Polyester based on full biomass monomer, preparation method and application

A biomass and polyester technology, applied in the field of polyester synthesis, can solve the problems of difficult processing, low melting point, poor mechanical properties, etc., and achieve the effects of low cost, improved thermal properties, excellent mechanical properties and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

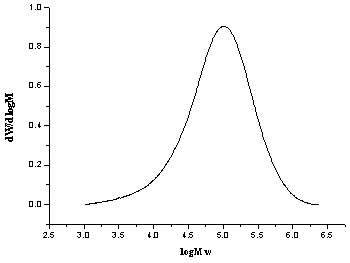

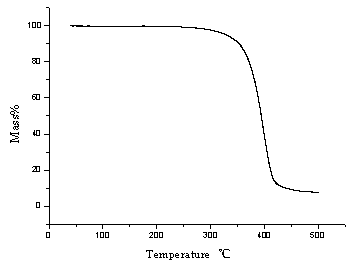

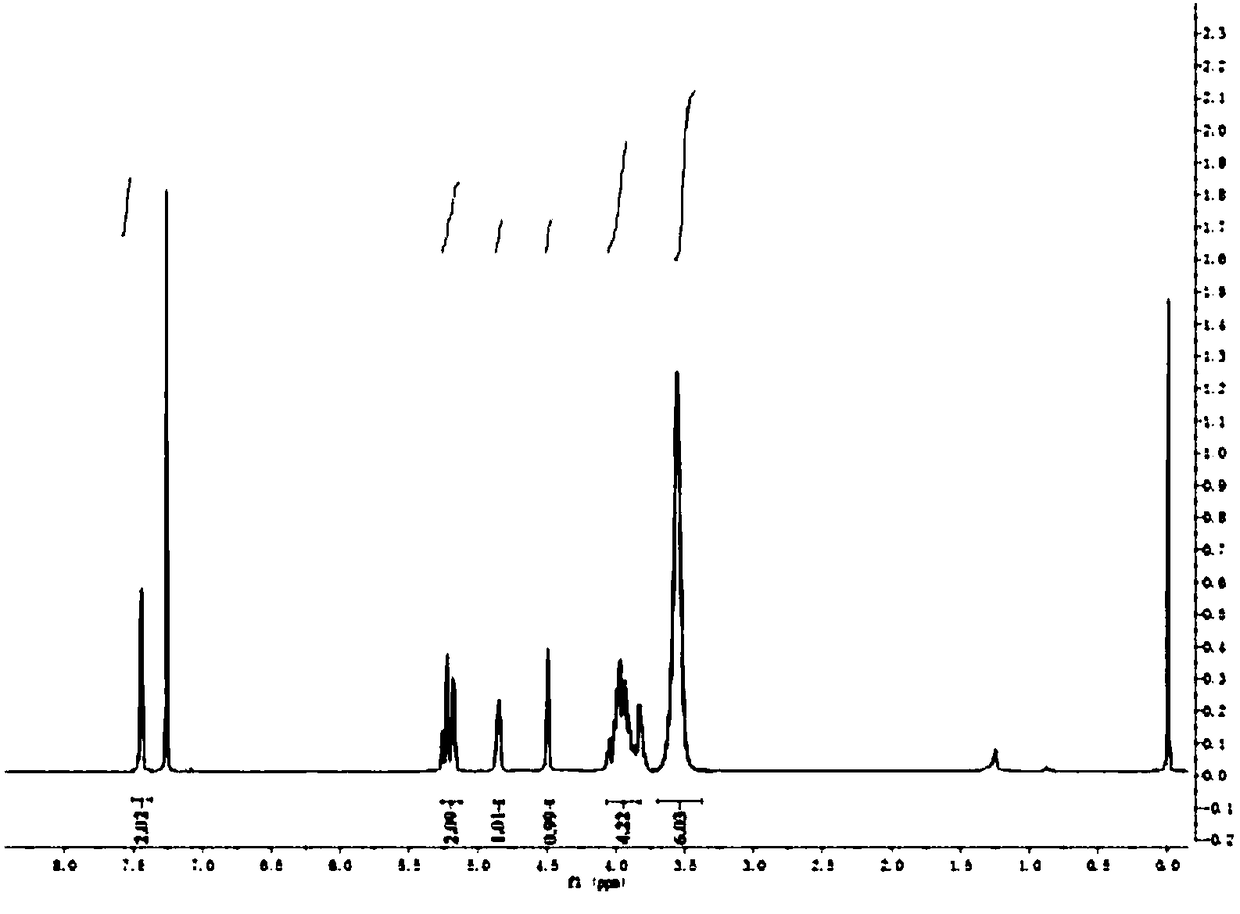

[0033] Example 1: 5.084 g (20 mmol) of 2,5-dimethoxy dimethyl terephthalate, 3.215 g (22 mmol) of isosorbide and 0.154 g (0.4 mmol) of isosorbide were sequentially added to a 50 mL single-necked flask ) diacetyl condensed o-aminophenol titanium complex, placed in a reactor at a reaction temperature of 120 ° C, and carried out a transesterification reaction for 4 hours under nitrogen protection to obtain a transesterified product; the obtained transesterified product and the catalyst were not separated, and placed in Under high vacuum at 200° C. and a pressure lower than 20 Pa, the reaction was carried out for 2 hours, then the heating was stopped, and the system was naturally cooled to room temperature by blowing nitrogen to obtain a crude polyester product. Add 40 mL of chloroform to the crude polyester, soak for 2 hours and then filter; take the clear liquid and add it dropwise to methanol to obtain a turbid system, centrifuge to obtain a precipitate, filter, then wash with 5...

Embodiment 2

[0039] Example 2: Add 5.084g (20 mmol) of 2,5-dimethoxy dimethyl terephthalate, 3.507g (24 mmol) of isosorbide and 0.171g (0.4 mmol) to a 50 mL single-necked flask ) zirconium complex of diacetyl condensate o-aminophenate, placed in a reactor with a reaction temperature of 120°C, under the protection of nitrogen, carried out a transesterification reaction for 4 hours to obtain a transesterified product; the obtained transesterified product and the catalyst were not separated, and placed in Under high vacuum at 200° C. and a pressure lower than 20 Pa, the reaction was carried out for 2 hours, then the heating was stopped, and the system was naturally cooled to room temperature by blowing nitrogen to obtain a crude polyester product. Add 40 mL of chloroform to the crude polyester, soak for 2 hours and then filter; take the clear liquid and add it dropwise to methanol to obtain a turbid system, centrifuge to obtain a precipitate, filter, then wash with 5 mL of methanol, filter and...

Embodiment 3

[0040] Example 3: Add 5.084g (20 mmol) of 2,5-dimethoxy dimethyl terephthalate, 3.780 g (26 mmol) of isosorbide and 0.061 g (0.4 mmol) in a 50 mL single-necked flask ) Zinc oxalate dihydrate, placed in a reactor at a reaction temperature of 120°C, and carried out a 4h transesterification reaction under nitrogen protection to obtain a transesterification product; the obtained transesterification product and the catalyst were not separated, and placed at 200°C and under a low pressure Under a high vacuum of 20 Pa, the reaction was carried out for 2 hours, then the heating was stopped, and the system was naturally cooled to room temperature by blowing nitrogen to obtain a crude polyester product. Add 40 mL of chloroform to the crude polyester, soak for 2 hours and then filter; take the clear solution and add it dropwise to methanol to obtain a turbid system, centrifuge to obtain a precipitate, filter, then wash with 5 mL of methanol, filter, and vacuum dry at 60 °C. 8.076 g of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com