Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Geopolymer cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geopolymer cement is a binding system that hardens at room temperature. It is a more environmentally friendly alternative to conventional Portland cement. It relies on minimally processed natural materials or industrial byproducts to significantly reduce the carbon footprint of cement production, while also being highly resistant to many common concrete durability issues.

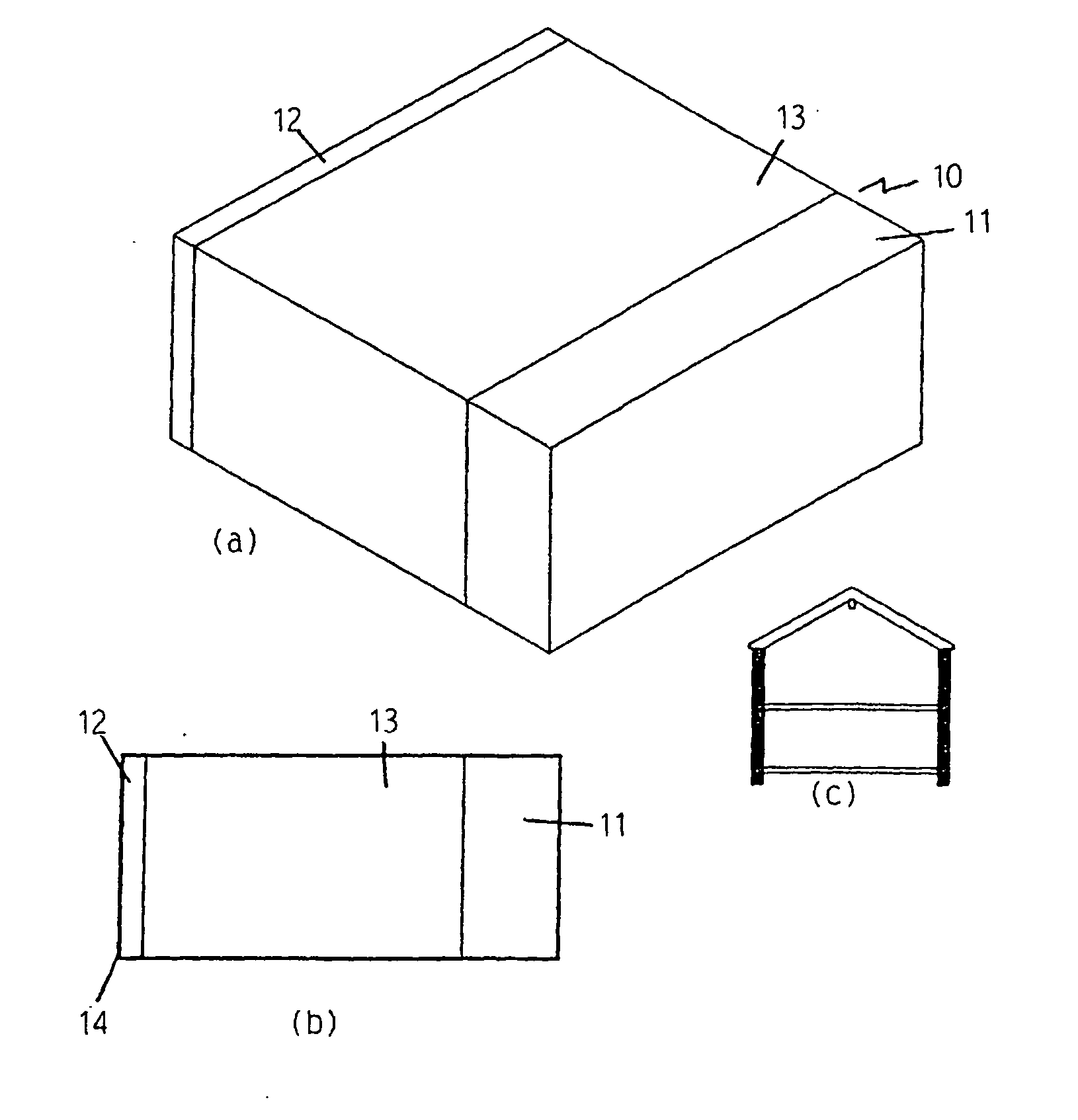

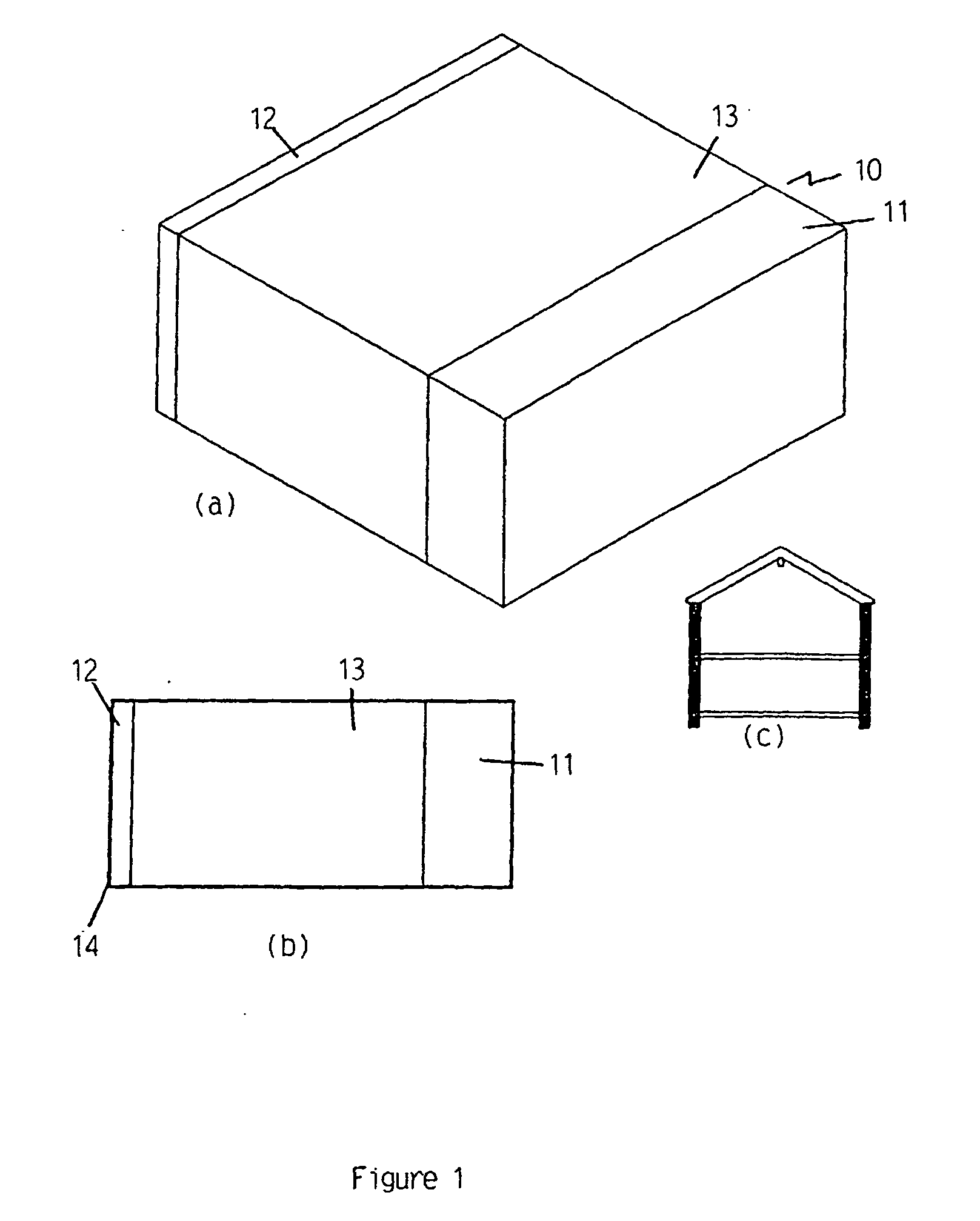

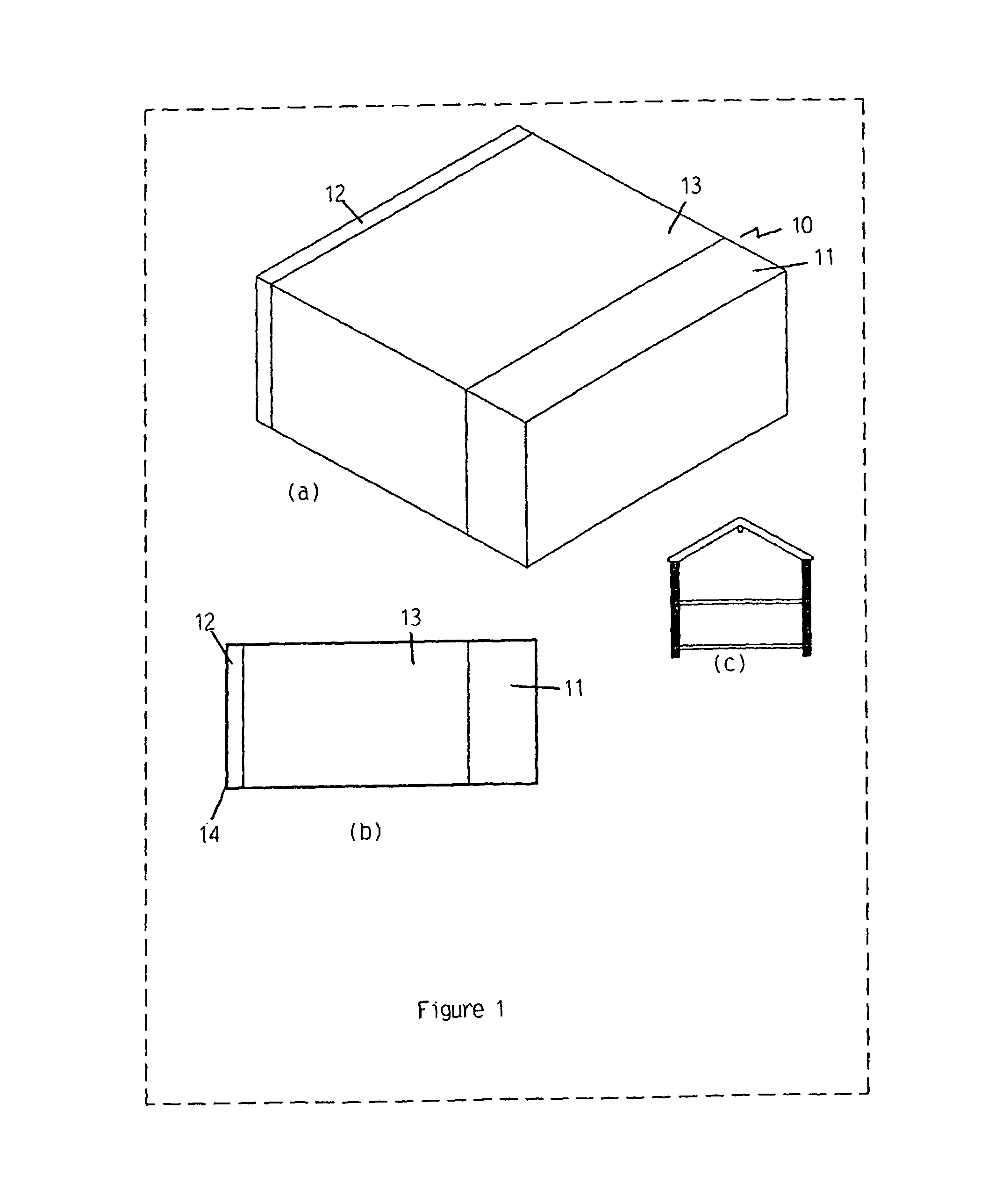

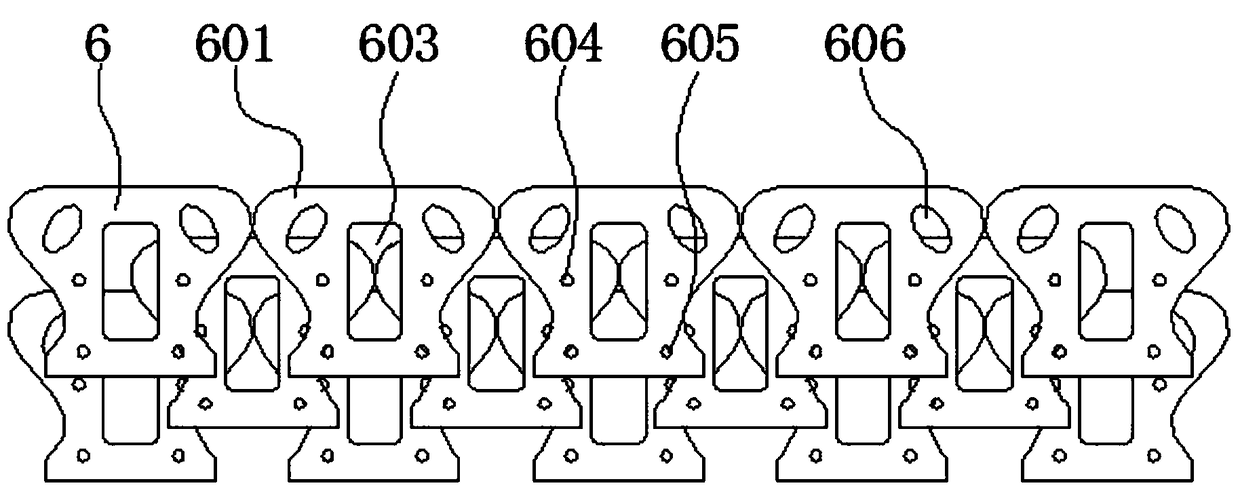

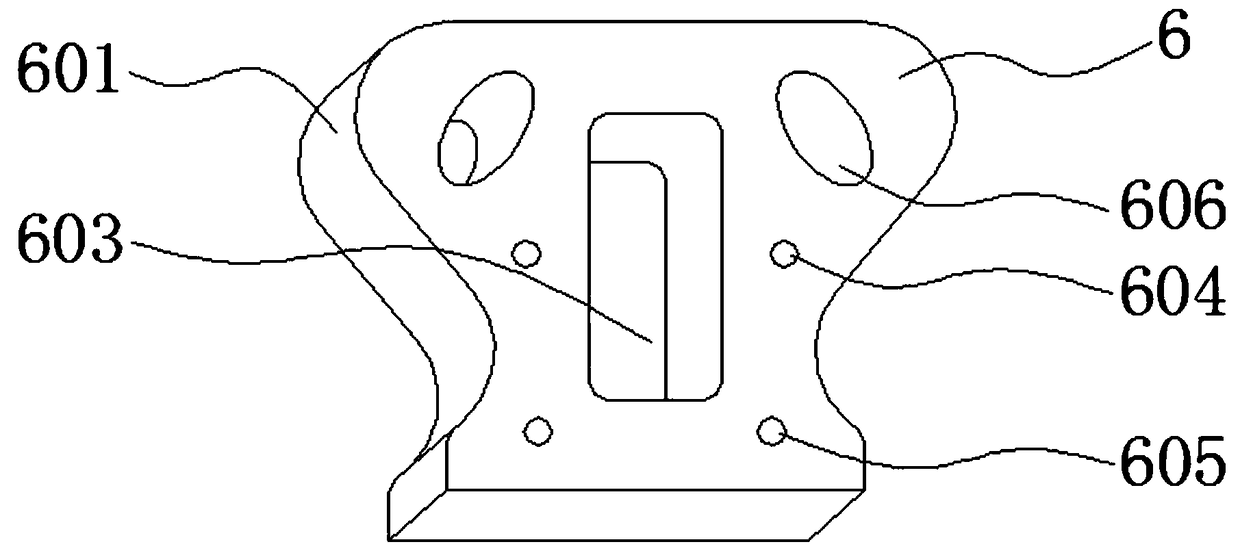

Geopolymeric structural building units and methods of manufacture thereof

ActiveUS20120260594A1Improve thermal efficiencyImprove thermal performanceSolid waste managementCement productionGeopolymer cementBuilding unit

The present invention provides a geopolymeric cement formed from a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline multiphase alumino-silicate material.The precursor comprises basaltic rock in which kaolinization is at an advanced stage, preferably Interbasaltic material found in Northern Ireland.The present invention also provides structural units for constructing a building, the structural units being manufactured using the geopolymeric cement of the invention.The invention also provides a process for producing a geopolymeric cement comprising a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline alumino-silicate geopolymer material for manufacturing geopolymeric structural building units having compressive strengths of greater than 3 N / mm2 and preferably having compressive strengths in the range of 12-25 N / mm2.

Owner:RANDOM TECH

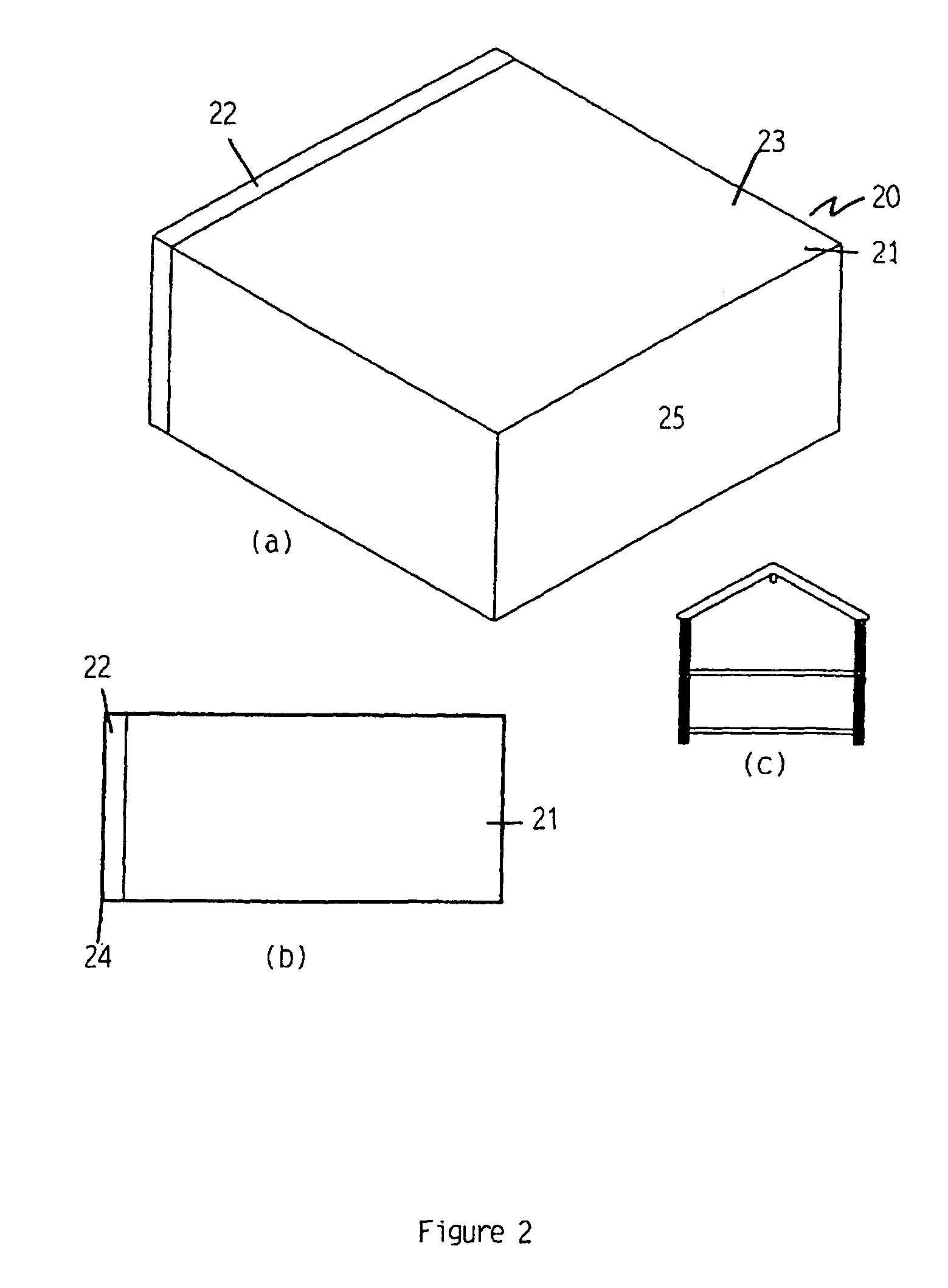

Preparation method for high-molecular compound-containing metakaolin-based geopolymer cement

