Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Renewable resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ethylene glycol from cellulose

ActiveCN101723802ALow costWide variety of sourcesOrganic compound preparationCatalyst activation/preparationHydrogen pressurePolyethylene glycol

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

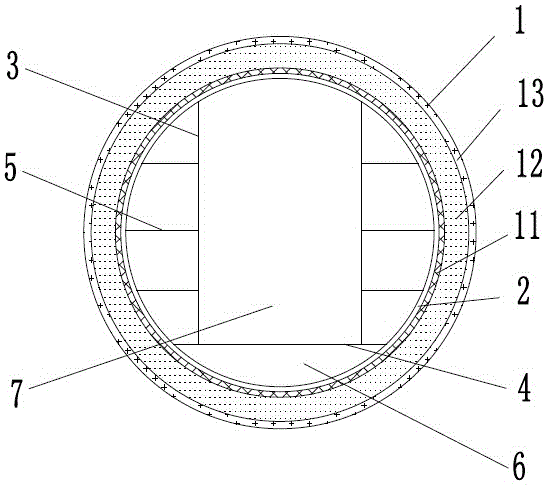

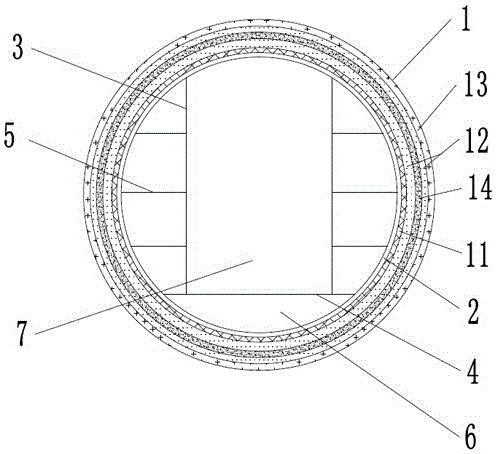

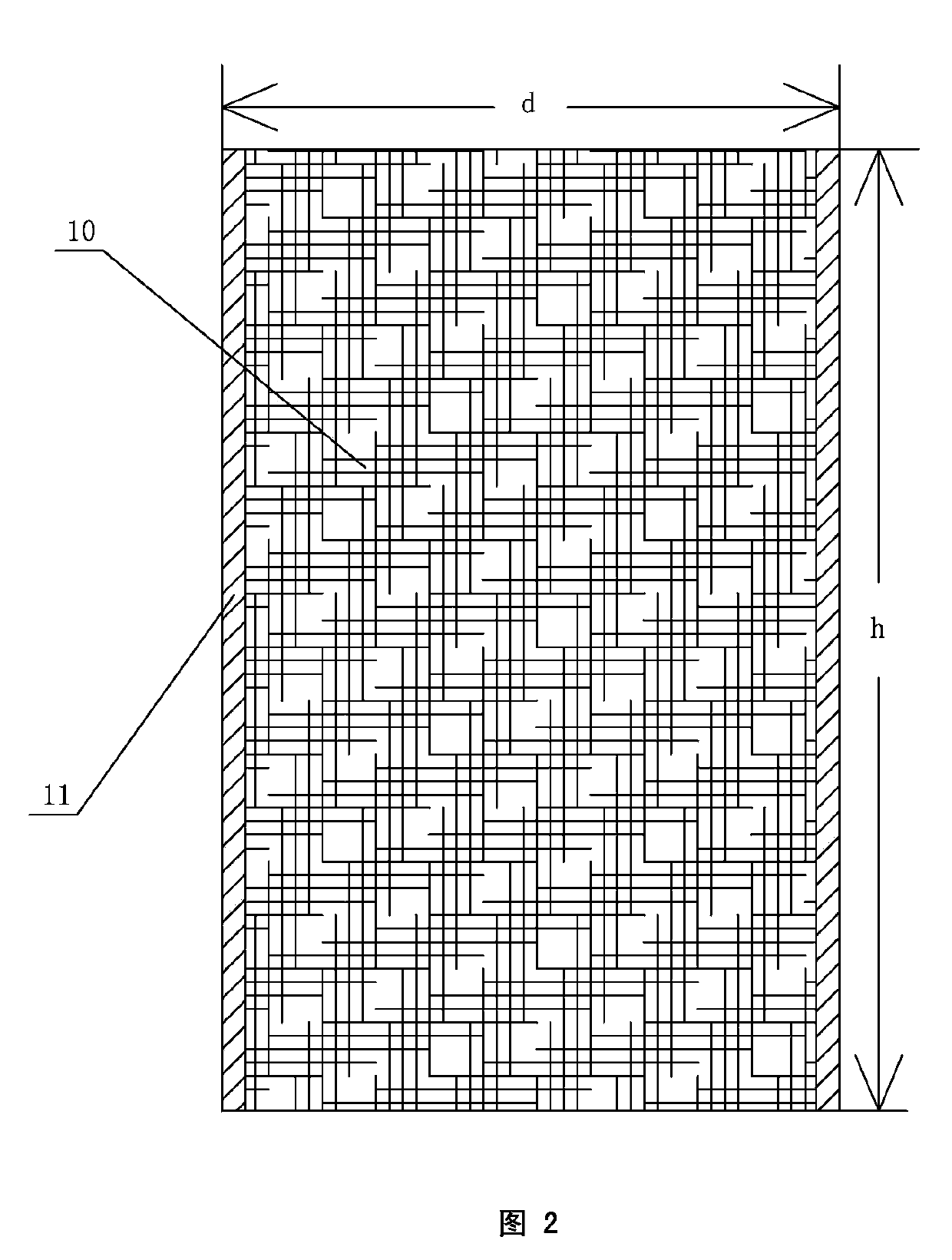

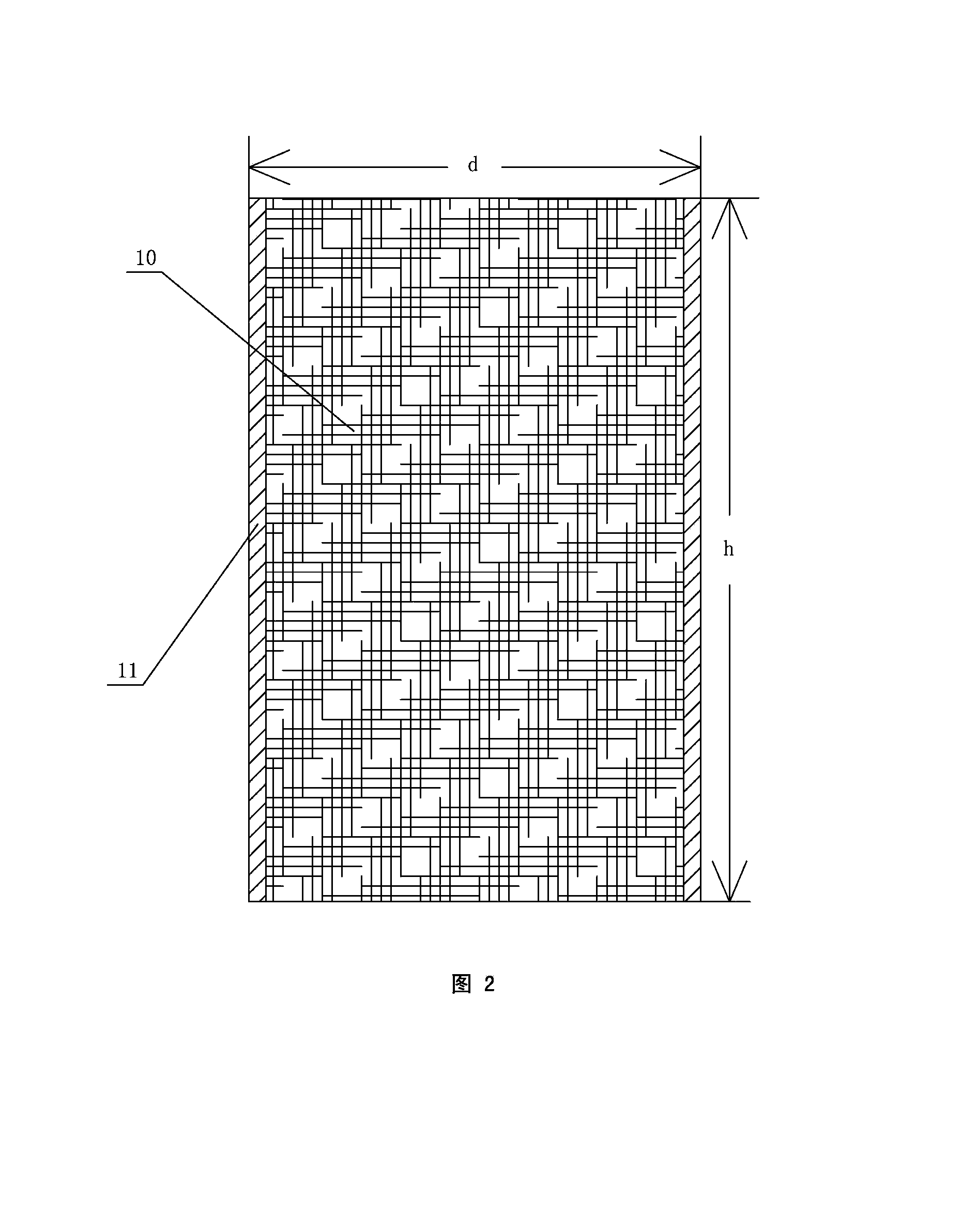

Prefabricated bamboo composite pipe gallery and manufacturing method thereof

InactiveCN105042213AReduce manufacturing costEnergy saving and environmental protection in the production processUnderwater structuresRigid pipesEngineeringWater soluble

The invention discloses a prefabricated bamboo composite pipe gallery, which is formed by connecting a plurality of prefabricated pipe joints, wherein each pipe joint comprises a pipe body, a force bearing mechanism, vertical supporting beams, a horizontal supporting beam and pipeline supports; the pipe body radially comprises a liner layer, a structure layer and an outer protection layer from inside to outside in sequence; the liner layer comprises flame-retarded resin and flame-retarded fabrics; the structure layer at least comprises a plurality of bamboo skin layers which are bonded with water soluble resin; the outer protection layer at least comprises flame-retarded resin; and the force bearing mechanism is fixed to the inner surface of the pipe body. The invention also discloses a method of manufacturing the prefabricated bamboo composite pipe gallery. The method comprises the manufacturing of the pipe body. The preparation method of the pipe body comprises the steps: (1) the liner layer is manufactured; (2) the structure layer is manufactured; and (3) the outer protection layer is manufactured. According to the invention, bamboo is utilized to manufacture a prefabricated pipe gallery, so that the intensity is good, the weight is light, the cost is low, the impermeability is good, the antiknock characteristic is strong, the construction is convenient, and the technical problems that the existing comprehensive pipe gallery consumes too many materials, the construction project amount is large, the construction period is long and the construction cost is high are solved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

Cardanol-based antioxidant as well as preparation method and application thereof

The invention discloses a cardanol-based antioxidant as well as a preparation method and application thereof. The cardanol-based antioxidant contains a compound with a structure shown as a formula (1): (shown in the description), wherein n ranges from 0 to 3; R1 and R2 are respectively and independently selected from H, alkyl, cycloalkyl, aryl, alkaryl or aralkyl; at least one of R3 and R4 has a structure shown as a formula (2) or (3): (shown in the description); R and R' are respectively and independently selected from H, alkyl, cycloalkyl, aryl, alkaryl or aralkyl; R5 is selected from -S-, -O-, -NH- or -(CH2)n'-; n' ranges from 0 to 3; Ra and Rb are respectively and independently selected from H, -OH, -SH, -NH2, alkyl, cycloalkyl, aryl, alkaryl or aralkyl; m and m' are any integer of 0 to 3 respectively. The cardanol-based antioxidant disclosed by the invention has the characteristics of greenness, environmental protection, antioxidation property, excellent thermal stability and extreme pressure resistance and the like; a preparation process has the advantages of simplicity, feasibility, mild conditions and wide application prospect in the fields of multiple oil products, fuel, plastic, rubber, fibers, coatings and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

