Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Increase the use of added value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display panel and display equipment

ActiveCN106959757AIncrease the use of added valueImprove accuracyInput/output for user-computer interactionPrint image acquisitionFingerprintComputer science

The invention discloses a display panel and display equipment. An optical fingerprint identification sensor and an optical gesture recognition sensor are integrated with the display panel, and a device and a module are not needed to be set outside the display panel to realize fingerprint identification and / or gesture recognition; and the display panel can also realize gesture recognition and / or fingerprint identification on the basis of realizing a display function, thereby increasing the use added value of the display panel. The display panel provided by the embodiment of the invention comprises an optical sensor structure used for fingerprint identification and / or gesture recognition, and the optical sensor structure comprises a light emitting layer and a photosensitive sensor.

Owner:BOE TECH GRP CO LTD

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

Comprehensive utilization method for effective components of wormwood

ActiveCN109363969AIncrease the use of added valueCosmetic preparationsToilet preparationsDistillationFuel oil

The invention relates to the technical field of the comprehensive utilization of plant resources and particularly relates to a comprehensive utilization method for effective components of wormwood. The comprehensive utilization method comprises the following steps: (S0) preparing wormwood leaves and wormwood roots: separating the wormwood into the wormwood leaves and the wormwood roots; (S1) preparing wormwood leaf raw materials; (S2) extracting wormwood leaf essential oil; (S3) refining a wormwood leaf essential oil extract: carrying out molecular distillation on the wormwood leaf essential oil extract, so as to obtain wormwood leaf essential oil heavy oil and wormwood leaf wax; (S4) extracting wormwood leaf general flavone and crude polysaccharide; and (S5) concentrating, separating andrefining wormwood leaf crude general flavone and crude polysaccharide extracting solutions, so as to obtain the wormwood leaf general flavones and crude polysaccharide. According to a process route, developed by the invention, for comprehensively utilizing the wormwood, the series products of main active components such as essential oil, general flavone, polysaccharide and wormwood root hydrolat in the wormwood can be furthest obtained, so that that the utilization additional value of the wormwood resource is greatly increased.

Owner:博罗县康祥岭南本草农业科技有限公司

System for measuring movement, position and physiological data

InactiveCN103690153AIncrease the use of added valueImprove the quality of lifeMeasurement devicesDiagnostic recording/measuringMeasurement deviceWeak current

An embodiment of the invention discloses a system for measuring movement, position and physiological data. The system comprises a measuring device, a terminal device and a service managing device. The measuring device is a shoe provided with a body-fat measuring device. The shoe comprises a measurement connecting terminal, a biologic impedance measurement device, a data converter and a signal transmitter. The measurement connecting terminal is used for connecting currents between two feet, the biologic impedance measurement device is used for measuring weak currents flowing through a human body and calculating a resistance value between the two feet, the data converter is used for converting the resistance value into a fat percentage and converting digital signals into electrical signals, and the signal transmitter is used for transmitting the electrical signals to the terminal device. According to the method, through the shoe which is capable of measuring body-fat quantity of human bodies and has integrated multiple functions, monitoring on movement, position and physiology of the human bodies can be compressively realized well, and costs of products in the prior art are reduced.

Owner:李诺吉

Hollow carbon nano-particles and wave-absorbing material prepared therefrom

ActiveCN107325787AUniform particle sizeObvious hollow shapeOther chemical processesFiltrationFreeze-drying

The invention provides hollow carbon nano-particles and a wave-absorbing material prepared therefrom. A preparation method of the hollow carbon nano-particles comprises the steps of mixing aniline, pyrrole, a non-ionic surface active agent and water to obtain a first solution; carrying out ice bath on an ammonium persulfate solution and adding the ammonium persulfate solution to the first solution to obtain a second solution; reacting the second solution, carrying out suction filtration, washing and freeze drying to obtain a head product; and carrying out carbonization treatment on the head product to obtain the hollow carbon nano-particles. A preparation method of the wave-absorbing material comprises the steps of adding graphene, the hollow carbon nano-particles and polypropylene to a torque rheometer for banburying to obtain a mixture; and carrying out hot pressing and cold pressing on the mixture to obtain the wave-absorbing material. By adopting the graphene and the hollow carbon nano-particles as wave-absorbing media and polypropylene as a carrier, the prepared wave-absorbing material can reach the effective absorption effect on an electromagnetic wave, and meanwhile, a series of advantages of low density and fatigue resistance of the polypropylene material are also integrated.

Owner:PETROCHINA CO LTD +1

Preparation method for aerogel vacuum insulation board and core material thereof

The invention provides a preparation method for a vacuum insulation board and a core material thereof. The preparation method uses a siliceous non-metallic mineral clay as a silicon source, obtains amixed water glass solution by a high temperature and high pressure alkali solution reaction, and achieves a preparation process without by-products. An inorganic / organic hybrid aerogel vacuum insulation board is prepared by an inorganic dispersion sol-gel method under a normal pressure, expensive silicon alkoxide chemical raw materials are replaced, so that the comprehensive utilization added value of non-metallic mineral clay in China is greatly increased, the process is simple and easy to implement, the cost is low, and large-scale application potential is achieved. The vacuum insulation board can be separately applied to a building thermal insulation project, have good anti-near-infrared performance, good strength and toughness, low cost, no cold and hot bridge phenomenon, long vacuum retention time and non-easy bag expansion and scratch, is combined with double-layer three-dimensional reinforced components, and achieves the possibility of preparation of the large-body vacuum insulation board.

