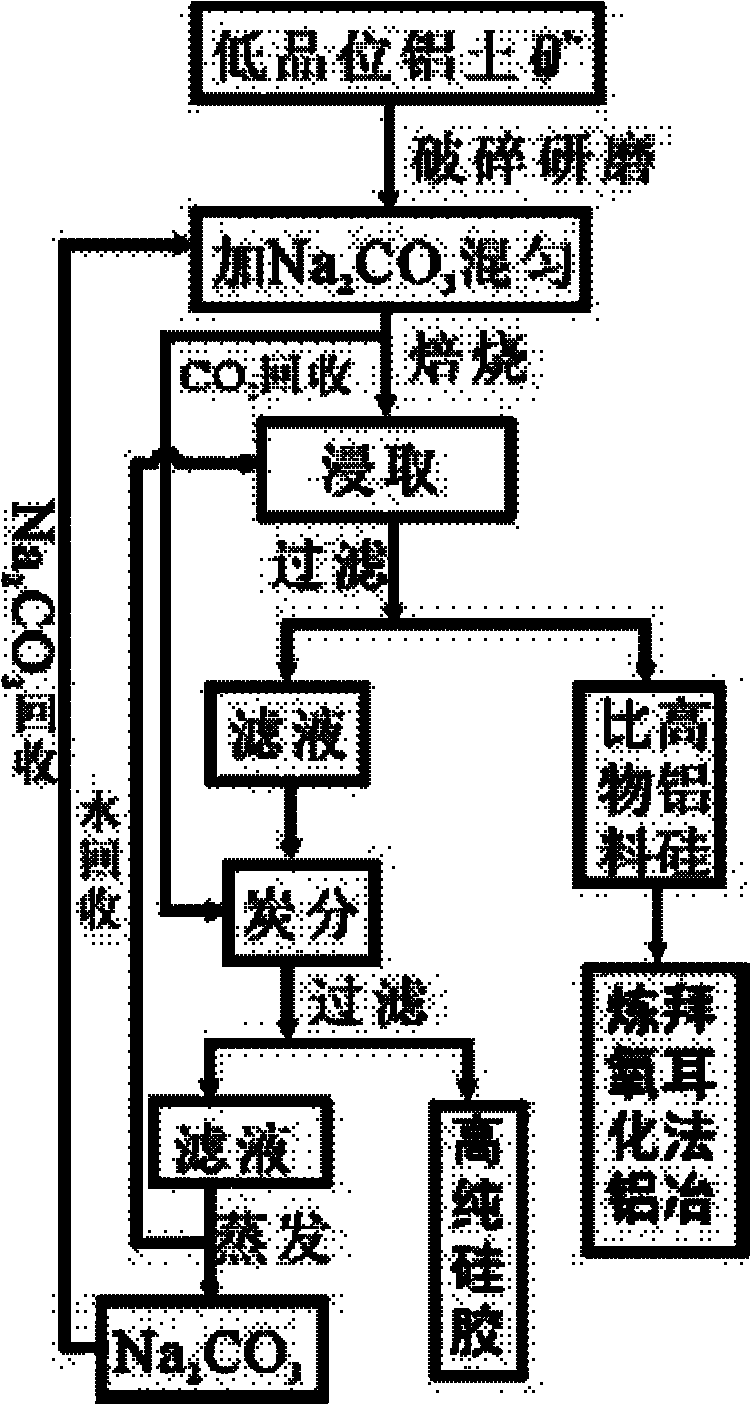

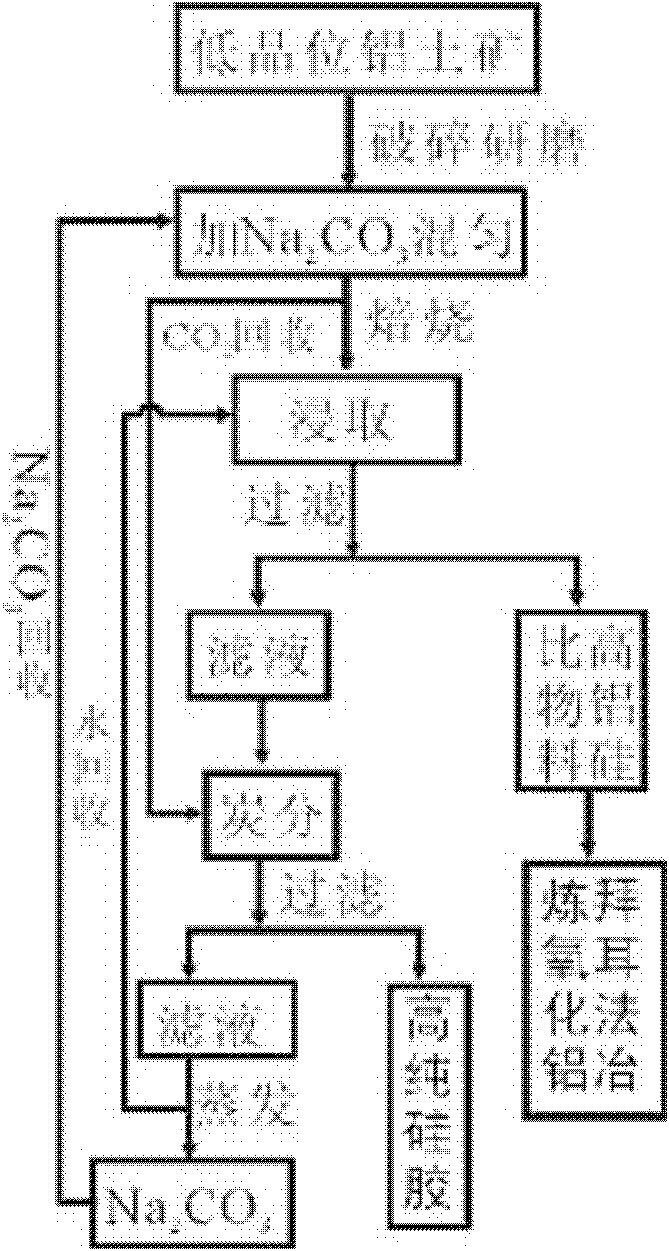

Method for improving alumina silica ratio of low-grade bauxite

A low-grade bauxite and aluminum-silicon ratio technology, which is applied in the field of improving the aluminum-silicon ratio of low-grade bauxite and purifying low-grade bauxite, can solve the problems of high cost, long process, and large output of red mud , to achieve the effect of reducing taste requirements and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) After crushing the low-grade bauxite, mix it with solid sodium carbonate at a ratio of 1:1.2 and grind it into a 100-mesh mixed material.

[0042](2), the mixed material obtained in step (1) was roasted for 50 minutes at a temperature of 150°C to obtain roasted clinker; during roasting, the calcining equipment was connected to the gas output pipe and connected to the carbon separation tank.

[0043] (3) Add an appropriate amount of water to the roasted clinker obtained in step (2), and make the solid-to-liquid mass ratio 1:5, and leaching for 40 minutes at a temperature of 50°C. After leaching, filter to obtain filtrate and filter residue respectively. It has been determined that the aluminum-silicon ratio (A / S) in the filter residue is 11, which satisfies the aluminum-silicon ratio condition of the material required for the subsequent Bayer process to produce alumina.

[0044] (4), after the filtrate obtained in step (3) is concentrated to 30% of the original solu...

Embodiment 2

[0047] (1) After the low-grade bauxite is crushed, it is mixed with solid sodium carbonate at a ratio of 1:1 and ground into a 200-mesh mixed material