The invention discloses a preparation method for high-molecular compound-containing metakaolin-based geopolymer cement. The preparation method is characterized by comprising the steps: taking the following raw materials in parts by weight: 100 parts of metakaolin, 50-70 parts of alkali-activator, 10-30 parts of water, and 0.1-15 parts of high-molecular compound, wherein the alkali-activator is prepared by mixing 10-40 parts of sodium hydroxide and 30-50 parts of sodium silicate by weight, and the high-molecular compound is one of polyvinyl alcohol, polyacrylamide and epoxy resin; mixing and agitating the raw materials for 3-6min into pulp, and injecting into a mold for forming; and curing for 24h under conditions that the temperature is 19-23 DEG C and the relative humidity is 90-95%, demolding, and continuing curing in a standard curing box to obtain the product. By adopting the preparation method, the high-molecular compound-containing metakaolin-based geopolymer cement prepared has high strength and less emitted carbon dioxide, thereby being novel environment-friendly cement.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Geopolymer cement and use thereof

InactiveCN102596848AReduce manufacturing costReduce harmful effectsSolid waste managementCement productionSuperplasticizerCrosslinked polymers

The present invention relates to a novel type of non-corrosive geopolymer cement in which said cement comprises a metakaolin or a mixture of metakaolin and of an aluminosilicate that is not thermally activated, in a weight ratio within the range extending from around 40:60 to around 80:20, and an alkaline silicate solution having an M2O:SiO2 molar ratio within the range extending from 0.51 to 0.60, M representing Na or K and also the use of a superplasticizer comprising a crosslinked polymer of acrylic acid in the manufacture of geopolymer cement.