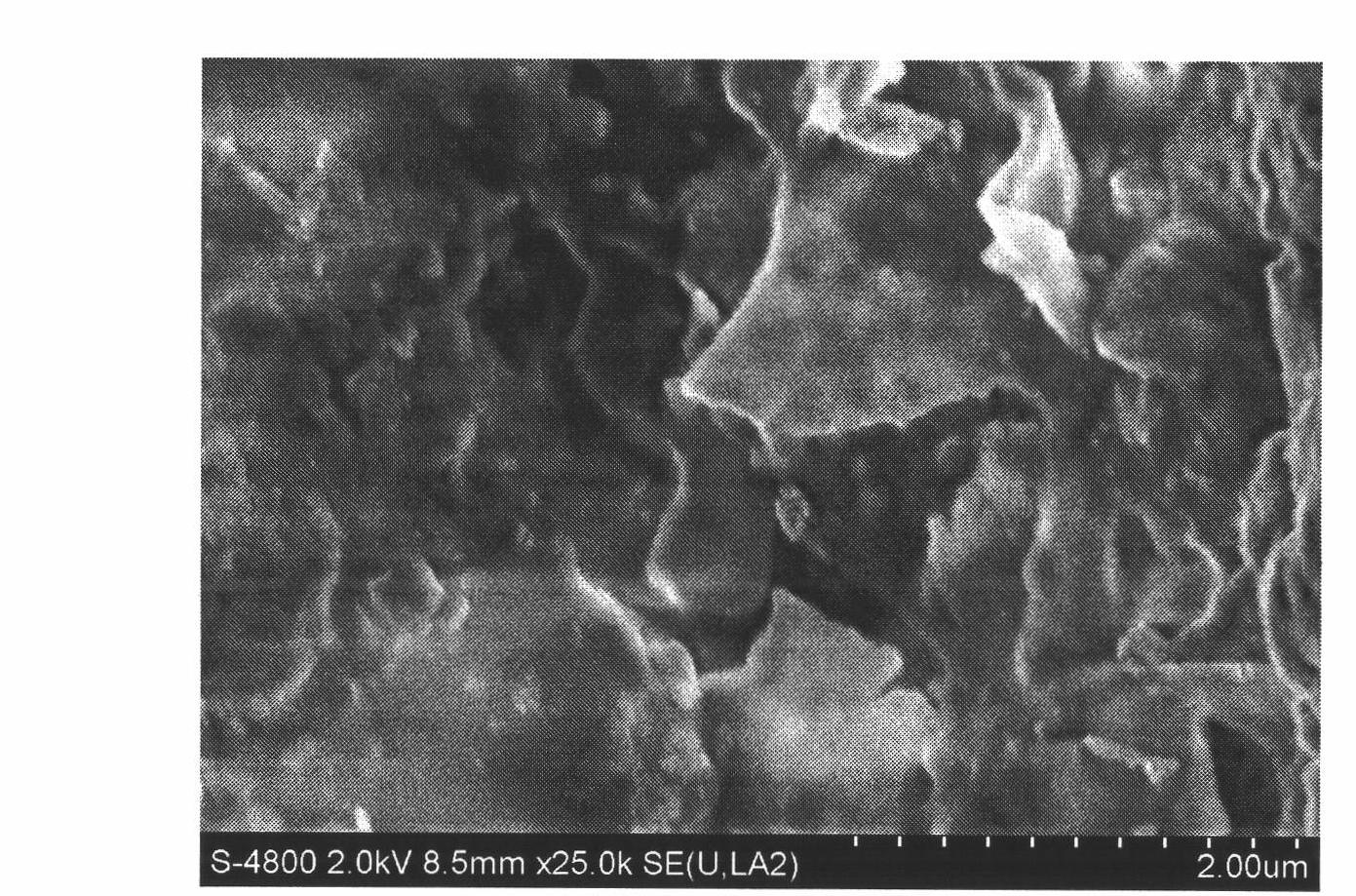

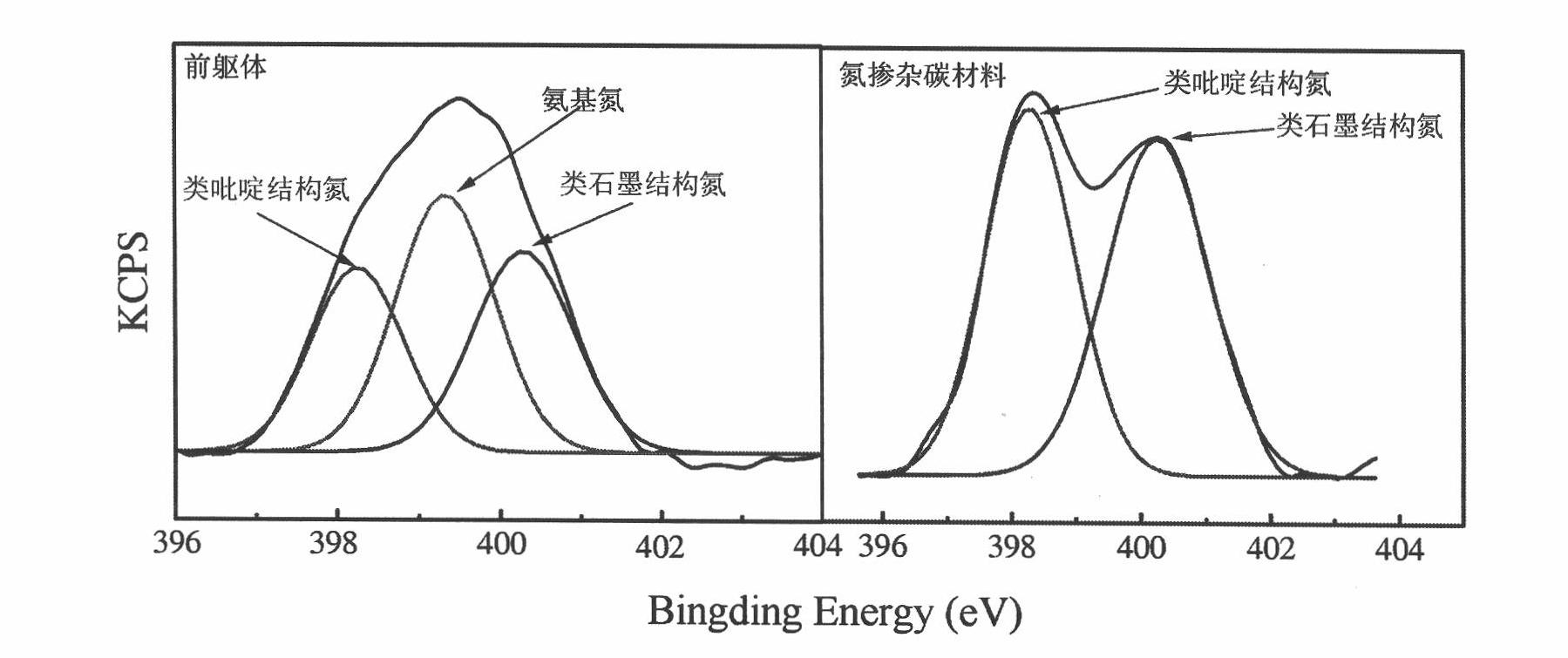

Preparation method of nitrogen-doped carbon material

InactiveCN102627268AEasy to buy raw materialsHigh nitrogen contentCarbon preparation/purificationCarbon sourceSucrose

Disclosed is a preparation method of a nitrogen-doped carbon material. The nitrogen-doped carbon material prepared in the invention has latent applications in the aspects of hydrogen storage, fuel cells, biosensors, supercapacitors and the like. According to the method, cane sugar is used as a carbon source, ammoniacal liquor is used as a nitrogen source, and the nitrogen-doped carbon material isprepared by simple steps of hydro-thermal carbonization, calcination in inert atmosphere and the like, wherein the hydro-thermal temperature is 160-200 DEG C, the concentration of the ammoniacal liquor is higher than 12%, and the carbonization temperature is 600-900 DEG C. Nitrogen doping amount can be controlled within the range of 17.8%-3.6% by adjusting hydro-thermal carbonization condition and calcination temperature. The prepared nitrogen-doped carbon material has a lamella shape with the lamellar thickness being about 200nm. Nitrogen atoms are mixed in graphitic carbon molecular networkmainly in graphite-like and pyridine-like structures.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

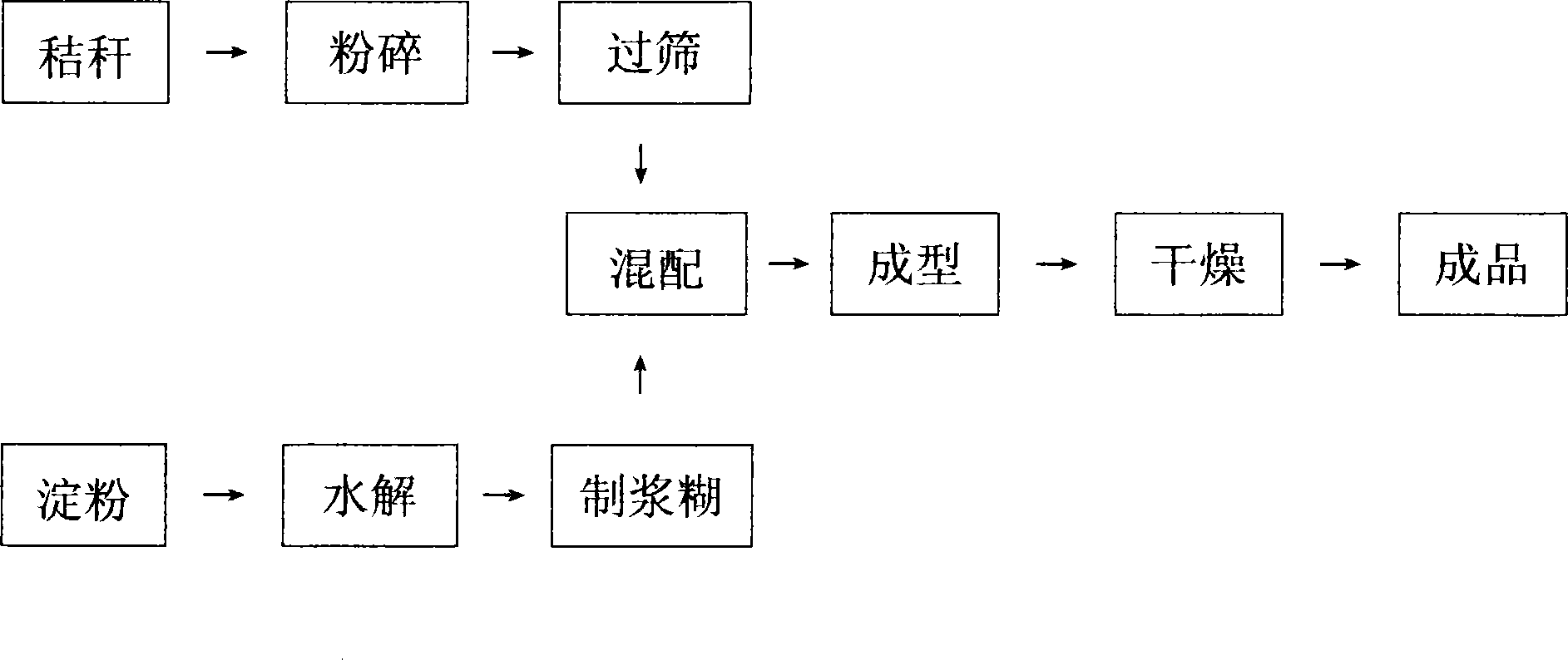

Biomass fuel forming method

InactiveCN101157876ANo pollution in the processSimple processBiofuelsSolid fuelsStarch pasteHydrolysis

The invention pertains to a forming process of biomass fuel, which is characterized in that the invention is formed by preparation of components and the technique processing and the weight ratio of main components are that: straw of 20-95, and starch of 2-60. The production technique process comprises the straw, grinding, sieving, starch, hydrolysis, forming starch paste, compounding, molding and drying processes. 10-120 meshes are sieved; Hydrolyzed starch / water=1 / 5-40; the molding adopts a pouring of mould vibration or an extrusion molding; a drying temperature ranges from 1-150 DEG C. The process has the advantages of simple technique, low investment, fast effect, low cost, convenience to popularize, and also the more ideal molding method of utilizing plant straws, fruits, rhizomes and organic refuse.

Owner:李学敏

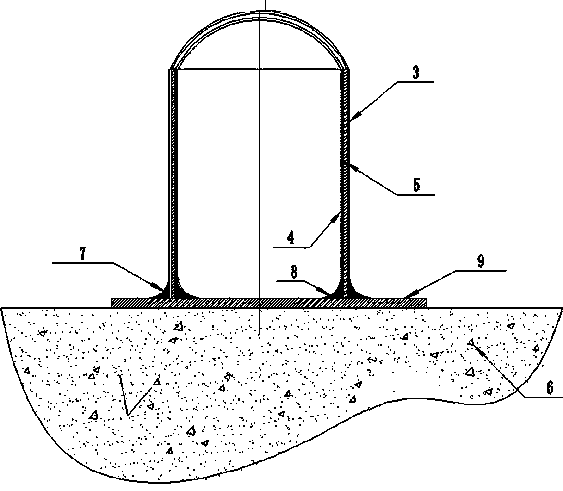

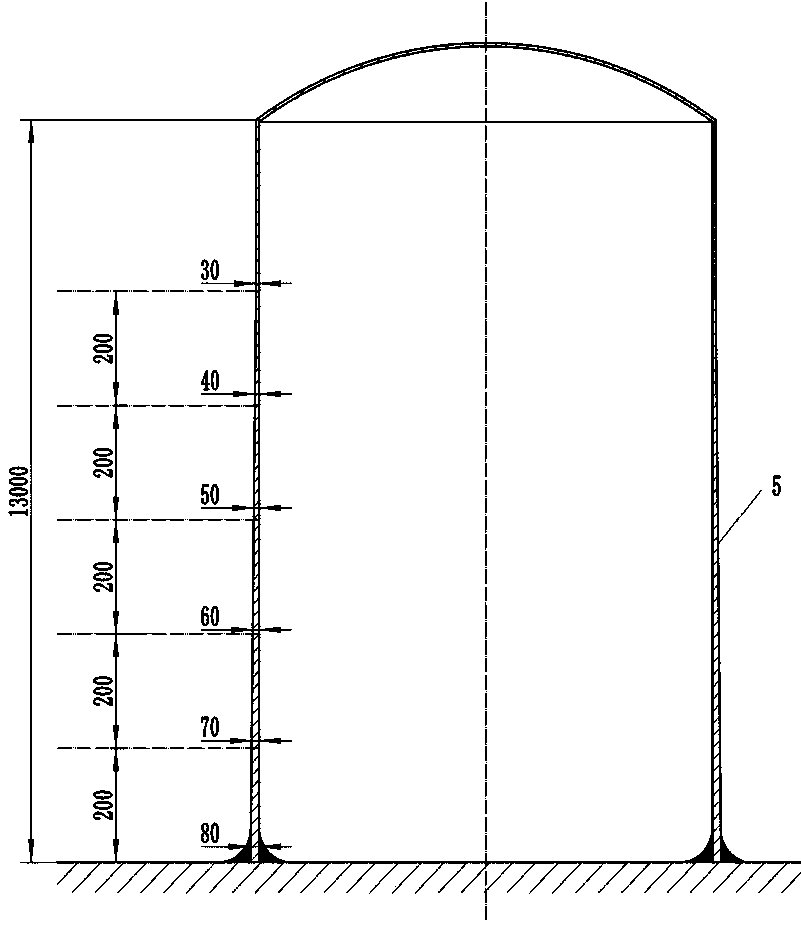

Preparation method for bamboo coiled composite vertical type storage tank

The invention relates to a preparation method for a bamboo coiled composite vertical type storage tank. The preparation method is characterized by comprising the following steps: preparing an end socket lining layer, an end socket enhancement layer and an outer protection layer in sequence so as to prepare a top end socket, then directly forming a tank bottom plane on the basis of a plane, manufacturing a storage tank main body, fixing the top end socket of the storage tank at the upper end of a matched storage tank main body die, preparing a storage tank main body lining layer, enabling the storage tank main body die to rotate around the axial line, enabling a coiling trolley to do up-and-down reciprocating motion in a rail, tidily arraying and coiling bamboo split rolls outside the storage tank main body lining layer and a combination part of the storage tank main body and the top end socket of the storage tank by virtue of relative motion between the storage tank main body lining layer and the top end socket of the storage tank, adding a resin mixture during coiling, performing solidification to form the storage tank main body enhancement layer, and finally coating the outer protection layer; sealing the inner side and outer side of the combination part of the tank bottom and the main body by virtue of resin and bamboo fiber non-woven cloth, pasting an arc transition region, and coating another outer protection layer after solidification is finished. The method is low in cost, environment-friendly in process and high in product quality.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