Owner:王贵然 +1

Environment-friendly carbon-hydrogen solvent low-pressure hydrogenation dearomatization reactor and catalyst packing method

ActiveCN106166469AReasonable and practical designImproved fluid distribution and pressure dropChemical/physical processesRefining by aromatic hydrocarbon hydrogenationProduct processingSolvent

The invention provides an environment-friendly carbon-hydrogen solvent low-pressure hydrogenation dearomatization reactor and a catalyst packing method. The method of layered matching packing of porcelain balls of different grain diameters and catalysts of different grain diameters and different shapes is adopted, material short pass or bed layer sinking can be prevented, fluid distribution and pressure drop in a catalyst bed layer are effectively improved, distribution and mixing effects of a hydrogen cooling system are enhanced, a reaction medium and a catalyst contact evenly, the medium in the reactor flows uniformly, and the reactor size is reduced on the whole, so as to guarantee an optimum depth and speed of hydrogenation dearomatization reaction, improve yield of ideal components, reduce device investment and product processing cost and improve comprehensive utilization added value of light dydrocarbon raw materials. The environment-friendly carbon-hydrogen solvent low-pressure hydrogenation dearomatization reactor has the advantages of being high in reaction efficiency, high in production capacity, convenient to manufacture and maintain and is intelligent in temperature control; and after fractionation, the purity of an alkane product is 99% or above.

Owner:DONGYING JUNYUAN PETROLEUM TECH DEV CO LTD

Full steel slag roller compacted concrete and preparation method thereof

The invention discloses a full steel slag roller compacted concrete and a preparation method thereof. The full steel slag roller compacted concrete comprises the following raw materials by weight: 24-37 portions of a steel slag composite powder, 45-65 portions of a steel slag aggregate, 11-18 portions of steel slag water washing mud and 3-5 portions of water. The method is as below: weighing the steel slag composite powder, steel slag aggregate, steel slag water washing mud and water according to the weight ratio; and uniformly mixing to obtain the full steel slag roller compacted concrete. The invention can play the recycling value of metallurgical wastes, reduce the cost of roller compacted concrete, and obtain great economic benefits. More important, application of the invention can economize natural gravel and cement, thereby saving natural resources and energy and protecting the ecological environment.