Owner:法国运输规划和运输网科学技术学院

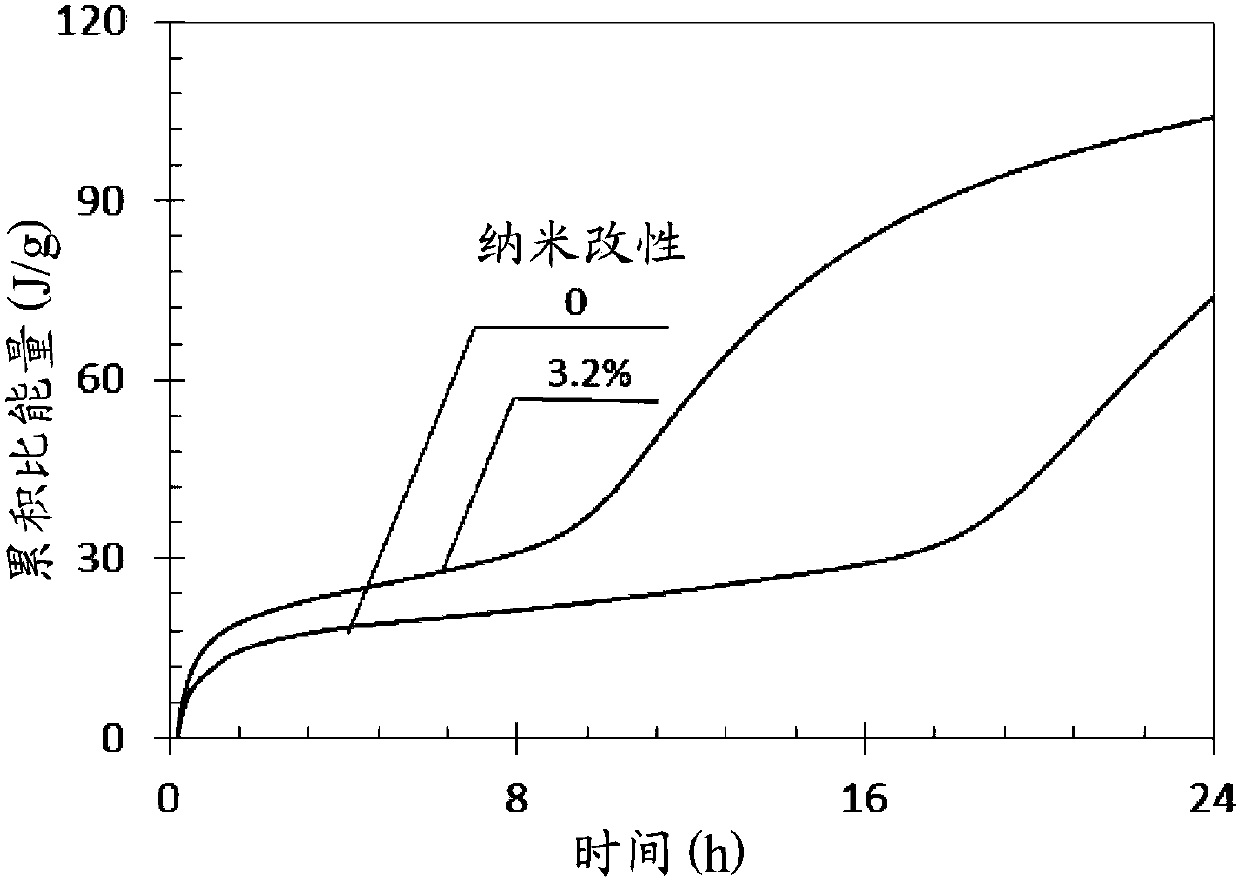

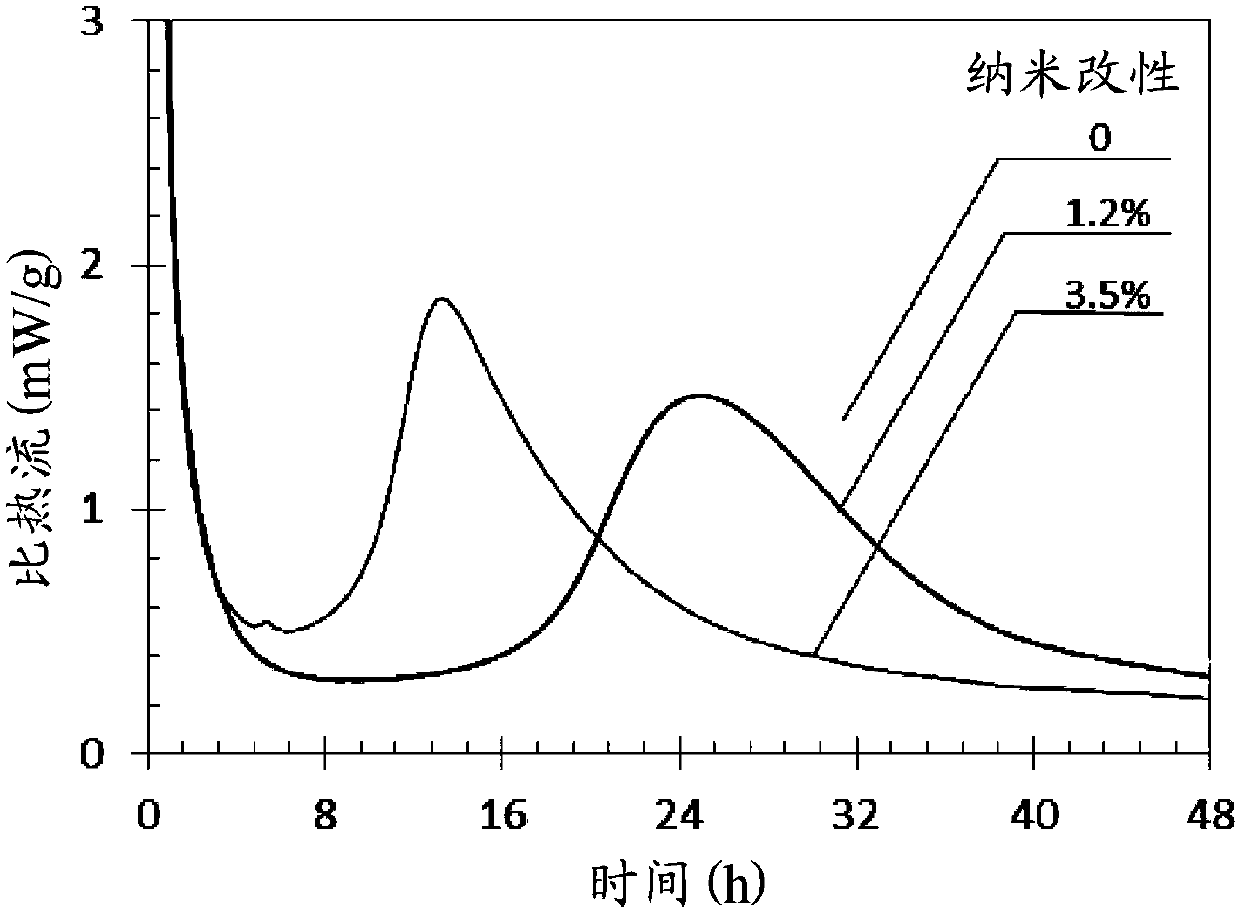

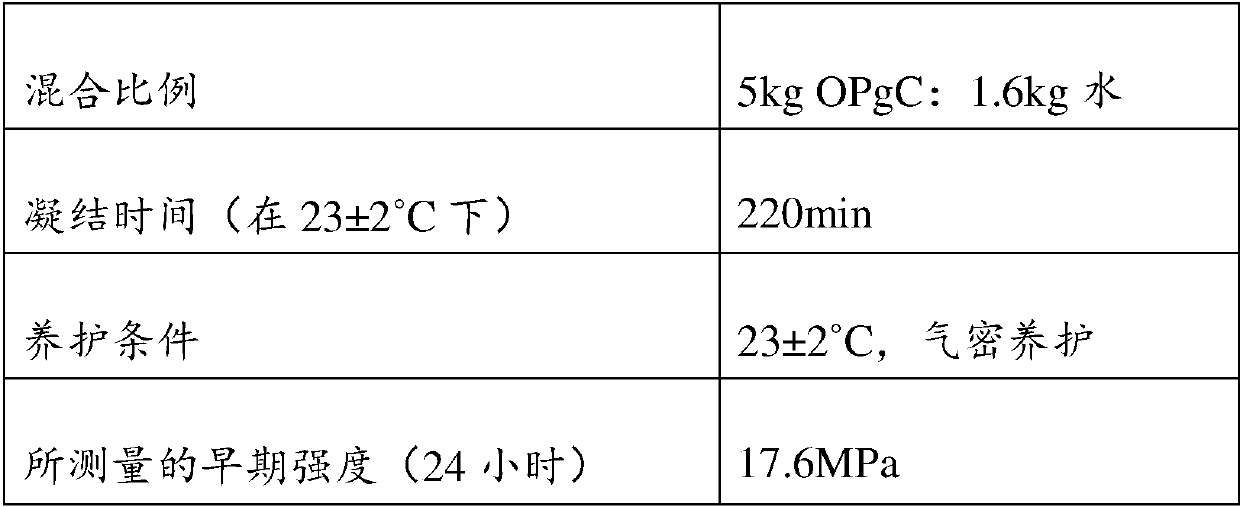

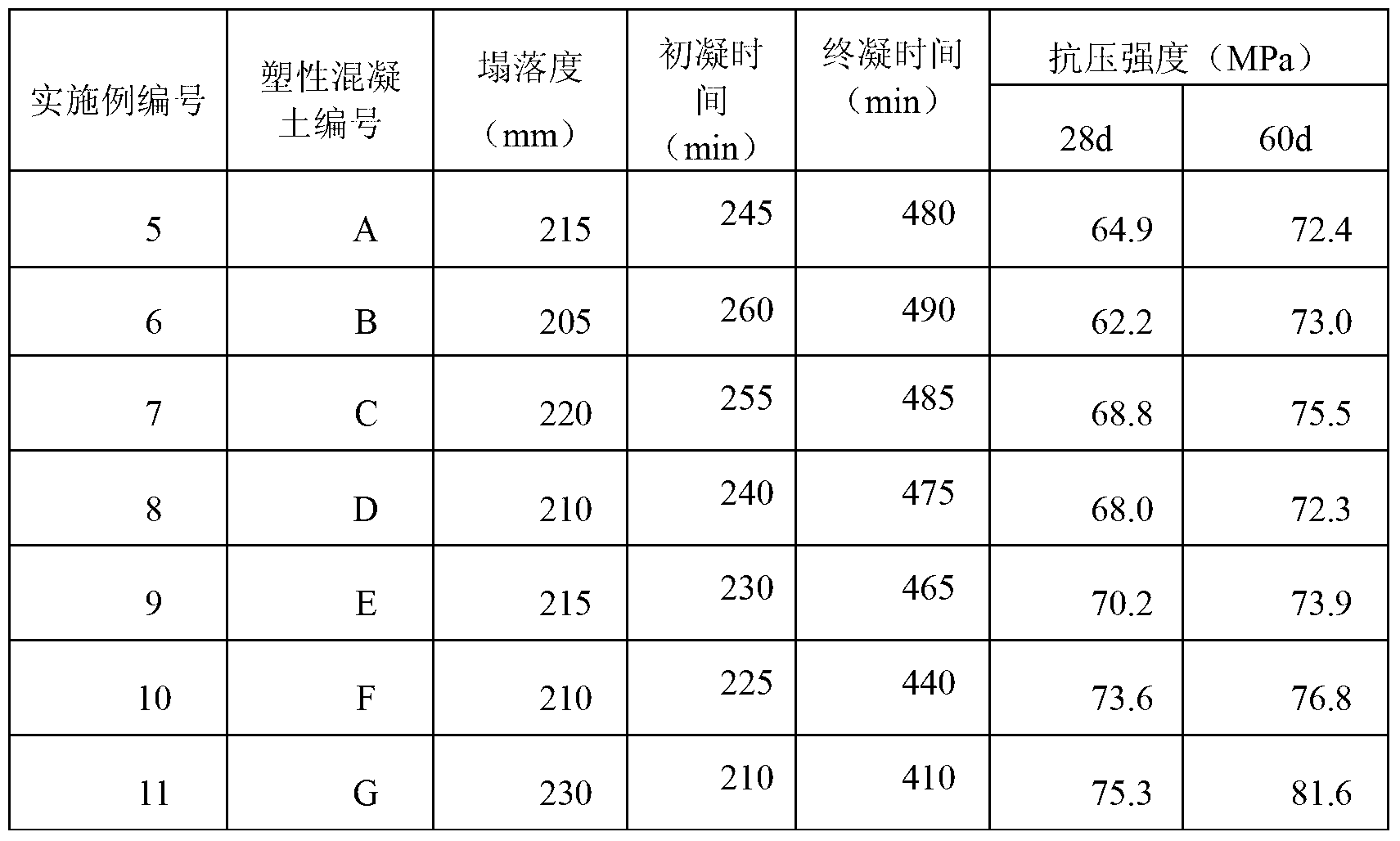

Nano-modified alkali-activated cementitious materials for rapid repair

A nano-modified dry-mixed alkali-activated cementitious, or one-part geopolymer cement (OPgC), material with high early strength is provided for rapid repair of cement-based infrastructure components.The OPgC may include an aluminosilicate rich material, an alkali material and a nano-modifier, and optionally include other functional admixtures and fibers. The OPgC can be freshly mixed with waterto obtain a repairing material. The OPgC may mix with water and fine or coarse aggregate to form mortar or concrete. The OPgC can be an alternative binding matrix for the development of an environmentally friendly and cost effective rapid repair material and can replace conventional adhesive matrix (including Portland cement, organic adhesives, etc.).

Owner:NANO & ADVANCED MATERIALS INST

Geopolymer cement

ActiveUS20150321954A1Accelerate strength growth rateHigh compressive strengthSolid waste managementCement productionSolid componentPolymer concrete

A solid component activator for use in a geopolymer cement containing a silico-aluminate material comprising a mixture of sodium silicate and sodium carbonate for activating the geopolymer cement by increasing reactivity of the silico-aluminate material in the geopolymer cement when forming geopolymer concrete.

Owner:CEMENT AUSTRALIA PTY

Compound activator and geopolymer cement concrete prepared from same

ActiveCN103172295ASuitable base stimulated activityReduce alkali chemical attackCement productionKaolin clayPolymer concrete

The invention provides a compound activator. The compound activator comprises triethanolamine, a naphthalene water reducer, quartz powder and lime milk. The invention further provides geopolymer cement concrete prepared from the compound activator. The geopolymer cement concrete comprises a binding material, an aggregate and the compound activator; by the geopolymer cement concrete per cubic meter, the addition amount of the binding material is 510-650kg, the addition amount of the aggregate