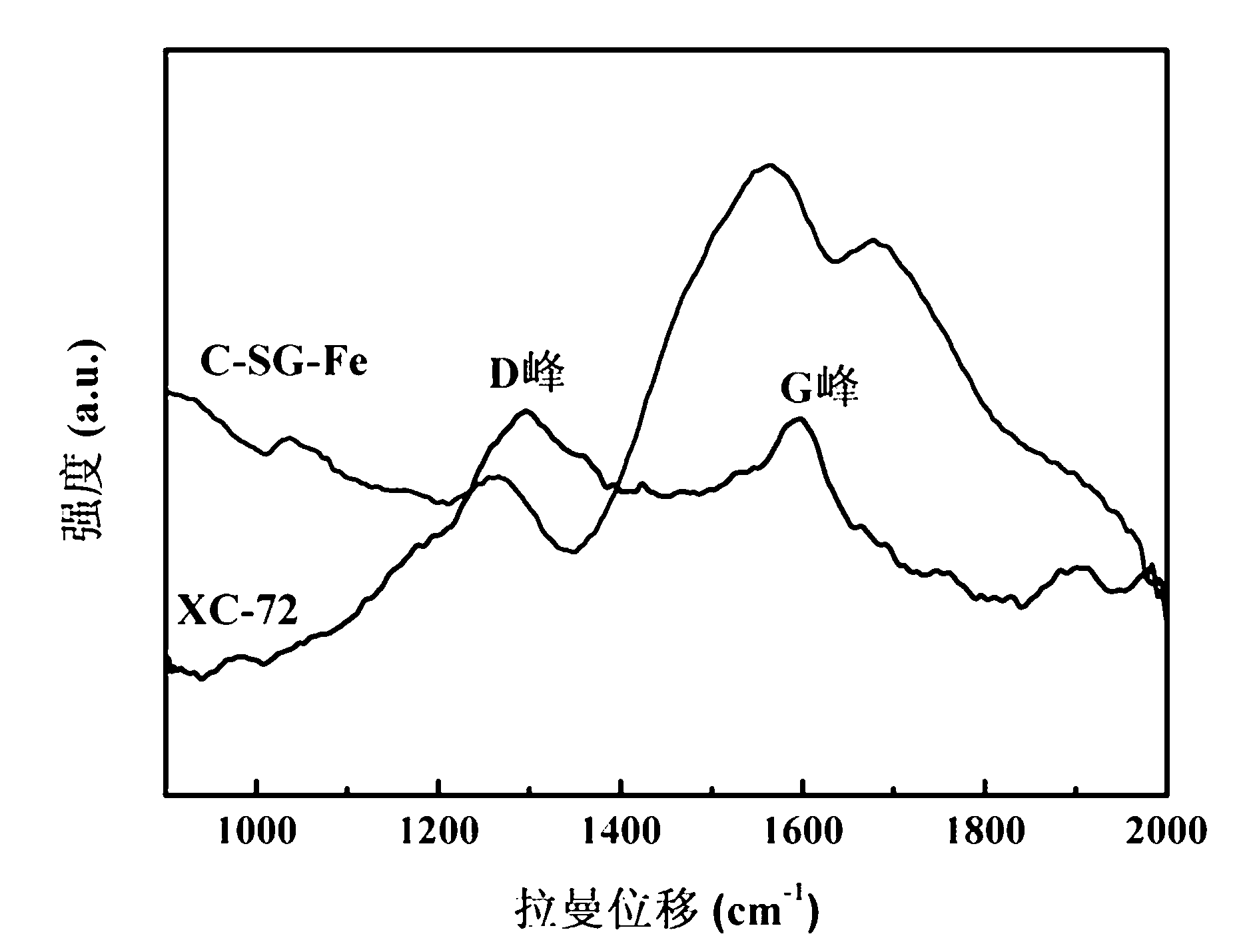

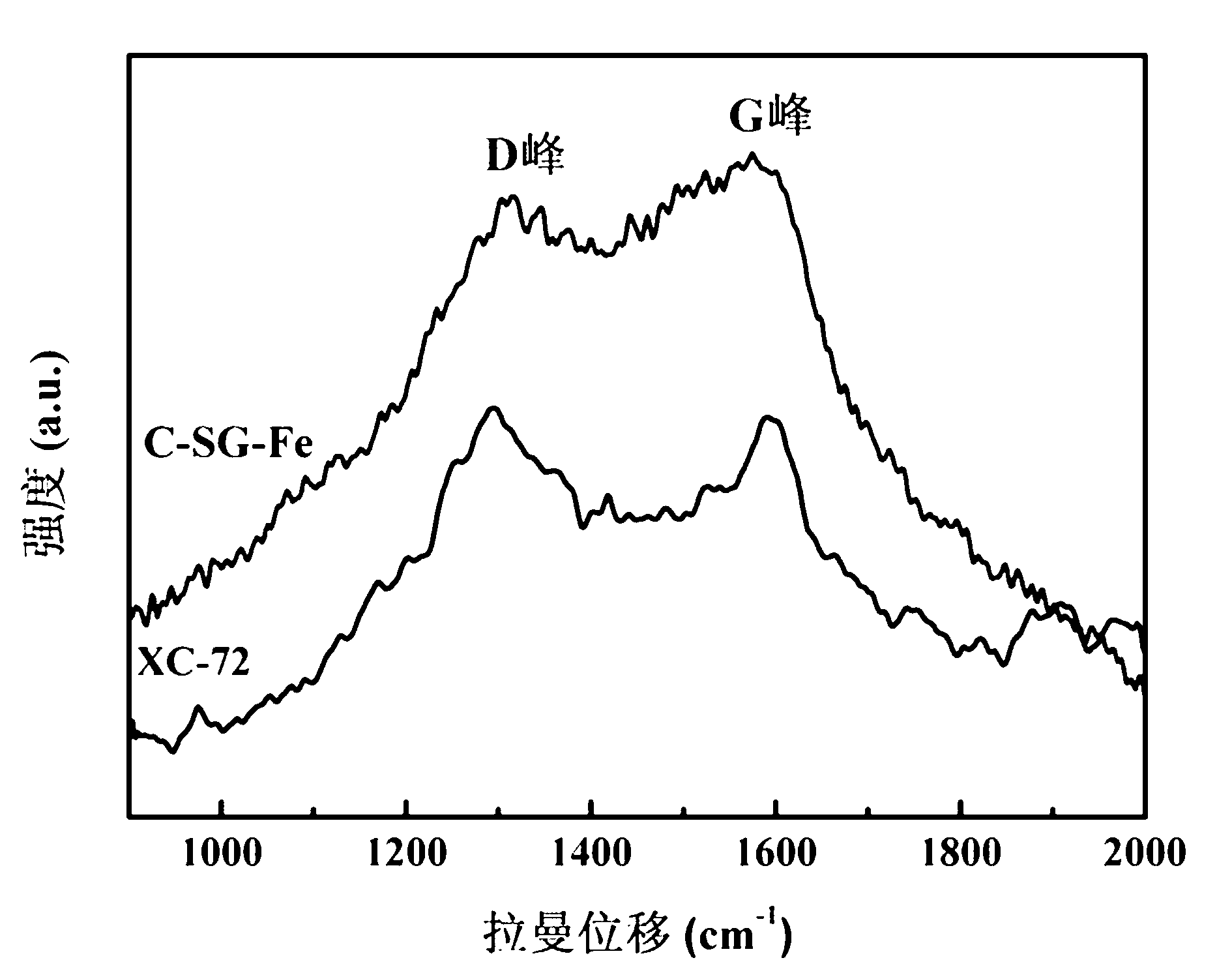

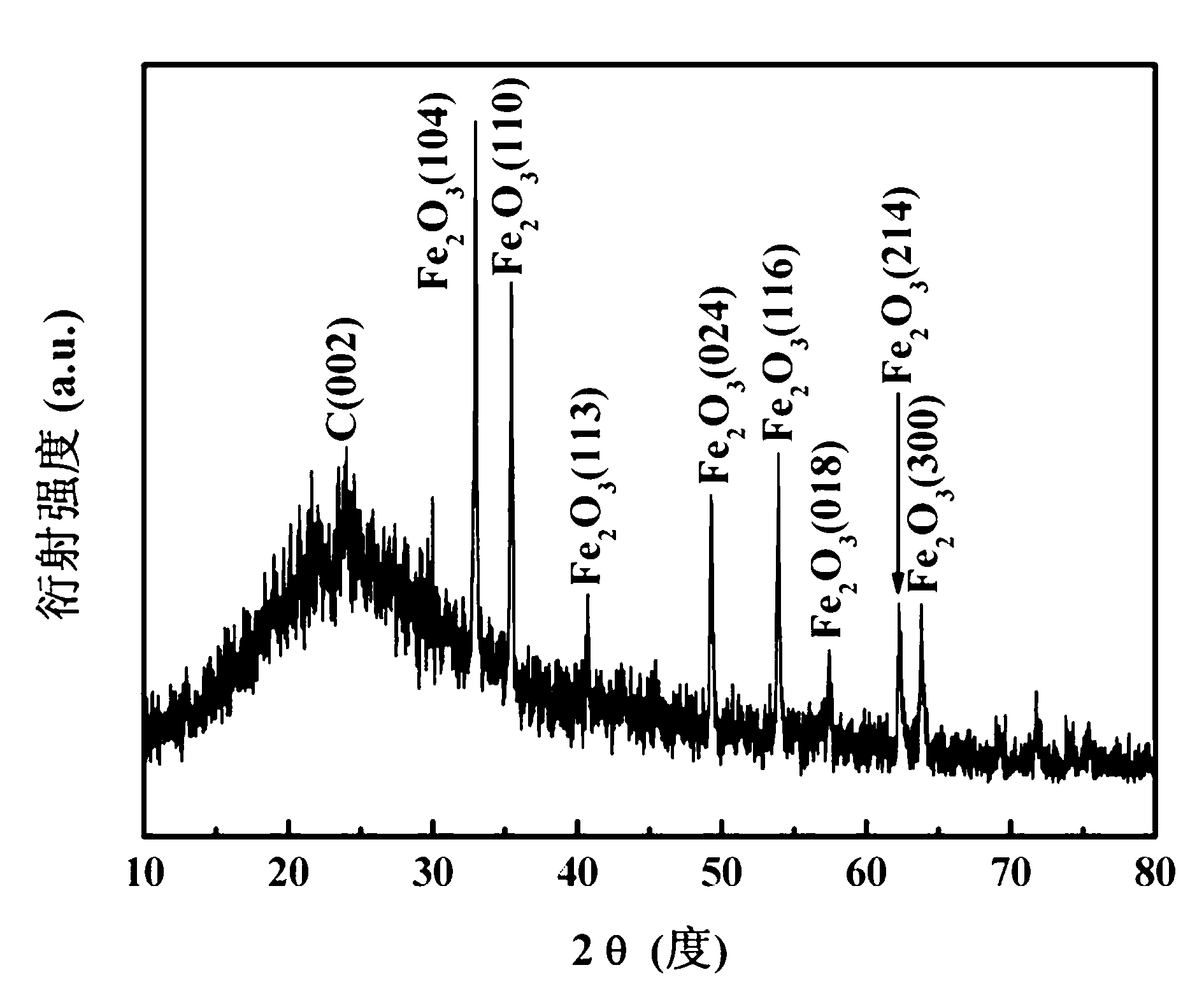

Preparation method of magnetic nitrogen-doped carbon materials

ActiveCN103295756ANo pollution in the processGuaranteed MagneticInductances/transformers/magnets manufactureHydration reactionPtru catalyst

The invention provides a preparation method of magnetic nitrogen-doped carbon materials. The method includes: using concentrated hydrochloric acid to adjust pH of mixed solvent of anhydrous ethanol and deionized water to 1-3, sequentially and fully dissolving or dispersing oxidation carbonization agent (ferric chloride hexahydrate), carbon source (saccharides), nitrogen source (glycine or melamine), mixing well, evaporating solvent, carbonizing at 60-80 DEG C for 40-50 hours, grinding carbonized products, and carbonizing the ground carbonized products at 180-200 DEG C for 4-6 hours to obtain the magnetic nitrogen-doped carbon materials which are promising in application prospect in fields such as fuel cell catalysts and super capacitors. The preparation method is mild in reaction condition, low in cost, simple to operate, and easy to control nitrogen contents in the nitrogen-doped carbon materials.

Owner:合肥碳艺科技有限公司

Preparation method of silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent

InactiveCN102994660AImprove flame retardant performanceImprove performanceLeather impregnationEthylenediaminePolymer science

The invention relates to a preparation method of a silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent. Leather flame-retardant technology and flame-resistant materials are rarely studied and developed in China, and studies of obtaining a functionality nanometer fat liquoring complex agent by using silane coupling agent modification montmorillonite and introducing the silane coupling agent modification montmorillonite to preparation of a fatting agent are rare. The preparation method includes fetching methanol and water, adding asilane coupling agents and Na-montmorillonite to the methanol and the water so as to obtain the silane coupling agent modification montmorillonite, enabling the silane coupling agent modification montmorillonite to thermostatically react with colza oil, and adding quadrol Al2O3, dropping a solution of acrylic acid and sodium hydrogen sulfite to obtain the silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent. The silane coupling agent modification montmorillonite functionality nanometer fat liquoring complex agent is excellent in flame resistant property, improves mechanical properties, filling ability, binding ability and the like of a product, and has the advantages of being reproducible in sources, non-toxic and pollution-free, good in biological degradability and the like.

