Method for producing geopolymer cement mortar through red mud and bauxite tailing

A cement mortar and geopolymer technology, applied in cement production, solid waste management, sustainable waste treatment, etc., can solve problems such as environmental pollution and safety hazards, waste of resources, land occupation, etc., and achieve low energy consumption and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

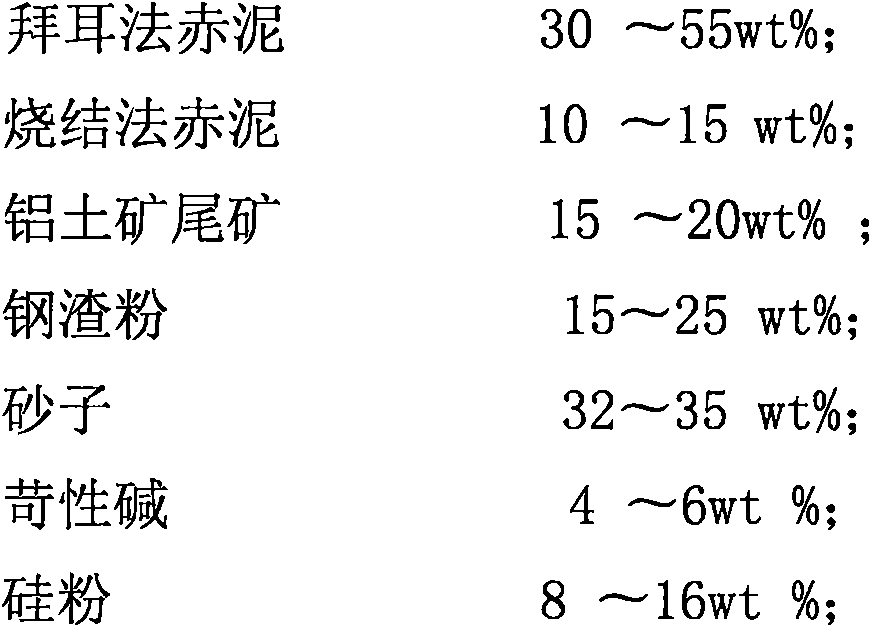

[0028] A method for producing geopolymer cement mortar from red mud and bauxite beneficiation tailings, the components and contents of the geopolymer cement mortar are:

[0029]

[0030]

[0031] According to above-mentioned components and content thereof, the preparation steps of this geopolymer cement mortar are:

[0032] The first step is to add caustic soda to Bayer process red mud, sintering process red mud, and bauxite beneficiation tailings, mechanically stir for 10-15 minutes, and then dry ball mill in a ball mill for 25-35 minutes to obtain ball abrasives ;

[0033] The second step is to put the ball abrasive into a medium-temperature kiln for modification, and the modification temperature is 600-650°C; keep it warm for 2-3 hours to prepare the modified material;

[0034] The third step is to cool the modified material at room temperature, then add steel slag powder and silicon powder to it, and then stir for 10 to 15 minutes to obtain a mixed material;

[003...

Embodiment 2

[0039] A method for producing geopolymer cement mortar from red mud and bauxite beneficiation tailings, the components and contents of the geopolymer cement mortar are:

[0040]

[0041] According to above-mentioned components and content thereof, the preparation steps of this geopolymer cement mortar are:

[0042] The first step is to add caustic soda to Bayer process red mud, sintering process red mud and bauxite beneficiation tailings, add caustic soda, mechanically stir for 10 to 15 minutes, and then dry ball mill in a ball mill for 25 to 35 minutes to produce get ball abrasive;

[0043] The second step is to put the ball abrasive into a medium-temperature kiln for modification, and the modification temperature is 550-600°C; keep the temperature for 2-3 hours to obtain the modified material;

[0044] The third step is to cool the modified material at room temperature, then add steel slag powder and silicon powder to it, and then stir for 10 to 15 minutes to obtain a mi...

Embodiment 3

[0049] A method for producing geopolymer cement mortar from red mud and bauxite beneficiation tailings, the components and contents of the geopolymer cement mortar are:

[0050]

[0051] According to above-mentioned components and content thereof, the preparation steps of this geopolymer cement mortar are:

[0052] The first step is to add caustic alkali to Bayer process red mud, sintering process red mud and bauxite beneficiation tailings, mechanically stir for 10-15 minutes, and then dry ball mill in a ball mill for 25-35 minutes to obtain ball abrasive ;

[0053] The second step is to put the ball abrasive into a medium-temperature kiln for modification, and the modification temperature is 500-550°C; keep the temperature for 2-3 hours to obtain the modified material;

[0054] The third step is to cool the modified material at room temperature, then add steel slag powder and silicon powder to it, and then stir for 10 to 15 minutes to obtain a mixed material;

[0055] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com