Nano-modified alkali-activated cementitious materials for rapid repair

A cementitious material, nano-modified technology, used in climate sustainability, sustainable waste treatment, cement production, etc., can solve problems such as high transportation costs, damage chemistry, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

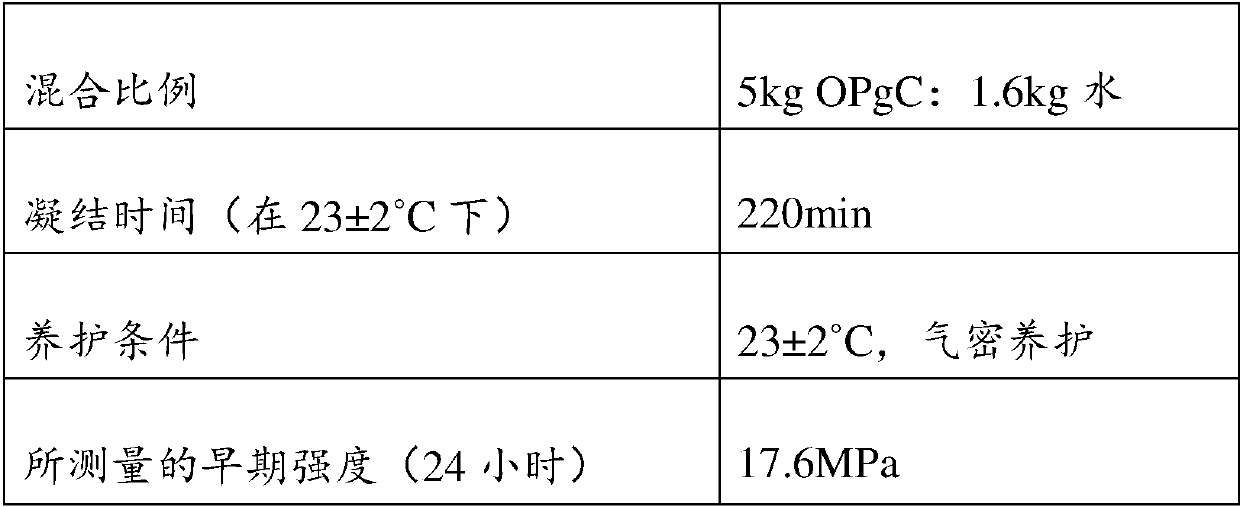

[0066] As a starting example, according to the above steps, the OPgC gel material without nano-modifier was prepared according to the following components and samples were prepared under the following conditions.

[0067]

[0068]

[0069]

[0070] Geopolymers are generally considered to be more environmentally friendly alternative cements compared to conventional Portland cement.

[0071] The presence of liquid alkali in traditional alkali-activated cement systems is a potential safety hazard, which may cause serious injury (such as chemical burns) during its use. Other disadvantages of traditional alkali-activated cement systems include inconvenient storage of materials, higher transportation costs, potential leakage of alkali solution, etc. Therefore, the dry blended geopolymer in the form of dry powder can obtain high early mechanical strength only by adding water and stirring at the construction site. Its easy storage and transportation characteristics are the m...

Embodiment 2

[0074] According to the above steps, the nano-modified OPgC gelling material was prepared according to the following components and samples were prepared under the following conditions.

[0075] Components of OPgC

Weight (g)

93-98

3-5

2-5

1-3

2.0

0.2

5.4

Nano silica

3.2

0

[0076] The mixing ratio

5kg OPgC: 1.6kg water

Coagulation time (at 23±2℃)

80min

Conservation conditions

23±2℃, airtight curing

Measured early strength (24 hours)