Owner:SHAANXI UNIV OF SCI & TECH

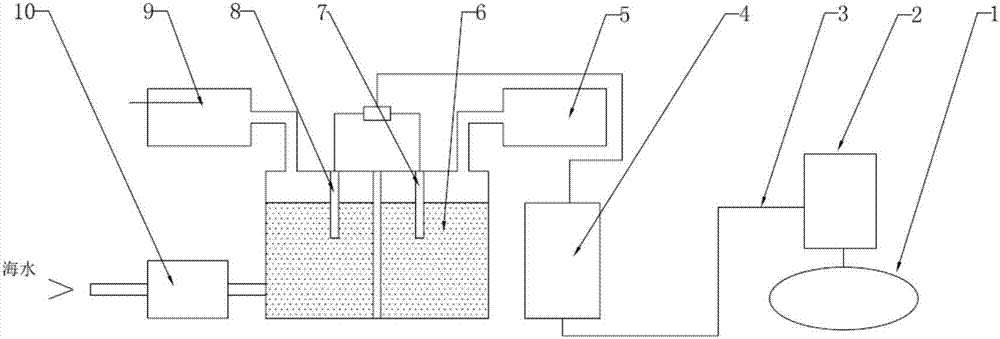

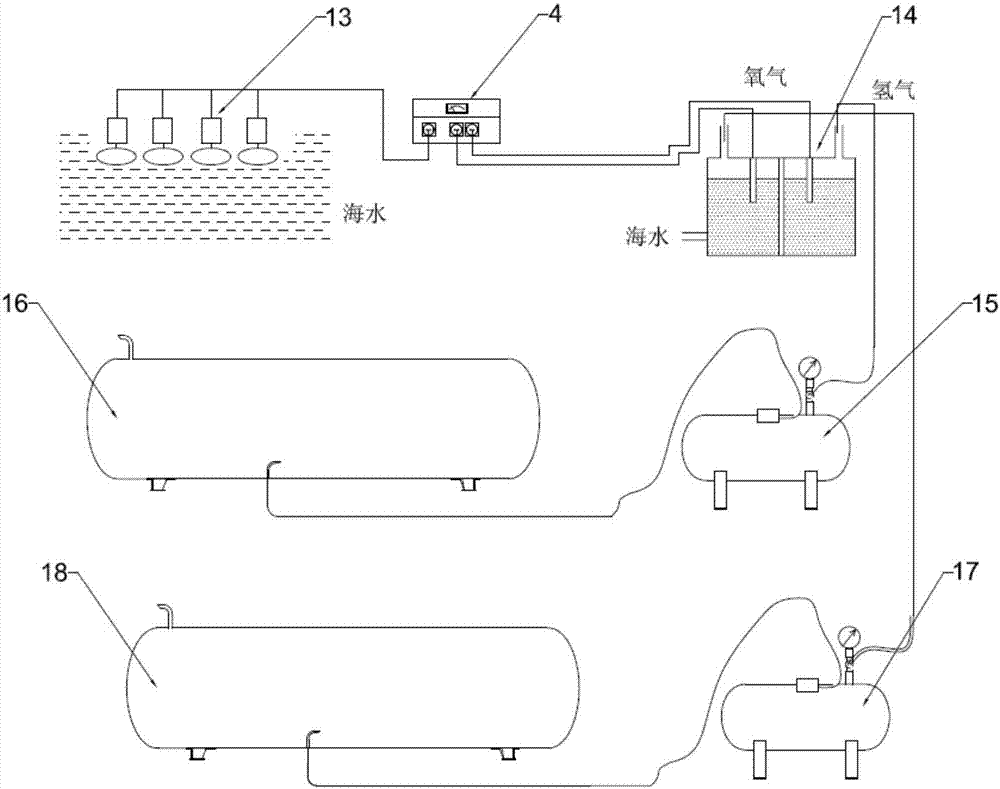

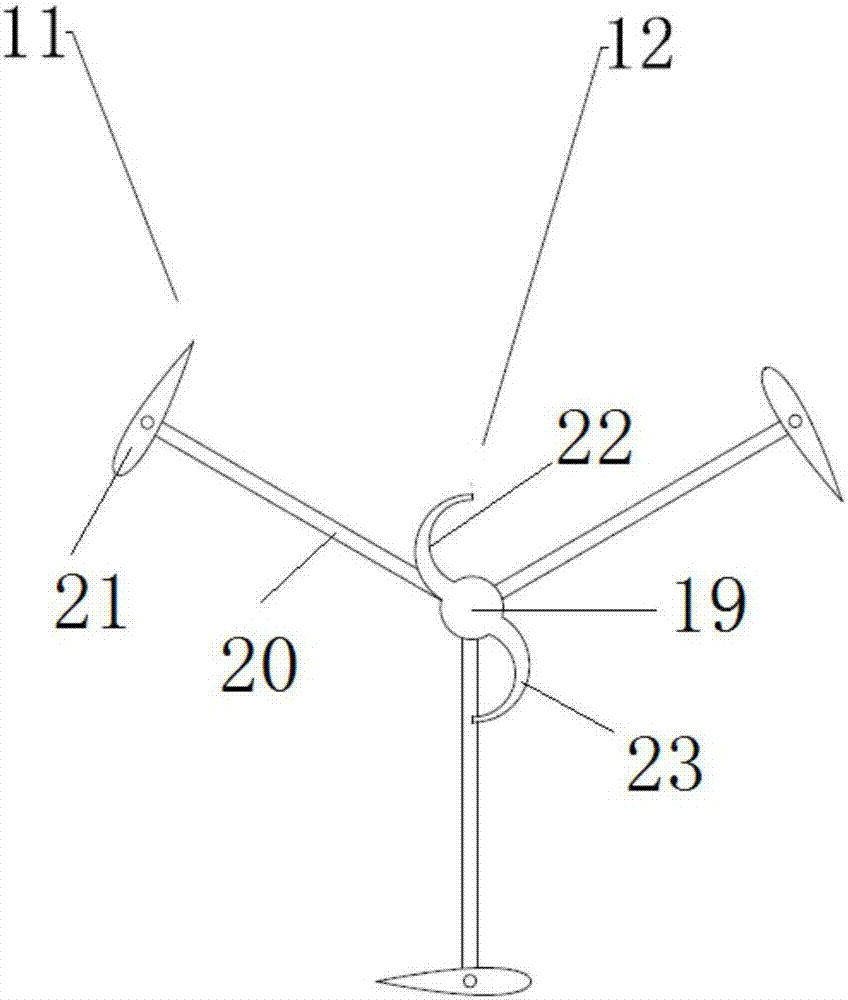

Device for preparing hydrogen and oxygen by using tidal current energy and seawater

PendingCN107881526ARenewable resourcesAbundant resourcesCellsGeneral water supply conservationEnergy absorptionOxygen

The invention discloses a device for preparing hydrogen and oxygen by using tidal current energy and seawater. According to the device for preparing the hydrogen and the oxygen by using the tidal current energy and the seawater, the problems that pollutants are generated, and a large amount of energy and fresh water resources are consumed are solved, the ocean tidal current energy is used as an energy source, the seawater is electrolyzed in an electrolytic cell so that the hydrogen can be prepared through the seawater, and the device has the advantages of being clean, efficient, free of pollution, and capable of storing and conveying the hydrogen and the oxygen . According to the technical scheme, the device comprises a tidal current energy power generation device and an electrolysis device, the tidal current energy power generation device comprises a tidal current energy power generation energy absorption unit, the tidal current energy power generation energy absorption unit is connected with a generator, and the generator provides a power supply for the electrolysis device; the electrolysis device is connected with a seawater desalination device; and the tidal current energy power generation energy absorption unit comprises a lift type energy absorption blade, a vertical center shaft of the lift type energy absorption blade is connected with a resistance type energy absorption blade, and the resistance type energy absorption blade and the lift type energy absorption blade can rotate around the vertical central shaft.

Owner:王启先

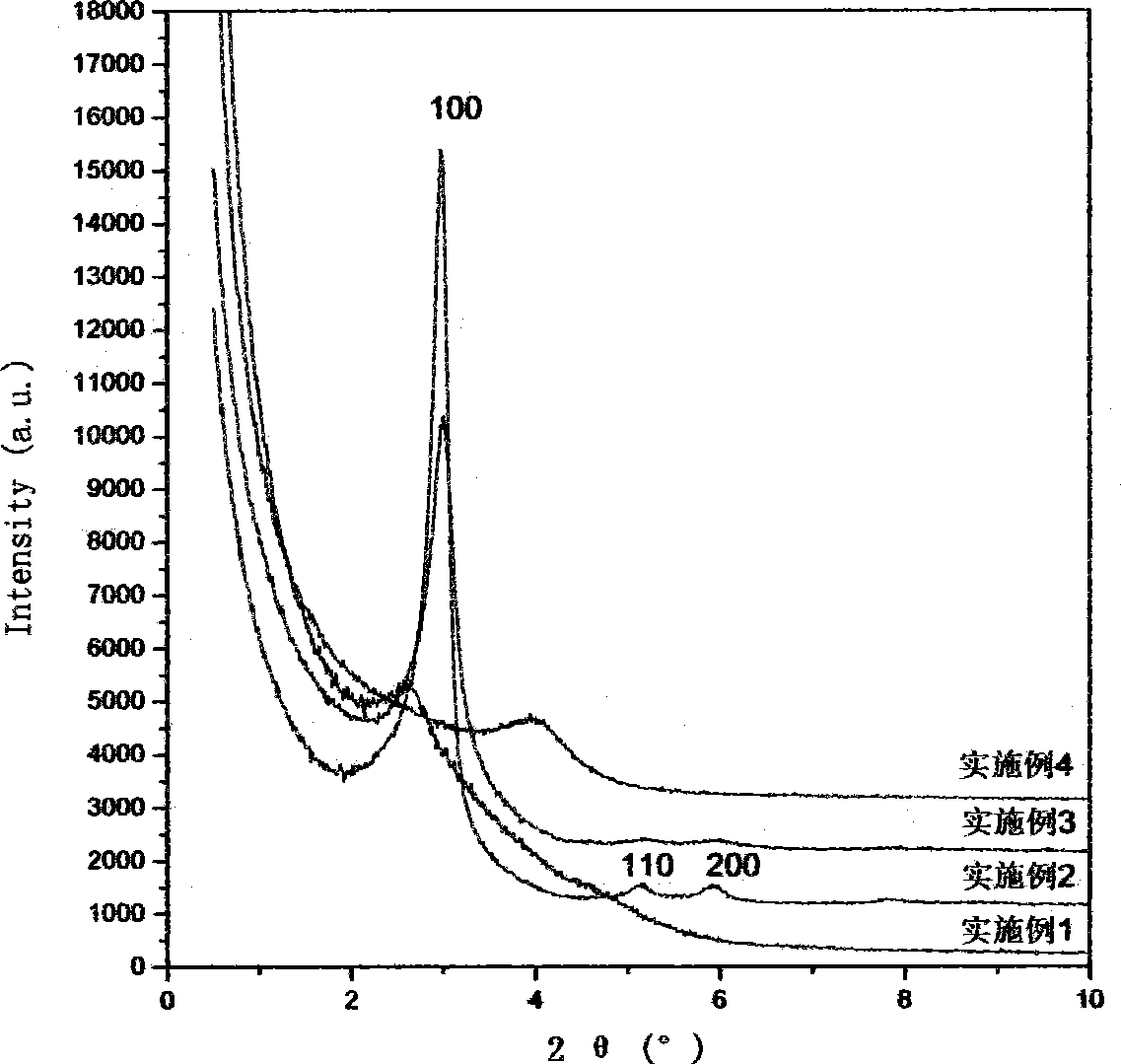

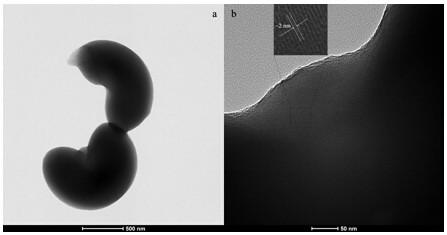

Synthesis method of ordered ultramicroporous silicon dioxide

InactiveCN104176738ANatural renewable resourcesRenewable resourcesSilicaMolecular sieveHydrothermal reaction

The invention discloses a synthesis method of ordered ultramicroporous silicon dioxide, which comprises the following steps: proportionally dissolving a silicon source and a template in deionized water, slowly and dropwisely adding an acid solution to a pH value while stirring, transferring into a hydrothermal reaction kettle, standing at a certain temperature to crystallize, washing, filtering, drying to obtain ultramicroporous silicon dioxide precursor powder, and calcining to obtain the ordered ultramicroporous silicon dioxide molecular sieve. The ultramicroporous silicon dioxide has the characteristics of large specific area, high pore volume and highly ordered pore size; and the synthesis method has the advantage of simple technique and low production cost, and is suitable for large-scale industrial production.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Matrix specially used for phoebe bournei seedling raising and production technology thereof

ActiveCN103355149ASingle sourceEasy to obtainCultivating equipmentsOrganic fertilisersGrowth plantCylindrus

The invention discloses a matrix specially used for phoebe bournei seedling raising. The matrix comprises the following components in percentage by weight: 65-75 of coir fibers, 10-15 of multi-time aggregation agent, 15-20 of plant growth promoting rhinoacteria (PGPR) composite bacterial fertilizer and 0.1-0.2 of humic acid and is block type. A production technology comprises the following steps of roughening the coir fibers, then adding a small amount of zymophyte for full fermentation treatment, uniformly mixing and stirring 80-85 of fermented coir fibers, 10-15 of multi-time aggregation agent, 15-20 of plant growth promoting rhinoacteria (PGPR) composite bacterial fertilizer and 0.1-0.2 of humic acid to obtain a mixture, and pressing the mixture into a fluffy cylindrical block through a shaping machine, and encircling the circumferential surface of the cylindrical block with non-woven cloth to form a culture matrix with a longitudinal through opening. The proportions of the constituent components of the special matrix considers the growth of the phoebe bournei raising seedlings, and the seedling raising matrix has a three-phase structure with high fertilizer preservation property, water retaining performance and ventilating property.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

High-fiber volume content polylactic acid homopolymer composite material and preparation method thereof

ActiveCN106671545AImprove mechanical propertiesRenewable resourcesSynthetic resin layered productsPolymer scienceEthylene Homopolymers

The invention discloses a high-fiber volume content polylactic acid (PLA) homopolymer composite material and a preparation method thereof. A reinforced phase is a PLA fiber of which the content of a dextrolactic acid structure unit (D-LA) is 0-10mol% and a matrix is PLA of which the content of the dextrolactic acid structure unit (D-LA) is 10-50mol%, or the reinforced phase is an isotactic composite polylactic acid (sc-PLA) fiber, wherein sc-PLA is a mixture of poly L-lactic acid (PLLA) and poly D-lactic acid (PDLA), the weight ratio of the PLLA to the PDLA is 1:1 and the matrix is PLA of which the D-LA content is 0-100mol%; and the volume content of the strengthened phase is 5-90mol%. The preparation method of the corresponding composite material comprises the steps of (1) processing the PLA fiber of a skin-core structure into fiber assemblies; (2) overlaying 1-1,000 layers of PLA fiber assemblies of the skin-core structure; and (3) forming a PLA homopolymer composite material through hot pressing of the PLA fiber assemblies of the skin-core structure on a hot press under the conditions that the pressure is 1-20MPa and the temperature is 100-210 DEG C. The obtained PLA homopolymer composite material can be applied to the fields of packaging, automobiles and the like.