Owner:宝武环科武汉金属资源有限责任公司

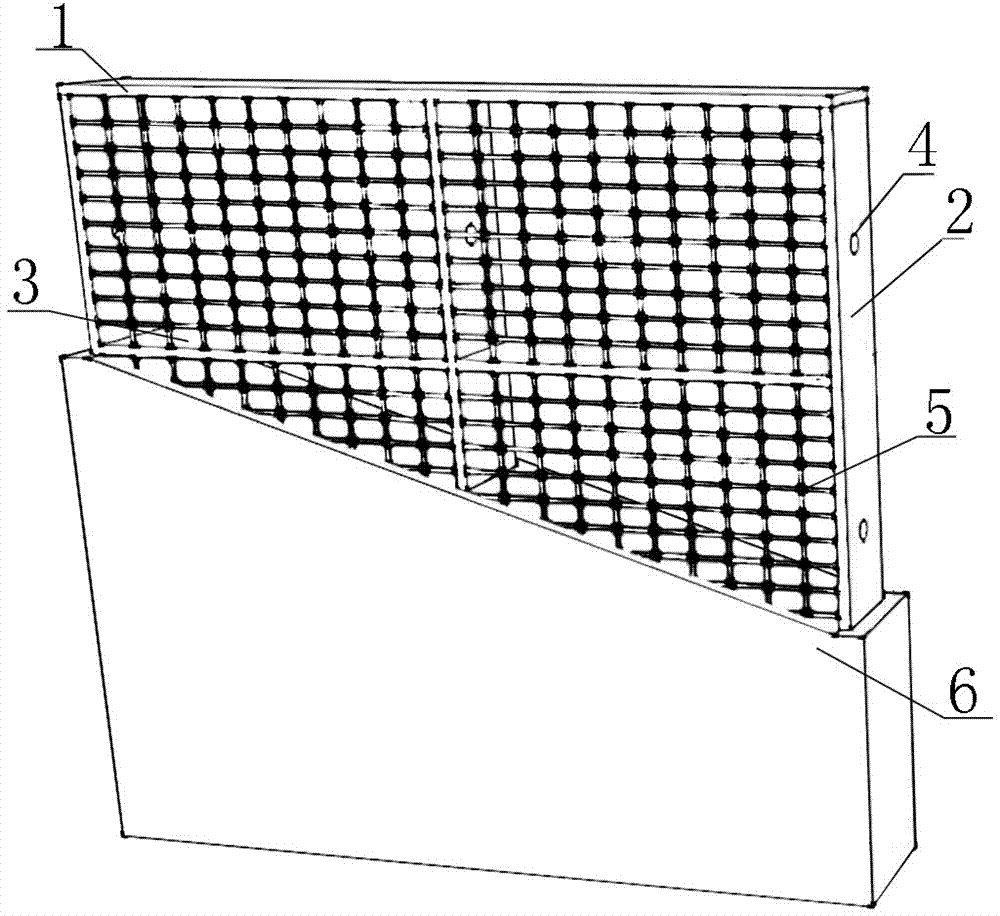

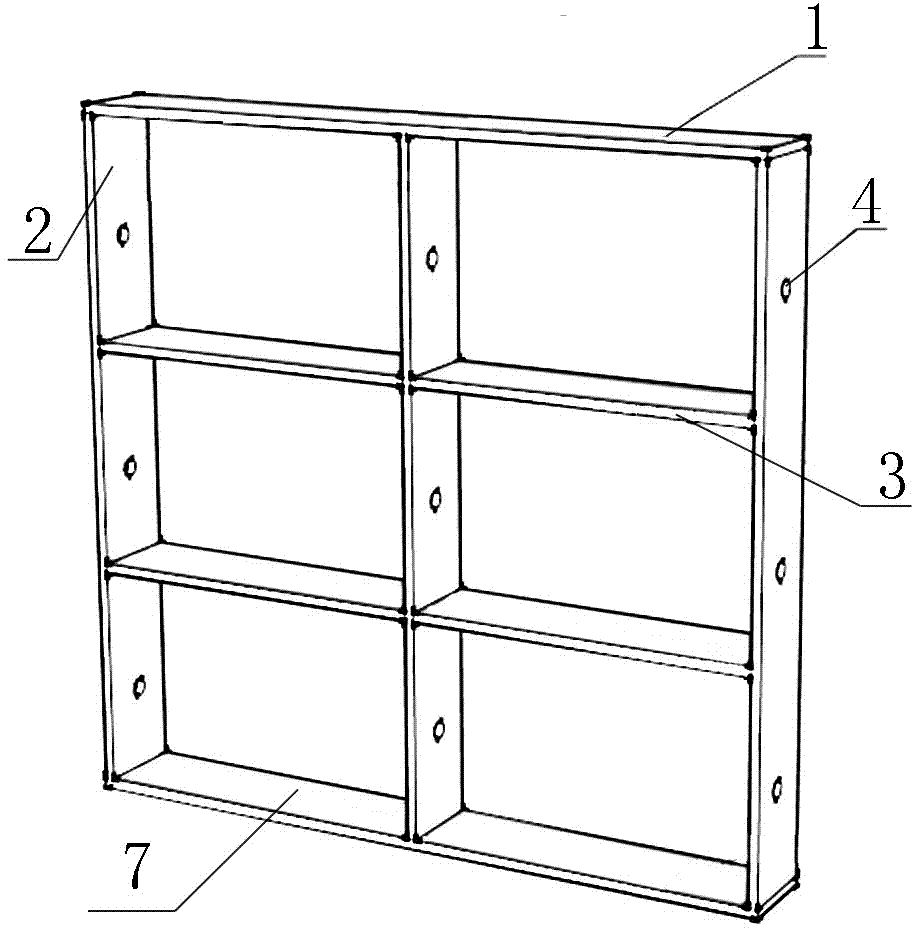

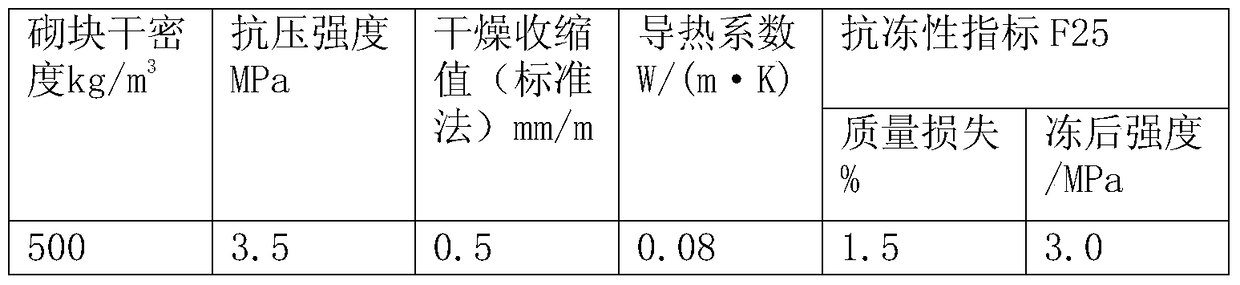

Iron tailing foam concrete and prefabricated steel-frame wall plate and construction method thereof

InactiveCN106892624AAvoid accumulationIncrease the use of added valueConstruction materialCeramicwareFoam concreteThermal insulation

Iron tailing foam concrete and a prefabricated steel-frame wall plate and a construction method thereof are provided, wherein the prefabricated steel-frame wall plate comprises a steel mesh frame, a plurality of wire meshes and a tier of iron tailing foam concrete cast outside the steel mesh frame and the wire meshes; the steel mesh frame is of rectangular mesh structure and comprises an upper guide beam, a lower guide beam, vertical supports and transverse supports; the upper guide beam is arranged horizontally at the top end of the steel mesh frame, and the lower guide beam is arranged horizontally at the bottom end of the steel mesh frame; the vertical supports in a group are connected between the upper guide beam and the lower guide beam transversely and parallelly at intervals; each vertical support is provided with a group of holes along its along axis at equal intervals; the wire meshes are connected within rectangular cells of the steel mesh frame respectively. The technical problem that accumulation of existing iron tailings affects the environment is solved, the prefabricated steel-frame wall plate with good thermal insulation property is produced with the iron tailing foam concrete, and a novel wall is provided for buildings.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Method of utilizing cordyceps militaris to inoculate castor silkworm 5-year larvae to cultivate silkworm cordyceps

ActiveCN109644779APrevent degradationIncreases infection zombification abilityCultivating equipmentsMushroom cultivationBiotechnologyContamination rate

A method of utilizing cordyceps militaris to inoculate castor silkworm 5-year larvae to cultivate silkworm cordyceps includes following steps: (1), selecting a cordyceps militaris host; (2), performing enlarged culture on a strain liquid preparation solution; (3), treating host castor silkworm after inoculating; (4), performing cultivation management on silkworm cordyceps fruiting bodies: inoculating a cordyceps militaris bevel mother strain onto a solid flat plate culture medium for activation, inoculating into a liquid culture medium, inoculating into healthy castor silkworm larvae after enlarged culture for infection ossification, and putting infected and ossified silkworm without bacteria spawning into a transparent plastic box after going through sterile treatment for culture management to obtain silkworm cordyceps. The advantage that castor silkworm larvae are big in size, soft in body and rich in nutrition is fully utilized to cultivate the fruiting bodies; infectious bacteria contamination rate is low, infection ossification rate and grass emerging rate are high, and obtained castor silkworm cordyceps is high in stability and fruiting body yield, rich in active ingredient content, suitable for large-scale production and wide in development prospect.

