Novel water-resistant gypsum-based self-levelling material

A gypsum-based, self-leveling technology, which is applied in the field of building materials, can solve problems such as poor surface hardness and poor water resistance, and achieve the effects of improving water resistance, ensuring later water resistance and strength, and improving water resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

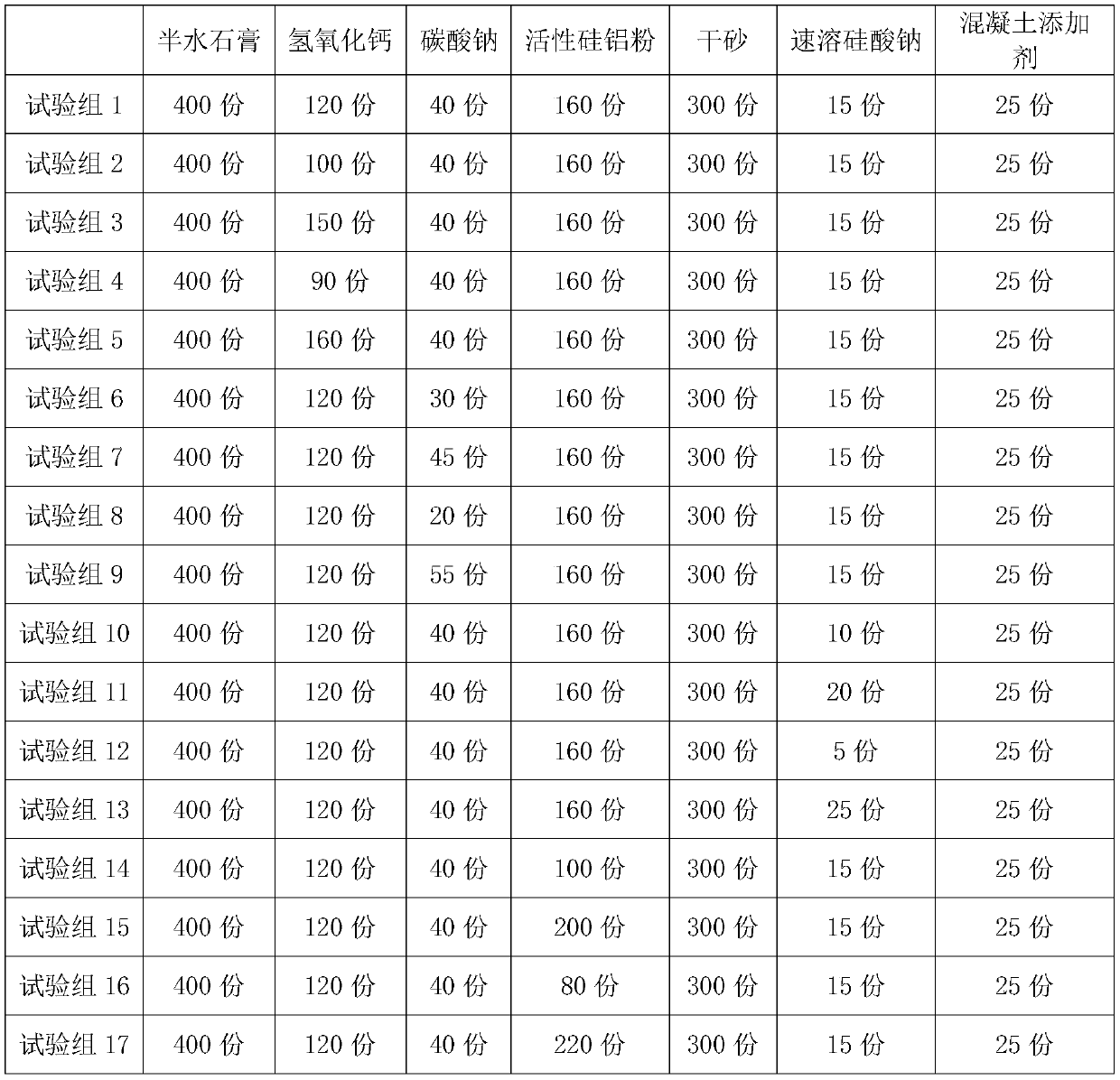

Method used

Image

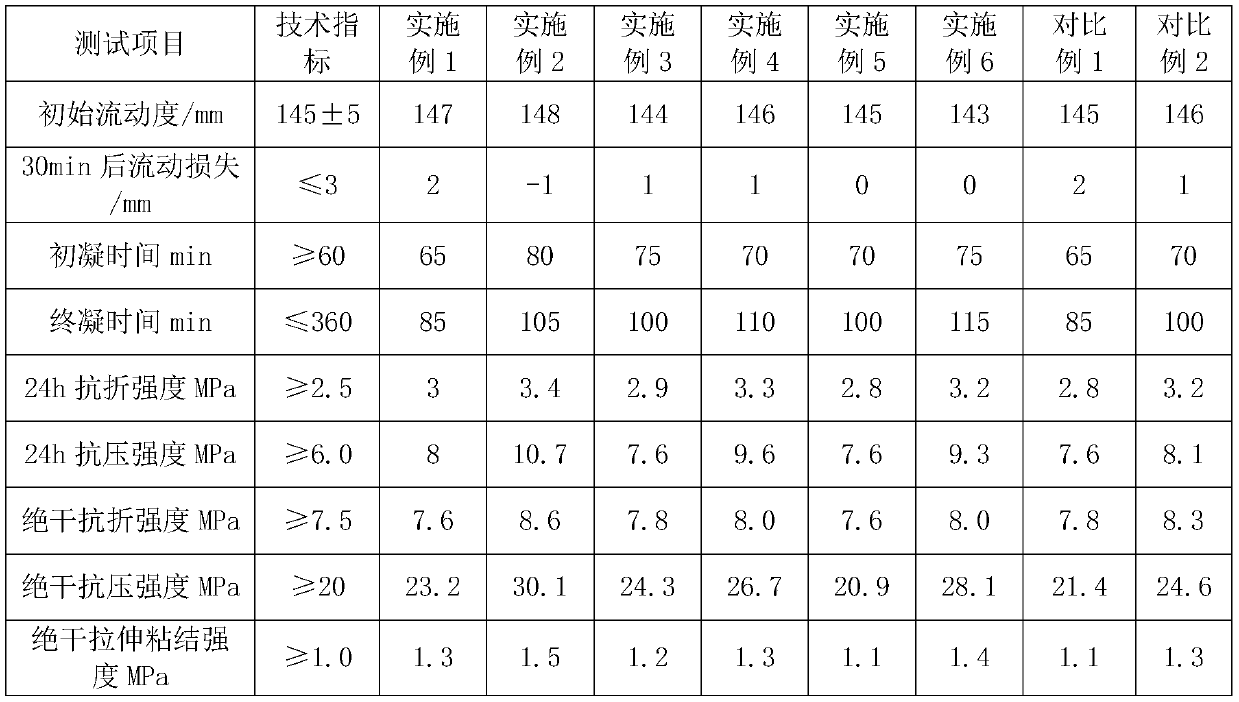

Examples

Embodiment 1

[0033] Take 300kg of α hemihydrate gypsum powder, 150kg of calcium hydroxide powder with a fineness of 300 mesh, 45kg of sodium carbonate, 200kg of silica fume with a particle size of less than 200 mesh, 300kg of washed and dried river sand continuously graded from 40 to 120 mesh, and sodium silicate 20kg of powder, 1.5kg of water reducer, 0.1kg of retarder, 0.4kg of suspending agent, and 1.5kg of defoamer. After mixing, a new type of water-resistant gypsum-based self-leveling material is obtained. Add 200kg of water and stir evenly before construction and testing its performance.

Embodiment 2

[0035] Take 500kg of β hemihydrate gypsum powder, 100kg of calcium hydroxide powder with a fineness of 300 mesh, 30kg of potassium carbonate, 100kg of fly ash with a particle size of less than 200 mesh, 250kg of continuously graded machine-made sand of 40-120 mesh, and 10kg of potassium silicate powder , water reducing agent 2kg, retarder 2kg, suspending agent 0.4kg, defoamer 1.5kg, reinforcing agent 10kg, after mixing, a new type of water-resistant gypsum-based self-leveling material was obtained, and 230kg of water was added to stir evenly before construction and testing its performance.

Embodiment 3

[0037] Take 350kg of β hemihydrate gypsum powder, 125kg of calcium hydroxide powder with a fineness of 300 mesh, 40kg of potassium carbonate, 150kg of slag with a particle size of less than 200 mesh, 350kg of machine-made sand with continuous gradation of 40-120 mesh, and 15kg of potassium silicate powder. Water agent 1.5kg, retarder 1kg, suspending agent 1.0kg, defoamer 1.0kg, reinforcing agent 30kg, after mixing, a new type of water-resistant gypsum-based self-leveling material was obtained, and 210kg of water was added to stir evenly before construction, and its performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com