Owner:JIANGNAN UNIV

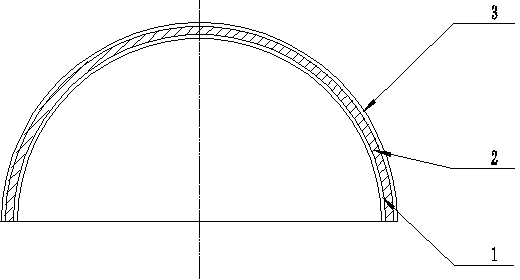

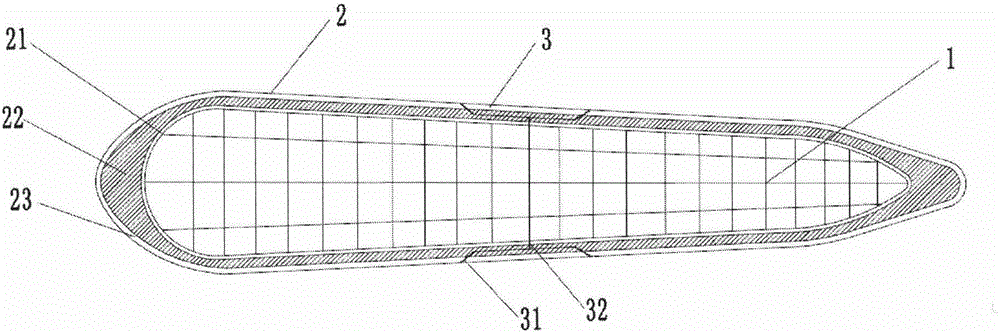

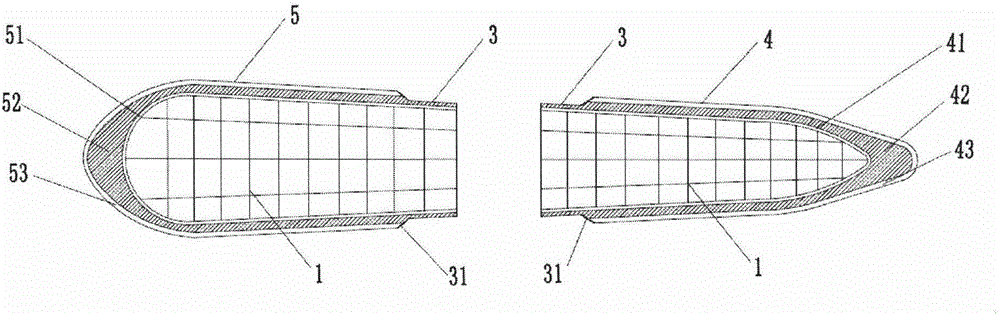

Submarine pressure shell and preparation method thereof

The invention discloses a submarine pressure shell which comprises a steel skeleton and a shell body, wherein the steel skeleton is fixed on the inner surface of the shell body; the shell body is formed by compounding a lining layer, a reinforcing layer and an outer protection layer sequentially from inside to outside; the reinforcing layer is formed by winding a bamboo skin sheet with adhered amino resin for multiple layers; and the lining layer and the outer protection layer are both formed by compounding bamboo fiber nonwoven fabric and epoxy vinyl ester resin. The invention also discloses a preparation method of the submarine pressure shell. The preparation method comprises the following steps: pretreatment of the bamboo skin sheet, resin preparation, thickness design, preparation of midship-stern shell body, preparation of a midship-bow shell body, connection of the steel skeleton and connection of the midship-stern shell body and the midship-bow shell body, wherein the steps are all carried out in a condition that the ambient humidity is lower than 40% RH. The submarine pressure shell prepared in the invention is green and environmentally friendly, light in weight and low in cost, and increases the travel speed and endurance mileage while the deformation resistance is strong and the damping property is good.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

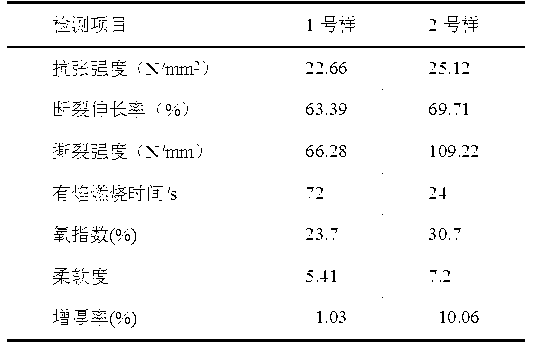

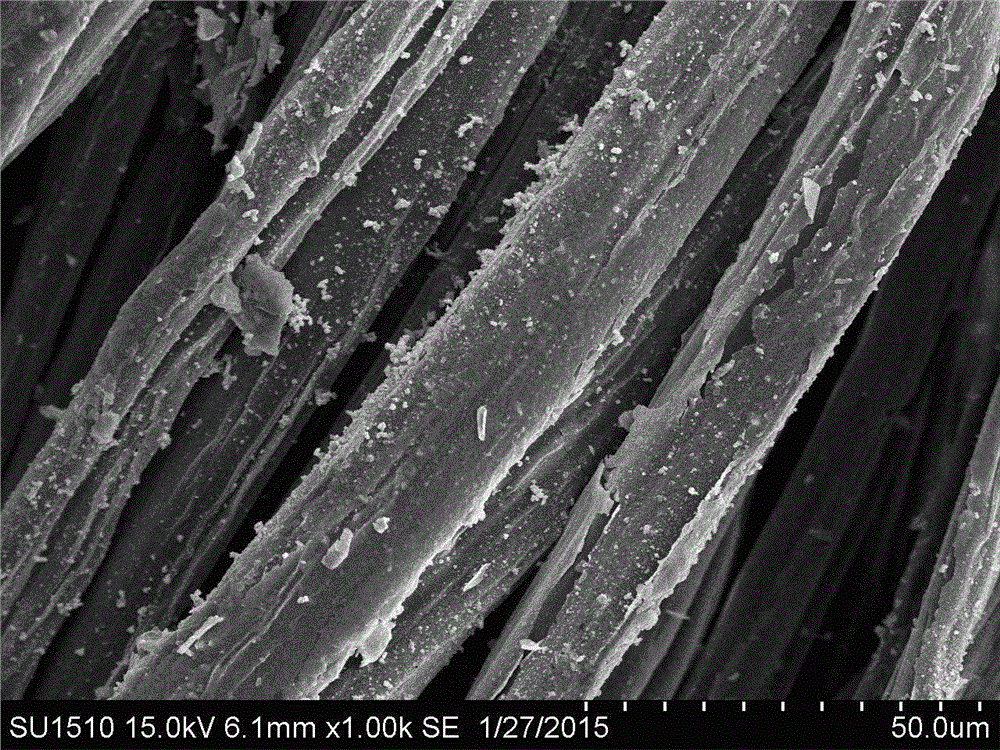

Preparation method of soybean-fiber composite fuse

The invention belongs to the field of electronic materials and relates to a preparation method of a soybean-fiber composite fuse. The preparation method has the characteristic of metallizing the surface of soybean fiber and comprises the following specific processes: cleaning the soybean fiber, modifying the surface, activating the surface and carrying out chemical copper plating and the like. The soybean-fiber composite fuse has the following advantages: (1) the use of toxic metals such as lead, tin and chromium is avoided; (2) the soybean fiber is protein fiber, belongs to renewable resources and is green and environment-friendly; (3) the content of metal copper is less, and the cost is low, so that the soybean-fiber composite fuse is a resource-saving type material; and (4) the application space of high-melting-point metals in the temperature fuse is expanded. The soybean-fiber composite fuse can be used for high and new-technology products such as flexible electronic devices and wearable electronic products, and is wide in market prospect.

Owner:FUDAN UNIV

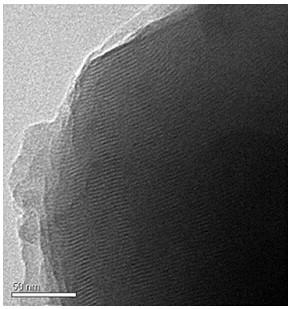

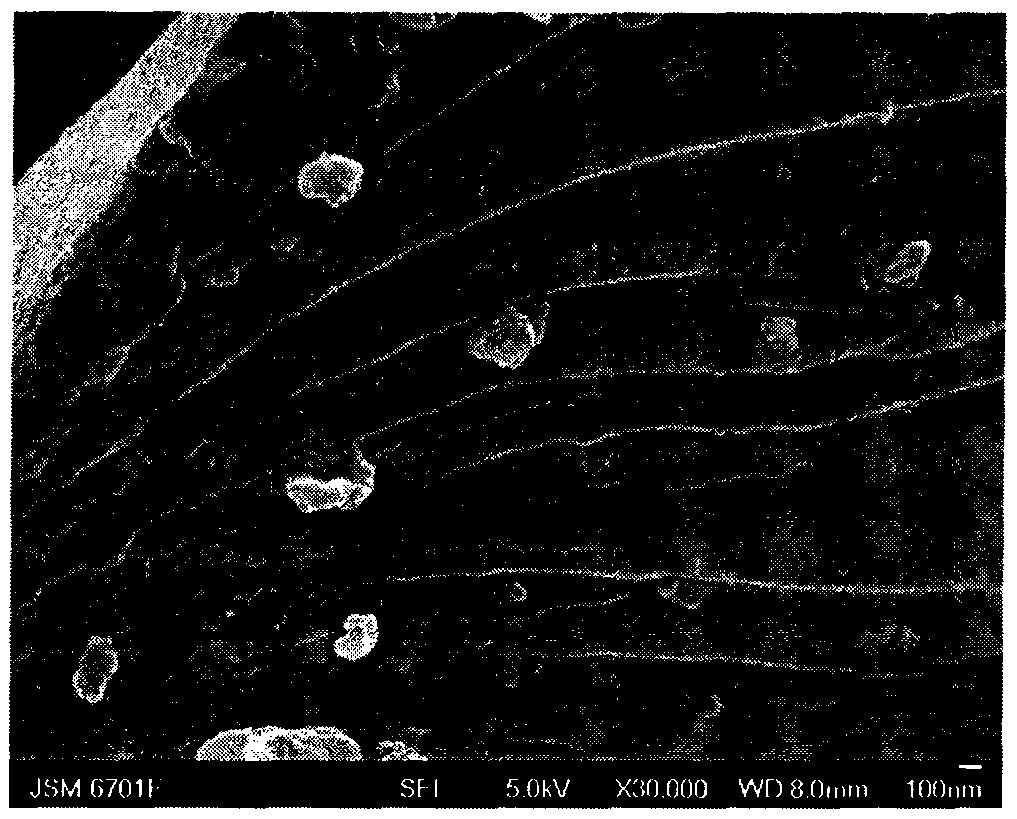

Carbon-nanometer-tube-carried-Ru-based catalyst and preparing method and application thereof

InactiveCN105771975ALow costRenewable resourcesOrganic compound preparationHydroxy compound preparationActive componentCarbon nanotube

The invention relates to a carbon-nanometer-tube catalyst, in particular to a carbon-nanometer-tube-carried-Ru-based catalyst and a preparing method and application thereof.The catalyst comprises an active component, an assistant and a carrier, wherein the carrier is carbon nanometer tubes, the active component is Ru, the assistant is one or several of metal and metallic oxide, and the molar ratio of the assistant metal element to the active component is (0-0.5):1; the weight percentage of the active component in the catalyst is 1%-10%; the metal is W or Mo or Re or Ir or La.The carbon-nanometer-tube-carried-Ru-based catalyst is good in selectivity and high in activity.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI +1

Method for preparing dimer acid type copolymerized polyamide hot melt adhesive

ActiveCN103555263AHigh temperature resistantSmall water absorptionAdhesivesEthylenediaminePropanoic acid

The invention discloses a method for preparing a dimer acid type copolymerized polyamide hot melt adhesive. The dimer acid type copolymerized polyamide hot melt adhesive is generated by using dimer acid, binary acid and diamine as raw materials and adding a molecular regulator through condensation polymerization, and the method comprises the following steps: putting 1 part by weight of dimer acid, 0.01-0.03 part by weight of binary acid and 0.005-0.012 part by weight of molecular weight regulator into a reactor; dropwise adding 0.05-0.1 part by weight of ethylenediamine and 0.05-0.09 part by weight of diamine into the reactor when the temperature rises to 90-150 DEG C; increasing the temperature to 230-250 DEG C in two hours, keeping the temperature to be 160-260 DEG C, and reacting for 1-5 hours; vacuumizing and decompressing to react for 1-2.5 hours, lowering the pressure in the reactor to normal pressure, and discharging, wherein the molecular weight regulator is one or more of glacial acetic acid, propionic acid, butyric acid and isobutyric acid. The dimer acid type copolymerized polyamide hot melt adhesive prepared by the method can be widely applied to shoe-making or electronic industry, and has the characteristics of high temperature resistance, small water absorption and environment friendliness; the preparation method is simple, the production is stable, the cost is low, and the raw material resource can be regenerated.

