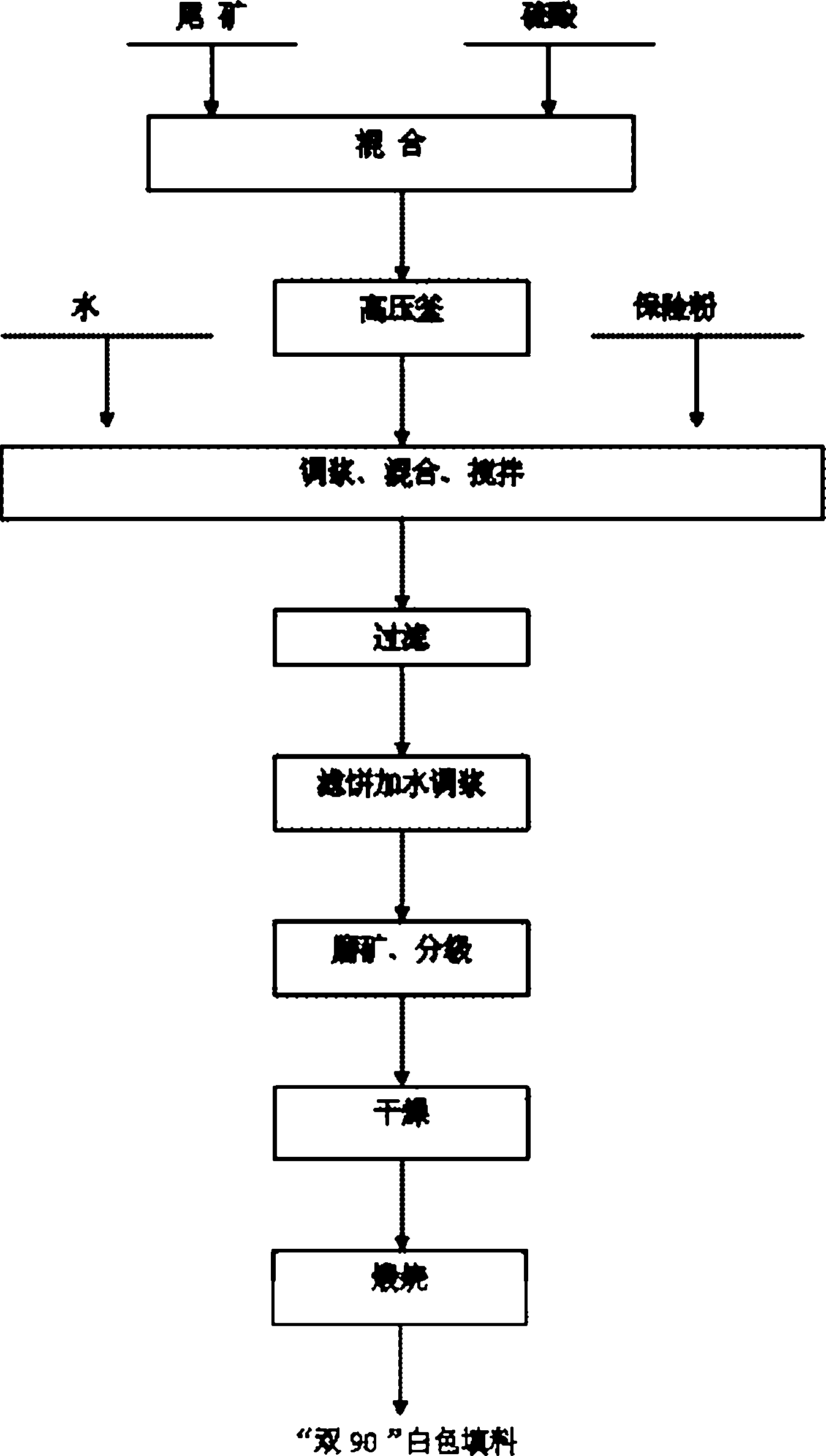

Method for preparing double-90 white filler from bauxite tailing

InactiveCN102675930AEffective iron removalEasy to removePigment physical treatmentSocial benefitsSodium dithionite

A method for preparing double-90 white filler from bauxite tailing comprises the following steps: firstly, heating the bauxite tailing and sulfuric acid at the temperature of 150-300 DEG C for 4-24 hours; secondly, adding water to adjust the pulp density and the pH value; adding sodium dithionite, performing reaction at the temperature of 25-90 DEG C and then filtering to obtain an ore sludge filter cake; adding water into the ore sludge filter cake and mixing to form ore pulp; grinding, grading and drying the ore pulp to obtain superfine powder with the grading content of 0.2 Mum and the whiteness of more than 90 percent; and finally, calcining the superfine powder at the temperature of 800-1000 DEG C to obtain the double-90 white filler. The double-90 white filler produced by the method disclosed by the invention has a high added value, can be applied to the fields of high-grade coating and paint, plastic, rubber and the like and has favorable economic benefits and social benefits. The method disclosed by the invention has the advantages of simple process, low cost, less investment and easiness in realization of industrial production. According to the method disclosed by the invention, the bauxite tailing can be treated in a large batch, the waste can be changed into valuables and a favorable technical path for treating and comprehensively utilizing the bauxite tailing is provided.

Owner:CENT SOUTH UNIV

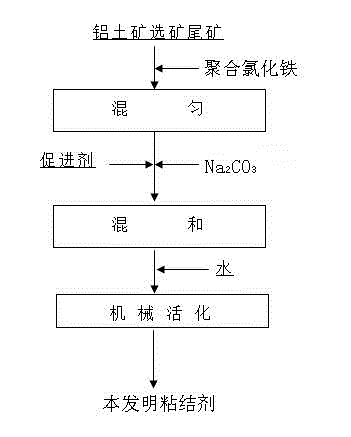

Bauxite tailings-based iron ore pellet binder and preparation method thereof

The invention discloses a bauxite tailings-based iron ore pellet binder. The bauxite tailings-based iron ore pellet binder is prepared by the following raw materials in percentage by weight: 70-85% of bauxite tailings, 10-20% of accelerant, 3-5% of polymerization ferric chloride, and 2-5% of Na2CO3. A preparation method of the binder comprises the following steps: after being evenly mixed, all the raw materials are activated by adopting a ball milling machine to obtain the bauxite tailings-based iron ore pellet binder. The invention aims at realizing efficient utilization of refractory secondary resources, and develops the bauxite tailings-based iron ore pellet binder which can serve as a substitute for a traditional binder (bentonite) in the iron ore pellet industry. Meanwhile, the land occupation by the tailings and the environmental harms caused by the tailings can be substantially reduced, so that the resource problem of the massive stacked tailings is solved and the production cost of pellets is reduced. Therefore, the bauxite tailings-based iron ore pellet binder has prominent economic and social benefits.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com