is 1410-1550kg, the specific value of the addition amounts of the compound activator and the binding material is (0.22-0.35):1, the water-binder ratio is 0.35-0.37, and the sand ratio of the aggregate is 25-35%; and the binding material comprises one or more of metakaolin, slag powder and pulverized fuel ash, and the aggregate comprises sand and cobbles. The geopolymer cement concrete provided by the invention is low in cost, can be maintained at a normal temperature and has the advantages of high strength, high volume stability and durability, so that the geopolymer cement concrete can be widely applied to building fields such as civil engineering, highways and bridges instead of common Portland cement.

Owner:北京中联新航建材有限公司

Method for producing geopolymer cement mortar through red mud and bauxite tailing

InactiveCN108726926ADoes not consume resourcesLow costSolid waste managementCement productionRed mudSlag

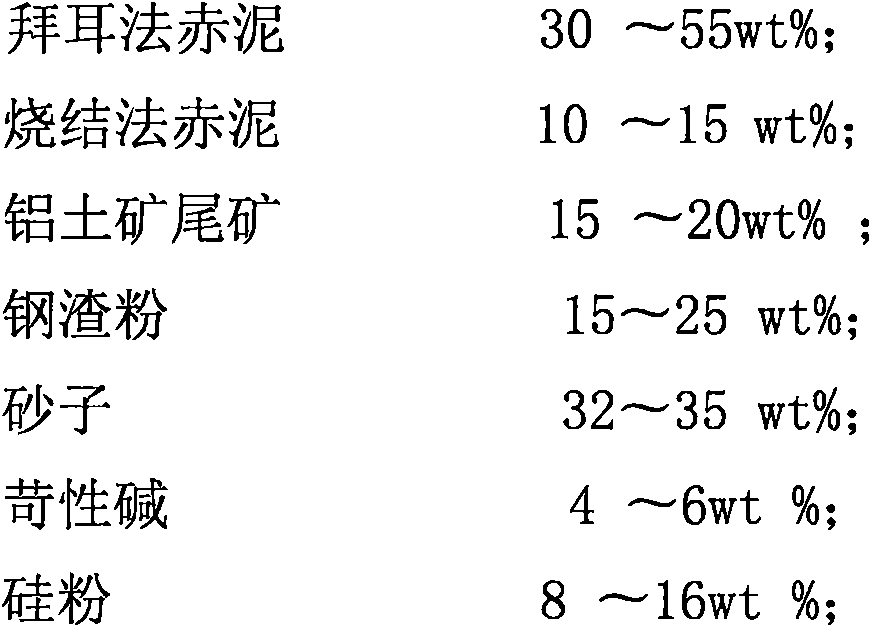

The invention discloses a method for producing geopolymer cement mortar through red mud and bauxite tailing. The geopolymer cement mortar is prepared from the following components: 30 to 55 wt percentof bayer red mud; 10 to 15 wt percent of sintered red mud; 15 to 20 wt percent of bauxite tailing; 15 to 25 wt percent of ground steel slag; 32 to 35 wt percent of sands; 4 to 6 wt percent of causticalkali; 8 to 16 wt percent of silicon powder. The method comprises the following steps: adding the caustic alkali into the bayer red mud, the sintered red mud and the bauxite tailing, and laying thematerials into a ball mill, so as to form a ball milling material; laying the ball milling material into a moderate temperature furnace to perform modification, so as to form a modified material; adding the ground steel slag and the silicon powder into the modified material, so as to form a mixture; laying the mixture into the ball mill, so as to form red mud and bauxite tailing geopolymer cement;uniformly mixing the geopolymer cement and the sands, adding water, and grouting while stirring. The geopolymer cement mortar has a wide flow range, forms hard paste, does not cause alkali-aggregatereaction, and belongs to a novel green building material with low cost and high performance.

