Lightweight, self-ballasting photovoltaic roofing assembly

a photovoltaic roof and self-balancing technology, applied in the safety of solar heat collectors, lighting and heating apparatuses, batteries, etc., can solve the problems of increasing assembly complexity, increasing manufacturing costs, and reducing the cost of solar cells, so as to facilitate the transition, reduce air pollution and global warming, and improve the cost competitiveness of photovoltaic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

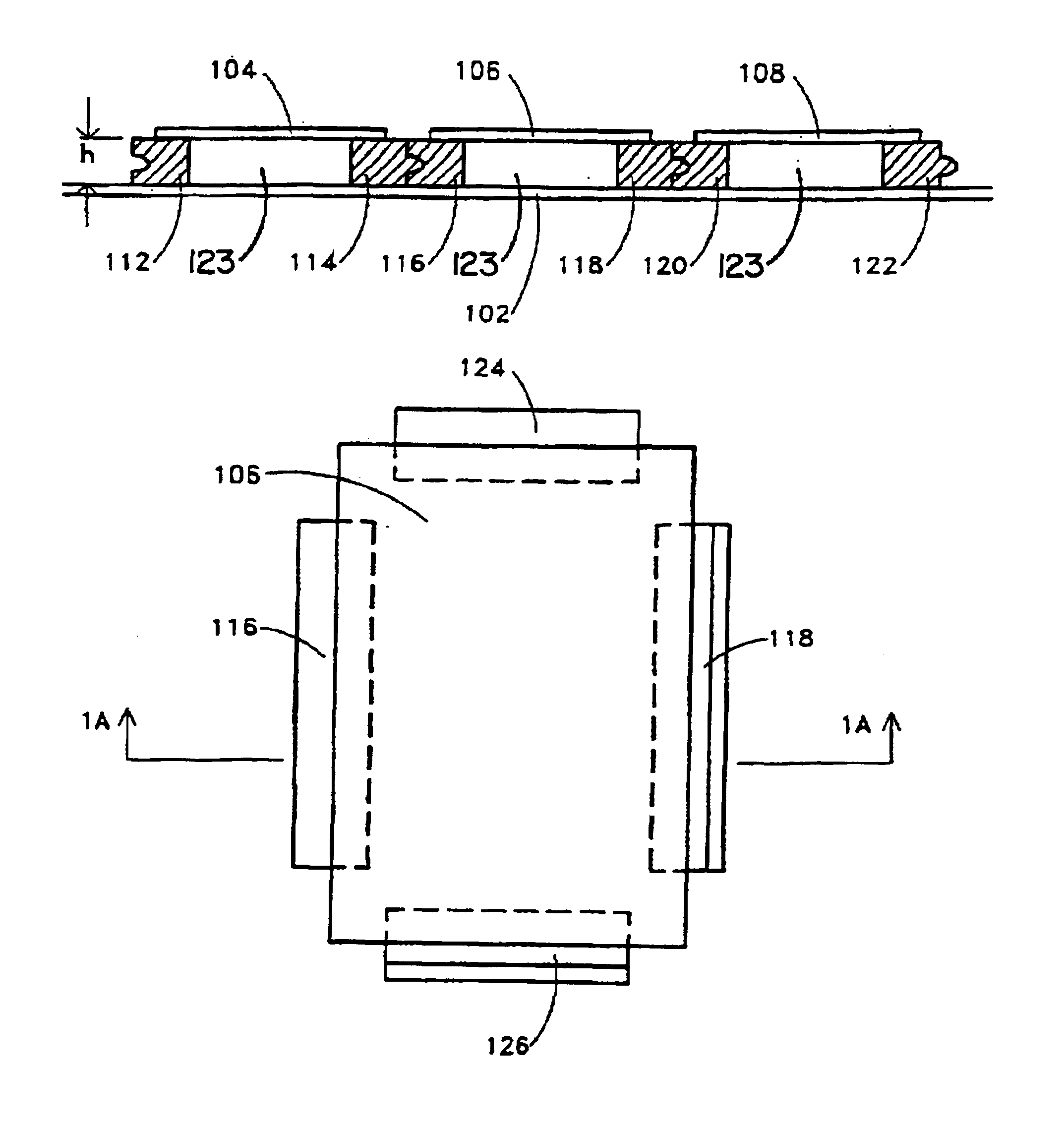