Owner:ANQING HONGTAI NEW MATERIAL

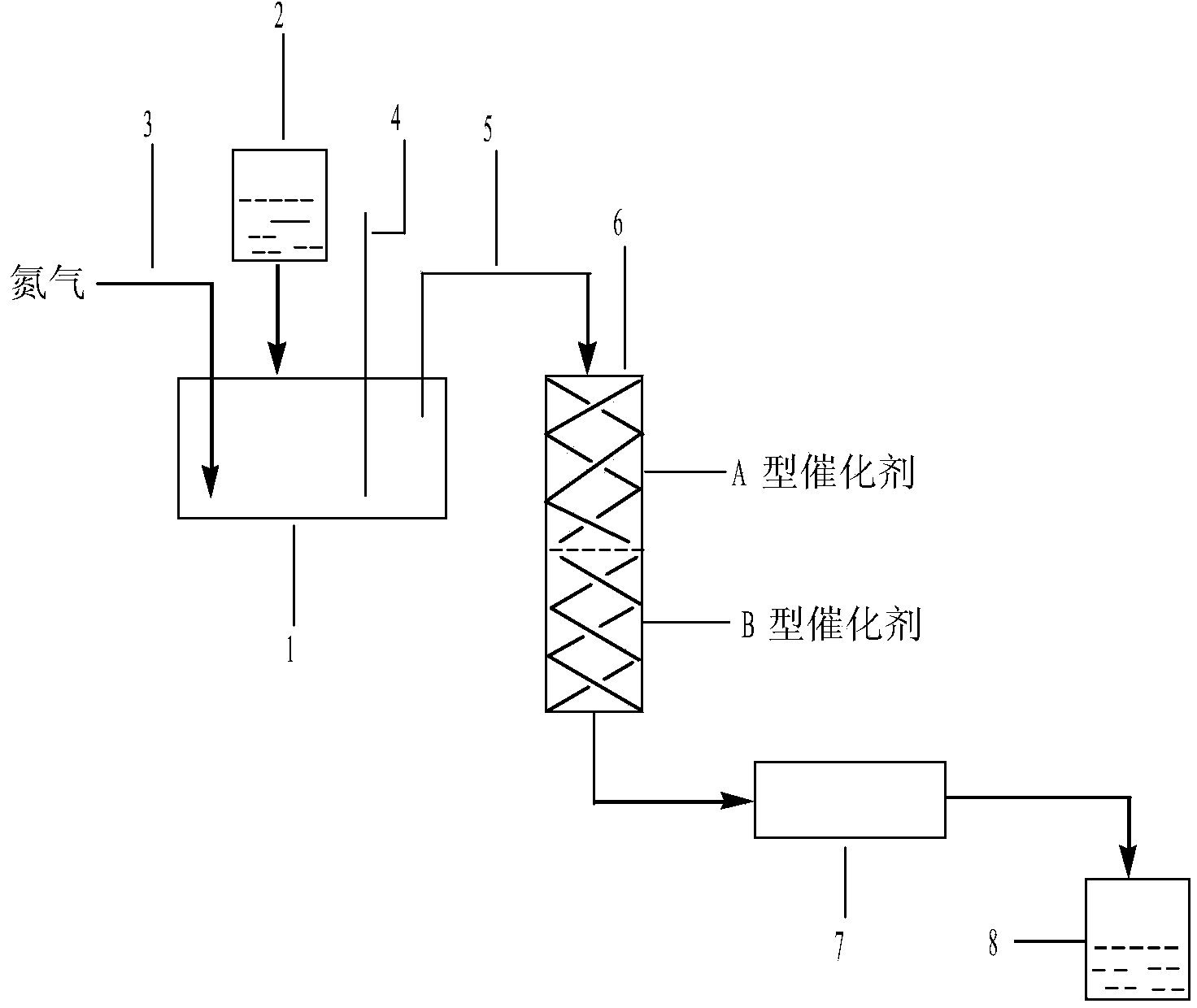

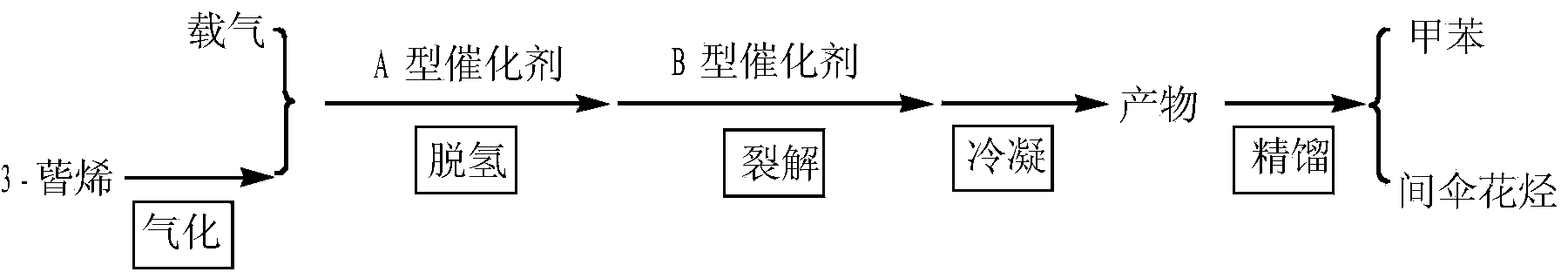

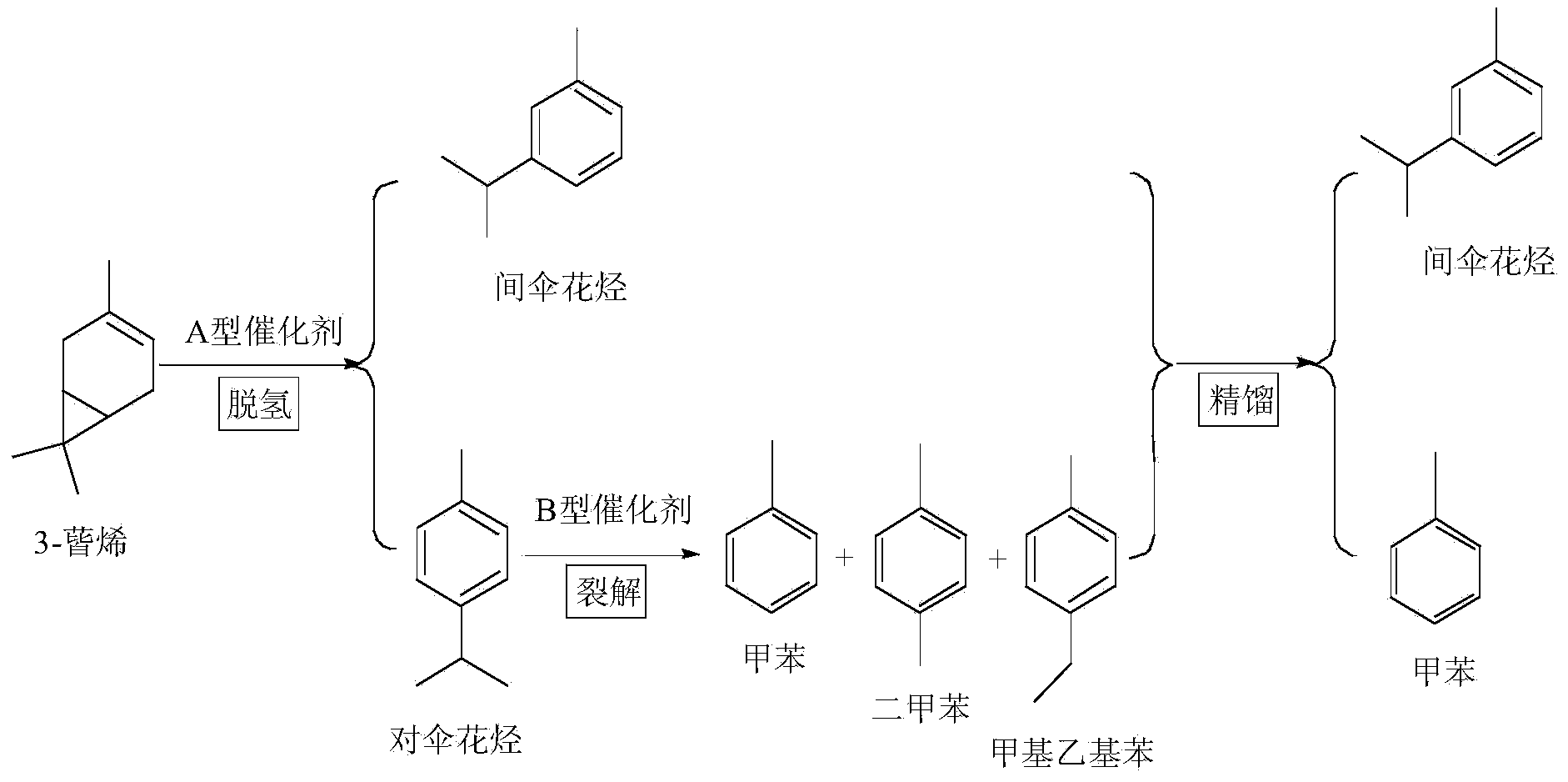

Method for preparing methylbenzene and m-cymene from 3-carene and device thereof

ActiveCN103524289AA new way to useEfficient way to useHydrocarbon by isomerisationHydrocarbonsCracking reactionCymenes

The invention discloses a method for preparing methylbenzene and m-cymene from 3-carene and a device of the method. 3-carene is subjected to isomerism to be a mixture of p-cymene and m-cymene under catalysis of an A-type catalyst, wherein the A-type catalyst is one or a mixture compounded from more of supported catalysts of platinum, palladium and nickel; the mixture of p-cymene and m-cymene conducts splitting reaction on p-cymene in the mixture on presence of a B-type catalyst so as to obtain a mixture with methylbenzene and m-cymene; the mixture is rectified, separated and purified to obtain methylbenzene and m-cymene; the B-type catalyst is one or a mixture compounded from more of ZSM-5 sodium type molecular sieve and ZSM-5 hydrogen type molecular sieve of various silica-alumina ratios. The method is green, simple and efficient, raw materials are natural and reproducible, and a product has property equivalent to natural products.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

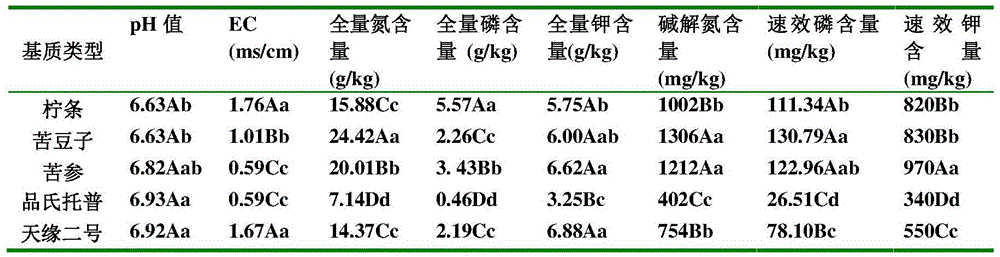

Method for producing vegetable culture medium and seedling culture medium by means of sophora alopecuroide

InactiveCN105613240ARenewable resourcesAbundant resourcesGrowth substratesCulture mediaBiotechnologyBran

The invention relates to a method for producing a vegetable culture medium and a seedling culture medium by means of sophora alopecuroide.The method is characterized by comprising the steps of smashing sophora alopecuroide straw, wetting the smashed sophora alopecuroide straw with water, adding organic fertilizer, urea, bran and enzymic preparations, conducting even mixing, conducting heap fermentation at the ambient temperature of 10-40 DEG C till temperature in a heap reduces to the ambient temperature, and preparing the eco-organic type soilless culture medium by mixing the obtained sophora alopecuroide fermented feed, organic fertilizer, perlite and vermiculite according to the volume ratio of 6: (1-2) : (2-3) : (2-3), or preparing the eco-organic type seedling culture medium by mixing the fermented feed, perlite and vermiculite according to the volume ratio of 7 : (1-2) : (1-2).By the adoption of the method, the sophora alopecuroide resource is developed and utilized reasonably and enriches the medium selection type of greenhouse vegetable soilless culture and industrialized seedling production in the northwest district as the medium raw material of soilless vegetable culture.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI

Wooden card manufacturing technology and wooden card

ActiveCN103331789ALow costRenewable resourcesWood veneer joiningWood layered productsSurface modificationEngineering

The invention discloses a wooden card manufacturing technology. The wooden card manufacturing technology comprises the following steps: manufacturing sheets; cutting the sheets into a wooden card blank with a high-precision digital cutting machine according to the dimensional requirement for manufacturing a wooden card; performing function setting on the wooden card blank; performing surface modification treatment on the wooden card blank; performing quality inspection, and packaging if the product is qualified; and manufacturing the wooden card with the technology. Compared with other products, the wooden card has the advantages that the card is made of wood, and the card is low in cost, low-carbon and environment-friendly, resource-renewable and meets the safety requirement; and moreover, the wooden card has comfortable hand feeling and taste of wood, is high-end in texture, and can meet the requirements of high-quality people and environment-friendly people.

Owner:李中伟

Preparation method for foam carbon

The invention discloses a preparation method for foam carbon. The method comprises the following steps: manufacturing a dough, carrying out foaming and molding, carrying out pretreatment, and carryingout carbonization and sintering so as to prepare the foam carbon. According to the invention, when higher requirements are required, graphitization treatment can be carried out under a protective atmosphere to obtain graphitized foam carbon. The method provided by the invention has the following advantages: a carbon source is a renewable resource, such as flour and corn flour, and is cheap and easily available; and the method provided by the invention has simple and safe process and low cost, and facilitates realizing industrialization.

Owner:SOUTH CHINA UNIV OF TECH

High-strength slurry-free polylactic acid yarn and preparation method thereof

InactiveCN110938905AImprove cohesionSimple preparation processFilament/thread formingConjugated synthetic polymer artificial filamentsYarnPolymer science

The invention discloses high-strength slurry-free polylactic acid (PLA) yarn and a preparation method thereof. The high-strength slurry-free PLA yarn is formed by PLA staple fibers with the linear density of 1.3-7.7 dtex and the length of 25-150 mm; and the PLA staple fiber is provided with a skin-core structure, a skin layer is low-melting-point PLA, a core layer is high-melting-point PLA, and amass ratio of the skin layer to the core layer is 5: 90-50: 50. The preparation method of the high-strength slurry-free PLA yarn comprises the following steps of drying raw materials of the skin layerand the core layer, respectively adding the raw materials into a hopper corresponding to a composite spinning machine, and carrying out melt conveying, spinning, air blast cooling, winding and feeding, oil bath stretching, steam bath stretching, tension heat setting, oiling, laminating, curling, loosening, and cutting processes to obtain the PLA staple fiber of the skin-core structure; and carrying out spinning with the PLA staple fibers of the skin-core structure as the raw material in order to prepare the PLA yarn, enabling the PLA yarn to pass through a pair of heating rollers and carryingout heating and pressure treatment on the PLA to prepare the high-strength slurry-free yarn, wherein the heating temperature is higher than the melting point of the PLA of the skin layer and is lowerthan the melting point of the PLA of the core layer; through the adhesion effect of the skin layer, the hairiness is reduced, the cohesive force between the fibers is increased, and the high strengthand free slurry of the yarn are realized. The prepared high-strength slurry-free PLA yarn can be used in the fields of textiles for clothing, textiles for decoration and industrial textiles.

Owner:JIANGNAN UNIV

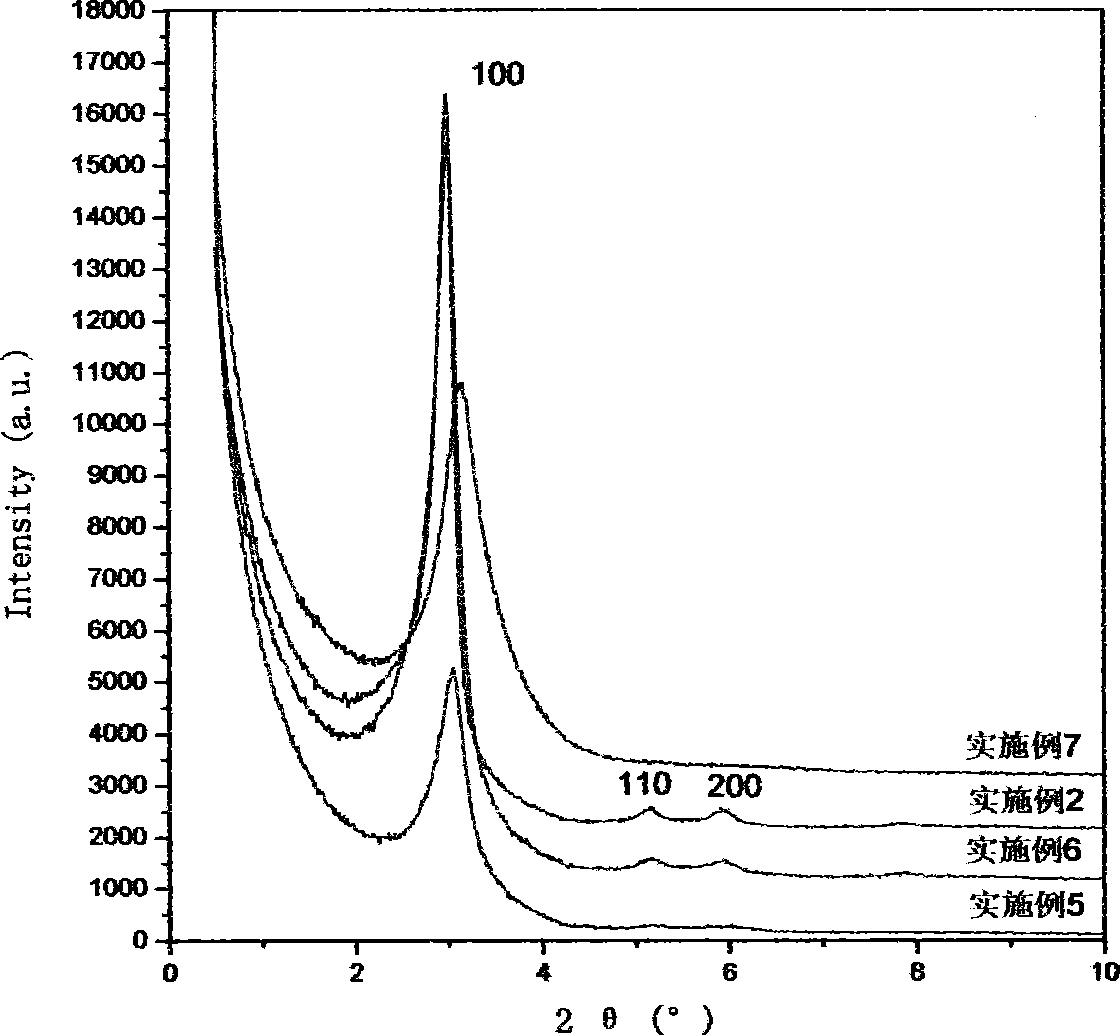

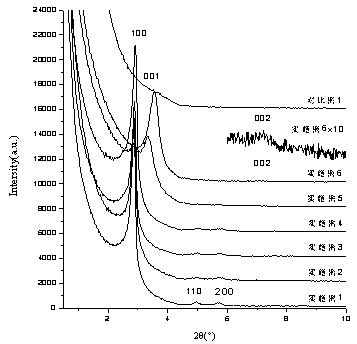

Layered ordered ultramicroporous material and synthesis method thereof

The invention belongs to the field of inorganic porous materials, and discloses a layered ordered ultramicroporous material and a synthetic method thereof. The method comprises the steps: dissolving acomposite template in deionized water at a certain temperature, adding an inorganic base to adjust the pH, dropping a silicon source under stirring, moving into a hydrothermal reaction kettle, allowing to stand for crystallization at a certain temperature for a period of time, and washing and drying to obtain a layered ordered ultramicroporous silica molecular sieve. The composite template is a mixture of cetyl trimethyl ammonium bromide and dehydroabietylamine. The synthesis method disclosed by the invention achieves the synthesis of layered ordered ultramicroporous silica. The raw materialsused in a synthesis process are natural and non-toxic, the resources are renewable, the cost is low, the synthesis method is simple, the conditions are mild and easy to control, and the prepared layered ordered ultramicroporous silica has a highly ordered pore structure with a pore size of about 2.0 nm, and can be widely used in the fields of adsorbents, catalysts, and drug controlled release.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Polyester based on full biomass monomer, preparation method and application

The invention discloses polyester based on a full biomass monomer, a preparation method and an application, and belongs to the field of polyester synthesis. Polyester takes 2,5-dimethoxy dimethyl terephthalate with a cyclic rigid group, and isosorbitol as raw materials, obtaining an ester exchange product through a catalytical ester exchange reaction, obtaining a polyester crude product through acatalytical polycondensation reaction, and performing solvent extraction, precipitant precipitation, filtration and drying to form target polyester. Synthesized polyester has the characteristics of high molecular weight, high heat performance, good mechanical properties and the like, and the characteristic of easy degradation in a natural soil environment as biobased polylactic acid. Polyester based on the full biomass monomer is mainly applied to preparing a bottle level polyester material.