Owner:鄢金松

Novel water-resistant gypsum-based self-levelling material

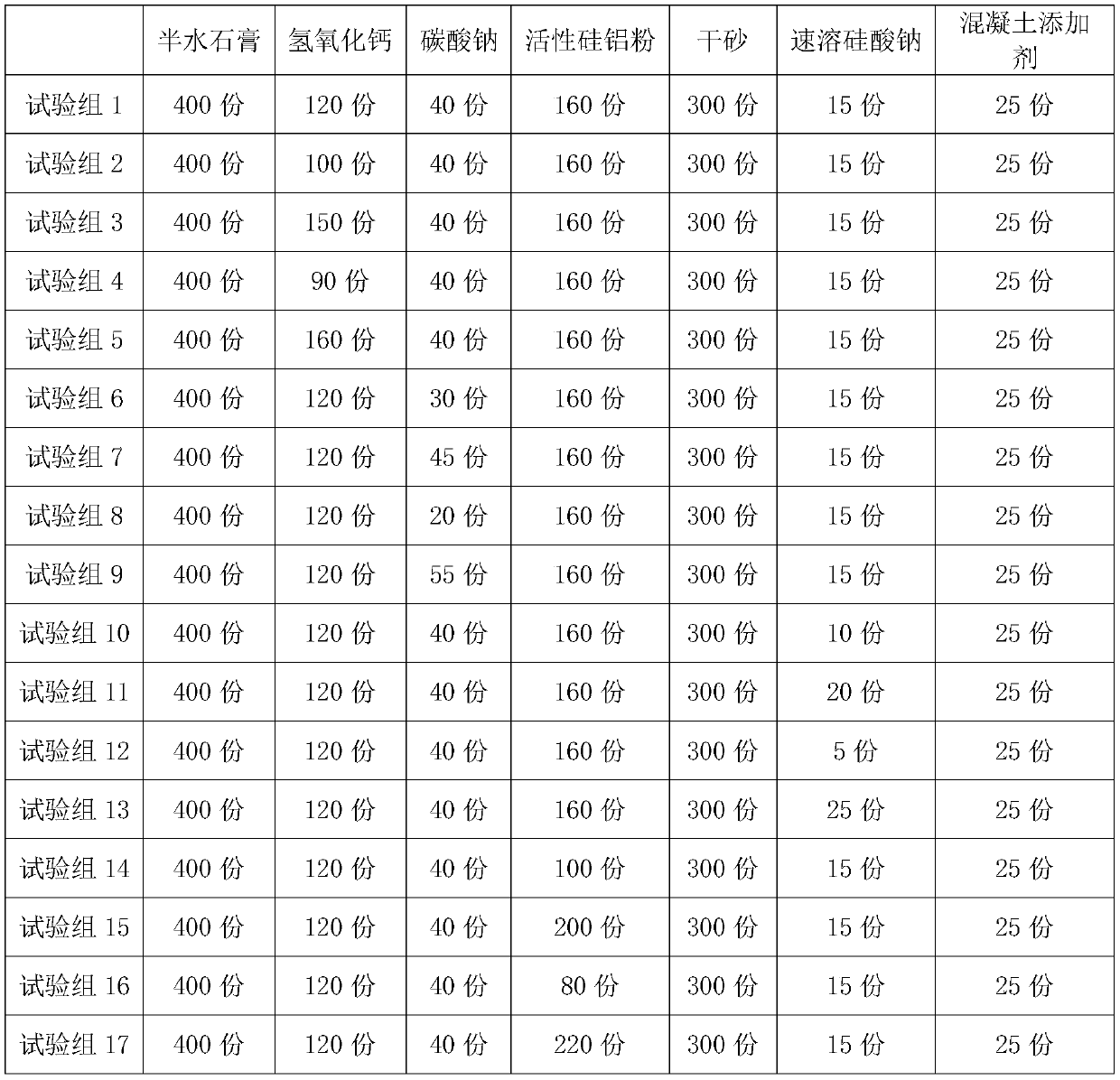

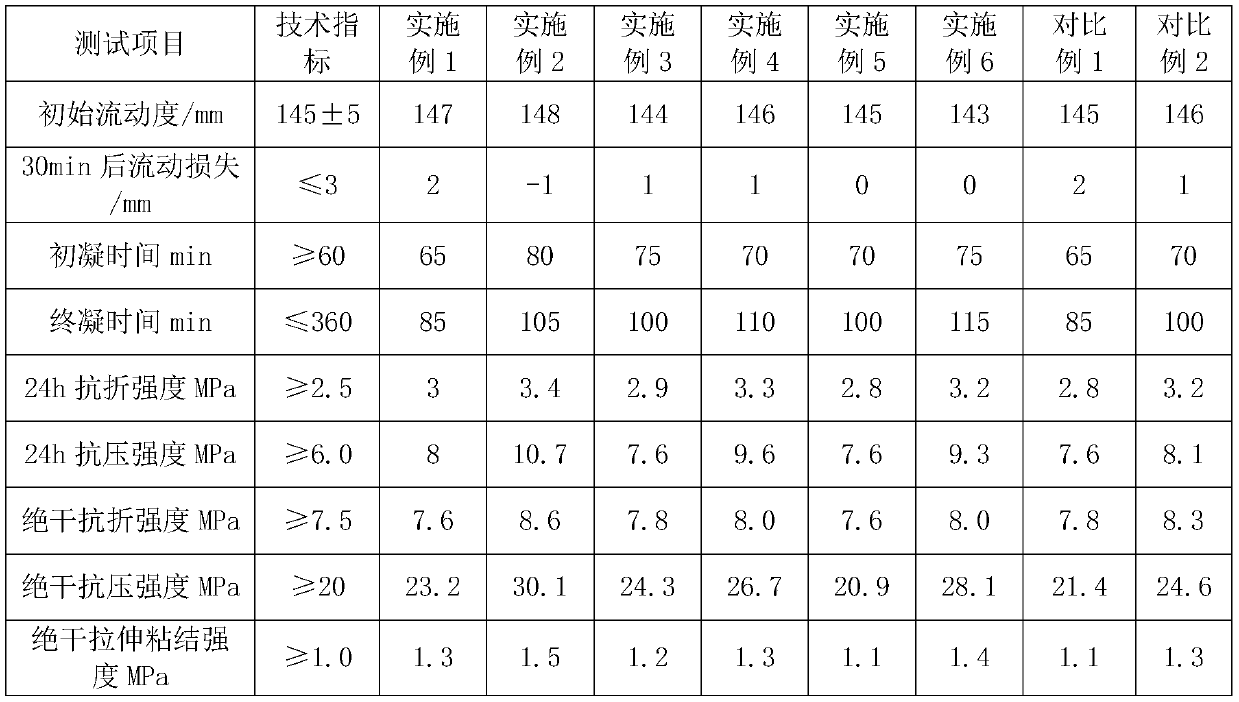

The invention belongs to the field of building materials, and particularly discloses a novel water-resistant gypsum-based self-levelling material. The self-levelling material comprises the following raw materials in parts by weight: 300-500 parts of semi-hydrated gypsum, 100-150 parts of calcium hydroxide, 30-45 parts of a soluble carbonate, 100-200 parts of active silicon-aluminum powder, 250-450parts of dry sand, 10-20 parts of instant water glass and 2.5-38.5 parts of a concrete additive. According to the self-levelling material provided by the invention, the calcium hydroxide powder is added into the gypsum base material, carbonate radicals are provided for carbonization of the calcium hydroxide by doping the soluble carbonate salt, the calcium hydroxide is promoted to be rapidly carbonized to generate water-insoluble calcium carbonate crystals, so that water resistance of the gypsum base material is quickly improved; and a part of strong alkali is generated while the calcium carbonate crystals are generated, and a combination of the strong alkali and the water glass can effectively promote a polymerization reaction of the active silicon-aluminum powder to generate a high-strength mesh silicon-aluminum tetrahedron, that is, geopolymer cement is generated, so that the later-stage water resistance and strength of the gypsum base material are continued to be improved.

Owner:成都宏基建材股份有限公司

Light foam concrete used for road and bridge filing and preparing method thereof

InactiveCN106927864APrevent penetrationReduce usageSolid waste managementCement productionFoam concreteSocial benefits

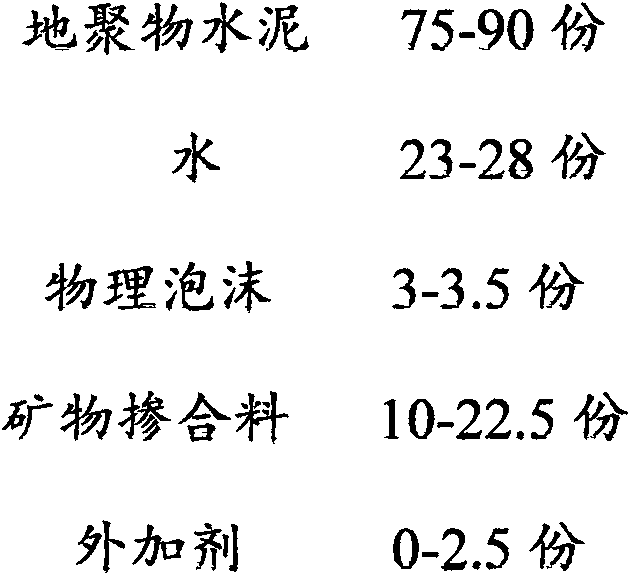

The invention discloses light foam concrete used for road and bridge filing and a preparing method thereof. The foam concrete is light in weight, higher in strength than common backfill materials and convenient to construct as the foam concrete is flowable plastic body during construction, uses a great deal of industrial solid waste such as steel slag, mineral waste residue and flyash and plant straw fiber and has remarkable economic, environment-friendly and social benefits. The light foam concrete is obtained through the following scheme that geopolymer cement, mineral admixtures, additives and modified plant straw fiber are mixed and stirred uniformly, an appropriate amount of water is added, and the materials are stirred into uniform and stable slurry; a foaming agent continues to be added into the slurry and stirred uniformly, and the stirring time is 5-10 min; filling construction work is carried out after uniform stirring.

Owner:CHANGZHOU YINENG TECH

Fly ash-based concrete

ActiveCN108546050AGuaranteed StrengthLight weightCement productionGeopolymer cementThermal stability

The invention discloses fly ash-based concrete. The fly ash-based concrete is prepared from the following raw materials in parts by mass: 200 to 300 parts of coarse aggregate of artificial fly ash, 50to 150 parts of fine aggregate of artificial fly ash, 5 to 20 parts of silica fume, 100 parts of geopolymer cement, 0.5 to 3 parts of water reducing agent, 20 to 40 parts of water and 5 to 15 parts of additive. By adopting the fly ash-based concrete disclosed by the invention, the strength of the concrete is ensured, and the bulk density of the concrete can be lowered. Meanwhile, and the fly ash-based concrete has excellent thermal stability and chemical stability. The fly ash is taken as a substrate material, so that the fly ash can be fully reused, and the problem of environmental pollutioncaused by the fly ash is solved.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Geopolymeric structural building units and methods of manufacture thereof

InactiveUS9126865B2Improve performanceSolid waste managementCement productionGeopolymer cementBuilding unit

The present invention provides a geopolymeric cement formed from a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline multiphase alumino-silicate material.The precursor comprises basaltic rock in which kaolinization is at an advanced stage, preferably Interbasaltic material found in Northern Ireland.The present invention also provides structural units for constructing a building, the structural units being manufactured using the geopolymeric cement of the invention.The invention also provides a process for producing a geopolymeric cement comprising a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline alumino-silicate geopolymer material for manufacturing geopolymeric structural building units having compressive strengths of greater than 3 N / mm2 and preferably having compressive strengths in the range of 12-25 N / mm2.

Owner:RANDOM TECH

Single-component regenerated geopolymer cement concrete

ActiveCN111548068AHigh activityImprove resource utilizationCement productionMining engineeringKaolin clay

The invention belongs to the technical field of concrete, and particularly relates to single-component regenerated geopolymer cement concrete. The concrete comprises following raw materials: recycledgeopolymer cement, water, natural fine aggregate, a recycled sand / powder mixture, coarse aggregate and an additive. The single-component geopolymer regenerated cement is prepared by mixing a volcanicash mineral admixture (such as fly ash and slag), the regenerated sand / powder mixture and a solid alkali activator and then carrying out ball milling. The geopolymer regenerated cement is produced byactivating the activity of the regenerated sand / powder mixture and the volcanic ash mineral admixture (such as fly ash, slag and meta-kaolin) by utilizing the mechanochemical action in the ball milling process. The regenerated sand / powder mixture is adopted to replace part of fine aggregate to produce the regenerated geopolymer cement concrete, so that the recycling value and the recycling rate ofthe regenerated sand / powder mixture are effectively improved.

Owner:FUZHOU UNIV

Geopolymer cement cover plate concrete and preparation method thereof

The invention discloses geopolymer cement cover plate concrete and a reparation method thereof. The geopolymer cement cover plate concrete comprises the following materials: Na2SO4, ordinary Portlandcement, coal ash (untreated power plant raw ash), sand, stone and water; the preparation method comprises the following steps: metering, mixing dry materials, preparing an excitant, uniformly stirringand performing vibration formation. The geopolymer cement cover plate concrete adopts geopolymer cement (comprising Na2SO4, ordinary Portland cement and coal ash) to replace a large amount of the traditional ordinary Portland cement, ensures that the cover plate concrete is excellent in workability, and the strength of the cover plate concrete is higher than that of ordinary Portland cement coverplate concrete, can further utilize a large amount of power plant raw coal ash, and has the advantages of low cost and good environmental protection property.

Owner:福建瑞森水泥制品发展有限公司

Novel Multifunctional Material for Workability of Geopolymeric System and its Process Thereof

ActiveUS20170349488A1Improve mechanical propertiesChange viscositySolid waste managementCement productionChemical reactionGeopolymer cement

The present invention relates to a novel multifunctional material for workability of geopolymeric system and its process thereof. The viscous characteristics in geopolymeric system are responsible for observed negligible workability of geopolymeric cement concrete system and which limits its broad application spectrum. The novel multifunctional material of the present invention prepared by digestion of siliceous agricultural waste i.e. Rice husk with aqueous alkaline materials involving simultaneous and synergistic chemical reactions among the various constituents of rice husk, aqueous alkaline compounds and optionally adding Cetyl trimethyl ammonium bromide (CTAB) to obtain in-situ synthesis of desired nano-sized multi functional agents lignin, hemicelluloses, cellulose, sodium silicate necessary for addressing the issue of workability and also improving the engineering properties of geopolymeric system for broad application spectrum.

Owner:COUNCIL OF SCI & IND RES

Hyaloclastite, sideromelane or tachylite pozzolan-based geopolymer cement and concrete and method of making and using same

The invention comprises a cementitious material comprising a natural pozzolan selected from hyaloclastite, sideromelane or tachylite, wherein the natural pozzolan has a volume-based mean particle size of less than or equal to 40 μm. The cementitious material also comprising an aqueous alkaline activating solution suitable for forming a geopolymer. A method making a cementitious material is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Foam lightweight concrete for road and bridge filling and preparation method thereof

InactiveCN108975942AFast condensationImprove stabilityCement productionCeramicwareFiberFoaming agent

The invention discloses foam lightweight concrete for road and bridge filling and a preparation method thereof and relates to the technical field of concrete preparation. A raw material formula of thefoam lightweight concrete comprises the following raw materials in parts by mass: 100 to 250 parts of geopolymer cement, 1.0 to 1.5 parts of a water reducing agent, 4 to 5 parts of an early strengthagent, 3 to 5 parts of an additive, 2 to 4 parts of fiber, 15 to 20 parts of a foaming agent, 30 to 60 parts of ultrafine slag powder, 10 to 12 parts of a gel material, 1 to 3 parts of diatom ooze and80 to 130 parts of water; the preparation method of the foam lightweight concrete comprises the following steps: (1) pouring the geopolymer cement, the water reducing agent, the early strength agent,the fiber, the ultrafine slag powder, the gel material, the diatom ooze and a proper amount of the water into a stirring pot according to the ratio and stirring and mixing; (2) continually adding thefoaming agent into the stirring pot and continuously stirring for 10 to 15 minutes; then adding the additive and continuously stirring 20 to 30 minutes. The concrete prepared by the invention has thecharacteristics of light weight and good commonality.