33.8 MPa

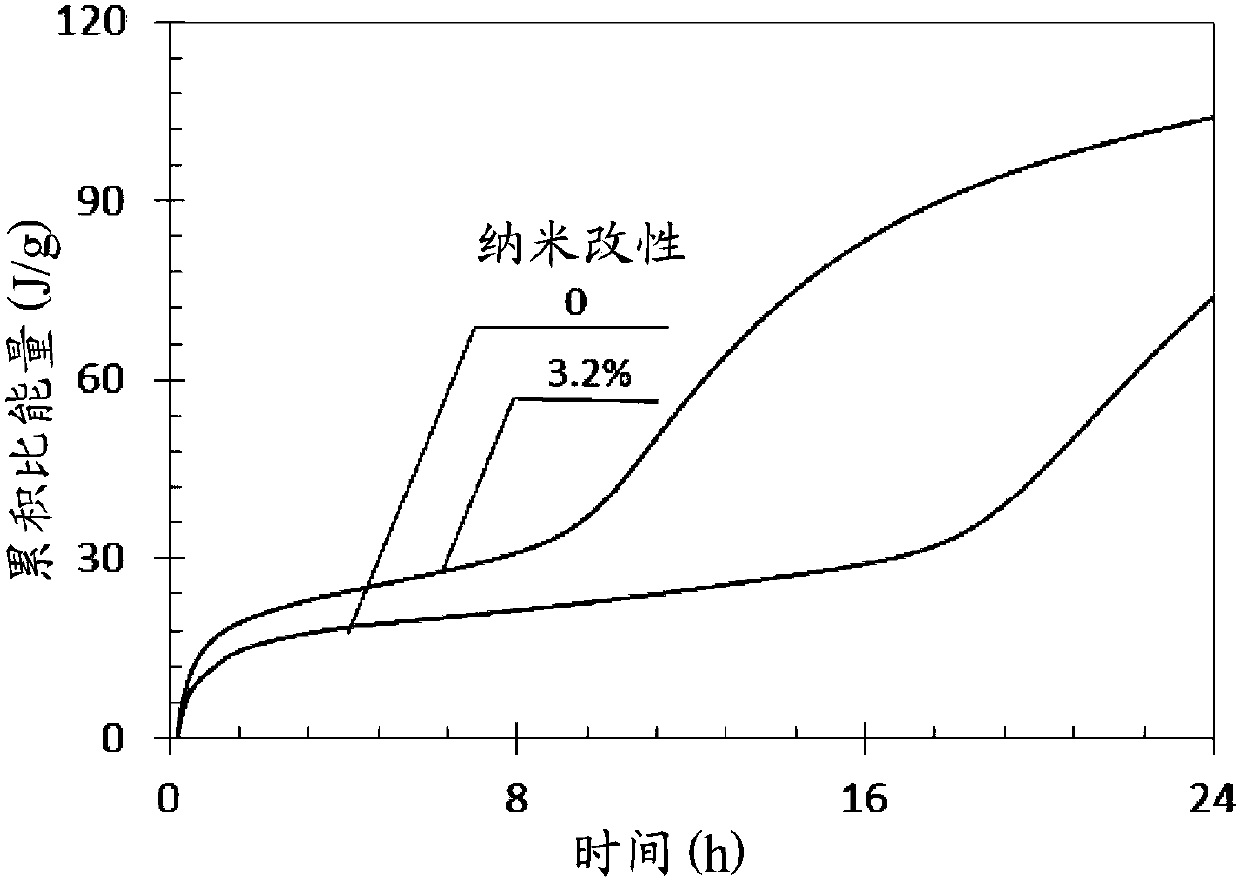

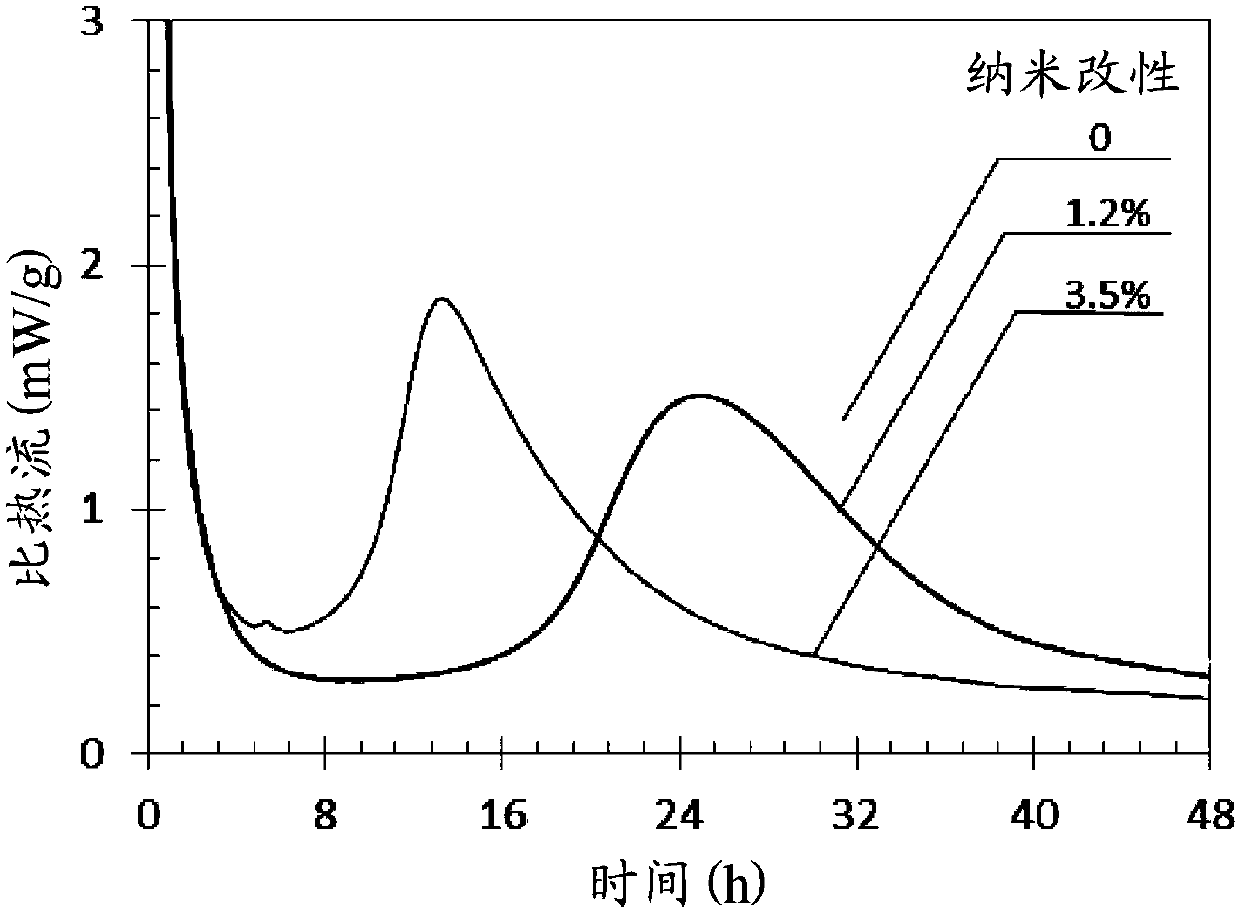

[0077] This example gives an example of a repair material of nano-modified OPgC. The addition of nano-modifiers improved the setting time. Compared with Example 1, the coagulation time has been shortened from more than 200 minutes to 80 minutes, which is conducive...

Embodiment 3

[0083] According to the above steps, OPgC paste was prepared according to the following components and samples were prepared under the following conditions.

[0084]

[0085]

[0086]

[0087] This example gives another successful example of OPgC. The control of the amount of base activator plays an important role in OPgC. The change of ASRM components affects its reactivity, and the deployment of alkali activator has a decisive effect on the workability of the fresh mixture and the chemical reaction process during the hardening process.

[0088] Compared with Example 1, the consumption of sodium silicate powder component increases in the present embodiment, and the consumption of alkali metal hydroxide remains basically unchanged. The formulation of the base activator induces an increase in early strength, while the setting time of the mixture is significantly shortened.

[0089] Comparing Example 1 and Example 3, adjusting the consumption of ASRM components and al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com