Owner:湖南省蚕桑科学研究所

Antistatic wood decorative material and manufacturing method thereof

ActiveCN107263642AImprove antistatic performanceImprove wear resistanceWood treatment detailsPretreatment apparatusMaterials preparationAntistatic agent

The invention provides an antistatic wood material manufacturing method simple in technology and equipment. An antistatic wood decorative material prepared through the method is excellent in antistatic performance, high in surface hardness and good in abrasion resistance, the surface resistivity of the antistatic wood decorative material is 1.0E+5omega-1.0E+6omega, and the volume resistivity is 1.0E+5omega.cm-1.0E+6omega.cm; unhealthy phenomena such as dust absorption and electro-discharge caused by static charge accumulation in the using process of the material can be avoided, and the surface abrasion resistance reaches 6000 r or larger; and the antistatic wood decorative material can be widely applied to surface decoration of high-end office buildings, intelligent office blocks and other occasions of which the requirements for antistatic performance and abrasion resistance are high. The manufacturing method comprises the steps of base material preparation, softening treatment, drying treatment, antistatic resin preparation, primary impregnation, predrying, medium-high temperature compression treatment, secondary impregnation, secondary drying and the like. An antistatic agent, an abrasion-resistant agent and other assistants are evenly mixed and then dispersed into low-molecular-weight melamine resin used for impregnation, so that antistatic resin is formed.

Owner:NANJING FORESTRY UNIV

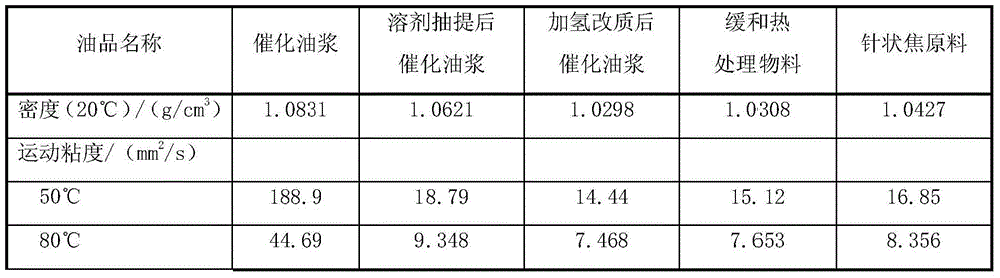

Method for producing petroleum coke

ActiveCN104862005AIncrease the use of added valueExpand sourceTreatment with hydrotreatment processesPetroleumAsphalt

The invention relates to a method for producing petroleum coke. The method utilizes high-sulfur, high-ash and high-asphalt inferior catalytic cracking oil slurry as a raw material and utilizes a solvent extraction-hydrofinishing-thermal cracking-reduced pressure distillation-delay coking combined technology to produce high-quality petroleum coke.

Owner:CHINA PETROLEUM & CHEM CORP +1

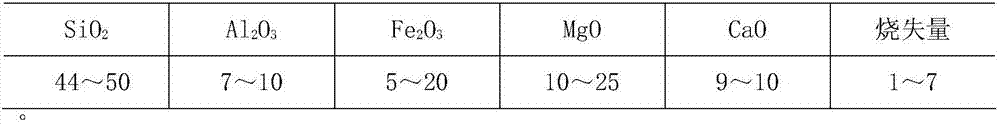

Preparation method of high-strength porous sound absorbing material

ActiveCN108529887AReduce accumulationSave and use added valueNoise reduction constructionGlass shaping apparatusSound barrierFoaming agent

The invention aims at disclosing a method of preparing a high-strength porous sound absorbing material by taking high-titanium blast furnace slowly cooled slag as principal raw materials. The preparation method comprises mixing the high-titanium blast furnace slowly cooled slag and siliceous materials, adding in foaming agent and fluxing agent to obtain a mixed batch, and then ball-milling and directly putting the mixed batch into a container for sintering by a designated sintering process. The preparation method of the high-strength porous sound absorbing material improves the utilization rate of the high-titanium blast furnace slag and achieves reutilization of waste resources as well as environmental protection. The prepared high-strength porous sound absorbing material is excellent insound absorbing performance, low in cost, non-combustible, toxic-free, corrosion-resistant and capable of avoiding producing dust jeopardizing health during installation; meanwhile, compared with foamglass sound absorbing materials, the high-strength porous sound absorbing material is higher in strength and hopeful to be applied to traffic network sound barrier sound absorbing materials.