Owner:中冶成都勘察研究总院有限公司

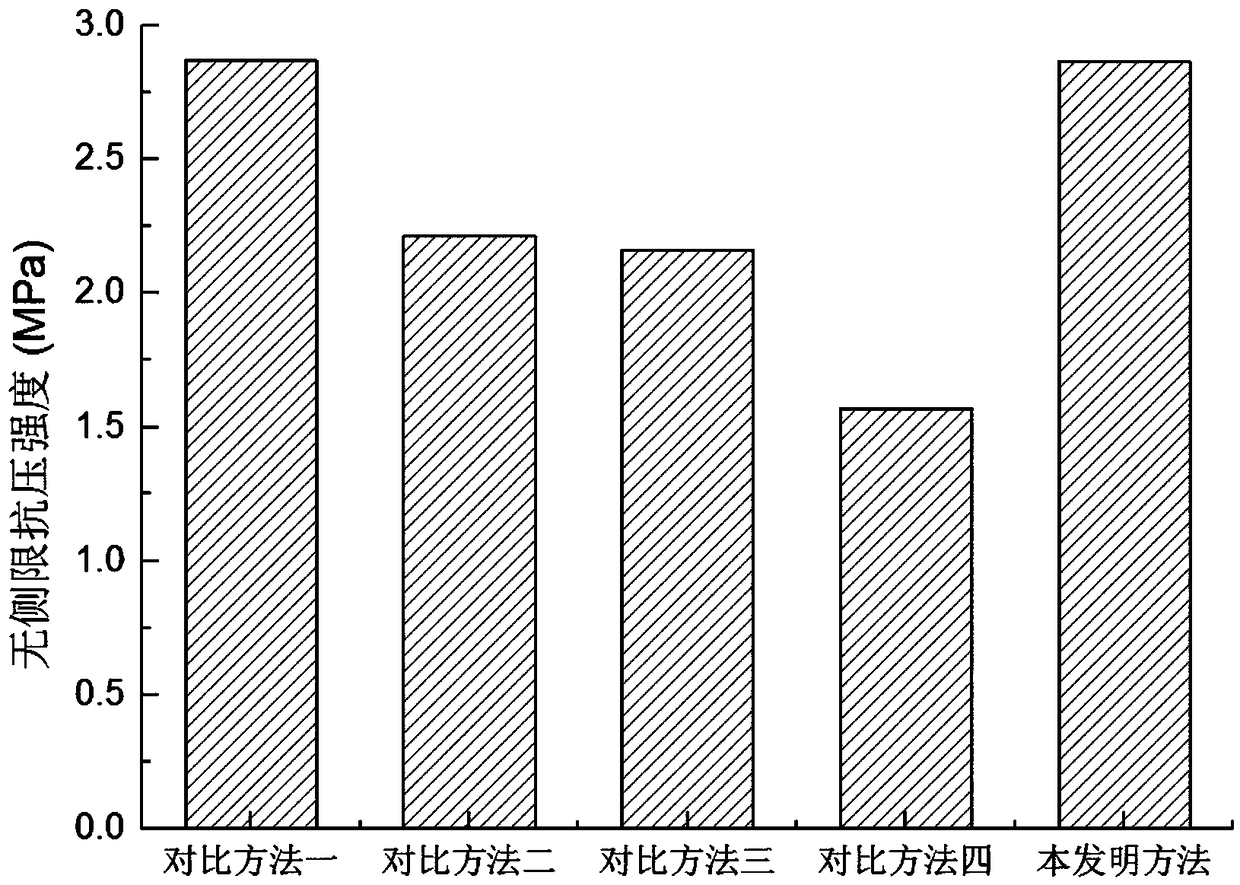

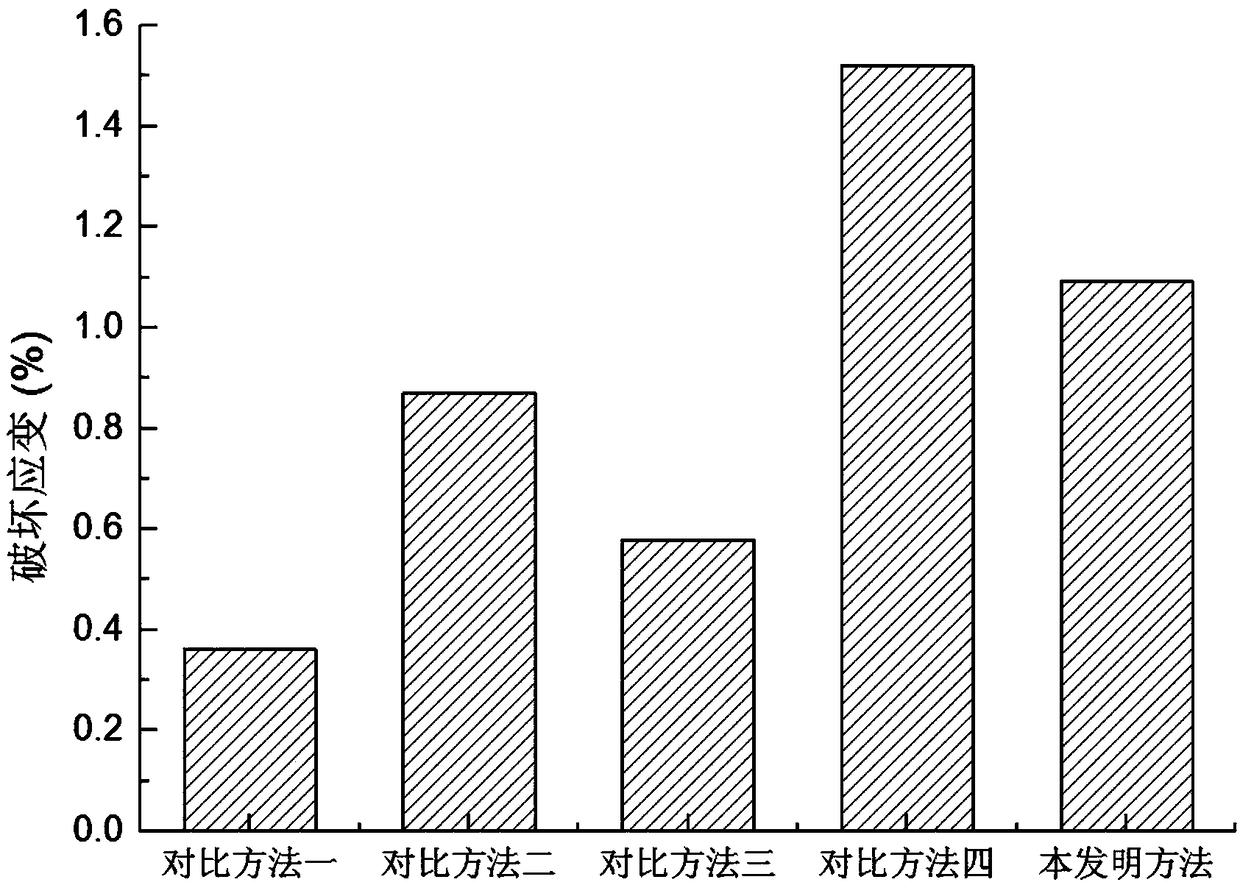

Mixing method for preparing geopolymer cement soil

ActiveCN108314343AConsider physical propertiesSolve the phenomenon of clumpingCement productionGeopolymer cementMetakaolin

The invention discloses a mixing method for preparing geopolymer cement soil. The mixing method comprises the following steps of drying, crushing and sieving a soil body firstly during preparation, then performing spraying humidification with an optimum moisture content, performing uniform mixing and infiltration for one day and night, adding metakaolin in wet soil, performing uniform mixing, preparing an alkali activator, spraying the alkali activator into the wet soil, performing uniform mixing, performing standing for 10mins, adding cement in the soil body, performing uniform mixing, and finally, spraying cement into the wet soil with a corresponding water-cement ratio for uniform mixing, wherein the alkali activator is prepared by mixing a NaOH solution with the concentration being 50percent and sodium water glass.

Owner:ANHUI UNIV OF SCI & TECH

Improved geopolymer cement

PendingUS20220185735A1Long and controllable open timeMore flowableCeramicwarePolymer scienceGeopolymer cement

The present invention provides a geopolymer cement, comprising: a geopolymer binder; and a setting control composition comprising: a viscosity control agent, a polymeric binder, and a retarding additive. The invention also relates to a geopolymer concrete comprising the geopolymer cement of the invention and aggregate material. The invention further relates to a method for controlling open time in a geopolymer composition, wherein a sufficient quantity of the setting control composition is added such that the open time is between 30 and 120 minutes. The present invention provides particular uses in construction of walls, flooring, and roofing, especially lightweight prefabricated panels intended to be used as structural, insulating or cladding elements.

Owner:MAKENIT PTY LTD

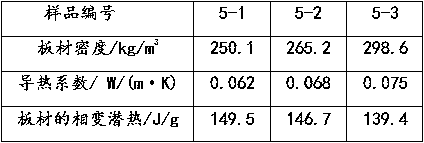

Preparation method of straw phase change plate with phase change heat storage and insulation function

