Light foam concrete used for road and bridge filing and preparing method thereof

A lightweight foam and concrete technology, applied in the field of engineering materials, can solve problems such as poor economy and long construction period, and achieve the effects of improving atmospheric environment, reducing pollution and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

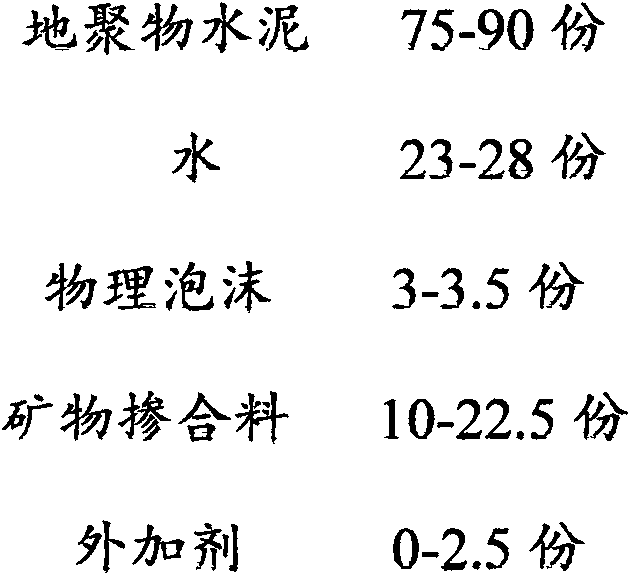

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the geopolymer cement is: pre-grinding the steel slag to a particle size of 100-150m 2 / kg, adding retarder and mineralizer to it, and then further grinding to a particle size of 310-560m 2 / kg to obtain geopolymer cement products. The weight of the retarder is 0.1-0.5% of the weight of the steel slag, and the weight of the mineralizer is 3.5-10.5% of the weight of the steel slag. The retarder is one or a combination of phosphogypsum, citrate gypsum, desulfurized gypsum and fluorogypsum. The mineralizer is a mineralized mixture formed by one or more of kaolin, bentonite, sepiolite and alkaline substances at 850-1100°C for 25-95 minutes, wherein kaolin, bentonite, sea The weight ratio of one or several compositions in the foam stone to the alkaline substance is 0.2-4.5:1. The alkaline substance is one or more of sodium hydroxide, potassium hydroxide, potassium carbonate, sodium bicarbonate, sodium carbonate, potassium bicarbonate.

[0034] T...

Embodiment 1

[0042] Mix and stir 58 parts of geopolymer cement and 42 parts of fly ash evenly, then add 23 parts of water, and stir to form a uniform and stable slurry; then continue to add 5 parts of physical foam to the slurry, stir evenly, and the stirring time is 10 minutes ; After mixing evenly, carry out the filling construction work.

[0043] The dry density of the foamed concrete obtained in this embodiment is 1046kg / m 3 , The 28-day compressive strength is 9.2MPa, and the thermal conductivity is 0.19W / (m·K).

Embodiment 2

[0045] Mix and stir 64 parts of geopolymer cement and 36 parts of blast furnace granulated slag powder evenly, then add 32 parts of water, and stir to form a uniform and stable slurry; then continue to add 4 parts of physical foam to the slurry, stir evenly, and the mixing time for 5 minutes; after stirring evenly, carry out the filling construction work.

[0046] The dry density of the foamed concrete obtained in this embodiment is 871kg / m 3 , The 28-day compressive strength is 6.7MPa, and the thermal conductivity is 0.16W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com