Owner:SICHUAN UNIV

Method for continuous extraction of tannin and pectin from persimmon peel

ActiveCN106380495AIncrease the use of added valueHigh nutritional valueEsterified saccharide compoundsSugar derivativesCross-linkFruit juice

The invention discloses a method for continuous extraction of tannin and pectin from persimmon peel. The method comprises the following steps: step 1, subjecting the persimmon peel to drying, crushing and sieving so as to obtain raw powder; step 2, subjecting the raw powder to extraction and centrifugation with methanol, acetone and chloroform successively so as to obtain a residue I, a residue II, a residue III and supernatant I, carrying out concentration and rehydration on the supernatant I so as to obtain a dilute tannin solution, adding cross-linking polyvinylpyrrolidone into the dilute tannin solution, carrying out high-pressure homogenization and centrifugation so as to obtain a precipitate, eluting the precipitate by using an ethanol solution with a mass concentration of 70 to 85% and carrying out concentration so as to obtain tannin; step 3, subjecting the residue III to degreasing with petroleum ether so as to obtain a residue IV; and step 5, continuously extracting pectin in the residue IV by using a fluctuating pressure difference method. With the continuous extraction method, three pectins with different average molecular weights and properties can be obtained and are applicable to production of fruit juice or beverages of different types a thickening agent and a stabilizing agent.

Owner:北京中农探味科技有限公司

Combined treatment method of waste lithium ion battery negative electrode and diaphragm

ActiveCN110444830AIncrease the use of added valueSave resourcesWaste accumulators reclaimingCarbon preparation/purificationElectrical batteryMass ratio

The invention discloses a combined treatment method of a waste lithium ion battery negative electrode and a diaphragm; the combined treatment method comprises the following steps of (1) carrying out crushing on the waste lithium ion battery negative electrode and the diaphragm, performing mixing to obtain mixed fragments, wherein the mass ratio of the negative electrode to the diaphragm is 5-10: 1; (2) putting the mixed fragments into a mixed solvent, stirring for 3-6 hours at the temperature of 70-140 DEG C, separating and recovering a copper foil from the solution, carrying out ultrasonic treatment on the residual solution at 0-70 DEG C, and separating to obtain a solid and a filtrate, and returning the collected filtrate to the step (2) to be repeatedly used as a solvent; and (3) carrying out high-temperature carbonization on the solid in an inert atmosphere to obtain the composite carbon material. According to the method, the high-additional-value utilization of the carbon materialand the diaphragm of the waste lithium ion battery can be realized, meanwhile, the copper foil can be recycled in an elementary substance form, the operation is simple, the cost is low, the environment is protected, and the like.

Owner:CENT SOUTH UNIV

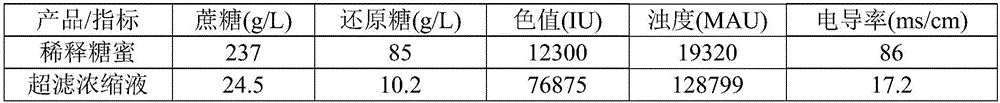

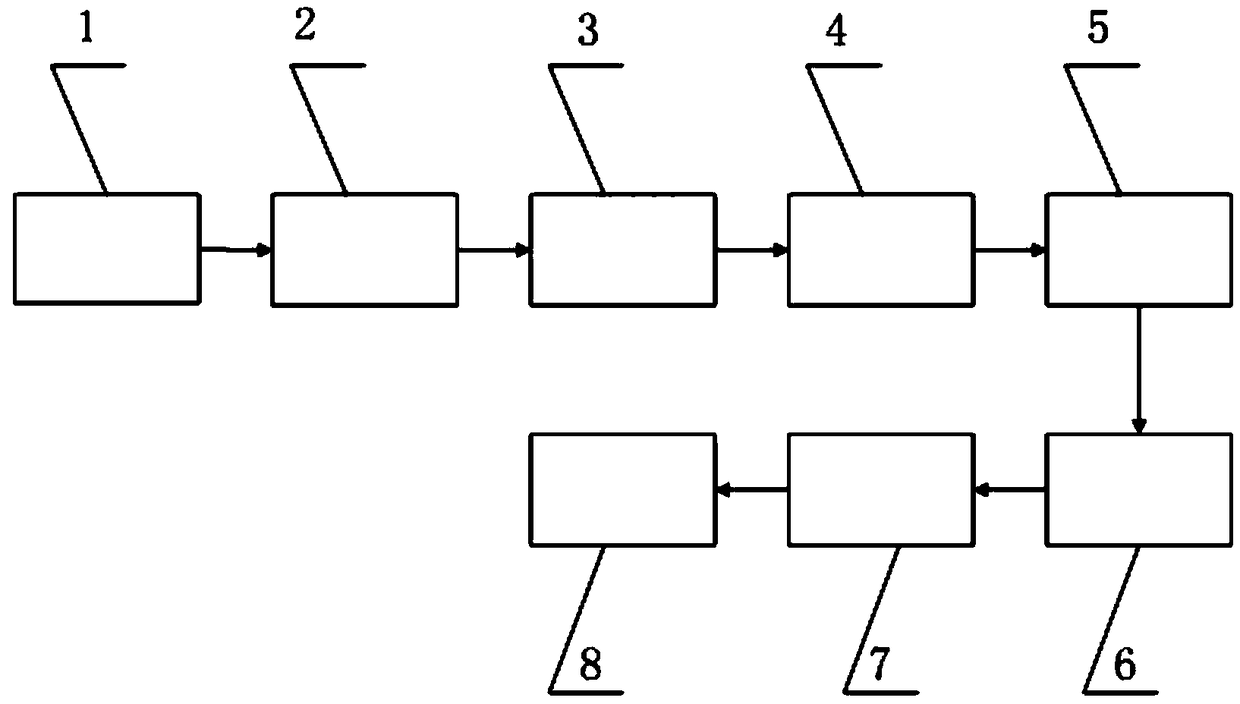

Technology for refining cane molasses by multistage membrane filtration

PendingCN107435084AAchieve removalRealize comprehensive utilizationPurification by physical meansCentrifugationFiltration