[0048] (2), the mixed material obtained in step (1) was roasted for 40 minutes at a temperature of 350° C. to obtain roasted clinker; during roasting, the calcining equipment was connected to the gas output pipe and connected to the carbon separation tank.

[0049] (3) Add an appropriate amount of water to the roasted clinker obtained in step (2), and make the solid-liquid mass ratio 1:7, and leaching for 50 minutes under the temperature condition of 40°C. After leaching, filter to obtain filtrate and filter residue respectively.

[0050] (4), after the filtrate obtained in step (3) is concentrated to 20% of the original solution, the CO output from step (2) is fed under normal pressure. 2 Carry out carbonation. The carbon content temperature is 50°C, and the carbon content is stopped when the pH value of the filtrate reache...

Embodiment 3

[0054] (1) After the bauxite tailings are crushed, they are mixed with solid sodium carbonate at a ratio of 1:2 and ground into a 200-mesh mixed material.

[0055] (2), the mixed material obtained in step (1) was roasted for 40 minutes under the temperature condition of 300° C. to obtain roasted clinker; during roasting, the calcining equipment was connected to the gas output pipe and connected to the carbon separation tank.

[0056] (3) Add an appropriate amount of water to the calcined clinker obtained in step (2), and make the solid-liquid mass ratio 1:6, and leaching for 20 minutes at a temperature of 50°C. After leaching, filter to obtain filtrate and filter residue respectively. It has been determined that the aluminum-silicon ratio (A / S) in the filter residue is 10, which satisfies the aluminum-silicon ratio condition of the material required for the subsequent Bayer process to produce alumina.

[0057] (4), after the filtrate obtained in step (3) is concentrated to 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com