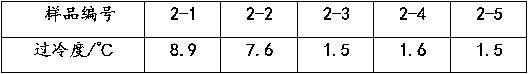

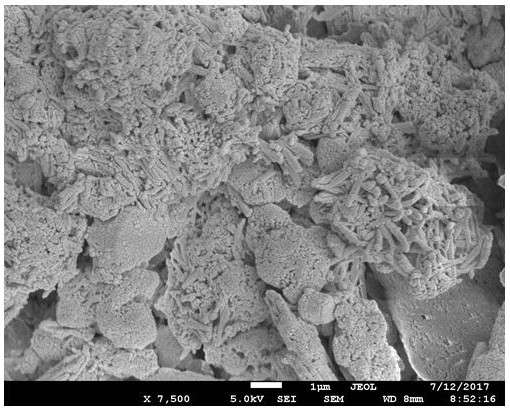

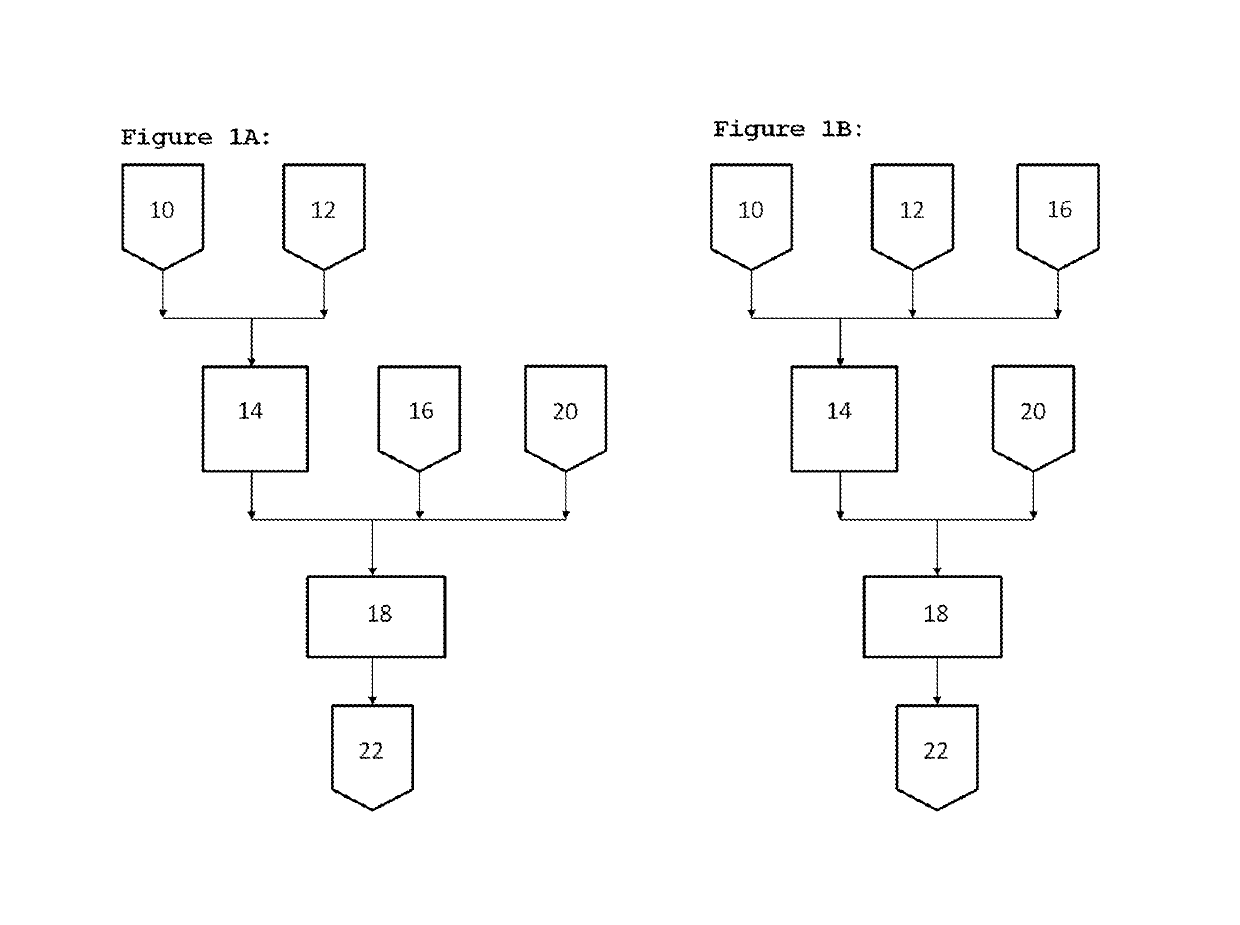

InactiveCN110434974AConducive to loadReduce subcoolingFlat articlesDomestic articlesCompression moldingApparent density

The invention discloses a preparation method of a straw phase change plate with a phase change heat storage and insulation function. According to the straw plate, environment-friendly and renewable crop straws are used as raw materials, a large number of micropores existing in the straw are used for loading and packaging an inorganic phase change material Na2SO4.10H2O, and the inorganic phase change material and the inorganic binder geopolymer cement are subjected to compression molding to obtain the straw plate. The preparation method comprises the first step of straw pretreatment, the secondstep of loading and packaging of phase change materials in micropores of straw, and the third step of compression molding of the straw plate. Compared with the prior art, according to the prepared straw plate, the apparent density is less than or equal to 300 kg / m<3>, the thermal conductivity is less than or equal to 0.08 W / (m.K), the phase change heat can reach 143.3 J / g, and the straw plate hasa good application prospect in the field of thermal insulation building materials.

Owner:江苏禾吉新材料科技有限公司 +1

Foam light-weight concrete and preparation method thereof

InactiveCN109231903AFast condensationImprove stabilityCement productionCeramicwareFiberFoaming agent

The invention discloses foam light-weight concrete and a preparation method thereof and relates to the technical field of preparation of concrete. A raw material formula comprises the following components in parts by mass: 150 to 200 parts of geopolymer cement, 1.0 to 1.5 parts of a water reducing agent, 4 to 5 parts of an early strength agent, 3 to 5 parts of an additive, 2 to 4 parts of fibers,15 to 20 parts of a foaming agent, 10 to 12 parts of a gel material, 1 to 3 parts of diatom ooze and 100 to 120 parts of water; the preparation method of the foam light-weight concrete comprises the following steps: (1) pouring the geopolymer cement, the water reducing agent, the early strength agent, the fibers, the gel material, the diatom ooze and a proper amount of the water into a stirring tank according to the ratio and stirring and mixing; (2) continually adding the foaming agent into the stirring tank and continuously stirring for 12 to 14min; then adding the additive and continuouslystirring for 35 to 40min. The concrete prepared by the method has the advantages of light weight and good commonality.

Owner:方涛

Geopolymer cement material and preparation method thereof

ActiveCN111847934APollution is easy to causeImprove performanceCement productionBreaking strengthCompressive resistance

The invention discloses a geopolymer cement material and a preparation method thereof. The geopolymer cement material comprises the following components in parts by weight: 15-35 parts of metakaolin,5-25 parts of slag, 3-23 parts of a waste catalyst, 10-42 parts of an excitant and 2-16 parts of water. According to the geopolymer cement material, slag and the waste catalyst can be turned into wealth, the geopolymer cement material not only has good compressive strength and breaking strength, but also can avoid loss of metal pollutants in the waste catalyst, the problem of single basic raw material of geopolymer cement is solved, and popularization and application of the geopolymer cement can be better promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

Geopolymer cement

ActiveUS10315952B2Improve responseStable storageSolid waste managementCement productionSolid componentPolymer concrete

A solid component activator for use in a geopolymer cement containing a silico-aluminate material comprising a mixture of sodium silicate and sodium carbonate for activating the geopolymer cement by increasing reactivity of the silico-aluminate material in the geopolymer cement when forming geopolymer concrete.

Owner:CEMENT AUSTRALIA PTY

Novel light-weight high-strength sand-based water-permeable brick

The invention discloses a novel light-weight high-strength sand-based water-permeable brick and a preparation method thereof. The water-permeable brick comprises, in parts by mass, 100 parts of geopolymer cement, 5-12 parts of a reinforcing agent, 1-10 parts of a thickener, 350-650 parts of high-strength pottery sand, 1.5-3.5 parts of a setting accelerator, 3-5 parts of a coloring agent, 0.5-3.0 parts of a water reducing agent and 15-20 parts of water. Mixing and stirring in a stirrer or a mixer are performed multiple times, and then the obtained mixture is placed in a brick making machine for vibration molding. Steel slag, fly ash and other large solid waste are utilized, and the defects of easily blocked pores, short water-permeable effective period and large density of existing water-permeable bricks are overcome. The prepared water-permeable brick has good water permeability, long water permeable effective period, high compressive strength and low density, and can be widely applied to sponge cities and other municipal engineering construction, the utilization added value of steel slag and other large solid waste is improved, and the ecological environment is protected.

Owner:江苏德智重工有限公司

Multifunctional material for workability of geopolymeric system and its process thereof

ActiveUS10023497B2Improve engineering performanceSaving environment protectionSolid waste managementCement productionChemical reactionDigestion

The present invention relates to a novel multifunctional material for workability of geopolymeric system and its process thereof. The viscous characteristics in geopolymeric system are responsible for observed negligible workability of geopolymeric cement concrete system and which limits its broad application spectrum. The novel multifunctional material of the present invention prepared by digestion of siliceous agricultural waste i.e. Rice husk with aqueous alkaline materials involving simultaneous and synergistic chemical reactions among the various constituents of rice husk, aqueous alkaline compounds and optionally adding Cetyl trimethyl ammonium bromide (CTAB) to obtain in-situ synthesis of desired nano-sized multi functional agents lignin, hemicelluloses, cellulose, sodium silicate necessary for addressing the issue of workability and also improving the engineering properties of geopolymeric system for broad application spectrum.

Owner:COUNCIL OF SCI & IND RES

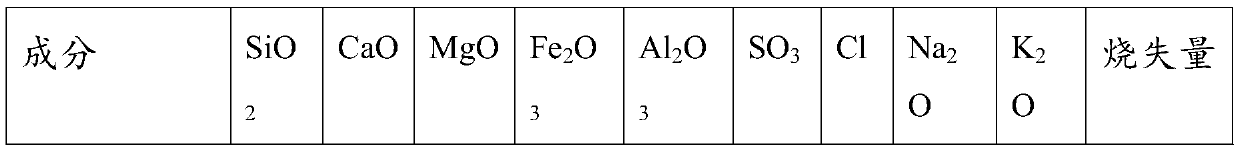

Preparation method of single-component geopolymer cement

The invention provides a preparation method of single-component geopolymer cement. Industrial by-products such as metal tailings, feldspar, papermaking white mud, cement kiln powder and the like of which the main components are SiO2, Al2O3 and Ca-containing compounds are utilized, a solid alkali activator is added, so that the single-component geopolymer cement can be prepared. On one hand, environmental pressure caused by the stockpiling of metal tailings is reduced; and on the other hand, the resource utilization of solid waste such as the metal tailings can be achieved due to wide sources and low prices of raw materials. The 28d cube compressive strength of the single-component geopolymer cement is 35-45MPa, so that the single-component geopolymer cement can be widely applied to concrete preparation, rock-soil body grouting reinforcement, highway or airfield runway rapid repair, concrete prefabricated part manufacturing, wall body building block manufacturing and production raw materials of permeable pavement bricks, kerbs and other building material products.

Owner:SANMING UNIV

Method for preparing assembled integrated boards

InactiveCN108774039AHigh tensile strengthAvoid crackingClimate change adaptationLaminationEnvironmental resistanceFiber

The invention discloses a method for preparing assembled integrated boards. The method comprises the following steps: first weighing the following raw materials in parts by weight: 15~25 parts of geopolymer cement, 15~35 parts of light ceramsite, 45~53 parts of modified mortar and 2~5 parts of straw fiber, then performing dry mixing on the raw materials in a stirrer for 2~8 minutes to obtain a rawmaterial mixture, weighing a certain amount of tap water, adding an additive to the tap water, then adding the tap water mixed with the additive to the raw material mixture, stirring for 3~8 minutesto obtain a slurry, pouring the slurry into a steel mold coated with an alkali-resistant plastic mesh cloth, placing polyethylene sheet with thickness of 70 mm and steel wire mesh sheets with thickness of 2 mm on both sides when the slurry is evenly spread to a thickness of 25 mm, pouring the slurry, adding a layer of the alkali-resistant plastic mesh cloth to the slurry when the thickness of theslurry reaches 25 mm, shaking and compacting with a vibrator, smoothing, demolding after 60~90 minutes, and natural curing for 7~10 days. The method replaces polystyrene particles with light inorganicceramsite to increase straw fiber and improve the tensile strength and impact resistance of the board, and the board has the characteristics of cracking resistance, environmental friendliness and soon.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Geopolymer cement retaining wall

ActiveCN109208634AGuarantee quality requirementsImprove stress resistanceArtificial islandsUnderwater structuresTerrainGeopolymer cement

The invention discloses a geopolymer cement retaining wall and relates to the technical field of retaining walls. The geopolymer cement retaining wall comprises a concrete layer, an expansion joint and a retaining structure; a cement layer is disposed above the left end of the concrete layer, and the asphalt layer is red only above the cement layer; the right side of the expansion joint is provided with a road block, and the expansion joint is located on the right side of the asphalt layer; a sand layer is disposed in a middle portion of the retaining structure, and the retaining structure islocated on a right side of the road block. The soil-polymerized cement retaining wall greatly increases the pressure bearing capacity while increasing the structure compared with the ordinary retaining wall. The improved structure is more complete in use and its structural flexibility is greatly improved, so that the entire structure can be applied to various terrains and earthwork structures, effectively meeting the needs of people.