The invention relates to a technology for refining cane molasses by multistage membrane filtration, comprising the following steps: decolouring clarification treatment is firstly carried out on molasses obtained after dilution and centrifugation by the use of an ultrafiltration membrane; an ultrafiltration concentrate is used for natural pigment extraction; an ultrafiltration permeate undergoes further decolouring and desalting through ion exchange resin and then enters a nanofiltration membrane system; after concentration and removal of impurities through the nanofiltration membrane, a nanofiltration concentrate continues to be recycled for crystallization and sugar production; a nanofiltration permeate undergoes reverse osmosis membrane concentration; a reverse osmosis concentrate is used for preparation of a functional sugary beverage; and a reverse osmosis permeate is used for dilution and filter wash of molasses during ultrafiltration membrane treatment process. By the technology provided by the invention, recycling and high-value utilization of molasses can be realized. The equipment is simple and is easy for continuous and automatic production. There is no chemical additive, and generation of waste molasses can be avoided.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Liquid crystal display recycling method

InactiveCN103506374AAlleviate tensionsIncrease the use of added valueSolid waste disposalHydrofluoric acidLiquid-crystal display

The invention relates to a recycling method, in particular to a liquid crystal display recycling method. The method comprises the following steps: two layers of glass substrates are detached by using external force, and the protective films on the surfaces of the glass substrates are torn off manually; the stripped glass substrates are put into a stainless steel ware passivated through concentrated alkaline; a lower layer glass substrate is soaked in a sodium hydroxide solution with the mass percent of 5-20 percent for 60-129 minutes; meanwhile, an upper layer glass substrate containing a chrome black matrix film is soaked for 50-121 minutes; an upper layer glass substrate containing a resin back matrix film is soaked for 27-38 minutes; heating is performed to boiling while stirring is performed, the polaroid removal is observed through naked eyes, and an optical metallographic microscope is used for observing the surfaces of the glass substrates; the lower layer glass substrate, which is not processed cleanly, is soaked in a sodium hydroxide solution with the mass percent of 5-15 percent for 8-31 minutes for removing under normal temperature, and the upper layer glass substrate containing the chrome black matrix film, which is not processed cleanly, is soaked for 49-174 minutes for removing, so that clean glass substrates are obtained. The recycling method provided by the invention is simple in process and low in cost, and the glass substrates can be processed cleanly.

Owner:SHAANXI SHENGMAI PETROLEUM

Synthesis method of crude phenol-based benzoxazines resin prepolymers

The invention discloses a synthesis method of crude phenol-based benzoxazines resin prepolymers. The method takes crude phenols, formaldehydes and primary amines compounds as raw materials, and comprises the steps of carrying out a reaction for 5-7 hours at the temperature of 70-90 DEG C, and then carrying out aftertreatment to obtain the crude phenol-based benzoxazines resin prepolymers. The synthesis method is easy in obtaining of raw materials, low in cost and suitable for large-scale industrial production; the synthesis method is simple in reaction technology, does not need any catalyst, does not need inert gas for protection, and is higher in yield and good in repeatability. The novel crude phenol-based benzoxazine resin prepared by the invention is the same as other benzoxazine resins, and can be cross-linked and solidified under the condition of heating or adding a catalyst so as to obtain corresponding thermosetting resin.

Owner:SOUTHWEST PETROLEUM UNIV +1

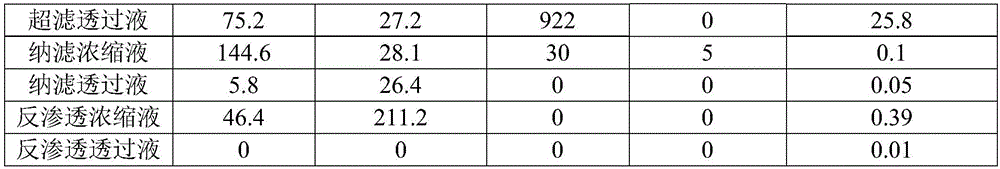

Preparation method of high-penetration microporous granular active carbon

The invention relates to a preparation method of high-penetration microporous granular active carbon, belonging to the technical field of waste recycling or reprocessing. The preparation method comprises the following steps: treating waste wool fiber with a sulfuric acid solution; performing acid rolling, baking carbonization and impurity removal; neutralizing and adding a nonionic detergent to remove fat; finally, cleaning and drying to obtain clean wool fiber; and pre-carbonizing and activating the clean wool fiber to obtain active carbon fiber. The preparation method provided by the invention is applied to the recycling of nonwoven wool fiber or waste wool fiber to prepare active carbon. With a remarkably large specific surface area, the active carbon has the advantages of relatively high compatibility, good adsorption capacity, uniform void volume distribution and the like in the using process.