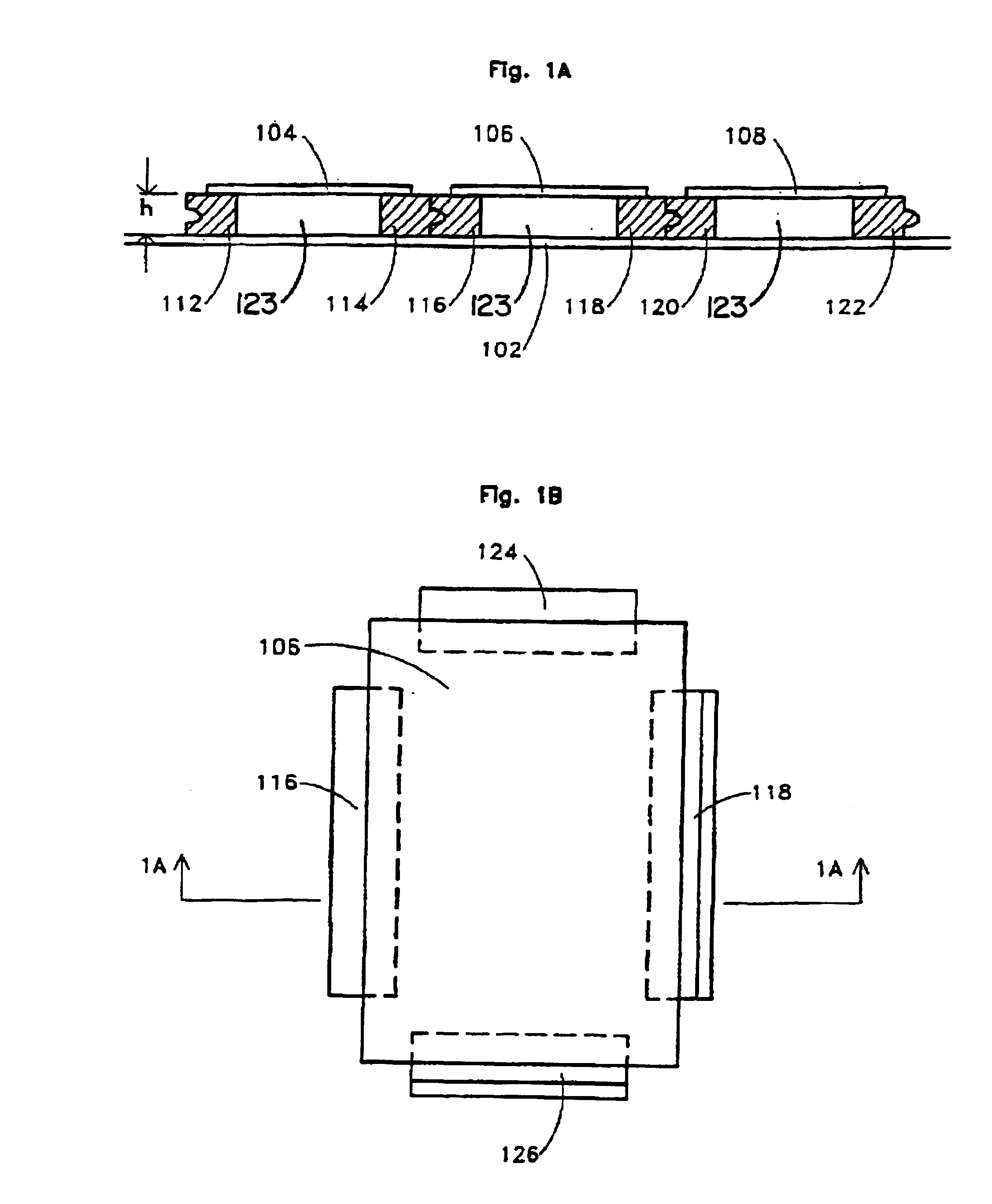

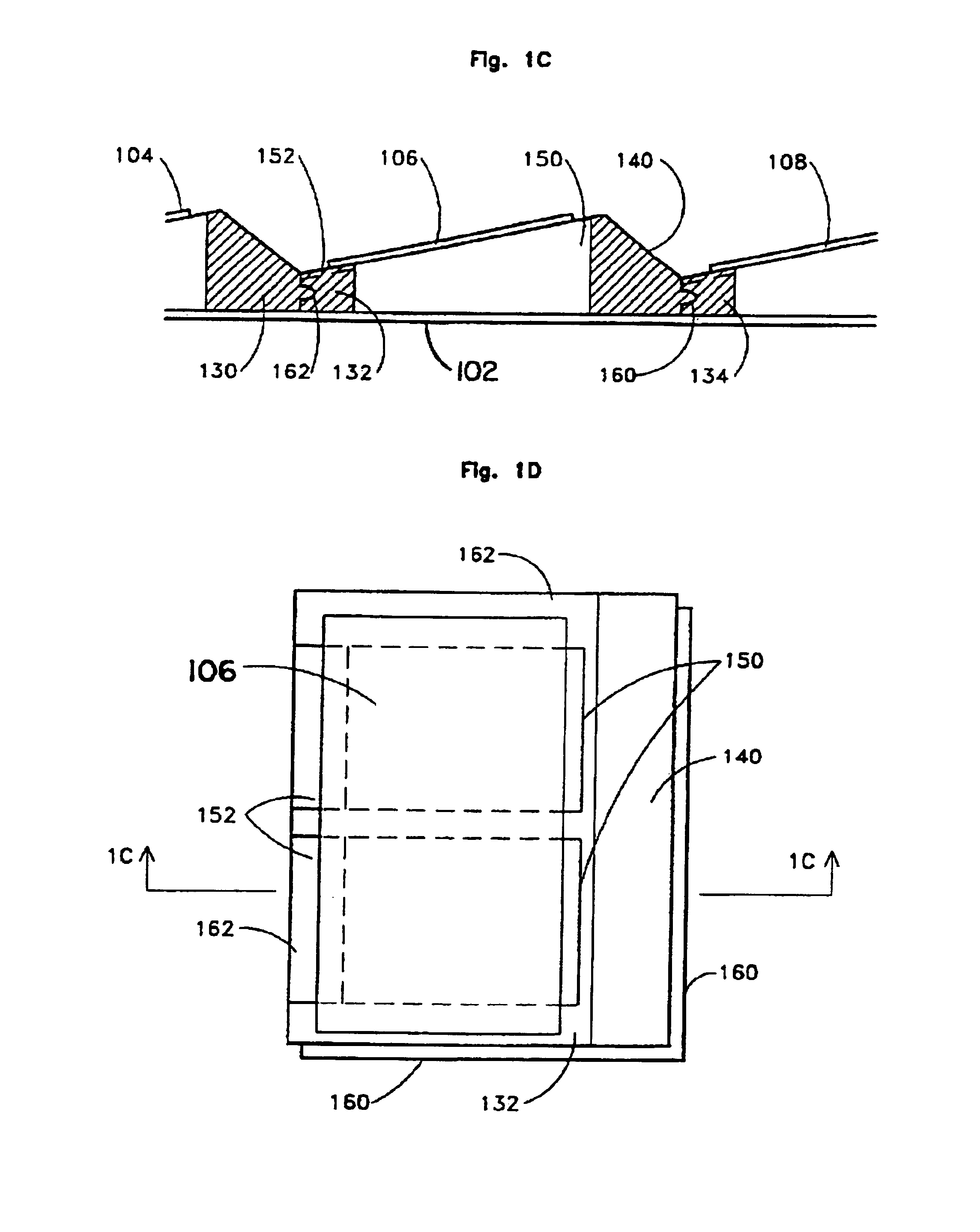

Description of FIGS. 1A-1D:

Spacer Geometry Directly on Roofing Membrane

[0033]FIG. 1A shows a sectional view of a photovoltaic roofing assembly. The assembly includes a plurality of photovoltaic modules 104, 106, 108, a plurality of pre-formed spacers, pedestals, or supports 112, 114, 116, 118, 120, 122 which are respectively disposed below the plurality of photovoltaic modules 104, 106, 108 and integral therewith, or fixedly connected thereto. Spacers 112, 114, 116, 118, 120, 122 are disposed on top of a roofing membrane 102. Photovoltaic modules 104, 106, 108 and the associated spacers 112-122 define open regions 123 beneath the photovoltaic modules.

[0034]Membrane 102 is supported on conventional roof framing (not shown), and may be attached thereto by conventional methods, such as fasteners or adhesives. Membrane 102 may also rest directly on an insulation block which is supported on conventional roof framing. Modules 104, 106, 108 are electrically connected using electrical condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com