Owner:FOSHAN UNIVERSITY

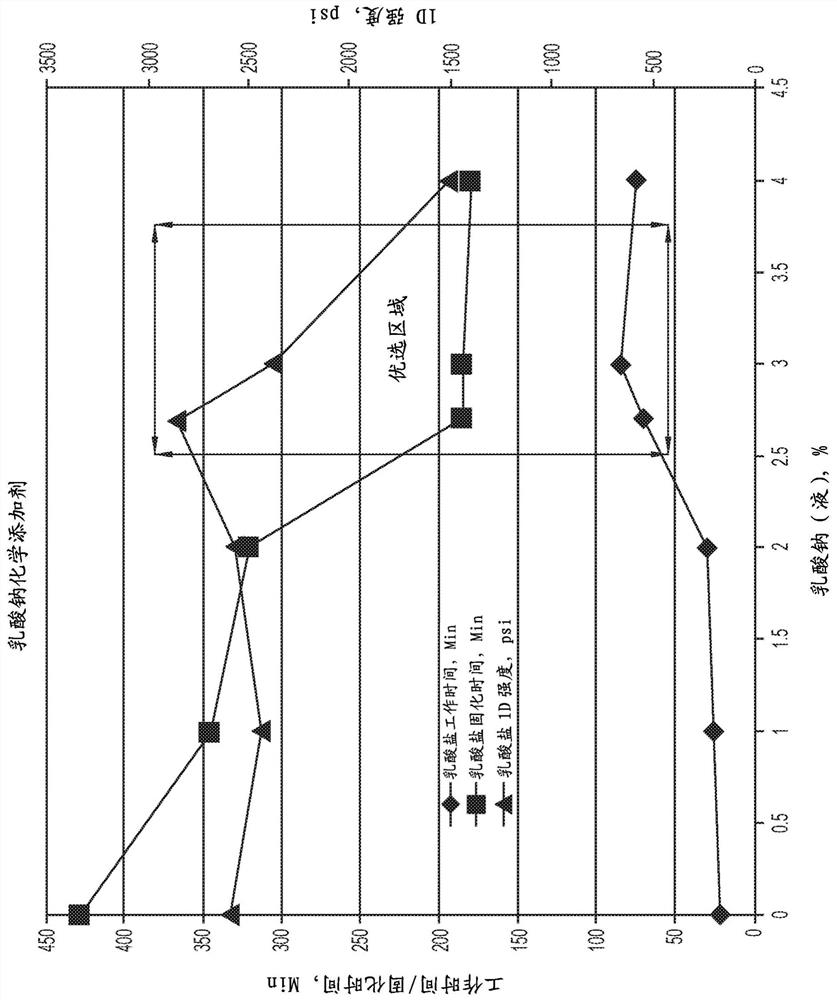

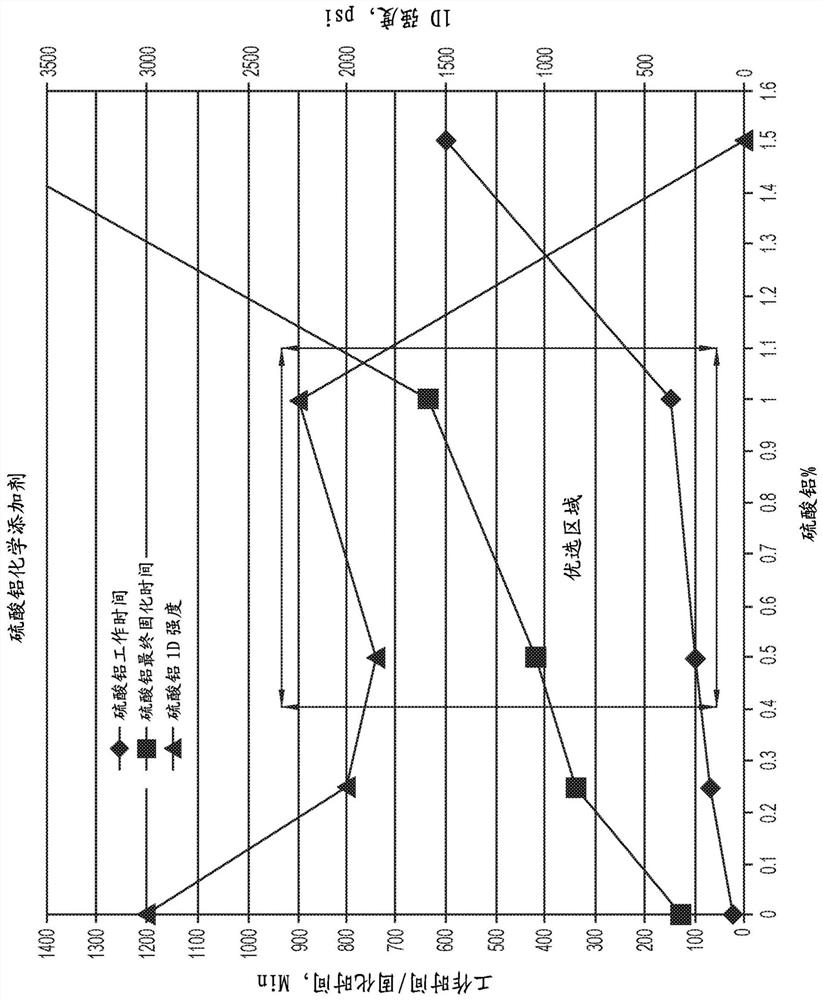

Additives for geopolymer cements

The present disclosure is directed to chemical additives for geopolymer cements that can improve the rheological properties of geopolymer cements. These chemical additives include sulfates and selenates of a specific formula as well as hydroxycarboxylic acid salts of Li, Na, and K including but not limited to glycolic, lactic, citric, mandelic tartaric, and malic acids. The chemical additives for geopolymer cements disclosed herein can facilitate the uniform mixing, increase the time mixtures can be transported, and improve the ability to place and finish concrete and mortars made with the geopolymer cements.

Owner:セモルトエルエルシー

Geopolymer cement modified by graphene and epoxy resin and preparation method thereof

The invention relates to geopolymer cement modified by graphene and epoxy resin, wherein the geopolymer cement contains a graphene / epoxy resin composite material. The graphene / epoxy resin composite material is used as a modifier for the geopolymer cement, so graphene can be evenly dispersed in the geopolymer cement, and the problem of easy agglomeration of graphene in a bulk material is solved. The mechanical properties, including impact resistance, tensile performance and bending performance, of the prepared modified polymer cement are greatly improved. As a building material, the geopolymercement is good in quality, uniform in composition and easy to industrialize.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

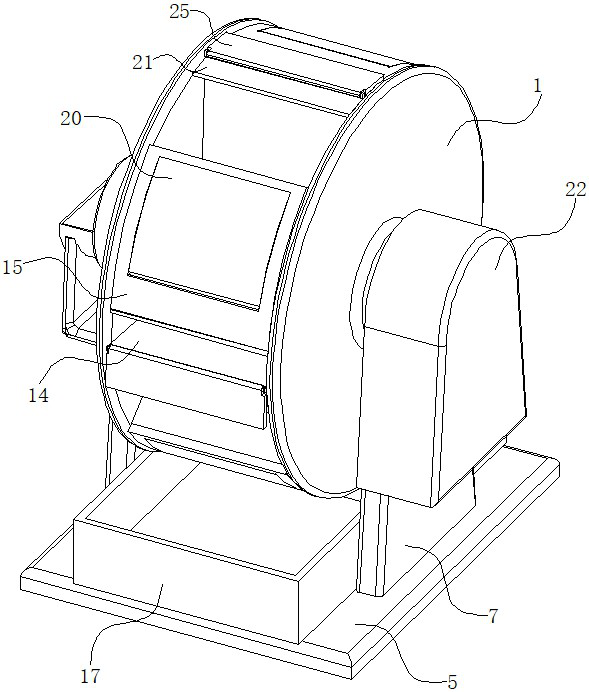

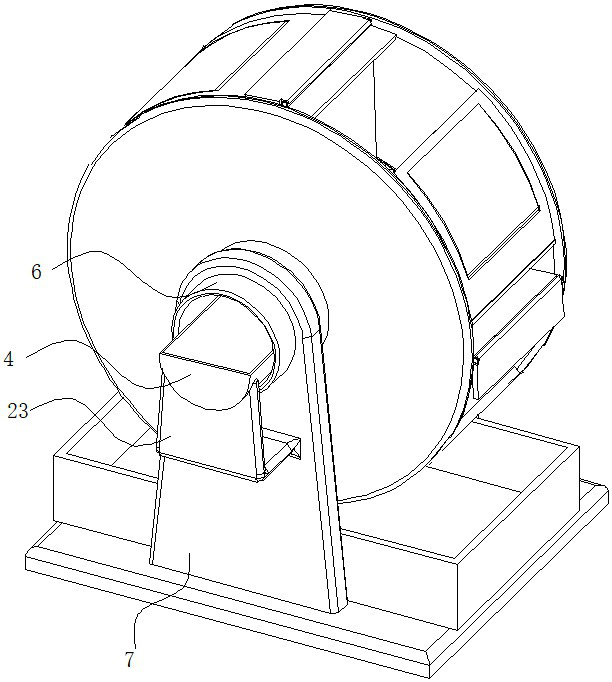

Automatic screening device for high-performance geopolymer cement-based composite material

InactiveCN114713491AFor automatic dischargeQuality improvementSievingScreeningGeopolymer cementMechanical engineering

The invention relates to the field of cement material screening, in particular to a high-performance geopolymer cement-based composite material automatic screening device which comprises a base, two clamping plates with opposite side faces are arranged above the base, the clamping plates are driven by a power device, and the power device can drive the two clamping plates to rotate synchronously; the screening device is characterized in that the first screening device is arranged between the two clamping plates, when materials roll on the first screening device, the first screening device can separate part of impurities, and the second screening device is arranged between the two clamping plates. When materials screened by the first screening device roll on the second screening device, the other part of impurities can be separated, small-diameter impurities are separated through the first screening device, large-diameter impurities are separated through the second screening device, the quality of the separated materials is effectively improved, operation is convenient, the automation degree is high, and the production efficiency is improved. And the working efficiency is effectively improved.

Owner:XINYANG VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com