Owner:SHAOXING UNIVERSITY

Method of preparing inorganic high molecular flocculant polysilicate ferric zinc from copper tailings

PendingCN107162134AIncrease the use of added valueTax reduction and exemption policy and environmental protection policyWater contaminantsWater/sewage treatment by flocculation/precipitationSodium silicateZinc

The invention provides a method for preparing an inorganic macromolecule flocculant polysilicate ferric zinc from copper tailing slag. Specifically, the copper tailings are heated, stirred, and allowed to stand under the action of acid and hydrogen peroxide to dissolve the copper tailings; the supernatant with the dissolved copper tailings is mixed with an acidic sodium silicate solution, and then stirred, reacted, and aged and other steps to obtain the inorganic polymer flocculant polyzinc iron silicate. The invention adopts the waste copper tailings as raw materials to prepare the polysilicate iron-zinc flocculant, which can greatly reduce the cost, and also utilizes the waste copper tailings.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Special soybean fertilizer capable of enhancing nitrogen utilization ratio

InactiveCN106748282AHigh strengthImprove hydrolytic stabilityCalcareous fertilisersBio-organic fraction processingPotassium persulfatePhosphoric acid

The invention discloses a special soybean fertilizer capable of enhancing nitrogen utilization ratio. The fertilizer is prepared from the following raw materials in parts by weight: 2-3 parts of nitrogin, 6-8 parts of cigarette rag, 44-48 parts of vinasse, 6-7 parts of weathered coal, 0.6-0.8 part of xylitol, 3-4 parts of ammonium molybdate, 4-5 parts of calcium carbonate powder, 1-2 parts of quartzite powder, 20-22 parts of waste newspaper, 2-3 parts of potassium persulfate, 30-33 parts of yellow meal worm manure, 0.7-1.0 part of ferric chloride, 0.5-0.6 part of ammonium ferrous sulfate hexahydrate, a right amount of 25% phosphoric acid solution and a right amount of water. The fertilizer is composed of the reasonably prepared raw materials according to the fertilizer demand rules of the soybeans. The nitrogin is added to implement the generation of the soybean root system symbiotic root nodules. The ammonium molybdate and other nitrogen components are properly added, thereby supplementing the demand for nitrogen in case of a small amount of rhizobia in the earlier period, and avoiding the excessive nutrient waste caused by abundant nitrogen fixation of rhizobia in the later period. The nitrogin and nitrogen components regulate the nitrogen demand of the soybeans under the synergic actions, thereby enhancing the nitrogen utilization efficiency.

Owner:闵军

Preparation method of tailings autoclaved bricks

The invention relates to a preparation method of tailings autoclaved bricks. The preparation method includes following steps: 1), stirring secondary tailings, carbide slag, cement and sand, and mixingwell to obtain a mixture; 2), using a brick machine to press and shape the mixture to obtain brick blanks; 3), standing and stacking the pressed brick blanks for maintenance to free water in the brick blanks to be removed; 4), feeding dewatered brick blanks into an autoclave for autoclaving maintenance to obtain the autoclaved bricks. Copper residue tailings are high in SiO2 content, exist mainlyas amorphous-state substances and are suitable for serving as a silicious material to produce autoclaved bricks; the carbide slag is high in yield and difficult to utilize, so that the technical scheme of utilizing the copper residue secondary tailings and adding the carbide slag to produce the autoclaved bricks solves the problem in utilizing the copper residue secondary tailings and provides aproper raw material for the autoclaved bricks.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for adjusting pH value of saccharified liquid

The invention discloses a method for adjusting the pH value of a saccharified liquid. In the method, a gluconic acid solution is used as a regulator, and the gluconic acid solution is mother liquor produced from gluconolactone. Therefore, the gluconic acid solution adopted in the invention can be used as a regulator for adjusting the pH value instead of hydrochloric acid and sulfuric acid, and thus, a discard solution is fully utilized to save process cost, increase the utilization added value of the lactone mother liquor and reduce the comprehensive cost of lactone production; meanwhile, the impurity contents of SO4<2-> and Cl<-> in a fermentation product are reduced to ensure that the SO4<2-> and the Cl<-> in the product are qualified without causing erosion to a tank body.

Owner:JIANGSU HUANYU KANGLI TECH

A kind of preparation method of high-strength porous sound-absorbing material

ActiveCN108529887BReduce accumulationSave and use added valueNoise reduction constructionGlass shaping apparatusSound barrierFoaming agent

Owner:SICHUAN UNIV

A method for producing aerated concrete with water-quenched copper tailings after copper selection and iron extraction

ActiveCN105271958BIncrease the use of added valueReduce dry shrinkageSolid waste managementCeramicwareSlurryCalcination

The invention provides a method for producing aerated concrete by using water quenching copper tailings being subjected to copper selection iron extraction, wherein the process comprises 1, raw material breaking grinding, 2, pulping, 3, material preparing stirring, 4, casting, 5, static gas forming, 6, cutting, 7, autoclave curing, and 8, discharging out of the kettle and packaging. According to the method, water quenching copper tailings of copper smelting plant is subjected to second copper selections through a flotation process, magnetic separation iron extraction is performed through a rotary kiln high temperature reduction calcination process to obtain a copper tailings ore pulp, and 35-40% by weight of the conveyed tailings ore pulp, 45-50% by weight of silica sand mortar, 10-15% by weight of lime slurry and 3-5% by weight of cement are directly conveyed into a stirring tank according to a certain weight percentage ratio so as to be subjected to mixing stirring without the dehydration and grinding treatment process, wherein the concentration is 55-60%, the curing pressure is 1.3 MPa, the curing temperature is 180-200 DEG C, and the curing time is 8 h. According to the present invention, the environmental pollution problem caused by the copper tailings accumulation is released, the produced aerated concrete building block meets the standard requirement, the production cost is low, the product drying shrinkage value is low, and the comprehensive utilization of the resources and energy-saving emission-reducing are achieved.