Owner:GUANGDONG YUESHENGRI PLASTIC SCI & TECH CO LTD

Special matrix for camphor tree seedling and production process thereof

ActiveCN103348904AEasy to get materialsHigh degree of ionizationCultivating equipmentsSoilless cultivationHumic acidCoir fiber

The invention provides a special matrix for camphor tree seedling, which is of a block shape and comprises the following components in parts by weight: 80-85 parts of coir fibers, 15-20 parts of a multi-aggregation agent, and 0.1-0.2 part of humic acid. The production process comprises the following steps: roughening the coir fibers, and adding little zymophyte for sufficient fermenting treatment; uniformly mixing and stirring the fermented coir fibers, the multi-aggregation agent and the humic acid to prepare a mixture; compressing the mixture by a molding machine to obtain a fluffy cylindrical block; and enclosing the periphery of the cylindrical block by a non-woven fabric to form a culturing matrix with upper and lower openings. The proportion of the components of the special matrix sufficiently takes the growth of camphor tree seedling, and the seedling matrix has an excellent three-phase structure of fertilizer and water maintenance and ventilation.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

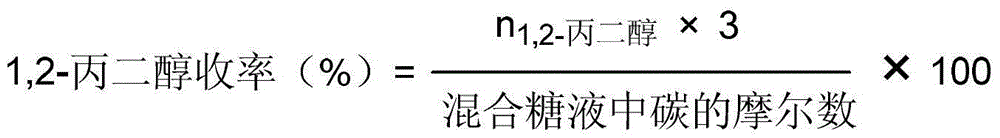

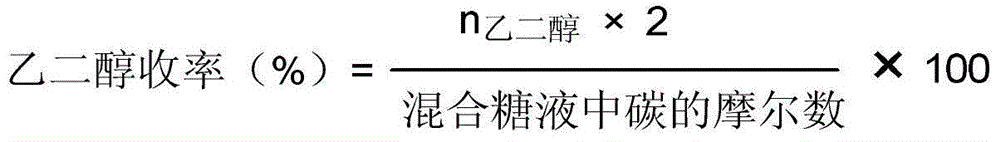

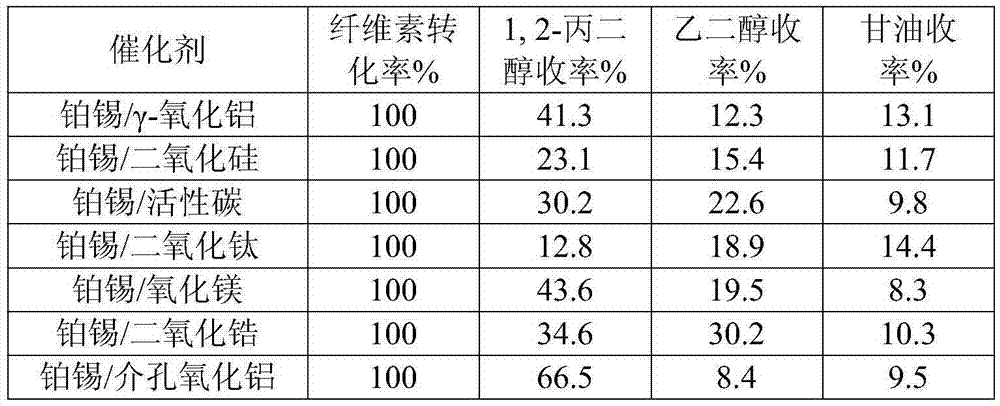

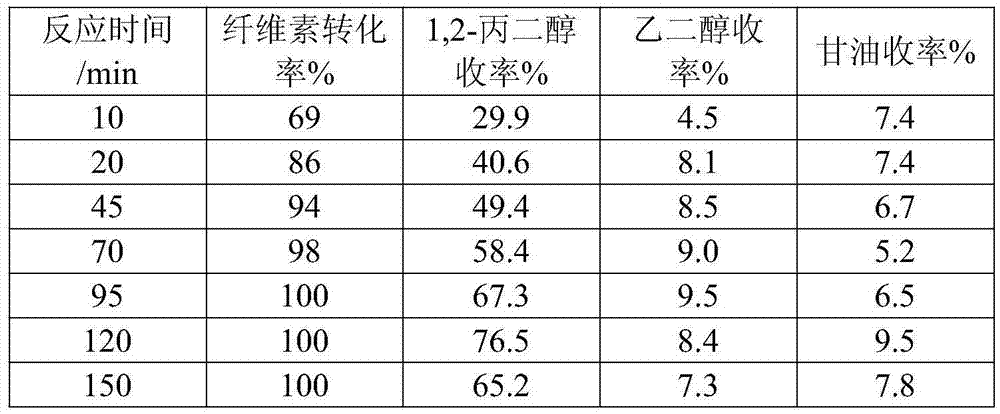

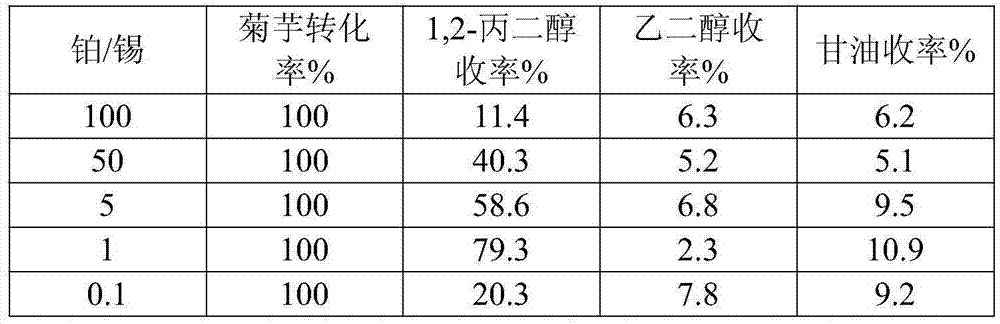

Method for preparing 1,2-propanediol by platinum tin-mesoporous alumina catalysis of carbohydrates

ActiveCN106866361AWide variety of sourcesLow costOrganic compound preparationHydroxy compound preparationHydrogen pressureSolvent

The invention provides a method for preparing 1,2-propanediol by platinum tin-mesoporous alumina catalysis of carbohydrates. According to the method, the carbohydrates are used as raw material, water is used as a solvent, mesoporous alumina supported platinum tin bimetal is used as a catalyst, and under hydrothermal conditions of the temperature of 120-300 DEG C and the hydrogen pressure of 1-15 MPa, through a one-step catalytic conversion process, the 1,2-propanediol is prepared from the carbohydrates with high efficiency, high selectivity and high yield. Compared with a conventional petroleum based 1,2-propanediol synthesis route, the reaction provided by the invention has the advantages of raw materials as renewable resources, high atom economy and environmental friendliness. In addition, compared with other technologies for preparing 1,2-propanediol with biomass as raw material, the process has the advantages of good stability of the catalyst, good circularity, easy recovery and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

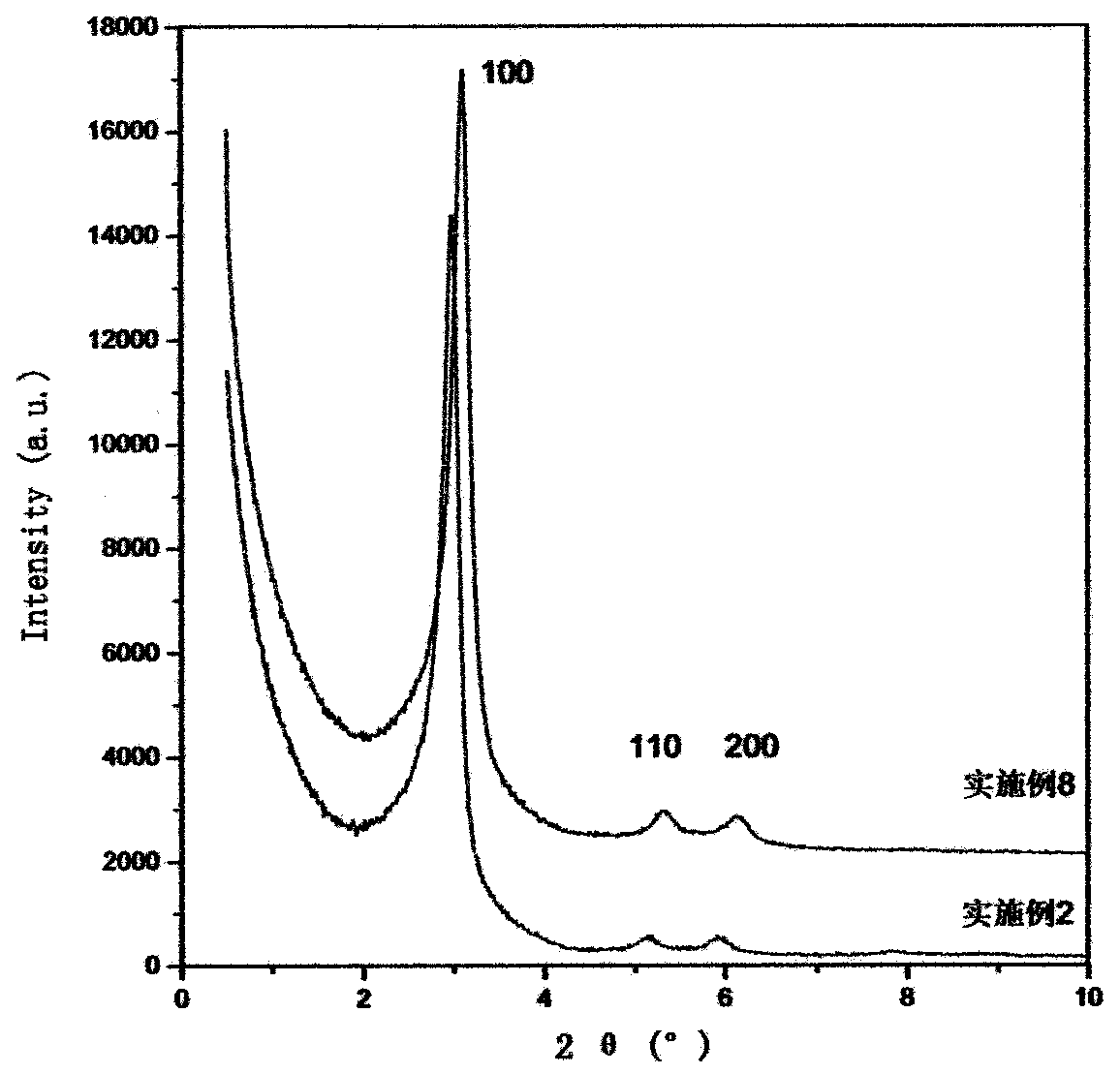

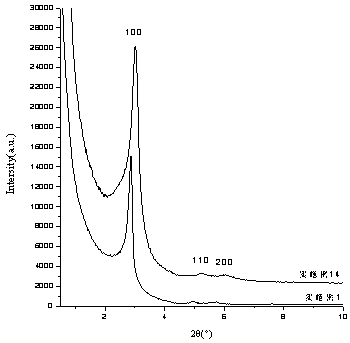

Synthesis method of ordered super-micropore material with broad bean shape

InactiveCN108975346ANatural renewable resourcesRenewable resourcesSilicaMolecular-sieve and base-exchange compoundsSynthesis methodsDissolution

The invention discloses a simple method for preparing an ordered super-micropore material with a broad bean shape. The method takes a template agent, an organic alkali source and an organic silicon source as raw materials, and ordered super-micropore material precursor powder with the broad bean shape is synthesized by utilizing a dissolution and standing crystallization method; then the ordered super-micropore material precursor powder is subjected to high-temperature calcination to obtain an ordered super-micropore silicon dioxide molecular sieve with the broad bean shape. The method disclosed by the invention has the advantages that dehydrogenated abietyl quaternary ammonium salt derived from a natural renewable raw material rosin is used as the template agent, sources are abundant andthe price is low; a prepared ordered super-micropore silicon dioxide material has the advantages of large specific surface area, high pore volume and narrow and ordered pore diameter distribution, andhas a wide application prospect in the aspects of shape selective catalysis, medicine solubilization and controlled release.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

PHBV mono-polymer composite material having high fiber volume content and preparation method thereof

ActiveCN106626535AImprove mechanical propertiesRenewable resourcesSynthetic resin layered productsLaminationPolymer compositesPolymer composite materials

The invention discloses a poly(3-hydroxybutyrate-co-3-hydroxyl pentanoate) (PHBV) mono-polymer composite material having high fiber volume content and a preparation method thereof. A reinforcing phase in the composite material is PHBV fiber with the 3-hydroxybutyrate (HV) content of 0-20 mol%, a substrate is the PHBV with the HV content of 10-100 mol%, and the volume content of the reinforcing phase fiber is 5%-90%. A preparation method of the composite material comprises the steps that 1, the PHBV fiber with a skin-core structure is processed into a fiber aggregate; 2, 1-1000 layers of PHBV fiber aggregates with the skin-core structures are superposed together; 3, the PHBV fiber aggregates with the skin-core structures are hot-pressed into the PHBV mono-polymer composite material on a hot-pressing machine under the pressure of 1-20 MPa and the temperature of 100-160 DEG C. The obtained PHBV mono-polymer composite material can be used in the fields of packaging, automobiles and the like.

