Method for producing petroleum coke

A petroleum coke and raw material oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of being unable to use inferior catalytic cracking oil slurry and produce needle coke, so as to expand the source of raw materials for production and improve The effect of using added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

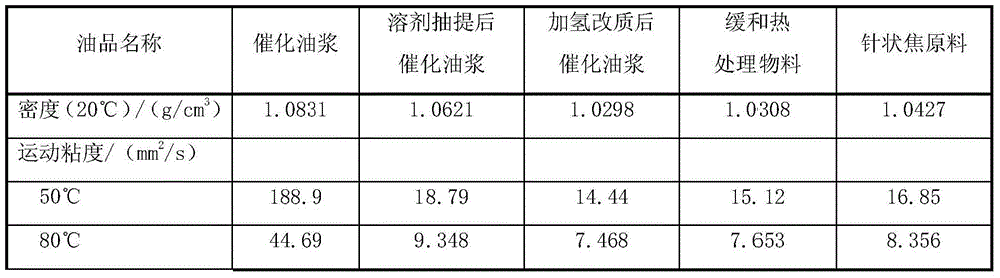

[0032] The raw material is catalytic cracking oil slurry, and its properties are listed in Table 1.

[0033]Use a mixed solvent with a mass ratio of butane / toluene of 1:1, mix it with the catalytic cracking oil slurry and stir it at a stirring temperature of 135°C, then set aside to settle at a settling temperature of 115°C and settling time for 18 hours. Non-ideal heavy components containing solid powder, heavy colloids and asphaltenes, and the upper light components are recovered by solvents and used as raw materials for subsequent processes.

[0034] The material distribution after solvent extraction is shown in Table 2. The hydrogenation protection agent adopts the RG-30B catalyst developed by the Chinese Academy of Sciences, and the hydrogenation refining agent adopts the RMS-30 catalyst developed by the Chinese Academy of Sciences, both of which are commercial agents produced by Changling Catalyst Factory of Sinopec Catalyst Branch. The hydrogenation reaction temperatur...

Embodiment 2

[0039] The method and raw materials are the same as those in the examples, except that thermally cracked heavy oil (distillation range 255° C. to 486° C.) is directly used as a raw material for delayed coking. The distribution of coking products is shown in Table 5, and the properties of petroleum coke are shown in Table 6. The results show that the direct coking of thermally cracked heavy oil without distillation cut, the coke yield decreased by 0.39 percentage points, and the CTE value increased by 0.05×10 -6 / °C.

[0040] Table 1 Properties of catalytic cracking oil slurry before and after raw material pretreatment

[0041]

[0042]

[0043] The material distribution of table 2 solvent extraction

[0044] solvent extraction

Yield, w / %

ideal component

88.3

Non-ideal components

11.7

total

100.0

[0045] Table 3 Distribution of delayed coking products

[0046] Coking products

Yield, w / %

coking d...

Embodiment 3

[0055] The raw material is an oil sample mixed in a certain proportion with pretreated catalytic cracking oil slurry and furfural extracted oil. The mixing proportion and properties are listed in Table 7. Among them, the catalytic cracking oil slurry uses a mixed solvent with a mass ratio of pentane / benzene of 1.1:1, mixes with the catalytic cracking oil slurry, stirs, the stirring temperature is 130°C, and then stands for precipitation, the standing precipitation temperature is 110°C, and the standing time is 20h , the non-ideal heavy components rich in solid powder, heavy colloids and asphaltenes in the lower part are separated, and the light components in the upper part are recovered by solvent and are the raw materials for subsequent processes.

[0056] The hydrogenation protection agent adopts the RG-30B catalyst developed by the Chinese Academy of Sciences, and the hydrogenation refining agent adopts the RMS-30 catalyst developed by the Chinese Academy of Sciences, both o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com