Technology for refining cane molasses by multistage membrane filtration

A sugarcane molasses and membrane filtration technology, which is applied in the production of sucrose, sugar production, and juice purification, etc., can solve the problems of inability to remove and utilize reducing sugar in molasses, reduce molasses generation, and complex components, and achieve high Value utilization, avoid generation and accumulation, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

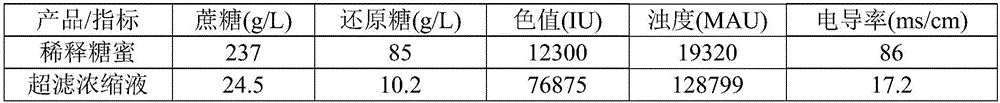

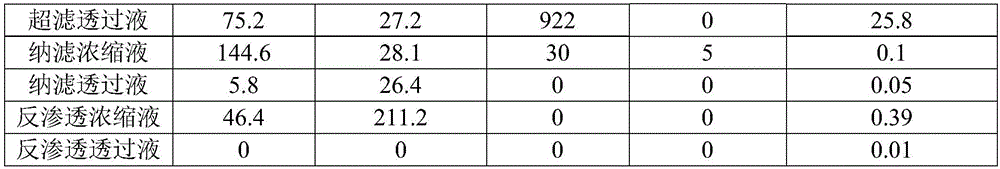

Embodiment 1

[0051] First pump 100kg of waste molasses into the buffer tank, add 100kg of pure water, heat and mix well, add food-grade sodium hydroxide to adjust the pH to 7.2, and then remove the suspended solids through a high-speed centrifuge and enter the ultrafiltration decolorization system. The ultrafiltration membrane module is Polyamide / polysulfone spiral membrane module, molecular weight cut-off is 1000Da, operating temperature is 65°C, pressure is 1.5MPa, after concentrating twice, continue to add 500kg of washing water to the ultrafiltration membrane module to obtain 600kg of decolorized and clarified ultrafiltration The permeate enters the anion-cation exchange resin mixed bed to continue decolorization and desalination. The diluted molasses after decolorization and desalination enters the nanofiltration membrane module for concentration. 65°C, pressure 3MPa, concentrated 2 times to get 300kg of nanofiltration concentrated liquid into the crystallization tank, 300kg of nanofil...

Embodiment 2

[0057] First, pump 100kg of molasses into the buffer tank, add 300kg of pure water, heat and mix, add food grade sodium hydroxide to adjust the pH to 7.2, and then remove the suspended solids through a high-speed centrifuge and enter the ultrafiltration decolorization system. Chemicalized polyethersulfone roll-type membrane module with a molecular weight cut-off of 2000Da, an operating temperature of 60°C and a pressure of 1MPa. After concentrating for 4 times, continue to add 300kg of wash water to the ultrafiltration membrane module to obtain 600kg of decolorized ultrafiltration permeate Enter the anion-cation exchange resin mixed bed to continue decolorization and desalination. The diluted molasses after decolorization and desalination enters the nanofiltration membrane module for concentration. Pressure 4MPa, concentrated 3 times to get 200kg of nanofiltration concentrated liquid into the crystallization tank, 400kg of nanofiltration permeate into the reverse osmosis membra...

Embodiment 3

[0060] First, pump 100kg of molasses into the buffer tank, add 600kg of pure water, heat and mix well, add food-grade sodium hydroxide to adjust the pH to 7.2, and then remove the suspended solids through a high-speed centrifuge and enter the ultrafiltration decolorization system. Chemicalized polyethersulfone roll-type membrane module, with a molecular weight cut-off of 5000Da, an operating temperature of 50°C, and a pressure of 1MPa. After concentration of 7 times, 600kg of decolorized ultrafiltration permeate is obtained and enters an anion-cation exchange resin mixed bed for further decolorization and desalination. The diluted molasses after decolorization and desalination enters the nanofiltration membrane module for concentration. The nanofiltration membrane module is a polyamide roll-type membrane module with a molecular weight cut-off of 400Da, an operating temperature of 65°C, and a pressure of 4MPa. After concentration of 4 times, 150kg of nanofiltration concentrate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com