Owner:北京中冶设备研究设计总院有限公司 +1

Method for preparing calcium sulfate whisker filler by using shale vanadium extraction and neutralization slag

InactiveCN108588839AImprove the added value of comprehensive utilizationSimple processPolycrystalline material growthFrom normal temperature solutionsFilter cakeResource utilization

The invention relates to a method for preparing a calcium sulfate whisker filler by using shale vanadium extraction and neutralization slag. The method comprises the following steps: smashing and pulverizing the shale vanadium extraction and neutralization slag to obtain shale vanadium extraction and neutralization slag powder; preparing and mixing the shale vanadium extraction and neutralizationslag powder, distilled water and a crystallizing aid according to a mass ratio of 1: (10 to 50): (0.05 to 0.3), putting the mixture into a container, performing hydrothermal reaction under an unsaturated vapor pressure condition at 120 to 180 DEG C, and filtering the solution to obtain a filter cake; under the condition of 50 to 100 DEG C, putting the filter cake into anhydrous ethanol, mixing thefilter cake with the anhydrous ethanol to obtain an anhydrous ethanol solution, wherein the content of the shale vanadium extraction and neutralization slag powder in the anhydrous ethanol solution is 5 to 15 weight percent; adding a modifier into the anhydrous ethanol solution, mixing and stirring the modifier and the anhydrous ethanol solution, filtering the solution while the solution is hot,and drying and depolymerizing the product, thus obtaining the calcium sulfate whisker filler. The method has the characteristics of simple process, short production period, high resource utilization rate and integration of preparation and modification; the prepared product has a large length-diameter ratio and a large activity index.

Owner:WUHAN UNIV OF SCI & TECH

Method for rapidly recovering punicalagin from pomegranate rind extraction waste based on solvent effect

ActiveCN113390988AIncrease the use of added valueSimple methodComponent separationMethanol waterElution

The invention relates to a method for rapidly recovering punicalagin from pomegranate rind extraction waste based on a solvent effect. According to the method, based on a solvent effect, methanol water, acetonitrile water or formic acid water is used as a dispersing solvent to disperse a precipitate (namely pomegranate rind extraction waste) generated in a precipitation pretreatment process of a pomegranate ring extract, and then a sample is injected to a reversed-phase chromatographic column for separation; and a solvent effect is formed in the separation process by controlling the volume and the elution strength of a sample injection solvent and the elution strength of a mobile phase. Large-polarity punicalagin is rapidly eluted at a solvent peak, and small-polarity impurities are retained on a reversed-phase chromatographic column, so that a separation effect is achieved. According to the method, the pomegranate rind waste with the punicalagin content of 12% can be rapidly purified into a punicalagin-rich component with the punicalagin content range of 18-40%. The method provided by the invention is simple and rapid, has high purification efficiency, and provides powerful support for recycling the pomegranate rind extraction waste obtained by precipitation pretreatment in the pomegranate rind extract.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Method of preparing inorganic polymer poly(iron silicate) flocculating agent from secondary copper slag

PendingCN107129017AReduce pollutionReduce manufacturing costSolid waste disposalWater/sewage treatment by flocculation/precipitationInorganic polymerImpurity

The invention provides a method for preparing inorganic polymer polysilicate iron flocculant from the secondary slag of copper slag, specifically, the secondary slag of copper slag is heated, stirred, allowed to stand, and the pH value is adjusted under the action of acid to obtain poly Silicic acid solution; Fe2(SO4)3 solution is obtained by crushing, stirring, reacting, filtering and other steps of rolled steel sheet; mixing and reacting Fe2(SO4)3 solution and polysilicic acid solution to obtain inorganic polymer polysilicate iron flocculant. The invention adopts the secondary tailing slag and can be used as the silicon source of the polysilicate iron flocculant. The rolled steel sheet is selected as the iron source, which has the characteristics of high iron content, less impurity elements, and large production volume, which can meet the requirements of polysilicate iron flocculant production.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Okra tea and its production process

The invention relates to okra tea and its production process, the production process comprises the following steps: refrigerating the okra fruits at the temperature of 0-10 DEG C for 10-14 hours; slicing the refrigerated okra fruits, blanching and drying, wherein the blanching temperature is 90-100 DEG C for less than 30 minutes and the drying temperature is 50-70 DEG C; performing a sterilization treatment to the dried okra fruits to obtain the okra tea. The preparation process of the present invention is simple and the production condition is mild, a plurality of nutrients of okra can be reserved so that the okra tea has abundant nutrition, the soluble sugar content in the okra tea can reach 38.01% and the water extraction is 44.17%, the okra tea is convenient for carrying and using which provides a novel sale channel and an utilization approach for okra.

Owner:SUGARCANE RES INST FUJIAN ACAD OF AGRI SCI

Method for anion anti-mite antibacterial fiber film for carpet

InactiveCN108411494AEffectively exert synergistic and sustained antibacterial effectSolve pollutionFilament/thread formingNon-woven fabricsFiberEcological environment

The invention relates to a method for preparing anion anti-mite antibacterial fiber film for a carpet, and belongs to the technical field of carpet preparation. The method utilizes chitosan dissolvedin an organic solution and adds active mineral powder to form a spinning solution, and then centrifugally spins to form fiber film; the dried fiber film is finished with anti-mite antibacterial slow-release liquid, thereby obtaining the anion anti-mite antibacterial fiber film. The anion anti-mite antibacterial fiber film not only has excellent antibacterial property, but also achieves the effectsof health care, oleophobicity and hydrophobicity, anti-ultraviolet performance and the like, and has low preparation cost, low equipment requirement, convenient operation control, high production efficiency, no pollution to the ecological environment and easy achievement of large-scale production.

Owner:HUBEI FUDENG CARPET CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com