Owner:JIANGNAN UNIV

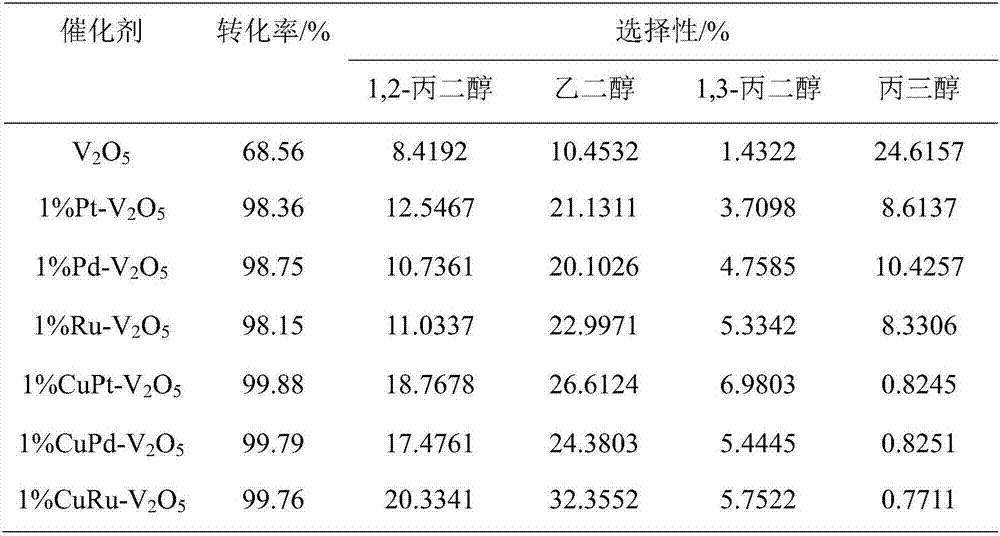

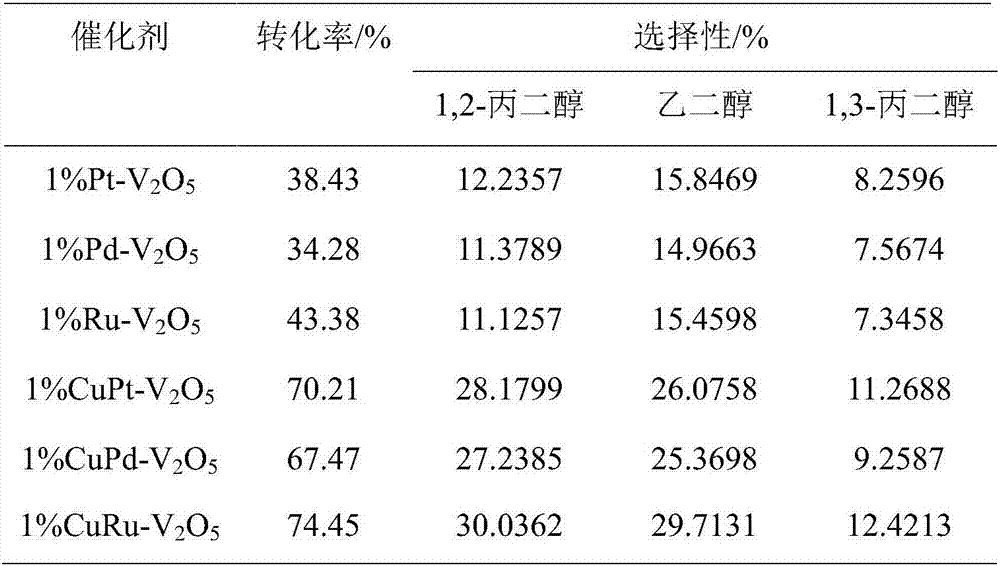

Metal loaded vanadic oxide catalyst and preparation method and application thereof

ActiveCN107008272APromote conversionMild conditions for hydrogenation reactionOrganic compound preparationHydroxy compound preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention discloses a metal loaded vanadic oxide catalyst and a preparation method and application thereof. The catalyst uses vanadic oxide as active ingredients; one or several kinds of metals of platinum, palladium, ruthenium and copper are added as loading metal ingredients. The preparation method comprises the following steps of sequentially dissolving vanadic salts, metal salts and complexing agents into water to prepare sol; performing stirring and heating to evaporate water to form gel; performing drying, roasting and grinding to obtain a finished product. The catalyst can efficiently degrade microcrystalline cellulose under the conditions of the temperature being 200 to 300 DEG C and the hydrogen pressure being 1 to 10 MPa; micromolecular alcohol substances are prepared. The preparation method of the catalyst is simple; the cost is low; the process achieves green and environment-friendly effects; the large-scale production is easy; the hydrogenation reaction conditions are mild; the cellulose conversion is high; the selectivity is good; a product is an important chemical engineering raw material.

Owner:SOUTHEAST UNIV

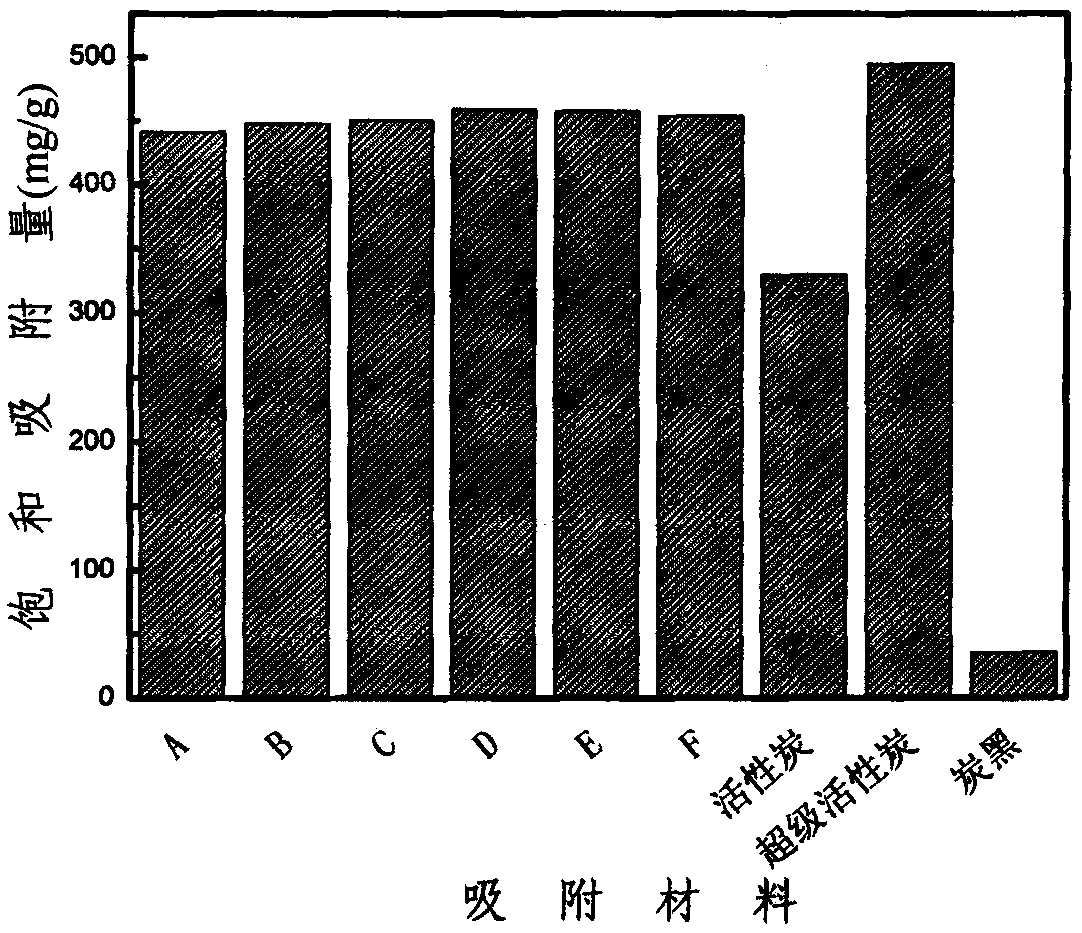

Method for preparing imporous carbon absorbent material

The invention discloses a method for preparing an imporous carbon absorbent material, which comprises the following steps of: firstly, taking sucrose, adding 98 percent sulfuric acid for carbonization in a mass ratio of 1:2-4 to obtain a carbon precursor; secondly, heating the carbon precursor to the temperature of between 150 and 180 DEG C, and pre-oxidizing the carbon precursor to a bread shape; thirdly, continuously oxidizing the product for 4 to 5 hours under the vacuum degree between 0.06 and 0.08MPa and at the temperature of between 220 and 230 DEG C, and absorbing the produced waste gas by using alkali liquor; and finally, performing vacuum cooling on the product to room temperature under the vacuum degree between 0.06 and 0.08MPa, and grinding to obtain the novel imporous carbon absorbent material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

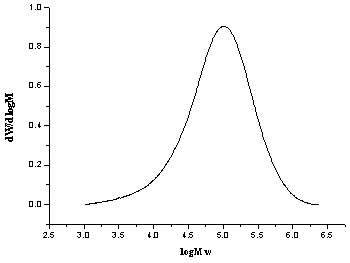

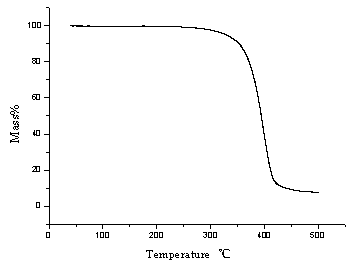

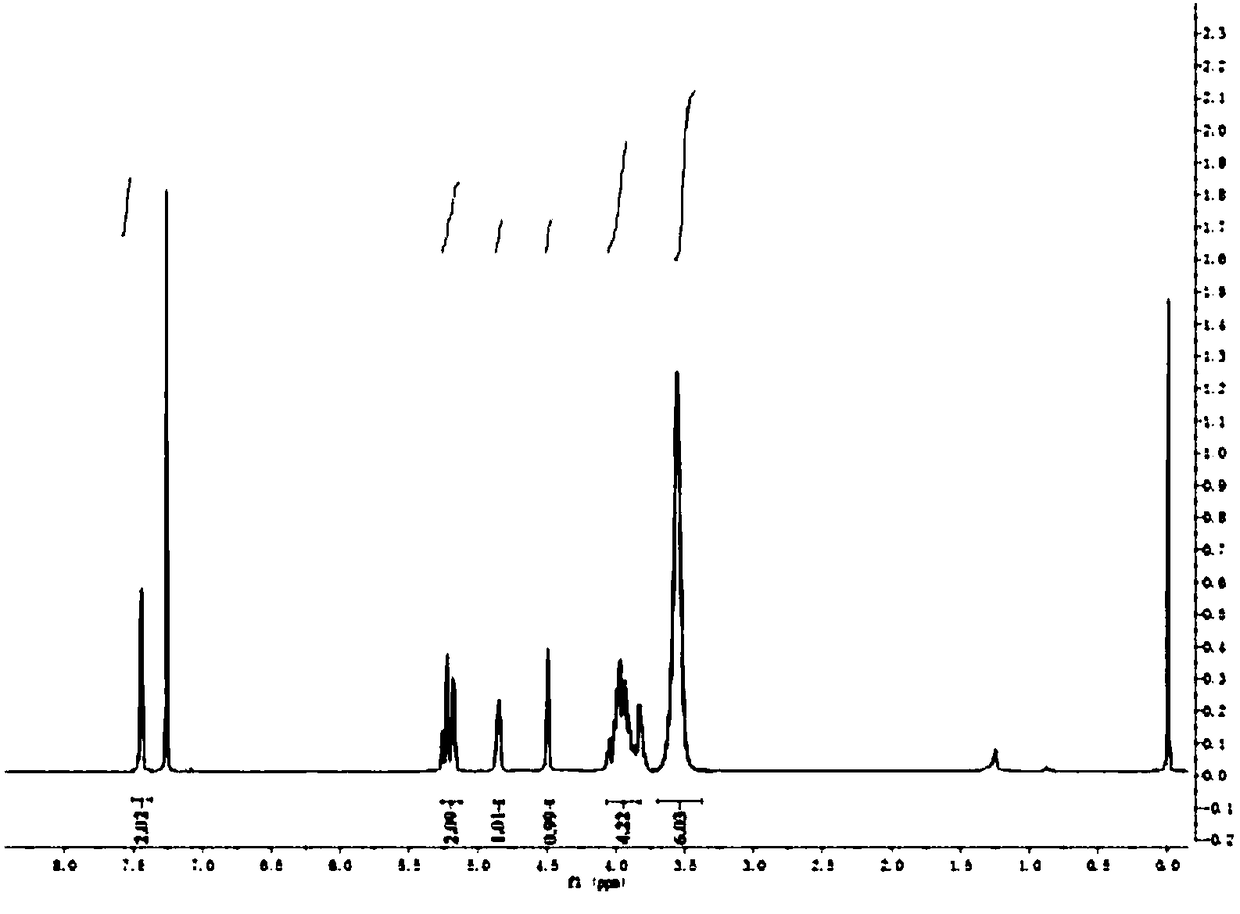

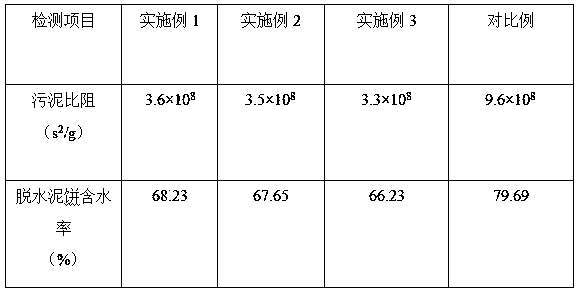

Preparation method of sludge conditioner

InactiveCN111018310AStrong anionicImprove hydrophilic abilitySludge treatmentSludgeSynthetic Polymeric Macromolecules

The invention relates to a preparation method of a sludge conditioner, which belongs to the technical field of sewage treatment. The sulfonated lignin grafted sodium acrylate copolymer is used as a raw material, a magnesium oxide modified zeolite molecular sieve is used as a carrier, and the sulfonated lignin grafted sodium acrylate copolymer is fixed on the carrier to prepare the sludge conditioner. The sulfonated lignin grafted sodium acrylate copolymer has the intermolecular force and reactivity of a polysaccharide compound; the mechanical and biological action stability and the linear chain expansion capability of synthetic macromolecules are also realized; sulfonated lignin contains a large number of -SO3H groups and has strong anionic property and strong hydrophilicity, a sodium acrylate copolymer is used as a graft comonomer, the spatial configuration of lignin is changed, the relative molecular mass is increased, functional groups with flocculation performance are introduced, and the flocculation performance of lignin is further improved.

Owner:周雯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com